Welding-free pin shaft and stop device

A stop device, welding-free technology, applied in the direction of connecting components, mechanical equipment, etc., can solve the problems of poor welding performance, complex stress situation, and pin stop failure, etc., to eliminate the risk caused by weld cracking, The effect of simple manufacturing process and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

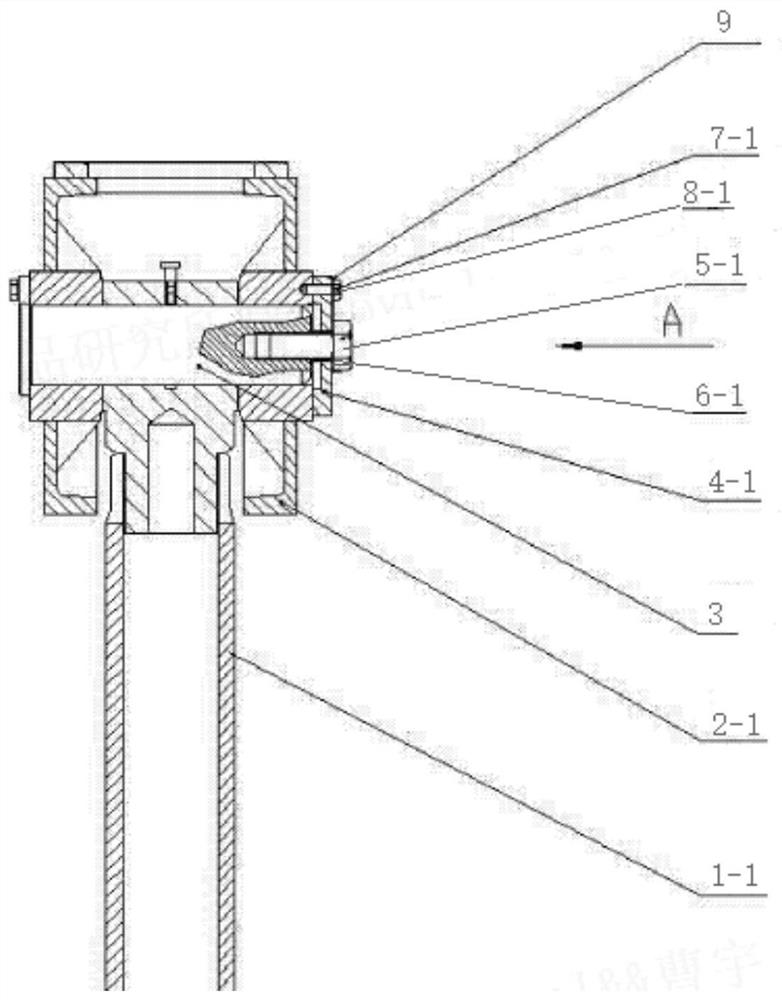

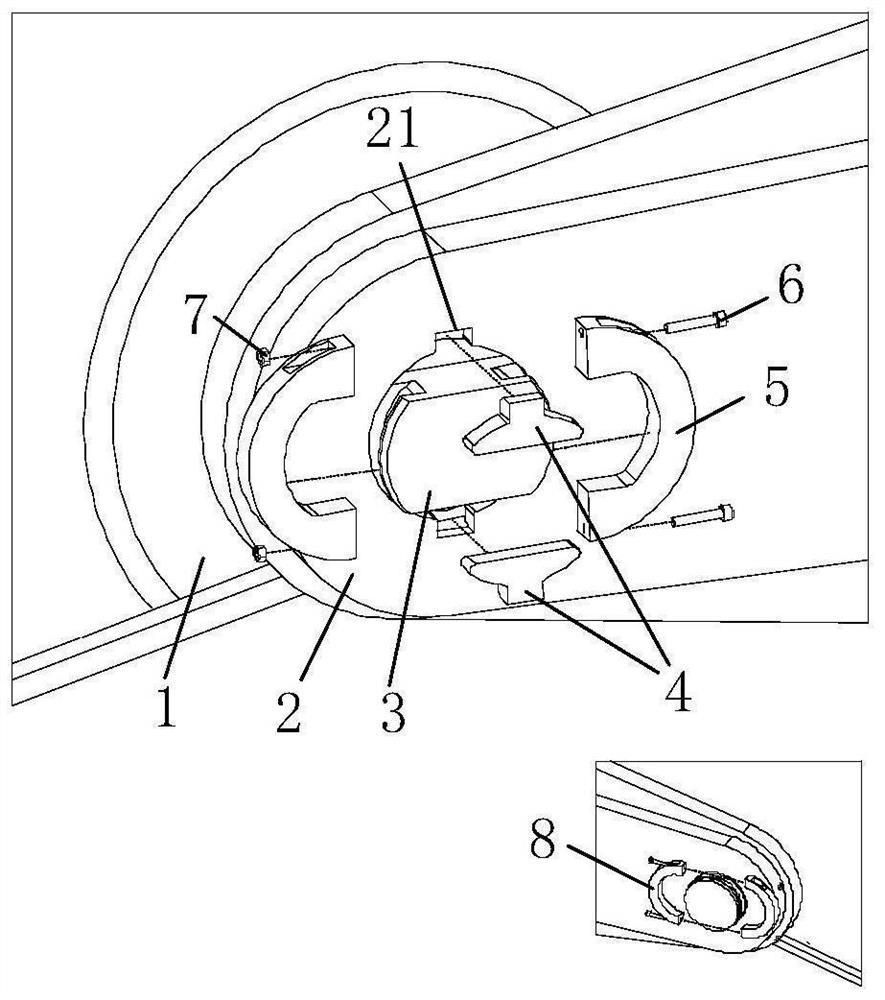

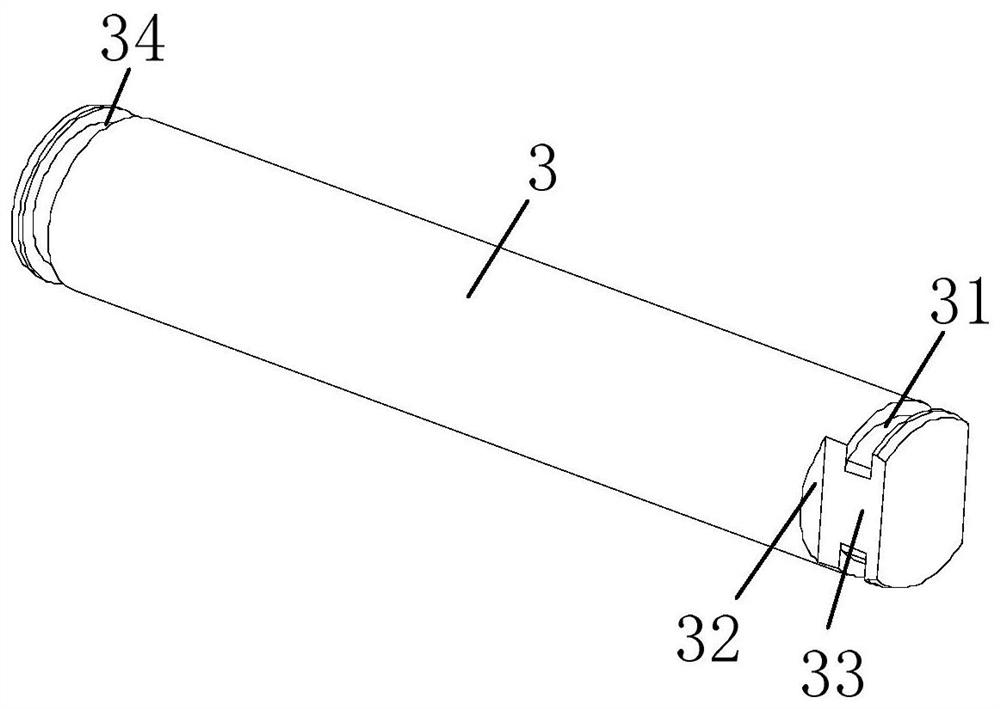

[0052] (1) First pass the pin shaft 3 normally through the rotating part 1 and the base part 2 to realize the hinge connection between the two; (2) Adjust the angle of the pin shaft 3 so that the gap formed by the cutting groove 33 and the stop groove 21 can just fit Put in the stop block 4, and then adjust the extension of the pin shaft 3, so that the stop block 4 can fit the termination surface 32 and not protrude from the surface of the base part 2; (3) buckle the two left stop rings 5 In the first annular groove 31, and each surface can be fit; (4) Use the screw 6 and the nut 7 to fasten the two left stop rings 5 together through the screw groove 53 and the screw through hole 54; (5) On the other side of the pin shaft, the two right stop rings 8 are fastened in the second annular groove 34, and the screws 6 and nuts 7 are also used to fasten the two right stop rings through the screw groove 82 and the screw through hole 83. The rings 8 are fastened together, finalizing t...

Embodiment 2

[0054] A welding-free stop device of the present invention can achieve the stop function described in the present invention by changing the shape of the pin shaft 3, the left stop ring 5, the right stop ring 8 and other components, such as changing the stop block 4 The shape of the ring, the shape of the stop ring, the installation and space arrangement, quantity, position, etc.;

Embodiment 3

[0056] Using a symmetrical structure, the shaft cut-off part can be made into a left-right symmetrical structure, and the same stop block and stop ring are used on both sides;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com