Method for preventing end face of wood from severely cracking

A wood and end face technology, which is applied in the direction of nailing staple tools, nailing tools, manufacturing tools, etc., can solve the problems of reduced anti-cracking effect, wood pollution, and increased production costs, so as to prevent large-scale cracks and improve wood utilization. The effect of efficiency and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

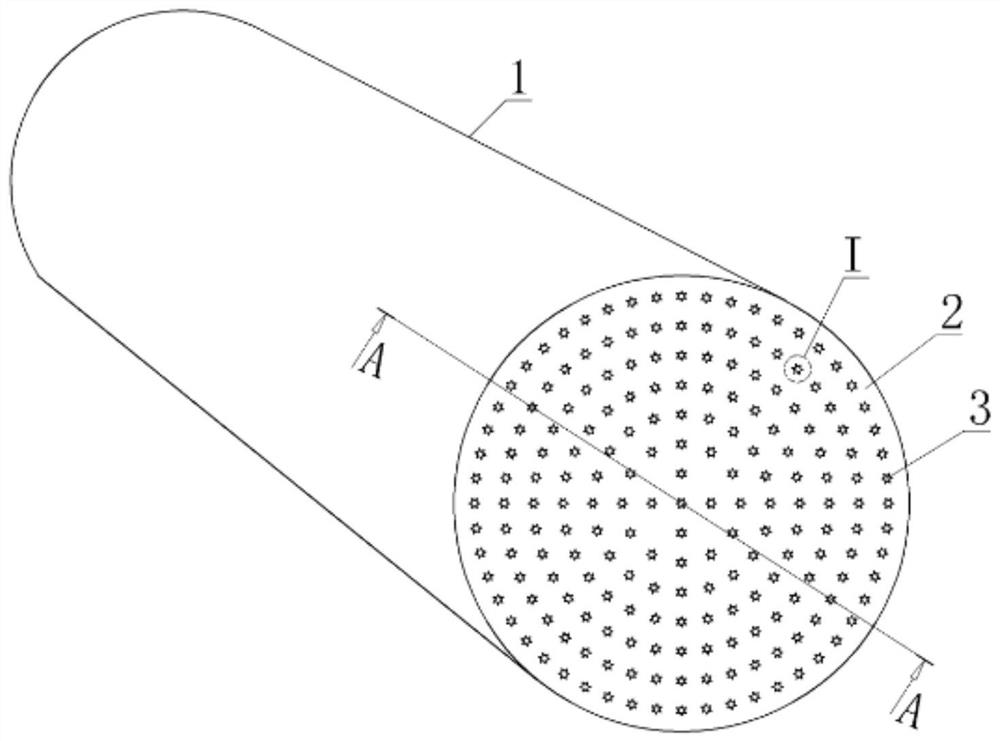

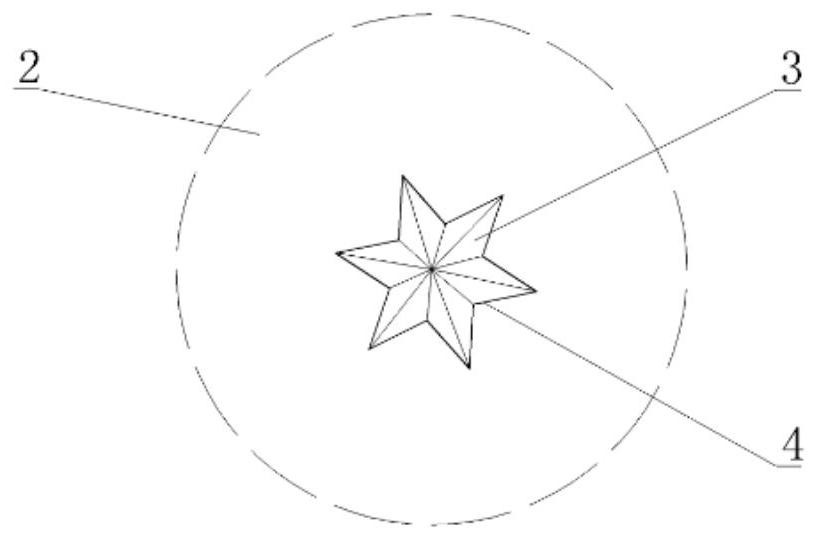

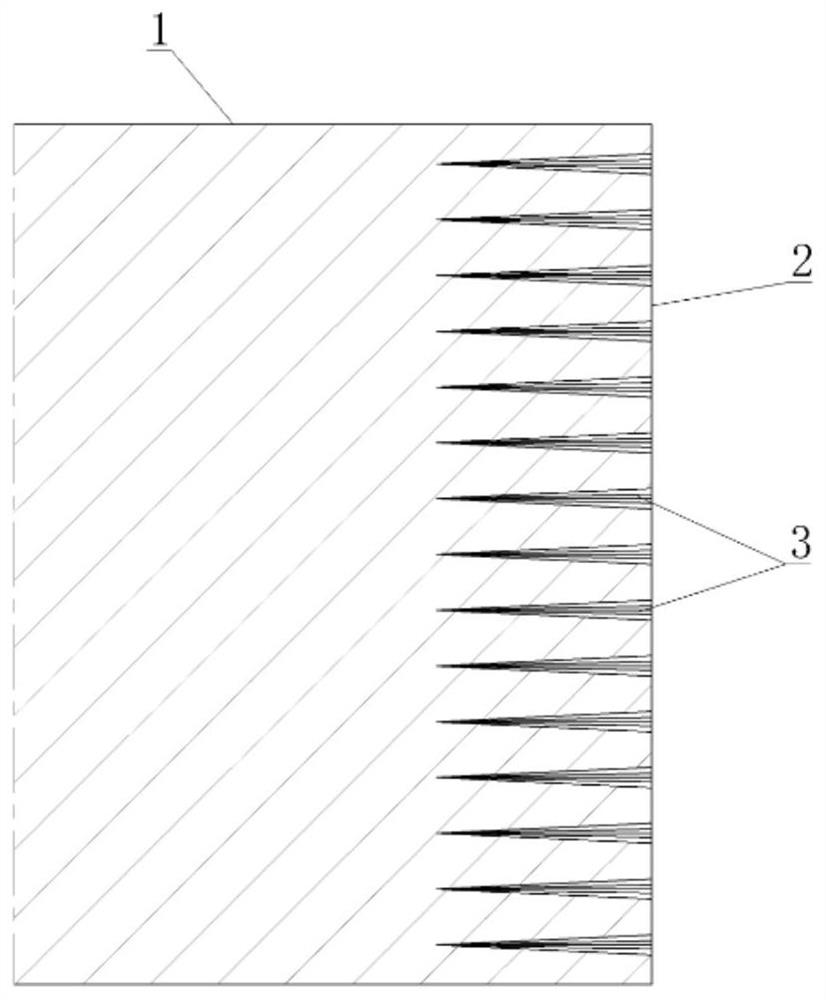

[0025] In order to prevent serious cracks on the end face of the wood, the large-scale cracks that may occur on the end face of the wood (the cracks are long in the vertical direction and wide in the transverse direction) are resolved into shallower, narrower, numerous, and evenly distributed fine cracks to save wood. The purpose of this invention, the present invention proposes the design idea of resolving wood drying shrinkage stress and growth stress by manufacturing prestress. When setting the prestress, the wood tissue is squeezed together regionally, the wood cells are flattened and deformed, and the density increases, forming a prestress perpendicular to the longitudinal direction of the wood, which is opposite to the direction of the tensile stress. Wood is a For a viscoelastic material, the release of prestress is a function of time, and the slow release process just offsets or weakens the effect of tensile stress. The method that the present invention prevents the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com