Integrated slurrying equipment

A kind of equipment and pulping technology, applied in the direction of clay preparation device, volume measuring instrument, pretreatment control, etc., can solve the problems of difficult slurry temperature adjustment, inaccurate material addition, low output of stirring device, etc., to improve the preparation speed and Slurry quality, precise and controllable ratio, and improved transportability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

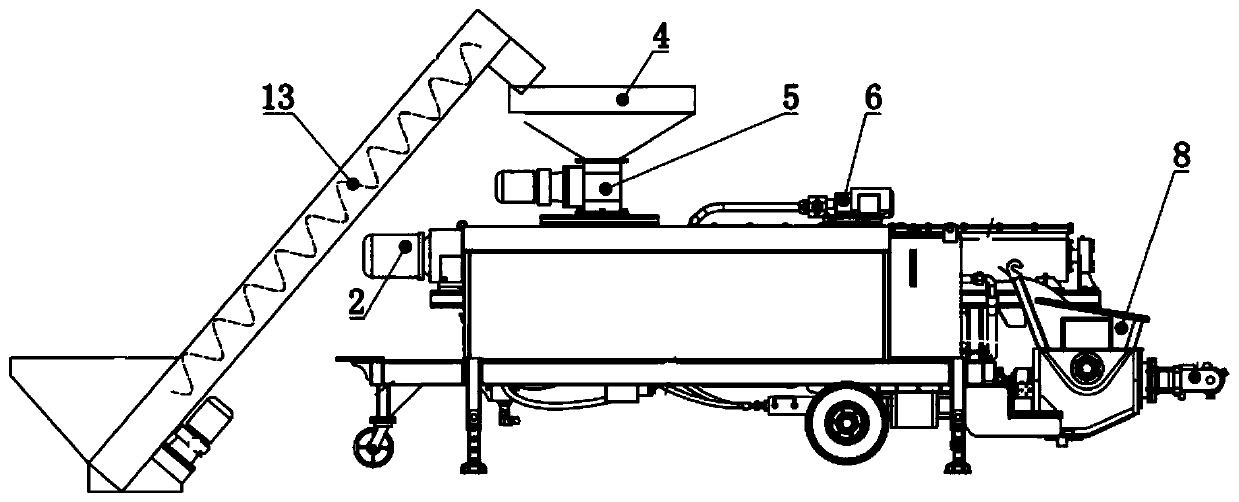

[0050] Such as image 3 As shown, in this embodiment, in order to avoid the operation height being too high during the use of the entire integrated pulping equipment, and to adapt to the addition of bagged materials, the material lifting and adding device 1 in Example 1 is replaced with a screw feeding device. The device 13, the feeding hopper of the screw feeding device 13 is arranged on the ground, the discharge port 19 of the screw feeding device 13 is located above the upper hopper 4, and the material is lifted into the upper hopper 4. Thus, the operating height of the entire integrated pulping equipment can be reduced, making it suitable for height-limited spaces such as basements.

[0051] Preferably, the discharge port 19 of the screw feeder is in sealing connection with the upper opening of the hopper 4 to avoid dust generation. Other structures of the integrated pulping equipment in this embodiment are the same as those in Embodiment 1, and will not be repeated here....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com