Patents

Literature

38results about How to "Lower operating height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hoisting method for main engine equipment of vehicle passenger ferry

InactiveCN106892054ARelieve pressureDoes not affect the normal production scheduleVessel designingLoad-engaging elementsPortal frameAutomotive engineering

The invention relates to the technical field of ship construction and particularly discloses a hoisting method for main engine equipment of a vehicle passenger ferry. The hoisting method sequentially comprises the steps that a portal frame tool is designed; the main engine equipment is hoisted on the tool; a translation track is laid on an entrance hatch of the main engine equipment; the main engine equipment and the tool are overall moved to a predetermined position through a tank trolley; the translation track and the tank trolley are dismantled in a jacking mode; and the main engine equipment is made to fall inside a cabin. According to the hoisting method, the time of entering the cabin of the main engine equipment can be freely controlled, and operation is easy convenient and efficient.

Owner:GUANGDONG XINCHUAN HEAVY IND

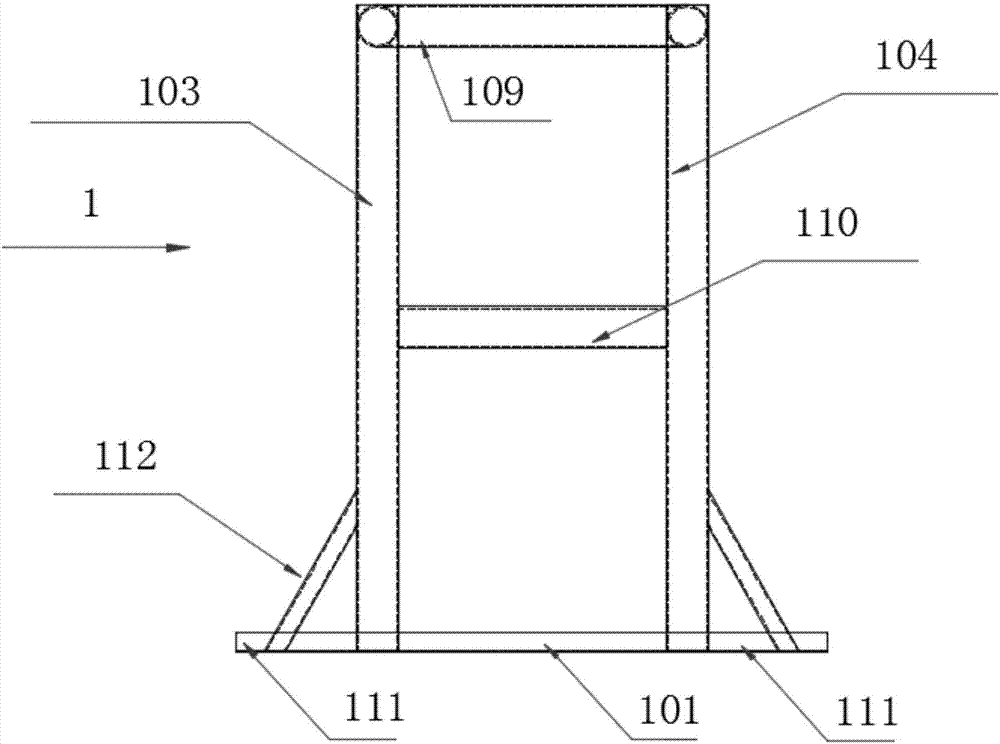

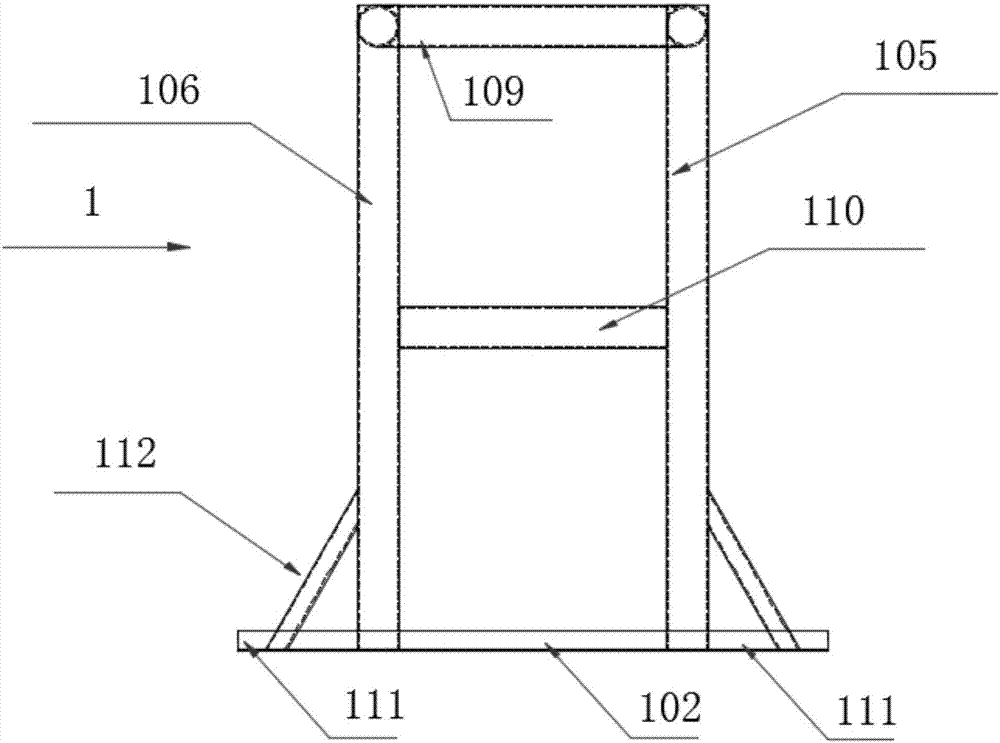

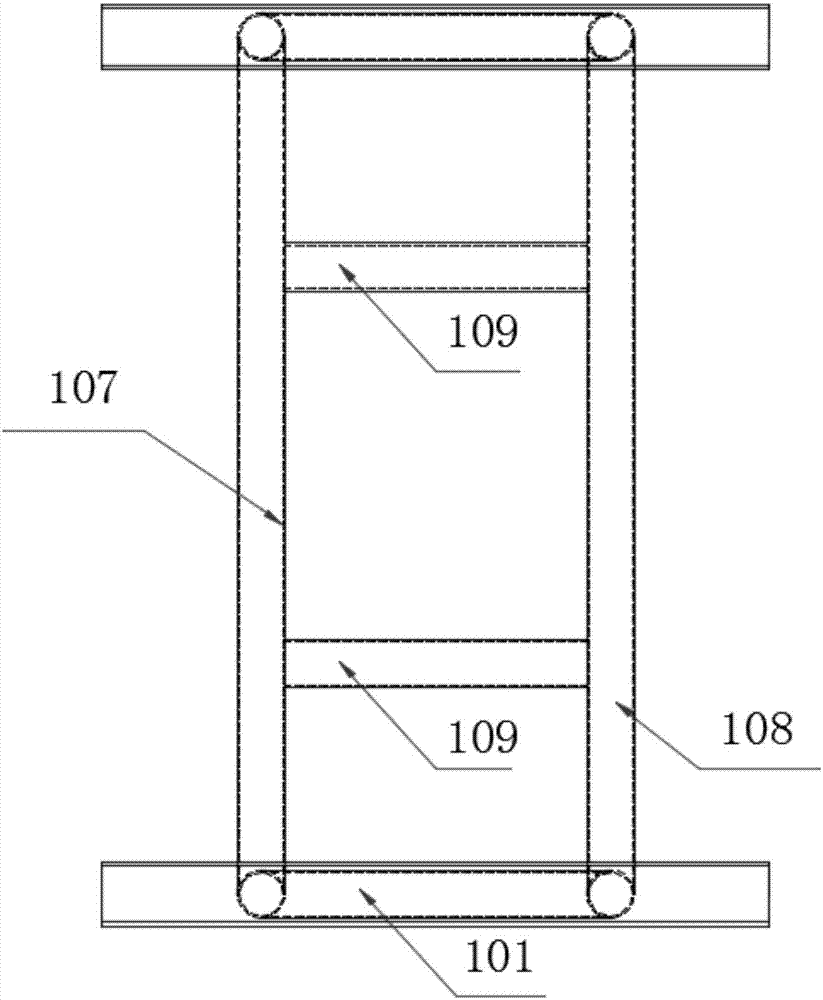

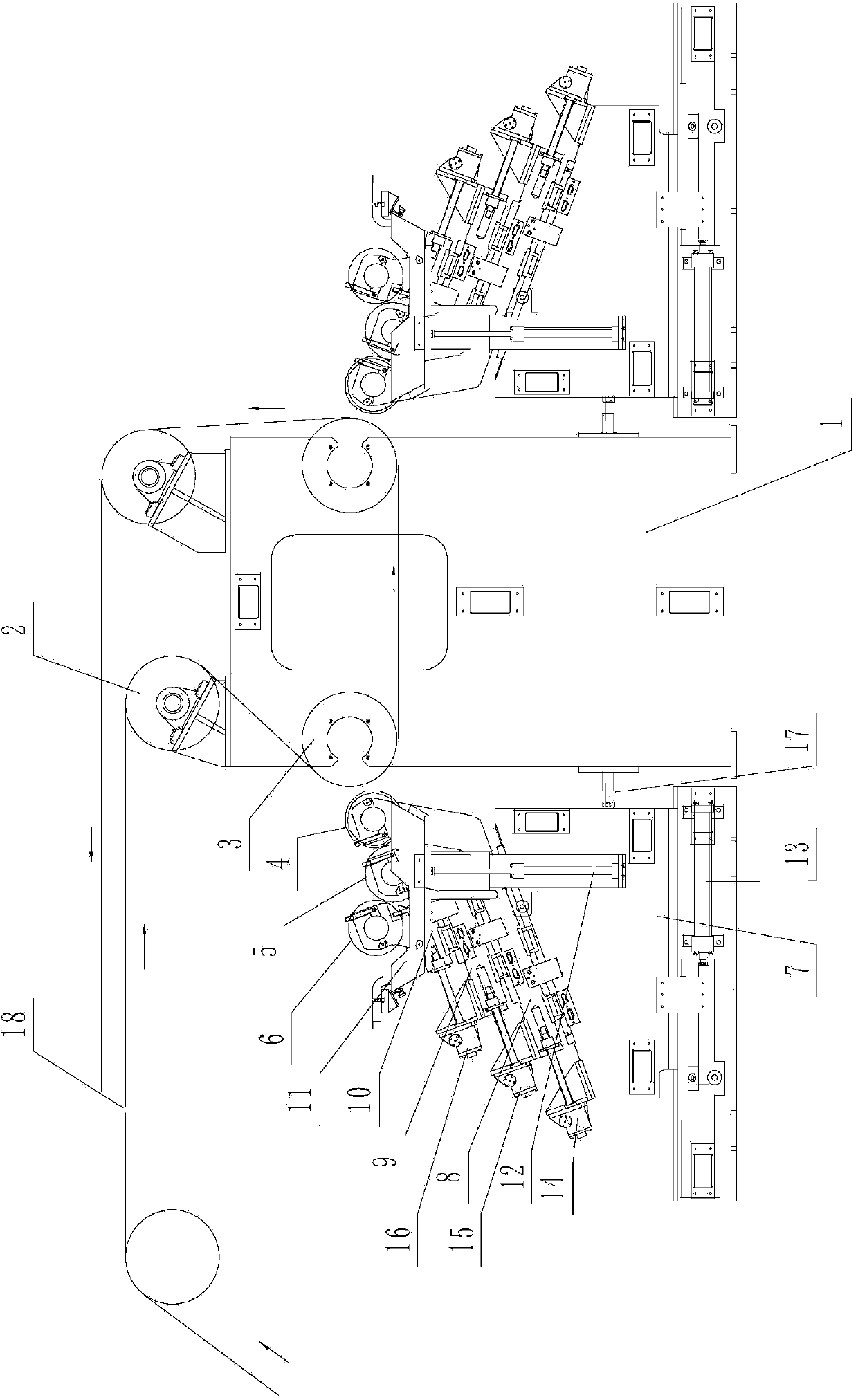

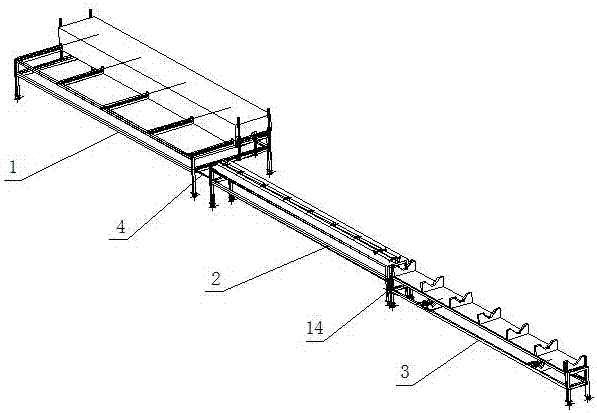

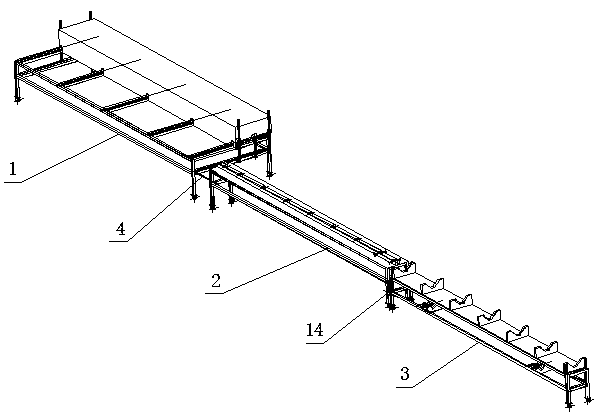

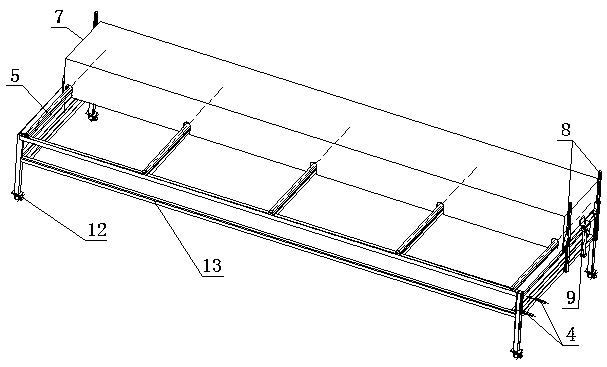

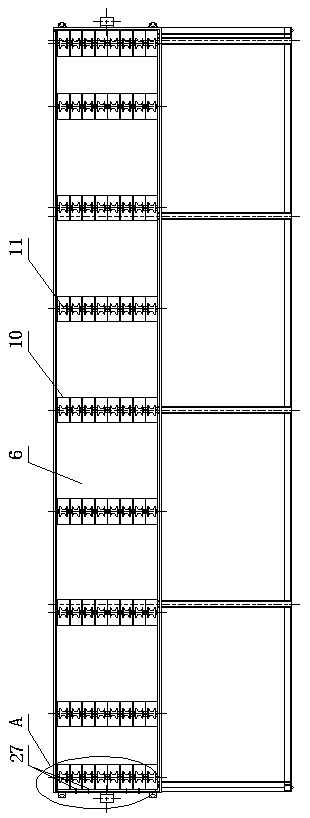

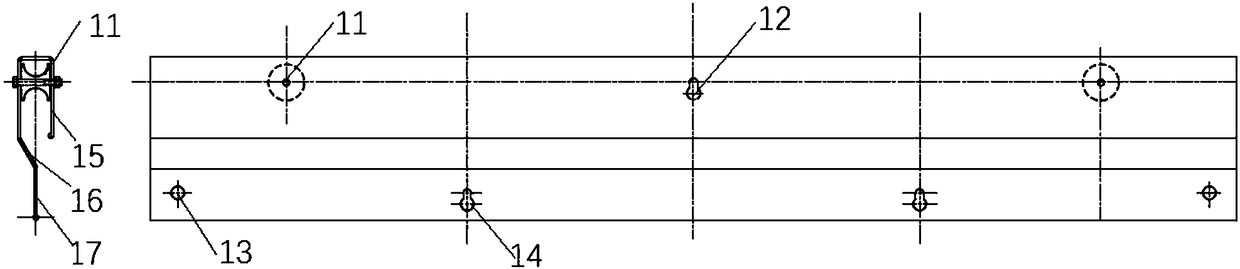

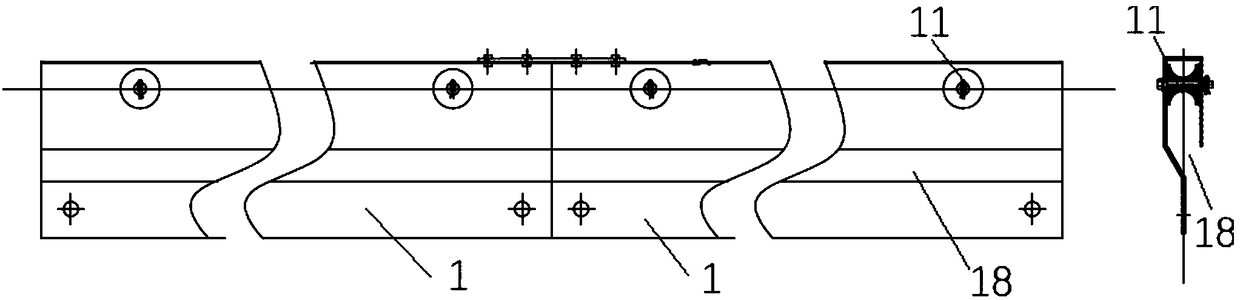

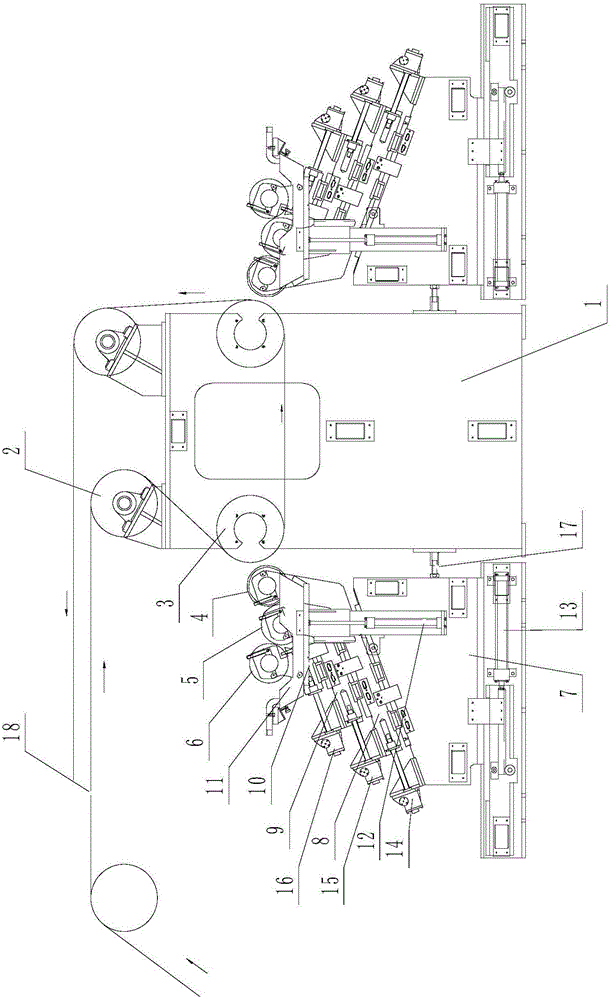

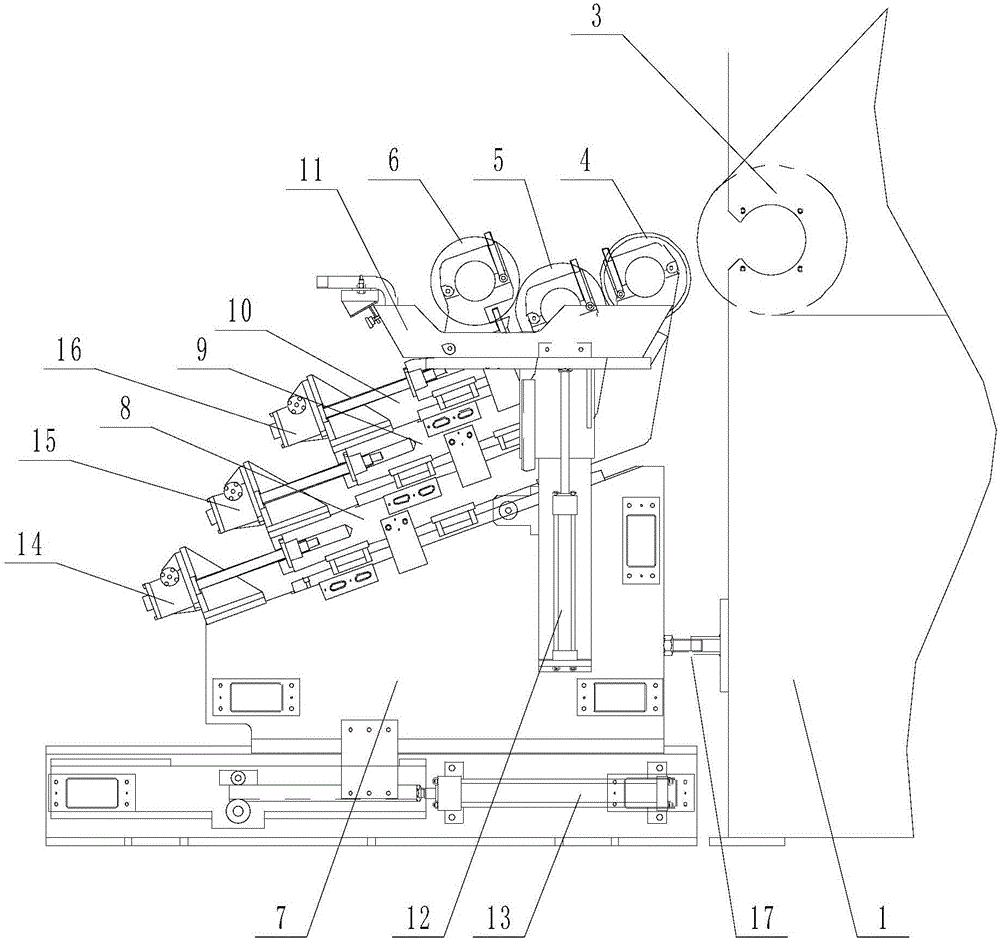

Convenient-to-operate common conveying device for vehicle doors and trunk lids

InactiveCN102092557AReduce labor intensityLower operating heightConveyorsUltimate tensile strengthConveyor belt

The invention discloses a convenient-to-operate common conveying device for vehicle doors and trunk lids, which is sued for solving the problems that the conveying device is inconvenient to manually operate and that one conveying device corresponds to only one kind of work pieces. The technical scheme is that: the common conveying device comprises an underframe and support frames fixed on the underframe; conveyor belts and material blocking plates are arranged on the support frames; after the conveying device is improved, lifting cylinders are arranged on the underframe; lifting cylinder rods are fixedly connected with the support frames; the conveyor belts comprise fixed conveyor belts and lifting conveyor belts; conveyor belt lifting cylinders are arranged at the support frames; and conveyor belt lifting cylinder rods are fixedly connected with the lifting conveyor belts. The common conveying device can reduce operation heights for workers to take and put the work pieces, greatly reduce the labor intensity of the workers, realize the applicability of one conveying device to the conveyance of the two kinds of work pieces, namely, the vehicle doors and the trunk lids, simultaneously save the occupation of a production site and reduce the tool cost, is favorable for improving the production efficiency and overcomes the shortcomings of waste of working hours and low production efficiency caused by the frequent replacement of the conveying devices.

Owner:GREAT WALL MOTOR CO LTD

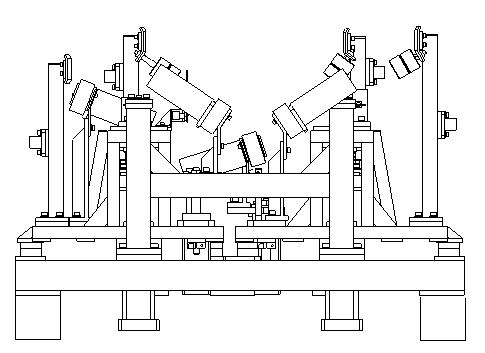

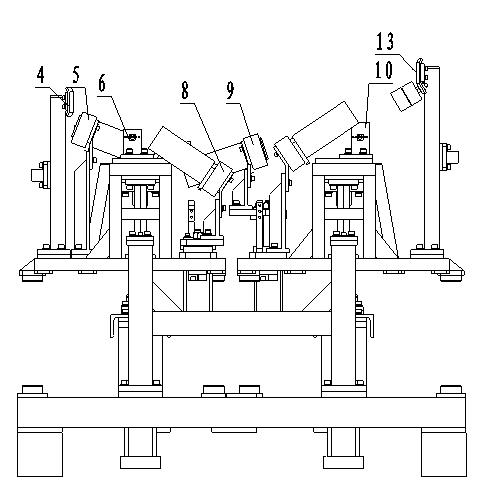

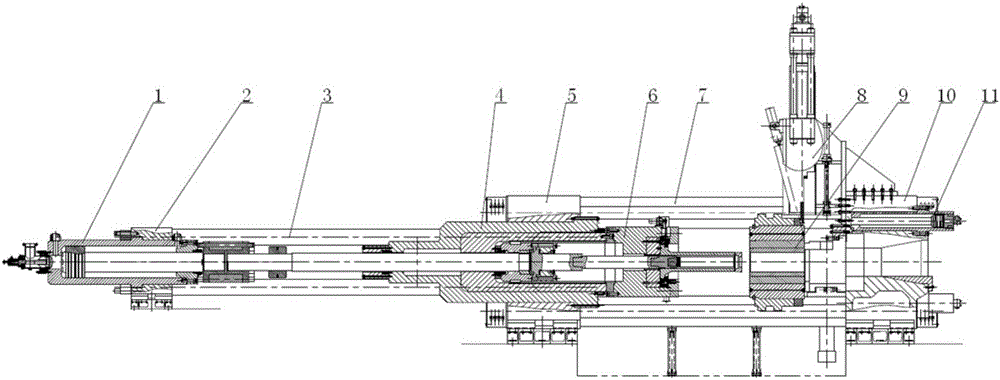

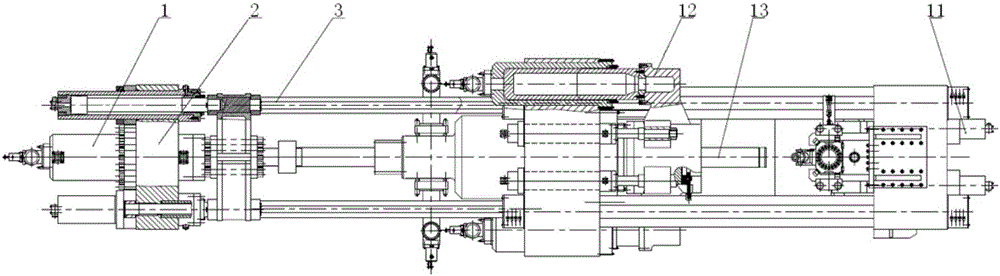

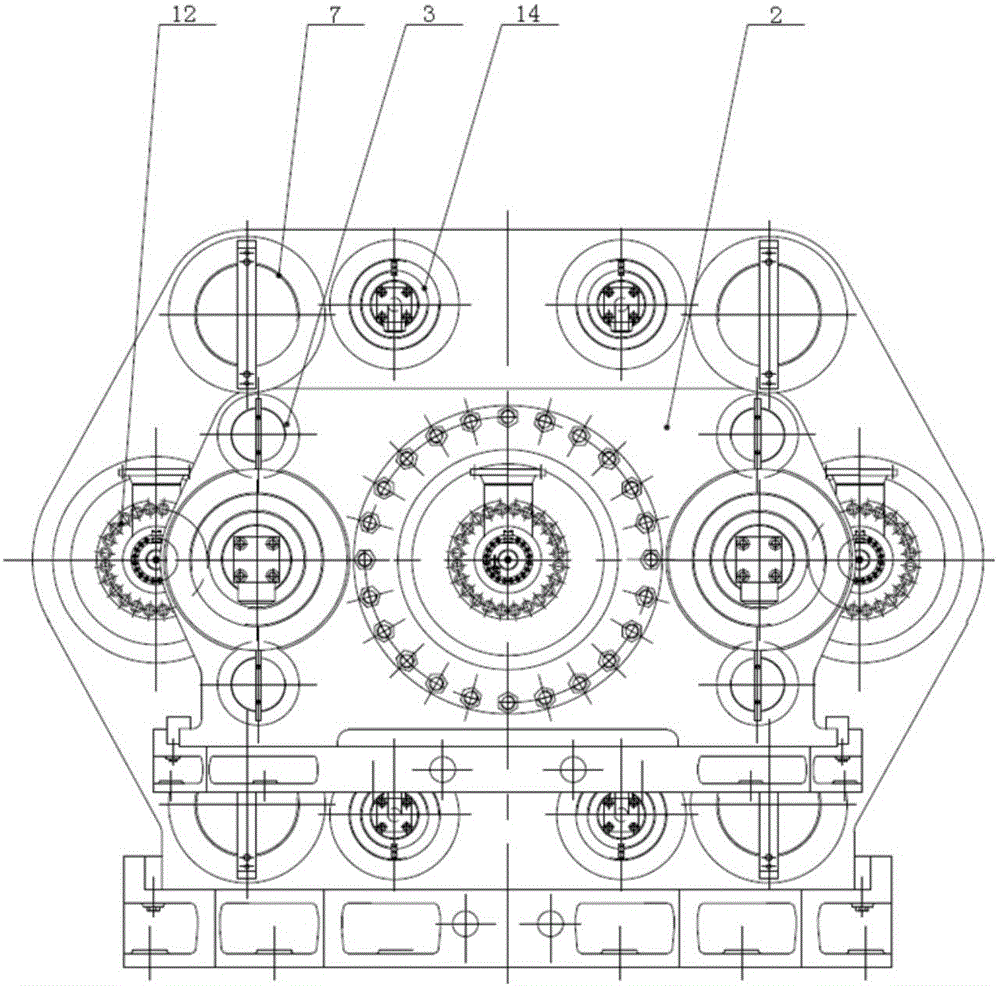

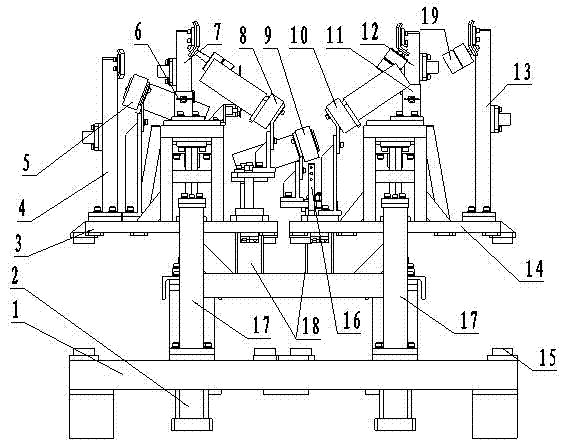

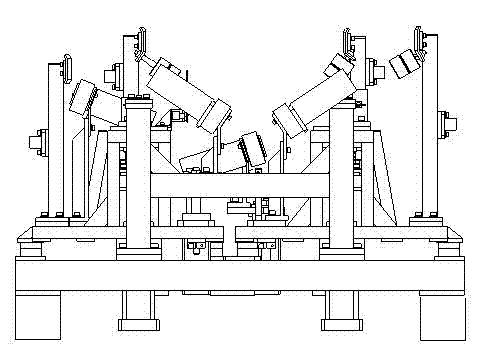

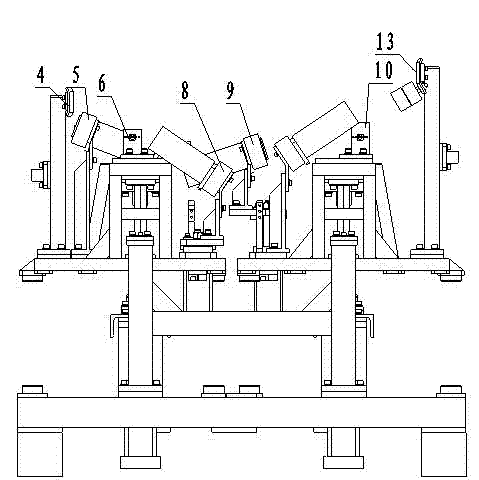

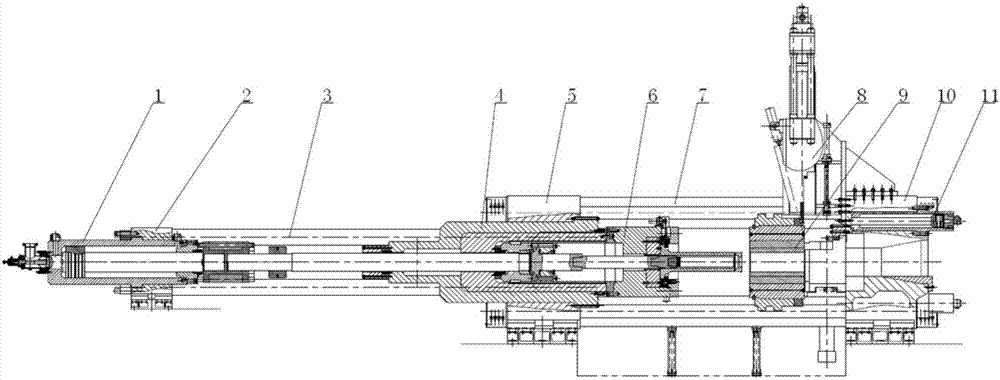

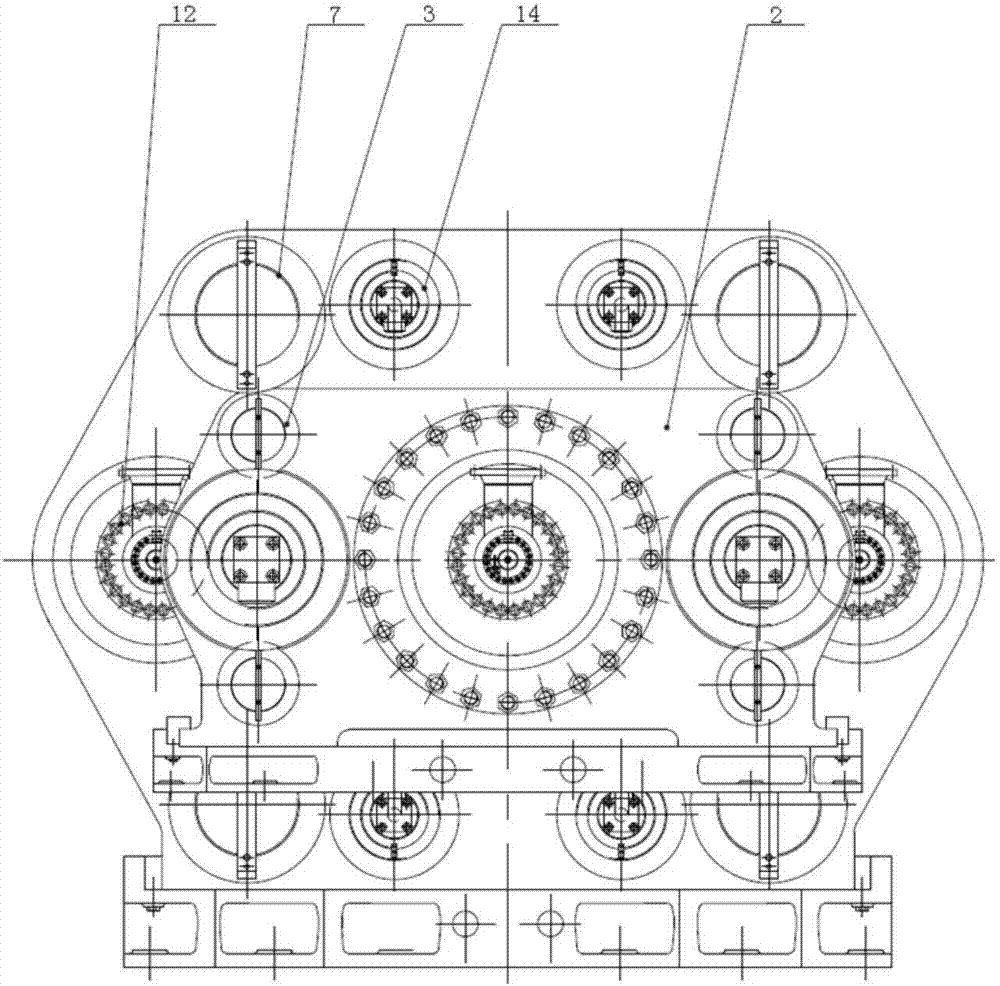

Main machine structure of super-heavy double-action extruding machine

ActiveCN105880305ASmall diameterReduce processing difficultyExtrusion mandrelsUltimate tensile strengthMechanical engineering

The invention belongs to the field of metallurgical equipment and particularly relates to a new structure of super-heavy extruding equipment. The new structure comprises a rear beam, pull rod pressing sleeves and a front beam which are used for forming an extruding machine prestressed rack, wherein an external perforation system is connected with the rear end of the rear beam and comprises a perforation rear beam provided with a fixed perforation cylinder and perforation pull rod pressing sleeves; two ends of each perforation pull rod pressing sleeve are connected with the extruding machine rear beam and the perforation rear beam respectively; a large main working cylinder is fixed on the extruding machine rear beam, small main working cylinders are symmetrically arranged on the left side and the right side of the large main working cylinder, and four side cylinders are symmetrically arranged on the upper side and the lower side of the large main working cylinder; a main plunger of the large main working cylinder is connected with a moving cross beam; an extruding tool is mounted on the moving cross beam; a pair of main scissors is fixed on the extruding machine front beam; and an extruding barrel is arranged between the extruding machine front beam and the moving cross beam. The main machine structure manner is designed for the structure of an extruding machine with the largest tonnage in the industry, the overall performance of the super-heavy extruding machine can be improved, and the strength and extruding precision of super-heavy backward extruding equipment can be improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

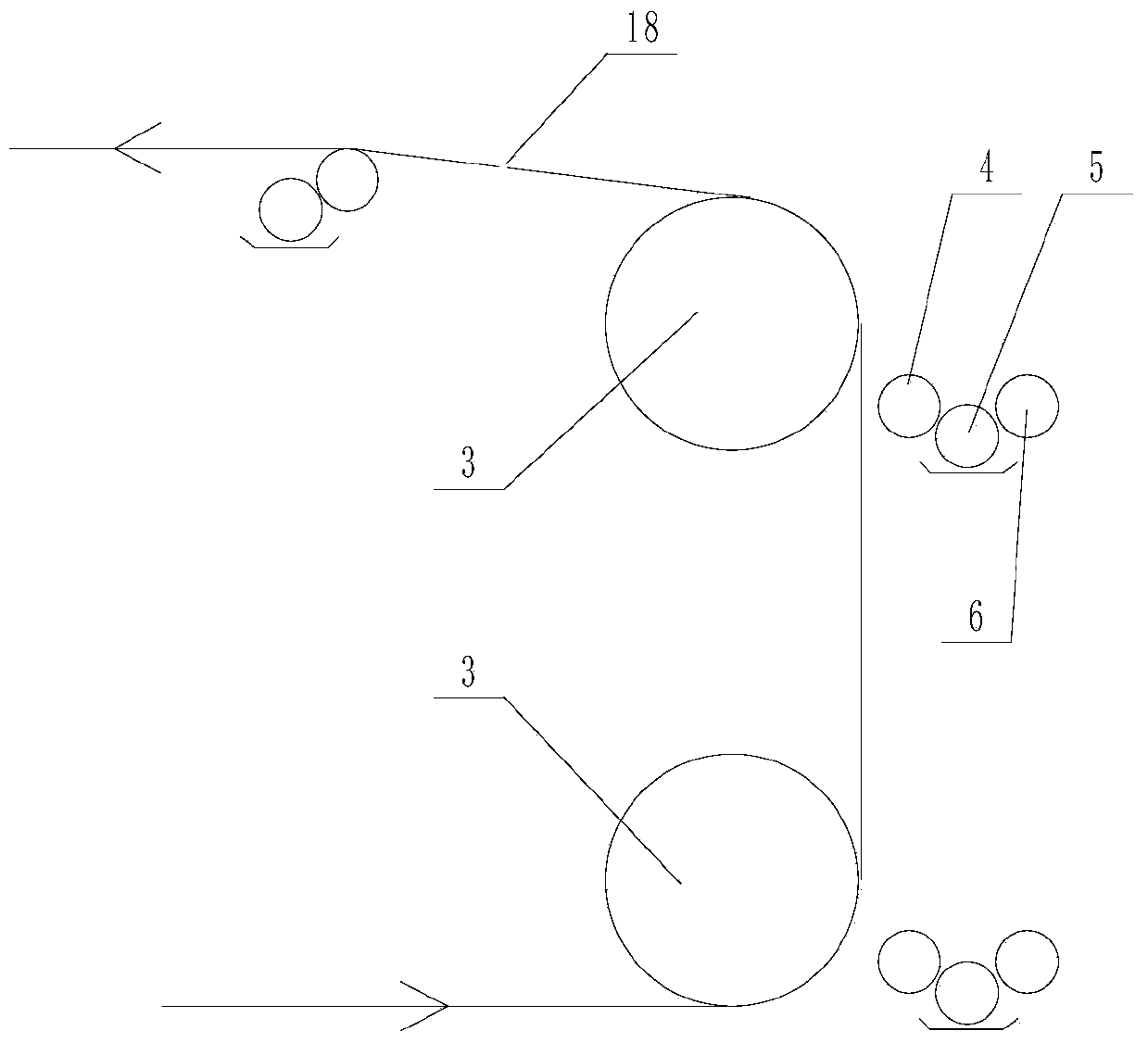

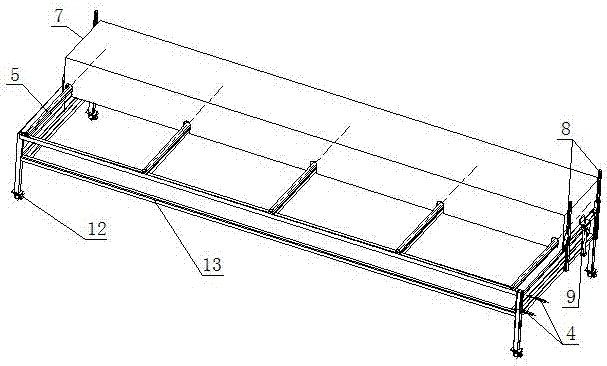

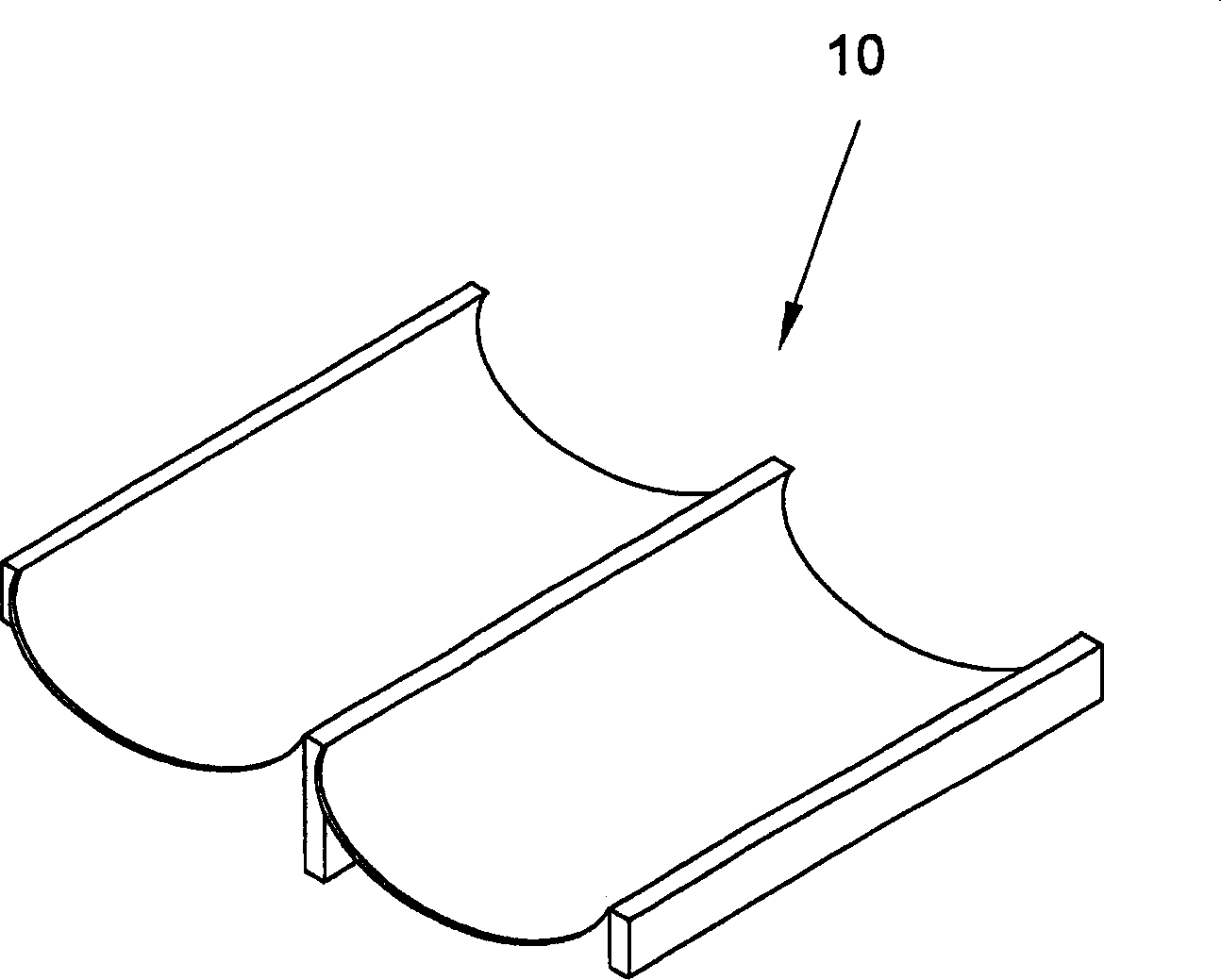

Coating machine for panels or coiled materials

ActiveCN104190589AAvoid wastingGuaranteed continuityLiquid surface applicatorsCoatingsPulp and paper industryCoating

The invention discloses a coating machine for panels or coiled materials. The coating machine comprises a rack, and multiple conveying rollers fixed on the rack, as well as at least two coating mechanisms, wherein each coating mechanism comprises a coating roller bracket arranged on the rack in a sliding mode; a coating roller is rotatably arranged on each coating roller bracket; a coating roller bracket adjusting mechanism is arranged between the rack and each coating roller bracket; a pick-up roller bracket with a pick-up roller is arranged on each coating roller bracket in the sliding mode; a pick-up roller bracket adjusting mechanism is arranged between each coating roller bracket and the corresponding pick-up roller bracket; a thickness defining roller bracket with a thickness defining roller is arranged on each pick-up roller bracket in the sliding mode; a thickness defining roller bracket adjusting mechanism is arranged between each pick-up roller bracket and the corresponding thickness defining roller bracket; a paint tray is arranged on the rack and contains oil paint; and the roller surface part of each pick-up roller is immersed into the oil paint. The coating machine does not need to be shut down for cleaning in the process of replacing oil paint of different colors or varieties, so that continuous production is guaranteed, the production efficiency is improved, and waste of the panels or coiled materials is avoided.

Owner:张家港市弘扬机械设备有限公司

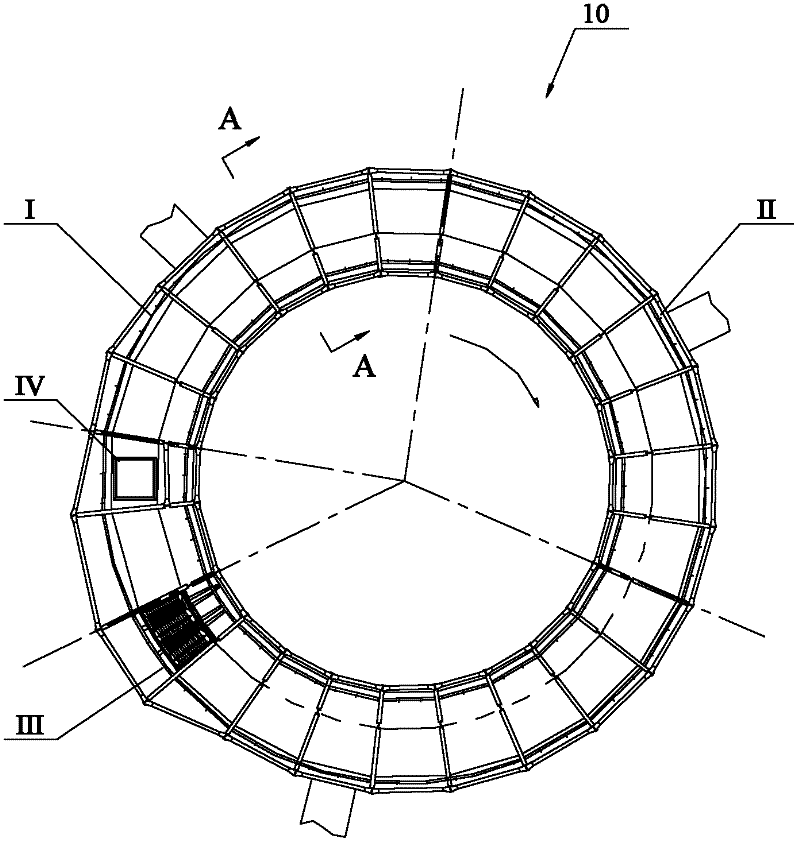

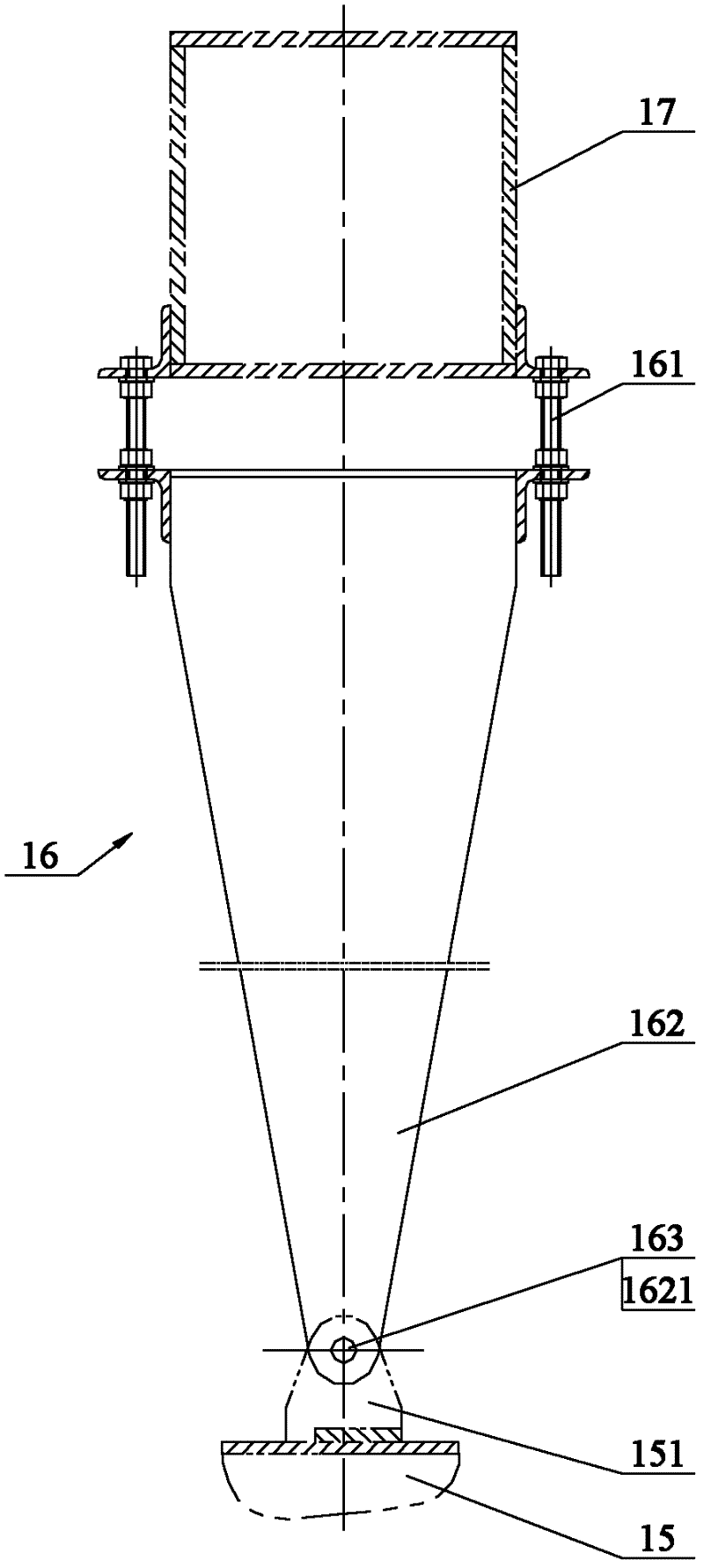

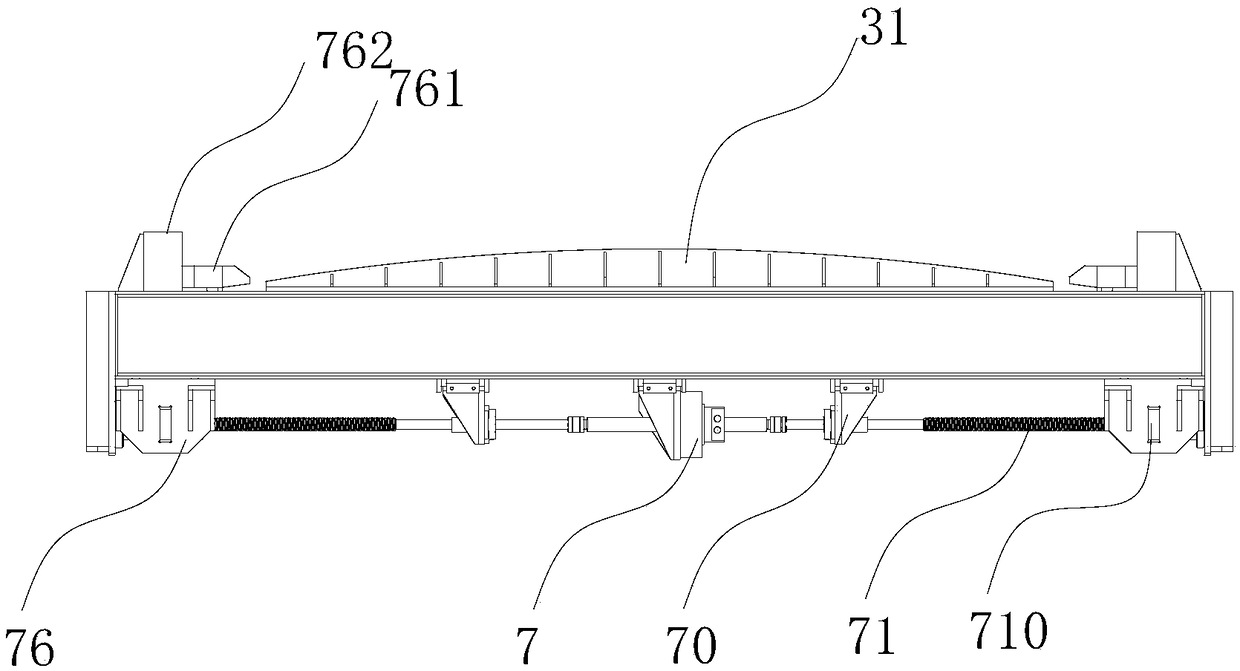

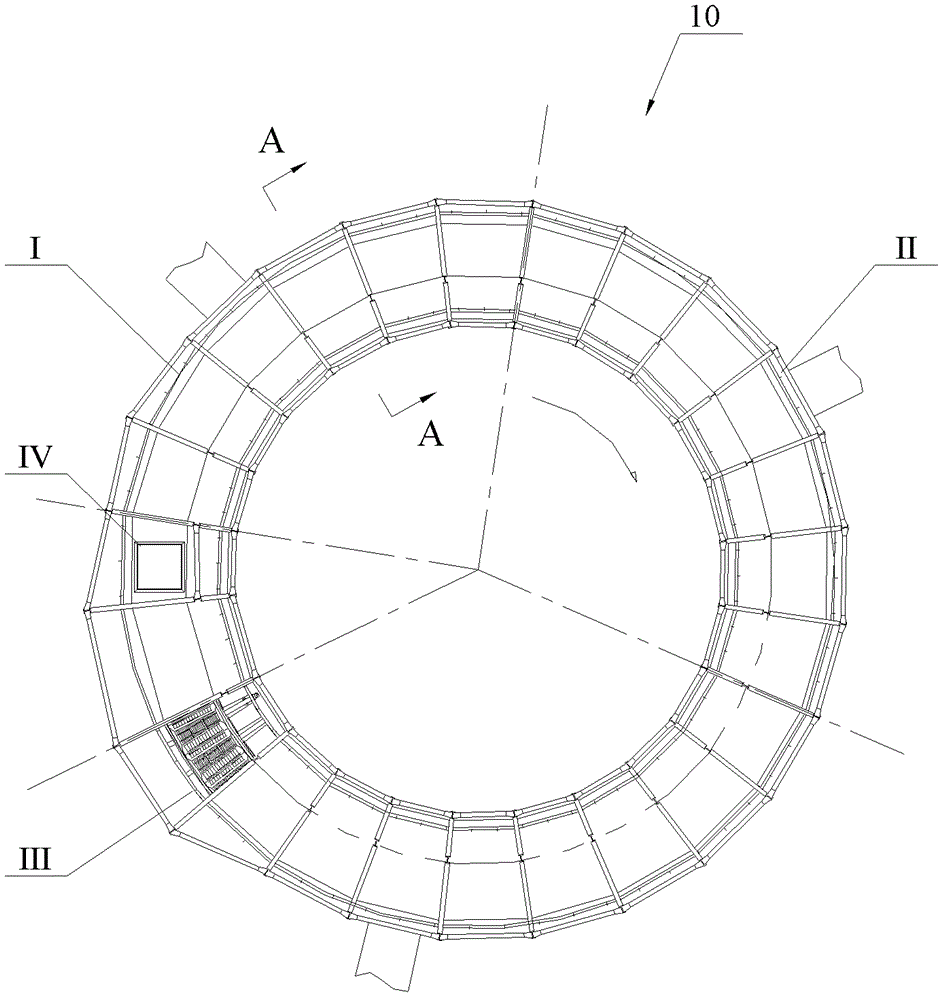

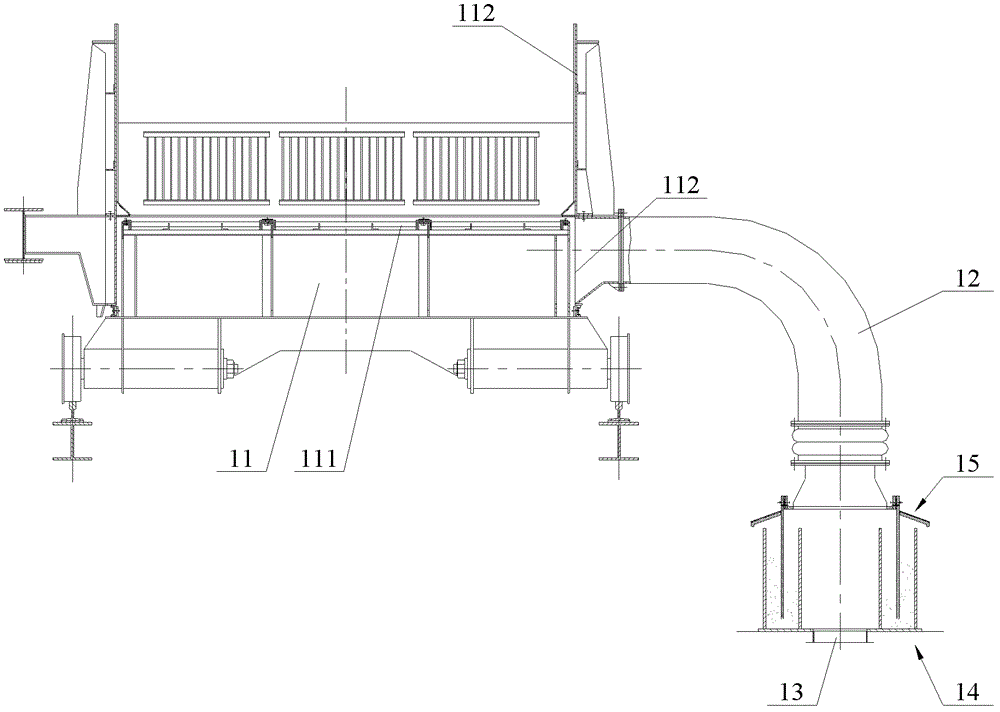

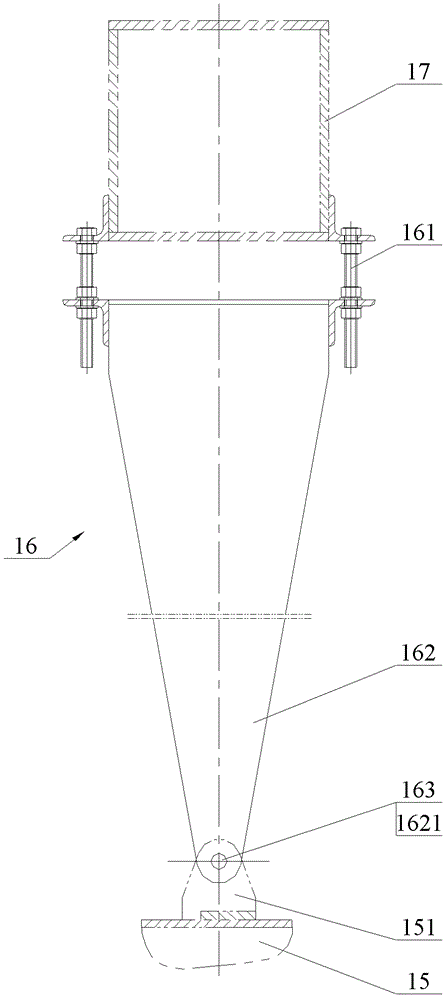

Lifting frame device and circular cooler with same

ActiveCN102353269AEnough maintenance spaceStable structureFurnace typesHandling discharged materialRelative displacementEngineering

The invention discloses a lifting frame device, comprising a lifting frame fixing member and four connecting members arranged from top to bottom in sequence; the upper end of the first connecting member is articulated with the lifting frame fixing member; opposite ends of the second connecting member and the first connecting member are in first screw-thread fit; opposite ends of the third connecting member and the second connecting member are nested, and the third connecting member and the second connecting member can undergo vertical relative displacement and are provided with matched lower stopping and limiting parts; opposite ends of the fourth connecting member and the third connecting member are in second screw-thread fit, and the lower end of the fourth connecting member is articulated with a gate-type sealing device; and the sum of vertical screw-out lengths of the first screw-thread fit and the second screw-thread fit is more than or equal to a predetermined vertical distance,and minimum vertical relative displacement between the third connecting member and the second connecting member meets a condition that both the first connecting member and the fourth connecting member can rotate around respect articulation points. The lifting frame device disclosed by the invention ahs the advantages of better operability and safety. Based on the lifting frame device, the invention further provides a circular cooler with the lifting frame device.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

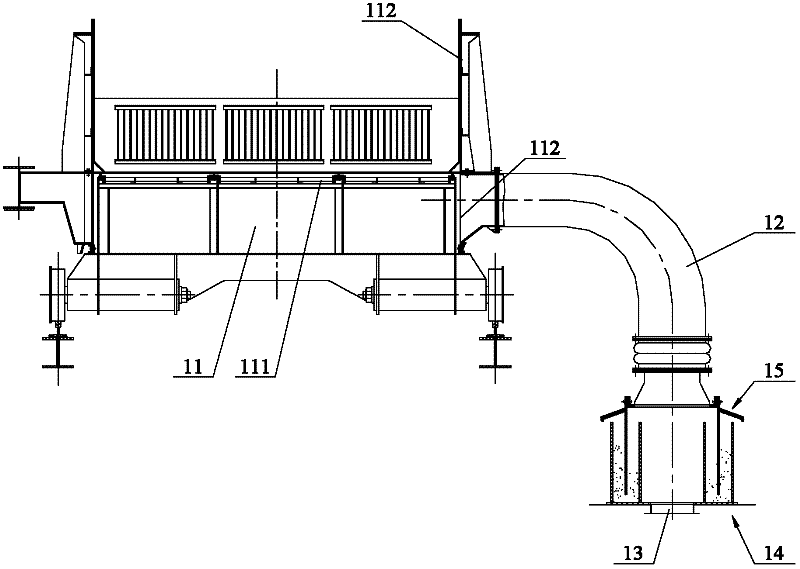

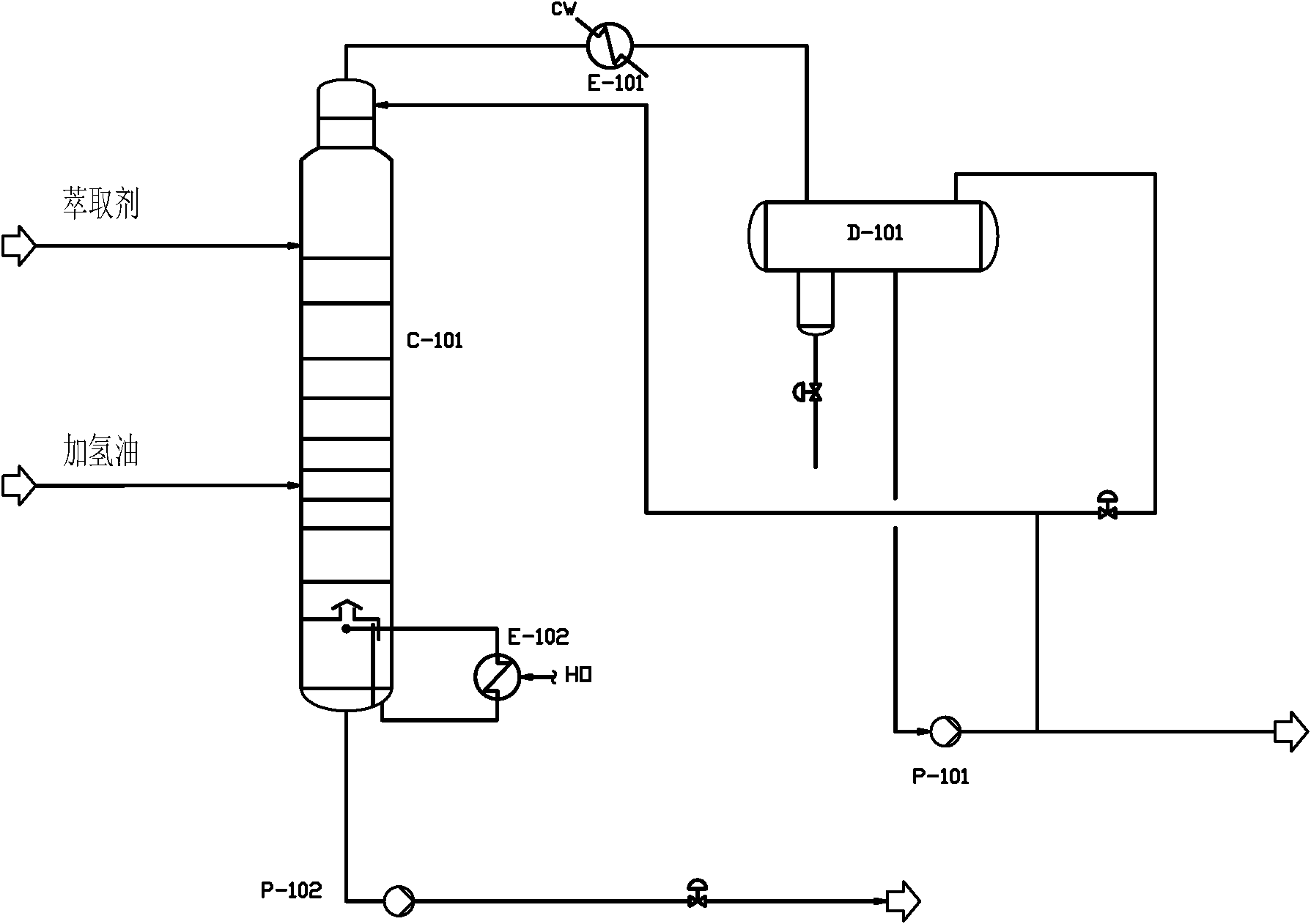

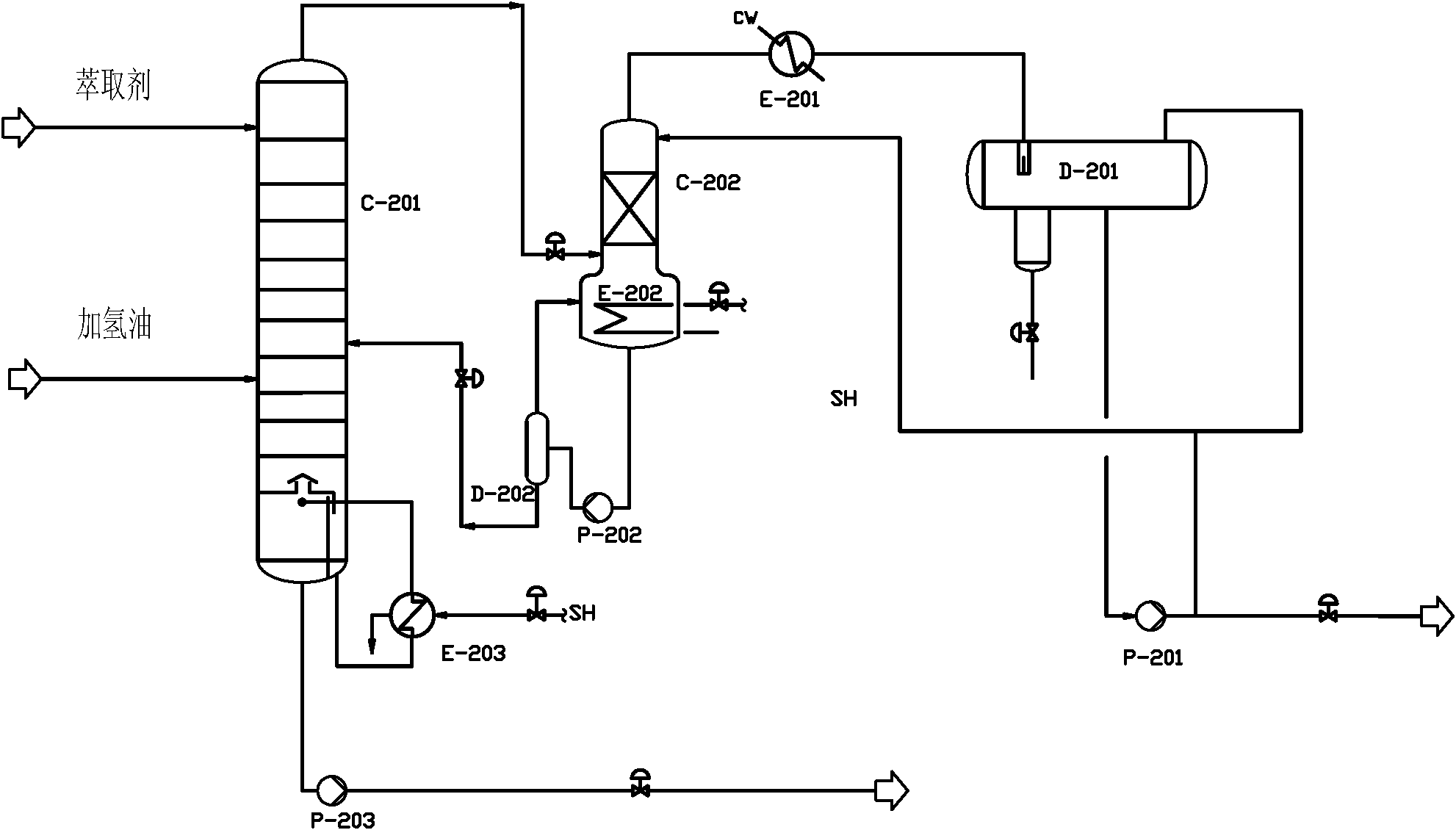

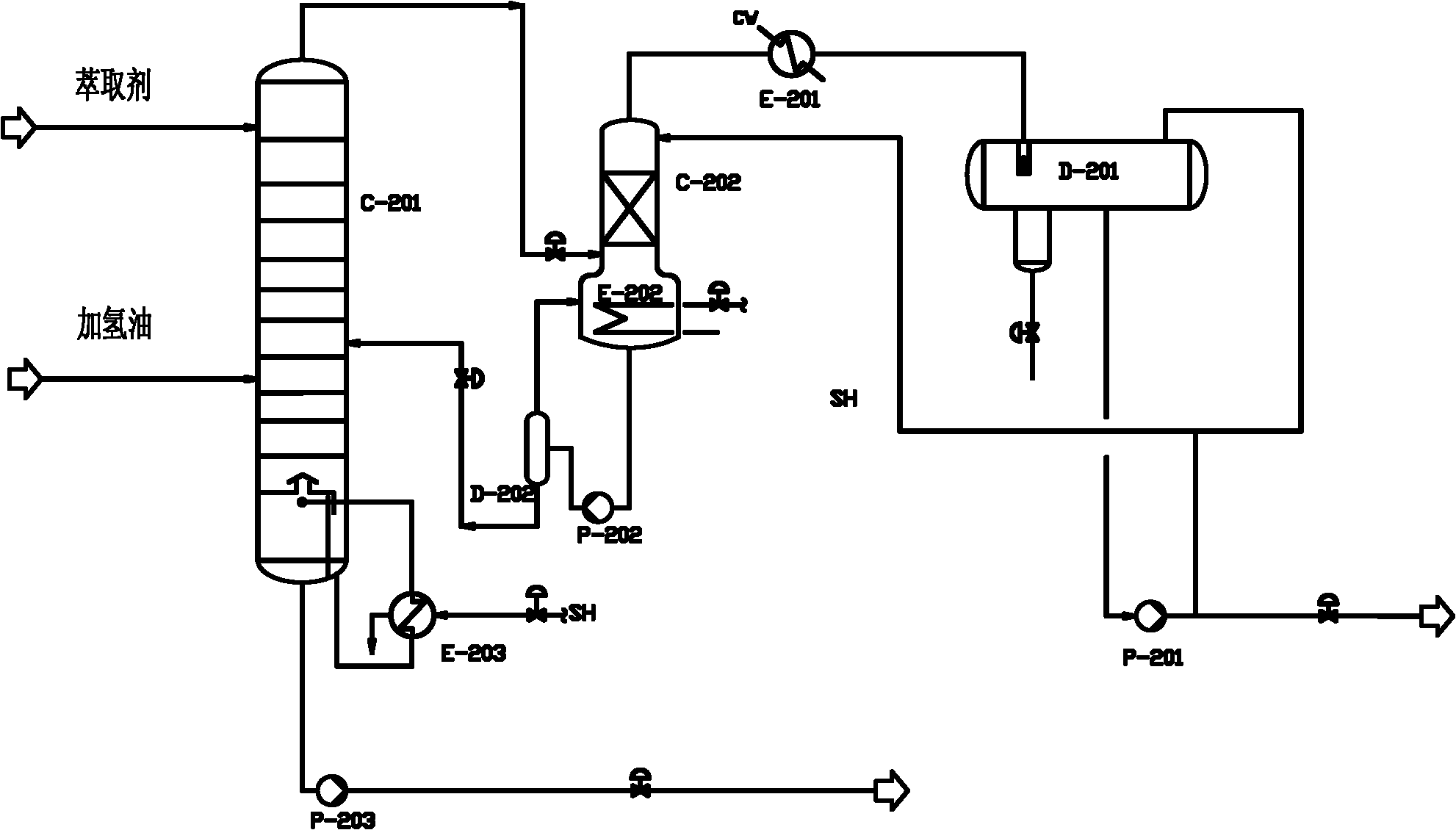

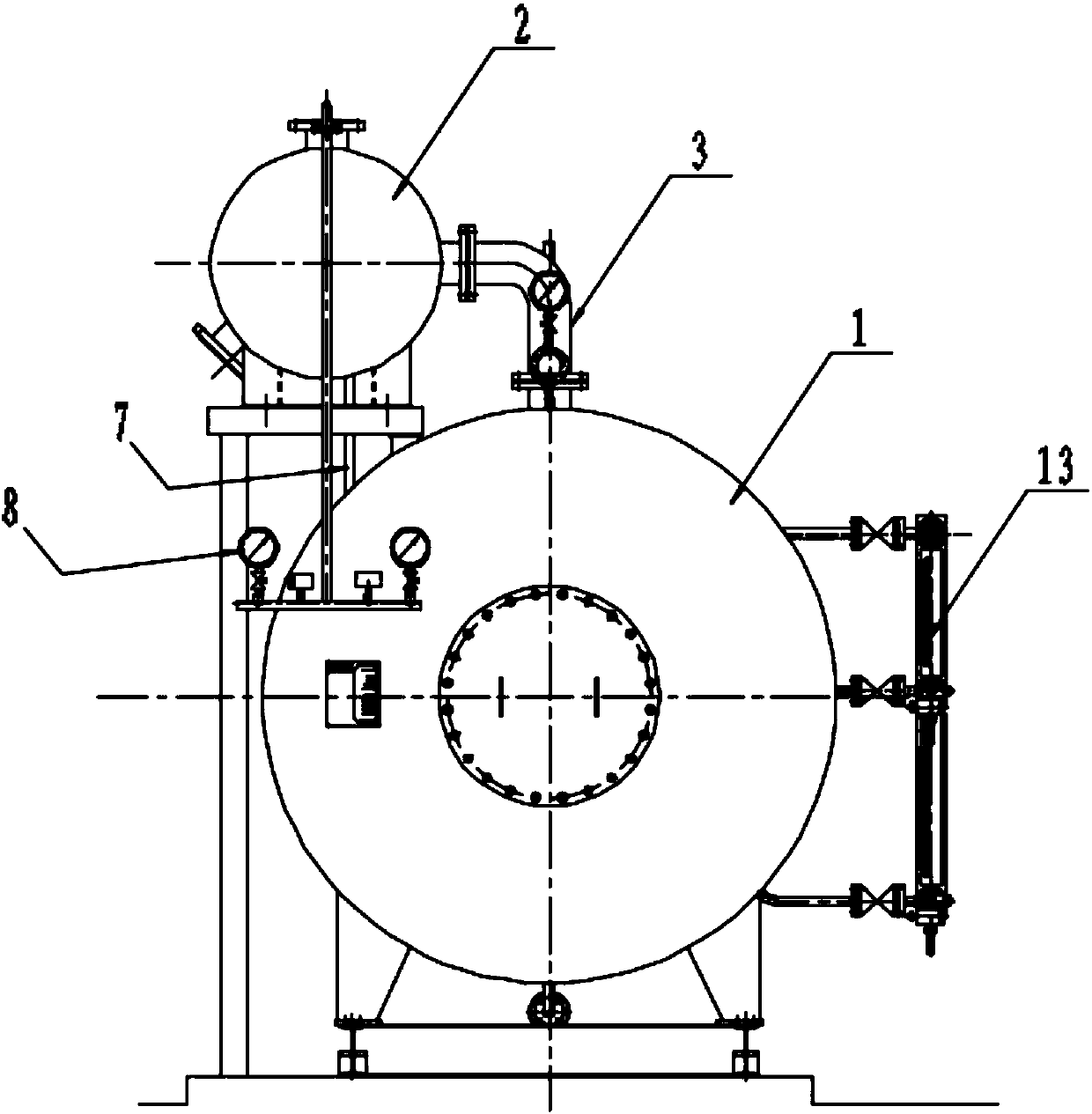

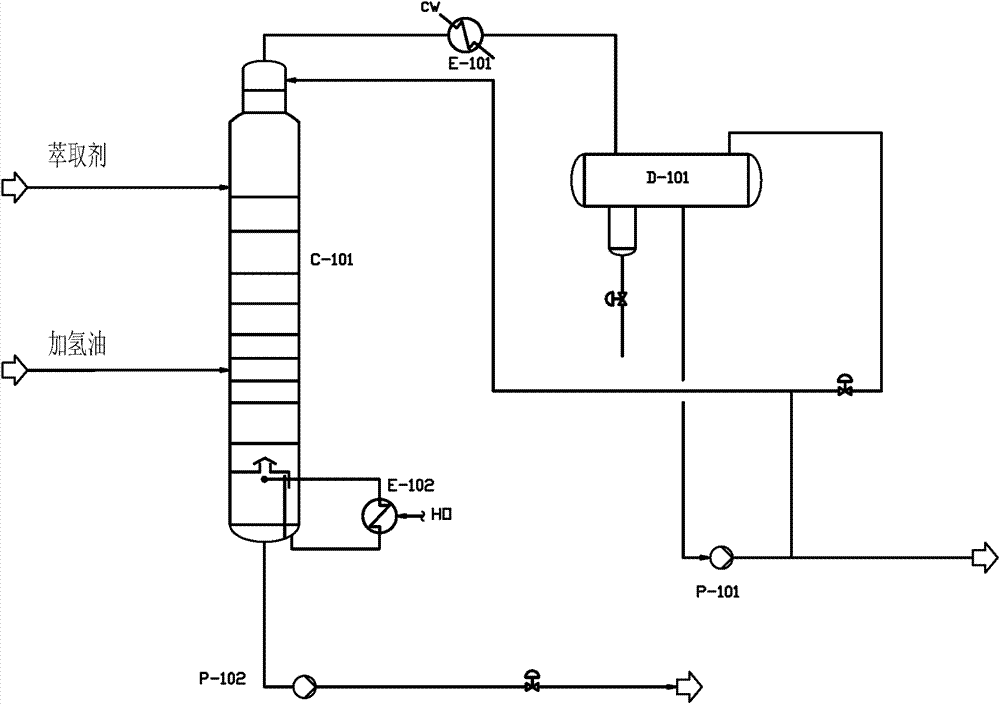

Extractive distillation process in hydrofining process of crude benzene

ActiveCN102126914APrevent falling backQuality improvementDistillation purification/separationBenzeneExtractive distillation

The invention relates to an extractive distillation process in the hydrofining process of crude benzene. The process comprises the following steps: 1) extractant enters from the top of an extractive distillation column, hydrotreated oil enters from the middle of the extractive distillation column; and the tower top product enters a stripping tower in a gaseous phase mode; 2) the tower top productof the extractive distillation column enters the stripping tower to perform distillation purification, the non-arene product in the top of the stripping tower is discharged, the heavy phase product at the bottom of the stripping tower is sent to a liquid-liquid separating tank by a pump; and 3) in the liquid-liquid separating tank, liquid is collected to obtain a heavy phase product and a light phase product, the heavy phase product containing extractant and arene are sent back to the extractive distillation column; and the light phase product, namely non-arene is sent back to the stripping tower. By adopting the process, the heavy non-arene can be effectively prevented from being sent to the extraction section of the extractive distillation column and the quality of product can be increased; and the total height of the extractive distillation column can be reduced, the manual operation is convenient to perform and the problem that the lack of heat caused by the overhigh extractive distillation column can be avoided.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

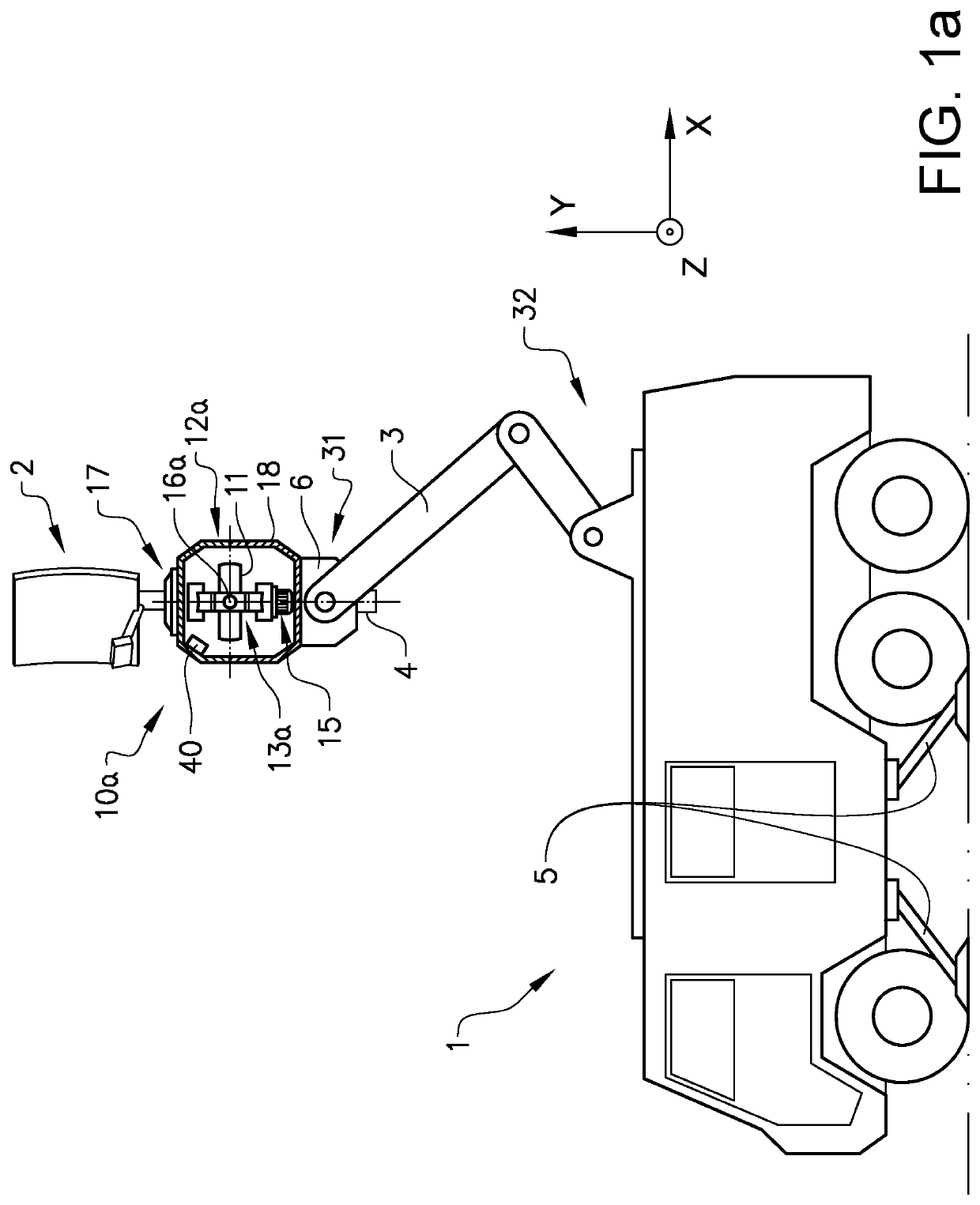

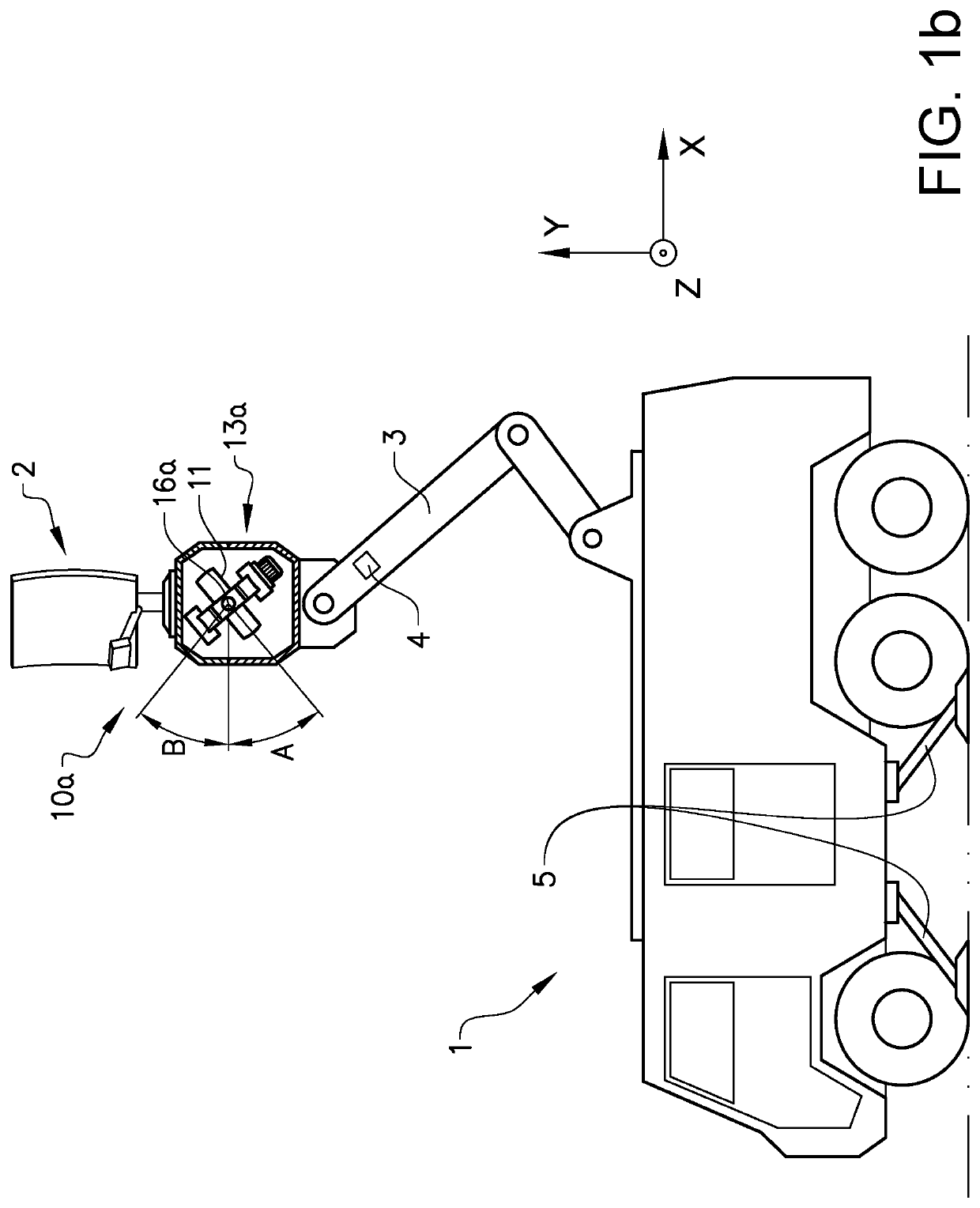

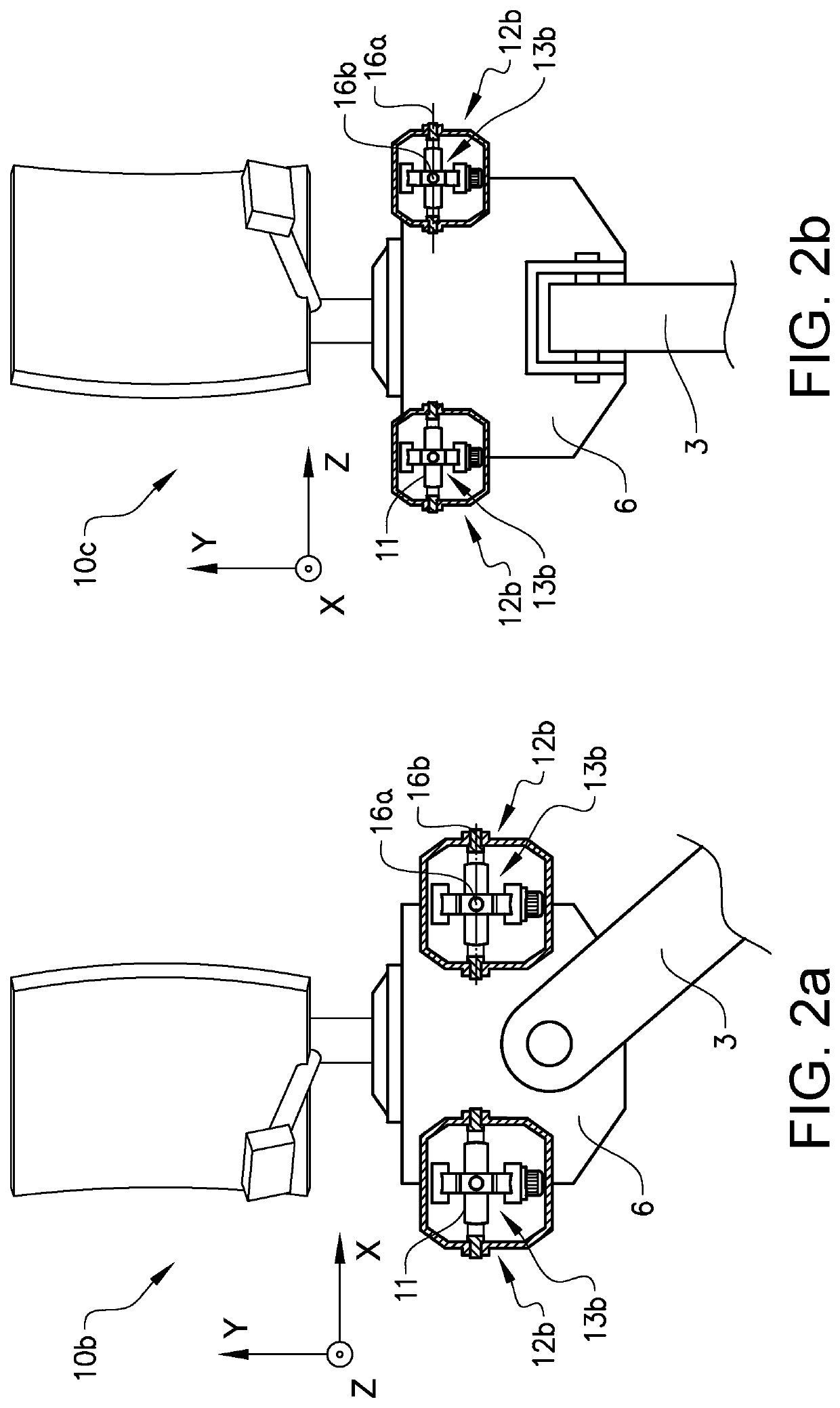

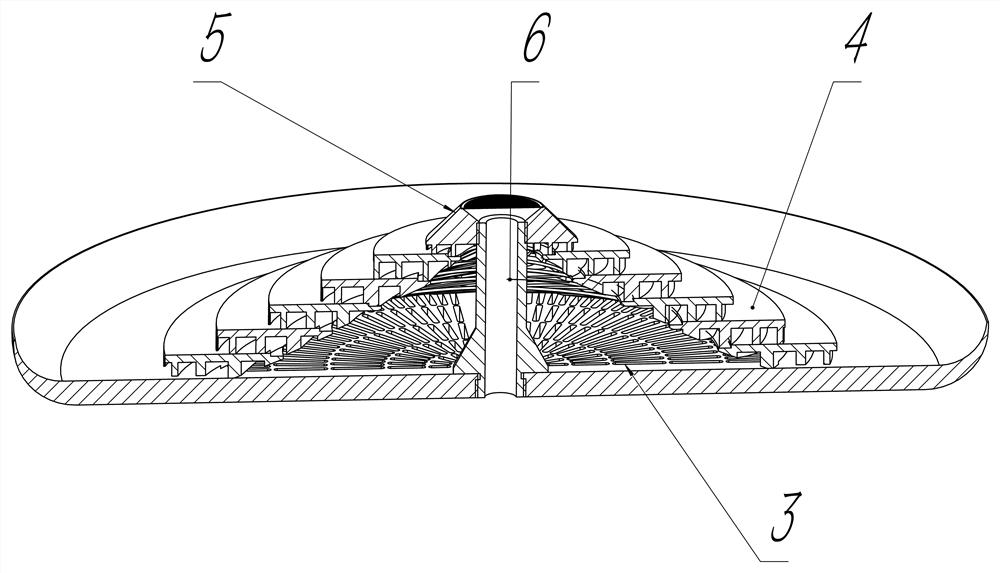

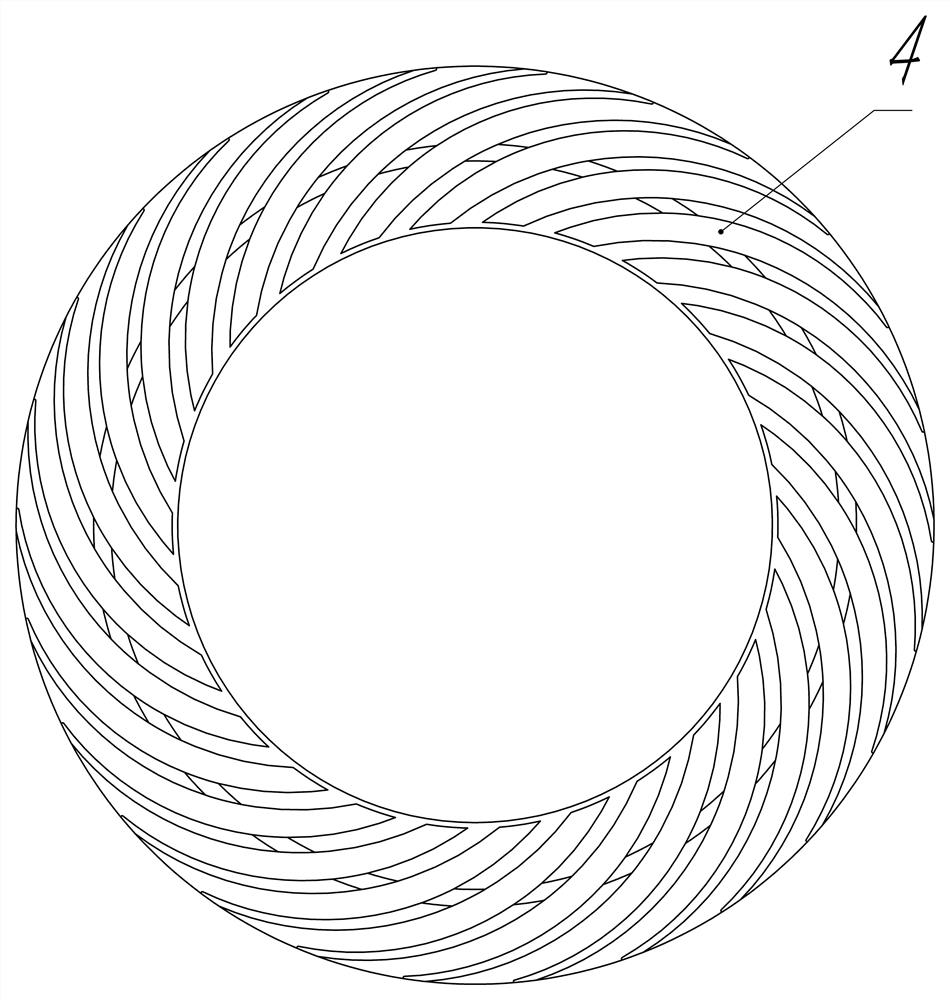

A stabilization arrangement for stabilization of an antenna mast

ActiveUS20190341670A1Lower operating heightAccuracy be affectedAntenna supports/mountingsVibration dampingPrecessionEngineering

A stabilization arrangement (10) for stabilizing an antenna mast (3), comprising an antenna mast (3) and a gyroscopic stabilizer device (12), wherein the gyroscopic stabilizer device (12) in turn comprises a flywheel (11), a flywheel axis (14), wherein the flywheel (11) is arranged about the flywheel axis (14), and a gimbal structure (13), wherein the flywheel (11) is suspended in the gimbal structure (13) and the gimbal structure (13) is configured to permit flywheel precession or tilting about at least one gimbal output axis (16). The gyroscopic stabilizer device (12) is fixedly arranged in connection to a first end portion (31) of the antenna mast (3) and the antenna mast (3) is fastenable to a supporting structure at a second end portion (32) of the antenna mast (3), wherein the gyroscopic stabilizer device (12) is configured to reduce movements in a plane perpendicular to the extension of the antenna mast (3).

Owner:SAAB AB

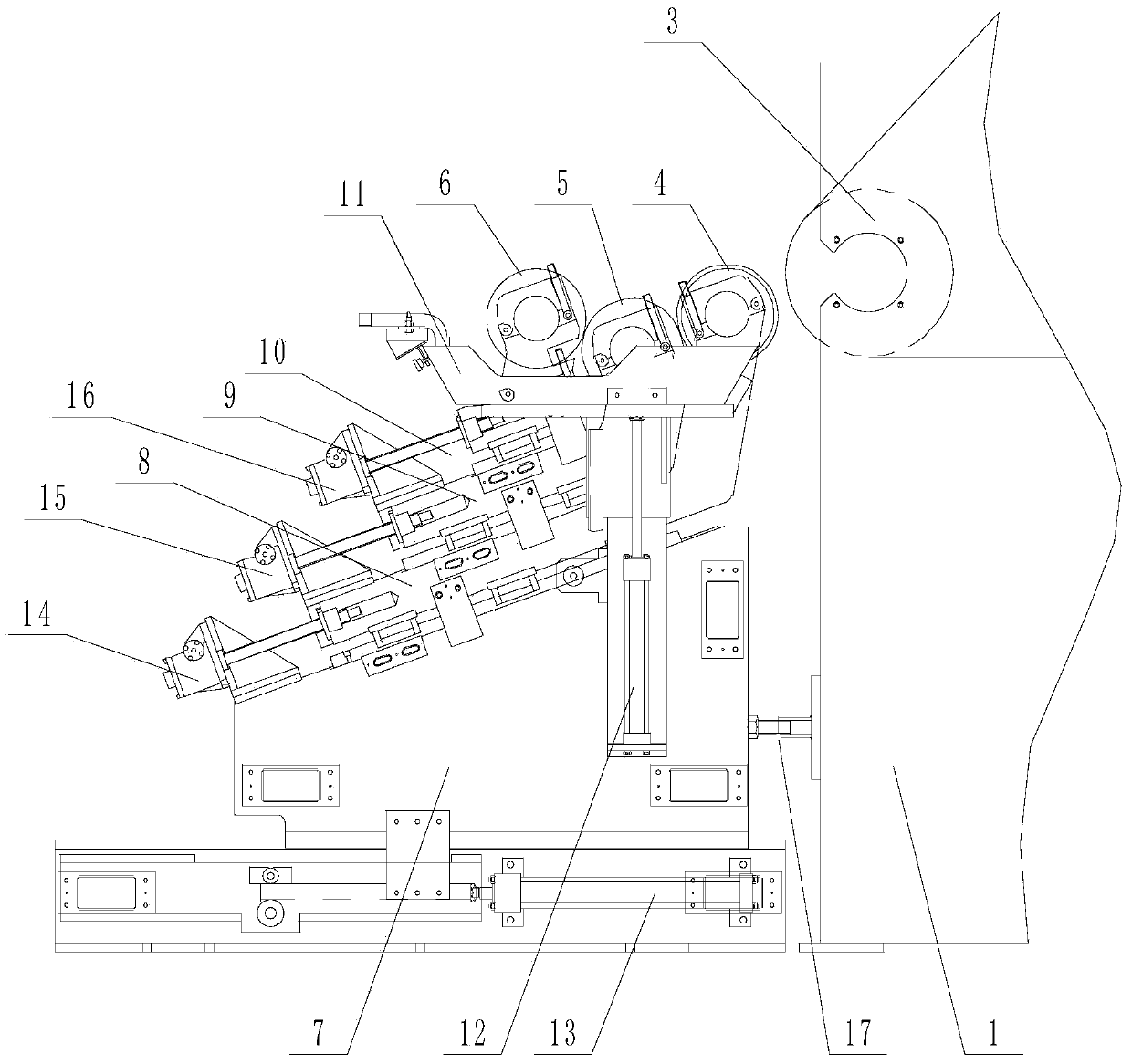

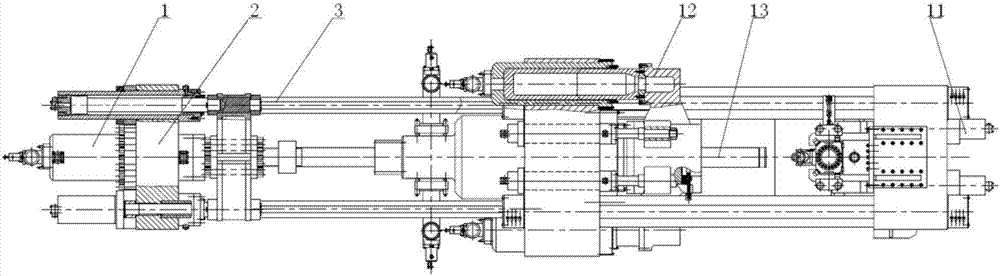

Large size sleeve pipe optical rod assembling equipment

ActiveCN107352787AReduce consumptionAchieve dryingGlass making apparatusEngineeringStructural engineering

The invention relates to large size sleeve pipe optical rod assembling equipment, and belongs to the technical field of optical rod and optical fiber processing. The equipment is composed of a core rod storage device, a core rod assembling device, and a sleeve pipe assembling device. The front termination of the core rod assembling device is provided with the core rod storage device through a connection piece A. The rear termination of the core rod assembling device is provided with the sleeve pipe assembling device through a connection piece B. The equipment can precisely place a preform core rod in a predetermined position in a sleeve pipe, which has been subjected to tapering, without any wear through an adjusting roller, an elevating mechanism, and a roller finely adjusting device, and completes the manufacturing of large size optical fiber preform. The large size sleeve pipe optical rod assembling equipment has low requirements on the height of used space; due to the functional module assembly structure, the equipment is easy to disassemble and transport, the core rods can be stored and dried intensively, the consumption amount of clean gas is low, the operation height is reduced, and the risk that core rods fall down and break is reduced.

Owner:湖北凯乐量子通信光电科技有限公司

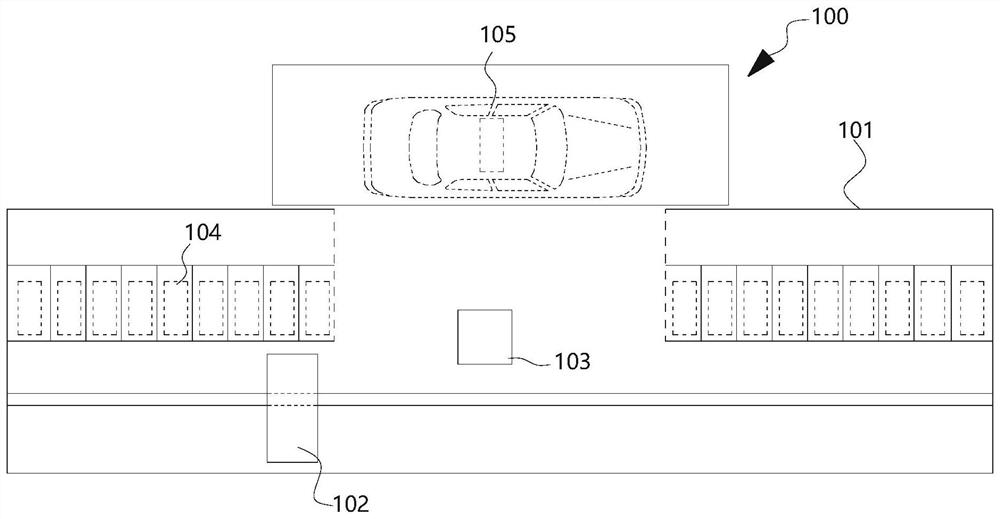

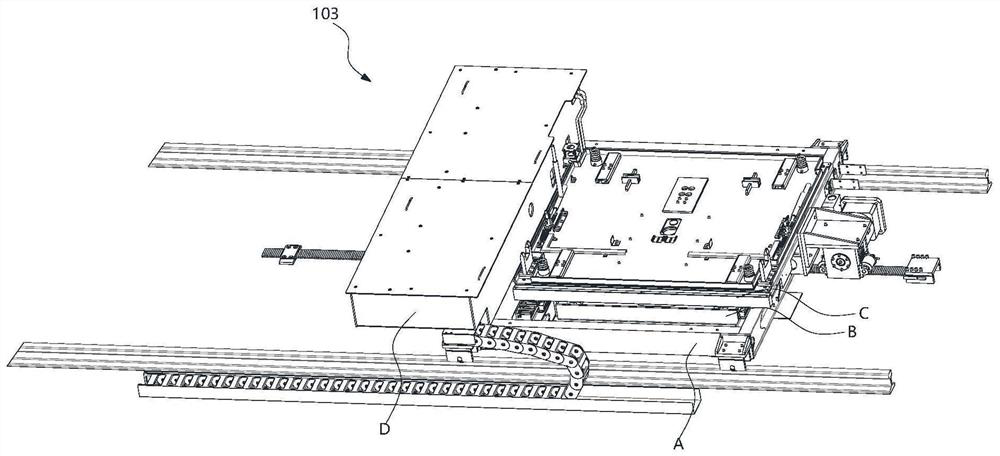

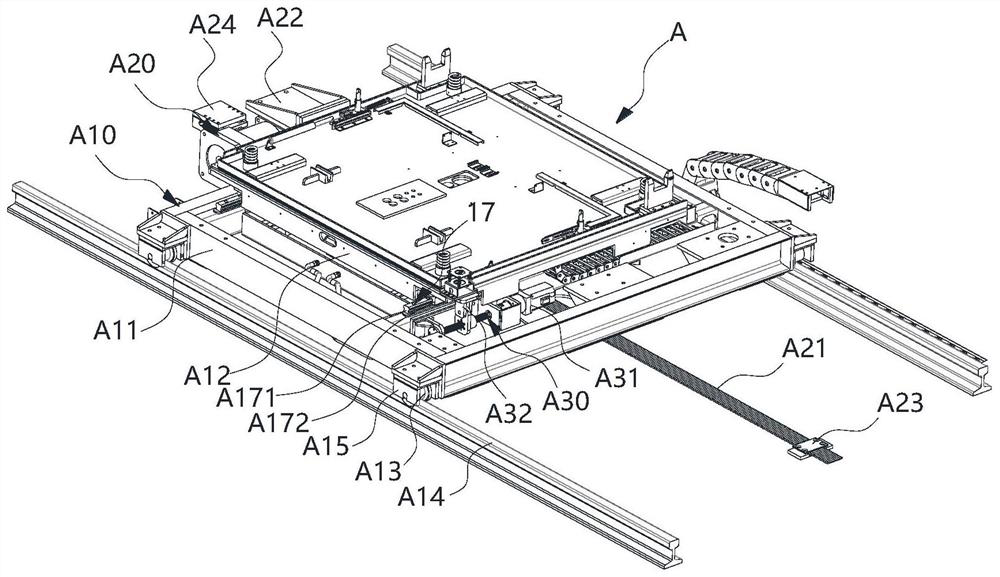

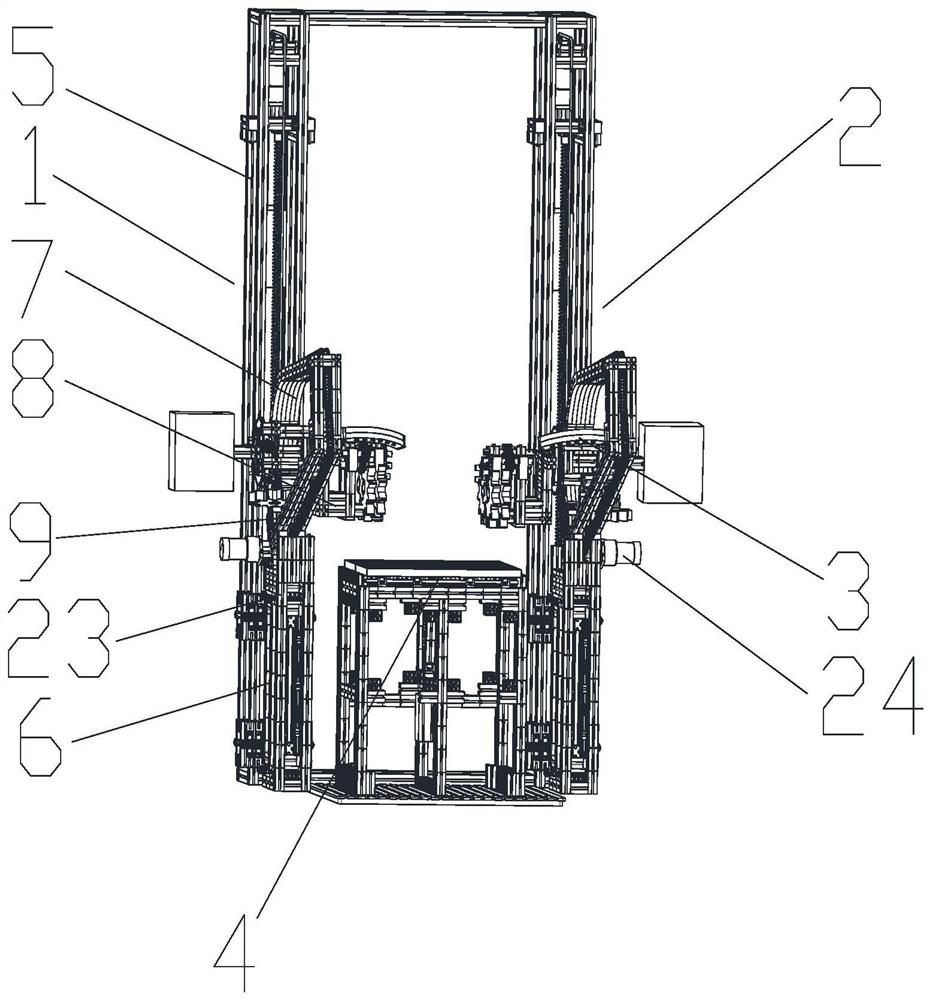

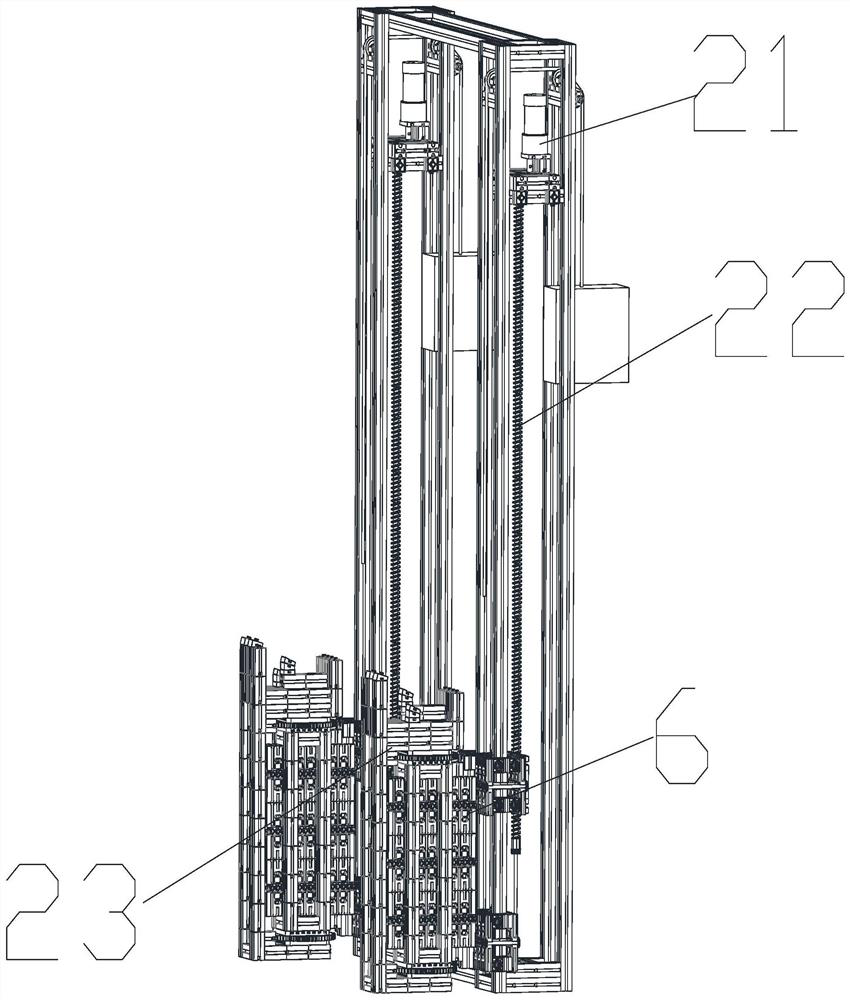

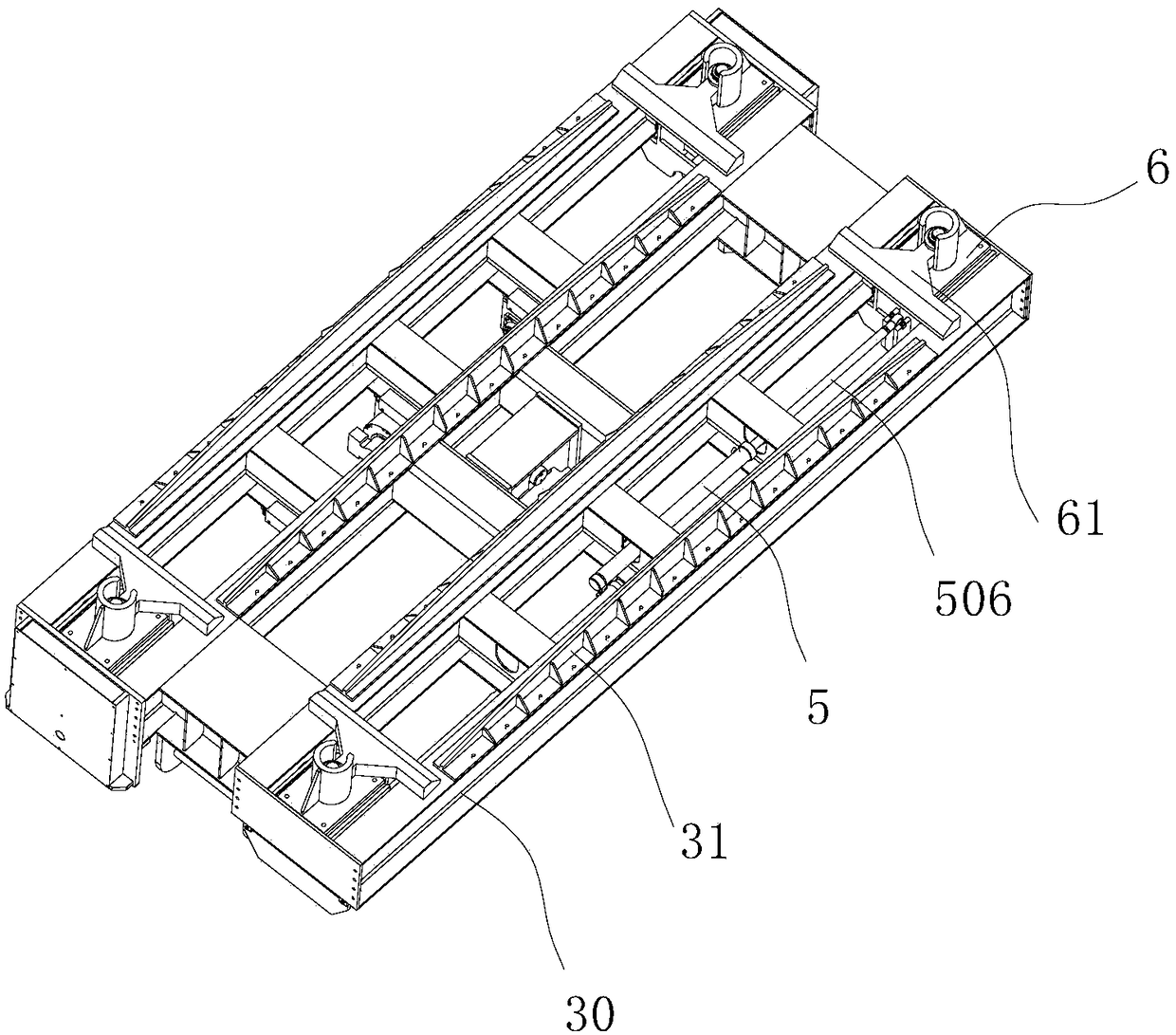

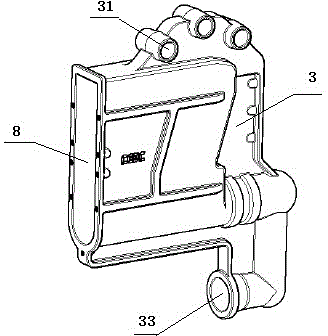

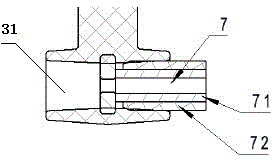

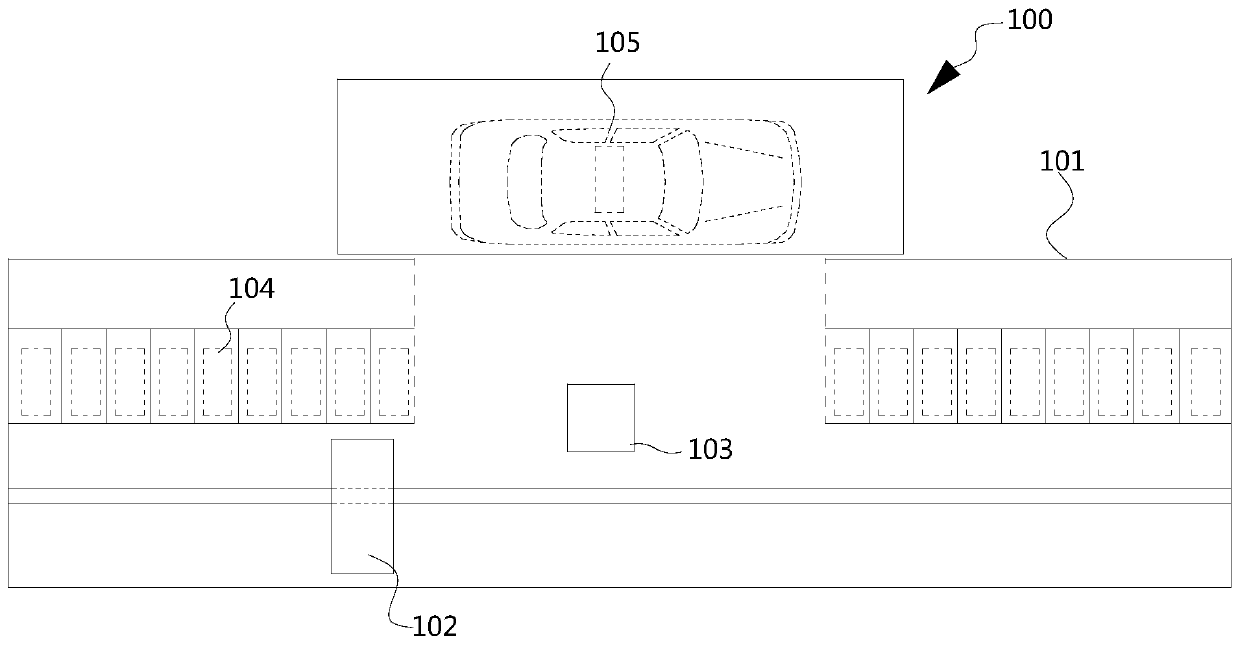

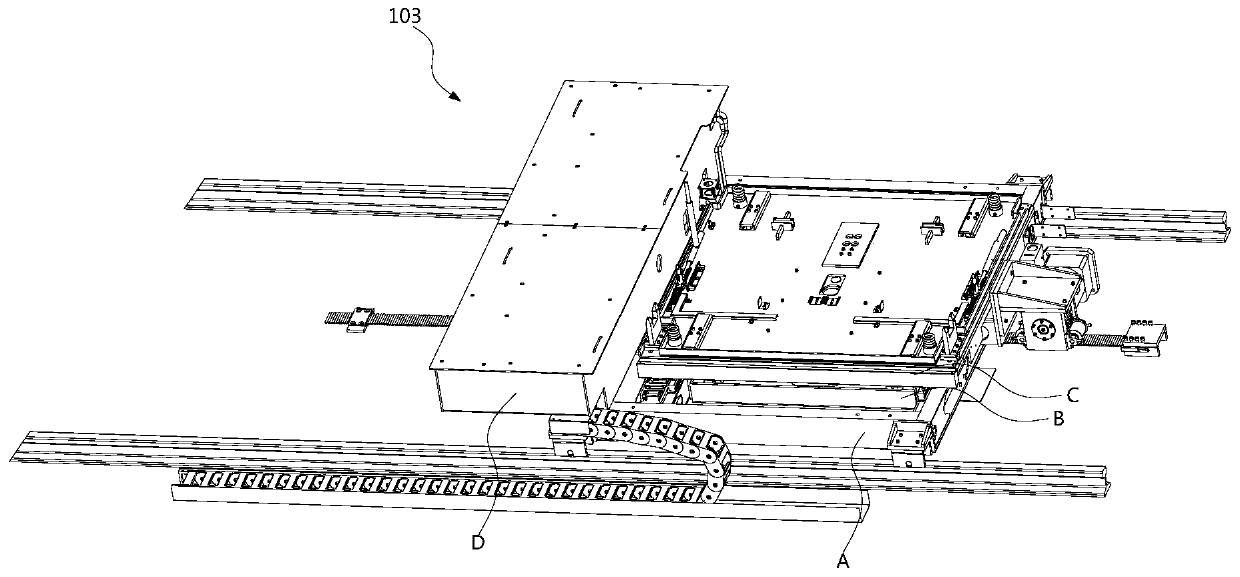

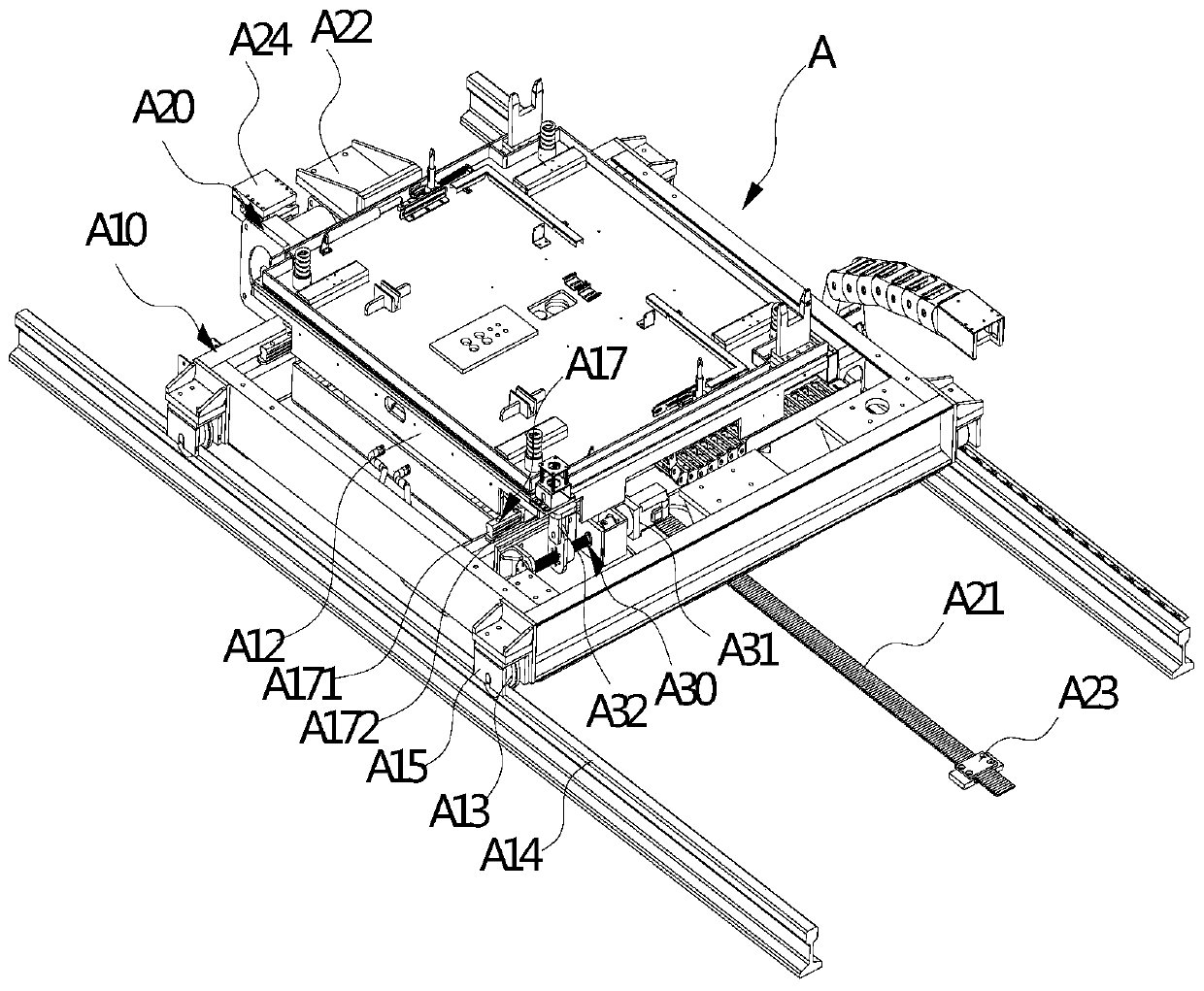

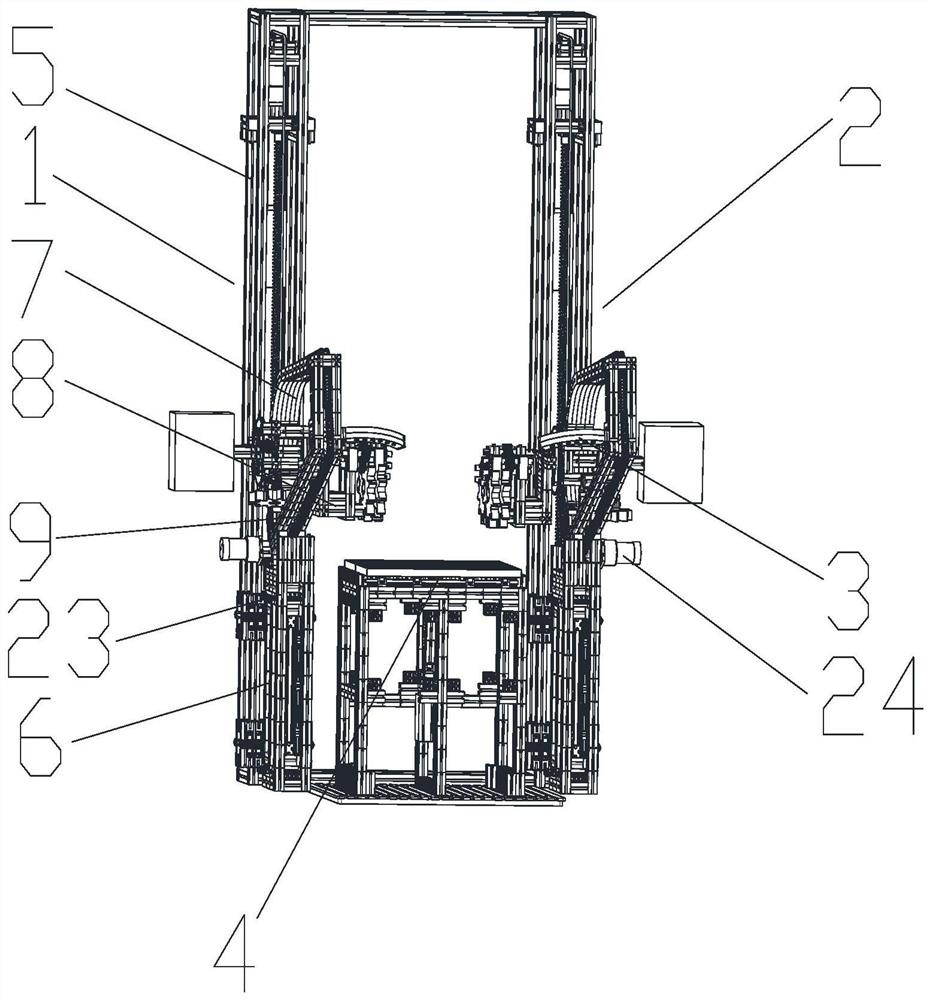

Battery replacement platform, battery mounting part and battery replacement moving device

PendingCN111645562ALower operating heightReduce replacement spaceCharging stationsVehicular energy storageElectrical batteryControl engineering

The invention discloses a battery replacement platform, a battery mounting part and a battery replacement moving device. The battery replacement moving device comprises a horizontal moving part used for driving the whole battery replacement equipment to move horizontally and comprises a moving frame used for moving and providing a mounting base and a horizontal driving device used for driving themoving frame to move; a vertical lifting part which is mounted on the horizontal moving part and used for driving the battery replacement platform to ascend and descend in the vertical direction; anda battery mounting part which is mounted on the vertical lifting part, is used for replacing and dismounting a battery, and comprises a battery replacement platform and a battery unlocking device mounted on the battery replacement platform. By means of the vertical lifting part, the operation height can be reduced to the maximum extent; therefore, the required replacement space is reduced, the movement stability and accurate positioning can be improved through the horizontal moving part, a battery at the bottom of the electric automobile can be automatically disassembled and replaced through the battery mounting part, and the disassembly and transportation of the battery of the electric automobile and the replacement of a new battery are automatically realized in the whole scheme.

Owner:SHANGHAI DIANBA NEW ENERGY RESOURCES SCI & TECH

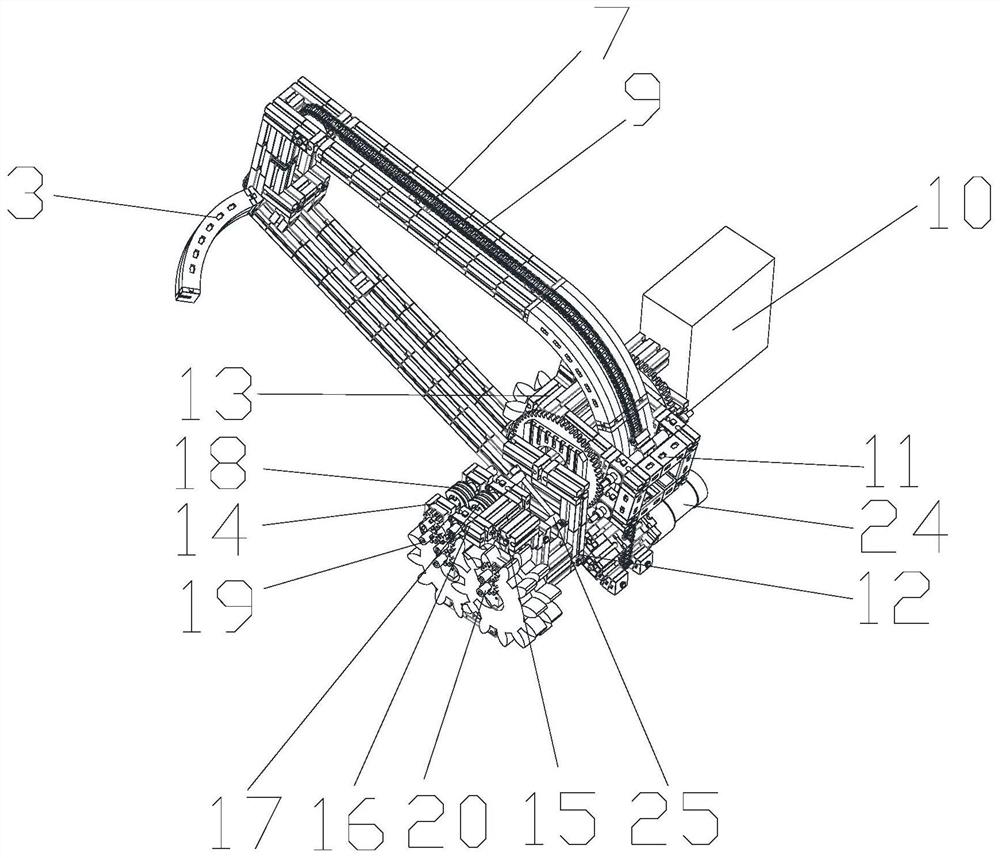

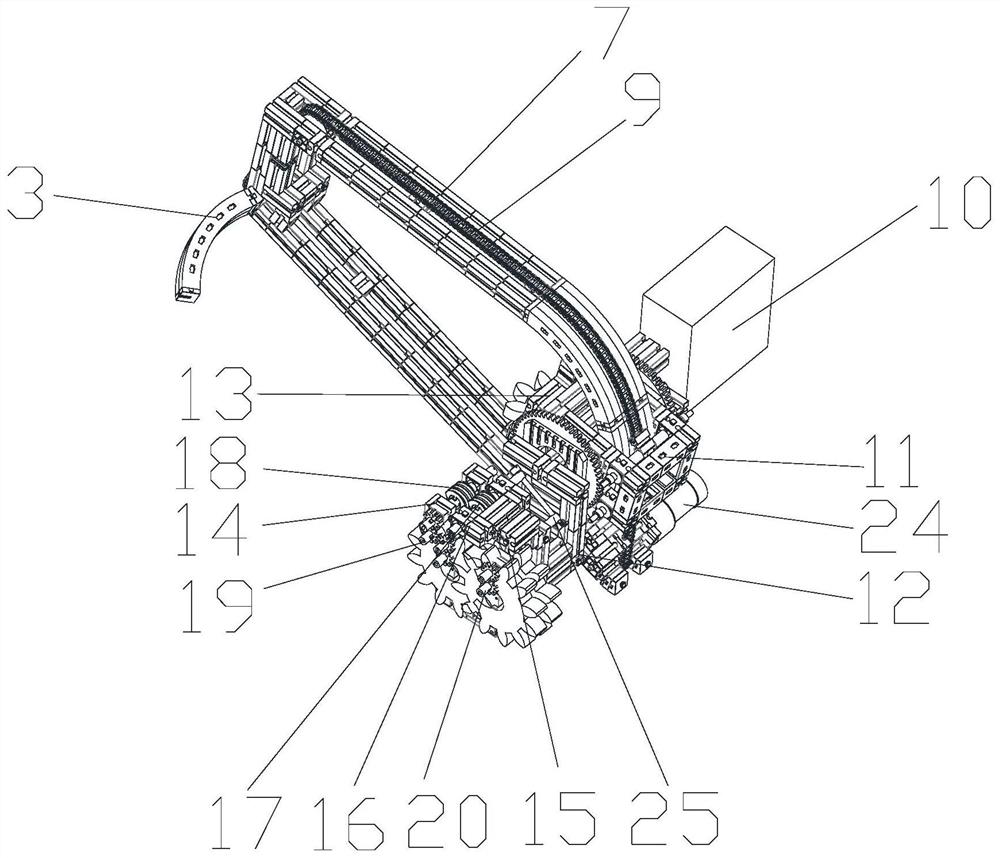

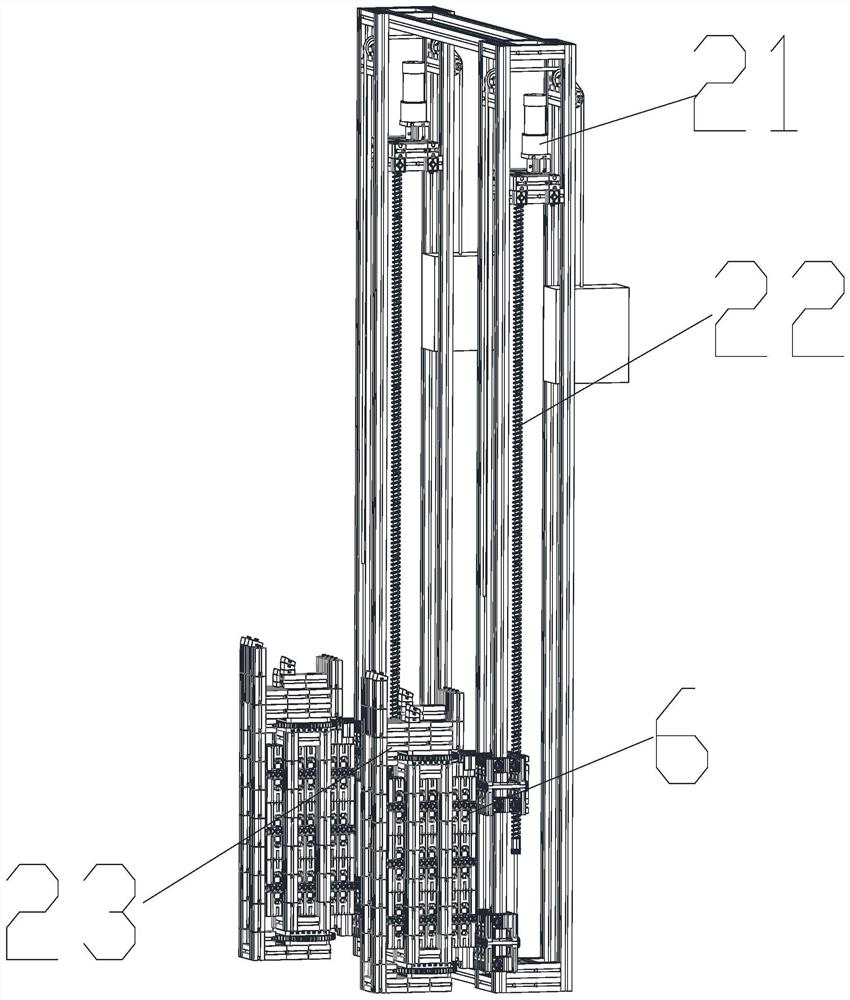

Auxiliary frame for putting on and taking off of sleeveless sweater

ActiveCN112056903ASolve the arms crossed raiseSolving the Difficulties of Pulldowns with Curved ArmsApparel holdersControl theoryChain drive

The invention relates to an auxiliary frame for putting on and taking off of a sleeveless sweater. The auxiliary frame comprises a first auxiliary frame and a second auxiliary frame which are symmetrically arranged, wherein the first auxiliary frame comprises a fixed support, a sliding block support is arranged in the height direction of the fixed support in a sliding mode, an arc-shaped front pull guide rail is arranged on the sliding block support, a manipulator is arranged on the front pull guide rail in a sliding mode, and a transmission chain used for driving the manipulator to slide is further arranged on the front pull guide rail; the manipulator comprises a sliding seat in transmission connection with the transmission chain, a rotating arm rotationally arranged on the sliding seat,a finger clamp mechanism fixed on the rotating arm and a rotating arm motor fixed on the sliding seat, the rotating arm motor is used for driving the rotating arm to rotate, and the finger clamp mechanism comprises a pressing support and a clothes gathering support which are oppositely arranged; a pressing plate is rotationally arranged on the pressing support, a first roller is rotationally arranged on the pressing plate, a second roller matched with the first roller to press the sleeveless sweater is rotationally arranged on the clothes gathering support, and a clothes gathering motor usedfor driving the second roller to rotate is further arranged on the clothes gathering support; and the structure of the second auxiliary frame is the same as that of the first auxiliary frame.

Owner:CHANGZHOU INST OF TECH

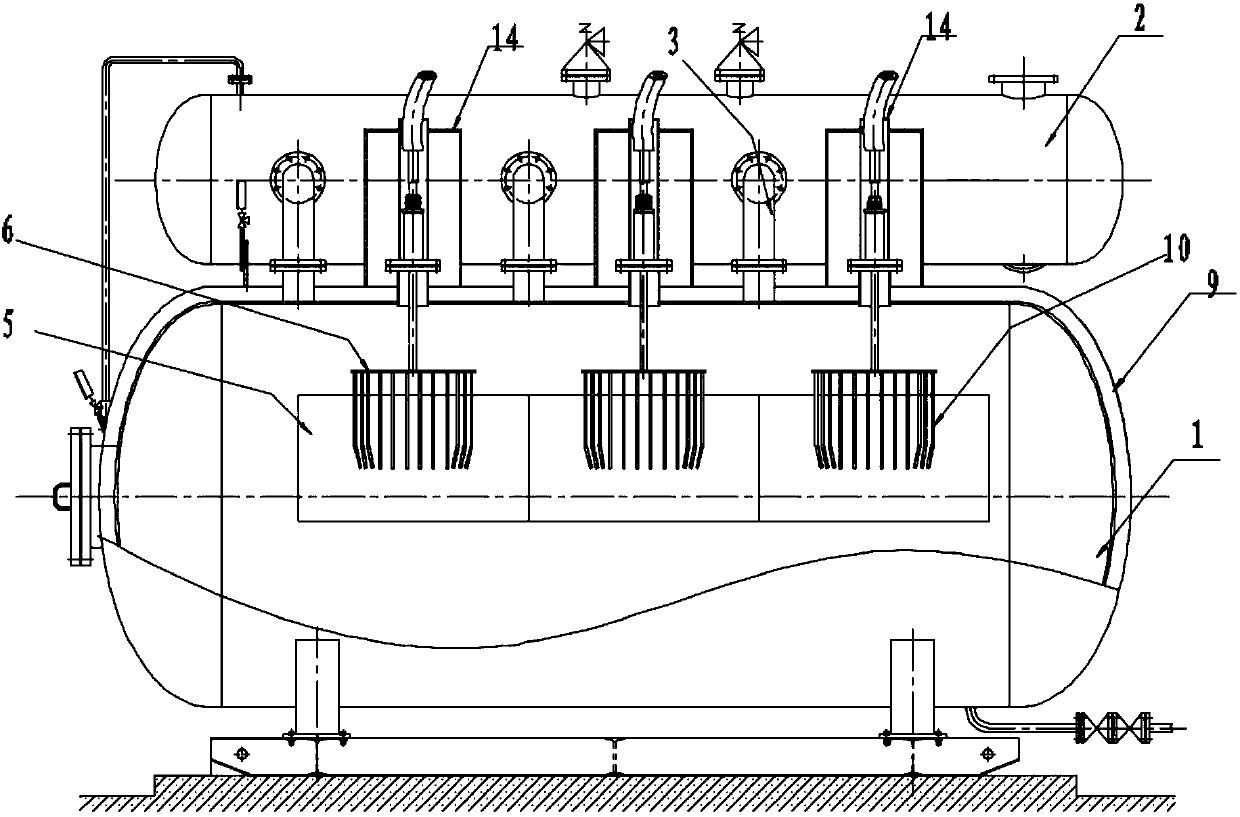

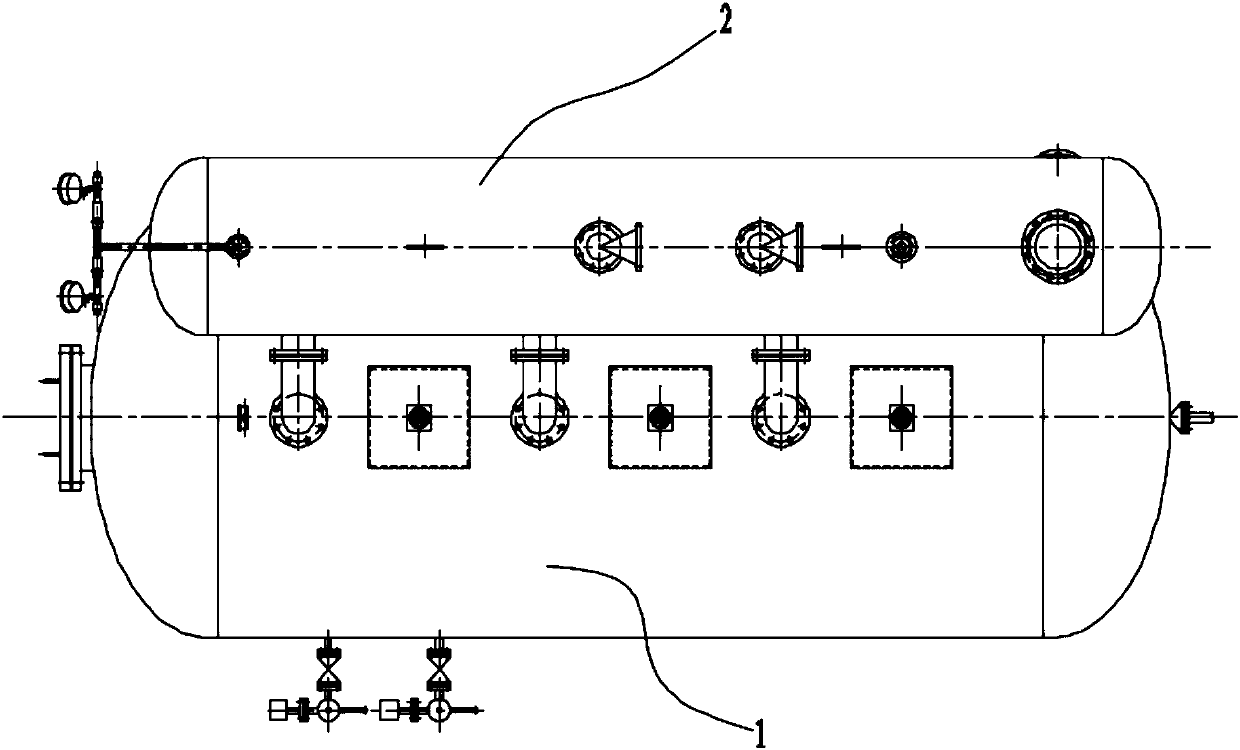

Phase-change-type boiler system

InactiveCN107655210AIncrease layout spaceLower operating heightStorage heatersSmall footprintEngineering

The invention relates to the technical field of boilers, in particular to a phase-change-type boiler system. The phase-change-type boiler system comprises a horizontal boiler cylinder body and a heatexchanger located at the top of the boiler cylinder body. The boiler cylinder body and the heat exchanger are connected through a plurality of steam channels and a water return pipeline. The top of the boiler cylinder body is connected with the heat exchanger through the steam channels. The bottom of the heat exchanger is connected with the boiler cylinder body through the water return pipeline. The phase-change-type boiler system has the advantages that high pressure can be used, the operating height is low, occupied areas are small, an electrode is arranged at the top of the boiler cylinderbody, and the arrangement space is large.

Owner:ZHEJIANG TUFF BOILER

Crude benzol hydrogenation refining process

InactiveCN106348998AReduce lossesHigh retention rateDistillation purification/separationHydrocarbonsThree stageExtractive distillation

The invention disclosed a crude benzol hydrogenation refining process. The crude benzol hydrogenation refining process comprises a raw material predissociation unit, a hydrofining unit, a predistillation unit, an unit of extractive distillation, an aromatic hydrocarbon refining unit and a xylene distillation unit, wherein the hydrofining unit comprises a reaction part and a steady part. The reaction part adopts a three stage hydrogenation. The first stage hydrogenation is the pre hydrofining reaction, while the second stage and the third stage hydrogenation are the main hydrofining reactions. The extractive unit distillation comprises an extractive distillation tower, a stripping tower and a liquid-liquid separation tank. When benzene is produced through the crude benzol hydrogenation refining process, the aromatic compound has the advantages of small loss, high retention rate of arene and high quality products.

Owner:SICHUAN DAXING ENERGY

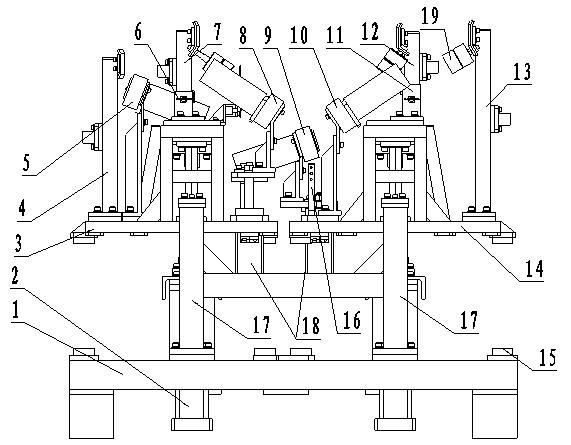

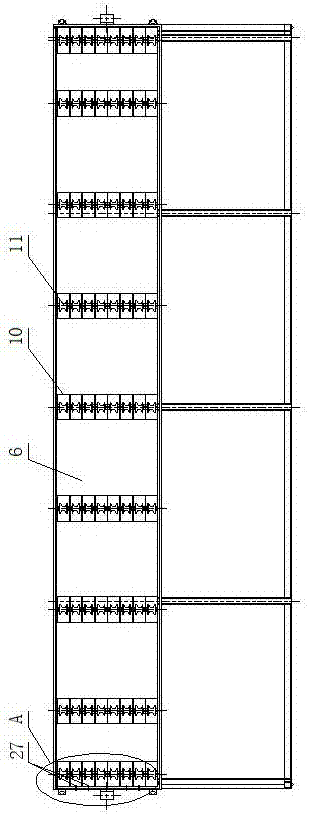

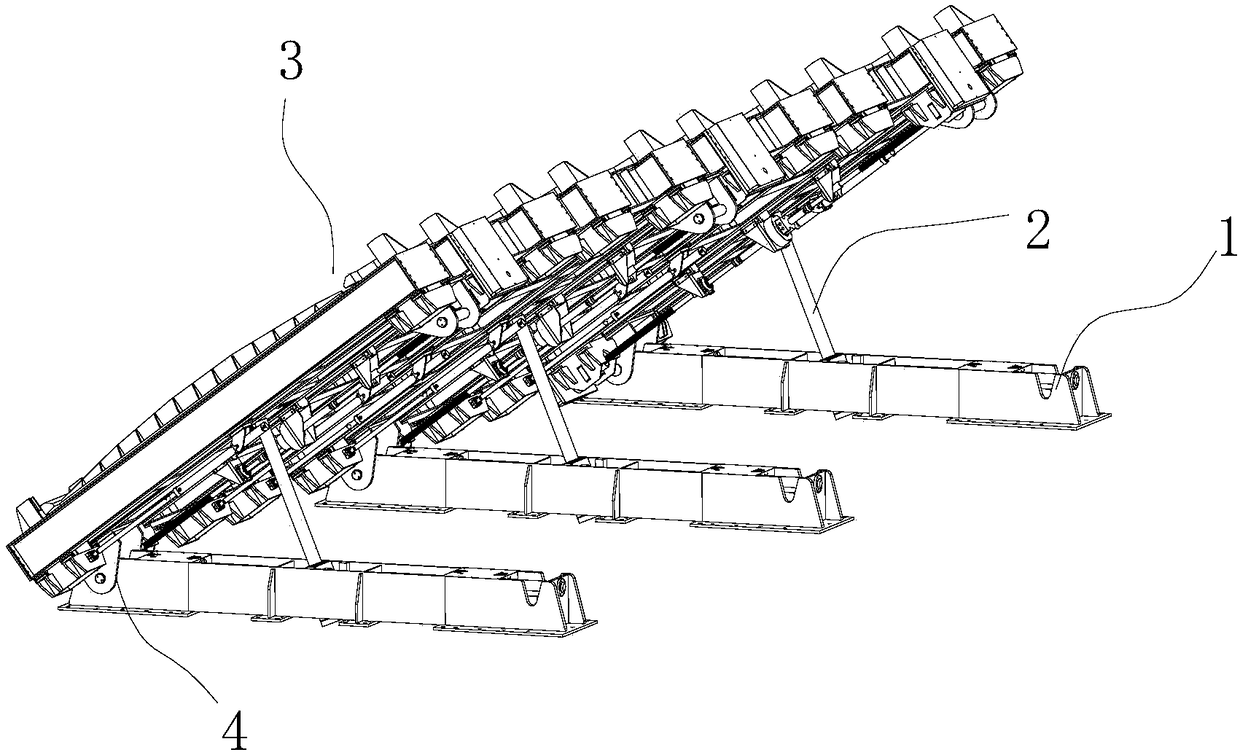

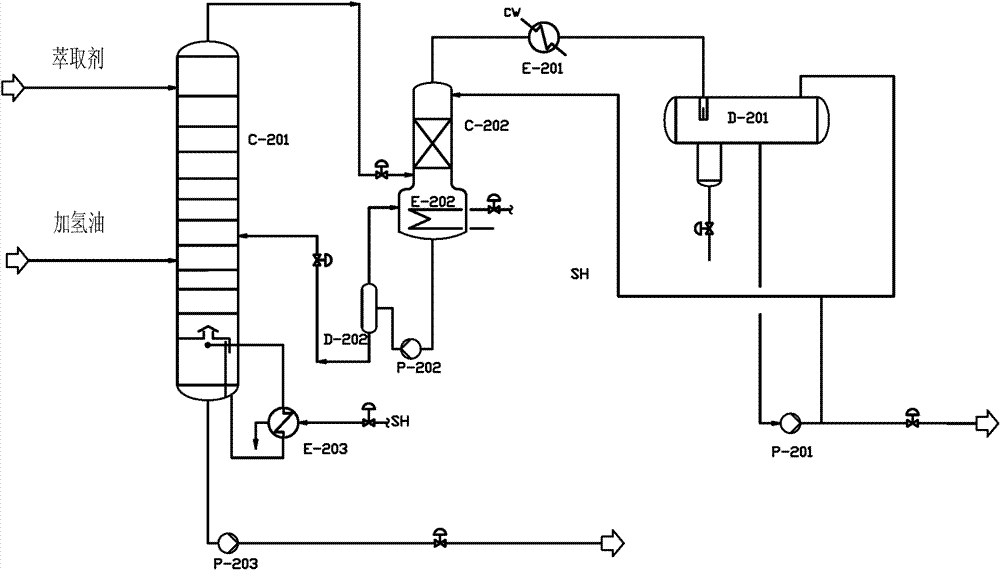

A bridge u-rib anti-deformation welding displacement table

ActiveCN106514118BReduce structural complexityDodge by forceWelding/cutting auxillary devicesAuxillary welding devicesRolloverAcute angle

The invention provides a bridge U-shaped rib plate reverse deformation welding positioning table which comprises supports, lifting devices and a supporting rack. The lifting devices are separately arranged in the middles of the supports and connected with the middle of the supporting rack. Pin shaft locking parts are arranged at the positions, corresponding to the supports, of the two ends of the supporting rack. After one end of the supporting rack is locked to the corresponding support, the corresponding lifting device rises to support the supporting rack to enable an acute angle to be formed between the supporting rack and the horizontal direction, and after the lifting device falls, the locking end of the supporting rack is unlocked, the other end of the supporting rack is locked to the corresponding support, and when the corresponding lifting device rises again, an acute angle is formed between the supporting rack and the other end of the support, and left-right rollover is achieved. The bridge U-shaped rib plate reverse deformation welding positioning table has the most important characteristics that the operation heights of workpiece feeding and discharging are effectively decreased, modification of foundation deep-excavation is not needed for a workshop, the capital construction cost is saved, and the mounting flexibility of equipment is improved.

Owner:刘俊宝

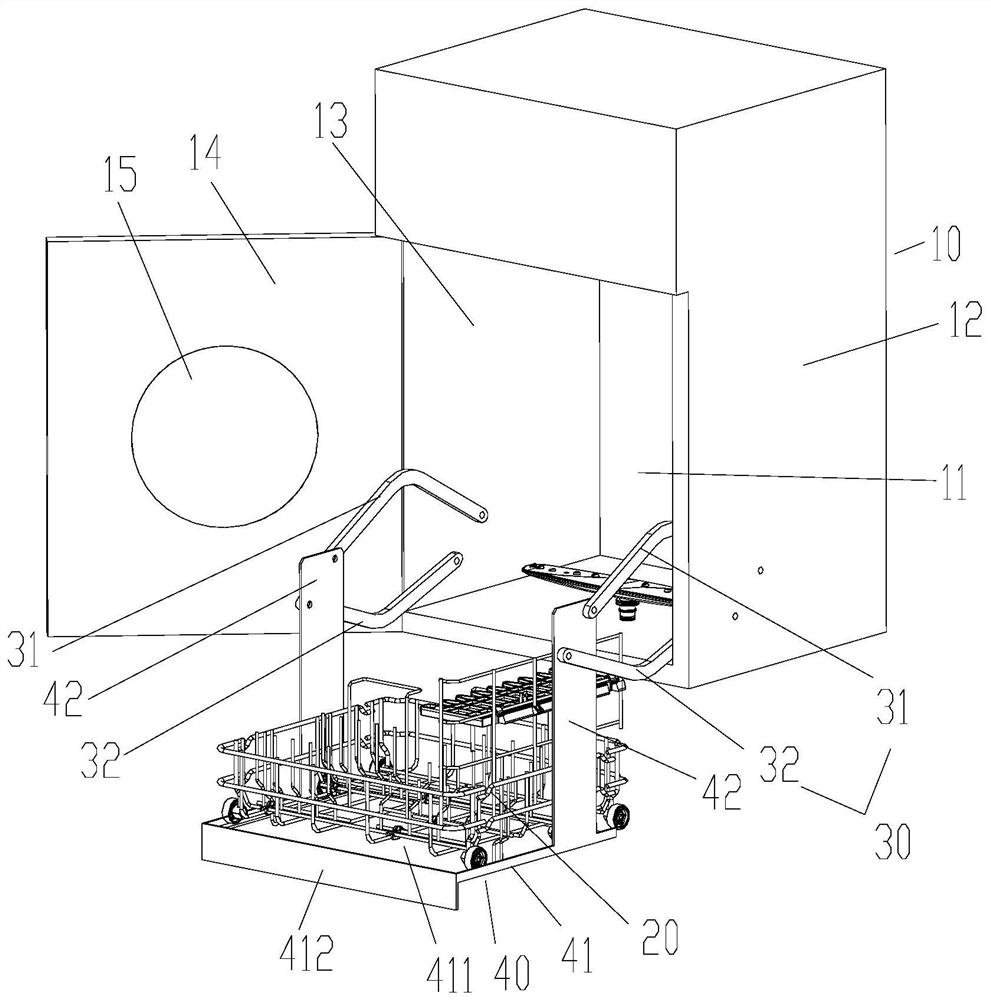

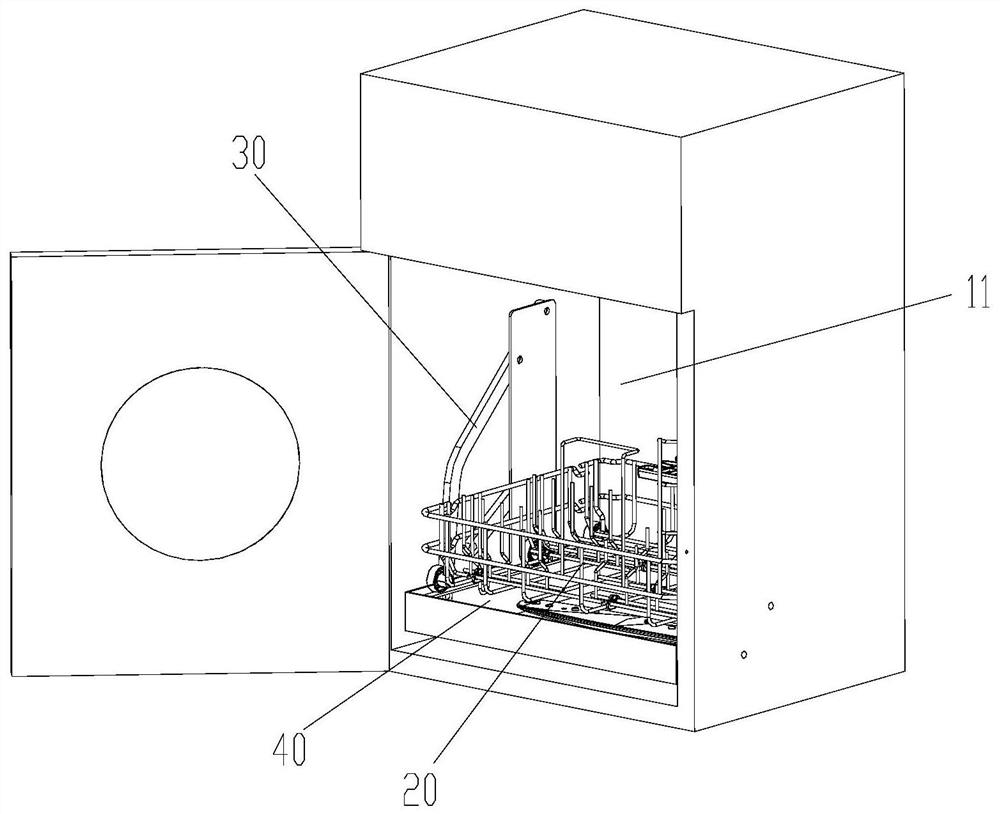

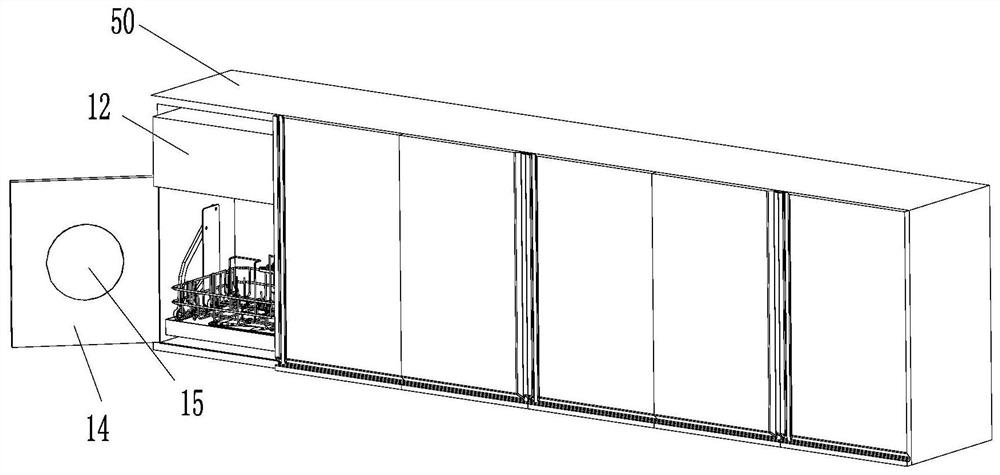

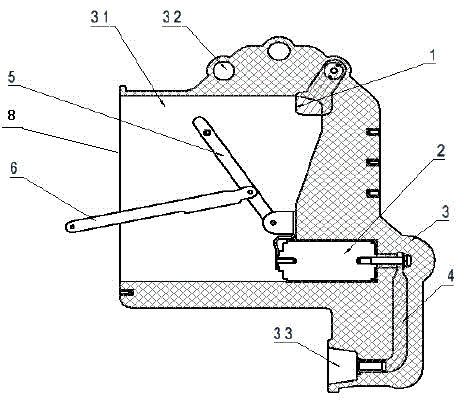

Dish-washing machine and dish-washing machine system with same

PendingCN111956150ASolve the problem of lack of installation spaceLower operating heightTableware washing/rinsing machine detailsMechanical engineeringWashing Dishes

The invention provides a dish-washing machine and a dish-washing machine system with the same. The dish-washing machine is used for being hung on an installation foundation and comprises a dish-washing machine main body, a dish basket and a connecting rod assembly, wherein the dish-washing machine main body is provided with a dish washing cavity; the dish basket is provided with a first position located in the dish washing cavity and a second position located outside the dish washing cavity; when the dish basket is located at the second position, at least part of the dish basket is located below the dish-washing machine main body; one end of the connecting rod assembly is connected with the dish basket, the other end of the connecting rod assembly is connected with the cavity wall of the dish washing cavity, and the connecting rod assembly is rotatably arranged so as to enable the connecting rod assembly to drive the dish basket to move between the first position and the second position. The dish-washing machine solves the problems that the operation is inconvenient and the installation space is lacked due to the fact that the position of a dish-washing machine in the prior art isset to be low.

Owner:GREE ELECTRIC APPLIANCES INC

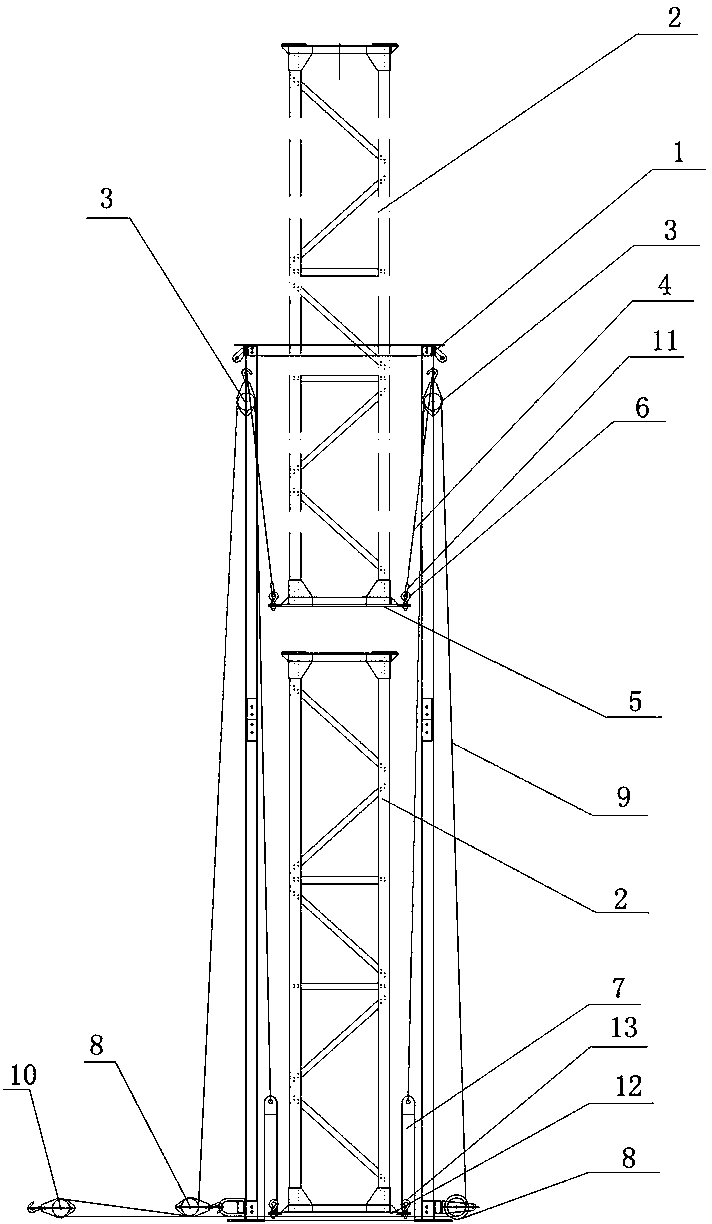

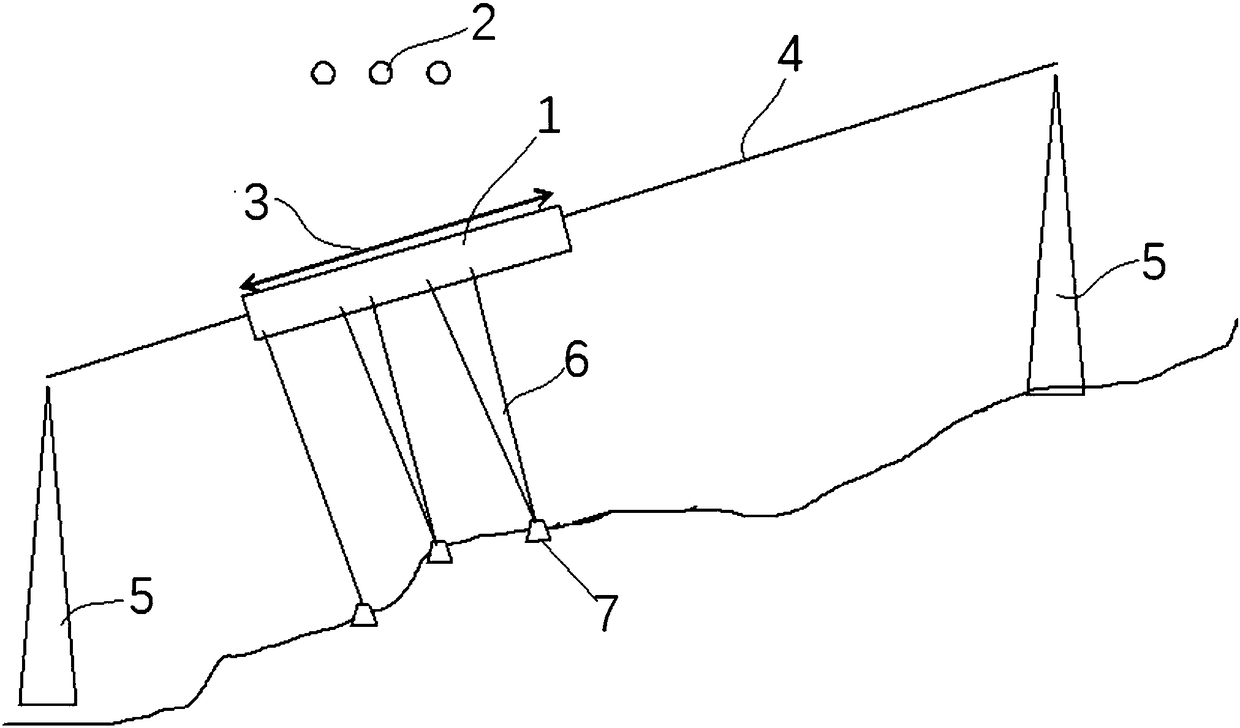

Inverted frame of emergency repair tower

The invention discloses an inverted frame of an emergency repair tower. The inversion frame comprises an inverted frame main body (1), wherein a lifting device is arranged on the inverted main body (1), a lifting end of the lifting device is connected with a hoisting plate (7), a first tray (5) on which tower sections (2) of the emergency repair tower are placed are movably connected onto the hoisting plate (7), two first hanging rings (6) are arranged on the first tray (5), the upper part of the inverted frame main body (1) is fixedly connected with two hanger ropes (4), the free ends of the two hook ropes (4) are connected with two hooks (11) which are hooked with the two first hanging rings (6) on the first tray (5) in a matching manner; and the inverted frame further comprises a second tray (12), and two second hanging rings (13) which are hooked with the two hooks (11) of the two hook ropes (4) in a matching manner are arranged on the second tray (12). The inverted frame of the emergency repair tower has the advantages of small occupied space and high working efficiency when the emergency repair tower is erected.

Owner:NINGBO TIANHONG POWER APPLIANCE +1

Extractive distillation process in hydrofining process of crude benzene

ActiveCN102126914BPrevent falling backQuality improvementDistillation purification/separationBenzeneExtractive distillation

The invention relates to an extractive distillation process in the hydrofining process of crude benzene. The process comprises the following steps: 1) extractant enters from the top of an extractive distillation column, hydrotreated oil enters from the middle of the extractive distillation column; and the tower top product enters a stripping tower in a gaseous phase mode; 2) the tower top product of the extractive distillation column enters the stripping tower to perform distillation purification, the non-arene product in the top of the stripping tower is discharged, the heavy phase product at the bottom of the stripping tower is sent to a liquid-liquid separating tank by a pump; and 3) in the liquid-liquid separating tank, liquid is collected to obtain a heavy phase product and a light phase product, the heavy phase product containing extractant and arene are sent back to the extractive distillation column; and the light phase product, namely non-arene is sent back to the stripping tower. By adopting the process, the heavy non-arene can be effectively prevented from being sent to the extraction section of the extractive distillation column and the quality of product can be increased; and the total height of the extractive distillation column can be reduced, the manual operation is convenient to perform and the problem that the lack of heat caused by the overhigh extractive distillation column can be avoided.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

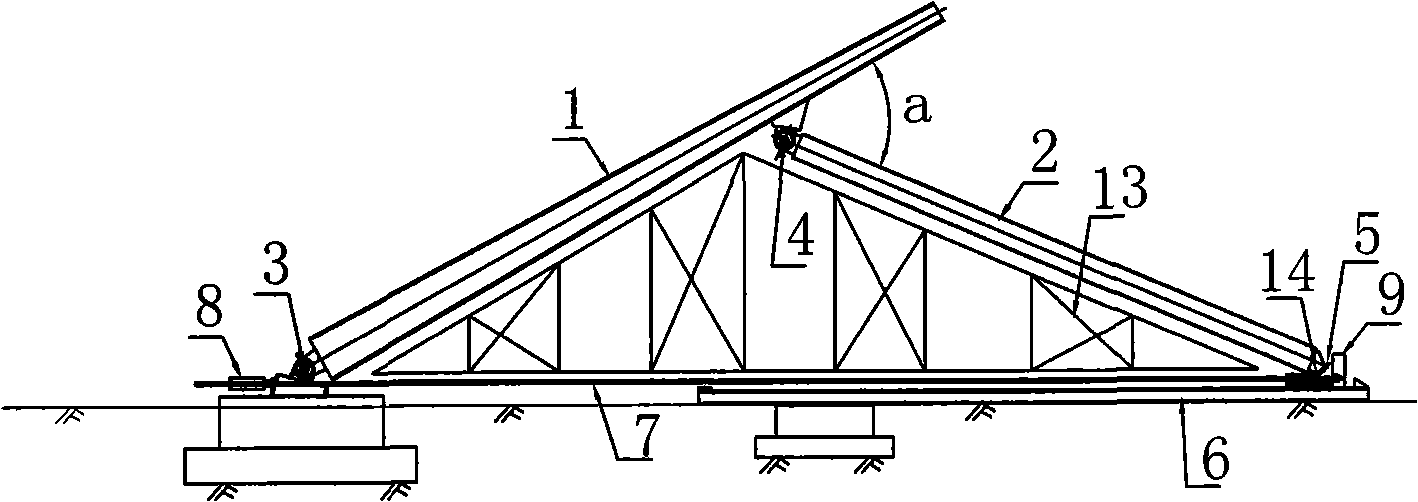

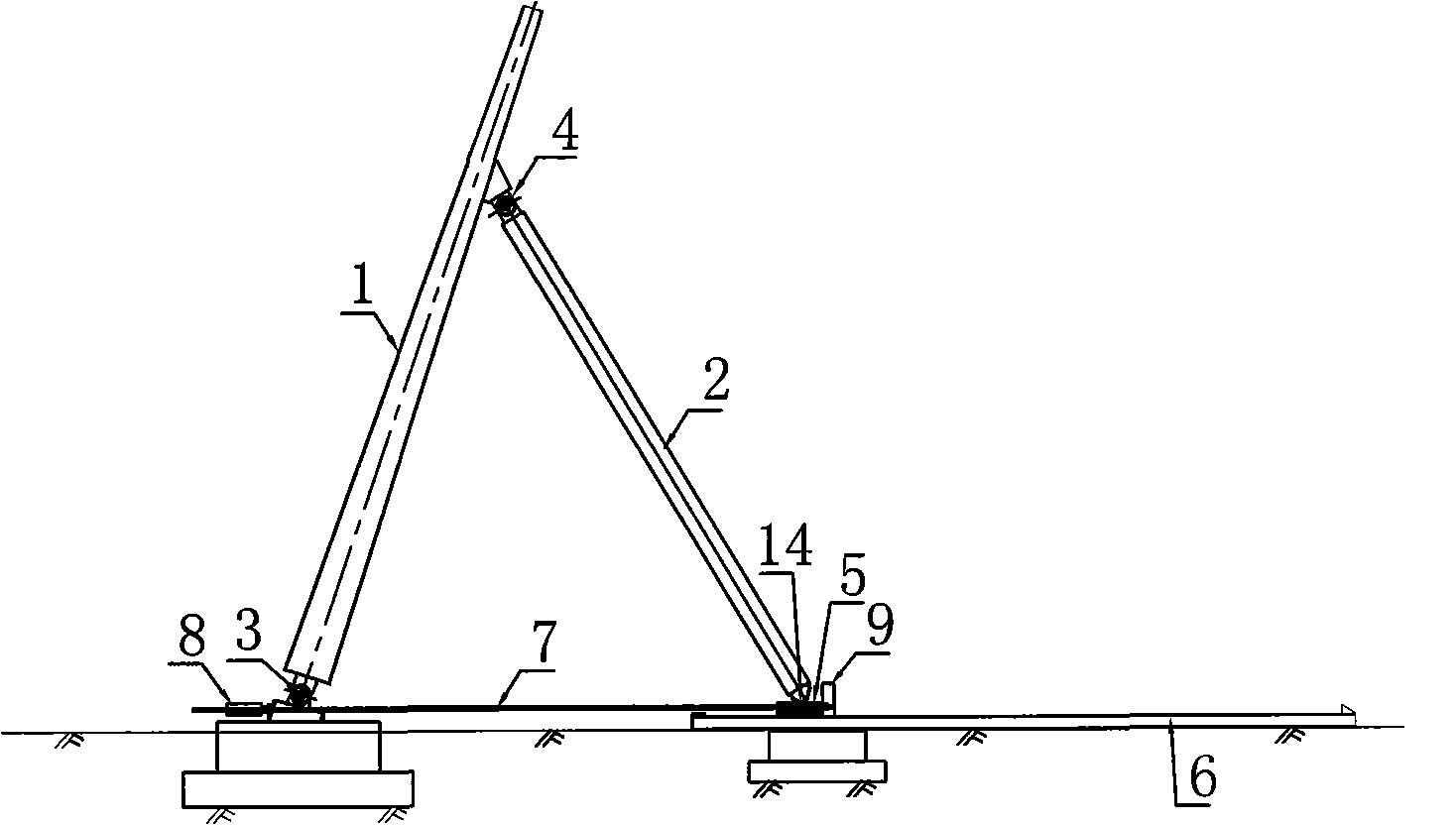

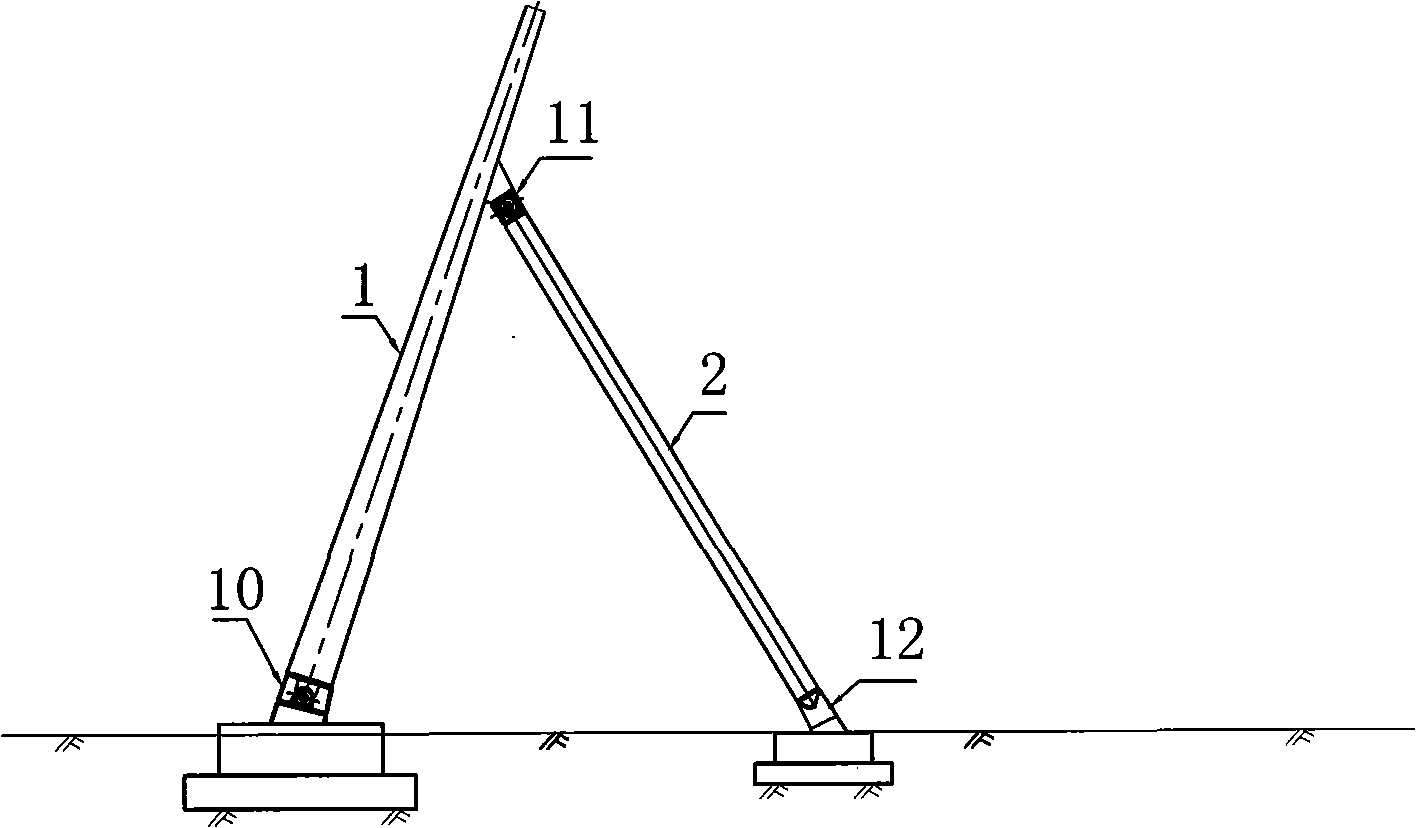

Steel tower self-lifting installation method

ActiveCN101250853BConvenient Tailored WeldingGuarantee the quality of tailor weldingBridge structural detailsBridge erection/assemblyEngineeringTower

The invention discloses a steel tower self elevating installation method, wherein a rotating hinge is arranged on the bottom portion of a steel tower main body, an auxiliary leg is hinged on the steel tower main body, after the steel tower main body and the auxiliary leg are welded on an assembling support on site, a tension system is arranged between a base of the steel tower and the bottom portion of the auxiliary leg, the steel tower is achieved to vertically rotate and lift to a scheduled position through tensioning the tension system, and then a fixed structure on the rotating hinge which is arranged on the bottom portion of the steel tower is arranged. The steel tower self elevating installation method has the advantages that: 1, the rotating hinge is arranged between the steel tower and the auxiliary leg and the steel tower and the base, the auxiliary leg of a herringbone steel tower is capable of directly using an inclined leg of the steel tower, thereby the steel tower and the auxiliary leg are convenient to be welded near the ground by lifting equipment on the ground, and the welding quality is easy to be guaranteed. 2, A prestressing tendon is arranged between the base of steel tower and the bottom portion of the auxiliary leg and supplies power for the vertical rotating of the steel tower through the tension of a jack, the steel tower lifts to the scheduled position by itself, the facilities are simple, the operation height is low, and the operation is convenient.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP

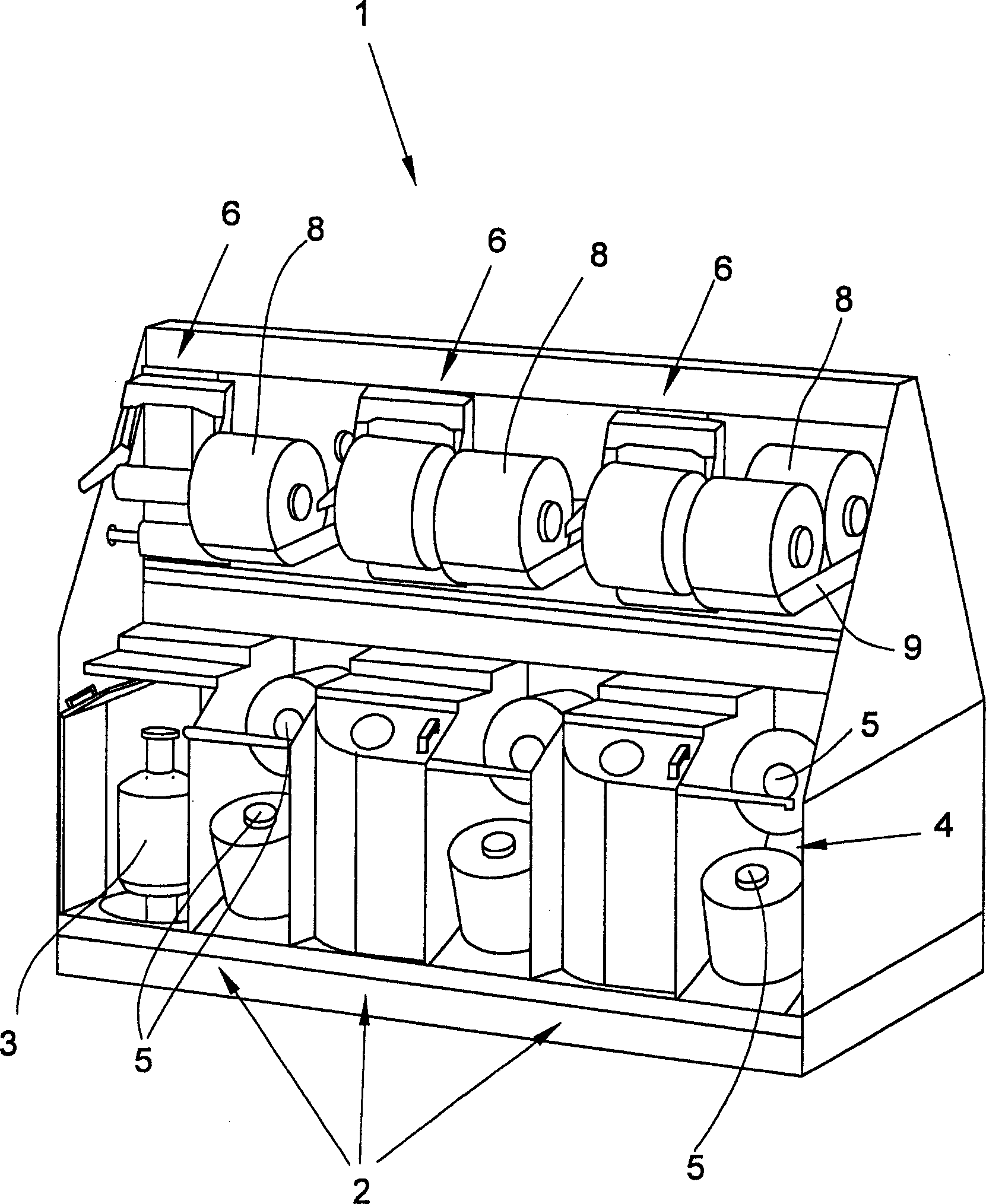

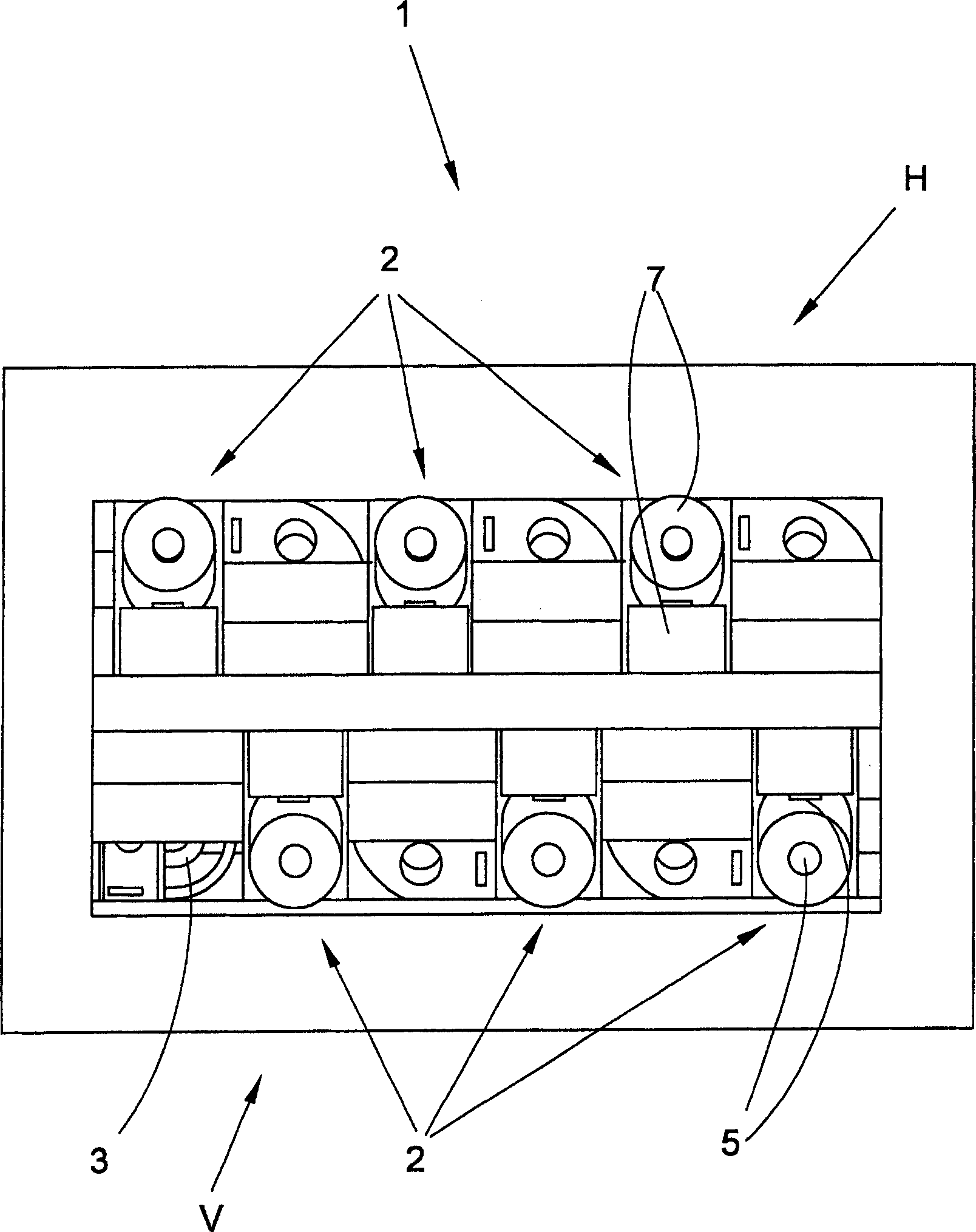

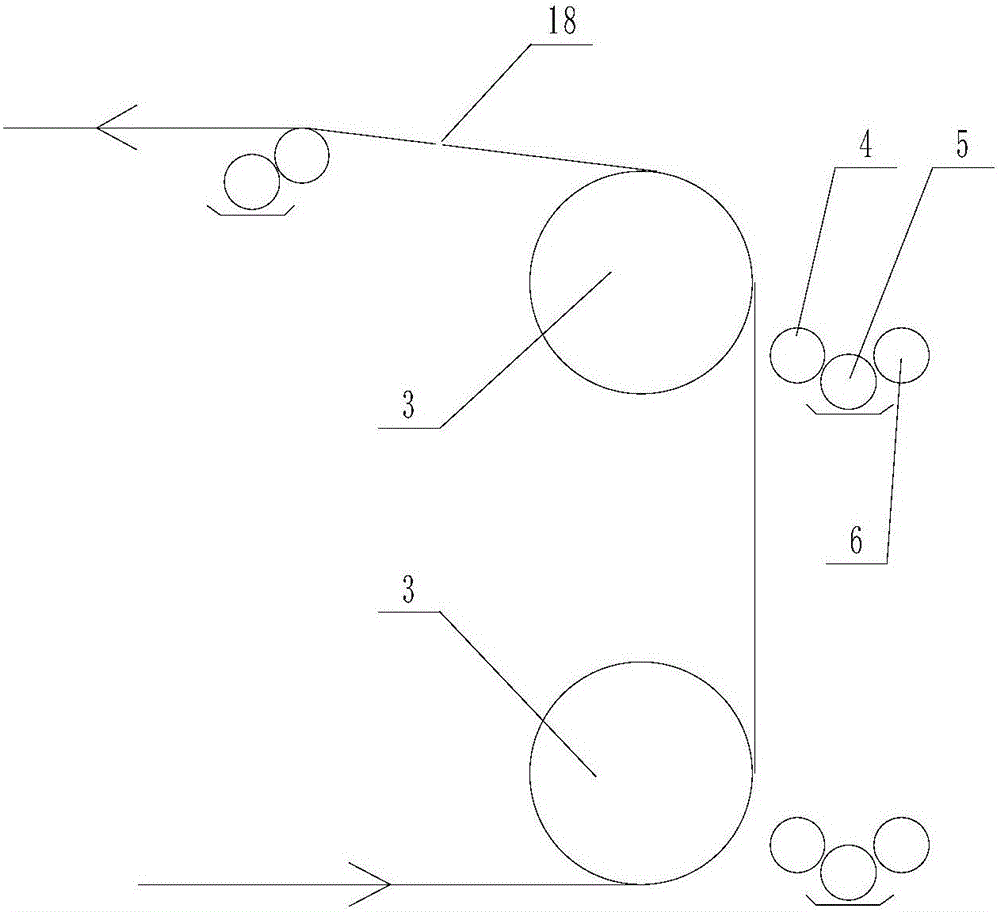

Textile machine for manufacturing bobbins of twisted yarn

InactiveCN1916249ALower operating heightLow maintenanceFilament handlingContinuous wound-up machinesYarnFiber

The invention provides a fiber machine for producing twisted yarn packagetextile. This fiber machine 1 is equipped with many working parts 2 arranged on both sides of the fiber machine in a longitudinal direction of the machine, wherein the working parts 2 each have a spindle 3, a winding unit 6 mounted on the fiber machine above the spindle 3, and a package creel 4, and the spindle 3 and the package creel 4 are arranged in parallel in each of the working parts 2.

Owner:SAURER GMBH & CO KG

Convenient-to-operate common conveying device for vehicle doors and trunk lids

The invention discloses a convenient-to-operate common conveying device for vehicle doors and trunk lids, which is sued for solving the problems that the conveying device is inconvenient to manually operate and that one conveying device corresponds to only one kind of work pieces. The technical scheme is that: the common conveying device comprises an underframe and support frames fixed on the underframe; conveyor belts and material blocking plates are arranged on the support frames; after the conveying device is improved, lifting cylinders are arranged on the underframe; lifting cylinder rodsare fixedly connected with the support frames; the conveyor belts comprise fixed conveyor belts and lifting conveyor belts; conveyor belt lifting cylinders are arranged at the support frames; and conveyor belt lifting cylinder rods are fixedly connected with the lifting conveyor belts. The common conveying device can reduce operation heights for workers to take and put the work pieces, greatly reduce the labor intensity of the workers, realize the applicability of one conveying device to the conveyance of the two kinds of work pieces, namely, the vehicle doors and the trunk lids, simultaneously save the occupation of a production site and reduce the tool cost, is favorable for improving the production efficiency and overcomes the shortcomings of waste of working hours and low production efficiency caused by the frequent replacement of the conveying devices.

Owner:GREAT WALL MOTOR CO LTD

A large size sleeve optical rod assembly equipment

ActiveCN107352787BReduce consumptionAchieve dryingGlass making apparatusLarge sizeAssembly structure

The invention relates to large size sleeve pipe optical rod assembling equipment, and belongs to the technical field of optical rod and optical fiber processing. The equipment is composed of a core rod storage device, a core rod assembling device, and a sleeve pipe assembling device. The front termination of the core rod assembling device is provided with the core rod storage device through a connection piece A. The rear termination of the core rod assembling device is provided with the sleeve pipe assembling device through a connection piece B. The equipment can precisely place a preform core rod in a predetermined position in a sleeve pipe, which has been subjected to tapering, without any wear through an adjusting roller, an elevating mechanism, and a roller finely adjusting device, and completes the manufacturing of large size optical fiber preform. The large size sleeve pipe optical rod assembling equipment has low requirements on the height of used space; due to the functional module assembly structure, the equipment is easy to disassemble and transport, the core rods can be stored and dried intensively, the consumption amount of clean gas is low, the operation height is reduced, and the risk that core rods fall down and break is reduced.

Owner:湖北凯乐量子通信光电科技有限公司

Insulation wrapping sheath and construction method for live spanning line

ActiveCN105932605BSimplify outage ride-through scenariosAdjust spanOverhead installationCable junctionsEngineeringSafety risk

The invention discloses an electrified cross line insulating packaged sheath and a construction method therefor. The sheath comprises a packaged sheath body made from a hard insulating material; a wire slot with a side face opening is formed in the packaged sheath body in the length direction; at least two insulating rolling wheels are arranged in the wire slot; and an operating hole matched with an insulating operating rod and a guiding rope pass-through hole for allowing a guiding rope to pass through are also formed in the packaged sheath body. According to the invention, the shortcomings of the construction technology in the prior art is overcome, and the problems of high difficulty, high cost, and high safety risk of the electrified cross construction are solved; and in addition, the electrified cross line insulating packaged sheath is simple and convenient to operate, low in cost and can be repeatedly used.

Owner:STATE GRID CORP OF CHINA +1

Coating machine for sheet or coil

ActiveCN104190589BAvoid wastingGuaranteed continuityLiquid surface applicatorsCoatingsEngineeringPaint roller

The invention discloses a coating machine for plates or coils, which includes a frame and several conveying rollers fixed on the frame. The coating machine also includes at least two coating mechanisms. The coating roller bracket on the frame, the coating roller bracket is rotated and installed with the coating roller, and the coating roller bracket adjustment mechanism is installed between the frame and the coating roller bracket; the coating roller bracket is slidingly installed with a pick-up roller The pick-up roller bracket, the pick-up roller bracket adjustment mechanism is arranged between the coating roller bracket and the pick-up roller bracket; A gauge roller bracket adjustment mechanism is installed between them, and a paint tray is also installed on the frame, and paint is filled in the paint tray, and the roller surface part of the pick-up roller is immersed in the paint. The coating machine does not need to be stopped for cleaning when changing paints of different colors or varieties, which ensures continuous production, improves production efficiency, and avoids waste of plates or coils.

Owner:张家港市弘扬机械设备有限公司

Super Heavy Duty Double Action Extrusion Machine Main Structure

ActiveCN105880305BSmall diameterReduce processing difficultyExtrusion mandrelsEngineeringUltimate tensile strength

The invention belongs to the field of metallurgical equipment and particularly relates to a new structure of super-heavy extruding equipment. The new structure comprises a rear beam, pull rod pressing sleeves and a front beam which are used for forming an extruding machine prestressed rack, wherein an external perforation system is connected with the rear end of the rear beam and comprises a perforation rear beam provided with a fixed perforation cylinder and perforation pull rod pressing sleeves; two ends of each perforation pull rod pressing sleeve are connected with the extruding machine rear beam and the perforation rear beam respectively; a large main working cylinder is fixed on the extruding machine rear beam, small main working cylinders are symmetrically arranged on the left side and the right side of the large main working cylinder, and four side cylinders are symmetrically arranged on the upper side and the lower side of the large main working cylinder; a main plunger of the large main working cylinder is connected with a moving cross beam; an extruding tool is mounted on the moving cross beam; a pair of main scissors is fixed on the extruding machine front beam; and an extruding barrel is arranged between the extruding machine front beam and the moving cross beam. The main machine structure manner is designed for the structure of an extruding machine with the largest tonnage in the industry, the overall performance of the super-heavy extruding machine can be improved, and the strength and extruding precision of super-heavy backward extruding equipment can be improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

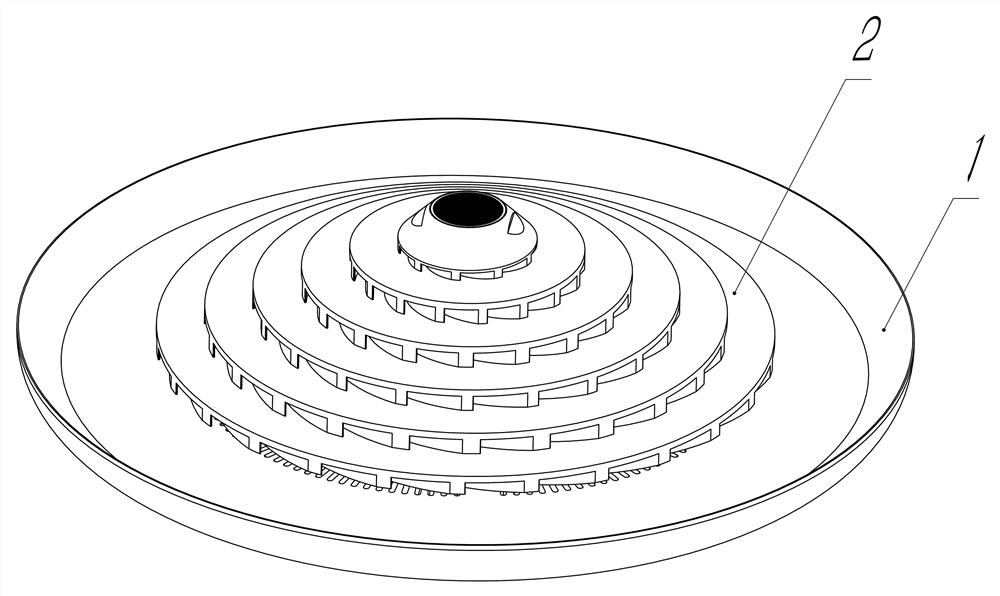

Ventilation chassis with pagoda structure and application of ventilation chassis in fluidized coating machine

InactiveCN114762649ALower operating heightExtend the fluidization pathPharmaceutical product form changeCoatingsEnergy consumptionRolling chassis

The invention relates to a ventilation chassis device with a pagoda structure, and belongs to the field of medicine, chemical engineering, materials and food equipment. Comprising a chassis and a pagoda structure, slotted ventilation holes are formed in an annular area around the center of the chassis, the part from the ventilation holes to the edge of the chassis is a solid part, and the edge of the chassis is of an R-angle design. The pagoda structure is installed above the ventilation holes and composed of a plurality of pagoda rings, a pagoda cap and a connecting rod, the pagoda rings are overlapped to form a pyramid shape, and the top end of the pagoda ring is fixedly connected with the connecting rod fixed to the center of the base plate through the pagoda cap. The ventilation chassis device with the pagoda structure is applied to the fluidization coating machine, so that materials can perform continuous spiral movement along with wind, the fluidization stroke of the materials in a cavity is prolonged, the bed collapse phenomenon and the adhesion phenomenon are avoided, the heat exchange rate of the materials is increased, the drying efficiency is improved, the energy consumption is reduced, and the utilization rate of coating liquid is improved.

Owner:四川海泰医药设备科技有限公司

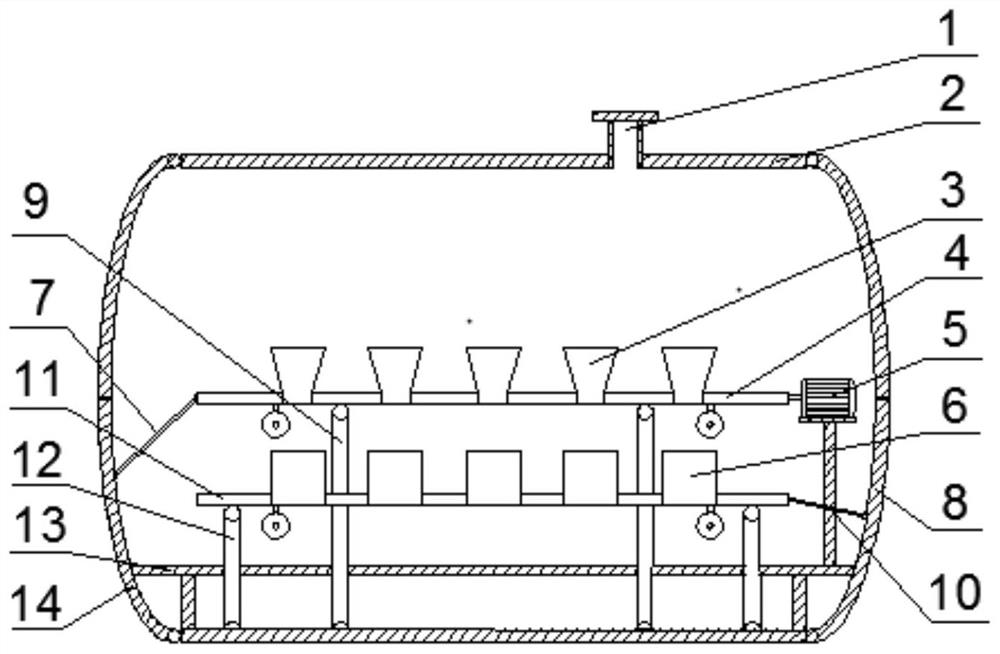

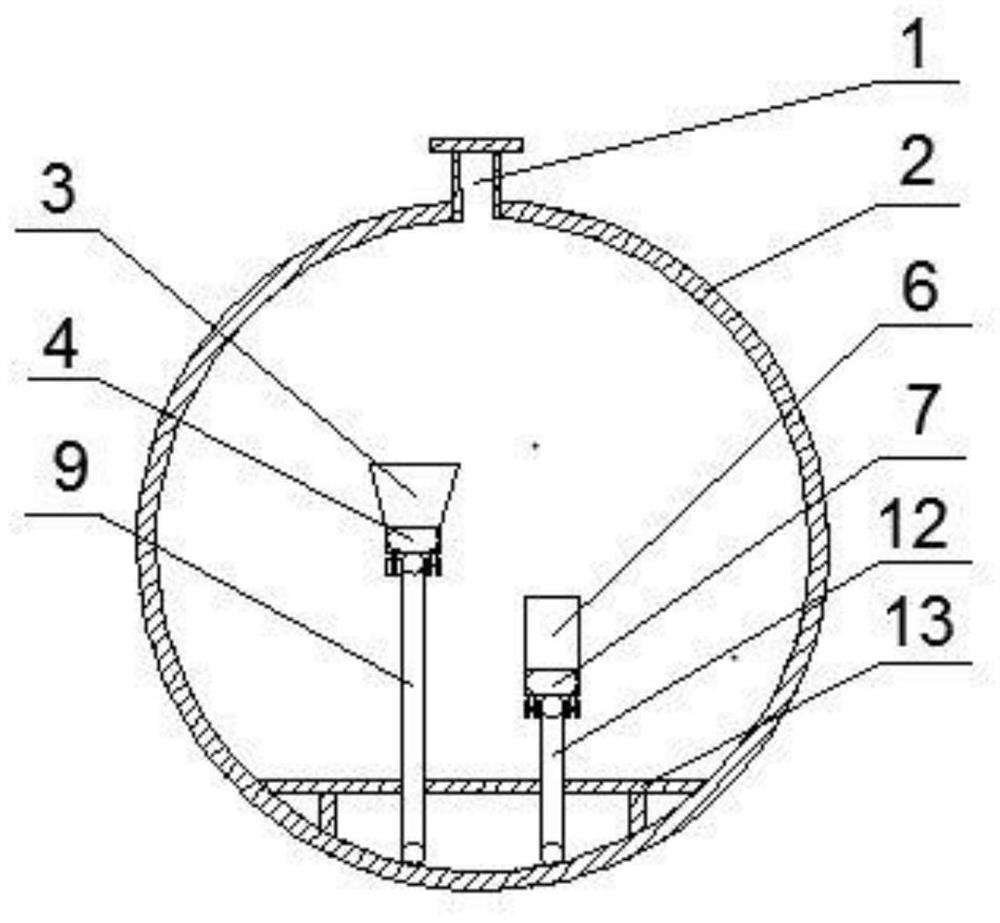

Tank body structure for vacuum pouring

The invention discloses a tank body structure for vacuum pouring, which belongs to the field of epoxy resin vacuum pouring and comprises a shell, a bottom table, a rotating motor, a pouring barrel, a pouring mold, a vent hole and sealing doors. A vent hole is formed in the top of the shell; the vent hole is externally connected with a vacuum pump; sealing doors are arranged at the left end and the right end of the shell respectively; the pouring barrel and the pouring mold are installed on the pouring frame, the pouring frame is connected to the shell through a rocker, the rotating motor controls rotation of the pouring frame, and the bottom table is fixedly welded to the bottom of the inner wall of the shell. The structure can perform multi-group pouring at the same time, and is high in pouring efficiency, simple in structure and easy and convenient to operate.

Owner:萍乡市凯越机电设备有限公司

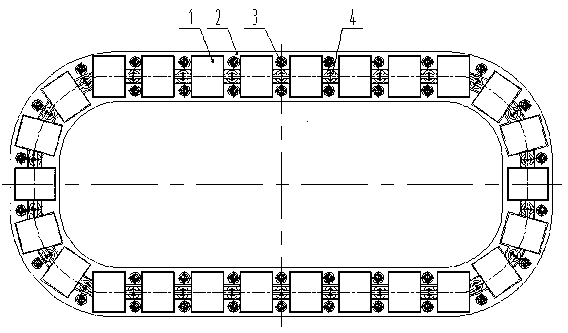

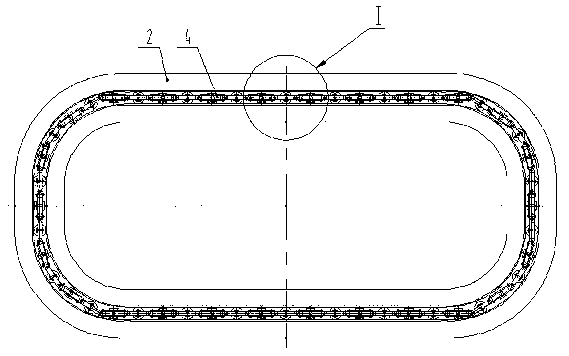

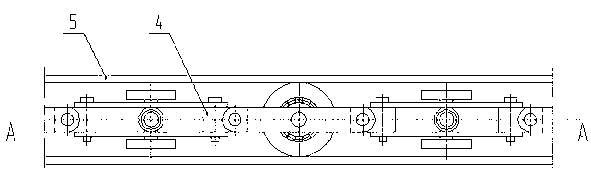

Ground rack type precision casting blank automatic cycle conveyor line

The invention discloses a ground rack type precision casting blank automatic cycle conveyor line which comprises a box body, a trench, ball supporting assemblies, a chain conveyor line and a ring-shaped guide rail. The trench is a closed ring-shaped trench. The chain conveyor line and the ring-shaped guide rail are arranged in the middle of the trench. The chain conveyor line is placed in the ring-shaped guide rail and is driven by a power driving device. The vertically placed ball supporting assemblies are arranged on the two sides of the ring-shaped guide rail of the trench. The box body is placed in the trench. The bottom portion of the box body is placed and supported on the ball supporting assembly. A shaft sleeve is fixedly connected with the middle portion of the bottom of the box body. A drive rod is arranged on the chain conveyor line. The drive rod is inserted into the shaft sleeve and is matched with the shaft sleeve in a spaced mode. In the process of conveying, the chain conveyor line is driven to move in the ring-shaped guide rail through the power driving device. The drive rod arranged on the chain conveyor line drives the box body to move through the shaft sleeve to achieve conveying of the box body. The ground rack type precision casting blank automatic cycle conveyor line has the advantages that occupied site of production line is small, the height of operation is low and automatic turnover circulating conveying can be achieved.

Owner:TAIZHOU XINYU PRECISION MFG CO LTD

Solid insulation ring main unit main insulation module

InactiveCN104466698ALower operating heightMeet the requirements of compactnessBus-bar/wiring layoutsSwitchgear arrangementsElectrical conductorEngineering

The invention provides a solid insulation ring main unit main insulation module which comprises an epoxy body, an isolation knife, an isolation knife fixed contact, a vacuum arc extinguish chamber and a conductor. The vacuum arc extinguish chamber is horizontally cast in the epoxy body and is fixedly connected with the conductor through a bolt. A cable joint connecting hole is formed in the epoxy body and connected with the conductor. The epoxy body is provided with a plurality of bus connecting holes and an isolation knife movement cavity. The end of the isolation knife fixed contact is cast into the epoxy body. The other end of the isolation knife fixed contact extends into the isolation knife movement cavity. The isolation knife is arranged in the isolation knife movement cavity. According to the solid insulation ring main unit main insulation module, the operating difficulty of a solid insulation ring main unit is lowered, the bus boundary dimension is reduced, the bus connecting way is simplified, and the requirement for compactness of the solid insulation ring main unit is better met.

Owner:中国能建集团装备有限公司南京技术中心

Battery swap mobile device and quick swap system

ActiveCN106515681BLower operating heightReduce replacement spaceCharging stationsVehicular energy storageElectrical batteryMobile device

The invention discloses a battery replacement method for replacing a battery of an electric automobile in a quick replacement system. According to the battery replacement method, a quick replacement system is used for achieving battery replacement of the automobile, the quick replacement system comprises a battery replacement moving device, and the battery replacement moving device comprises a horizontal moving part used for driving the whole battery replacement equipment to move horizontally and comprises a moving frame used for moving and providing a mounting base and a horizontal driving device used for driving the moving frame to move; a vertical lifting part which is mounted on the horizontal moving part and used for driving the battery replacement platform to ascend and descend in the vertical direction; and a battery mounting part which is mounted on the vertical lifting part, is used for replacing and dismounting a battery, and comprises a battery replacement platform and a battery unlocking device mounted on the battery replacement platform. By means of the vertical lifting part, the operation height can be reduced to the maximum extent; therefore, the required replacementspace is reduced, the movement stability and accurate positioning can be improved through the horizontal moving part, a battery at the bottom of the electric automobile can be automatically disassembled and replaced through the battery mounting part, and the disassembly and transportation of the battery of the electric automobile and the battery replacement are automatically realized in the wholescheme.

Owner:SHANGHAI DIANBA NEW ENERGY RESOURCES SCI & TECH

An auxiliary rack for putting on and taking off a pullover

ActiveCN112056903BResolve the difficulty of movementLower operating heightApparel holdersElectric machineryEngineering

The present invention is an auxiliary frame for putting on and taking off a pullover, which comprises a symmetrically arranged first auxiliary frame and a second auxiliary frame. The first auxiliary frame includes a fixed bracket. There is an arc-shaped front pull guide rail on the seat, and a manipulator is installed sliding on the front pull guide rail, and a transmission chain for driving the manipulator to slide is also provided on the front pull guide rail. The rotating arm on the seat, the finger clamp mechanism fixed on the rotating arm and the rotating arm motor fixed on the sliding seat, the rotating arm motor is used to drive the rotating arm to rotate, and the finger clamp mechanism includes a pressing bracket and a clothes folding bracket set oppositely , the pressing bracket is rotated with a pressing plate, the pressing plate is rotated with a roller one, and the clothes-folding bracket is rotated with a roller two that cooperates with the roller one to compress the pullover. Clothes machine, the structure of the second auxiliary frame is the same as that of the first auxiliary frame.

Owner:CHANGZHOU INST OF TECH

Lifting frame device and circular cooler with same

ActiveCN102353269BEnough maintenance spaceStable structureFurnace typesHandling discharged materialRelative displacementEngineering

A hanger device (50) and an annular cooler having same, the hanger device (50) comprising a hanger fastener (51) and four connecting pieces (52, 53, 54, 55) disposed in sequence from top to bottom; the upper end of the first connecting piece (52) is hinge-connected to the hanger fastener (51); between the opposing ends of the second connecting piece (53) and the first connecting piece (52) is a first threaded fit; the opposing ends of the third connecting piece (54) and of the second connecting piece (53) are nested together, and between the two opposing ends is allowed a vertical relative displacement with mating lower-stop limiting units (E); between the opposing ends of the fourth connecting piece (55) and the third connecting piece (54) is a second threaded fit, the lower end of the fourth connecting piece (55) being used to hinge-connect to a gate-type sealing device (60); and the sum of the vertical unscrewed lengths of the first threaded fit and the second threaded fit is greater than or equal to a vertical preset distance (L); the minimum vertical relative displacement between the third connecting piece (54) and the second connecting piece (53) enables both the first connecting piece (52) and the fourth connecting piece (55) to rotate around respective hinge points. The hanger device (50) has improved operability for installation and adjustment.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com