System and method for vacuum pouring of insulation resin used for motor rotor

A technology of motor rotor and insulating resin, which is applied in the direction of laying solid insulation, etc., can solve the problems of not considering the vacuum degree requirements of resin mixing, large temperature deviation in the oven working room, and affecting the quality of glue filling, so as to eliminate the risk of colloid cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

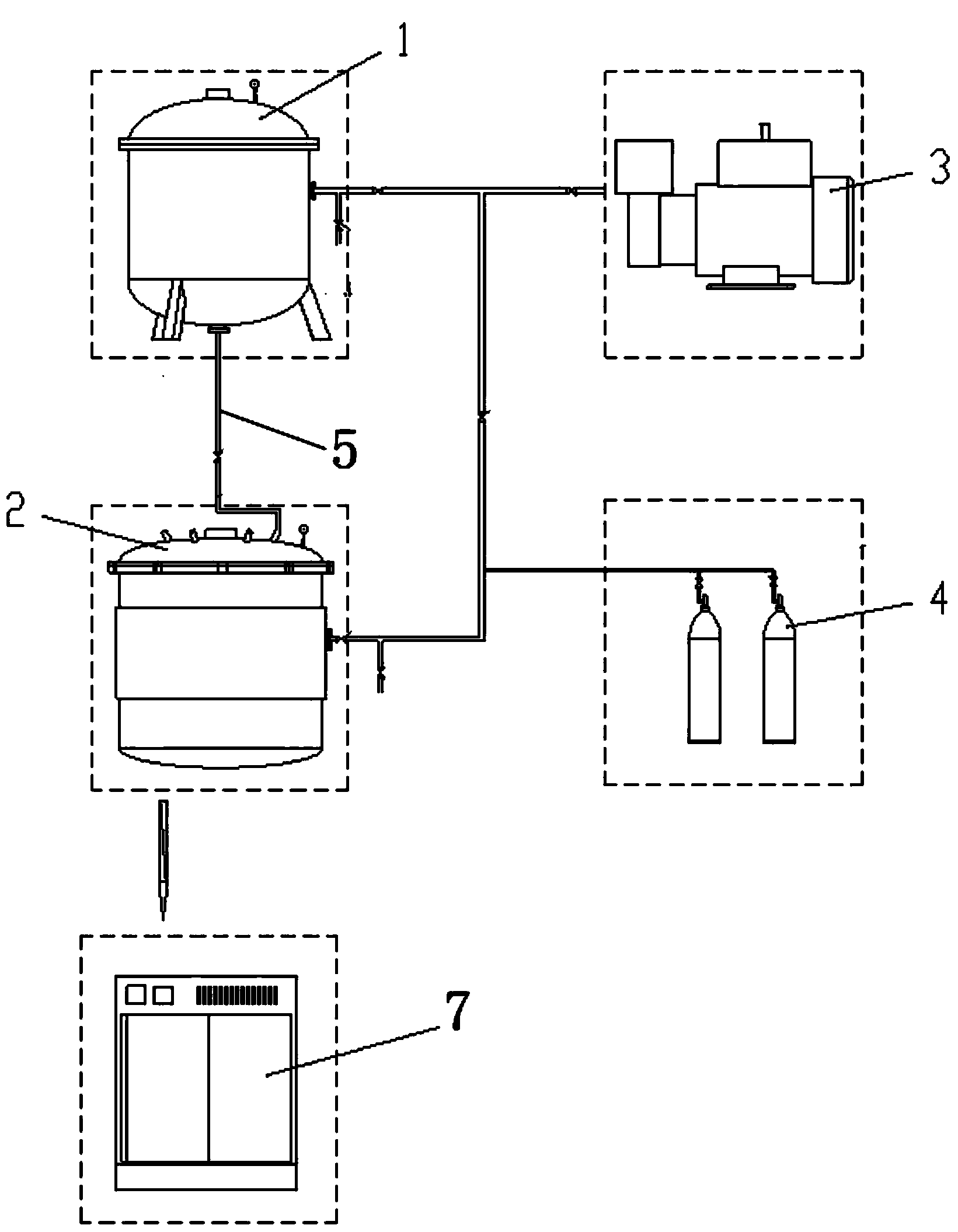

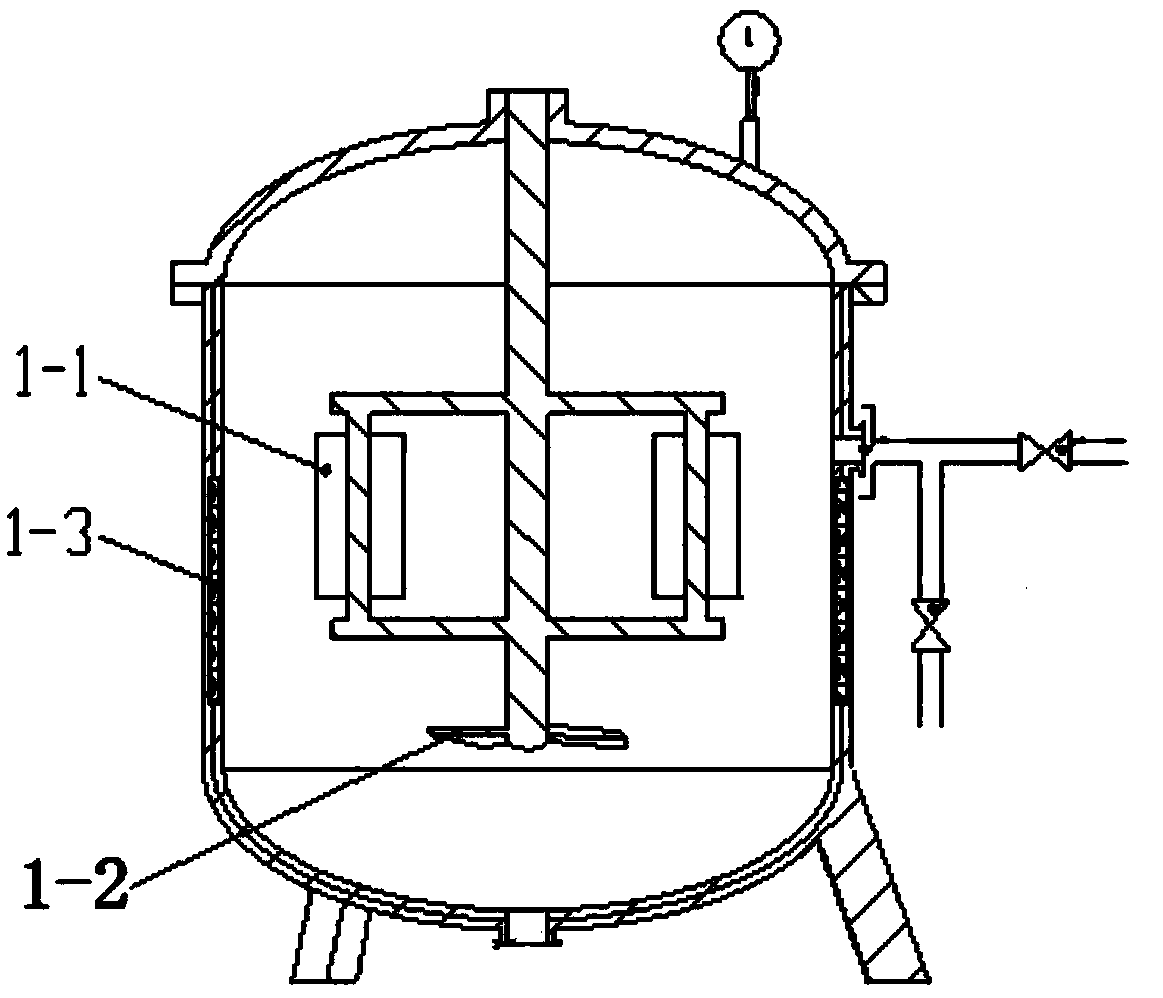

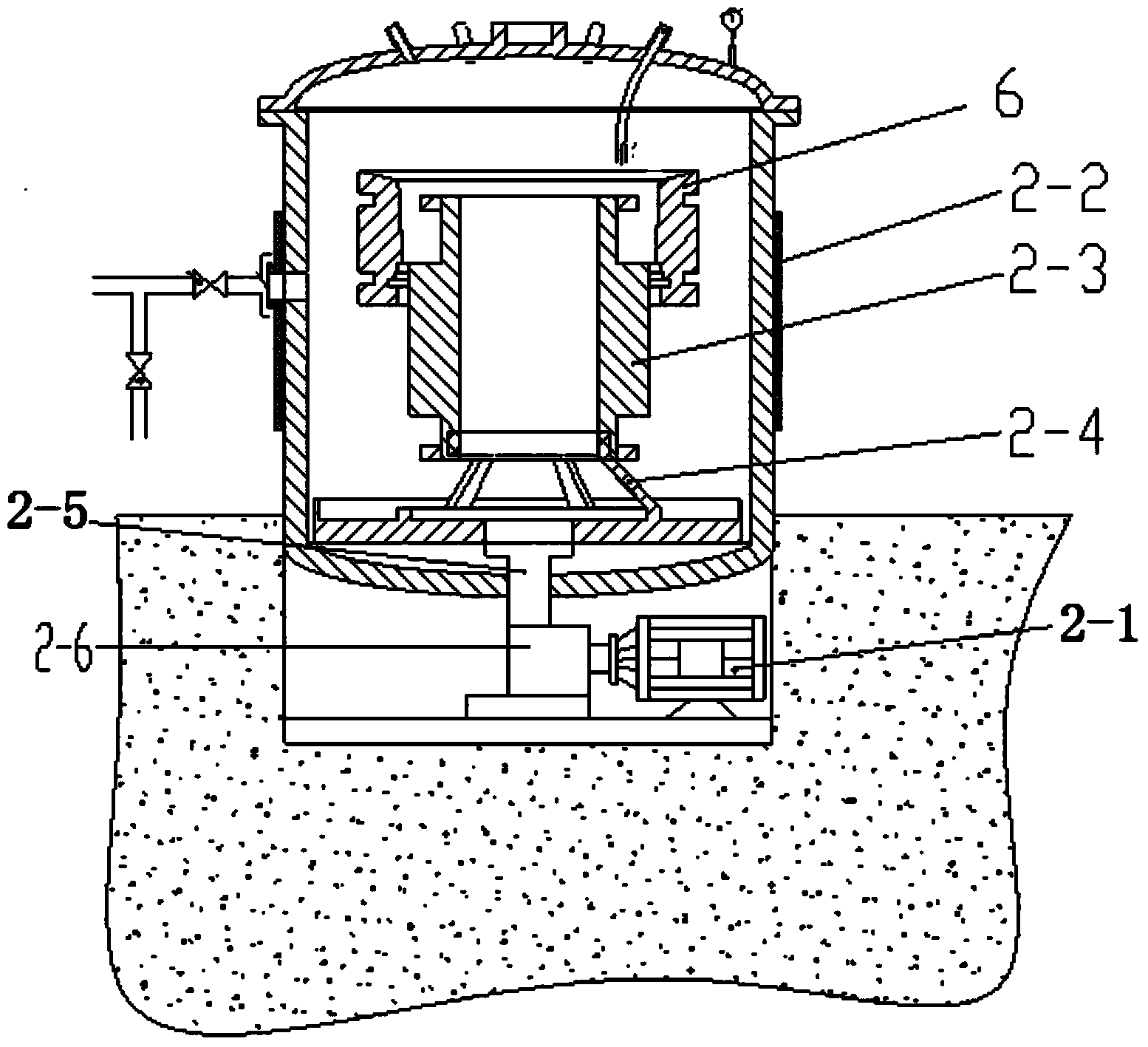

[0029] Referring to the accompanying drawings, a motor rotor insulating resin vacuum pouring system includes a vacuum glue filling tank 2, a rubber delivery pipe 5, a vacuum pump 3, a high-pressure inert gas delivery device 4, a vacuum emulsifier 1, a vacuum pump 3 and a high-pressure inert gas delivery The device 4 is connected to the vacuum glue filling tank 2 respectively through pipelines, the vacuum emulsifying machine 1 is connected to the vacuum glue filling tank 2 through the rubber delivery pipe 5, the vacuum emulsifying machine 1 is provided with a stirring device 1-1, and the vacuum emulsifying machine 1 is connected to the vacuum pump 3 , the resin to be glued is mixed in the vacuum emulsifier 1. In order to increase the contact area when the resin is stirred, the stirring device 1-1 is a frame-type propeller structure, and the stirring devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com