Patents

Literature

42results about How to "Avoid wasted man-hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

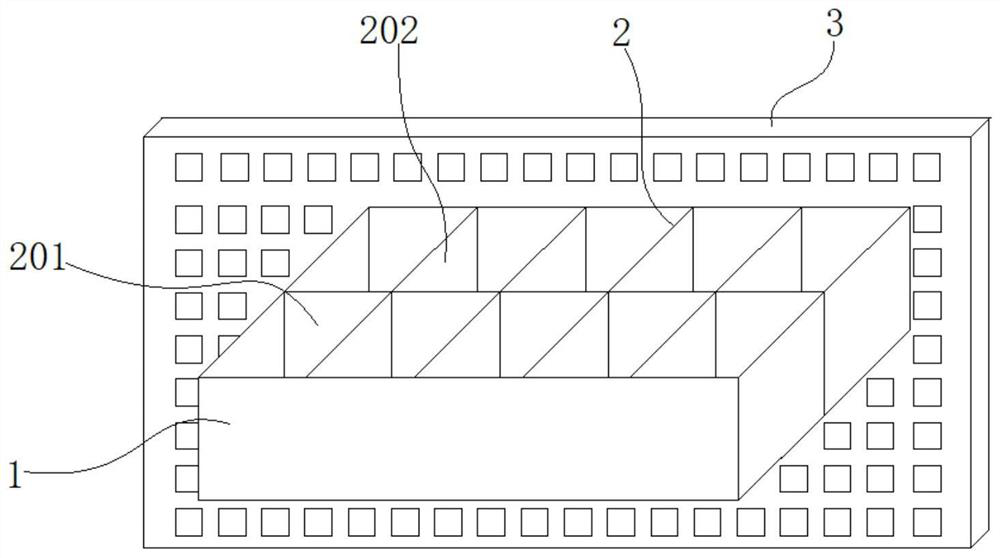

Method for directly carrying out innocent treatment on electrolytic manganese residues in filter pressing plate frames

InactiveCN104690080ALow installation costReduce labor costSolid waste disposalMagnesiumPolyacrylamide

Provided is a method for directly carrying out innocent treatment on electrolytic manganese residues in filter pressing plate frames. The electrolytic manganese residues treated through the method are filter cakes obtained after filter pressing in the filter pressing plate frames of a plate-and-frame filter press, and sodium dihydrogen phosphate, calcium oxide, magnesium oxide and polyacrylamide are included in a treating agent. The method comprises the steps that 1, the electrolytic manganese residue filter cakes in all the filter pressing plate frames are washed through solutions obtained by mixing the sodium dihydrogen phosphate and water; 2, after the magnesium oxide, the calcium oxide and the polyacrylamide are dissolved in filter liquor collected in the step 1, the electrolytic manganese residue filter cakes are washed again; 3, filter liquor generated in the step 2 is collected, the plate-and-frame filter press is loosened to unload the filter cakes, and the electrolytic manganese residues generated after the innocent treatment are obtained. According to the method, soluble manganese in the electrolytic manganese residues is fixed, meanwhile, soluble ammonia nitrogen in the electrolytic manganese residues is fixed, and compared with the prior art, the advantages in the prior art are kept, the defects in the prior art are overcome, and the total cost of innocent treatment on the electrolytic manganese residues is lowered.

Owner:CHONGQING UNIV

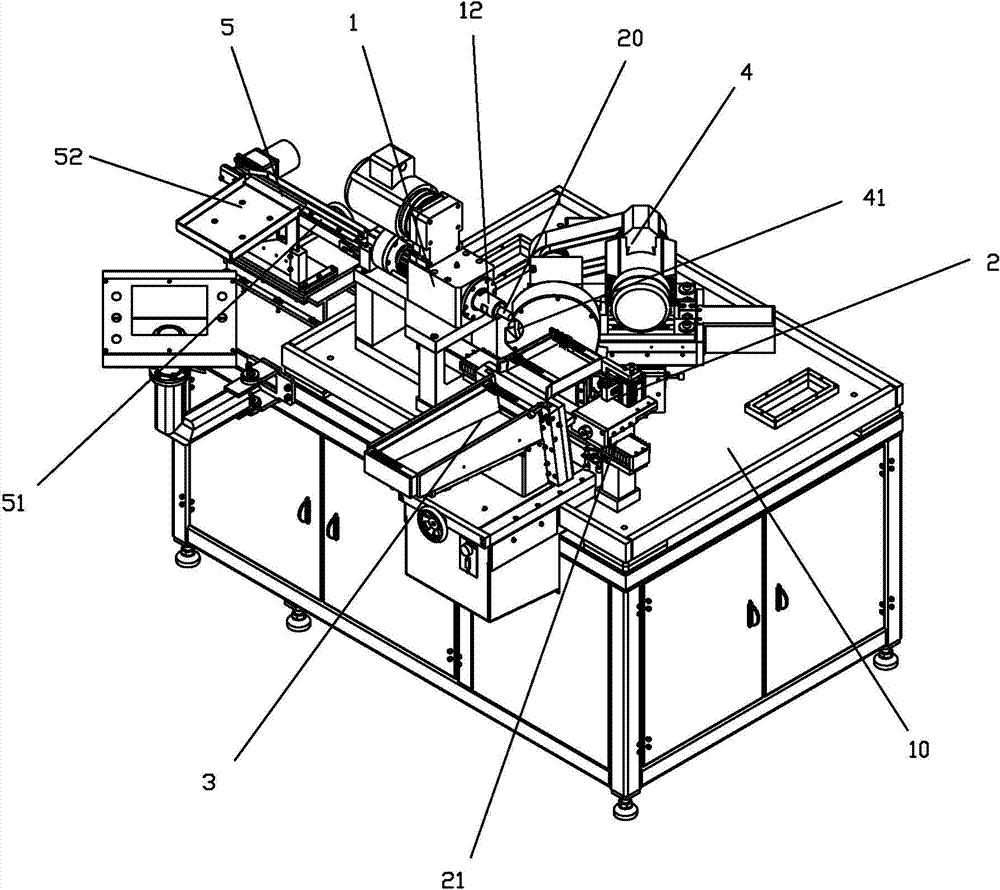

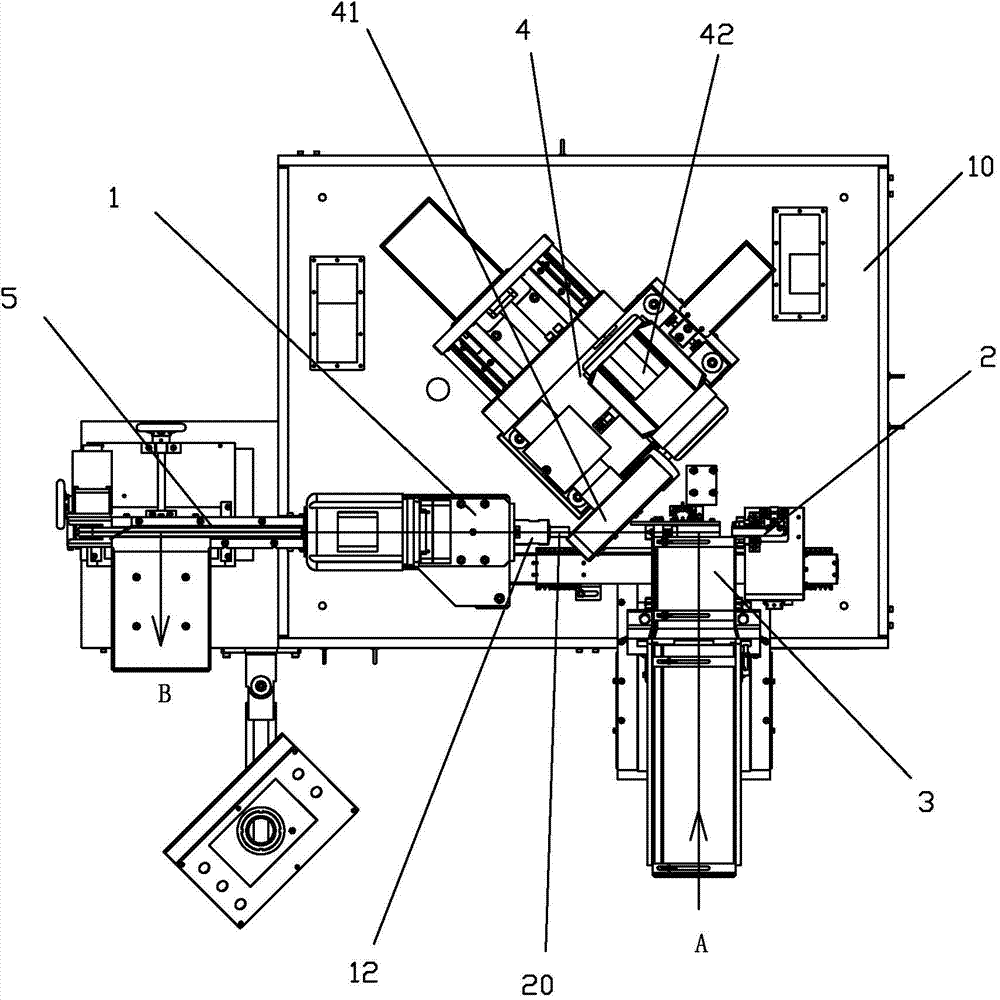

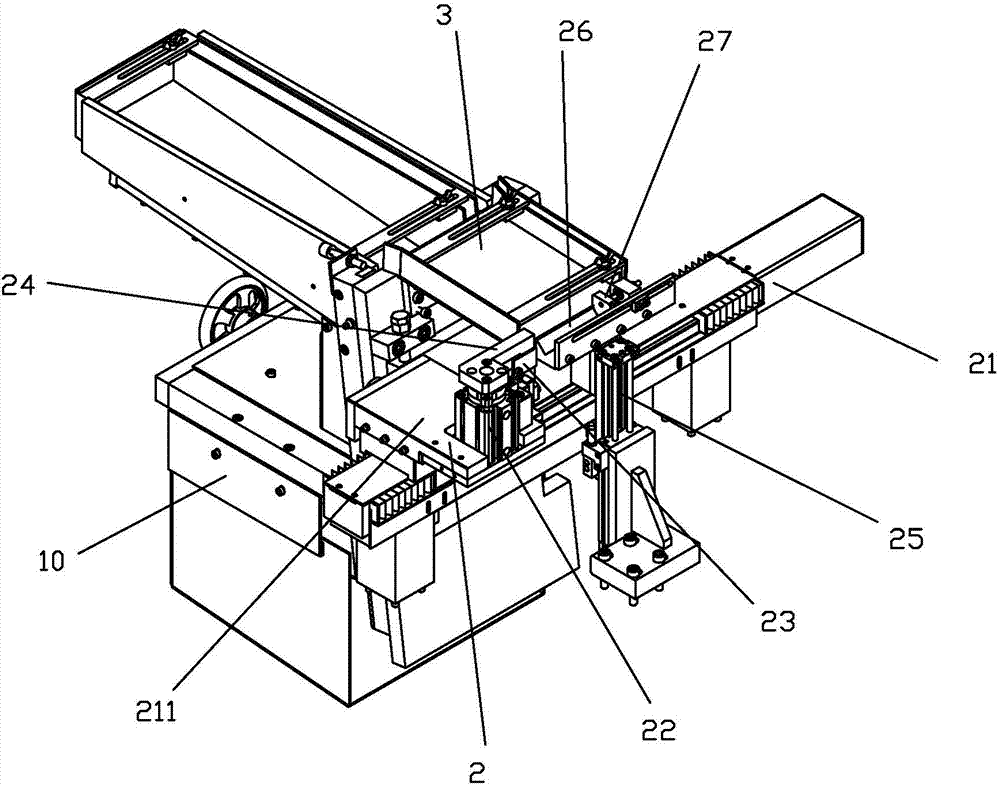

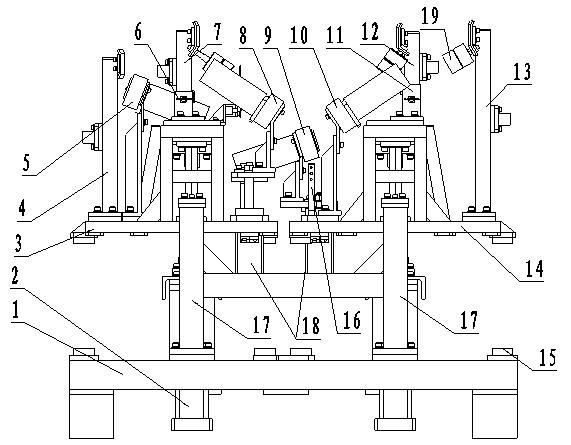

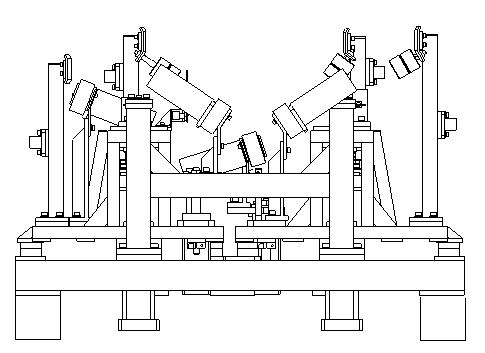

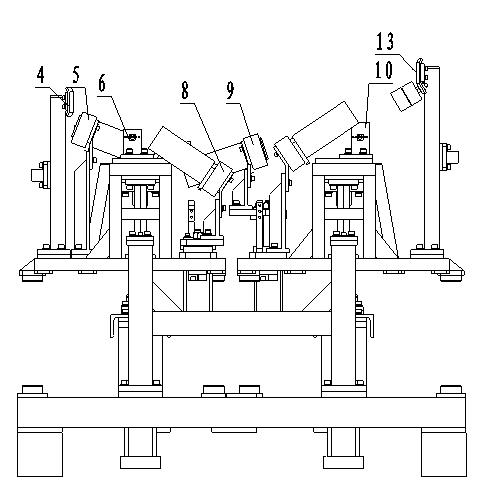

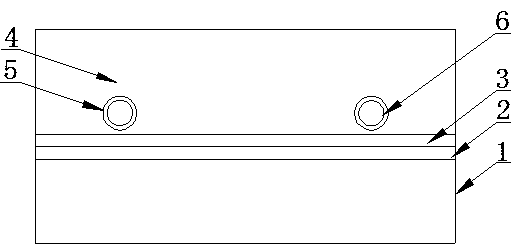

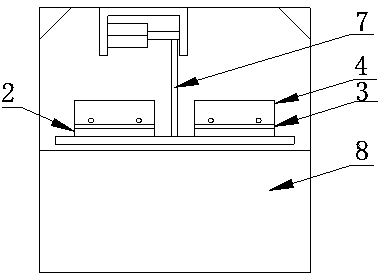

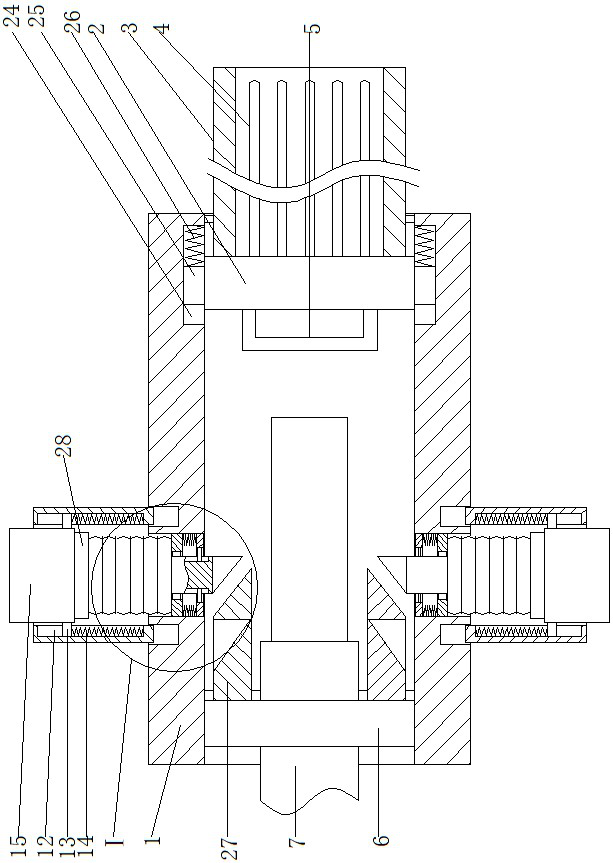

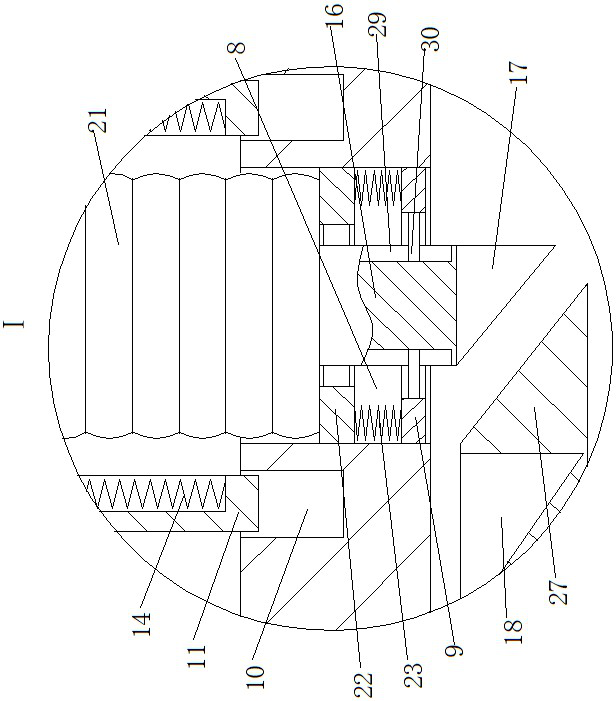

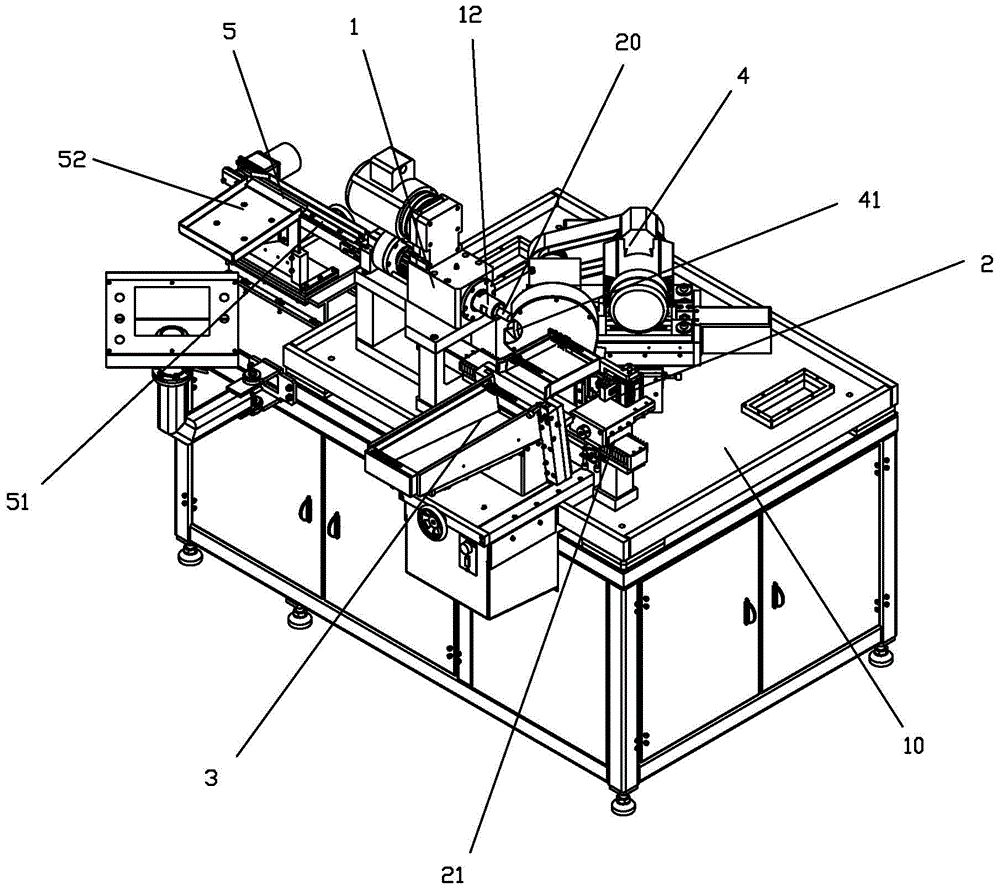

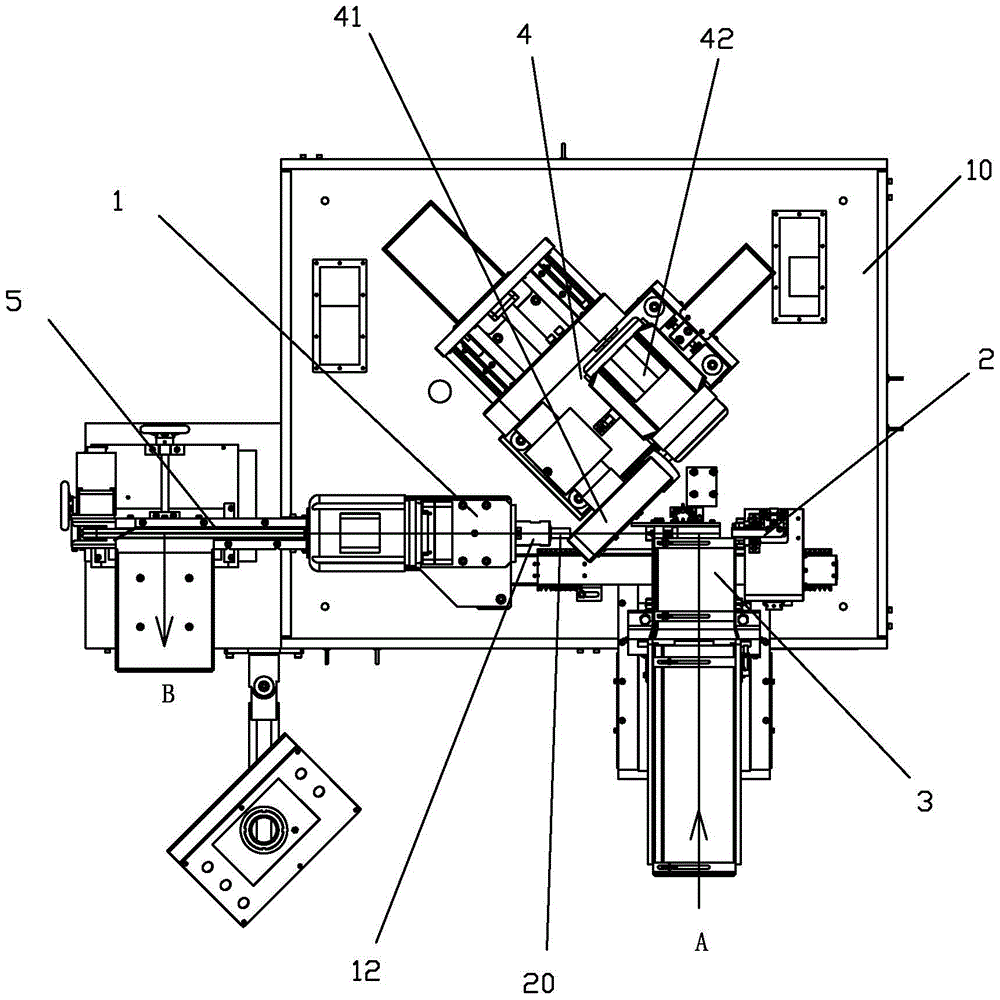

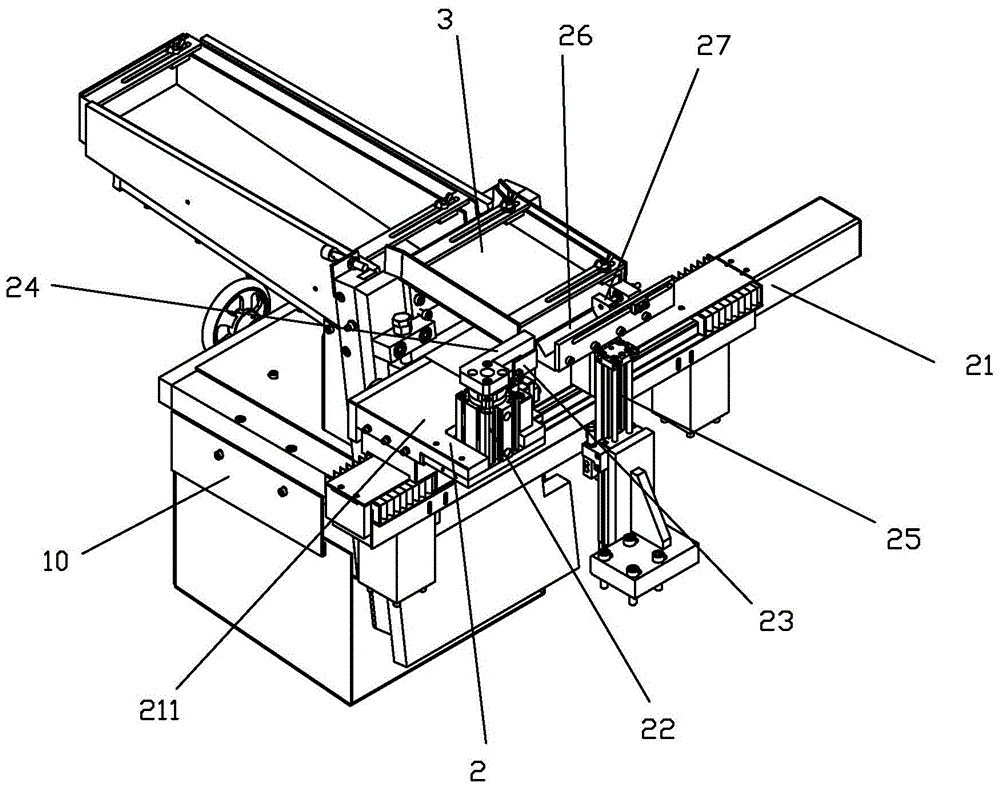

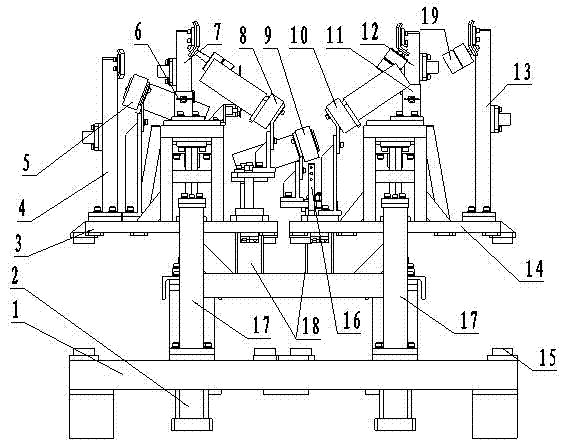

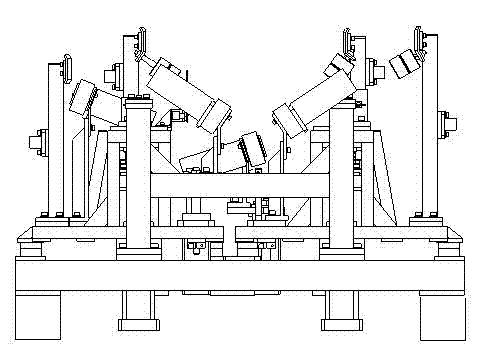

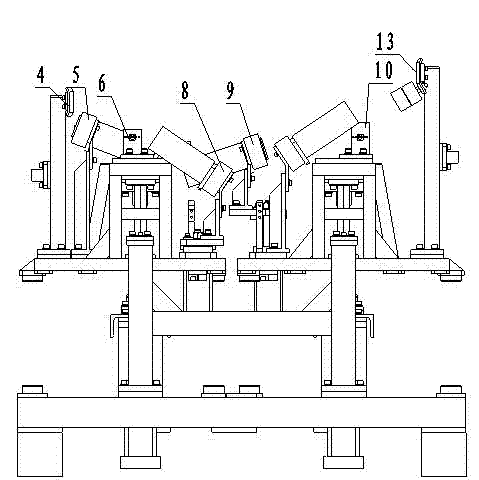

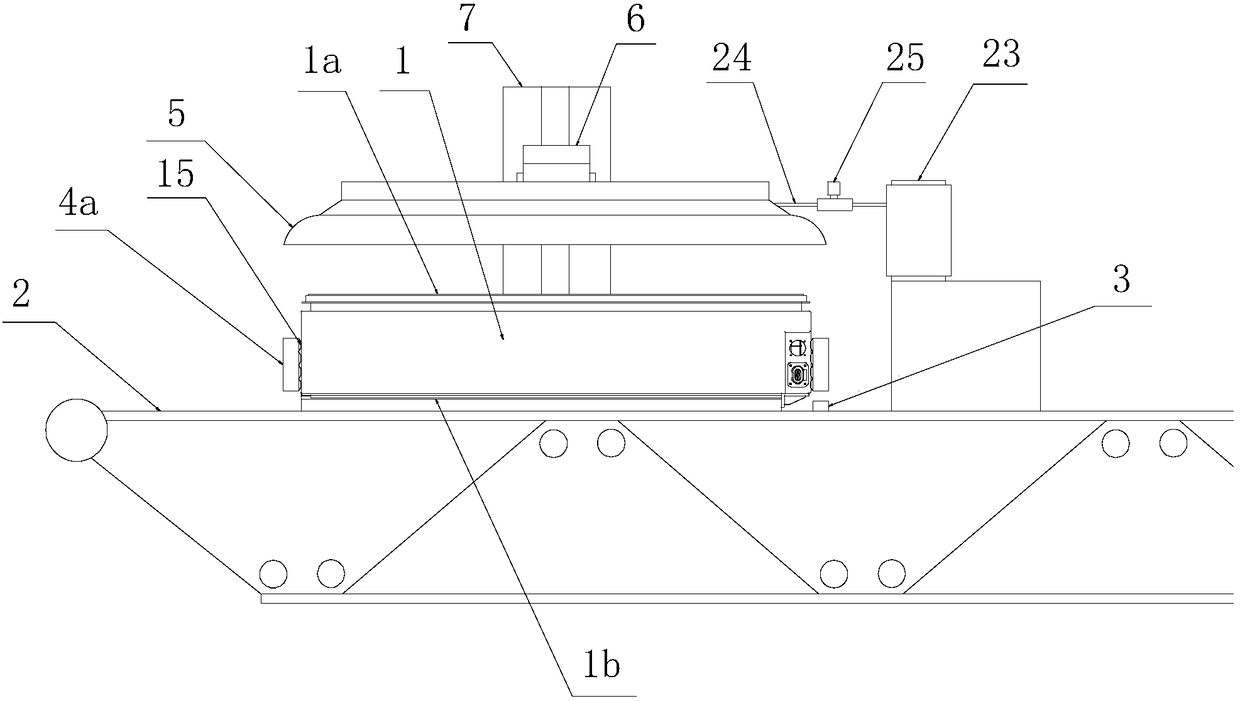

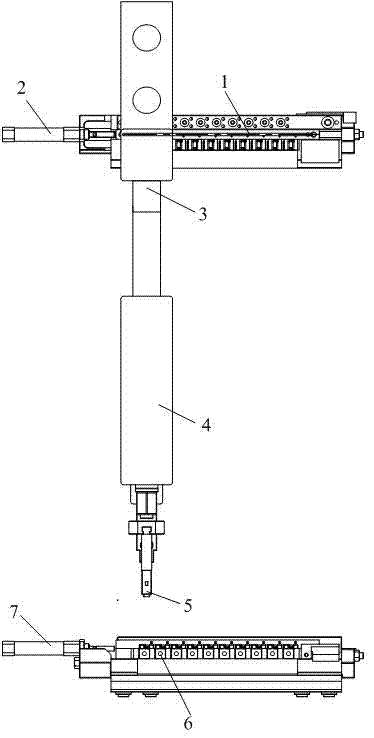

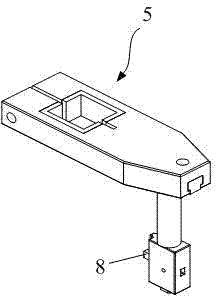

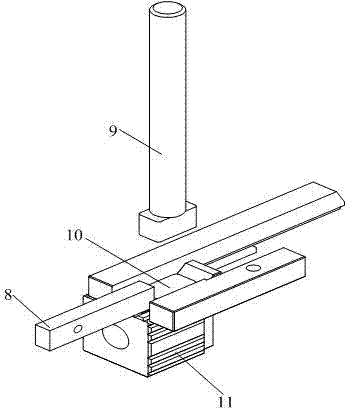

Linear feeding and discharging mechanism of full-automatic bar chamfering machine

ActiveCN103769970AAvoid wasted man-hoursCompact structureEdge grinding machinesGrinding feedersEngineeringMechanical engineering

The invention discloses a linear feeding and discharging mechanism of a full-automatic bar chamfering machine. The linear feeding and discharging mechanism of the full-automatic bar chamfering machine comprises a work head mechanism, a feeding mechanism and a receiving mechanism. The work head mechanism comprises a clamping head used for clamping bars and a spindle used for driving the clamping head to rotate. A hollow inner cavity is formed in the spindle, and the bars at the front end of the spindle can be conveyed out toward the rear end of the spindle along the hollow inner cavity. The feeding mechanism comprises a linear feeding precision linear module which can make linear reciprocating movement, and the linear feeding precision linear module is arranged at the position where linear reciprocating movement can be made in the axis direction of the spindle of the work head mechanism to enable the bars of the work head mechanism to be pushed in the hollow inner cavity of the spindle along a straight line. The receiving mechanism is arranged to enable the bars discharged by the hollow inner cavity of the work head mechanism to be conveyed to a receiving position in a linear mode. According to the linear feeding and discharging mechanism, the feeding mode is changed into a front positioning mode from a rear positioning mode, the feeding mode of front feeding and front discharging is changed into a work head inside linear discharging mode, so that the entire structure of the mechanism is compact, and the production efficiency and the product percent of pass are improved while the requirement for precision can be met.

Owner:XIAMEN TUNGSTEN

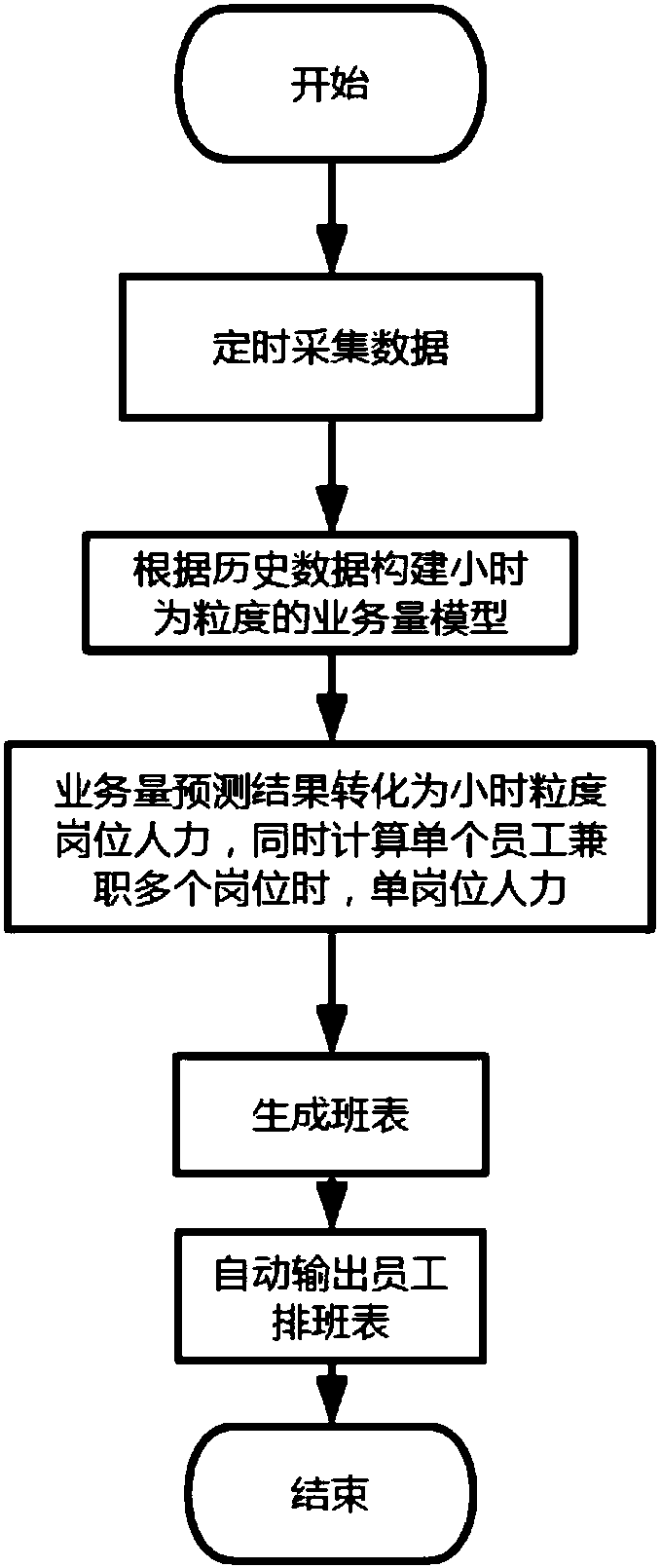

Scheduling method based on single employee competent to multiple jobs

InactiveCN108256755AAvoid wasted man-hoursMeet the complex scheduling needs of multi-skilled and concurrent positionsMachine learningResourcesDistribution systemGenetic algorithm

The invention discloses a scheduling method based on a single employee competent to multiple jobs. According to the method, a high-precision business volume prediction result is obtained through a machine learning model, a business volume prediction model is modified with significant factors taken into account, and the model precision is improved. The multiple jobs of a task are decomposed based on a queuing theory, an optimized genetic algorithm is used to satisfy the scheduling constraints of a single employee with multiple jobs and company labor regulations, and thus, a humanized schedulingresult is obtained. Based on the transformation of the human distribution pattern, the managers are liberated from the heavy scheduling work, the scheduling result is more fair and just, and the employees' enthusiasm for work is improved. Moreover, an intelligent human distribution system improves the service perception and satisfaction of customers.

Owner:SUNYARD SYST ENG CO LTD

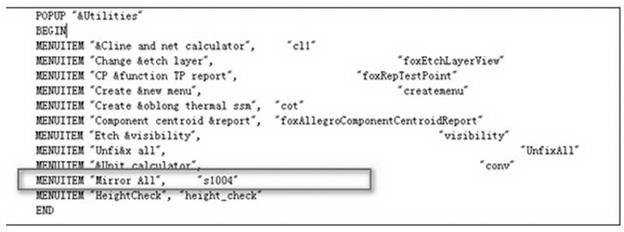

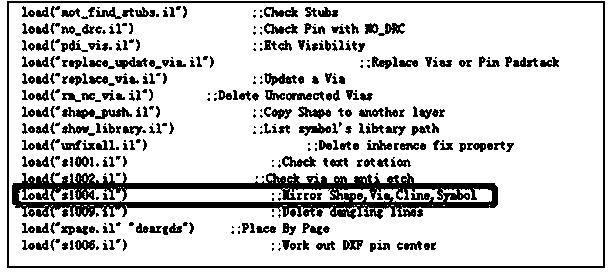

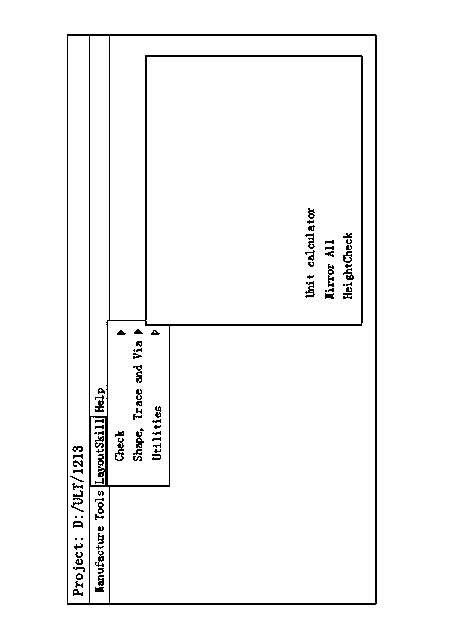

Implementation method of Skill program of automatic mirroring Layout design

InactiveCN103809977AAvoid wastingAvoid wasted man-hoursSpecific program execution arrangementsComputer architectureCopper foil

The invention discloses an implementation method of a Skill program of automatic mirroring Layout design. In PCB Layout design, the Skill program is implemented by modifying partial configuration files of software, and therefore a background database of the Layout design is modified directly. According to the implementation method, the Skill program is used, mirroring of parts, wiring, via holes and copper foil can be carried out together, waste of a large amount of work done at the early stage of Layout is avoided, a large amount of working hour waste caused by re-layout and rewiring after part mirroring is avoided, and therefore working efficiency is improved.

Owner:SHANDONG CHAOYUE DATA CONTROL ELECTRONICS CO LTD

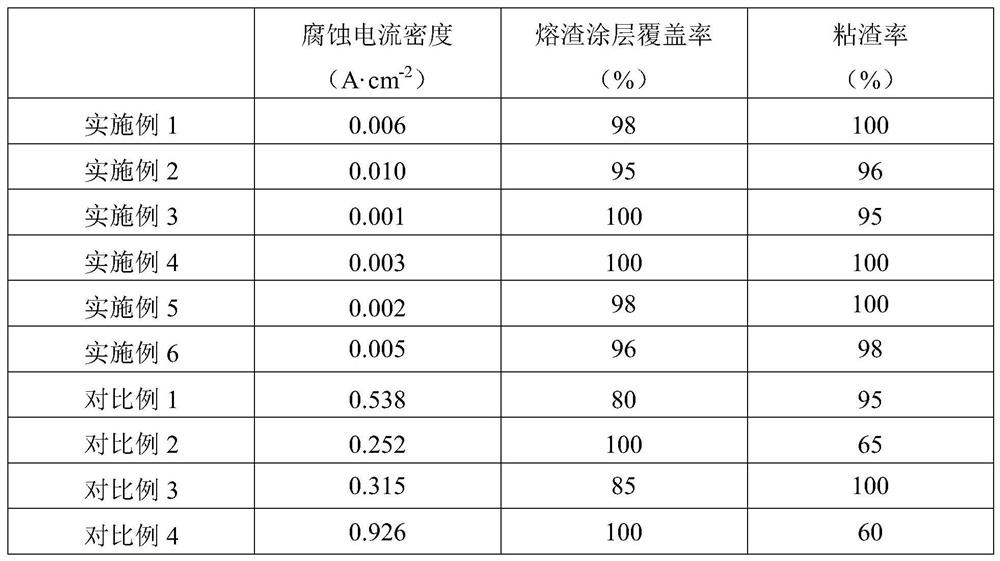

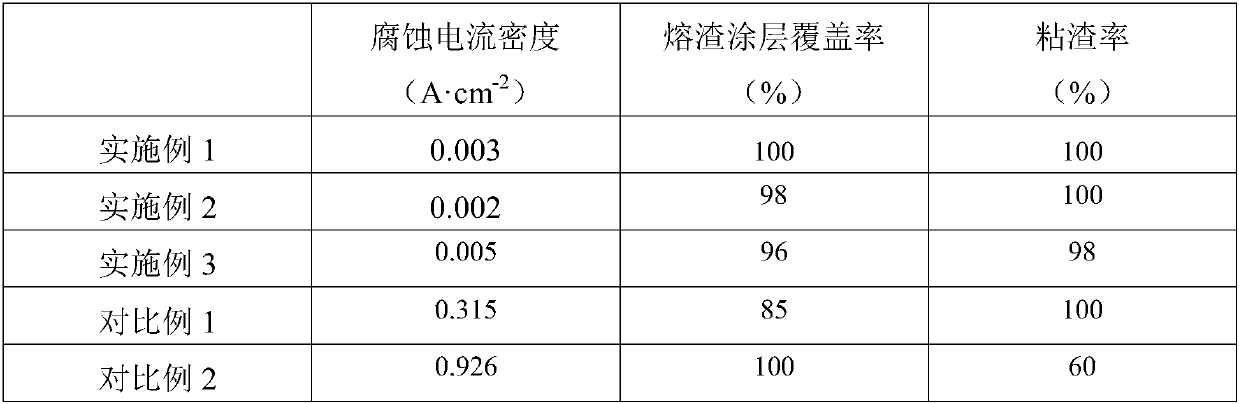

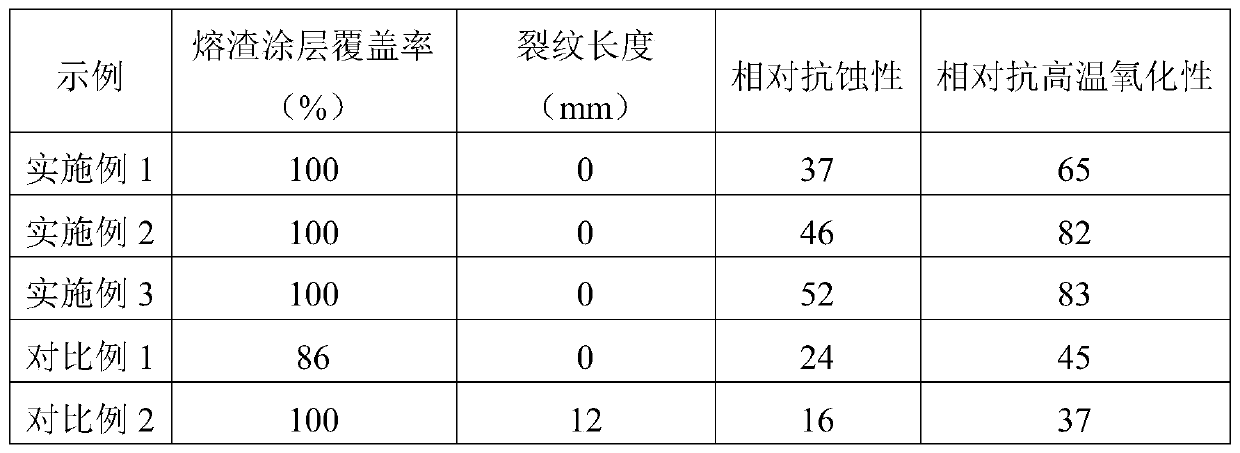

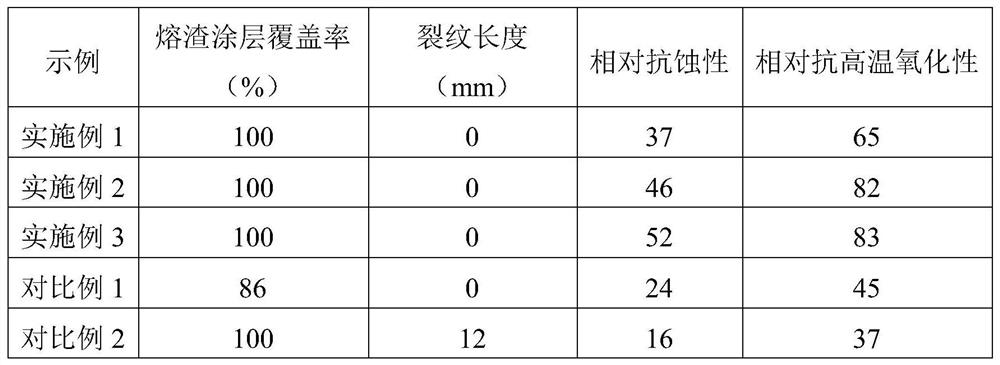

Self-shielded flux-cored wire for generating slag coating with special protective performance and preparation method

ActiveCN111644780AWith anti-seawater corrosionThe preparation method is simple and easyWelding/cutting media/materialsWelding/soldering/cutting articlesPotassium carbonateMolten slag

Owner:JIANGSU UNIV OF SCI & TECH

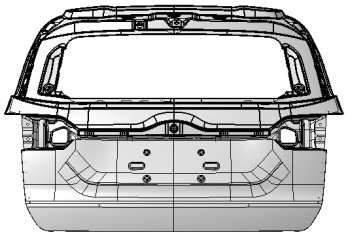

Convenient-to-operate common conveying device for vehicle doors and trunk lids

InactiveCN102092557AReduce labor intensityLower operating heightConveyorsUltimate tensile strengthConveyor belt

The invention discloses a convenient-to-operate common conveying device for vehicle doors and trunk lids, which is sued for solving the problems that the conveying device is inconvenient to manually operate and that one conveying device corresponds to only one kind of work pieces. The technical scheme is that: the common conveying device comprises an underframe and support frames fixed on the underframe; conveyor belts and material blocking plates are arranged on the support frames; after the conveying device is improved, lifting cylinders are arranged on the underframe; lifting cylinder rods are fixedly connected with the support frames; the conveyor belts comprise fixed conveyor belts and lifting conveyor belts; conveyor belt lifting cylinders are arranged at the support frames; and conveyor belt lifting cylinder rods are fixedly connected with the lifting conveyor belts. The common conveying device can reduce operation heights for workers to take and put the work pieces, greatly reduce the labor intensity of the workers, realize the applicability of one conveying device to the conveyance of the two kinds of work pieces, namely, the vehicle doors and the trunk lids, simultaneously save the occupation of a production site and reduce the tool cost, is favorable for improving the production efficiency and overcomes the shortcomings of waste of working hours and low production efficiency caused by the frequent replacement of the conveying devices.

Owner:GREAT WALL MOTOR CO LTD

Automatic temperature adjusting technology

ActiveCN110359084AAccurate temperature regulationThermostat SciencePolycrystalline material growthBy pulling from meltMan-hourEngineering

The invention provides automatic temperature adjusting technology. The automatic temperature adjusting technology is used for automatic temperature adjusting in temperature stabilizing process, and comprises following steps: 1, the liquid surface temperature of a silicon solution is detected, main power setting is carried out based on the liquid surface temperature, and temperature adjusting is carried out to adjust the liquid surface temperature to a fusion welding temperature; 2, overheating fusion welding is carried out; 3, an automatic cooling power is set, and automatic cooling is carriedout; and 4, a seeding power is set, temperature stabilizing is carried out to reach a seeding temperature, and seeding is carried out. The beneficial effects are that: simulation of artificial operation is carried out, so that copying of temperature adjusting logic in artificial temperature stabilizing is realized, temperature adjusting is more accurate, scientific, and consistent, automatic standard unmanned automatic process is realized, and man-hour waste and abnormal accidents caused by lack of artificial experience are avoided.

Owner:内蒙古中环晶体材料有限公司

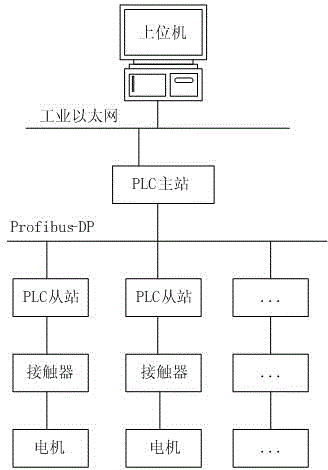

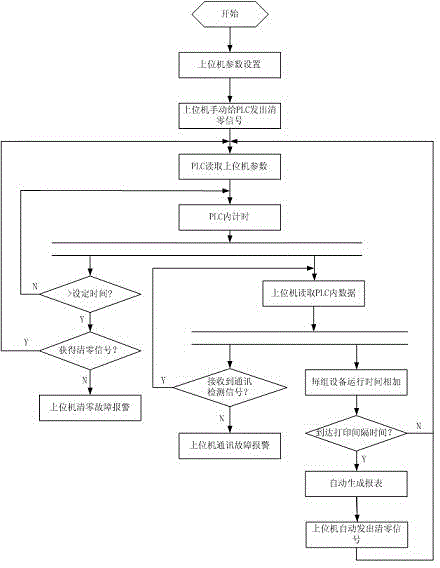

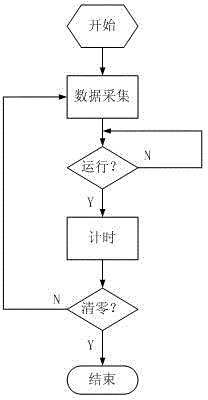

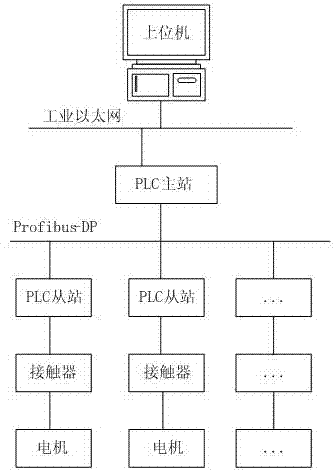

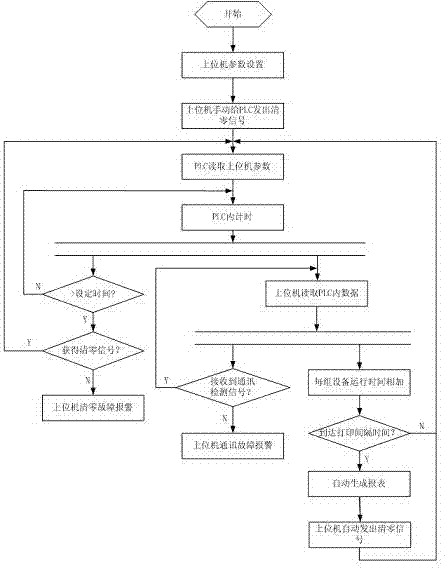

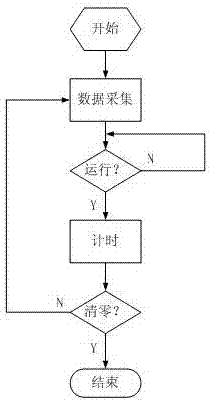

PLC (Programmable Logic Controller)-based automatic timing system and timing method thereof

ActiveCN104635702AAvoid wasted man-hoursSave purchase costTotal factory controlProgramme total factory controlProduction lineIndustrial Ethernet

The invention relates to a PLC (Programmable Logic Controller)-based automatic timing system and a timing method thereof, which are used for automatically calculating the workload per shift of workers in a metal product plant. The system comprises a motor, an alternating current contactor, a PLC controller and an upper computer, wherein the motor is arranged at one end of a finished product line; the PLC controller is used for acquiring a switching signal of the alternating current contactor, calculating the running time of the motor, and transmitting data to the upper computer over an industrial Ethernet network; the upper computer is used for calculating the yields of each draw bench and each nail making machine according to the running time of the motor, and directly generating a report for calculating the work amount of each worker; meanwhile, the upper computer is used for transmitting a zero clearing command to a PLC main station; after the PLC main station clears all data of a current shift, the system starts a new round of timing. By adopting the automatic timing system, the waste of labor-hour caused by weighting of finished products before the workers get off work every day is avoided, the purchasing and maintaining costs of weighing equipment are saved, meanwhile the production rhythm is accelerated, and the production efficiency is increased.

Owner:JIANGSU YONGGANG GROUP CO LTD

Method for harmless treatment of electrolytic manganese slag directly in filter plate frame

Provided is a method for directly carrying out innocent treatment on electrolytic manganese residues in filter pressing plate frames. The electrolytic manganese residues treated through the method are filter cakes obtained after filter pressing in the filter pressing plate frames of a plate-and-frame filter press, and sodium dihydrogen phosphate, calcium oxide, magnesium oxide and polyacrylamide are included in a treating agent. The method comprises the steps that 1, the electrolytic manganese residue filter cakes in all the filter pressing plate frames are washed through solutions obtained by mixing the sodium dihydrogen phosphate and water; 2, after the magnesium oxide, the calcium oxide and the polyacrylamide are dissolved in filter liquor collected in the step 1, the electrolytic manganese residue filter cakes are washed again; 3, filter liquor generated in the step 2 is collected, the plate-and-frame filter press is loosened to unload the filter cakes, and the electrolytic manganese residues generated after the innocent treatment are obtained. According to the method, soluble manganese in the electrolytic manganese residues is fixed, meanwhile, soluble ammonia nitrogen in the electrolytic manganese residues is fixed, and compared with the prior art, the advantages in the prior art are kept, the defects in the prior art are overcome, and the total cost of innocent treatment on the electrolytic manganese residues is lowered.

Owner:CHONGQING UNIV

Self-protection flux-cored wire capable of generating slag coating with special protection performance and preparing method

InactiveCN110919236AWith anti-seawater corrosionThe preparation method is simple and easyWelding/cutting media/materialsWelding/soldering/cutting articlesPotassium carbonateMolten slag

The invention discloses a self-protection flux-cored wire capable of generating slag coating with special protection performance and a preparing method. The self-protection flux-cored wire comprises alow-carbon steel belt and core powder. The low-carbon steel belt is filled with the core powder. The core powder comprises, by mass, 60-80% of glass powder, 2-8% of zirconium oxide powder, 0.05-0.85%of graphene powder, 2-8% of sodium potassium carbonate powder, 1-3% of potassium titanate powder, 2-5% of rutile powder, 1-5% of corundum powder, 1-3% of sodium fluosilicate powder and the balance iron powder, wherein the core powder accounts for 13-25% of the total weight of the flux-cored wire. The self-protection flux-cored wire has the advantages of omitting the slag removal process, reducingslag discharge, and increasing the material utilization rate, and the slag coating has special protection functions of preventing seawater corrosion and the like. The traditional pursuit of improvement of slag detachability is changed, the strong 'bonded slag' welding wire is developed for the first time, the slag is turned into the protection coating, slag is turned into coating, the slag function is expanded, and the base body / coating integral forming preparation technology is developed.

Owner:JIANGSU UNIV OF SCI & TECH

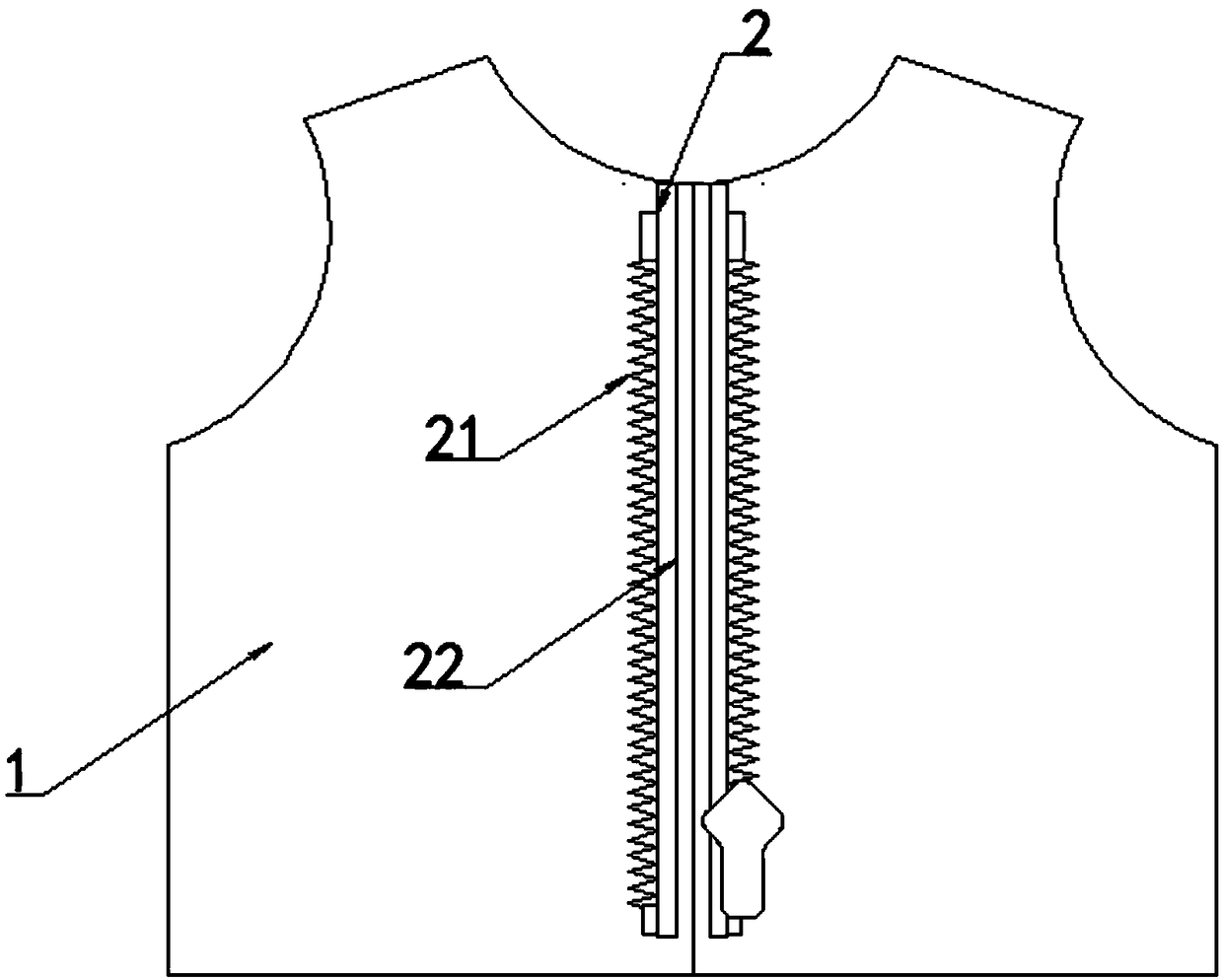

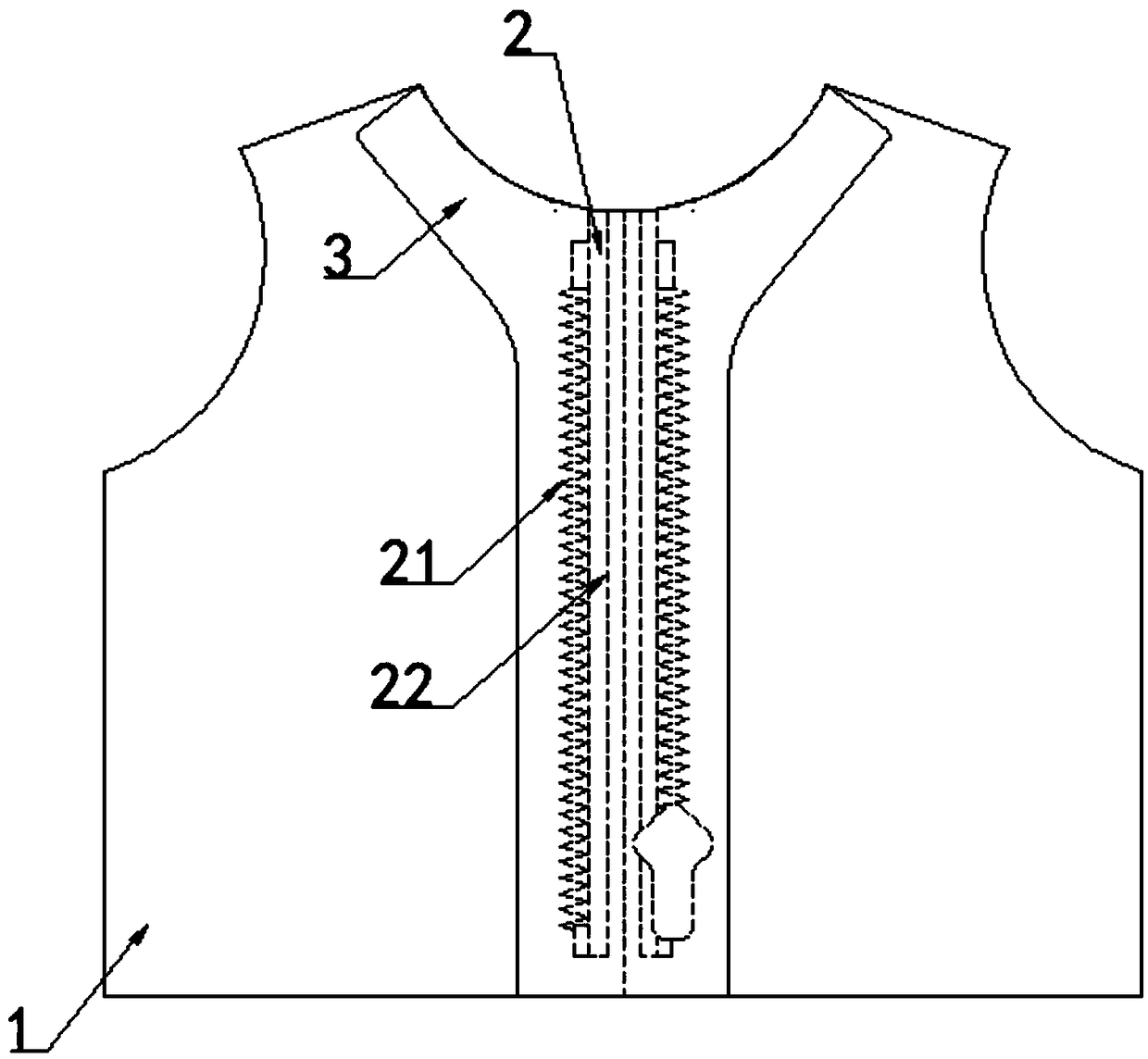

Upper garment top fly manufacturing method

Owner:JIANGXI INST OF FASHION TECH

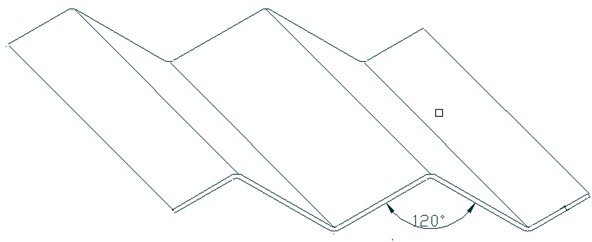

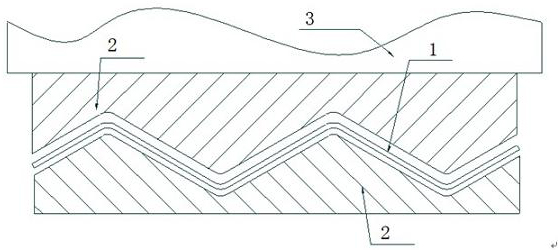

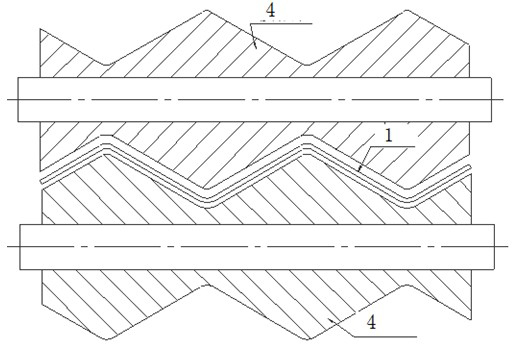

Manufacturing device and manufacturing method of wavy sheet for steel structure of heat exchange system

InactiveCN102319830AEasy to produceIncrease productivityHeat exchange apparatusProcess engineeringIndustrial engineering

The invention provides a manufacturing device and a manufacturing method of a wavy sheet for a steel structure of a heat exchange system, and the device is structurally characterized in that an upper row and a lower row of wavy wheels in the same shape with the wavy sheet, two groups of positioning wheels, one group of leveling wheels, one group of shaping wheels and an adjusting frame are arranged, wherein the shape of each wavy wheel is gradually changed from a cylinder to the shape of the wavy sheet; the two groups of positioning wheels and the one group of leveling wheels are arranged at the front ends of the wavy wheels so as to ensure the correct relative positions of a wavy sheet material and the wavy wheels; and the one group of shaping wheels and the adjusting frame are arranged at the tail ends of the wavy wheels so as to ensure the correct shaping of the wavy sheet. By adopting the manufacturing device and the manufacturing method, the traditional processing mode is thoroughly changed, the complex die manufacturing is abandoned, the stability of the product quality is improved, and the shaping wheels and the adjusting frame can be suitable for different materials so as to enable the product quality to be stable and reliable. The cost is greatly reduced, and a strip-shaped steel coil of the preset fixed size is adopted for replacing the cutting of a steel plate in the traditional process, thereby avoiding the waste of working time and the waste of remnants caused by cutting of the plate.

Owner:JIANGSU HAIXUN IND GROUP SHARE

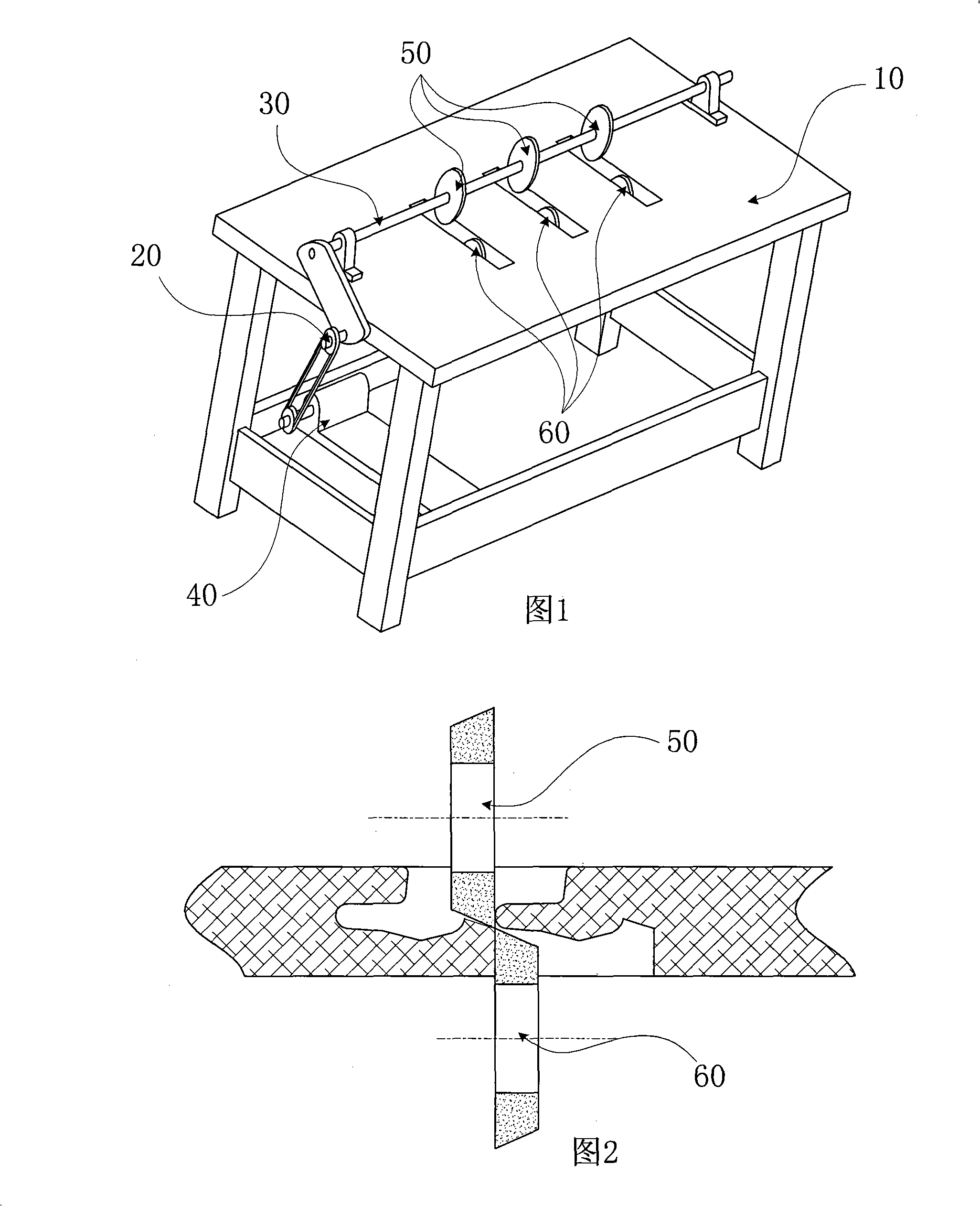

Separating and cutting method and device for side surface lock catch type sheet

A cutting machine for side-locking section comprises a working bench (10), a power control and drive mechanism (20), an upper drive shaft (30) and a lower drive shaft (40); the upper drive shaft (30) and the lower drive shaft (40) are separately equipped with upper saw blades (50) and lower saw blades (60); the opposite ends of the upper saw blades (50) and the lower saw blades (60) are stuck together and the cutting edges at the sticking point of the upper saw blades (50) and the lower saw blades (60) are connected in the radial direction. The upper saw blades (50) are a plurality of blades which are coaxially equipped with equal interval and the lower saw blades (60) are a plurality of blades corresponding to the upper saw blades (50) one by one. The present invention, by adopting the method and equipment, could further optimize the processing of the special section and save materials; at the same time, the invention could avoid man-hour waste caused by repeated processing.

Owner:圣象(江苏)木业研究有限公司

Assembly tooling for annular net cabinet

InactiveCN106002875AStable supportImprove assembly efficiencyAssembly machinesWork benchesInstabilityAssembly line

The invention relates to an assembly tooling for an annular net cabinet and aims at solving the problem of instability in supporting during assembly of the annular net cabinet in the prior art. For solving the technical problem, the assembly tooling for the annular net cabinet is designed as follows: a gas tank connecting structure for being connected with a gas tank is arranged on vertical frames; and when the gas tank needs to be assembled, the gas tank is fixed on the assembly tooling by the gas tank connecting structure, and then can be stably placed on the ground or other working faces by means of a stable supporting surface of the base, thereby realizing stable support for the gas tank.

Owner:HENAN PINGGAO GENERAL ELECTRIC CO LTD +2

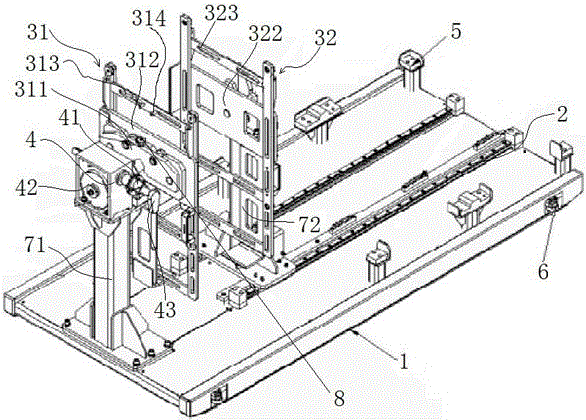

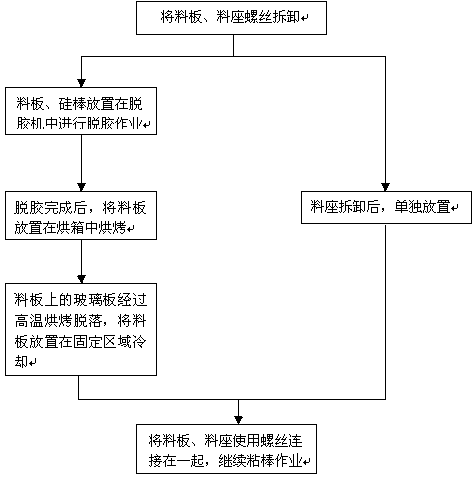

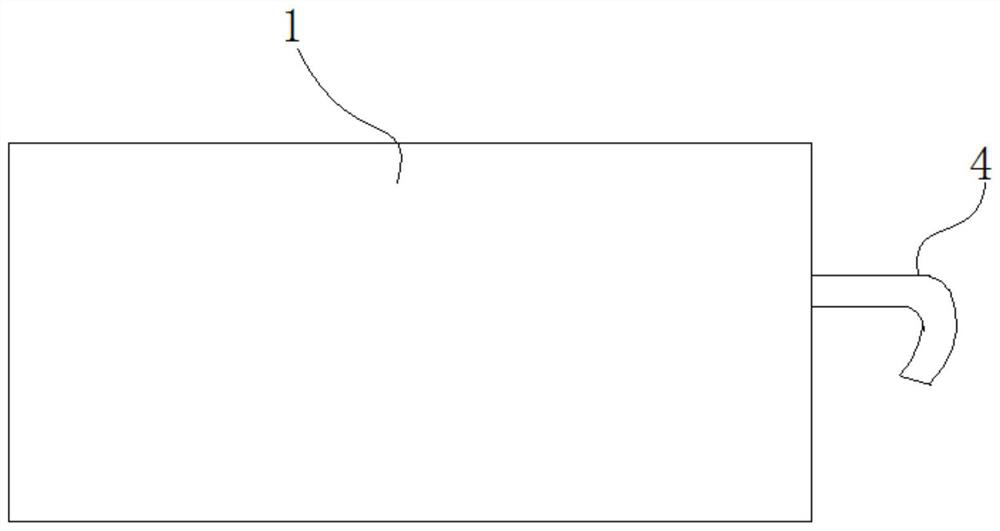

Solar silicon wafer processing method and device

InactiveCN103522428AIncrease production capacityAvoid wasted man-hoursWorking accessoriesFine working devicesEngineeringWater boil

The invention relates to a solar silicon wafer processing method and device. First, two through holes are formed in a material base, and then rod gluing operation is conducted; after a solar silicon rod is cut, two round metal rods are inserted in the two round holes in the material base respectively, and the solar silicon rod, a glass plate, a material plate and the material base are integrally placed in a skip car of a degumming machine together through the two round metal rods; a solar silicon wafer falls off through a degumming process, and a mechanical arm is used for integrally placing the glass plate, the material plate and the material base in a water boiling box together; the glass plate on the material plate falls off through water boiling, and then the mechanical arm is used for transporting the material plate and the material base back to a rod gluing table integrally; rod gluing operation continues to be conducted after the material plate and the material base are cooled. Due to the fact that the material plate and the material base are connected together all the time in the whole processing process, the problems that work hours are wasted and processing quality has hidden dangers as a result of frequent dismounting and mounting of the material plate and the material base are effectively avoided, labor intensity of manpower is lowered, and production capacity of the solar silicon wafer is improved.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

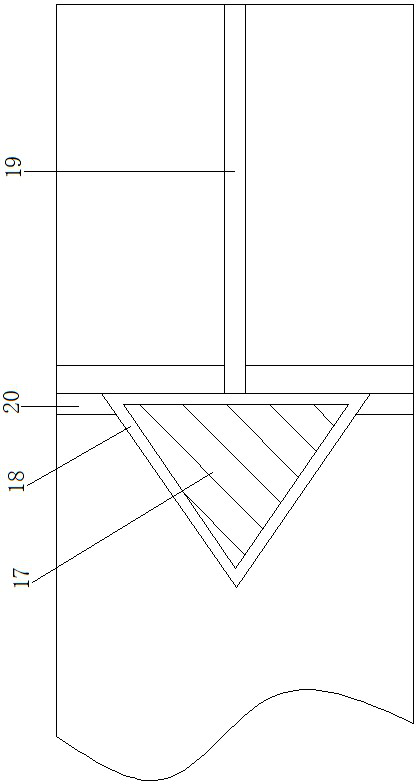

Novel power cable connecting device

ActiveCN111987654APrevent slippageEasy to peel offApparatus for joining/termination cablesPower cableFire - disasters

The invention discloses a novel power cable connecting device. The device comprises a connecting pipe, a connector is mounted at the right end in the connecting pipe; a socket ring is fixedly installed on the right side of the connector, a plurality of annularly-distributed contact pins located in the socket ring are fixedly installed on the right side of the connector, a conductive elastic piecelocated in the connecting pipe is fixedly installed on the left side of the connector, an installation ring is arranged at the left end of the inner side of the connecting pipe, and a conductive wireis arranged on the inner side of the installation ring. According to the invention, the triangular pyramids play a role in cutting and stripping wires and cables and also play a role in fixed-size cutting; the vertical surface of the triangular pyramid is matched with the vertical surface of the triangular pyramid-shaped groove; the conductive wire can be effectively prevented from slipping from the connecting device, accidents such as fire disasters are prevented, the mounting process of the device is also simple, the conductive wire can be fixed and prevented from slipping only by insertingthe conductive wire from the left side of the connecting pipe, and subsequent maintenance of the conductive wire and the device is facilitated for workers.

Owner:河南乾和机电设备有限公司

Self-protective flux-cored wire for in-situ generation of glass slag coating and preparation method thereof

ActiveCN110919234AExempt from removalHigh bonding strengthWelding/cutting media/materialsSoldering mediaSlag (welding)Iron powder

The invention discloses a self-protective flux-cored wire for in-situ generation of a glass slag coating and a preparation method thereof. The self-protective flux-cored wire comprises a low carbon steel strip and flux-cored powder; the steel strip is filled with the flux-cored powder; the flux-cored powder comprises the following components in percentage by mass: 60-80% of ferroboron, 5-12% of wollastonite powder, 3-7% of ferrosilicon, 1-5% of white mud powder, 1-3% of sodium fluoride powder, 1-3% of potassium titanate powder and the balance iron powder, wherein the flux-cored powder accountsfor 12-22% of the total weight of the self-protective flux-cored wire. According to the self-protective flux-cored wire, the slag removal process is eliminated, discharged waste residues are reducedand the material utilization rate is increased. Furthermore, the slag function is expanded for the first time, a technology for generating the slag coating in situ is provided, and the glass slag coating generated in situ has the functions of preventing corrosion and oxidation and protecting welding seams.

Owner:JIANGSU UNIV OF SCI & TECH

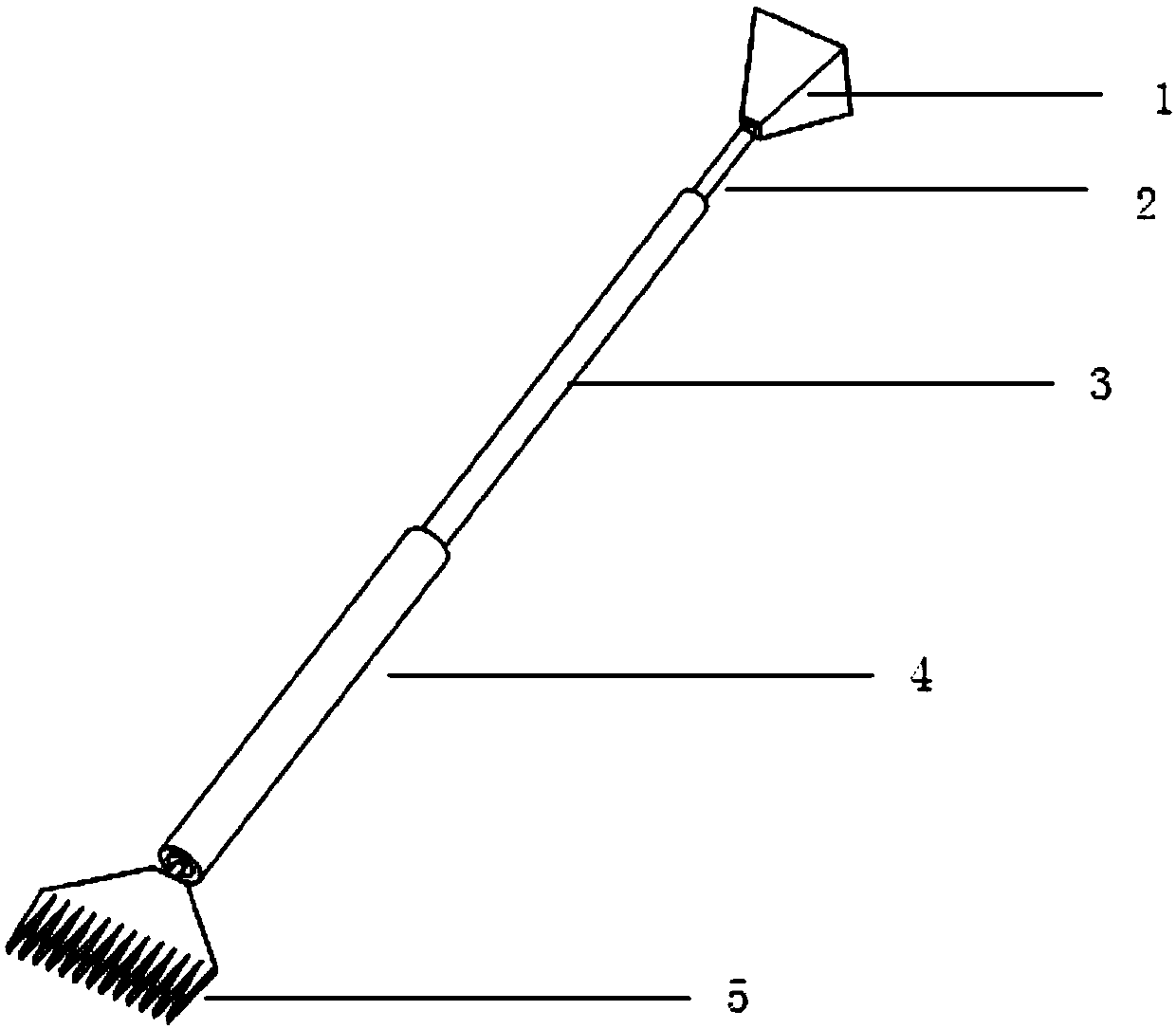

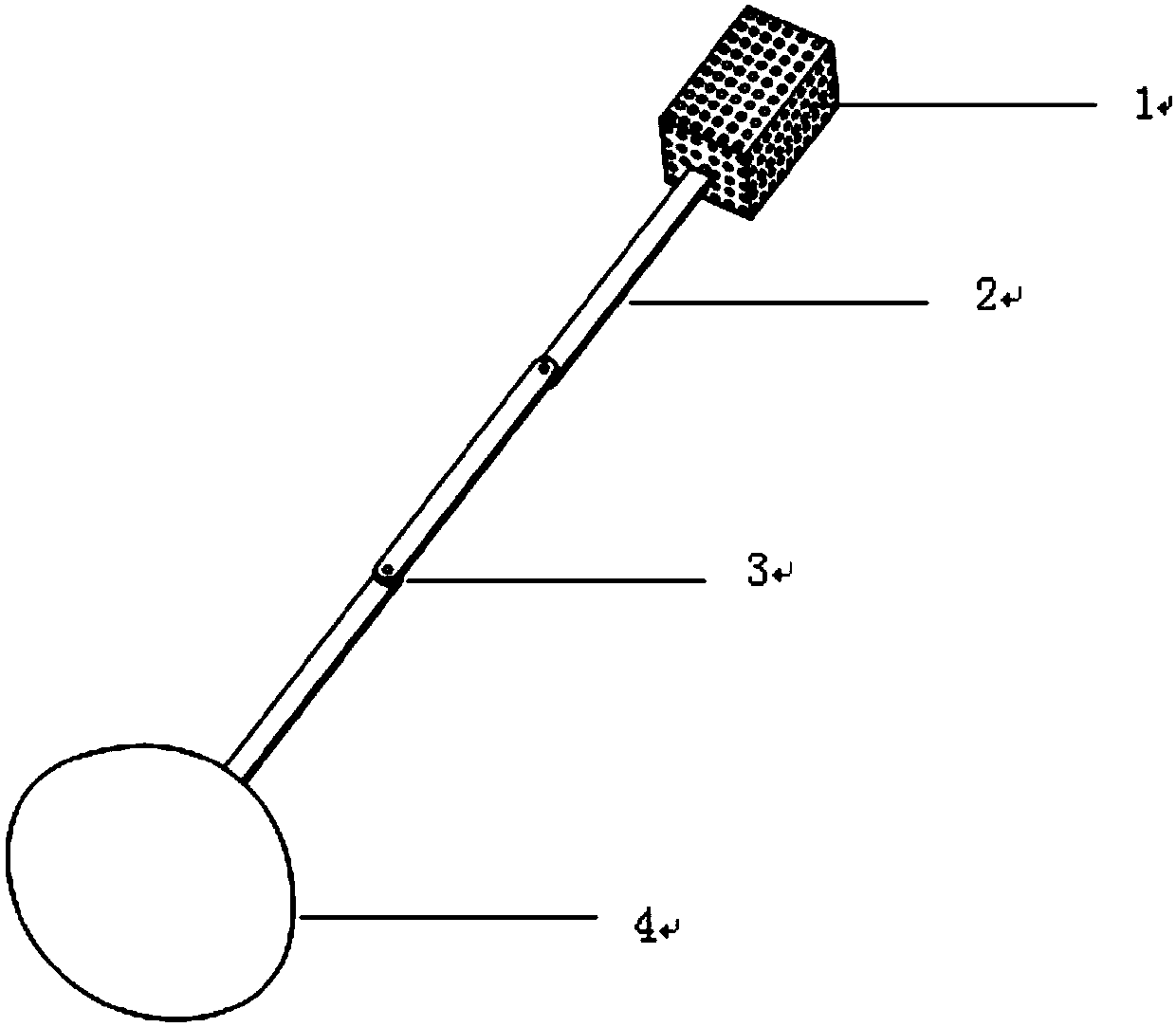

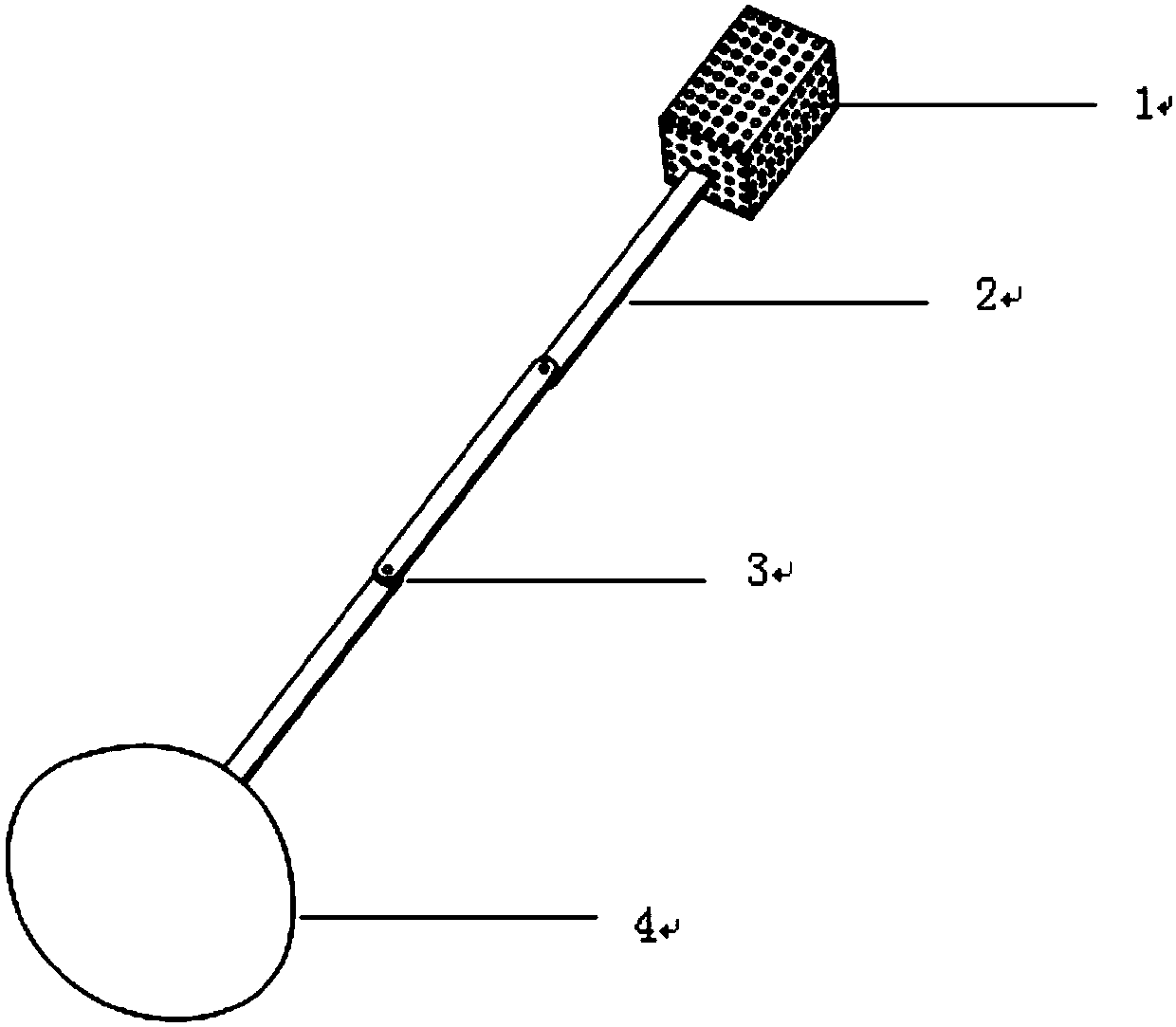

Walnut picker

The invention provides a walnut picker. The walnut picker comprises an elastic container, a first rod body, a second rod body, a third rod body and a grass raking machine; the first rod body, the second rod body and the third rod body are designed through nesting, the elastic container is movably connected with the first rod body, and the grass raking machine is movably connected with the third rod body. According to the walnut picker, the problems of quick picking and accurate picking are solved, man-hour waste and fruit missing are avoided, and the walnut picker can have the advantages of being low in tool cost and high in work efficiency.

Owner:新昌县海联园林工程有限公司

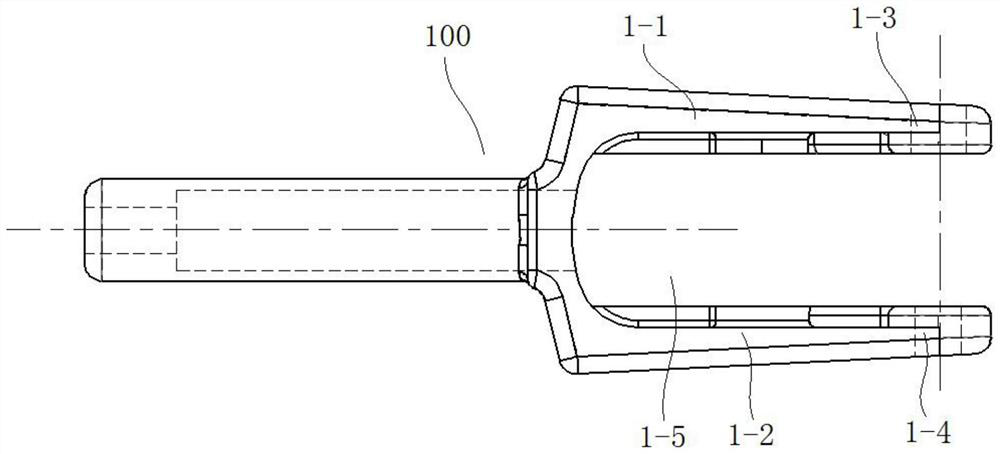

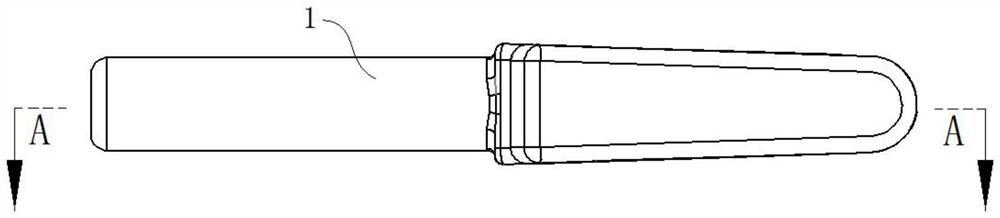

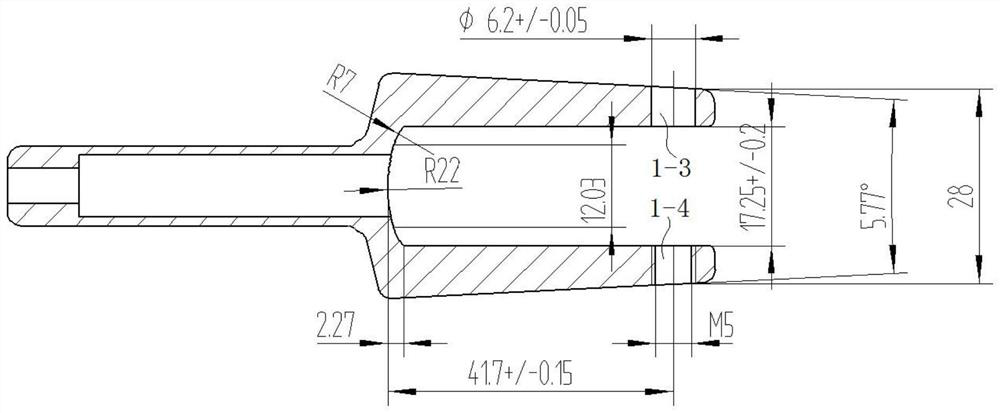

Machining tool, machining system and machining method for handle part

PendingCN114260728ANovel structural designPrecise positioningPositioning apparatusMetal-working holdersEngineeringMachining system

The handle part machining tool comprises a bottom plate, a positioning plate and a part clamp, a first positioning face is arranged on the upper surface of one side of the bottom plate, the positioning plate is arranged on the bottom plate, the positioning plate and the first positioning face are arranged in a spaced mode, and a second positioning face is arranged on the upper surface of the positioning plate; the part clamp is arranged on the side, away from the first positioning face, of the bottom plate and used for being connected with the tail end of the handle part blank. The machining tool is ingenious and novel in structural design, the first positioning face is arranged to carry out veneering supporting on the side plate, needing threaded hole machining, of the handle opening, the second positioning face is arranged to carry out veneering supporting on the side plate, needing through hole machining, of the handle opening, and the problem that the side plate deforms and collapses due to the fact that the side plate of the handle opening is directly punched can be effectively solved. The invention further provides a processing system and a processing method of the handle part, the processing size of the handle part blank can be ensured on the premise of ensuring reliable tool positioning, meanwhile, the processing efficiency is improved, and the production cost is reduced.

Owner:石家庄达辛科技有限公司

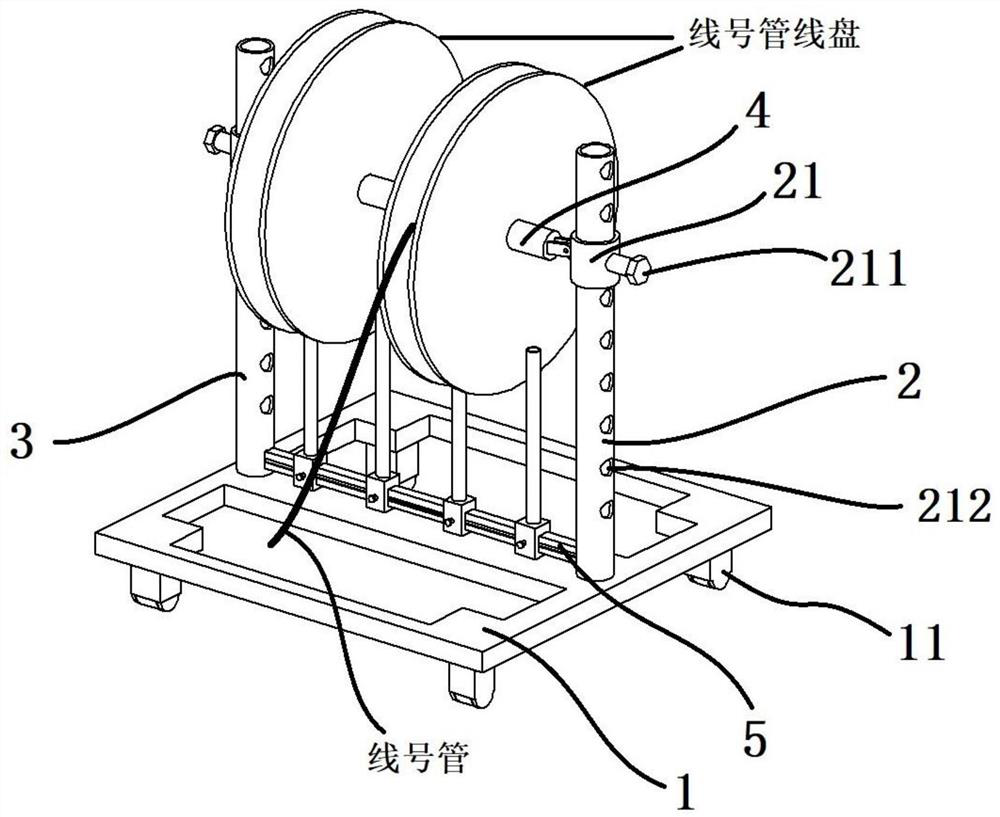

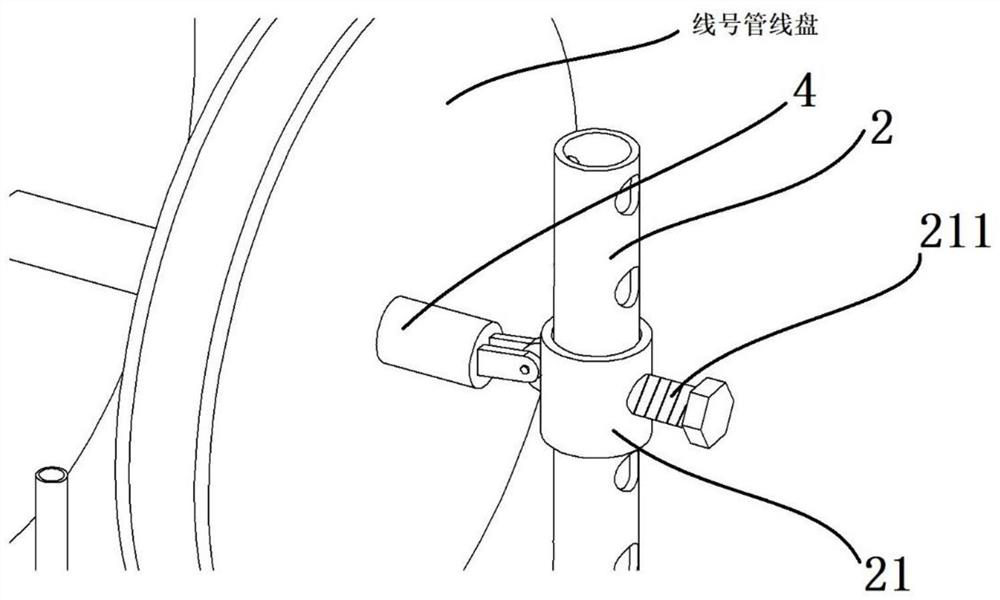

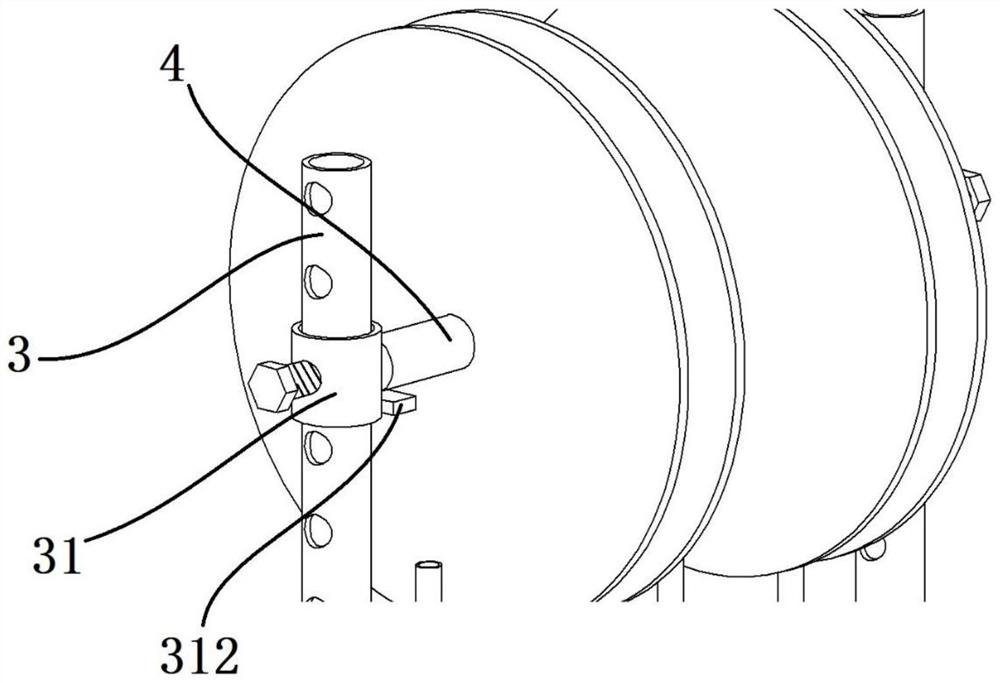

Wire marker tube printing tool

The invention provides a wire marker tube printing tool. The wire marker tube printing tool comprises a base, two vertical rods and a horizontal rod. The two vertical rods are arranged at the two endsof the upper surface of the base correspondingly. The vertical rods include the first vertical rod and the second vertical rod which are parallel. The first vertical rod and the second vertical rod are sleeved with a first adjusting ring and a second adjusting ring correspondingly. The horizontal rod comprises a connecting end and a movable end. The connecting end is hinged to the first adjustingring arranged on the first vertical rod. The wire marker tube printing tool provided by the invention ensures that various types of wire marker tubes can be simultaneously processed and printed, canbe matched with any wire marker tube printer and achieves the production and processing continuity. Labor-hour waste and labor cost increase caused by frequent switching of materials are avoided. Thewire marker tube printing tool can ensure that the font of printed wire markers is clear. Waste of wire marker tube materials is avoided. Meanwhile, the production efficiency and the product processing reliability and safety are improved.

Owner:RENERGY ELECTRIC TIANJIN

A linear feeding and discharging mechanism of a bar material automatic chamfering machine

ActiveCN103769970BAvoid wasted man-hoursCompact structureEdge grinding machinesGrinding feedersReciprocating motionEngineering

The invention discloses a linear feeding and discharging mechanism of a full-automatic bar chamfering machine. The linear feeding and discharging mechanism of the full-automatic bar chamfering machine comprises a work head mechanism, a feeding mechanism and a receiving mechanism. The work head mechanism comprises a clamping head used for clamping bars and a spindle used for driving the clamping head to rotate. A hollow inner cavity is formed in the spindle, and the bars at the front end of the spindle can be conveyed out toward the rear end of the spindle along the hollow inner cavity. The feeding mechanism comprises a linear feeding precision linear module which can make linear reciprocating movement, and the linear feeding precision linear module is arranged at the position where linear reciprocating movement can be made in the axis direction of the spindle of the work head mechanism to enable the bars of the work head mechanism to be pushed in the hollow inner cavity of the spindle along a straight line. The receiving mechanism is arranged to enable the bars discharged by the hollow inner cavity of the work head mechanism to be conveyed to a receiving position in a linear mode. According to the linear feeding and discharging mechanism, the feeding mode is changed into a front positioning mode from a rear positioning mode, the feeding mode of front feeding and front discharging is changed into a work head inside linear discharging mode, so that the entire structure of the mechanism is compact, and the production efficiency and the product percent of pass are improved while the requirement for precision can be met.

Owner:XIAMEN TUNGSTEN

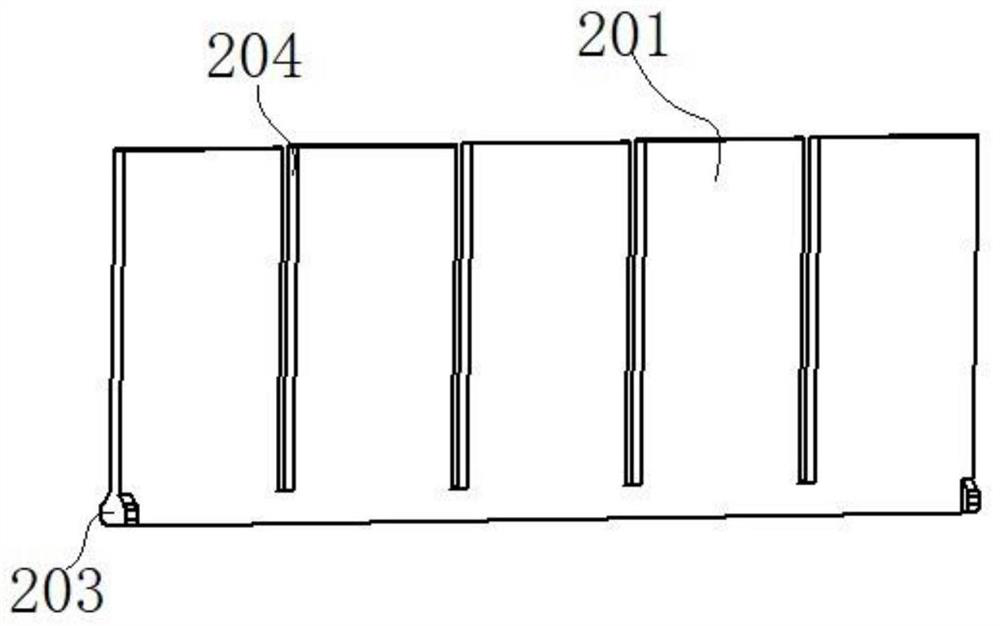

Adsorption type multifunctional material box

The invention provides an adsorption type multifunctional material box. The adsorption type multifunctional material box comprises a box body, wherein an opening is formed in the top of the box body; a containing groove used for storing materials is formed in the box body; the interior of the containing groove is divided into a plurality of storage bins through partition plates; a supporting plate is arranged on the back face of the box body; a plurality of installation positions are arranged on the side, close to the box body, of the supporting plate; and the box body is correspondingly installed in the installation positions of the supporting plate through hooks. According to the adsorption type multifunctional material box, the materials are convenient to store and take, rapid matched use can be achieved, continuity of production and machining is achieved, labor hour waste and labor cost increase caused by frequent switching and assembling of the materials are avoided, and the production efficiency is effectively improved.

Owner:RENERGY ELECTRIC TIANJIN

Convenient-to-operate common conveying device for vehicle doors and trunk lids

The invention discloses a convenient-to-operate common conveying device for vehicle doors and trunk lids, which is sued for solving the problems that the conveying device is inconvenient to manually operate and that one conveying device corresponds to only one kind of work pieces. The technical scheme is that: the common conveying device comprises an underframe and support frames fixed on the underframe; conveyor belts and material blocking plates are arranged on the support frames; after the conveying device is improved, lifting cylinders are arranged on the underframe; lifting cylinder rodsare fixedly connected with the support frames; the conveyor belts comprise fixed conveyor belts and lifting conveyor belts; conveyor belt lifting cylinders are arranged at the support frames; and conveyor belt lifting cylinder rods are fixedly connected with the lifting conveyor belts. The common conveying device can reduce operation heights for workers to take and put the work pieces, greatly reduce the labor intensity of the workers, realize the applicability of one conveying device to the conveyance of the two kinds of work pieces, namely, the vehicle doors and the trunk lids, simultaneously save the occupation of a production site and reduce the tool cost, is favorable for improving the production efficiency and overcomes the shortcomings of waste of working hours and low production efficiency caused by the frequent replacement of the conveying devices.

Owner:GREAT WALL MOTOR CO LTD

PLC-based Automatic Timing System and Its Timing Method

ActiveCN104635702BAvoid wasted man-hoursIncrease production capacityTotal factory controlProgramme total factory controlProduction lineIndustrial Ethernet

Owner:SUZHOU SITRI WELDING TECH RES INST CO LTD

Self-shielded flux-cored welding wire with in-situ glass slag coating and preparation method thereof

ActiveCN110919234BExempt from removalHigh bonding strengthWelding/cutting media/materialsSoldering mediaSlag (welding)Iron powder

The invention discloses a self-protecting flux-cored welding wire with a glass slag coating formed in situ and a preparation method thereof, which comprises a low-carbon steel strip and a flux-core powder, and the flux-core powder is filled in the steel strip, and the flux-core powder is manufactured according to The mass percentage includes the following components: 60-80% ferroboron, 5-12% wollastonite powder, 3-7% ferrosilicon, 1-5% white mud powder, 1-3% fluorine Sodium chloride powder, 1-3% potassium titanate powder, the balance being iron powder, the core powder accounts for 12-22% of the total weight of the welding wire. The welding wire provided by the invention not only eliminates the slag removal process, reduces waste slag discharge, improves material utilization, but also expands the slag function for the first time, and proposes the in-situ generation of slag coating technology. The in-situ generated glass slag coating has Anti-corrosion and anti-oxidation, with the function of protecting the weld.

Owner:JIANGSU UNIV OF SCI & TECH

Automatic overheating process

ActiveCN110363398AAutomatic detection of shrinkage in diameterAvoid wasted man-hoursResourcesManufacturing computing systemsEngineering% diameter reduction

The invention provides an automatic overheating process, which is used for carrying out overheating welding within overheating welding time after seed crystal is automatically reduced in a temperaturestabilizing process, and comprises the following steps of: S1, measuring the diameter of the seed crystal, carrying out timing, and recording the maximum value of the diameter of the seed crystal inthe timing process; S2, carrying out automatic temperature adjustment according to the liquid level temperature of the silicon solution, and adjusting the liquid level temperature of the silicon solution to the welding temperature; S3, carrying out overheating welding and timing, and recording the minimum value of the seed crystal diameter in the timing process; and S4, calculating an overheatingdiameter reduction difference value of the seed crystal, and judging whether overheating is completed or not according to the overheating diameter reduction difference value. The method has the beneficial effects that automatic overheating is carried out according to the operation steps of manually judging overheating of the seed crystals, the phenomenon of diameter shrinkage during overheating ofthe seed crystals is automatically detected, labor hour waste and abnormal accidents caused by insufficient artificial experience are avoided, the temperature stabilizing labor hour is shortened, theyield is increased, and the competitiveness of enterprises is improved.

Owner:内蒙古中环晶体材料有限公司

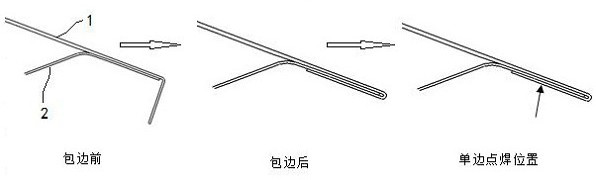

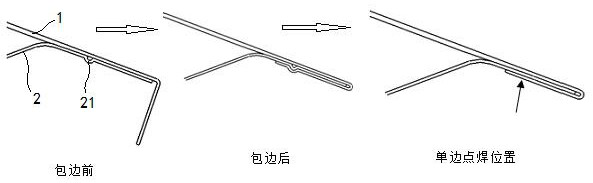

Method for improving single-side spot welding quality of covering part covered edge and single-side spot welding protrusion die

ActiveCN112453667AImproving the quality of unilateral spot welding of hemmingGuaranteed not to deformResistance welding apparatusStructural engineeringSpot welding

The invention relates to a method for improving the single-side spot welding quality of a covering part covered edge and a single-side spot welding protrusion die. The method is characterized by comprising the following steps that 1, a protrusion is additionally arranged at a single-side spot welding position of an inner plate by using the single-side spot welding protrusion die, and the protrusion on the inner plate protrudes towards the inner side of a vehicle body; 2, a covering part is subjected to edge covering, and after edge covering, a protrusion structure is formed on an outer plate on the inner side of the vehicle body along with the protrusion on the inner plate; and 3, single-side spot welding is conducted on the covering part covered edge. According to the method and the die,the protrusion is additionally arranged at the single-side spot welding position of the inner plate, the inner plate is isolated from the outer plate on the outer side of the vehicle body, heat cannotbe directly transmitted to the outer plate on the outer side of the vehicle body during single-side spot welding, and it is guaranteed that the outer plate on the outer side of the vehicle body doesnot deform.

Owner:CHERY AUTOMOBILE CO LTD

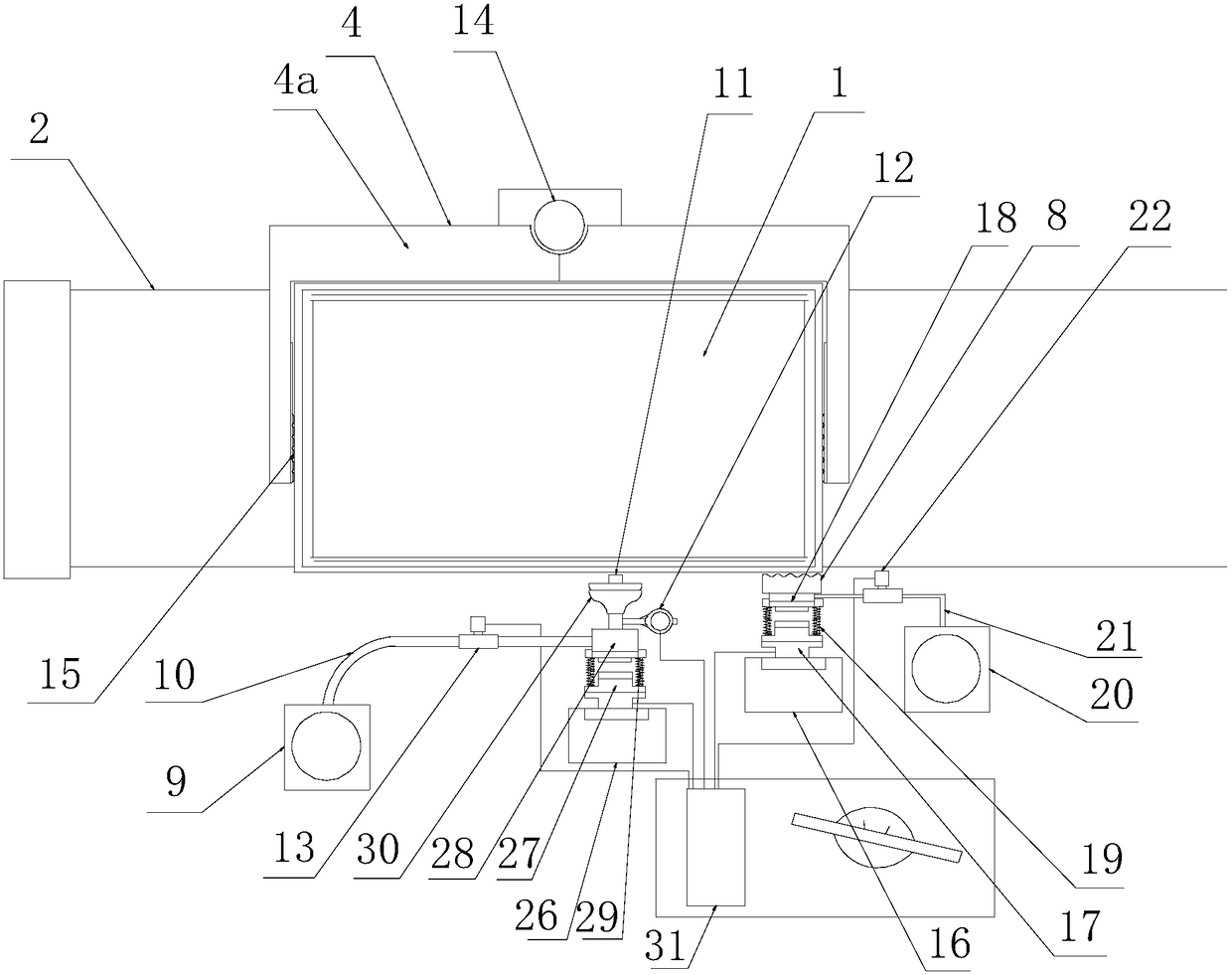

Automobile battery box air tightness automatic detection device

ActiveCN105865729BSpeed up deliveryHigh degree of automationMeasurement of fluid loss/gain rateAutomotive batteryAtmospheric pressure

The invention discloses an automated detection device for air tightness of an automobile battery box. A line body is adopted to convey the automobile battery box, an air tightness detection station is arranged beside the line body, the automobile battery box is stopped on the air tightness detection station through signal switch control, the air tightness detection station is provided with an automobile battery box positioning mechanism, a cover box joint part sealing mechanism, a plug-in module insertion hole sealing mechanism and an air pressure detection mechanism, the mechanisms replace manpower with controller coordination control to complete external sealing and air inflation of the automobile battery box and air pressure detection, efficiency is improved greatly while high detection precision can be provided so that detection quality can be guaranteed, and production cost is lowered.

Owner:SUZHOU ZHONGXIN METALWORKS

Receiver thin film welding and assembling device

InactiveCN102861977APositioning without gapsAvoid wasted man-hoursResistance welding apparatusEngineeringPiston

The invention relates to a receiver thin film welding and assembling device comprising a welding head moving cylinder, a welding head and a welding fixture, wherein the cylinder seat of the welding head moving cylinder is arranged on a linear slide rail, the piston of a rectilinear motion driving cylinder is in drive connection with the cylinder seat of the welding head moving cylinder, the welding head is installed on the piston of the welding head moving cylinder, an auxiliary locating mechanism and an upper electrode, which are arranged side by side, are arranged on the welding head, the welding fixture is arranged on a machine platform below the welding head, a fixture clamping cylinder is in drive connection with the welding fixture, and a lower electrode is arranged on the welding fixture. The device is used for welding receivers of moving-iron earphones and surdomute earphones; and the receiver thin film welding and assembling device is suitable for occasions with high locating precision and micro products during welding process. The receiver thin film welding and assembling device is used for guaranteeing gapless locating through high precision movement and the locating mechanism.

Owner:KERUI AUTOMATION TECH SUZHOU

Walnut picking tool special for morning and evening

The invention provides a walnut picking tool special for the morning and the evening. The walnut picking tool comprises a sponge body, folding arms, break points and a picking device. The sponge bodyand the picking device are arranged on the two sides of the folding arms respectively, and the break points are arranged between the folding arms. According to the walnut picking tool special for themorning and the evening, the purposes of rapid picking and precise picking in the morning and the evening can be effectively achieved, man hour waste and leakage of fruits are avoided, and the performance of the low tool cost and the high working efficiency can be taken into consideration.

Owner:新昌县海联园林工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com