Light bridge deck composite reinforcement structure for solving bridge deck fatigue cracking problem

A technology for fatigue cracking and strengthening structures, which is applied in the direction of bridge reinforcement, bridges, bridge parts, etc. It can solve the problems of cracking at the bottom of the ultra-high performance concrete layer, uneven shear stiffness of the interface, and large weld length, etc., to achieve interlayer connection Reliable, extended fatigue life, high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

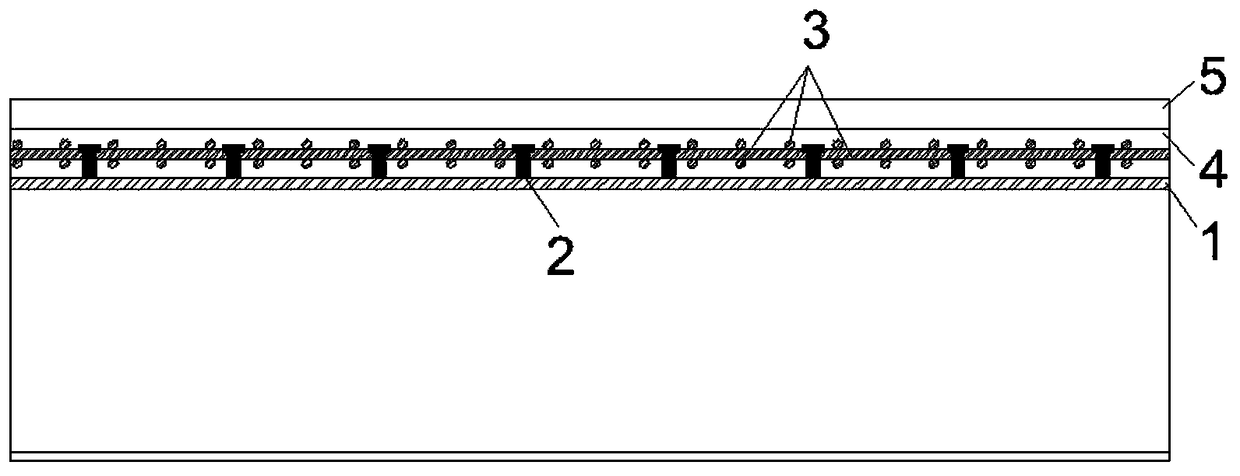

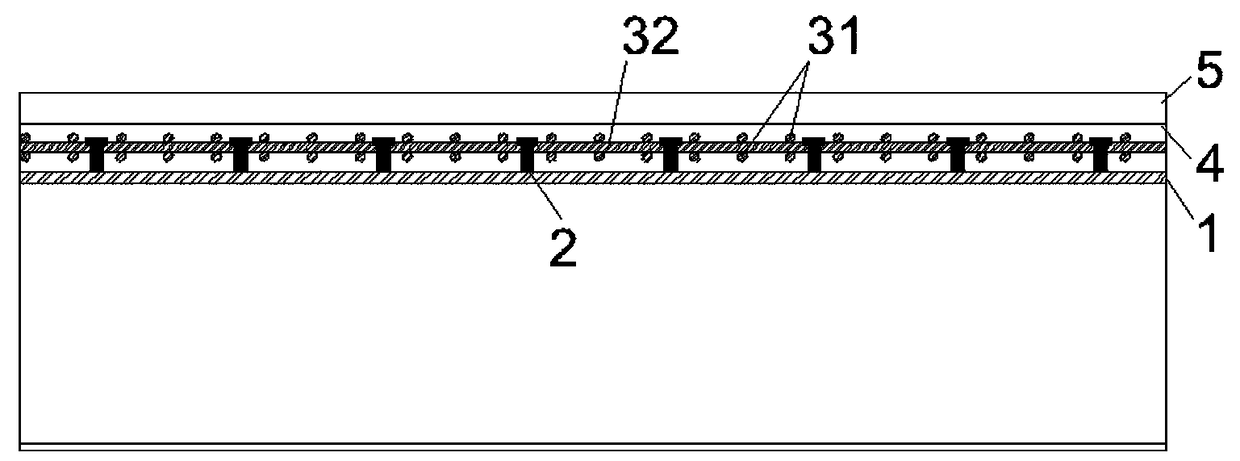

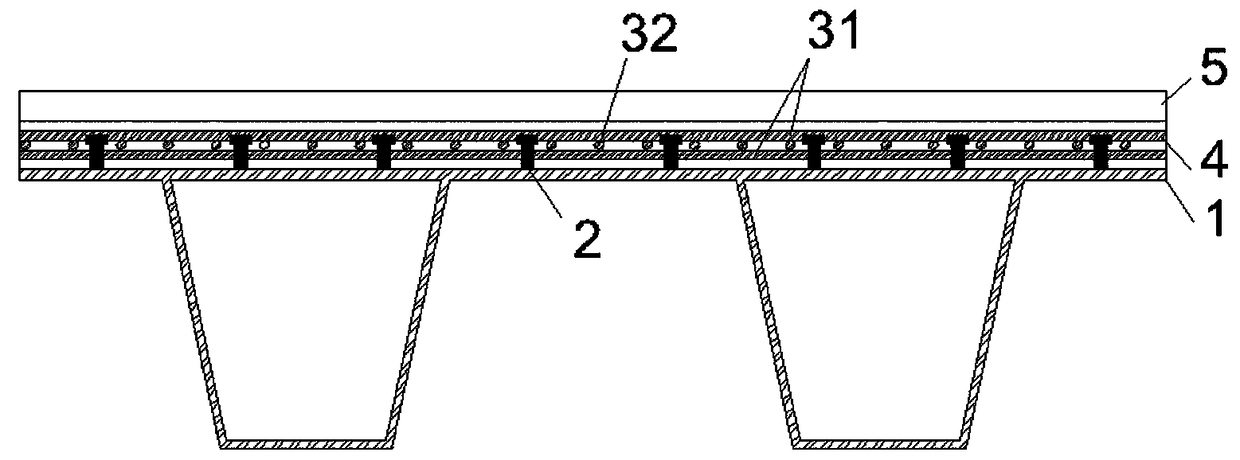

[0035] Embodiment 1, refer to Figure 1 to Figure 4 , including the cracked steel bridge deck, shear connectors, steel mesh, ultra-high performance concrete layer and wear layer, the shear connectors are set on the cracked steel bridge deck, and the steel mesh is placed on the cracked steel bridge deck Above, the ultra-high-performance concrete layer is poured on the cracked steel bridge deck, and the shear connector is covered, and the steel mesh is connected to the cracked steel bridge deck, and the wearing layer is covered with the ultra-high-performance concrete layer.

Embodiment 2

[0036]Embodiment 2, the steel mesh of the present invention is made up of longitudinal steel bars and transverse steel bars that criss-cross each other, including adopting a three-layer steel mesh structure, the transverse steel bars of the three-layer steel mesh structure are located at the upper and lower layers of the steel mesh, and the longitudinal steel bars are located at the upper and lower layers of the steel mesh. In the middle layer, the spacing of the transverse steel bars of the upper layer and the lower layer may be the same or different. refer to Figure 1 to Figure 4 , and the rest are the same as the combination of any of the above embodiments or two or more embodiments.

Embodiment 3

[0037] Embodiment 3, the positions of the upper layer transverse reinforcement and the lower layer transverse reinforcement of the reinforcement mesh of the present invention can be on the same vertical line. refer to Figure 1 to Figure 4 , and the rest are the same as the combination of any of the above embodiments or two or more embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com