Reliable flange sealing structure for heat exchanger unit pipeline

A heat exchange unit and flange sealing technology, which is applied to flange connections, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve problems such as damage to electrical cabinets, affecting heating, and potential safety hazards, and achieves a simple and reasonable structure , prevent pipeline leakage, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

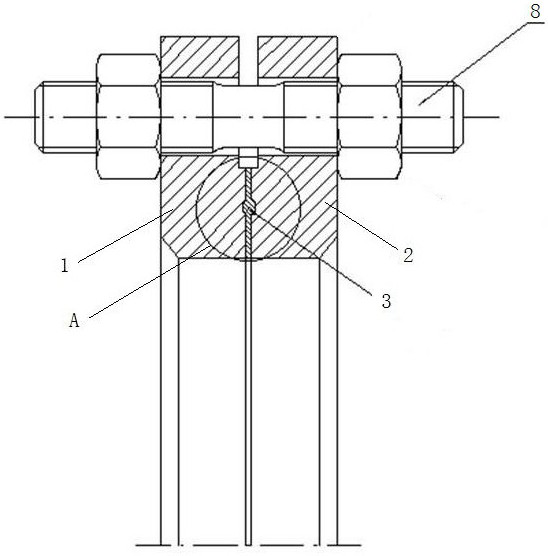

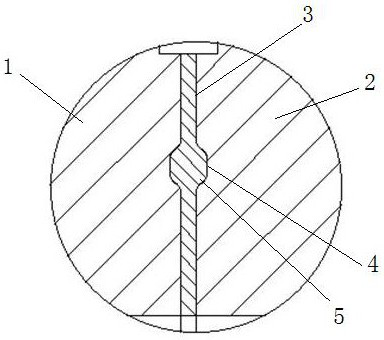

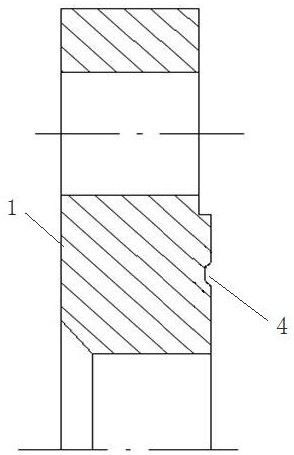

[0019] In the past, the standard of flanges used in heat exchange units was based on national standards GB... or chemical industry standards HG.., and sometimes international ANSI or JIS standards; in order to seal reliably, metal gaskets must be used, because metal gaskets The cost of the sheet is relatively high, which directly affects the economic benefits of the enterprise when the output of the heat exchange unit is large. If the EPDM flat gasket is used, the gasket often deforms during the operation of the unit, breaks away from the flange sealing surface, and sticks out of the flange sealing surface, making the heat exchange unit unable to work normally, sometimes causing the heat exchange station to be flooded or The electrical cabinet is damaged, which threatens personal safety in severe cases, resulting in heating shutdown for maintenance and affecting heating.

[0020] Below in conjunction with accompanying drawing, the application is described in detail:

[0021] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com