Method for improving single-side spot welding quality of covering part covered edge and single-side spot welding protrusion die

A cover, unilateral technology, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of waste of man-hour and cost, affecting the appearance quality of the whole vehicle, deformation of the outer panel of the vehicle body, etc., to ensure the A surface Quality, easy on-site debugging, avoiding cost and labor time waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

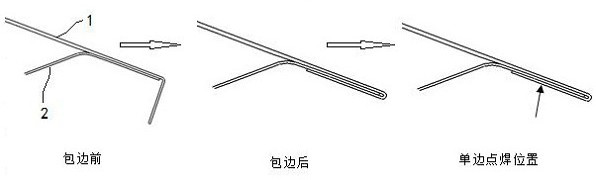

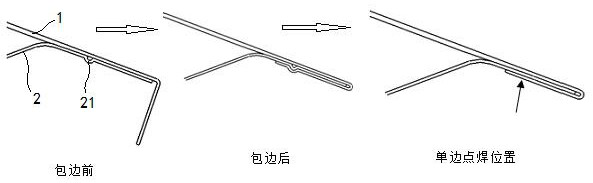

[0031] Figure 3 to Figure 8 It shows a method for improving the quality of one-side spot welding of the cover part hemming and the specific implementation of the one-side spot welding convex mold of the present invention. Figure 3 to Figure 4 It is a schematic diagram of wrapping and unilateral spot welding of body panels in this embodiment; Figure 5 to Figure 8 It is a structural schematic diagram of a single-side spot welding convex mold in this embodiment.

[0032] Such as image 3 and Figure 4 As shown, the method for improving the unilateral spot welding quality of cover hemming in the present embodiment comprises the following steps:

[0033] Step 1, using a unilateral spot welding convex hull mold, adding a convex hull 21 to the unilateral spot welding position of the inner panel 2, and the convex hull 21 on the inner panel 2 protrudes toward the inner side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com