Patents

Literature

169results about How to "Guaranteed temperature requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

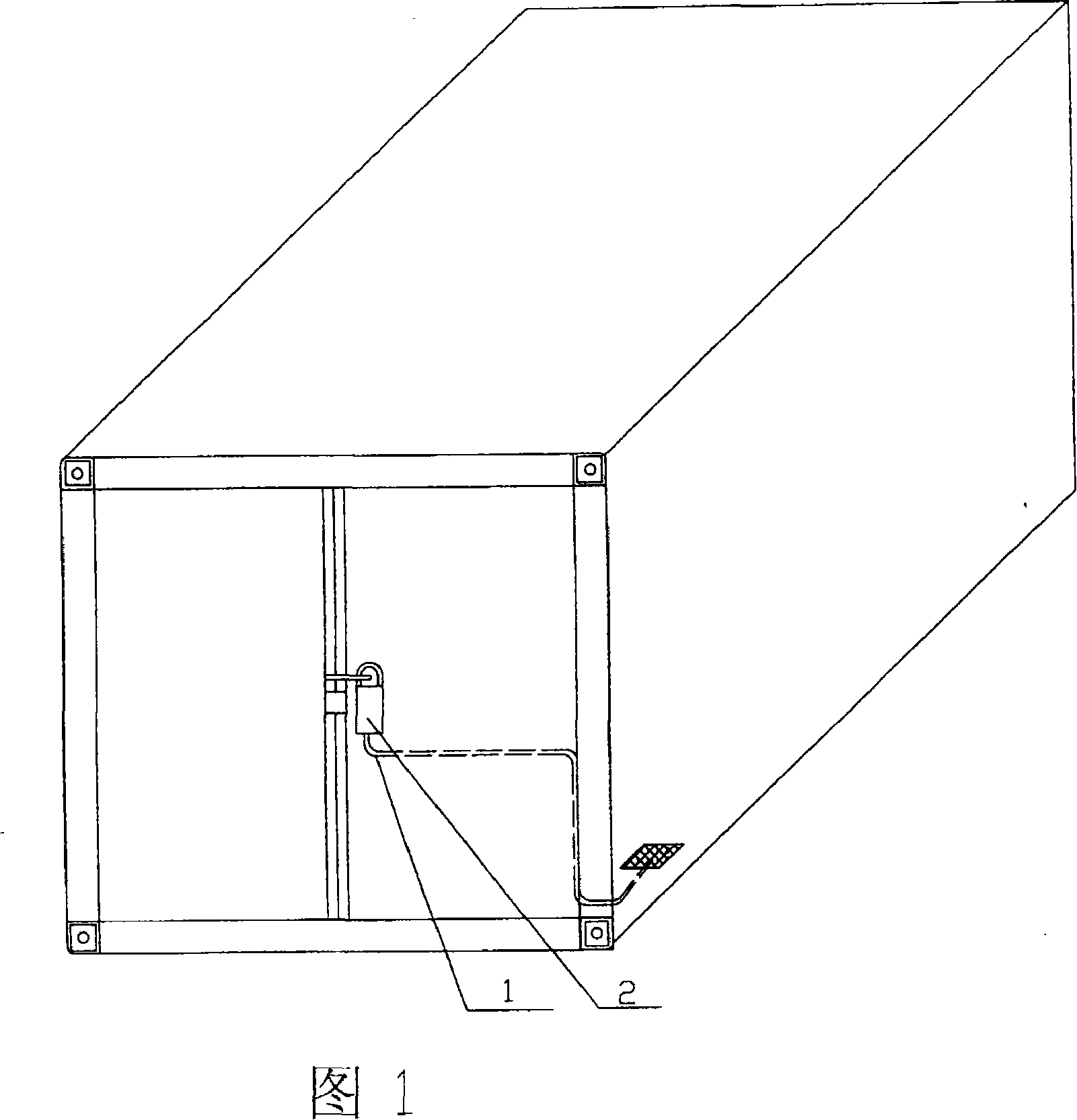

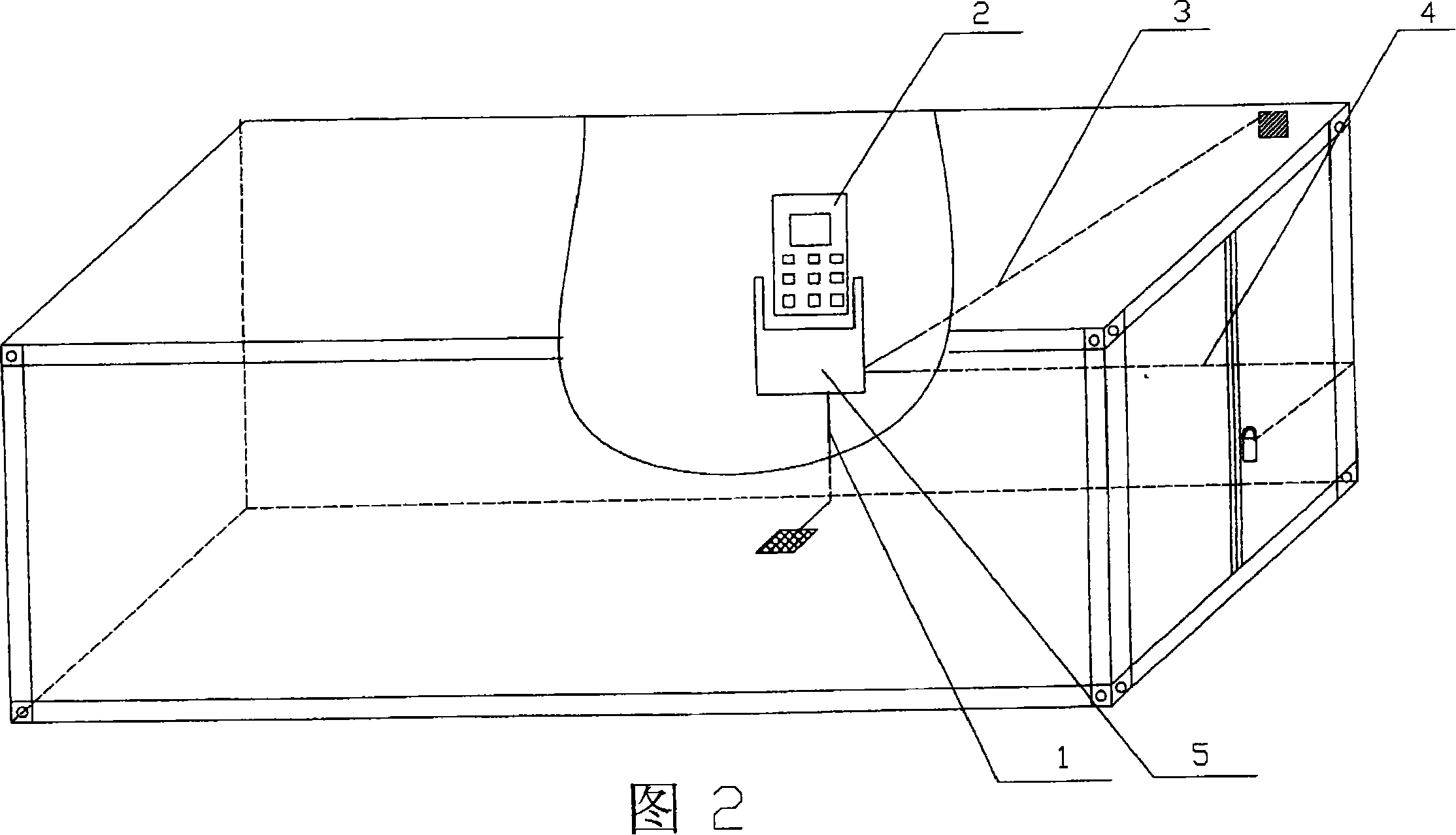

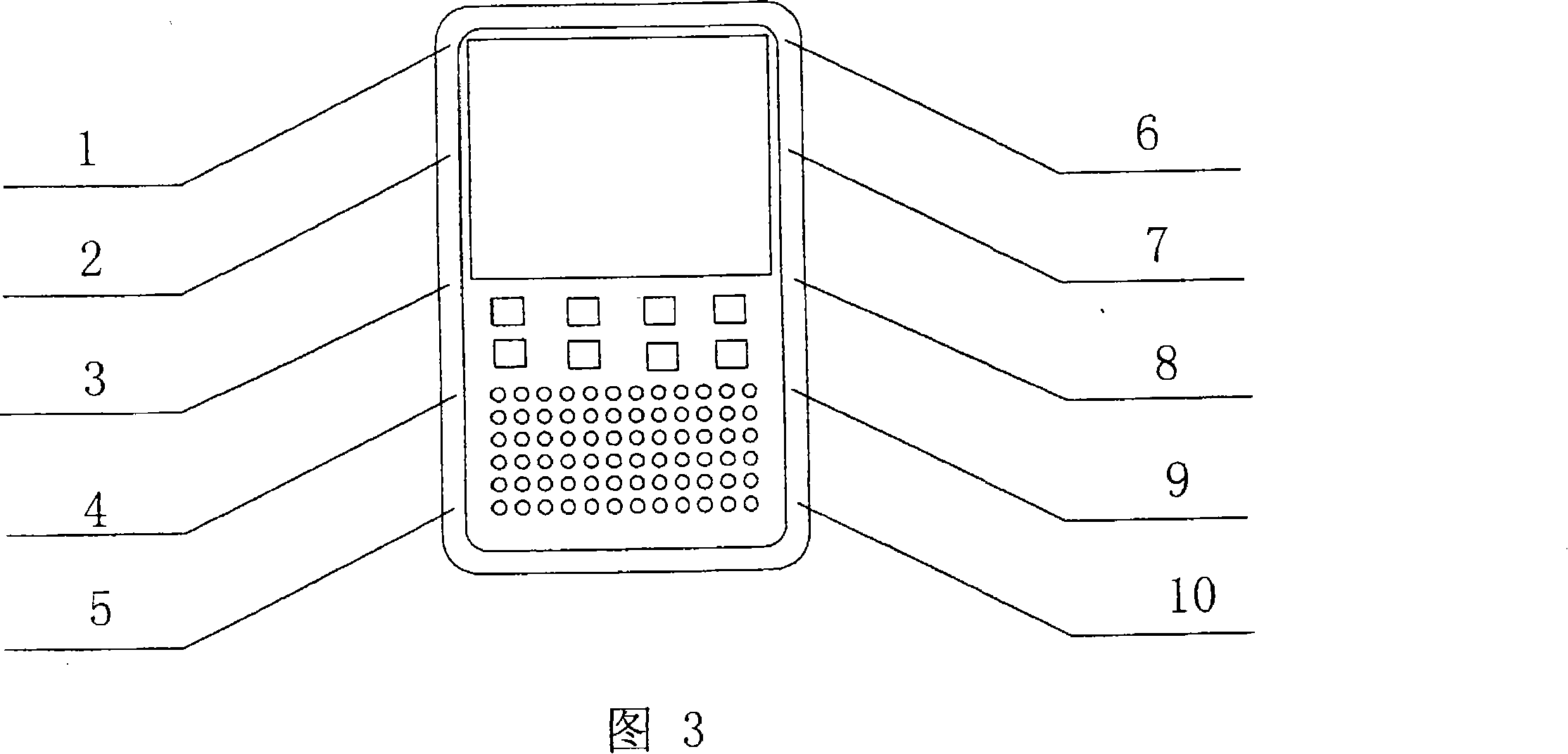

Intelligent container or the like and use thereof

InactiveCN101229869AIncrease useReduce volumeTemperatue controlLarge containersIntelligent NetworkLogistics management

The invention relates to an intelligent container or the analogs thereof, which is technologically characterized in that the invention consists of two parts of the installation power and an intelligent terminal with an entrance guard and an electronic lock (an intelligent lock) which is built-in arranged in an antenna integration; by combining with a lifting device, the invention is provided with an intelligent container with a function of lifting self-loading and unloading or the analogs. By integrated application of the technology such as the intelligent terminal combining with satellite positioning, the wireless communication, the RFID radio frequency identification, the network and the computer calculation, the real-time performance, the controllability and the security of freight transportation in the container can be solved and extend to a client as a temporary warehouse, which saves the automobile resources and waiting time and realizes the freight path information management which is a highest level of logistics business that anyone loads or unloads the freight anywhere and at anytime, the freight is in any location and in any status, the recording and monitoring of the freight environmental status in transporting the freight and the freight information and flow business can be inquired, traded and stowage planned on the network.

Owner:沈军

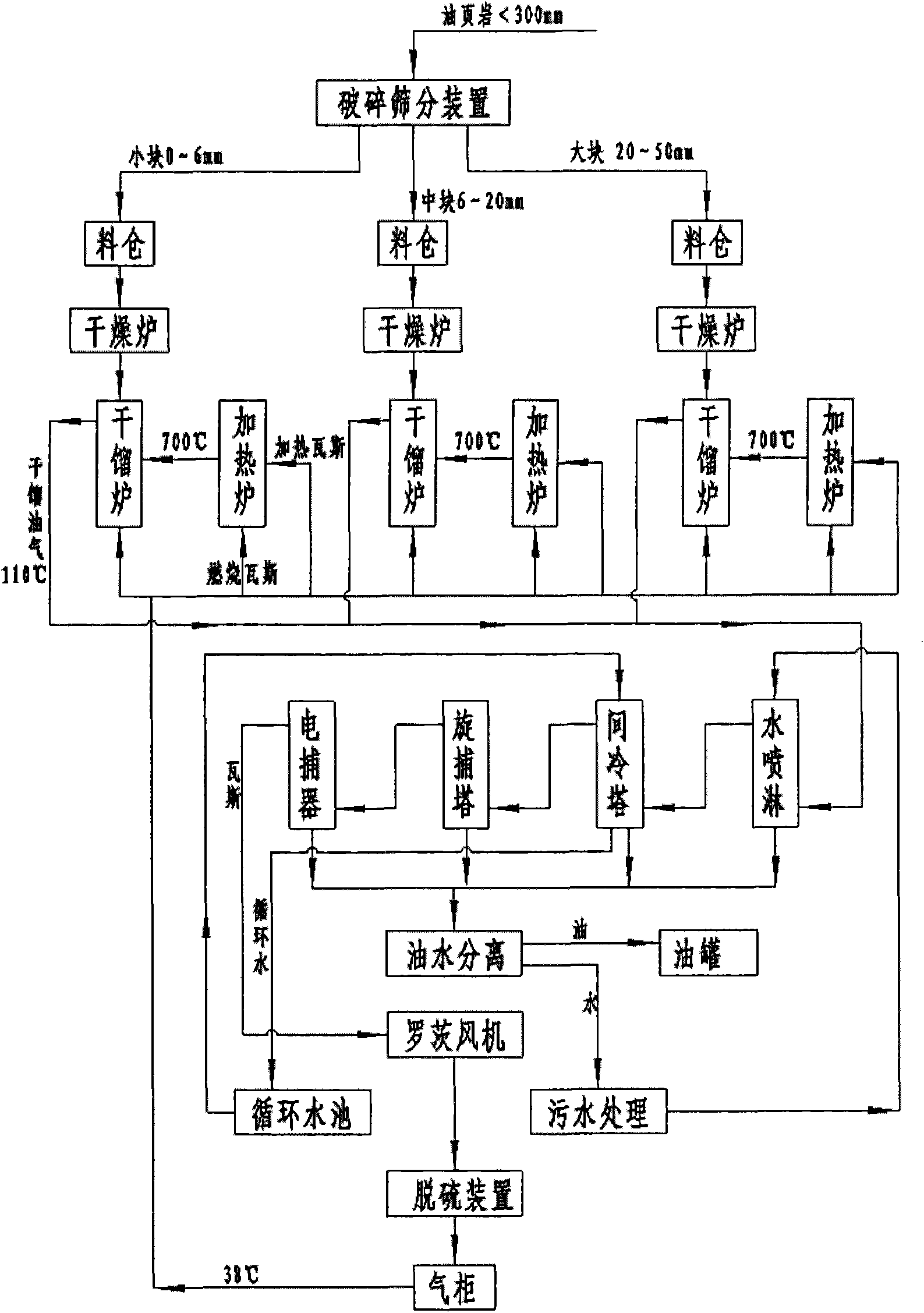

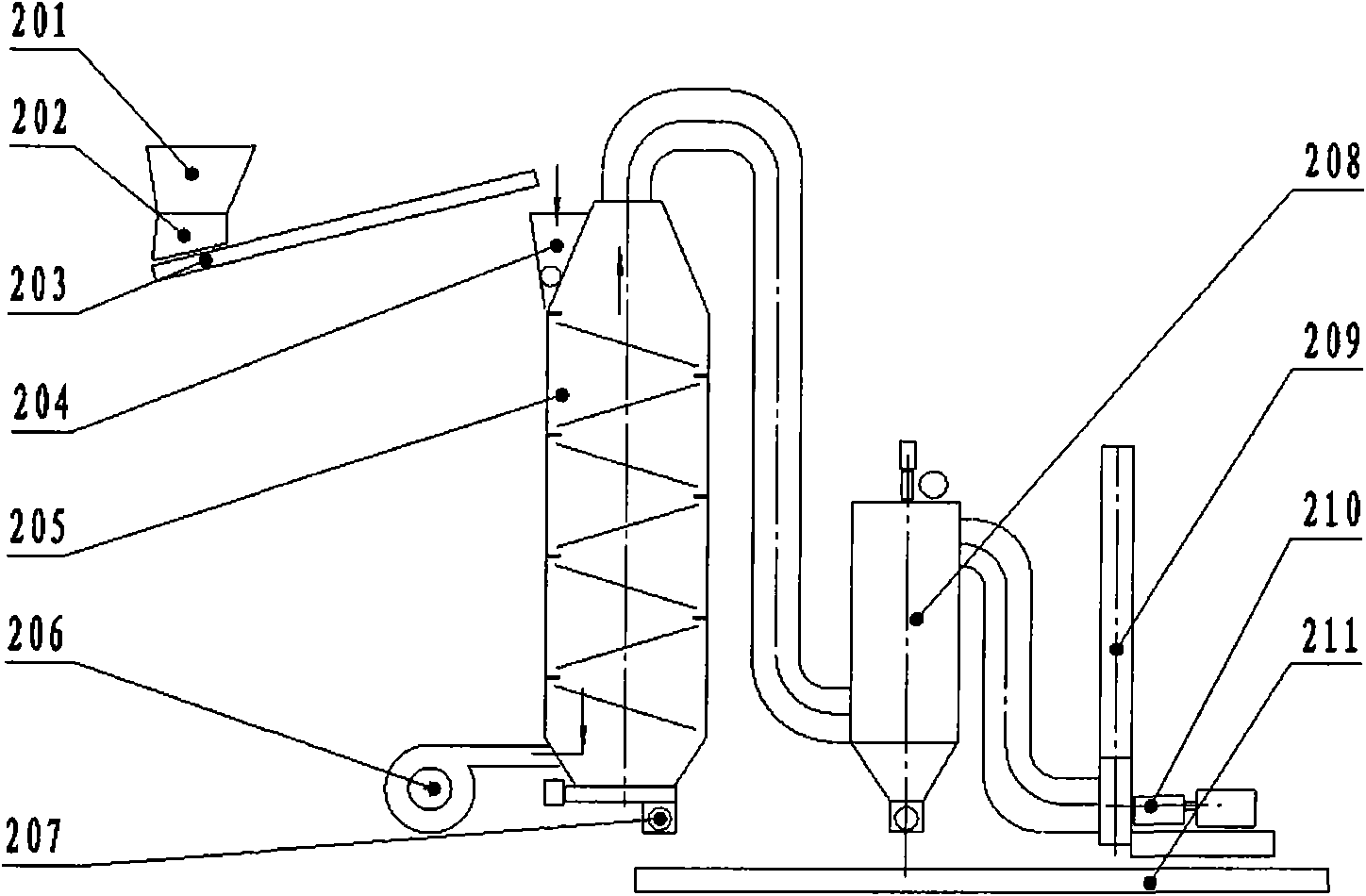

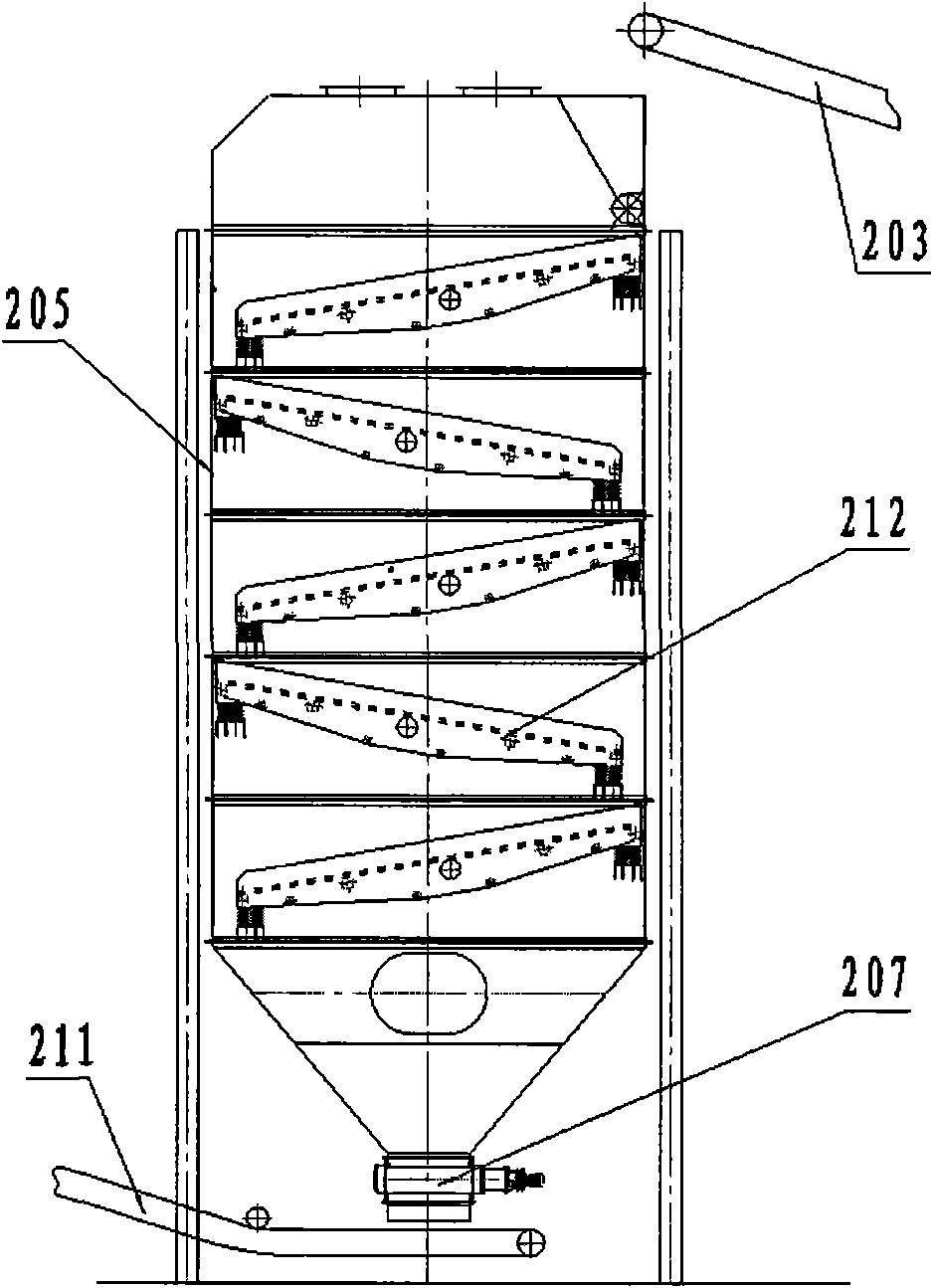

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

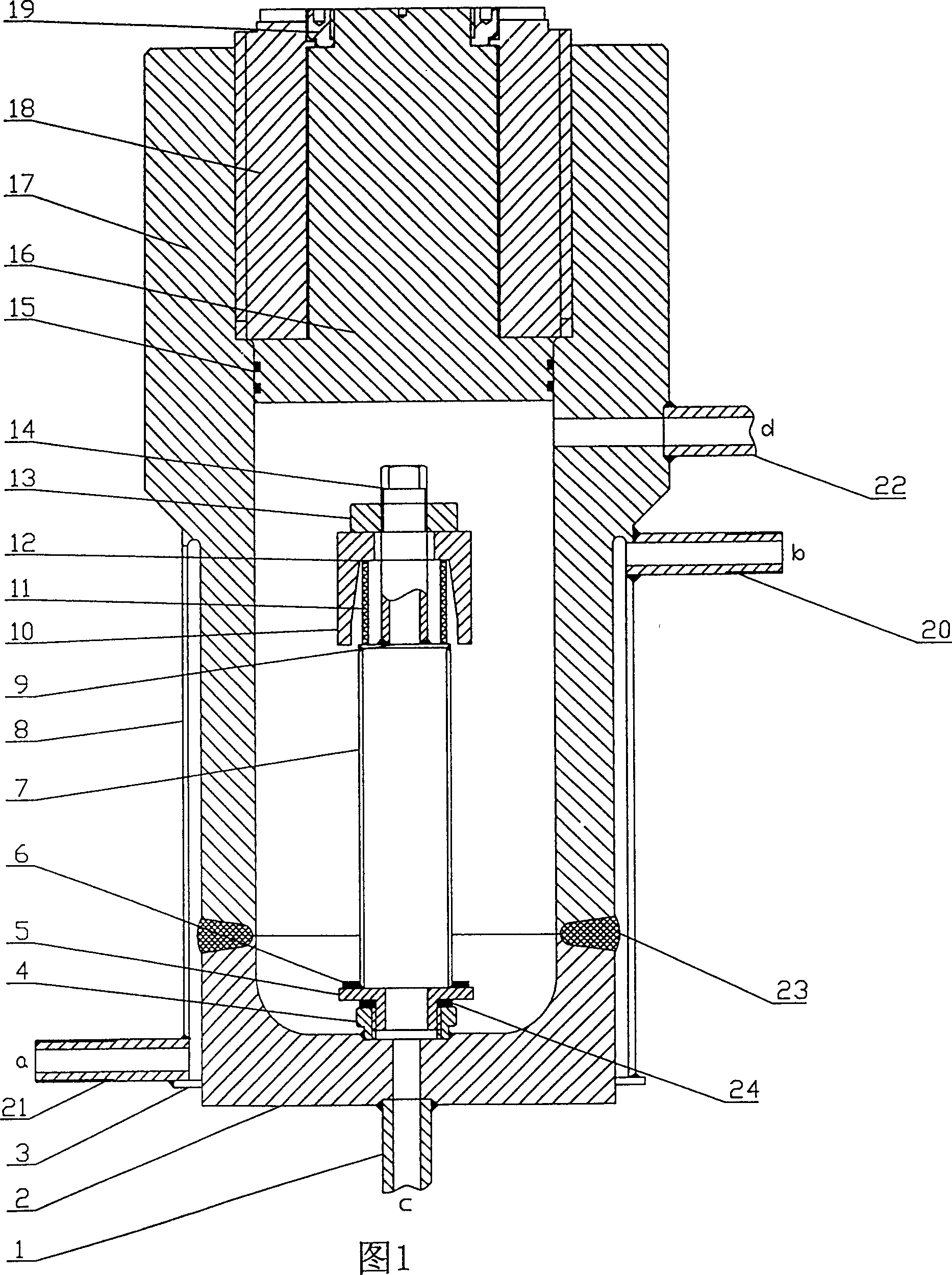

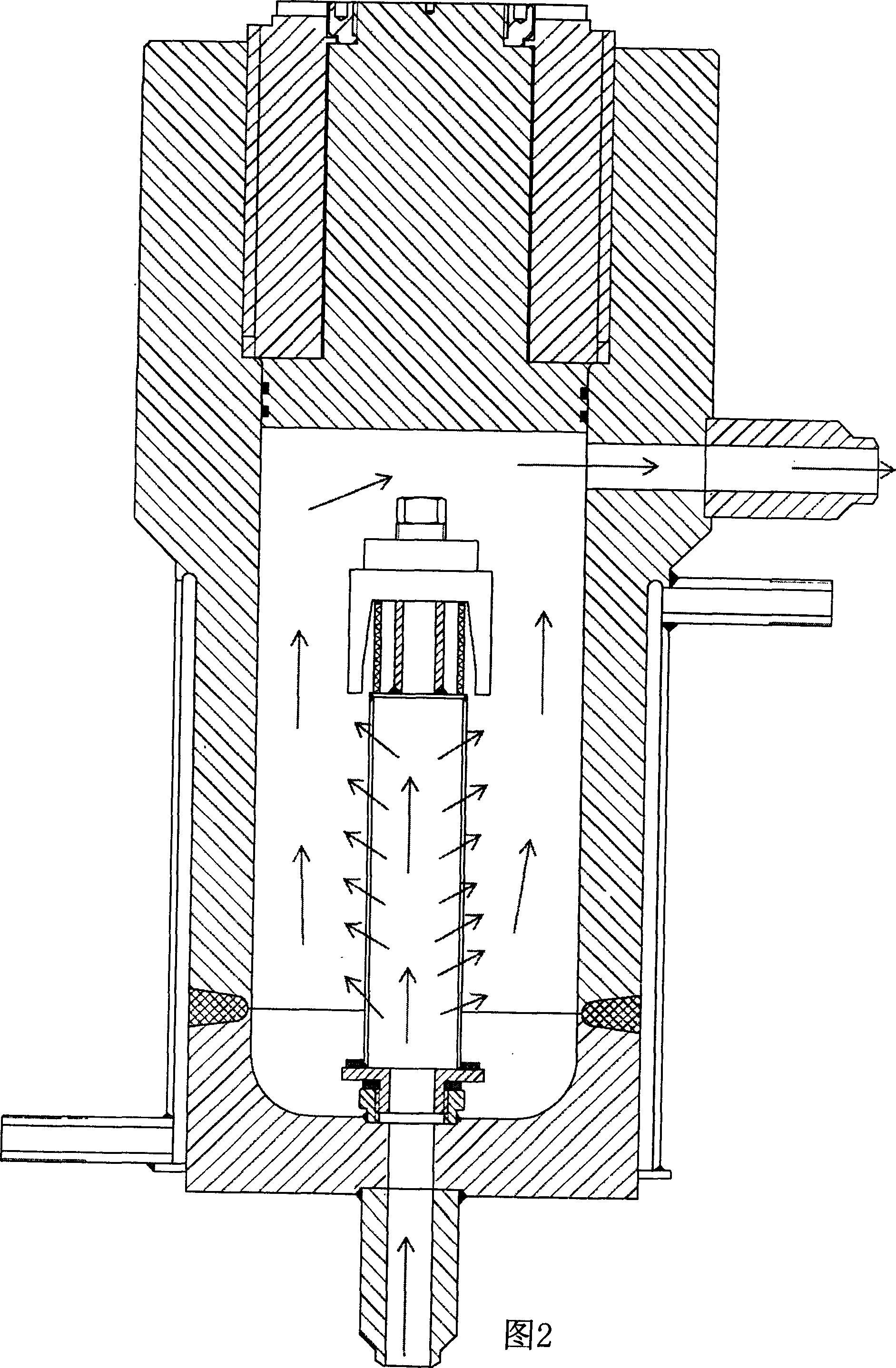

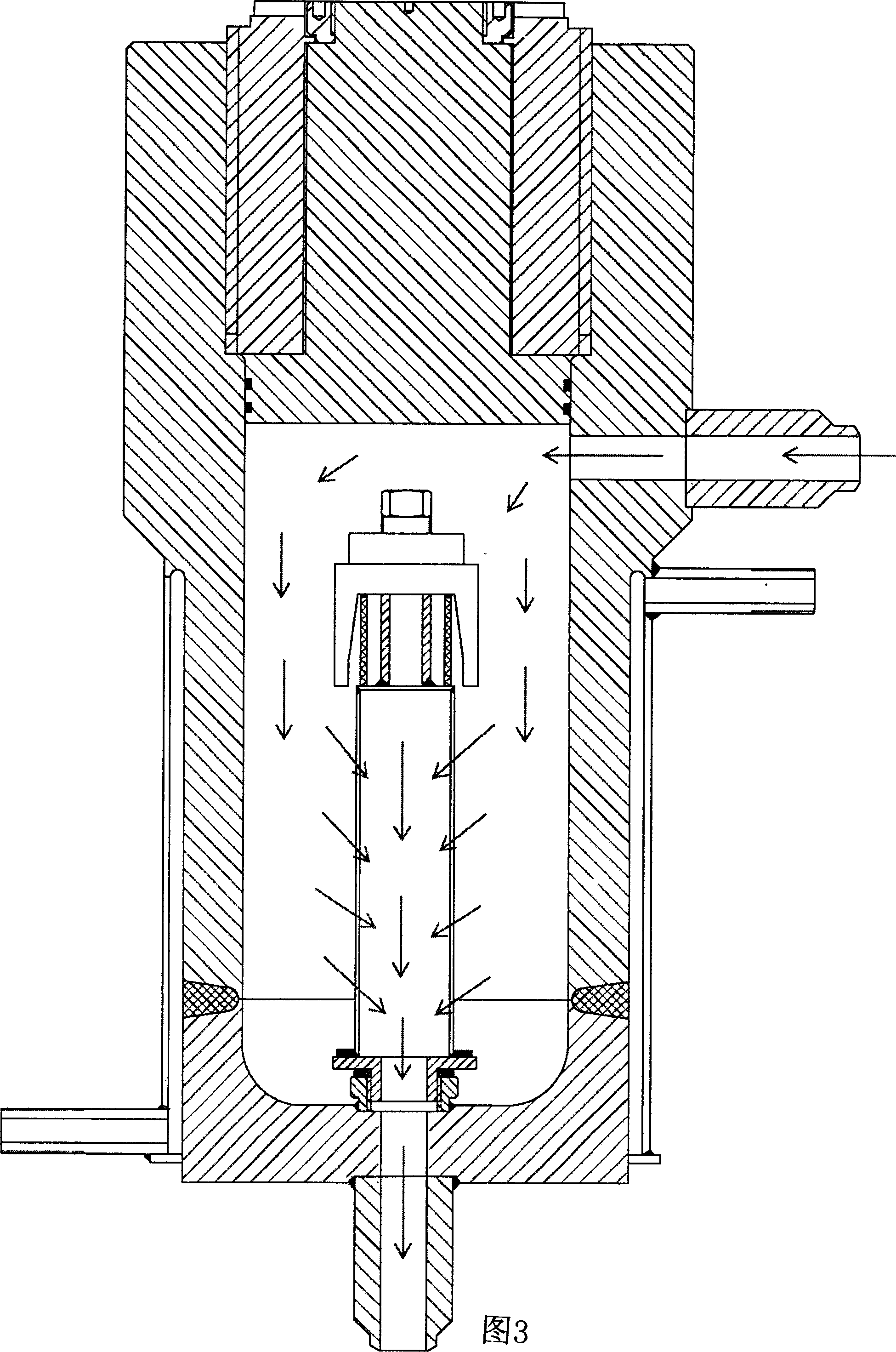

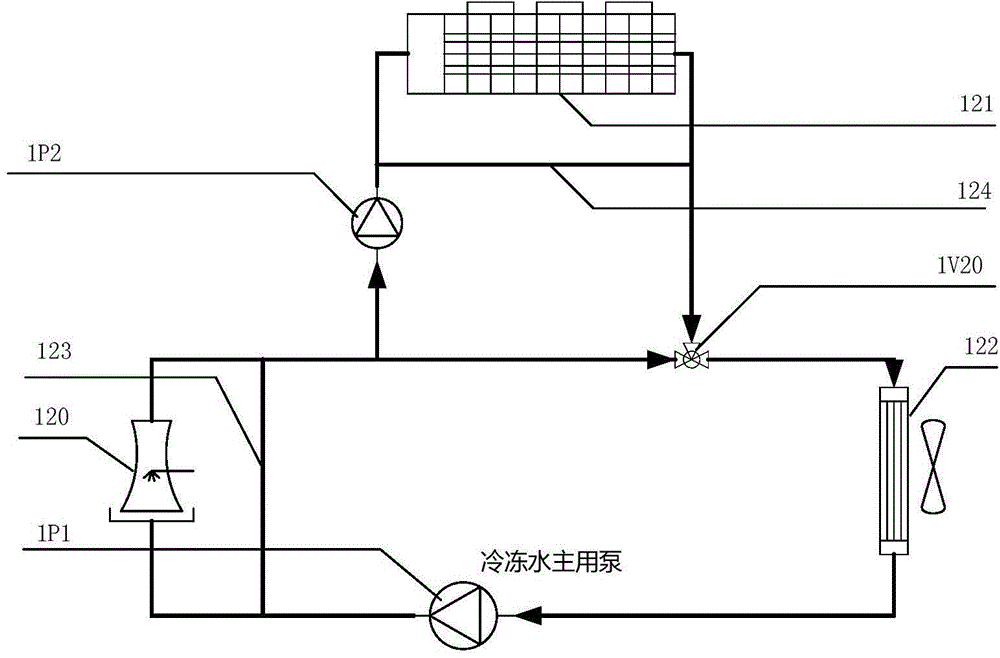

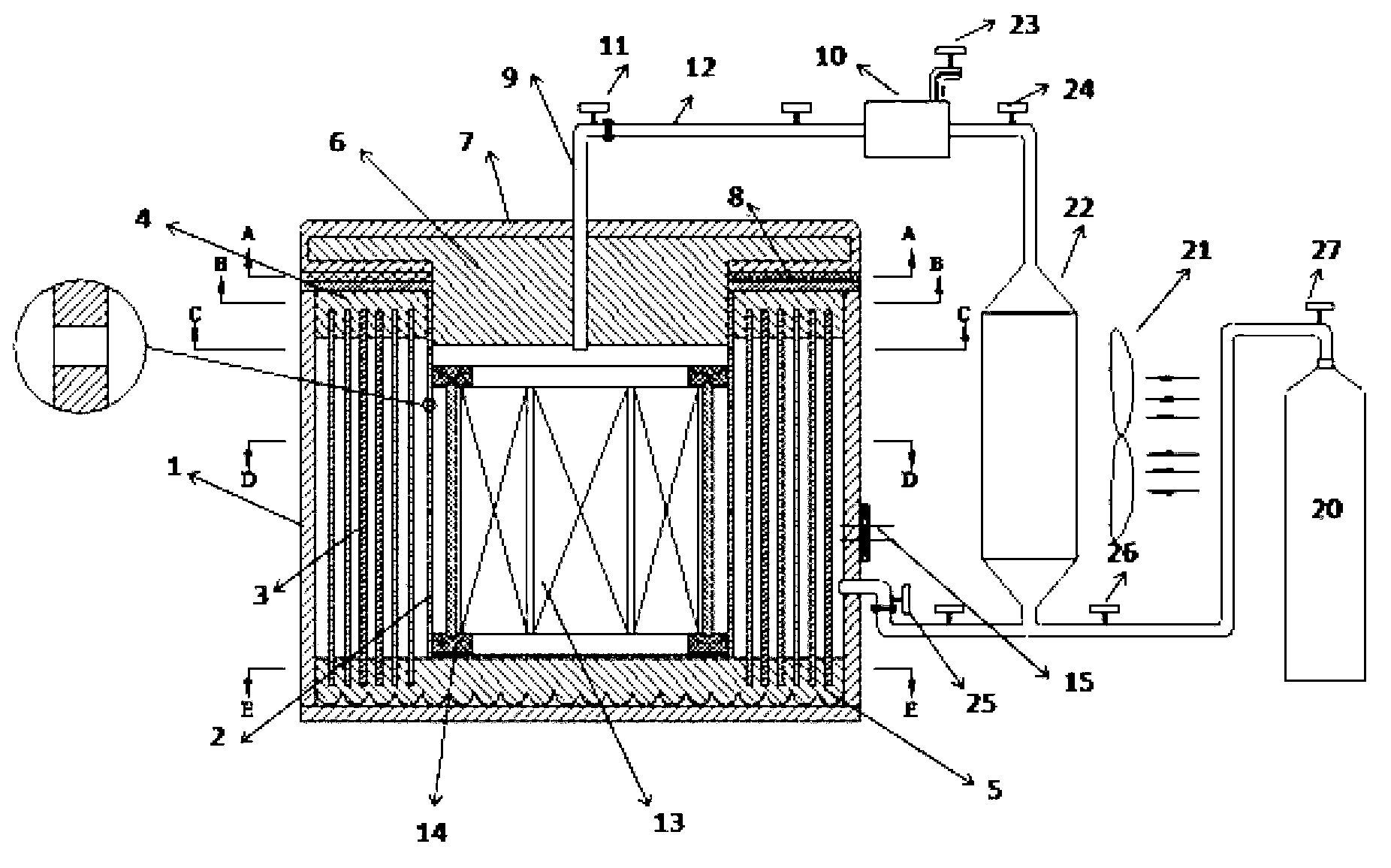

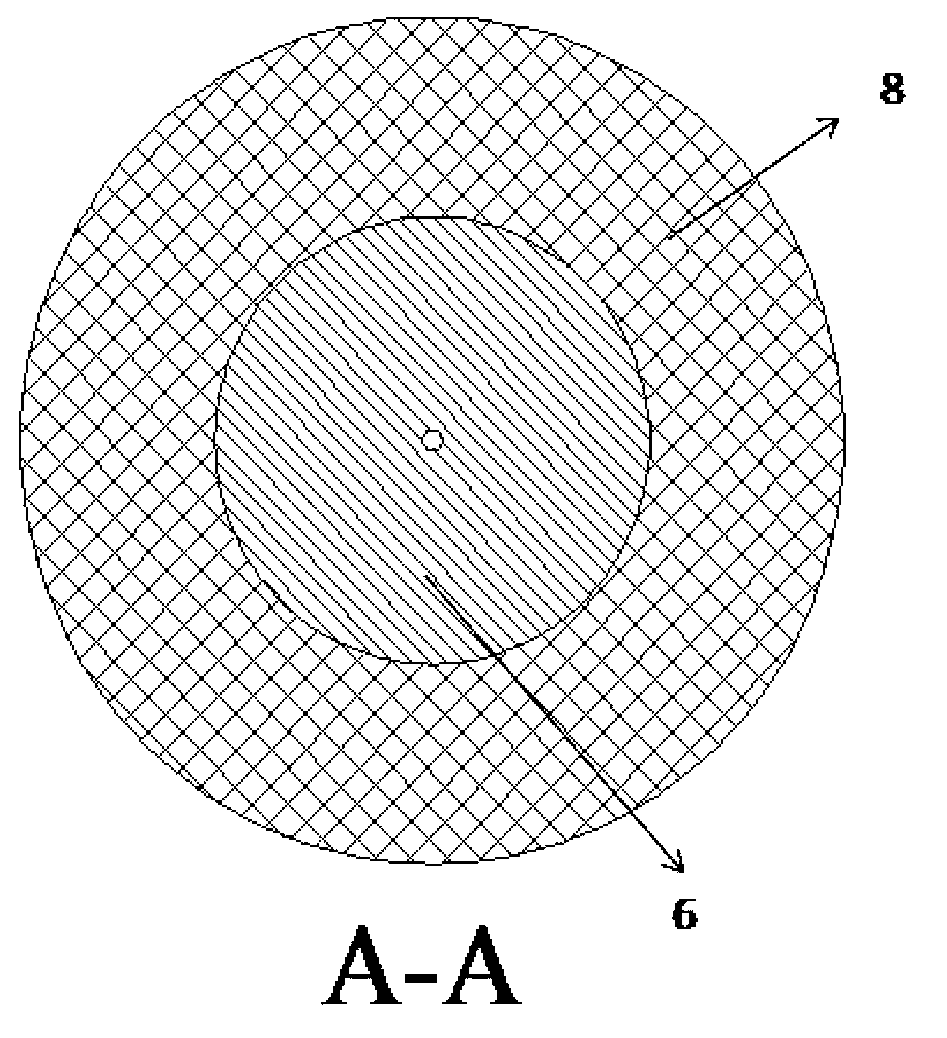

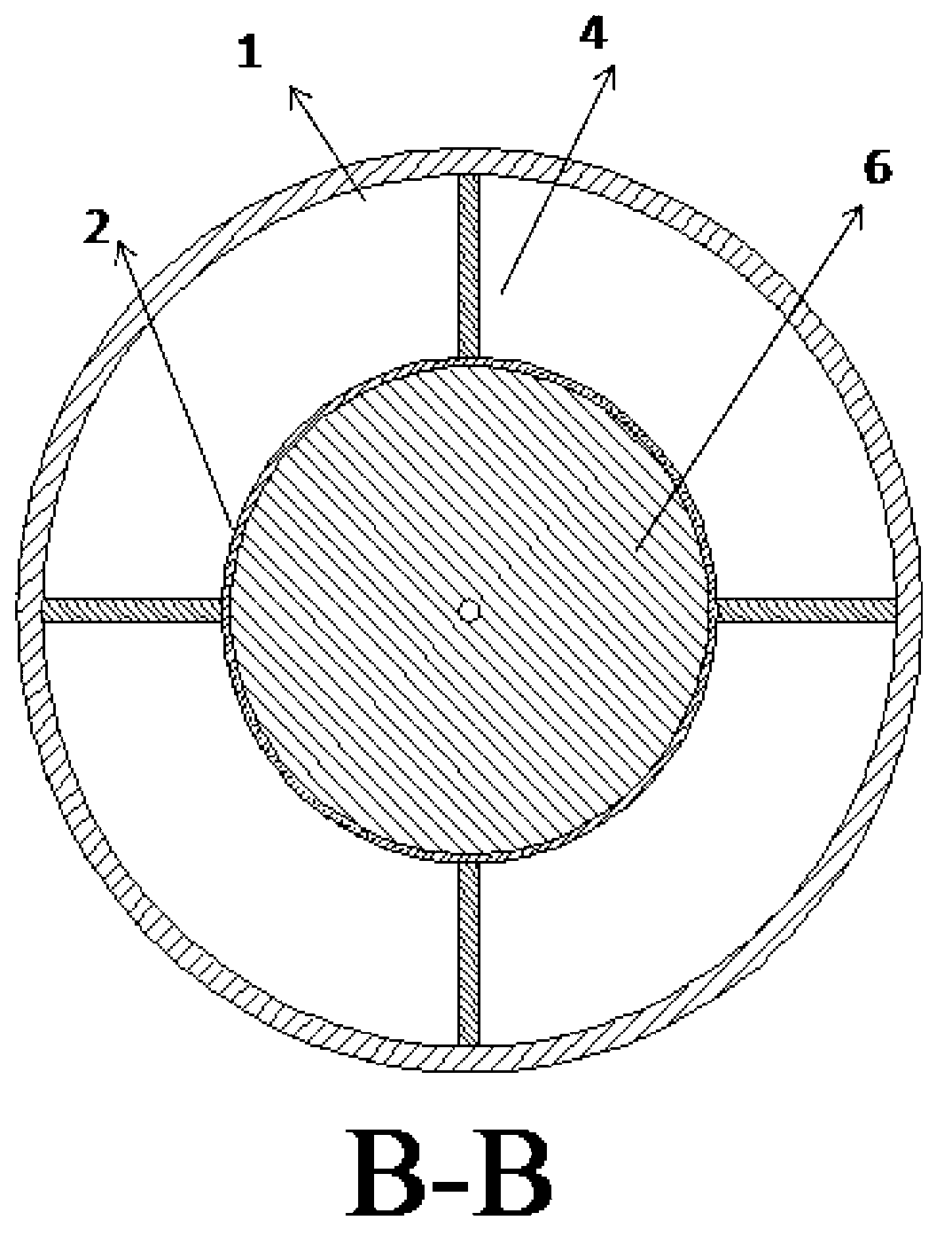

Dying still in supercritical CO2 dyeing device

InactiveCN1807742ARealize the operation process of dynamic dyeingReduce dye liquor vortexTextile treatment containersDyeing processEngineeringMechanical engineering

This invention discloses a dyeing kettle of the over-critical carbon-dioxide dyeing device, which is to use for the dyeing of the textile, including arranging the barrel and the sealed convex shoulder flat that is on the upper part of the barrel; the center opening of the barrel's bottom connects with the first connector, the inside center opening of barrel connects with the inner barrel by the support cell; the wall of the inner barrel is arranged with the filter hole uniformly, the upper of the inner barrel connects with the second cover; the barrel wall opening of the barrel's upper connects with the second connector; the under part of the barrel connects with the nip cover, which has the ring space with the barrel, and the upper of the ring space is sealed in the protruding stage that outside the barrel, and the first cover is sealed in the under part, one side of the ring space's under part opening connects with the first adapter, and the other side of upper part opening connects with the second adapter. This invention realizes the combining of the technology of the textile internal dyeing and external dyeing, and the dynamic dyeing in the over-critical dyeing method.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Artificial inoculation and controlled fermentation process of producing traditional bean jam

The artificial inoculation and controlled fermentation process of producing traditional bean jam belongs to the field of improved and industrialized production process of traditional food. The production process of bean jam has artificial inoculation to prepare yeast, temperature control in the fermentation stage, addition of saccharomycete and lactic acid bacillus in proper fermentation stage, and simulation of natural fermentation process to promote the bean jam mature. The said production process has shorted period less than 50 days while maintaining the flavor of the traditional fermented bean jam unchanged basically.

Owner:JIANGNAN UNIV

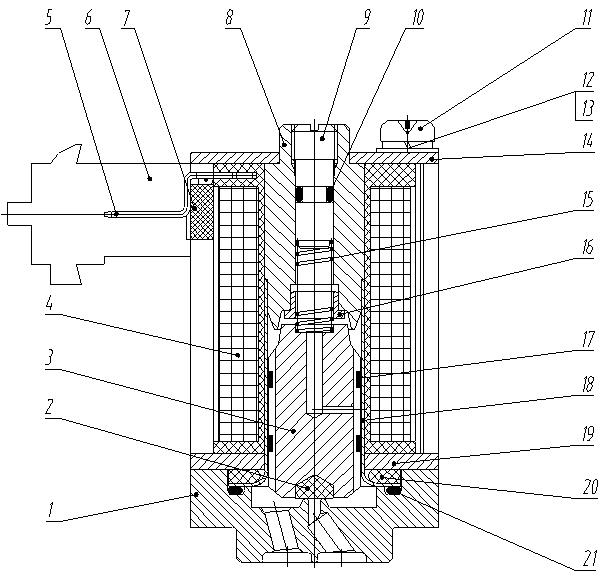

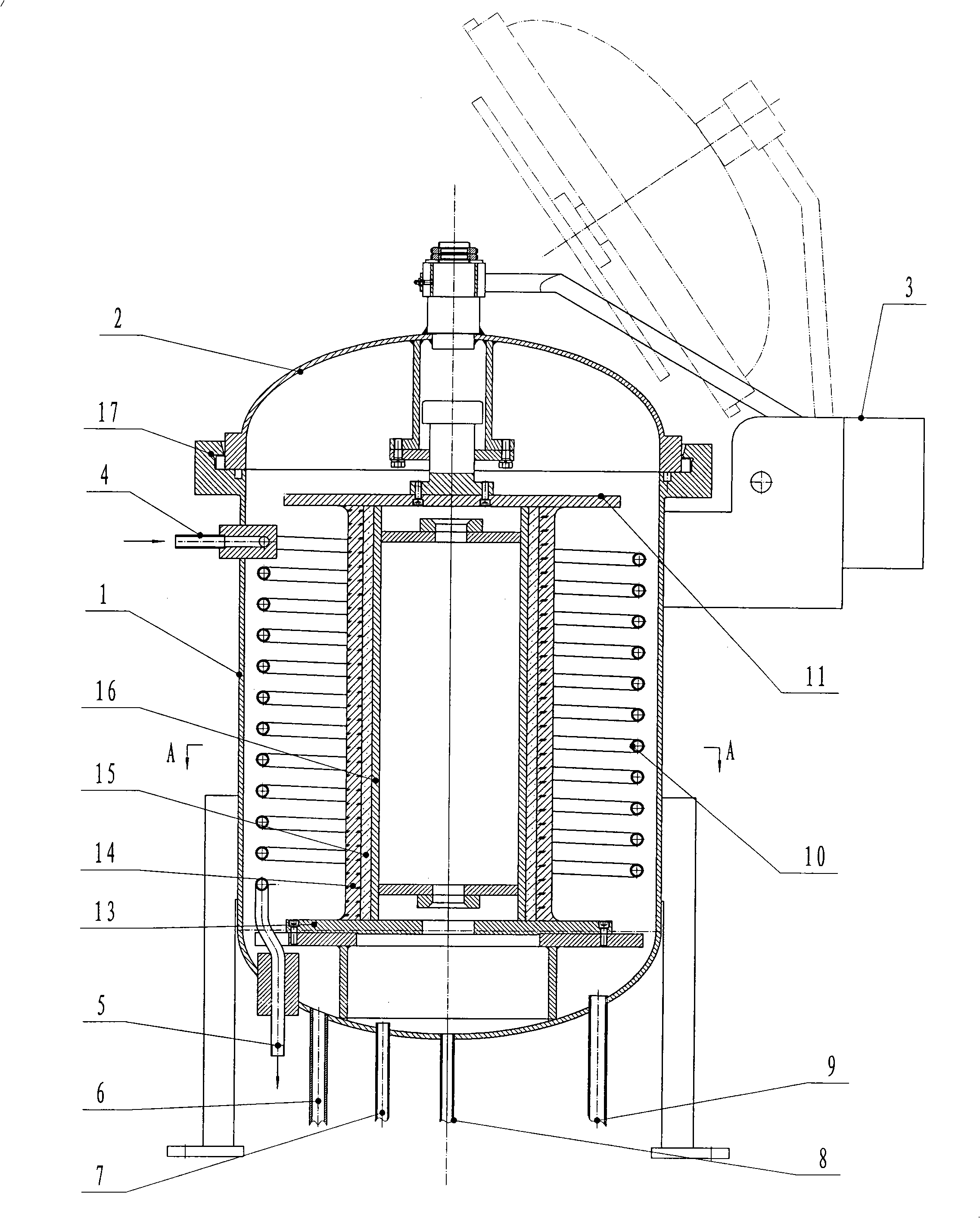

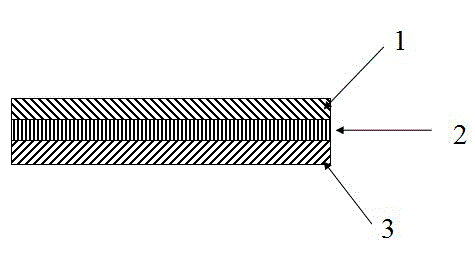

Proportional electromagnetic valve for electrically controlled high-pressure common-rail fuel injection system of diesel engine

InactiveCN102506217AMeet the use requirementsControl on and offOperating means/releasing devices for valvesFuel injection apparatusDriving currentCommon rail

The invention discloses a proportional electromagnetic valve for an electrically controlled high-pressure common-rail fuel injection system of a diesel engine and relates to an electromagnetic valve. A position at which a fixed iron core (8) and a movable iron core (3) of the electromagnetic valve attract each other is a conical polar plane. The fixed iron core (8), the movable iron core (3), a guide pipe (18), a spiral spring (15), an electromagnetic coil (4), a square iron core (19), a shell (14) and a valve body (1) jointly form the electromagnetic valve in an assembling way. When driving current is input into the electromagnetic coil, a magnetic field is generated through a magnetic path in the valve, electromagnetic force with magnitude which is in proportion with the magnitude of the driving current and is not related to a stroke is generated relative to the movable iron core, the movable iron core is enabled to overcome spring force to move, the movable iron core stops moving at a balance point of the two kinds of force and therefore is kept at a stable position, and the movable iron core can proportionally and continuously move according to the magnitude of the driving current to control the opening of the valve. Under complex working conditions under which the diesel engine works, the electromagnetic valve not only can stably control the on / off of a fuel path, but also can accurately and proportionally control the flow of the fuel path according to the driving current.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

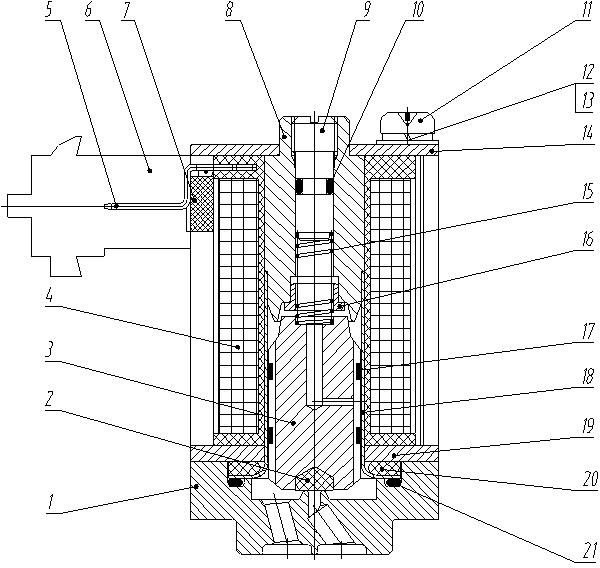

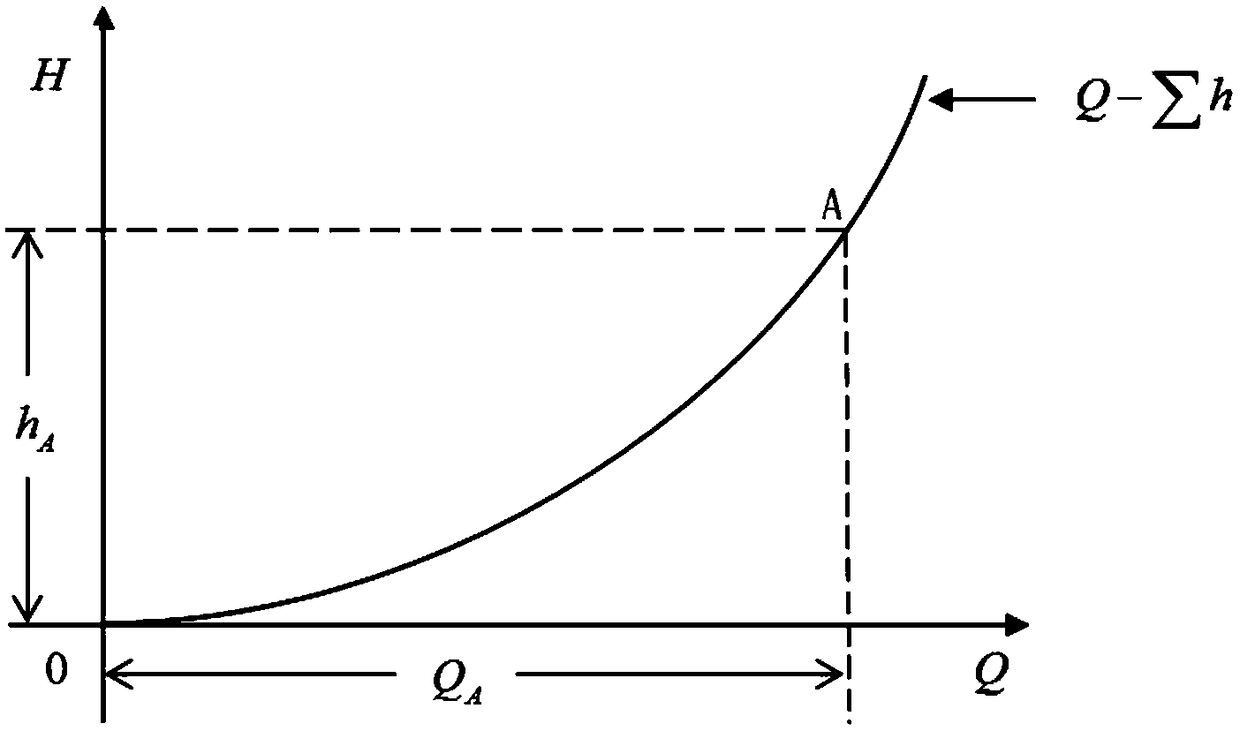

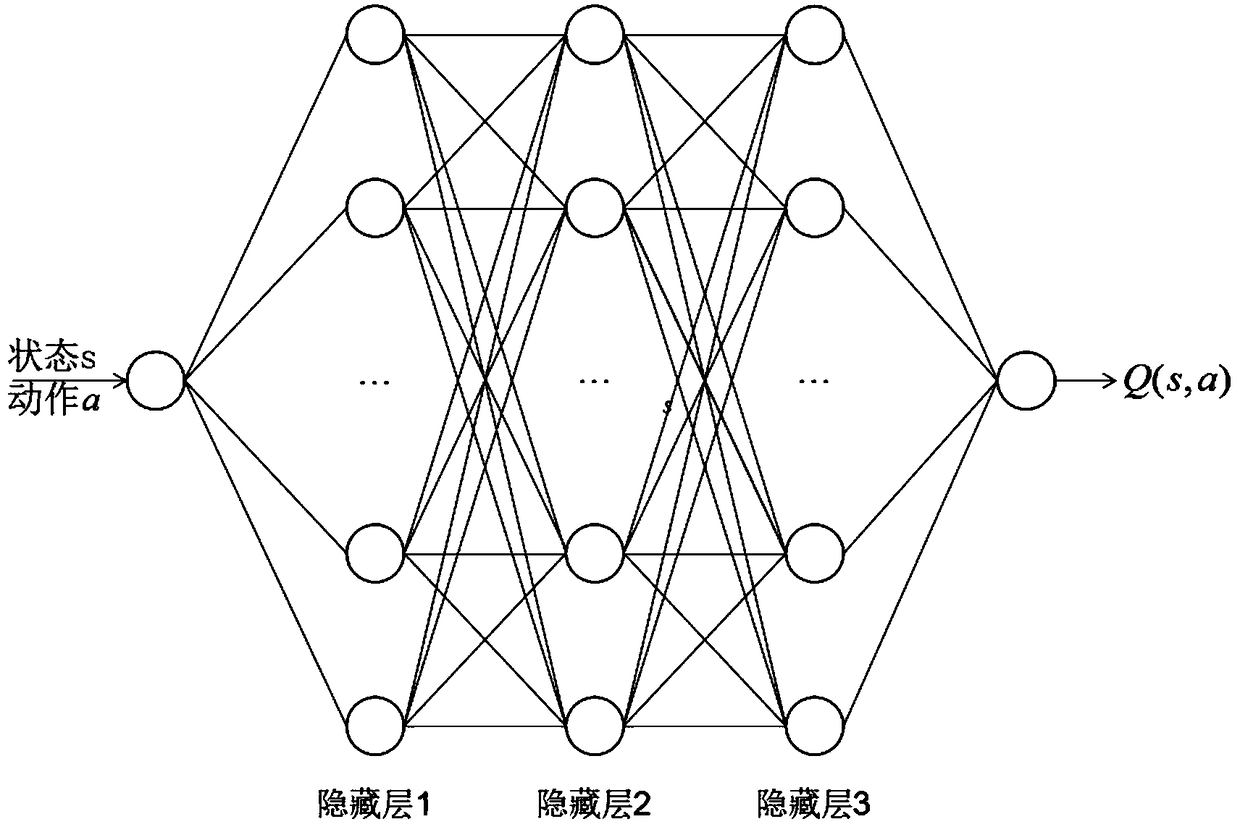

Pure electric vehicle cooling system control method based on deep reinforcement learning

ActiveCN109193075AStable speedAvoid frequent start and stopSecondary cellsPower batteryPid control algorithm

The invention relates to a pure electric vehicle cooling system control method based on deep reinforcement learning, which comprises the following steps: first, obtaining the temperature of the powerbattery of the pure electric vehicle, the working current of the power battery, and the ambient temperature information; Construct DDPG algorithm model, carry on reinforcement learning training, get agroup of optimal PID control parameters of electronic pump. The PID control quantity is obtained by the PID input quantity, and the electronic pump is controlled based on the PID control quantity. The work of the electronic pump changes the flow rate of coolant in the power battery cooling system to achieve the purpose of cooling the power battery. At the same time, the information of the power battery is transmitted to the environment sensing module, and the first step is returned to circulate the whole process. The invention introduces the depth reinforcement learning into the PID control algorithm, the depth reinforcement learning can better interact with the environment, has the self-learning function, adapts to the dynamic characteristics of the uncertain system, and therefore can adapt to the complex and changeable characteristics of the pure electric vehicle running environment, and realizes on-line control under different actual scenes.

Owner:HEFEI UNIV OF TECH

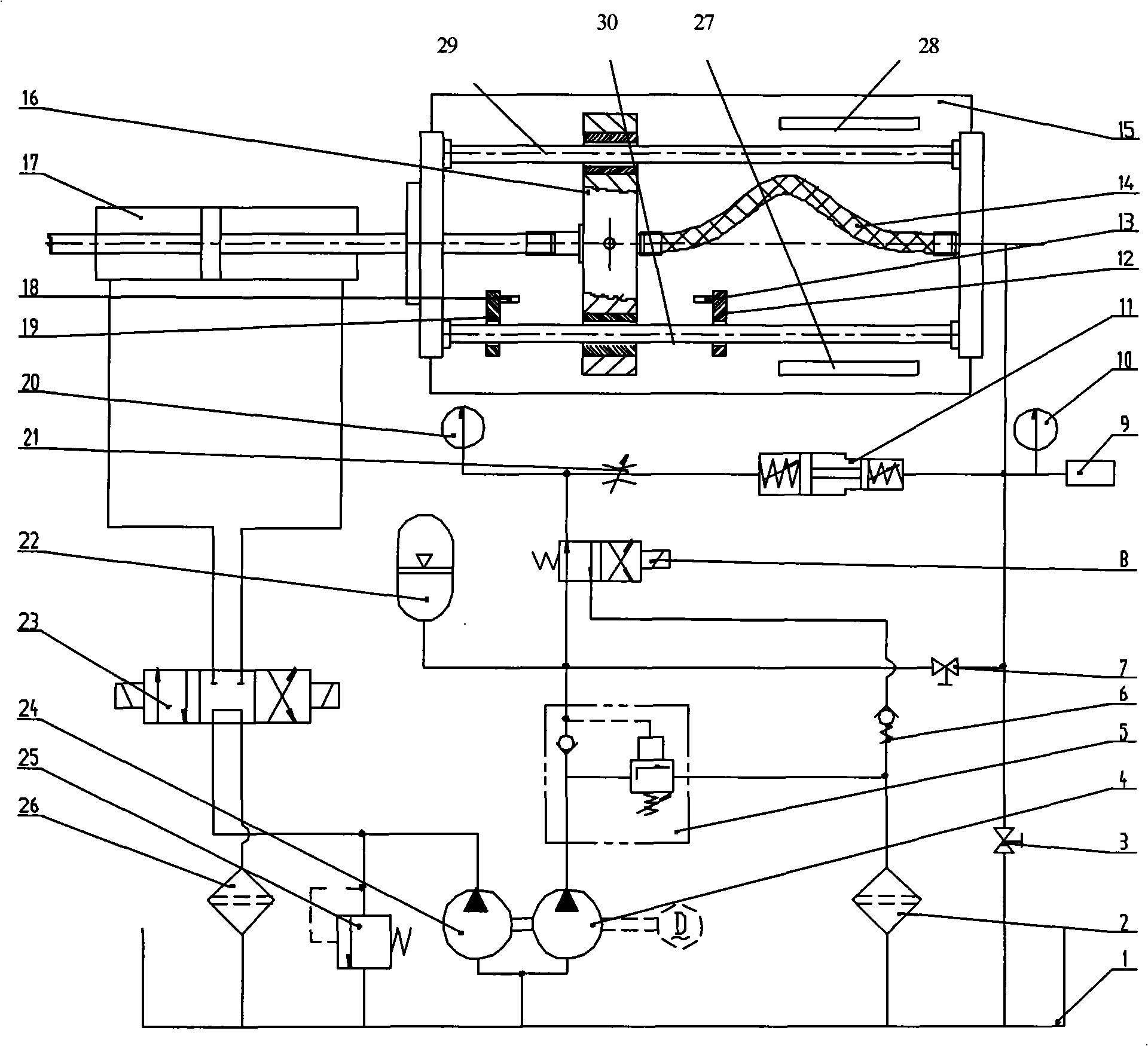

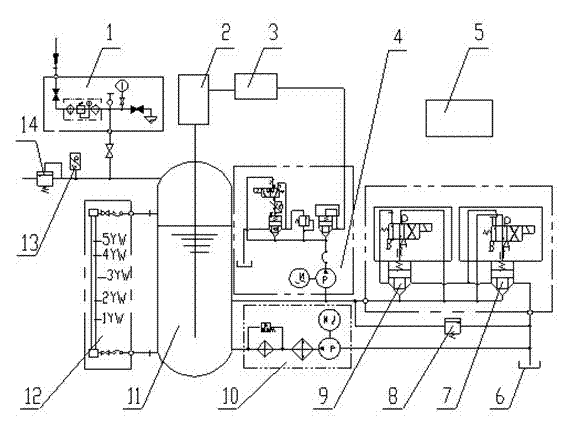

Hydraulic hose performance test experiment table

InactiveCN101672747AAdjustable bendGuaranteed temperature requirementsWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesHydraulic cylinderHydraulic pump

The invention relates to a hydraulic hose performance test experiment table mainly comprising an electric control system, an impact load system, a bending driving system of a hose to be tested, and anenvironmental simulator which are connected mutually, wherein the impact load system mainly comprises a hydraulic oil pump I, an unloading spillover valve, an accumulator, a two-position four-way magnet valve, a throttle , a pressure booster, a stop valve, a counterbalance valve, an oil return filter I, a pressure gauge, a pressure sensor, an oil tank, a connection oil pipe, a joint, and the like; the bending driving system of a hose to be tested mainly comprises a hydraulic oil pump II, a safety valve, an oil return filter II, a three-position four-way magnet valve, a hydraulic oil cylinder,a connection oil pipe, a joint, and the like; and the environmental simulator mainly comprises an environmental chamber body and an electric heater, an ultraviolet emitter and a bending degree controller of a hose to be tested, which are arranged in the environmental chamber body. The experiment table can test a plurality of hoses simultaneously, test the experimental pressure wave shape of the hoses to be tested on line and estimate the fatigue lifetime of the hoses to be tested; and the invention has simple structure, easy operation, little energy consumption and high reliability.

Owner:徐州沃土资产管理有限公司

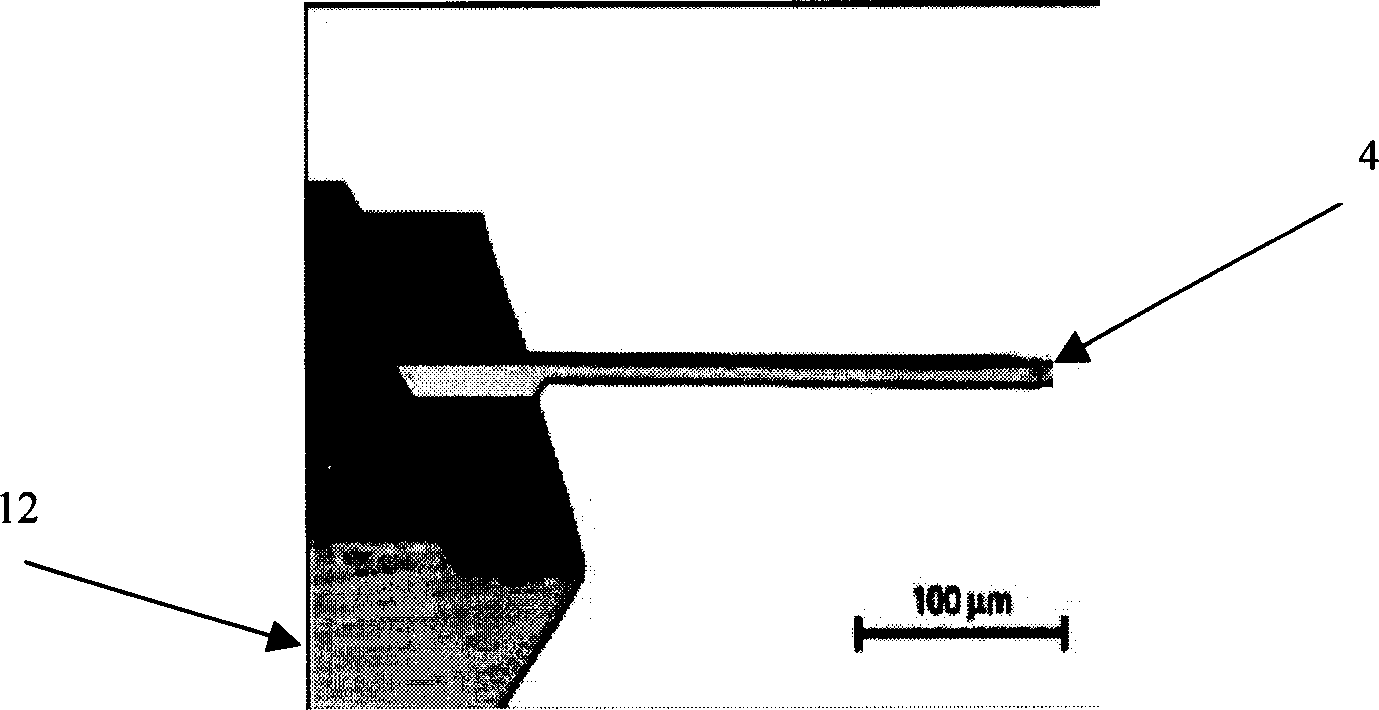

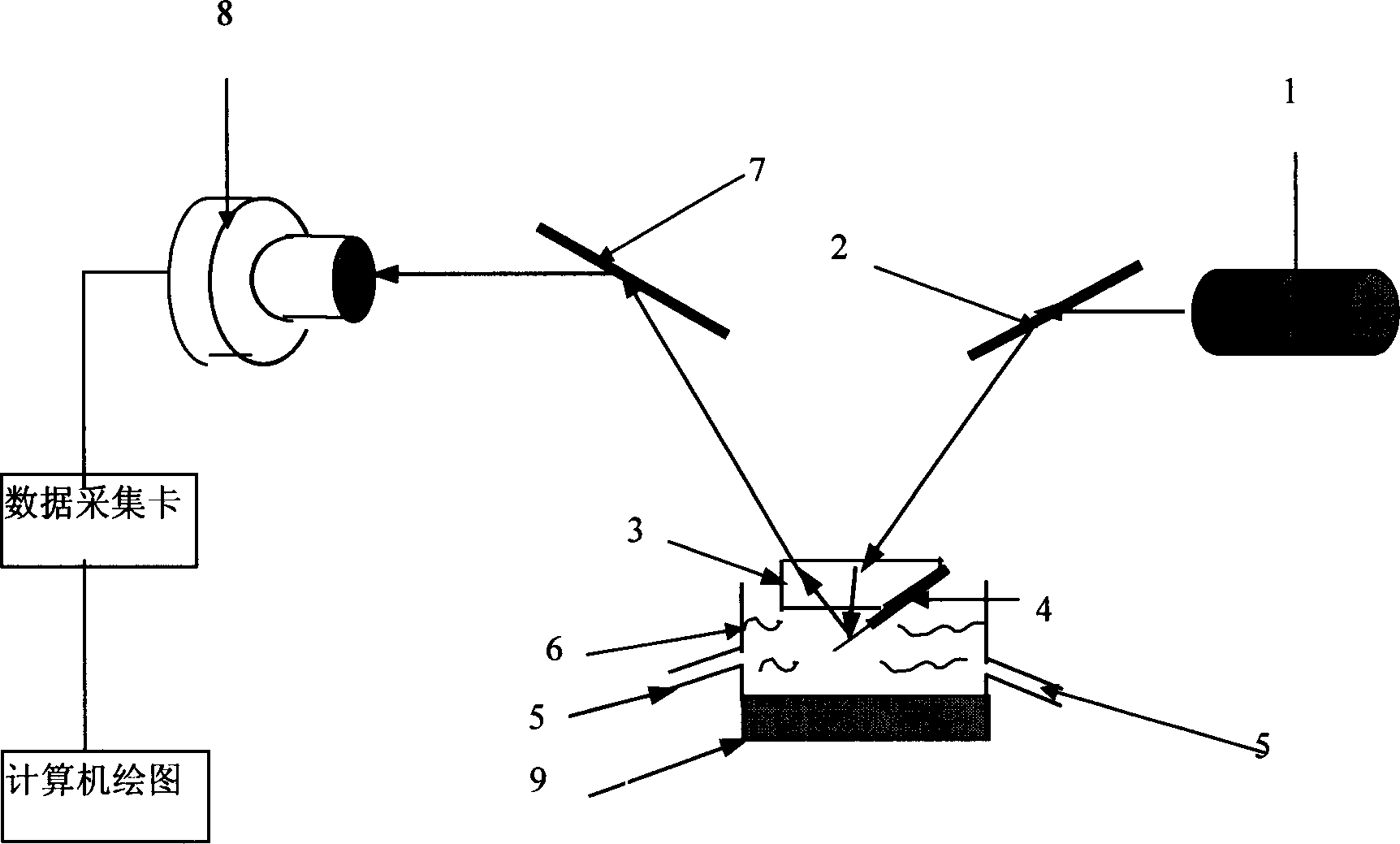

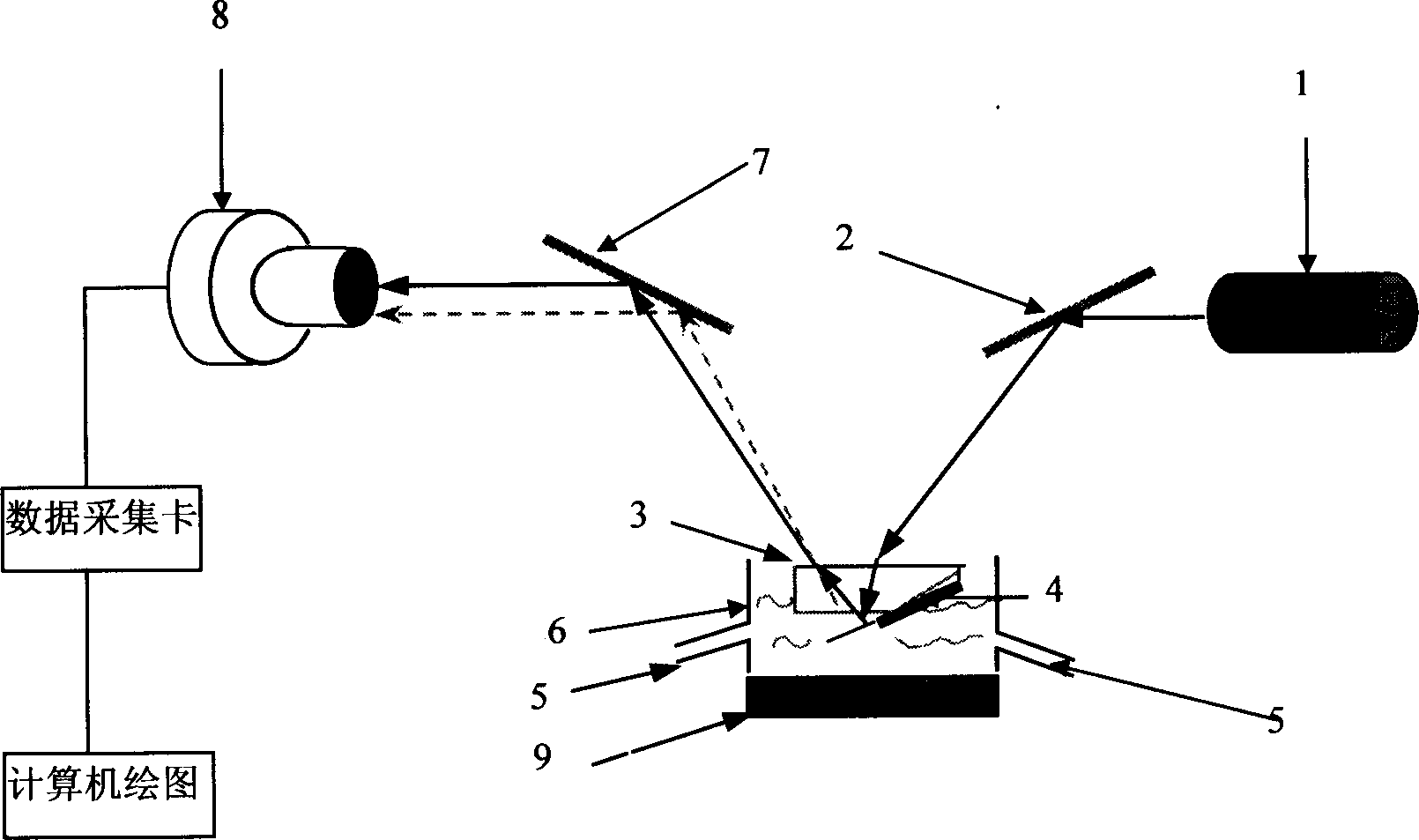

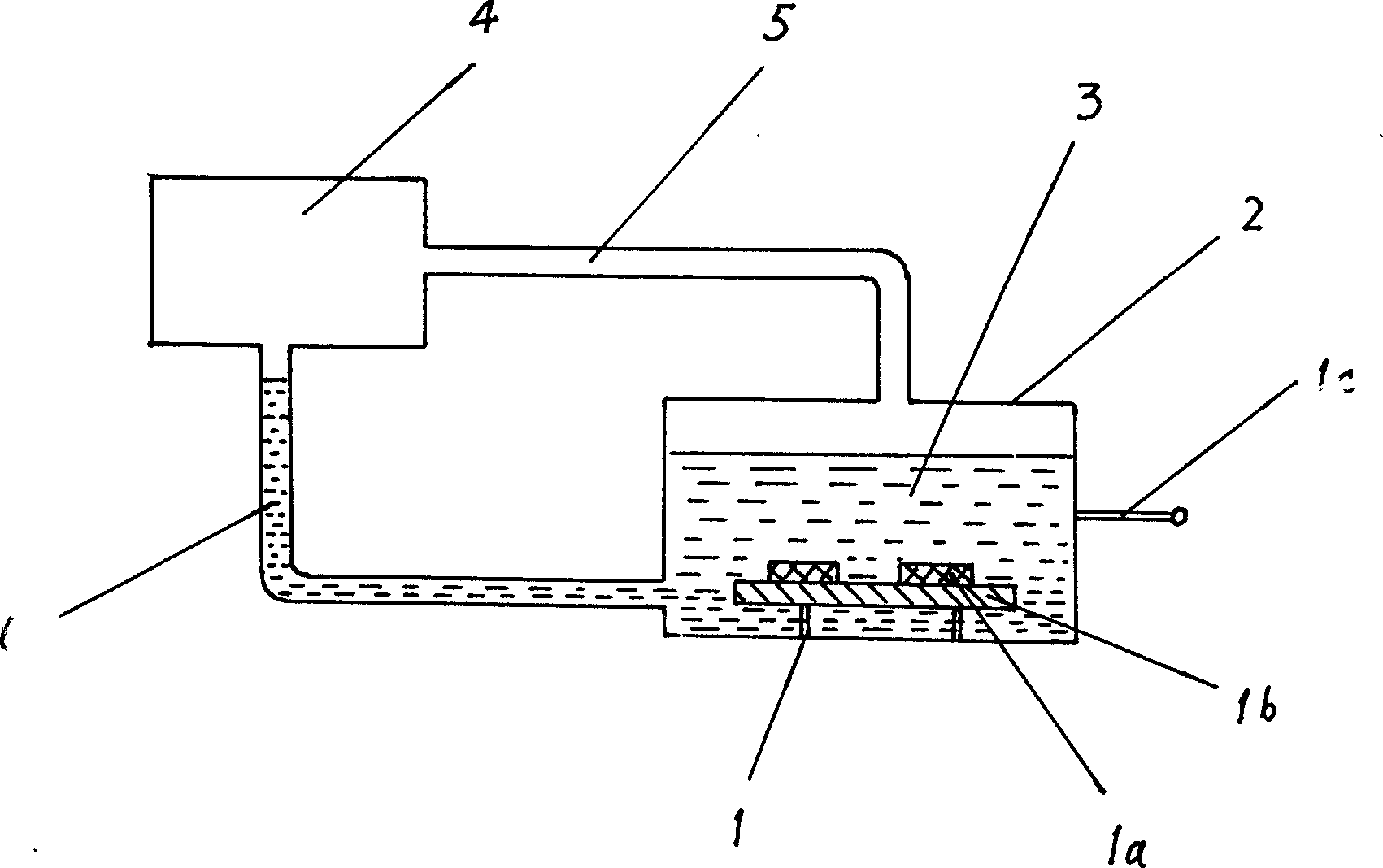

Method and devices of biochemical detection by using micro semi girder

InactiveCN1796989AHigh sensitivityGuaranteed temperature requirementsSurface/boundary effectMaterial electrochemical variablesSurface stressData acquisition

The invention is a biochemical detecting method and device using micro cantilever beam, using a micro cantilever made of silicon coated with biochemical sensitive layer as a biochemical molecule detecting element. As the measured matter enters into the bio-sensitive layer, the bio-sensitive layer absorbs the molecules of the measured matter to make the molecules of the measured matter and those of the bio-sensitive layer interact on each other by force so as to make the micro cantilever beam generate a surface stress whose change will bend the micro cantilever beam, a laser beam reflected from the back of the micro cantilever beam is received by a position sensitive detector, the deformation of the micro cantilever beam will make the laser spot shift on the position sensitive detector, the position sensitive detector converts the optical signal displacement into an electric signal, which is collected through a data collection card into a computer and expressed by image. The invention has high sensitivity and can serve as a biochemical sensor for detecting trace biochemical molecules.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Packing, workshop and method for carrying out harmless treatment on dead livestock

InactiveCN103028593ASimple recipeLow costAgricultural buildingsSolid waste disposalPathogenic microorganismAfter treatment

The invention relates to packing, a workshop and a method for carrying out harmless treatment on dead livestock. The packing comprises base stocks and microbial flora, wherein the base stocks comprise rice hulls, sawdust and rice brans; the weight ratio of the microbial flora to the base stocks is (5 to 10):1,000; and the microbial flora comprises one or more of bacillus subtilis, lactic acid bacteria and saccharomycetes. The packing, the workshop and the method for carrying out harmless treatment on the dead livestock have the benefits that the harmless treatment process has simple steps and does not require special equipment; all the dead livestock can be subjected to high temperature rotten treatment to be changed into humus in short time; pathogenic microorganisms such as bacteria, virtues and the like are all killed; treatment is carried out completely; no epidemic hidden danger is reserved; and after treatment is completed, the obtained humus can be used for planting flowers, planting vegetables and the like.

Owner:LINYI XINCHENG JINLUO ANIMAL HUSBANDRY CO LTD

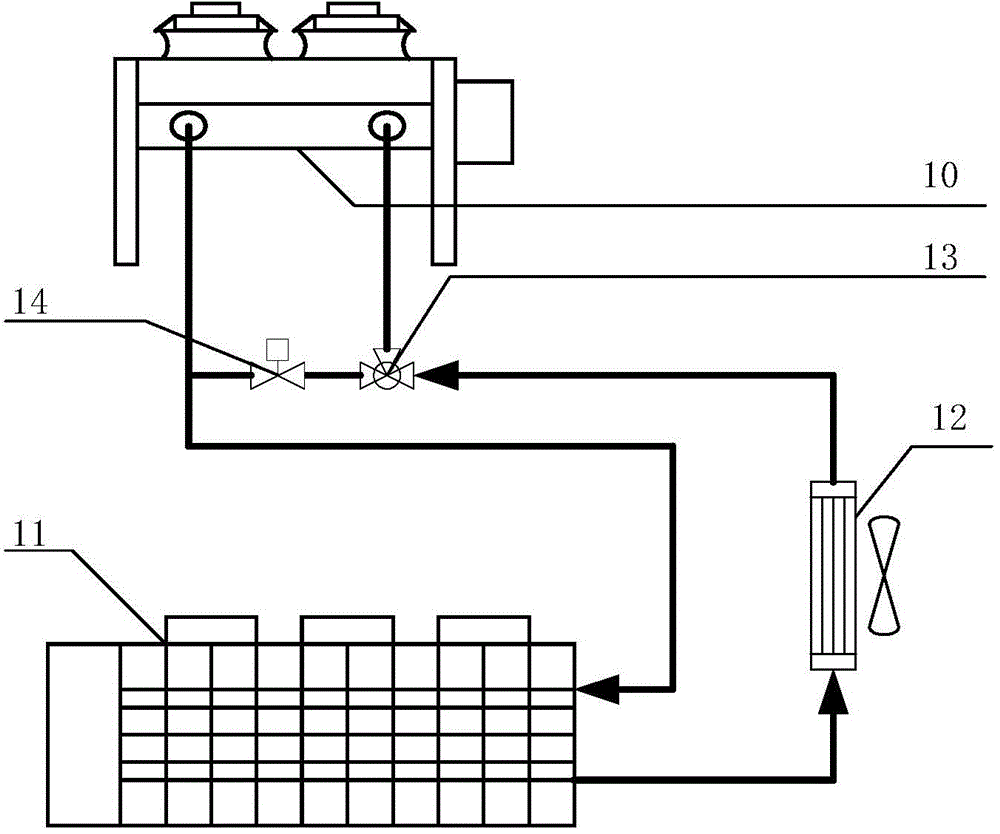

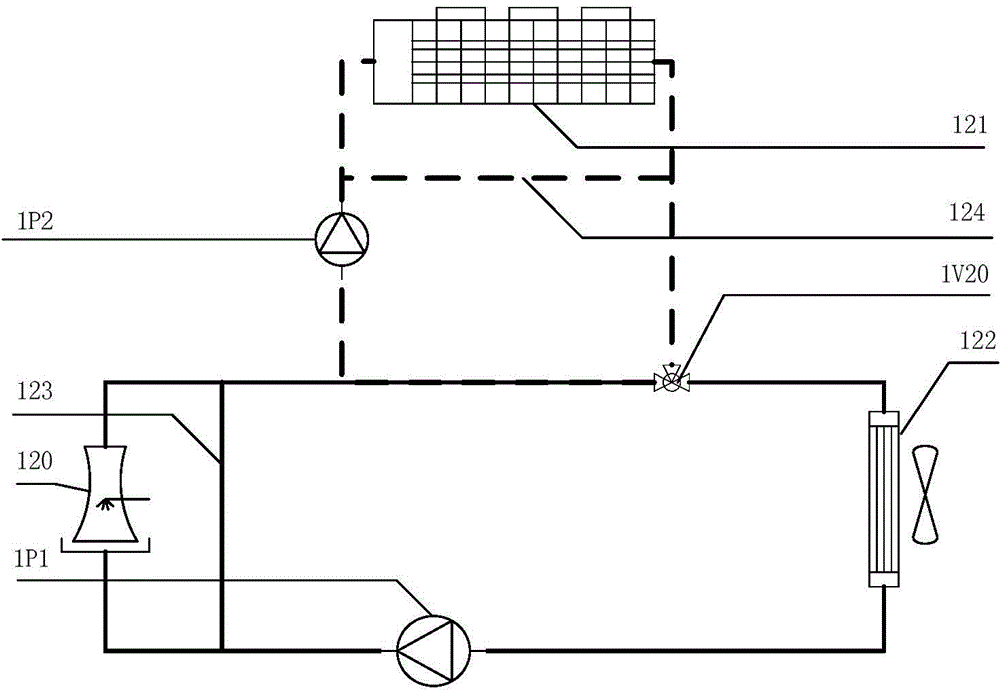

Chilled-water cooling system

ActiveCN106032919AShorten the lengthImprove cycle efficiencyHeat storage plantsSteam/vapor condensersNuclear engineeringData center

The invention discloses a chilled-water cooling system, which comprises a natural cooling loop consisting of a natural cooler, a chilled-water main pump, a pipeline and an end heat exchanger and a mechanical cooling loop consisting of a chilled-water main engine, a chilled-water auxiliary pump and a pipeline. By controlling a conduction-isolation device between the mechanical cooling loop and the natural cooling loop, the effect of mainly adopting the natural cooler and assistantly adopting mechanical cooling is achieved, thereby reducing energy consumption, improving the efficiency of a refrigeration system and furthermore reducing the cost of the refrigeration system. The present invention is applicable to any place where the natural cooling technology is applied for the purpose of cooling, such as a data center or a machine room.

Owner:ALIBABA (CHINA) CO LTD

Driving belt vulcanizing boiler

A transmission belt vulcanizing boiler comprises a gum cover, an inner cavity between a cover plate and a supporting plate, an outer cavity between the gum cover and the transmission belt vulcanizing boiler, a steam inlet and a steam outlet of the inner cavity, and a pressure air inlet and a pressure air outlet of an outer cavity; wherein, the outer cavity is provided with a high temperature steam heating pipe which is provided with a high temperature steam inlet and a high temperature steam outlet. The high temperature steam heating pipe heats the pressure air in the outer cavity, which ensures the temperature requirement of the outer cavity and ensures high heat energy utilization rate. The high temperature steam heating pipe solely regulates the temperature of the outer cavity, thereby the temperature and pressure of the outer cavity being easy to control. The high temperature steam heating pipe is adopted to prevent steam from dissipating. The inner cavity and the outer cavity share a set of steam heating system, thereby saving energy consumption. The steam inlet of the inner cavity is connected with a pumping line, which is beneficial to the full combination of a belt tube and a mould. The transmission belt vulcanizing boiler also has the advantages of raising product vulcanization quality, shortening vulcanization time and saving steam consumption.

Owner:青岛信森机电技术有限公司

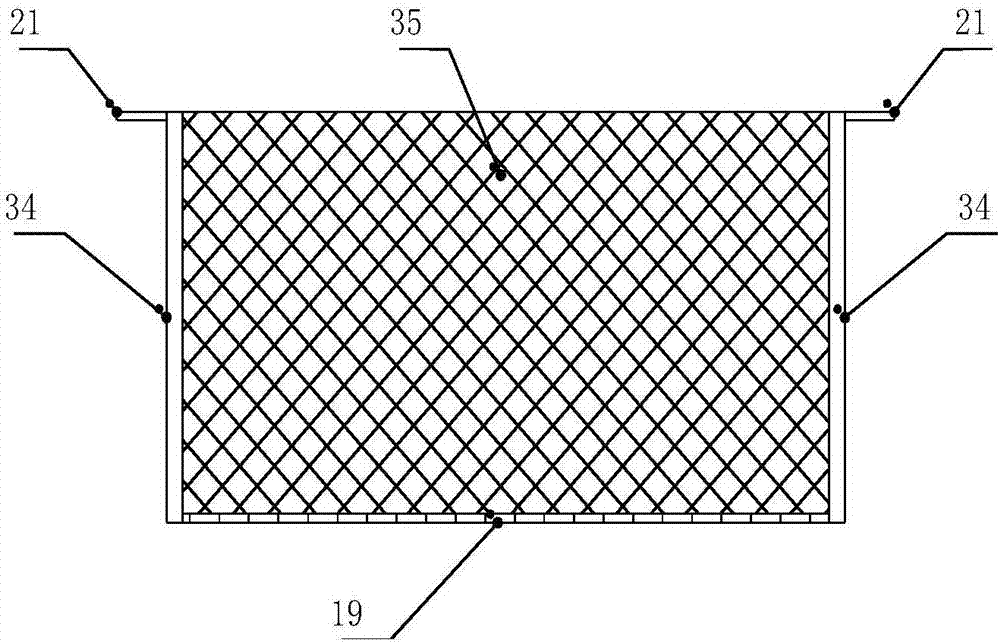

Ultrasonic root system cleaning machine and working method thereof

PendingCN107036869AAvoid damageGuaranteed temperature requirementsPreparing sample for investigationCleaning using liquidsSludgeMechanical engineering

The invention discloses an ultrasonic root system cleaning machine and a working method thereof. The ultrasonic root system cleaning machine comprises a machine body. A top cover plate is fixedly connected to the upper portion of the machine body, and a cleaning basket is connected to the lower portion of the top cover plate. A cleaning chamber is arranged in the machine body, and comprises a main cleaning chamber. A soil settling chamber is arranged below the main cleaning chamber, and a deposition chamber is arranged below the soil settling chamber. A mud discharger is arranged in the deposition chamber and connected with a driving mechanism, and the driving mechanism is connected with an integrated controller. A dirt discharge hole is formed under the position, stretching out of the machine body, of the deposition chamber. An ultrasonic generator I and an ultrasonic generator II are oppositely installed on the inner sides of the machine body respectively and connected with the integrated controller, and the integrated controller is used for adjusting the frequency and power of the ultrasonic generator I and the ultrasonic generator II. The problems of power and frequency adjustment, machine bottom sludge discharge and root system damage are effectively solved, and the working efficiency of the cleaning machine is improved.

Owner:INNER MONGOLIA UNIV FOR THE NATITIES

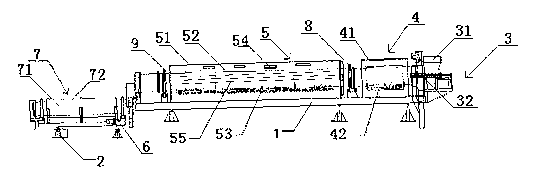

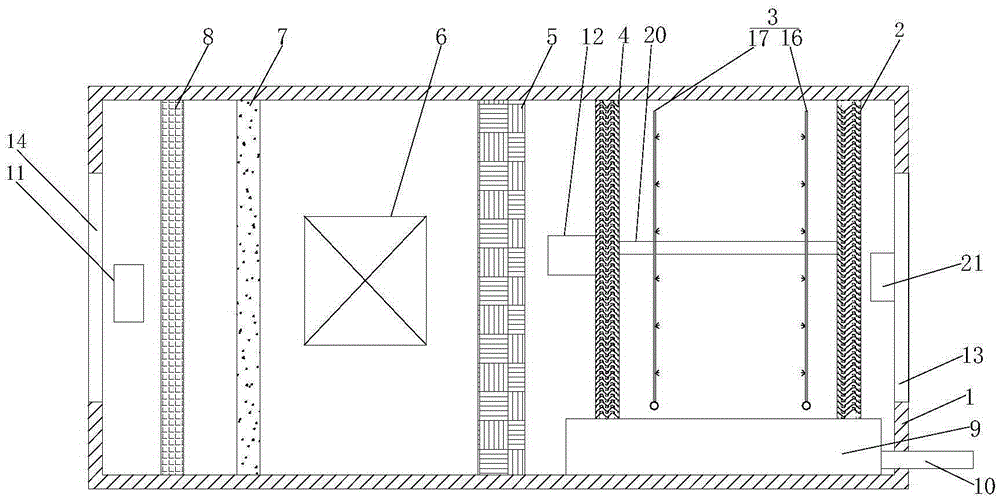

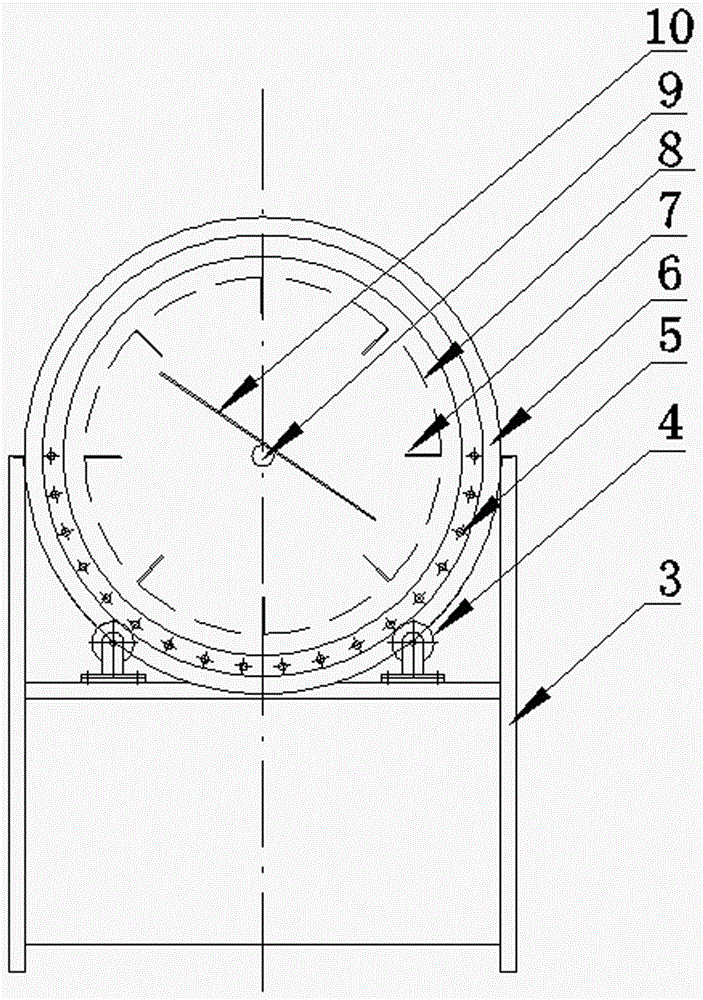

Cobalt hydroxide rotary drying device

InactiveCN103292582AGuaranteed temperature requirementsUniform temperatureDrying solid materialsDrying machines with non-progressive movementsCobalt hydroxideElectric heating

The invention discloses a cobalt hydroxide rotary drying device which comprises a base, a support, a feeding device, a low-temperature drying device, a high-temperature roasting device and a cooling device. The feeding device, the low-temperature drying device, the high-temperature roasting device and the cooling device are sequentially fixed on the base, wherein the support is arranged at the lower end of the base and used for supporting, the low-temperature drying device comprises a first heat preservation layer and a first electric heating furnace tube arranged in the first heat preservation layer, and the high-temperature roasting device comprises a second heat preservation layer, a second electric heating furnace tube, a rotary cylinder body and a lifting board. The second electric heating furnace tube is arranged between the heat preservation layer and the rotary cylinder body, the lifting board is vertically arranged on the inner wall of the rotary cylinder body, the cooling device comprises a third heat preservation layer and a cooler arranged in the third heat preservation layer, and the cooling device is used for conducting cooling and discharging on dried cobalt hydroxide. The cobalt hydroxide rotary drying device has the advantages that the yield is large, energy consumption is low, the temperature is uniform and few metal foreign bodies are led in.

Owner:NANTONG RESHINE NEW MATERIAL

Cultivation and pruning method for Sichuan pepper trees

InactiveCN109220465AAddressing Adaptive IssuesSolve the initial weak growthGrowth substratesCulture mediaDiseaseEconomic benefits

The invention discloses a cultivation and pruning method for Sichuan pepper trees and belongs to the technical field of crop planting. The method comprises the steps of 1, selection and treatment of agarden field; 2, seed collection and treatment; 3, seedling raising; 4, management at the seedling period; 5, overwintering management at the seedling period; 6, transplantation and interplanting; 7,cultivation management and pruning; 8, prevention and control of diseases and pests. By adopting the method, the Sichuan pepper trees and coptis chinensis are interplanted for cultivation, compared with common interplanting cultivation, coptis chinensis and the Sichuan pepper trees grow robustly, the yield of Sichuan peppers per plant is increased by 2.7%, the yield of coptis chinensis per seedling raising pit area is increased by about 8.5%, and the good economic benefit is achieved.

Owner:王斌

Plate drying system

InactiveCN104344700ASmooth dischargeEvenly heatedDrying gas arrangementsDrying machines with progressive movementsCombustion chamberProcess engineering

The invention discloses a plate drying system. The plate drying system consists of a drying chamber (1), a combustion furnace (2), a heat conduction system and a plate conveying system, wherein the drying chamber (1) is arranged into a rectangular shape, the roof and the side walls of the drying chamber (1) are built through the laying of thermal insulating materials, a combustion furnace thermodetector is arranged outside the drying chamber (1), and the combustion furnace (2) is provided with a combustion chamber (4) and a hot air chamber (3). The adopted plate drying system improves the plate drying rate, reduces the production cost and improves the consistency of plate quality.

Owner:JIANGXI XIANGHE IND

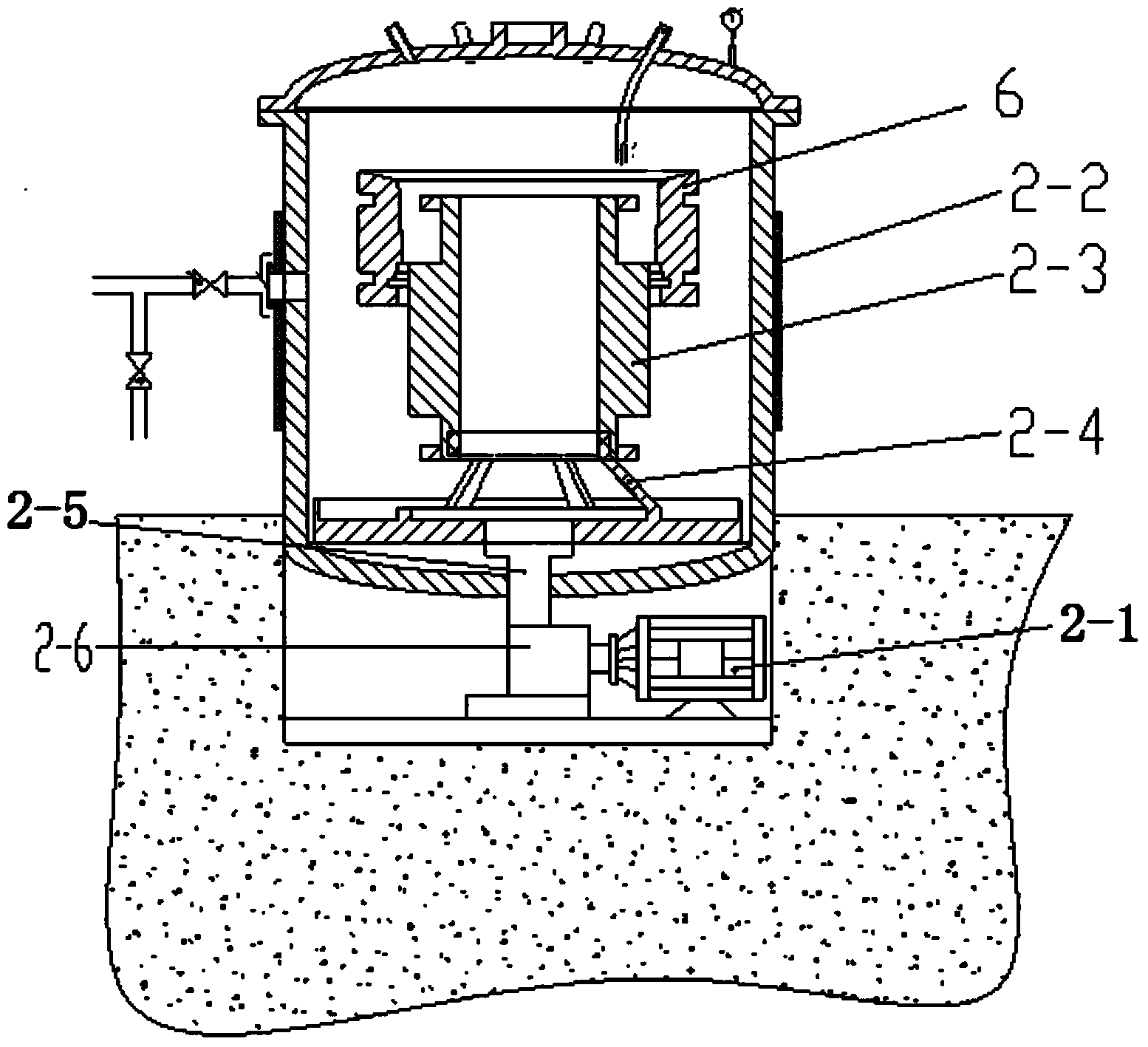

Automatic liquid supplementing and draining system with liquid filling tank

ActiveCN102489650AImprove oil absorptionExtend your lifePipeline systemsForging press drivesOil supplyLiquid level sensor

The invention belongs to a forging oil hydraulic press system, in particular to an automatic liquid supplementing and draining system with a liquid filling tank in a fast forging oil hydraulic press system; the automatic liquid supplementing and draining system with the liquid filling tank is characterized by at least comprising the liquid filling tank, an oil supply loop, an oil discharging loop and a working oil line, wherein the oil supply loop and the oil discharging loop are connected with the liquid filling tank, and the working oil line supplies working oil to a working cylinder; the liquid filling tank is connected with a liquid level sensor and a charging loop; when the automatic liquid supplementing and draining system works, the charging loop charges 0.3-0.5 MPa of air pressure into the liquid filling tank, the liquid level sensor detects the oil level of the liquid filling tank; when the oil level is lower than a low oil level, an electric control unit controls the oil supply loop to supply oil to the liquid filling tank; and when the oil level is high than a high oil level of the liquid filling tank, the oil supply loop stops working, and the electric control unit controls the oil discharging loop to work. The automatic liquid supplementing and draining system has the advantages that the oil absorption condition of a main pump device is improved and the pressure impact and vibration of the system are reduced, thereby the working efficiency of the oil hydraulic press is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

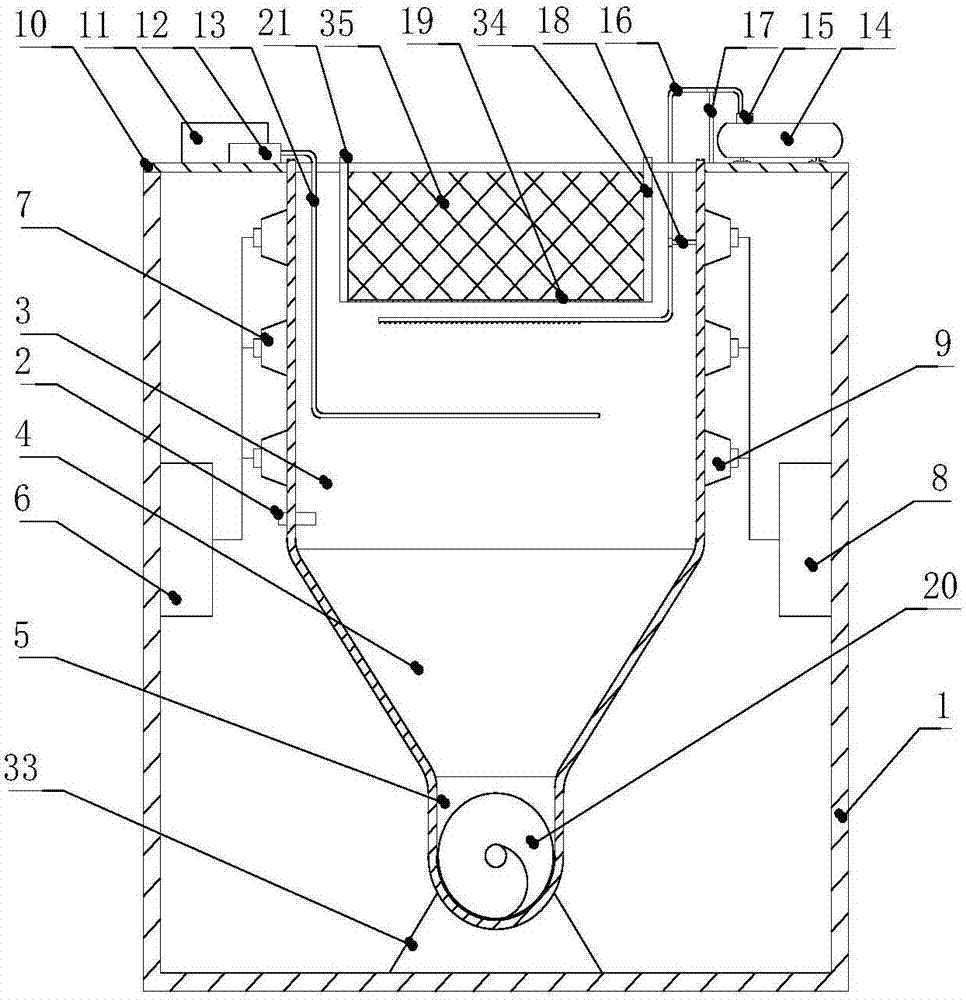

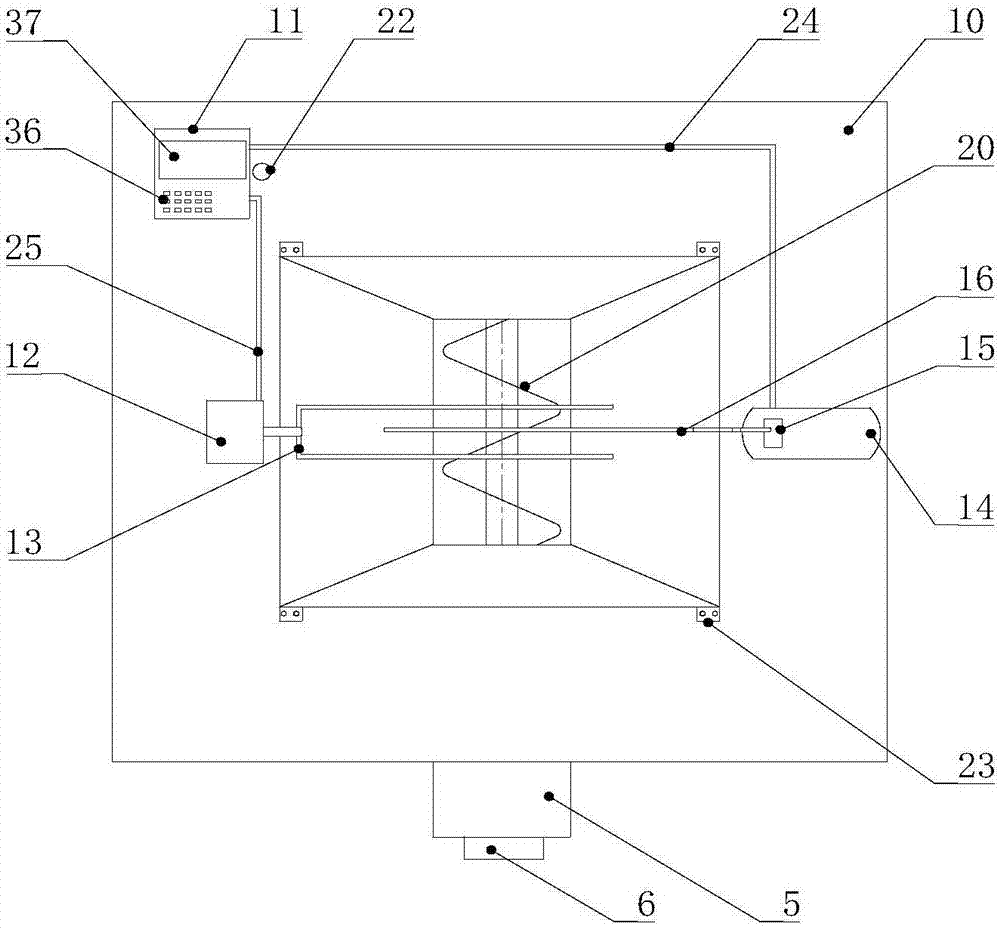

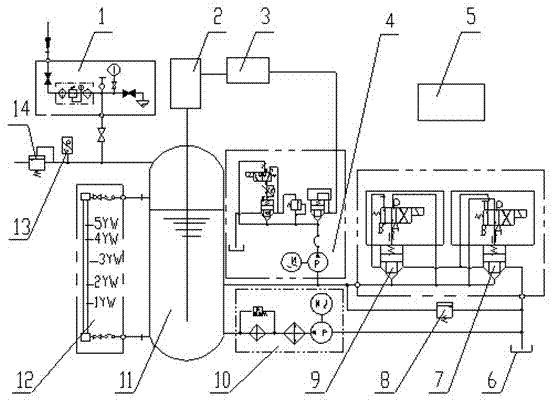

Air-conditioning unit with dedusting function

InactiveCN105423433AGuaranteed work efficiencyGuaranteed temperature requirementsMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention provides an air-conditioning unit with a dedusting function. The air-conditioning unit with the dedusting function comprises a machine shell, a V-shaped baffle board, a spraying device, a W-shaped baffle board, a heat exchanger, a draught fan, a first filter, a second filter, a water collection box, a blow-off pipe, a temperature sensor, an electromagnetic vibrator and a controller. An air inlet is formed in the first end of the machine shell. An air outlet is formed in the second end of the machine shell. The V-shaped baffle board, the spraying device, the W-shaped baffle board, the heat exchanger, the draught fan, the first filter and the second filter are sequentially arranged in the machine shell in the direction from the air inlet to the air outlet. The water collection box is located in the machine shell and located below the V-shaped baffle board, the spraying device and the W-shaped baffle board. The blow-off pipe is communicated with the outside and the water collection box. The electromagnetic vibrator is connected with the W-shaped baffle board. The temperature sensor is located in the machine shell and located on the side, close to the air outlet, of the second filter. The spraying device, the temperature sensor, the heat exchanger and the electromagnetic vibrator are all connected with the controller.

Owner:ANQING LIUXI IND EQUIP

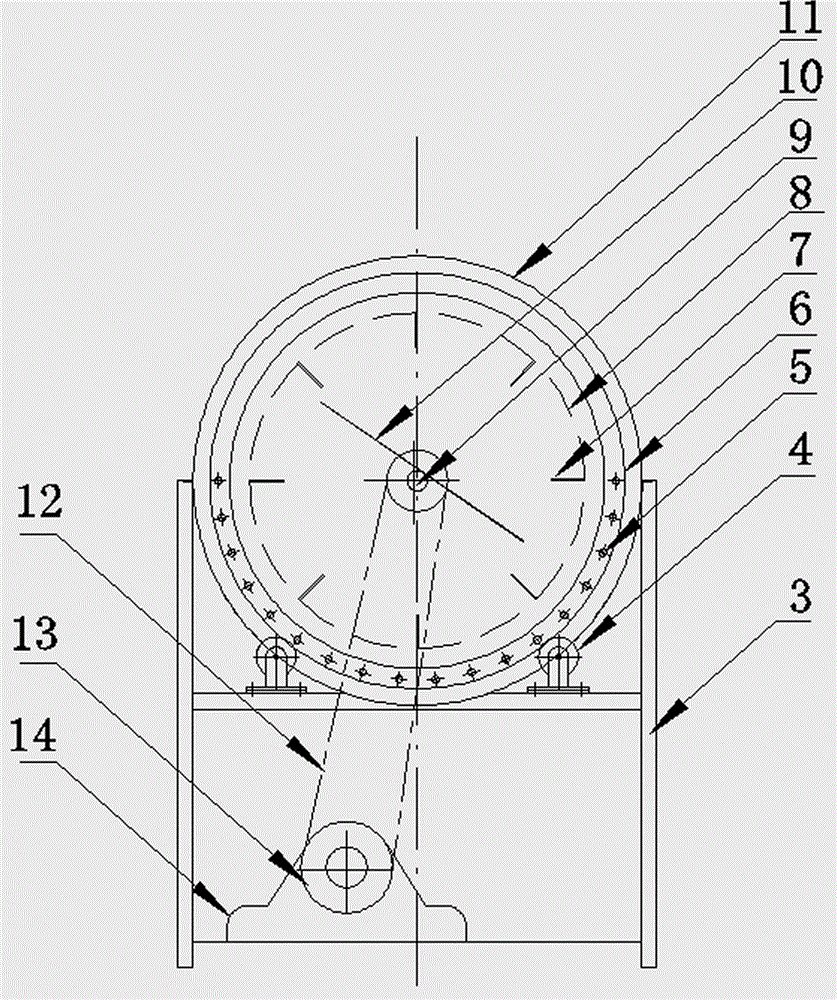

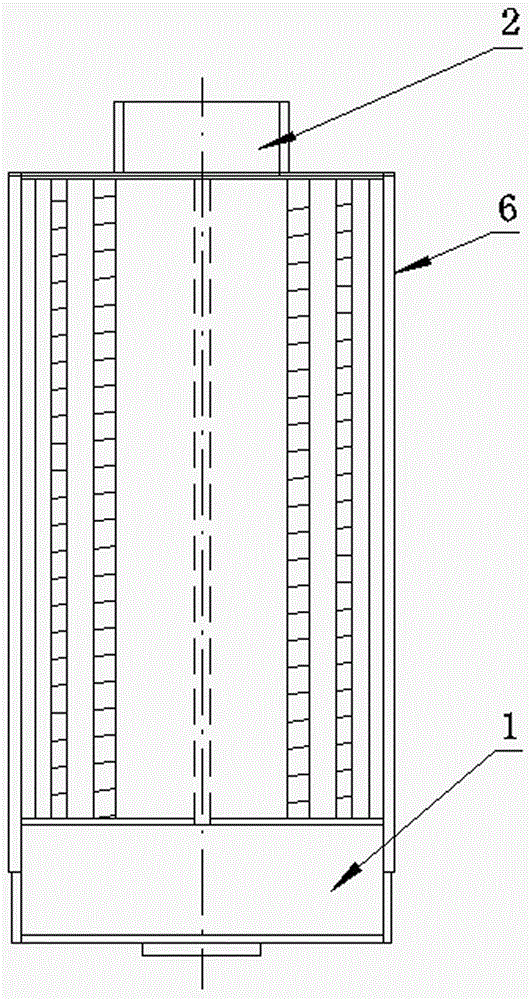

Baking apparatus and baking process for oolong tea

InactiveCN106035782AImprove baking efficiencyReduce the transfer linkPre-extraction tea treatmentThermodynamicsHeater Rod

The invention discloses a baking apparatus and baking process for oolong tea. The baking apparatus is prepared at first and is provided with a rotary drum, a rotary drum support, an electric heating rod, a motor transmission device, a plurality of stir-frying blades, a stir-frying guide plate, a helical groove, a discharge outlet, a feed inlet and a transmission mechanism driving rotation of the rotary drum. Controlling principles for baking in the invention are that a continuous baking mode of simultaneous feeding and discharging is employed and cooperated with three parameters consisting of set blanking speed, electric furnace temperature and rotating speed of the rotary drum, so rapid drying of the oolong tea is controlled, the water content of the oolong tea and optimal fire meet process requirements, the oolong tea can maintain a certain degree of dryness, and the fragrance and taste of the oolong tea are improved; so the product quality of the oolong tea is improved to a greatest extent.

Owner:福建茶叶进出口有限责任公司

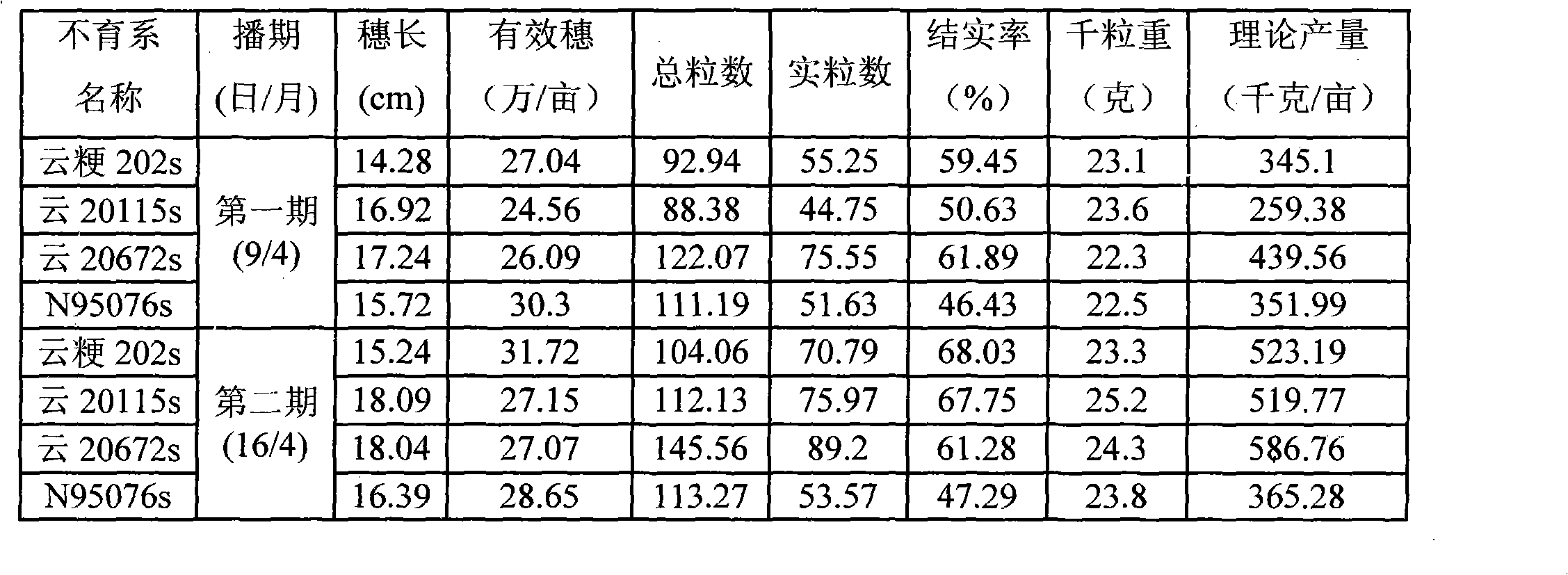

Method for technically propagating dual-purpose genic male sterile rice at high altitudes

InactiveCN102648690AFertility Sensitive Period Temperature Requirement GuaranteeGuaranteed temperature requirementsRice cultivationDual purposeHigh yielding

The invention relates to a high-production low-danger propagation technology of a photo thermo sensitive genic male sterile rice, in which the propagation cost and the danger of the photo thermo sensitive genic male sterile rice are lowered by utilization of the natural low-temperature condition at high altitudes, the difficulties in propagating the dual-purpose genic male sterile rice are avoided and the development of a two-line hybrid rice is promoted. The method comprises the following steps: selecting a propagation base at appropriate altitudes that the latitude is 24 degree to 26 degree and the altitude is 1500 m to 1650 m; arranging a sowing season that the heading and flowering stage can be on about August 10th and the seeding time is generally on April 1st to April 16th at the altitudes of 1500 m to 1650 m; implementing the cultivation management technology that transplant is carried out when the sterile line leaf age is 4-5 leaves, compact planting is conducted moderately, the planting space is generally 15cm*20cm or 13cm*15cm for single-plant interposition; and arranging temperature reduction facilities in abnormal temperature in areas with favorable irrigation conditions, so that the temperature can be lowered by cold water in a mountain spring once the external temperature becomes abnormal and can not meet the temperature requirement of the sterile line in the sensitive stage.

Owner:YUNNAN JINRUI SEED IND

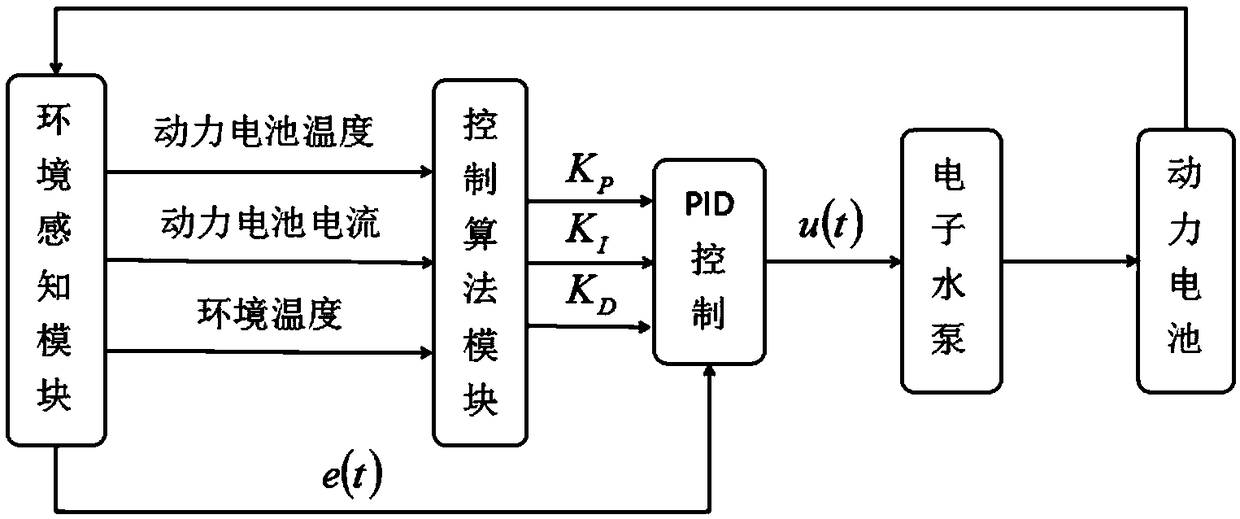

Active evaporating radiation tech of power semiconductor device or modular

InactiveCN1601733AImprove cooling efficiencyImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceElectrical conductor

In the invention, body case of power semiconductor device or module is fabricated to a hollow sealed shell body. Condenser is installed above the shell body. The said sealed shell body and condenser are connected to each other through pipe. Shell body of semiconductor device or module is as case of evaporator so as to form fully enclosed cooling circulation system. The disclosed cooling circulation system possesses very high cooling and heat radiation efficiency. Heat conductivity of the said system is more than 350 times of heat conductivity of good conductor (such as solid copper) with same geometrical size. Power semiconductor devices and modules with different power are available. The invention is suitable for cooling device with large power or devices in large installation density.

Owner:原泽

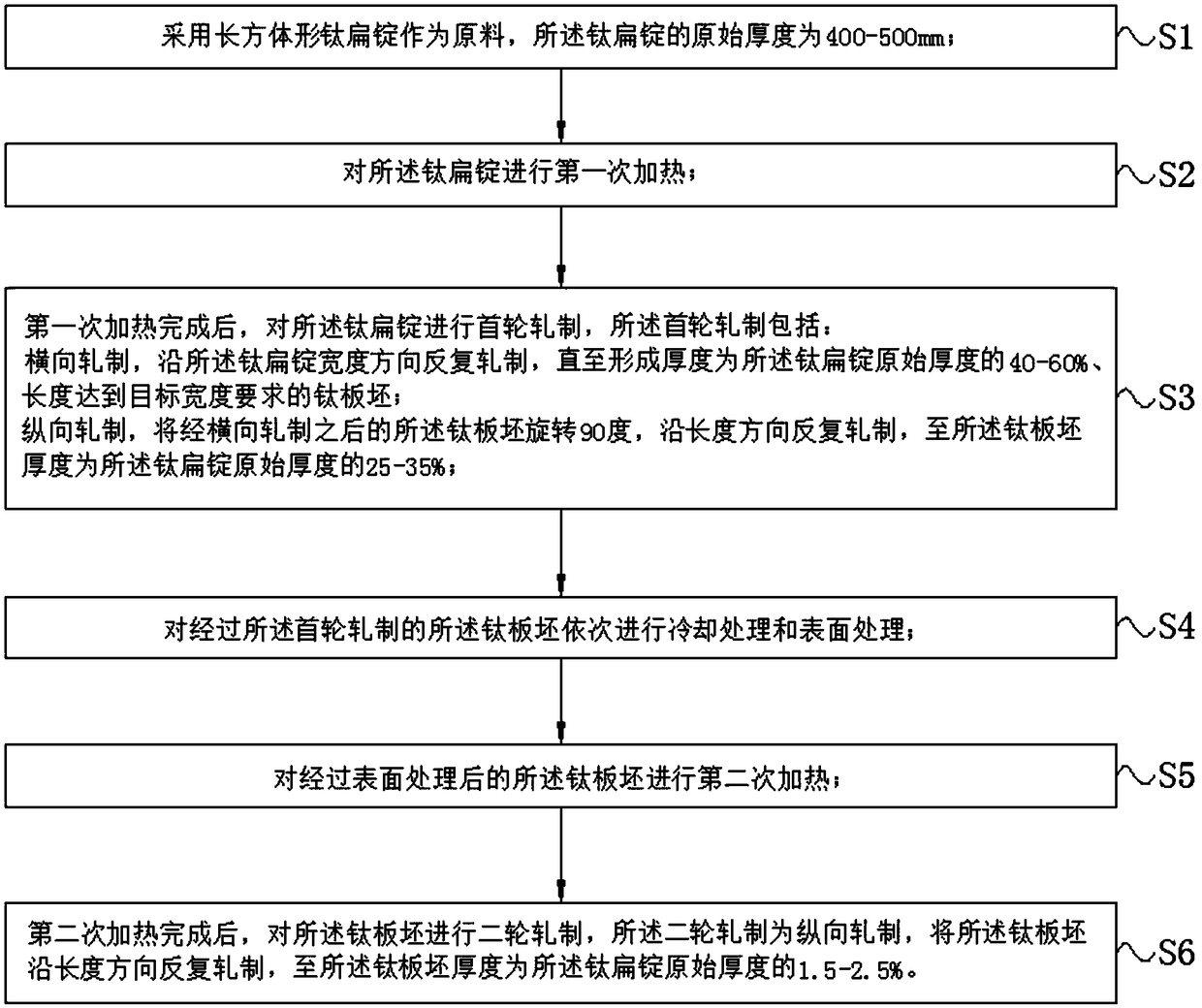

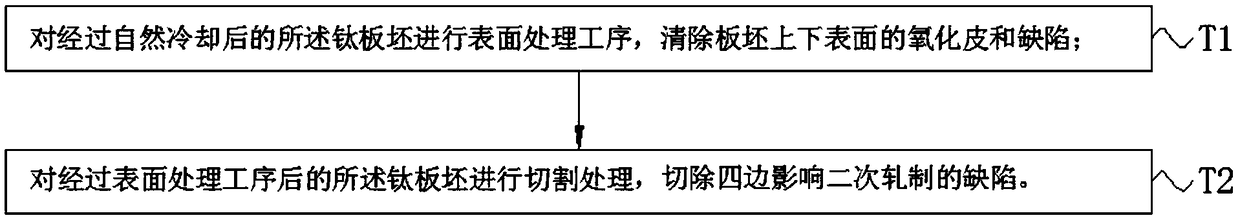

Technological method for manufacturing ultra-wide titanium plate

The invention relates to the technical field of metal material machining, in particular to a technological method for manufacturing a ultra-wide titanium plate. The method comprises the steps that a 400-500 mm thick cuboid titanium flat ingot is adopted as a raw material, and first-time heating is performed on the titanium flat ingot; after heating is completed, first-time rolling is performed onthe titanium flat ingot, wherein transverse rolling is performed, repeated rolling is performed in the width direction of the titanium flat ingot, and a tantalum plate blank with the length meeting the target width requirement and the thickness meeting the requirement for 40-60% of the original thickness of the titanium flat ingot; longitudinal rolling is performed, the titanium plate blank is repeated rolled in the length direction till the thickness is 25-35% the original thickness of the titanium flat ingot; after the titanium plate blank obtained after first-time rolling is naturally cooled, surface treatment is performed; second-time heating is performed on the titanium plate obtained after surface treatment; after heating is completed, second-time rolling is performed on the titaniumplate blank, second-time rolling is longitudinal rolling, and the thickness of the titanium plate blank is 1.5-2.5% the original thickness of the titanium flat ingot. According to the technological method, the ultra-wide titanium plate can be manufactured, the material utilization rate is increased, and the machining period is shortened.

Owner:宝鸡聚和信装备技术有限公司

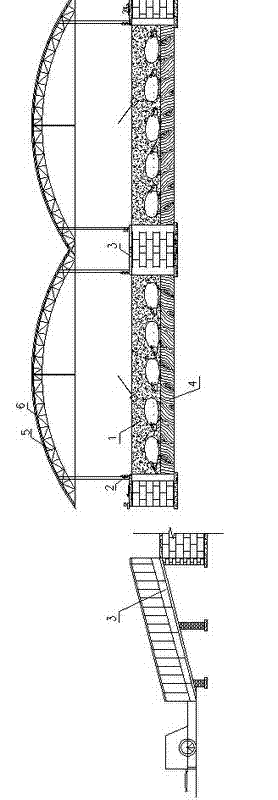

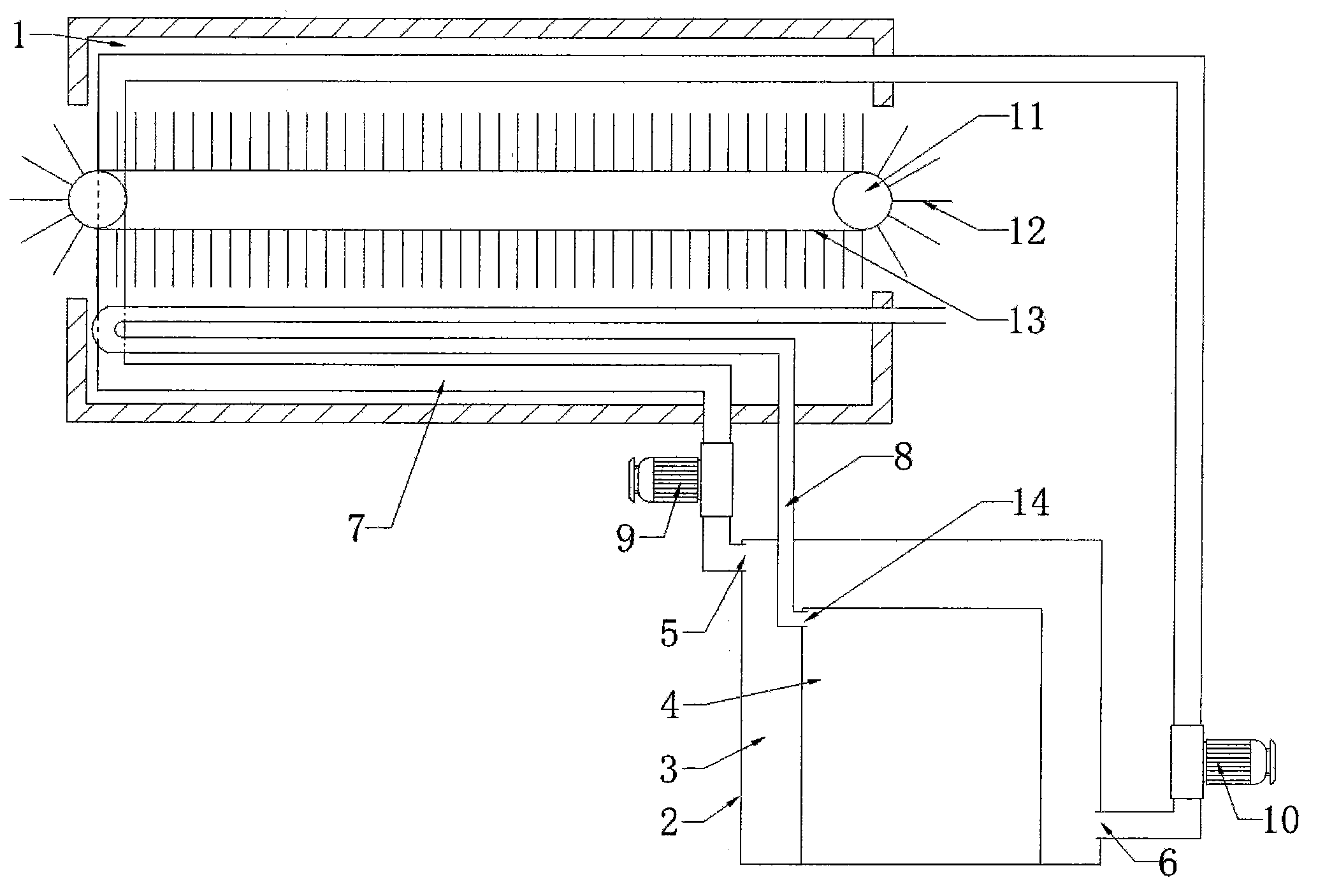

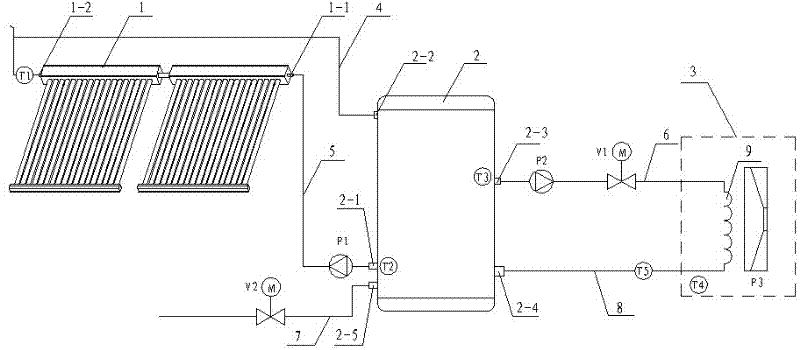

Heat supply system for curing tobacco at three sections with solar energy

ActiveCN102415606AIncrease temperatureReduce consumptionTobacco preparationSolar heat devicesWater pipeRadiation

The invention discloses a heat supply device for curing tobacco at three sections with solar energy. The device comprises a solar heat collector, wherein the inlet and the outlet of the solar heat collector are communicated with a hot water storage tank respectively; the other side of the hot water storage tank is provided with a heating circulating water outlet and a heating circulating water inlet; a heat supply circulating water outlet pipe and a heat supply circulating water inlet pipe are arranged on the heating circulating water outlet and the heating circulating water inlet respectively; a heat supply pipe which is positioned in a tobacco curing chamber is arranged between the two pipes; and a hot air fan or a heat exchanger is arranged in the tobacco curing chamber. In the invention, solar energy heat supply and auxiliary heat supply for the tobacco curing chamber are adopted, so that the indoor temperature of the tobacco curing chamber is raised; the temperature in the hot water storage tank can be up to 30-99 DEG C according to different solar radiation amounts and different weather conditions of different places; and by using solar energy, the indoor temperature of the tobacco curing chamber can be raised to 30-70 DEG C, the consumption of the conventional energy is lowered, and the pollution is greatly lowered.

Owner:四季沐歌(洛阳)太阳能有限公司

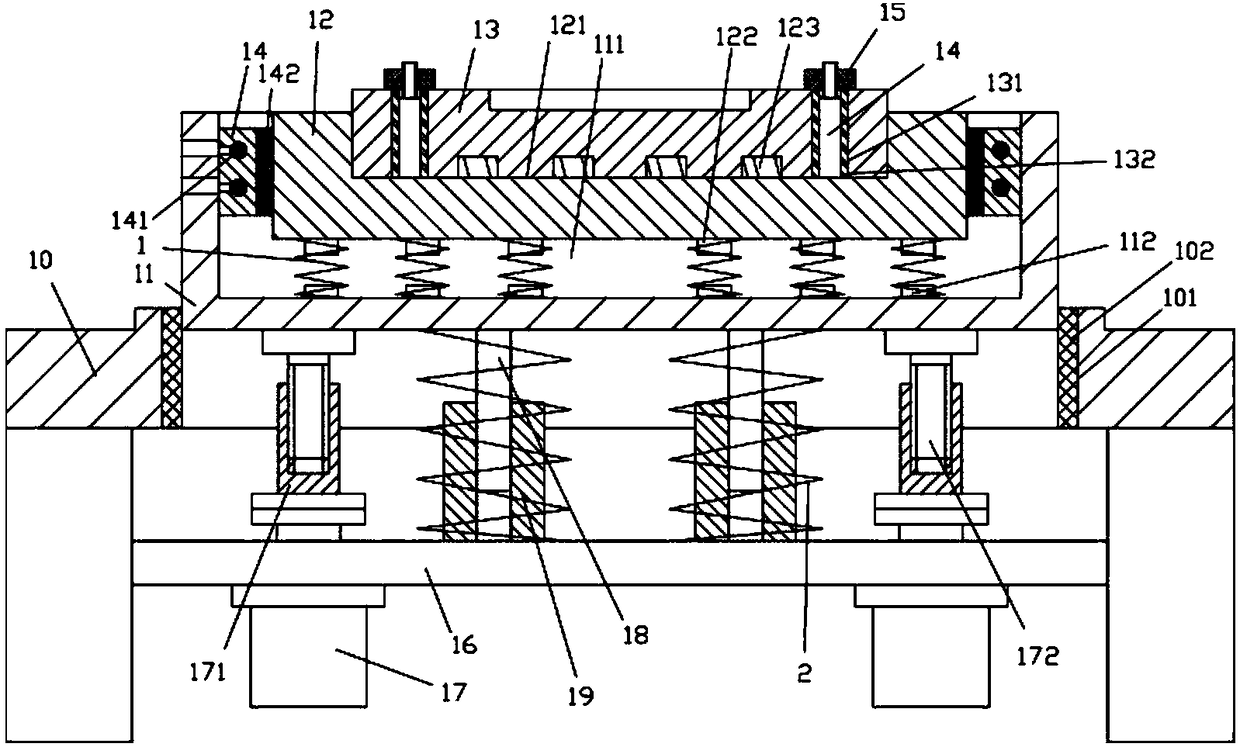

Lower die fixing mechanism capable of finely adjusting height

InactiveCN108176771AGuaranteed temperature requirementsQuick installation and removalShaping toolsEngineeringThreaded rod

The invention discloses a lower die fixing mechanism capable of finely adjusting the height. The fixing mechanism comprises a machine frame, wherein a central vertical groove is formed in the middle of a top plate of the machine frame, and a lower mounting block is inserted into the central vertical through groove in an inserted mode; a bottom supporting plate is arranged below the top plate of the machine frame, the side walls of the bottom supporting plate are fixed on the inner side walls of lower supporting legs of the machine frame, and fine adjustment motors are fixed on the bottom surfaces of the two sides of the bottom supporting plate; output shafts of the fine adjustment motors penetrate through the bottom supporting plate and are connected with lifting screw sleeves through couplers, lifting threaded rods are in threaded connection with the lifting screw sleeves, and the top ends of the lifting threaded rods are fixed on the bottom surface of the lower mounting block; and amounting groove is formed in the top surface of the lower mounting block, a middle mounting block is arranged in the mounting groove, and a lower die mounting groove is formed in the middle of the topsurface of the middle mounting block. According to the lower die fixing mechanism capable of finely adjusting the height, a lower die is rapid in installation and disassembly, furthermore, annular electric heating rods are arranged and have the effect of heating the lower die, the temperature requirement for stamping metal is guaranteed, moreover, the lower die can be subjected to fine adjustmentin height, and the stamping requirement is met.

Owner:DONGGUAN TIANHE ELECTROMECHANICAL DEV CO LTD

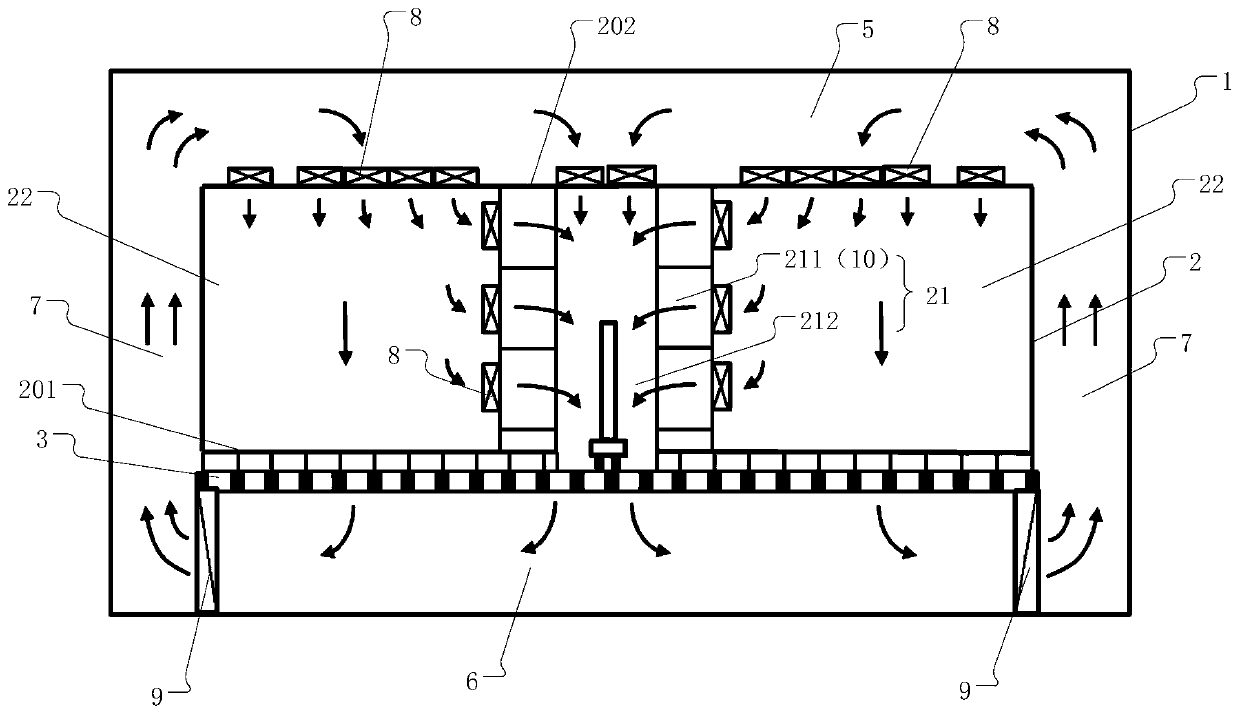

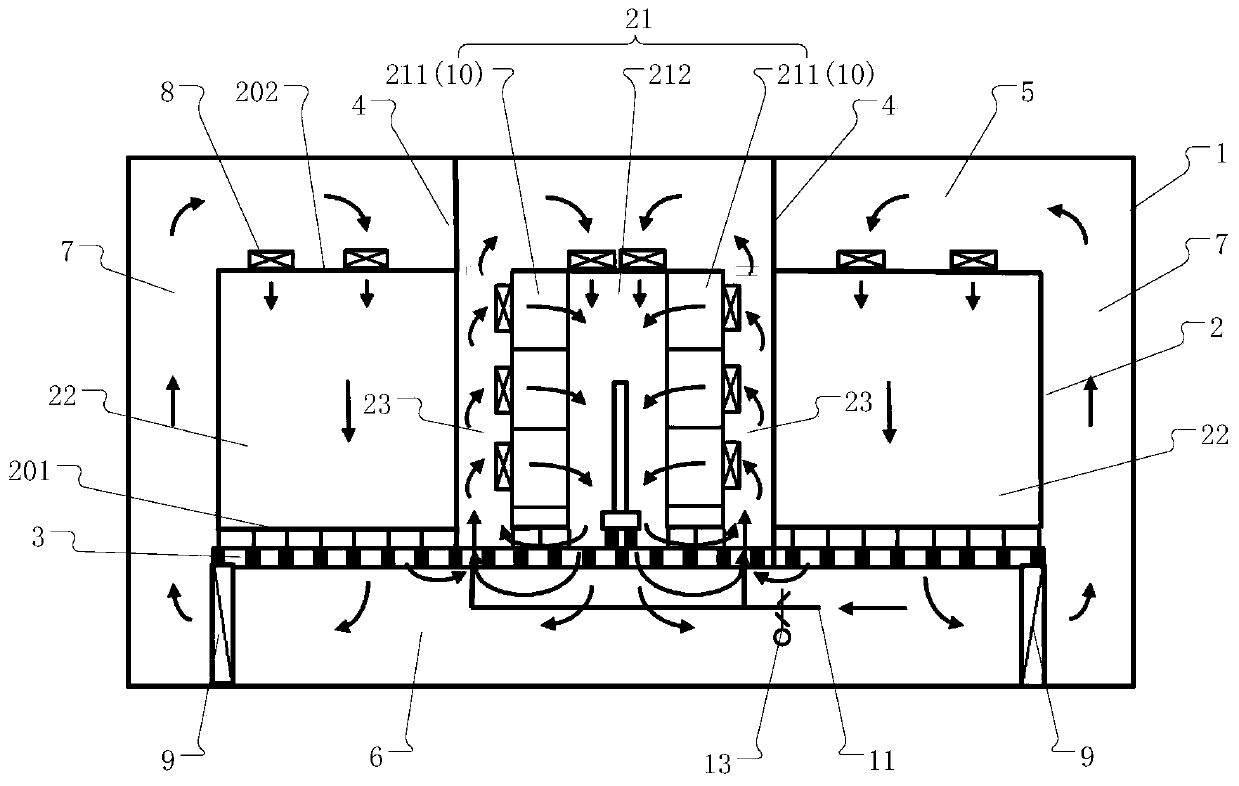

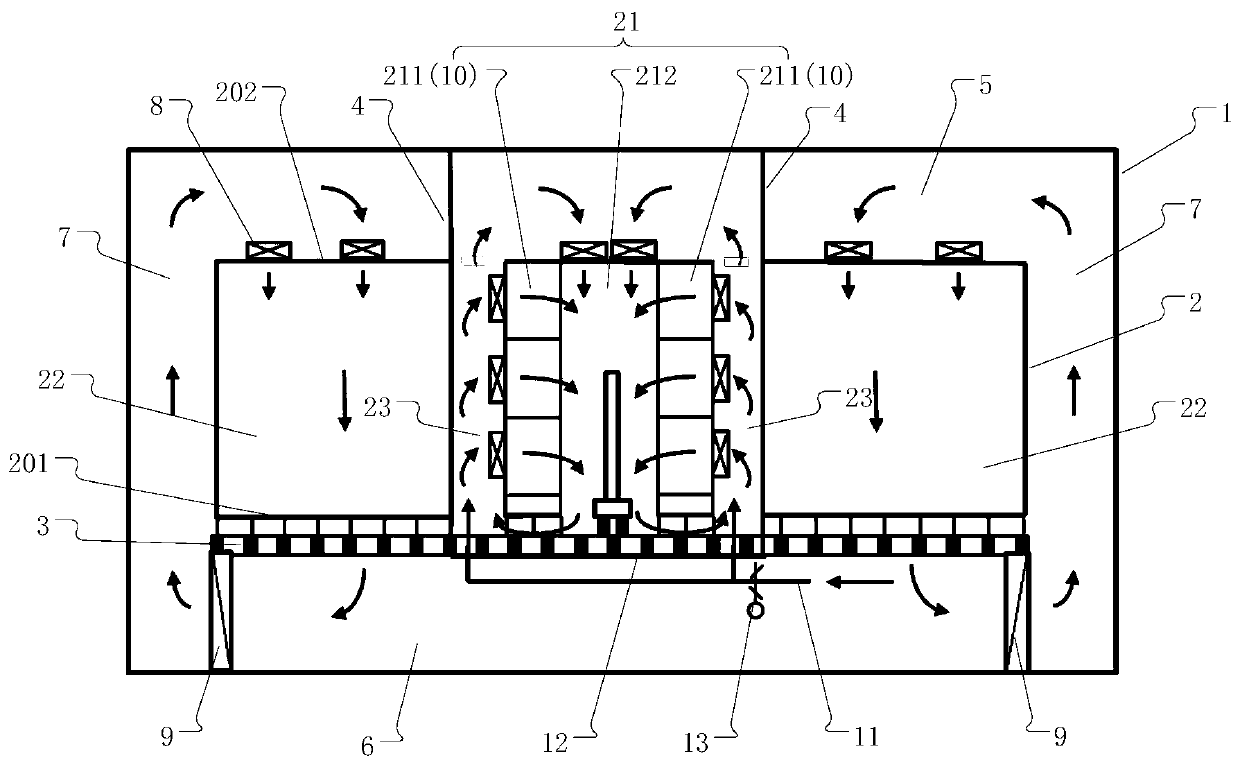

Clean workshop

InactiveCN110307610ASmall footprintReduce in quantityMechanical apparatusLighting and heating apparatusDisplay deviceEngineering

The invention relates to the technical field of flat panel display production and manufacturing, and discloses a clean workshop. A material storage and transfer area and process production areas whichare positioned on the two sides of the material storage and transfer area are arranged in a clean room; a material storage rack group is arranged in the material storage and transfer area; partitionpanels are arranged on the two sides of the material storage rack group; the top of each partition board extends to the top of an upper technical interlayer, and the bottom of each partition board isconnected with a wafer board; the material storage rack group comprises two rows of material storage racks; an air return passage is formed by the gap between each row of the material storage racks and the adjacent partition board and communicates with the upper technical interlayer; a plurality of fan filter units are arranged on each row of the material storage racks; a material transfer area isformed between two rows of the material storage racks; an air flow channel which communicates with the material transfer area and the adjacent air return passage is formed in the bottom of each row of the material storage rack; a fresh air supply pipe is arranged in a lower technical interlayer; and an air outlet of the fresh air supply pipe communicates with each air return passage.

Owner:S Y TECH ENG & CONSTR CO LTD

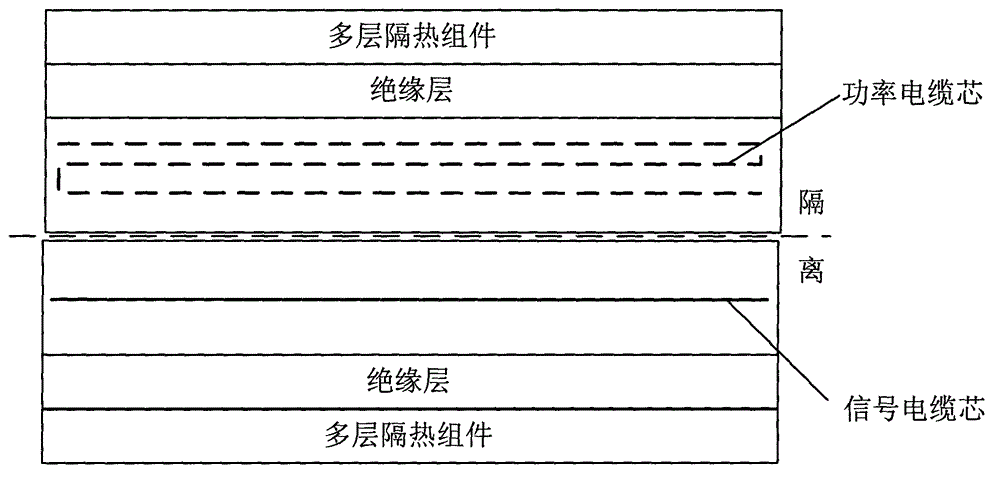

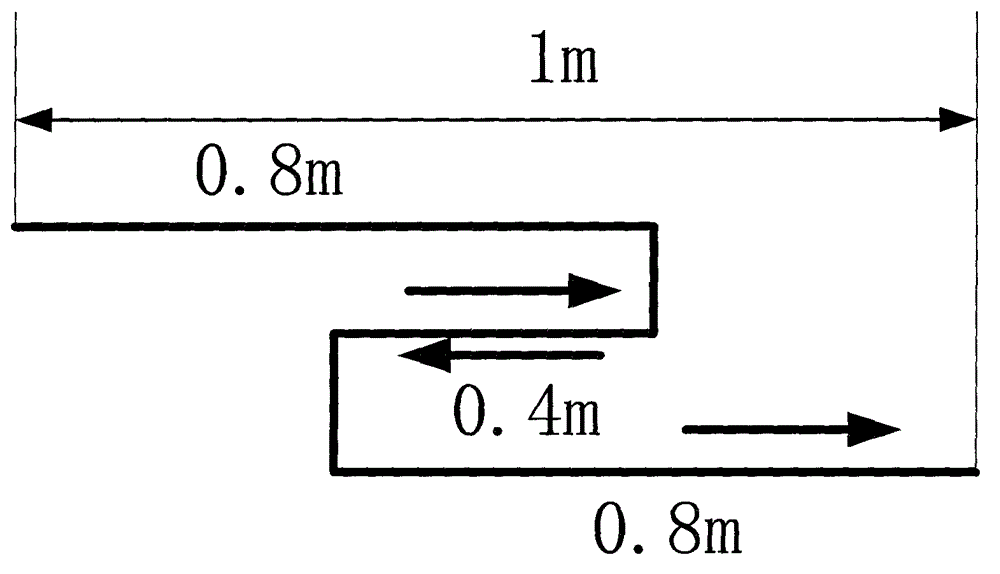

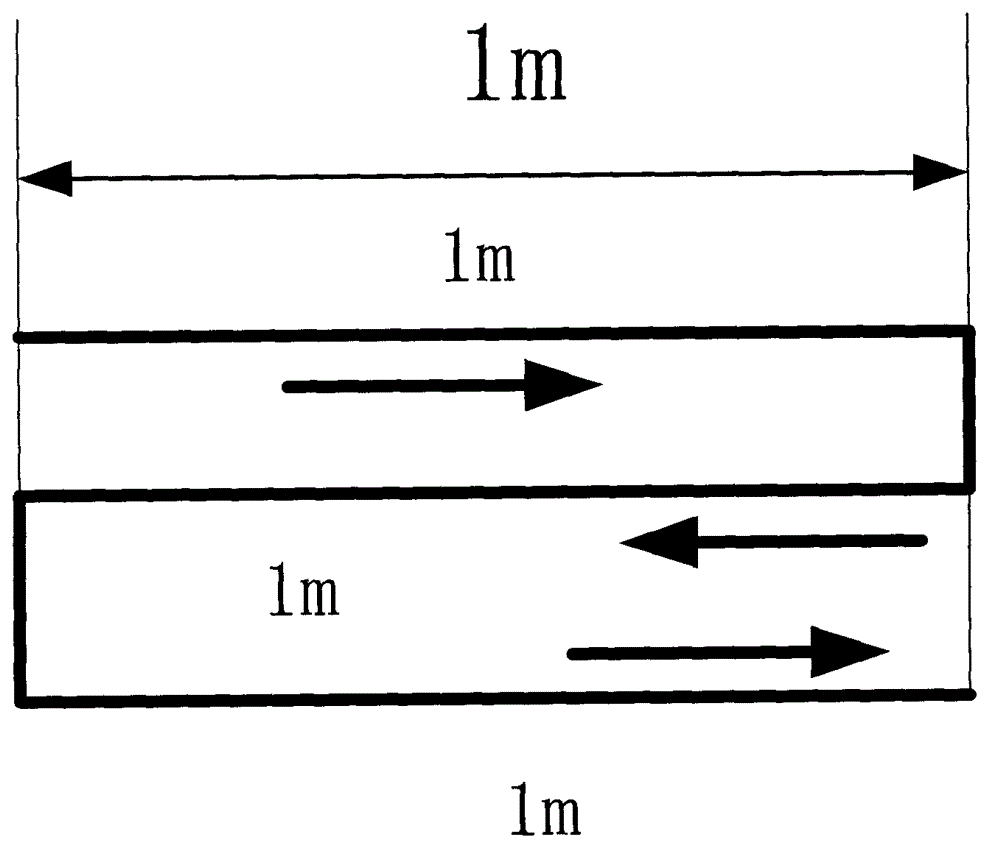

Thermal design method for extra-planetary rotary cable bunch

ActiveCN102881385ASimple designImprove reliabilityManufacturing wire harnessesCable designEngineering

The invention belongs to the technical field of extra-planetary cables, and relates to a thermal design method for an extra-planetary rotary cable bunch. The method is particularly applicable to extra-planetary cables having high requirements on temperature. The method includes: isolating a power cable core and a signal cable core; determining heating power required by the extra-planetary rotary cable bunch through numerical simulation, and designing the length of the power cable core to enable intrinsic heat productivity of the power cable to be the required heating power, so that heat can be completely and reasonably used; and coating a plurality of heat insulating components on the outer surface of the cable bunch. The temperature requirement of cables can be met by means of heating of the power cable core according to intrinsic conditions of the cables, and the method is simple and effective while reliability is improved. According to ground tests, the temperature can be increased by about 100 DEG C when the cable bundle adopting the method is compared with cable bundles taking no measure, and effects are evident. In addition, cables designed by the method are simple in structure and lightweight.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

High-pier pouring forming method applied to bridge construction

ActiveCN103437288AGuaranteed temperature requirementsAvoid the impact of constructionBridge structural detailsBridge erection/assemblyCold weatherBuilding construction

The invention discloses a high-pier pouring forming method applied to bridge construction. The high-pier pouring forming method is characterized by comprising the following steps that (1) a heat insulation shed is built; (2) multiple sections of equilong templates are adopted to be superimposed to form a high-pier pier body template inside the heat insulation shed; (3) on the basis of the formed high-pier pier body template, a high-pier pier body with the same height as the high-pier pier body template is poured inside the heat insulation shed in one step; (4) all templates under the topside template are dismounted, and in addition, the topside template is used for the template installation support during the pouring of the lower section of pier body; (5), the pouring height of each section of later high-pier pier body is the sum of the heights of the templates except the topside template in the step (4), and the high-pier pier bodies are sequentially poured until the pouring is completed; and (6) the high-pier pier bodies are maintained in the heat insulation shed to carry out heat insulation maintenance until the final formation is realized. Through the scheme, the high-pier pouring forming method has the advantages that the influence of cold weather on the bridge construction is avoided, the construction quality is ensured, and high practical values and promotion values are realized.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

Vacuum brazing furnace using metal quartz integral radiant heater

InactiveCN103157875AHigh heat conversion efficiencyImprove insulation effectHeating appliancesMetal working apparatusVacuum pumpingRadiant heater

The invention discloses a vacuum brazing furnace using a metal quartz integral radiant heater. The vacuum brazing furnace using the metal quartz integral radiant heater comprises a furnace body, a vacuum-pumping system, a vacuum heating system and a cooling and tail portion gas collecting system, wherein the vacuum heating system is arranged in the furnace body, the vacuum-pumping system is connected with the furnace body, and the cooling and tail portion gas collecting system is simultaneously connected with the vacuum-pumping system and the furnace body. According to the vacuum brazing furnace using the metal quartz integral radiant heater, a metal quartz integral radiant heating piece which is higher in thermal conversion efficiency, more stable in radiancy and indeformable in high temperature is adopted, and structure arrangement is compact; a plurality of layers of heat insulation protection plates are arranged in the vacuum furnace, heat loss is reduced, and temperature needs for brazing are guaranteed; forced cooling type is short in cooling time, and production efficiency is improved; and the way of recycling use is adopted for used inert gases, leakage is reduced, and high economical efficiency is achieved.

Owner:SHANGHAI JIAO TONG UNIV

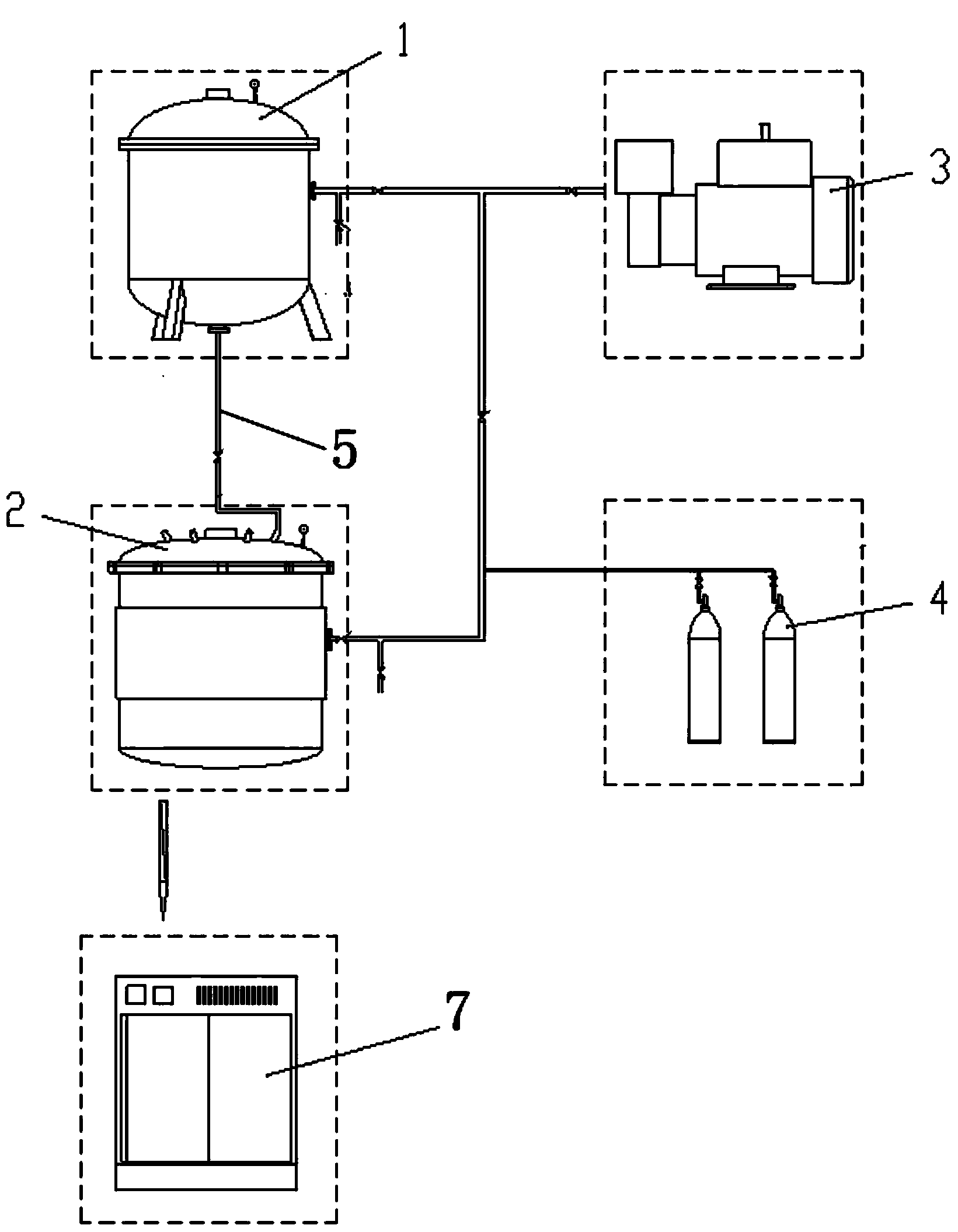

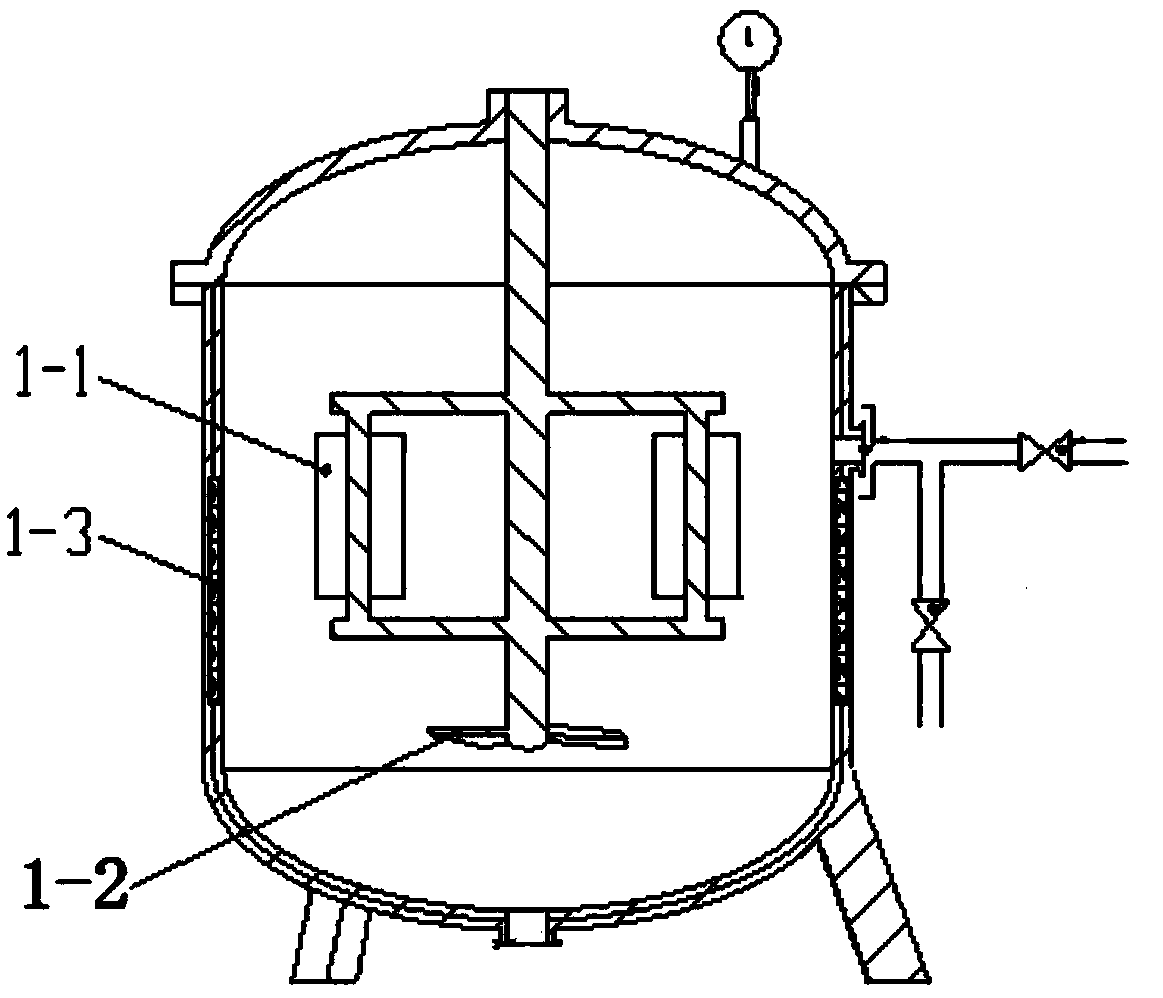

System and method for vacuum pouring of insulation resin used for motor rotor

InactiveCN104410229ARequirements for maintaining vacuumConducive to constant temperature curingApplying solid insulationEmulsionHigh pressure

The invention relates to a system for vacuum pouring of insulation resin used for a motor rotor. The system comprises a vacuum glue filling tank, a vacuum pump, a high-pressure inert gas transmitting device, a vacuum emulsion machine and a glue transmitting pipe, wherein the vacuum pump and the high-pressure inert gas transmitting device are respectively connected with the vacuum glue filling tank by virtue of a pipeline; the vacuum emulsion machine is connected with the vacuum glue filling tank by virtue of the glue transmitting pipe; a stirring device is arranged in the vacuum emulsion machine; the vacuum emulsion machine is provided with a device which is connected with the vacuum pump; the resin to be filled with glue is mixed in the vacuum emulsion machine. According to the system, the vacuum emulsion machine is additionally arranged, the vacuum degree requirement during mixing of the resin is ensured; the discharge of the gas in the resin is facilitated. The invention also relates to a method for vacuum pouring of the insulation resin for the motor rotor.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

High-barrier transparent composite packaging film applicable to boiling sterilization process

InactiveCN105563967AImprove barrier propertiesMoisture-proofSynthetic resin layered productsPolyesterPolyurethane adhesive

The invention provides a high-barrier transparent composite packaging film applicable to a boiling sterilization process. The composite packaging film is successively provided with, from exterior to interior, an outer printing layer, an intermediate barrier layer and an inner heat sealing layer, wherein the layers are bonded together by a polyurethane adhesive, the outer printing layer is a bisynchronously drawing nylon film, the intermediate barrier layer is a polyester film coated with polyvinylidene chloride emulsion, and the inner heat sealing layer is a boiling-grade casting polypropylene film. The high-barrier transparent composite packaging film applicable to the boiling sterilization process meets requirements of the process for sterilizing food by boiling at 121 DEG C for 30 min, can effectively overcome the problems that a conventional high-barrier composite packaging film is non-transparent and aluminum foils easily fracture when the conventional high-barrier composite packaging film and aluminum foil soft-plastic packaging bags are subjected to vacuum-pumping packaging, and has the characteristic of a three-layer composite structure; and the high-barrier transparent composite packaging film has good transparency, puncture resistance and mechanical strength and has high barrier performance which is equivalent to high barrier performance of a plastic-aluminum composite film.

Owner:湖北宏裕新型包材股份有限公司

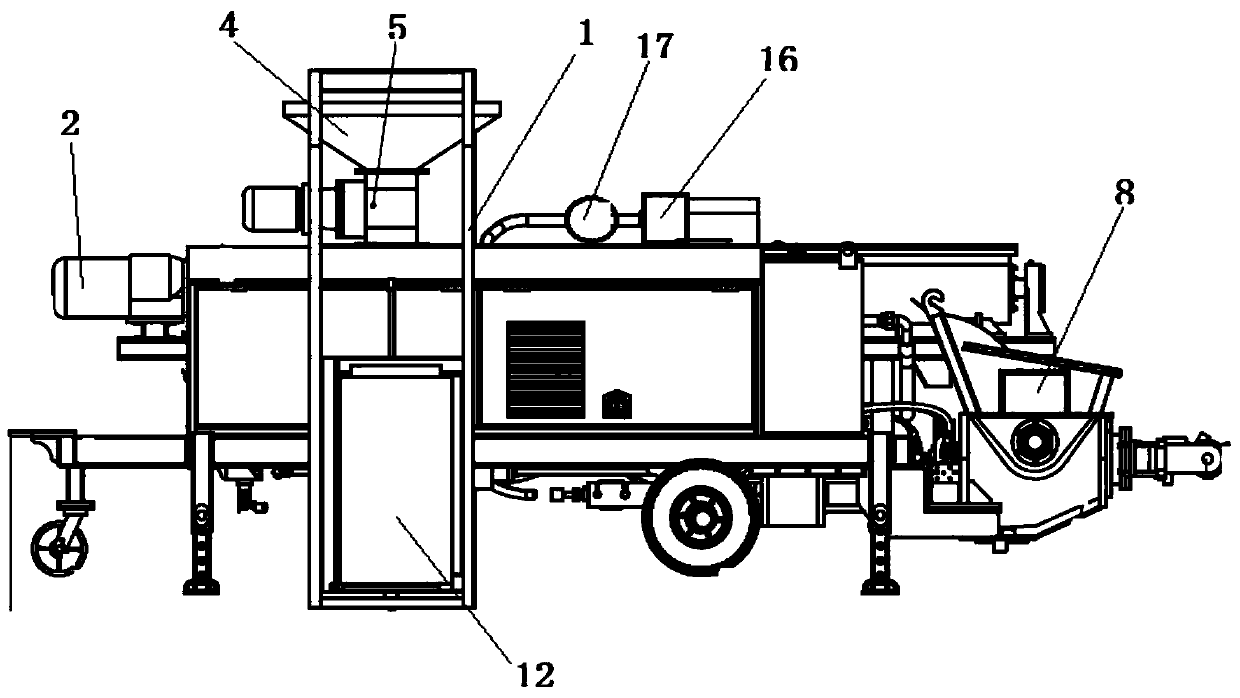

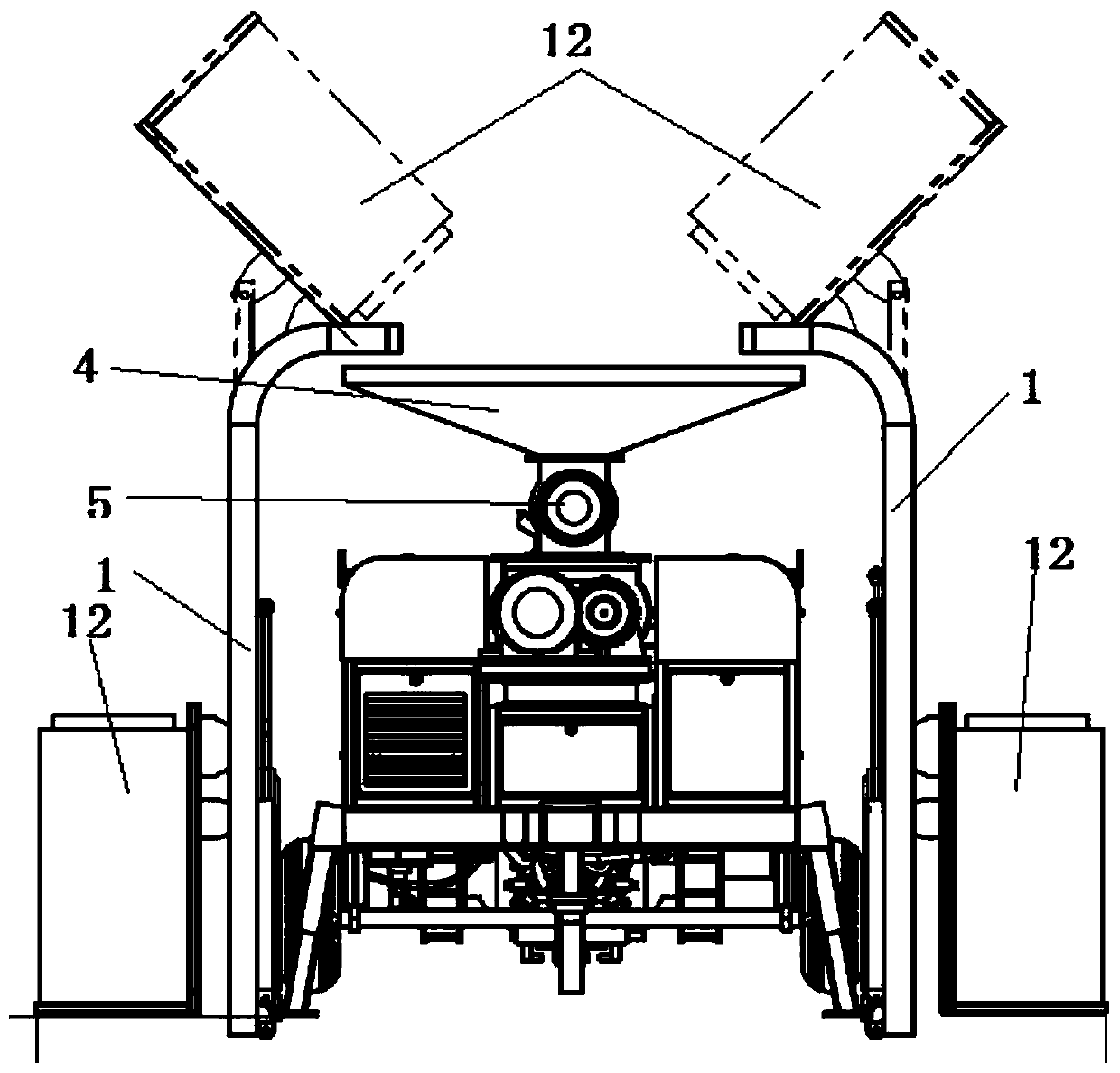

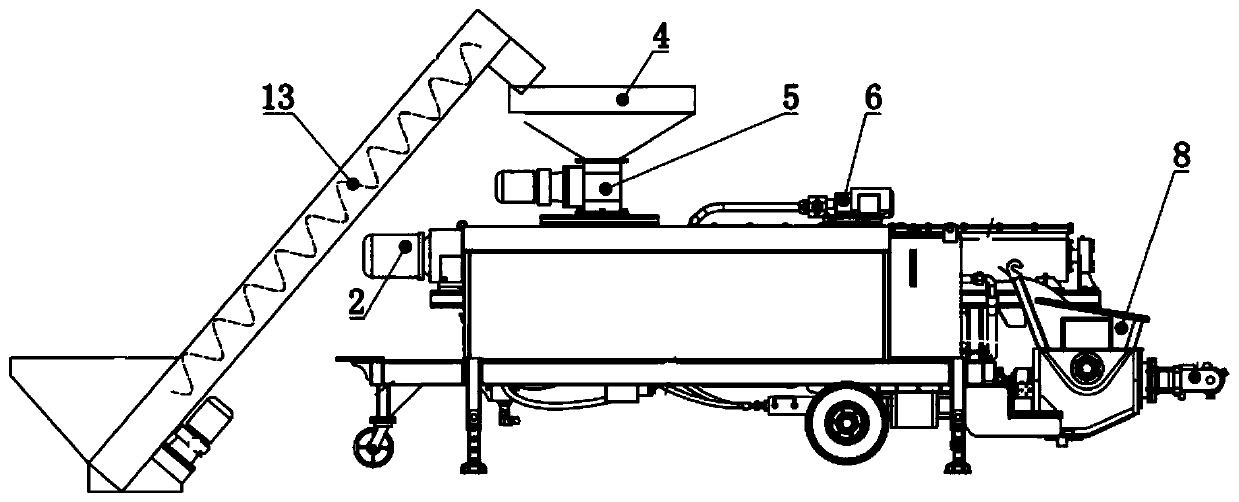

Integrated slurrying equipment

PendingCN111300640APrecise and controllable ratioReduce floor heightDischarging apparatusMixing operation control apparatusWater supply networkProcess engineering

The invention belongs to the technical field of slurry preparation, and particularly relates to integrated slurrying equipment. The integrated slurrying equipment comprises a feeding device and a stirring device; the feeding device comprises a feeding hopper and a quantitative water supply system, wherein a quantitative discharging valve is arranged at the lower end of the feeding hopper, and materials in the feeding hopper are added into the stirring device; the quantitative water supply system is used for quantitatively adding water into the stirring device, and a temperature regulator is arranged in the quantitative water supply system and can regulate the water outlet temperature of the quantitative water supply system; the stirring device comprises a stirring cavity, a stirring shaftand a power device, the stirring shaft is transversely arranged, the feeding device is arranged at one end of the stirring cavity, and a discharging port is formed in the lower portion of the other end of the stirring cavity; one ends, close to the feeding device, of the stirring blades are located in front of the rotation direction of the stirring shaft, slurry is pushed to move towards one end of the discharging port while stirring is conducted, the occupied height of the integrated slurrying equipment is greatly reduced, and the transportation trafficability of the integrated slurrying equipment is improved.

Owner:HENAN QIANGNAI NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com