Water supply system of railway vehicle

A technology for water supply systems and railway vehicles, applied to railway car body components, railway auxiliary equipment, sanitary equipment, etc., can solve problems such as increased maintenance costs, pipeline cracks, pressure sensor failures, etc., to improve work reliability and practicability , Reduce maintenance costs, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

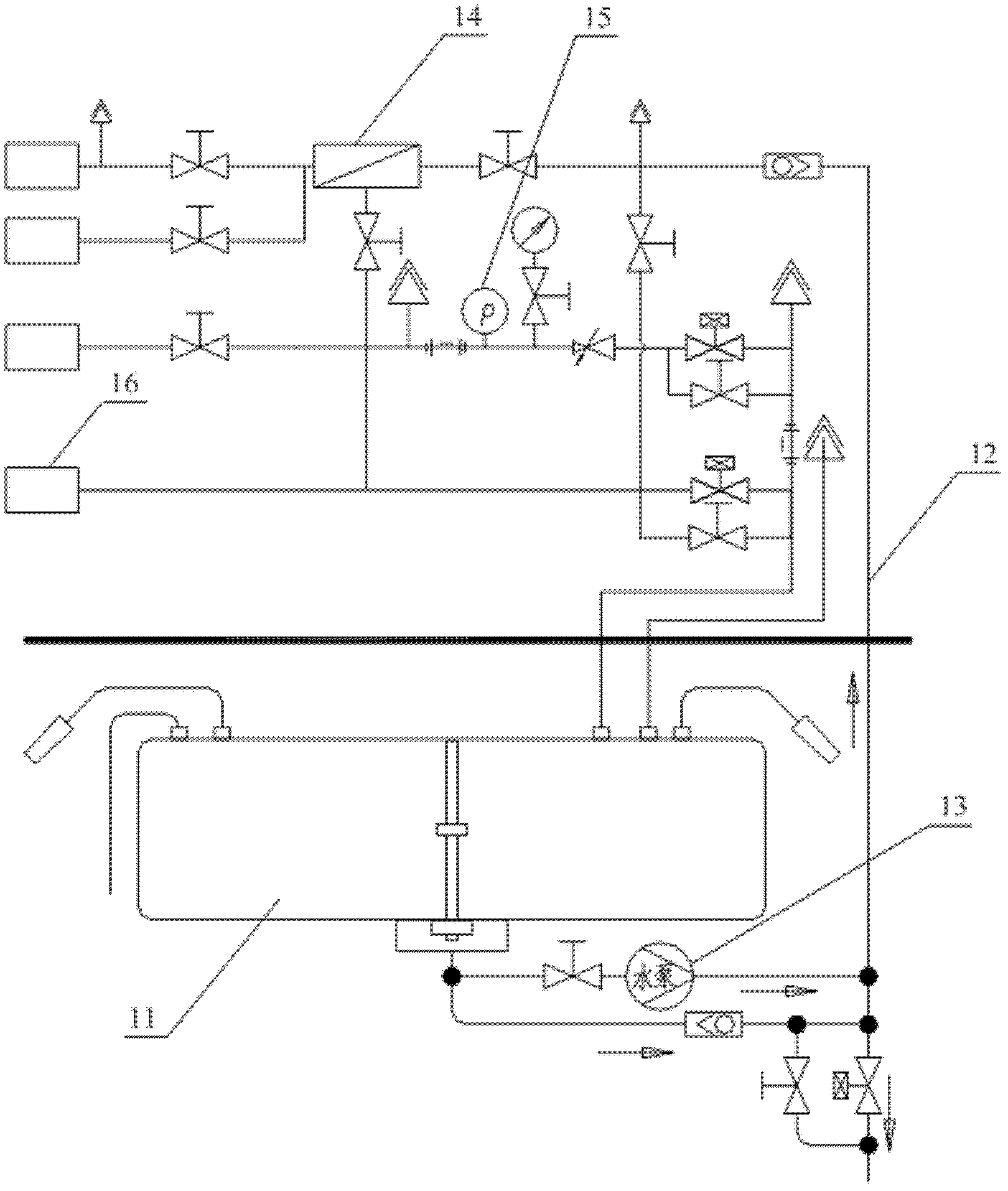

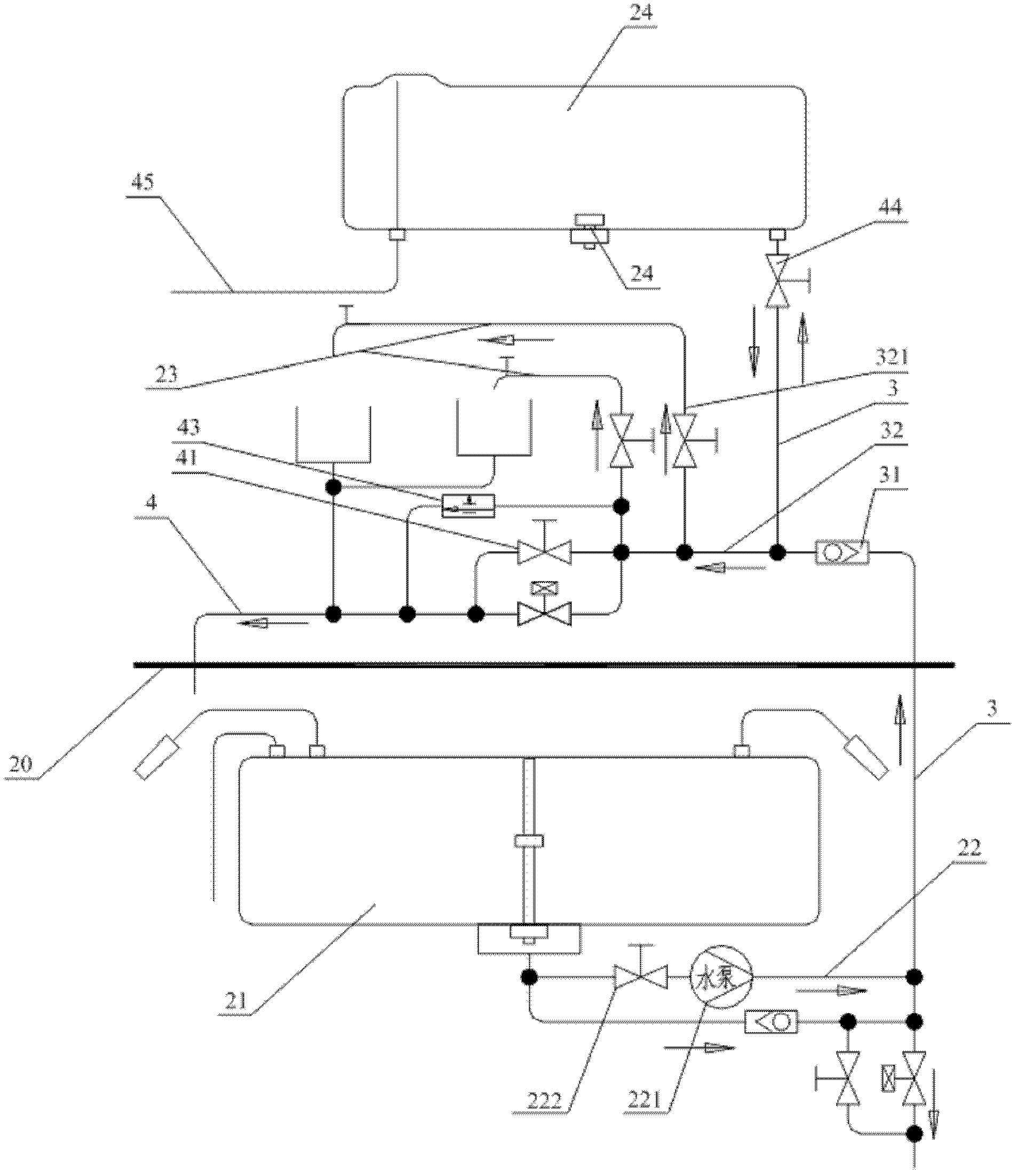

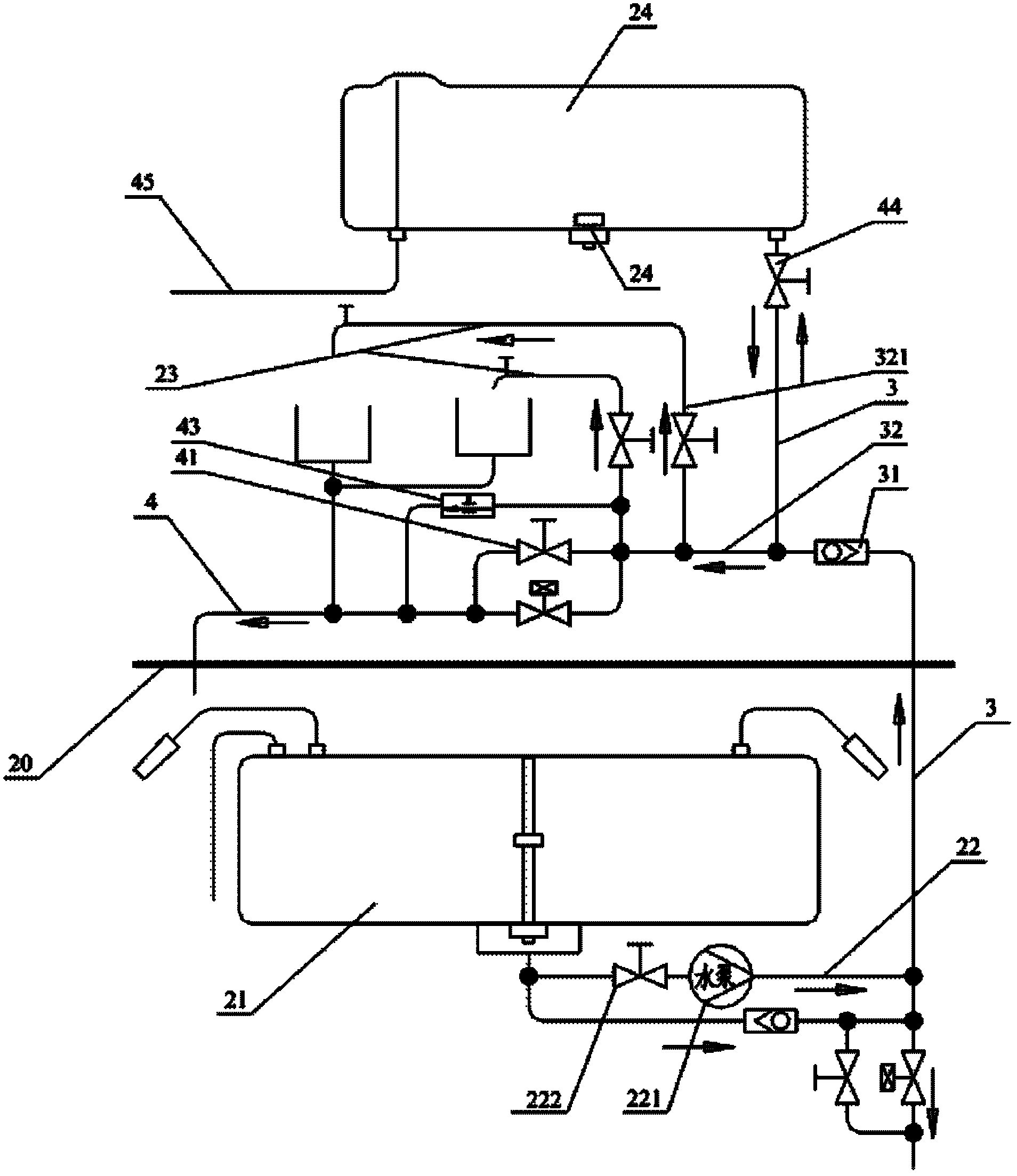

[0017] This embodiment provides a water supply system for railway vehicles, please refer to figure 2 , including: a water tank 21 fixedly arranged below the vehicle body chassis 20, a water pump device 22, at least one water device 23 arranged above the vehicle body chassis 20, and a control module (not shown) fixedly arranged in the vehicle body And the intermediate water tank 24 that is fixedly arranged on the top of the vehicle body chassis 20 and above all the water equipment 23 is provided with a collection device for detecting the liquid level in the intermediate water tank 24 and obtaining the liquid level signal in the intermediate water tank 24; the water tank 21 The outlet pipe of the water pump is connected with the input end of the water pumping device 22, and the output end of the water pumping device 22 is connected with the intermediate water tank 24 through the water supply pipeline 3, and the water supply pipeline 3 is provided with for preventing the water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com