Convenient-to-operate common conveying device for vehicle doors and trunk lids

A trunk lid and easy-to-operate technology, which is applied in the field of automobile manufacturing, can solve the problems of occupying a large production site, increasing labor intensity of workers, and increasing the cost of tooling for enterprises, so as to overcome low production efficiency, reduce labor intensity, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

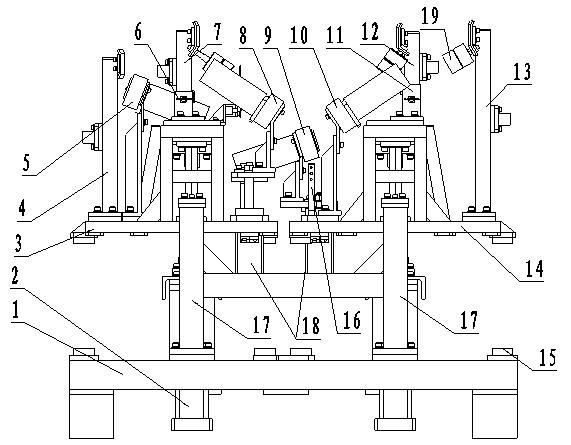

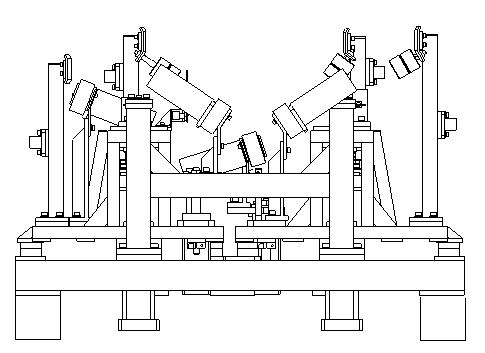

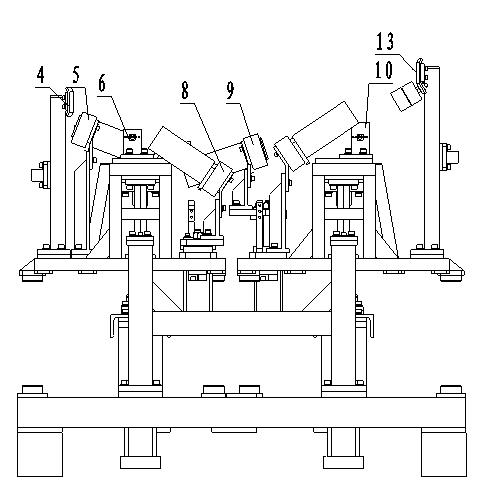

[0016] see figure 1 , figure 2 , the present invention comprises an underframe 1, two lifting cylinders 2 are placed symmetrically at the underframe, a left support frame 3 and a right support frame 14 are arranged symmetrically on the upper part of the underframe, and conveyor belts and stoppers are arranged on the left and right support frames. sheet. The present invention adopts two support frames and two lifting cylinders to realize the lifting action of the conveying device. The reason is that if one support frame and one cylinder are used to lift, the entire upper support frame structure will cause instability when lifting and descending; if If one support frame is used and two cylinders are lifted, there will be asynchronous problems, which will cause uneven stress on the overall structure of the device and cause excessive wear on the cylinders. In the present invention, the support frame is designed as a left and right split structure, and each support frame is lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com