A system reinforcing method for a steel plate combined continuous beam

A technology of composite beams and steel plates, used in bridge reinforcement, bridges, bridge maintenance, etc., can solve the problems of bridge deck cracking, insufficient bearing capacity of steel plate composite beams, etc., to prevent cracking, eliminate cracking risks, and increase bending resistance and resistance. Effect of Torque Moment of Inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The system strengthening method for steel plate composite continuous beams according to the present invention will be described below with specific examples.

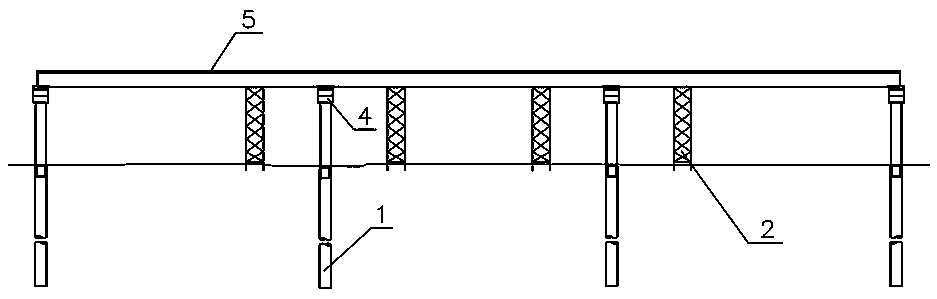

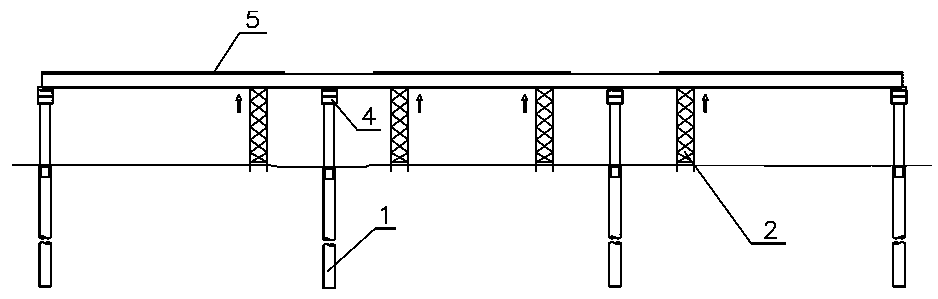

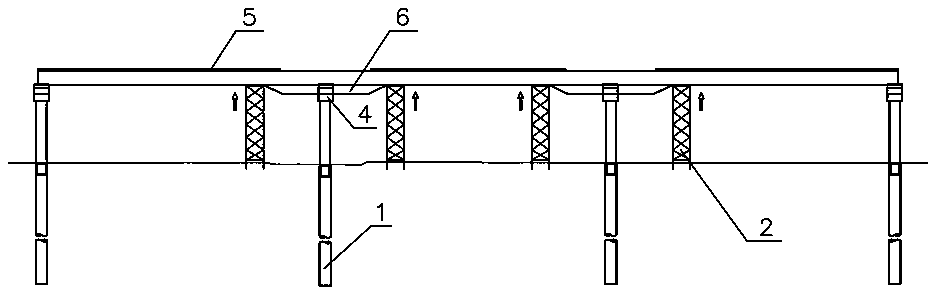

[0029] Such as Figure 1-10 The bridge shown in the figure adopts the form of double main girders of equal height, with 3×40m as a joint. The height of the original main girder is 2.2m. The specific reinforcement steps are as follows:

[0030] The first step is to set up a temporary support near the zero point of the composite beam bending moment, and install a jack on the temporary support. Specifically, under the premise of considering the construction needs, such as figure 1 As shown, a temporary support 2 is erected at 12m on the left and right sides of each middle pier 1, and the above four temporary supports 2 are all in the zero moment zone of the composite beam; after the temporary support 2 is erected, a jack is installed on it.

[0031] The second step, such as figure 2 As shown, the composite bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com