Upper garment top fly manufacturing method

A production method and technology for tops, which are applied in the direction of sewing tools, clothing, clothing, etc., can solve problems such as dislocation of left and right front pieces, and achieve the effects of avoiding dislocation, high accuracy and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

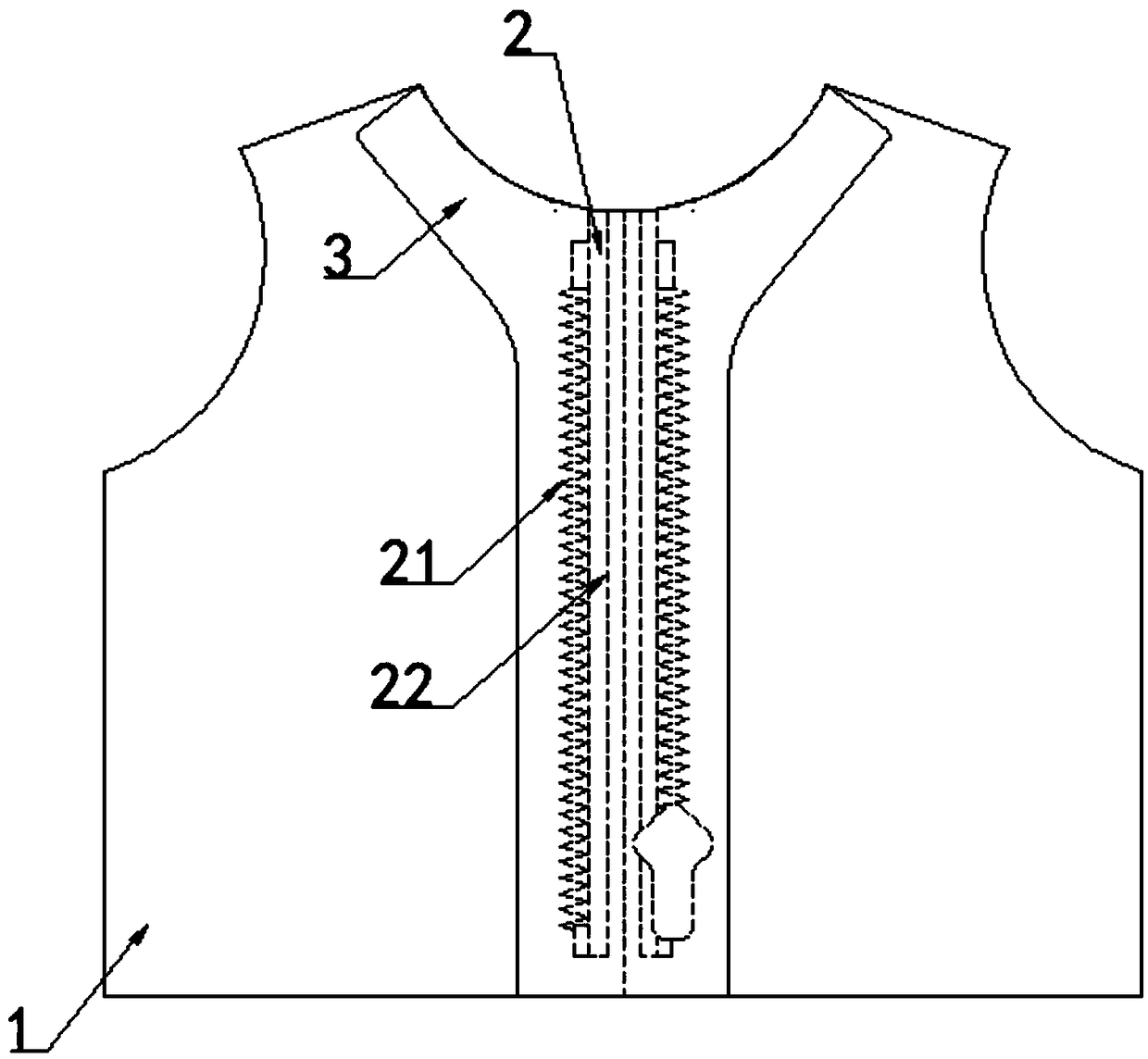

[0037] Such as Figure 1 to Figure 6 As shown, it is embodiment 1 provided by the present invention, and this embodiment is a method for making a jacket placket, comprising the following steps:

[0038] 1. Board making, according to the style and size of the jacket, make a sample of the entire front piece. During the board making process, reserve all the margin required for installing the left and right zippers and sewing the left and right front pieces at the center line of the sample of the front piece; For loose fabrics, the margin required for the left and right front seams should also be reserved.

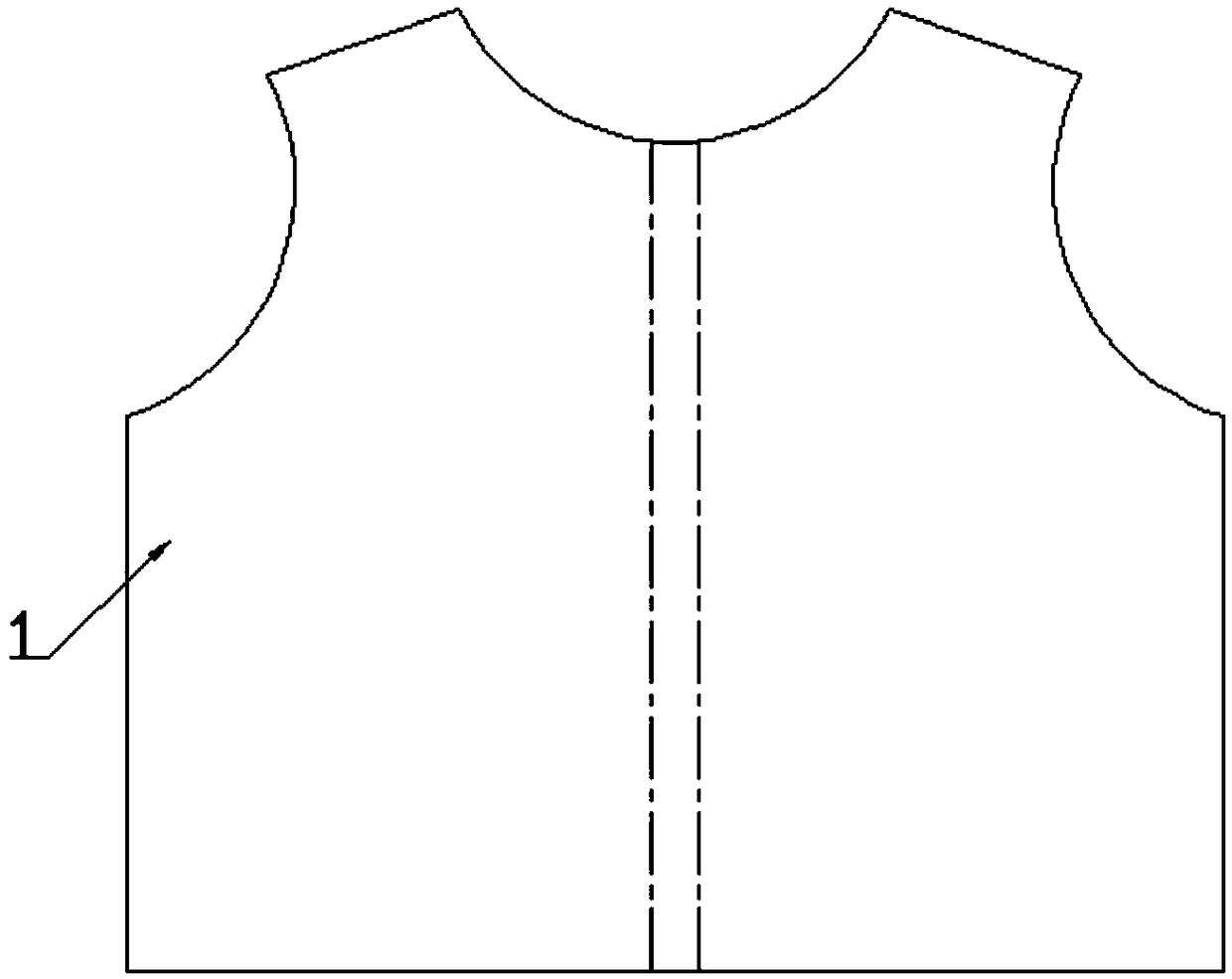

[0039] 2. Cut the material. Check the relative position between the pattern on the fabric and the sample. After placing the sample, the cutter will cut according to the sample, and cut out the front piece of fabric from the entire piece of fabric. The fabric cut out in the blanking step is as follows: figure 1 shown.

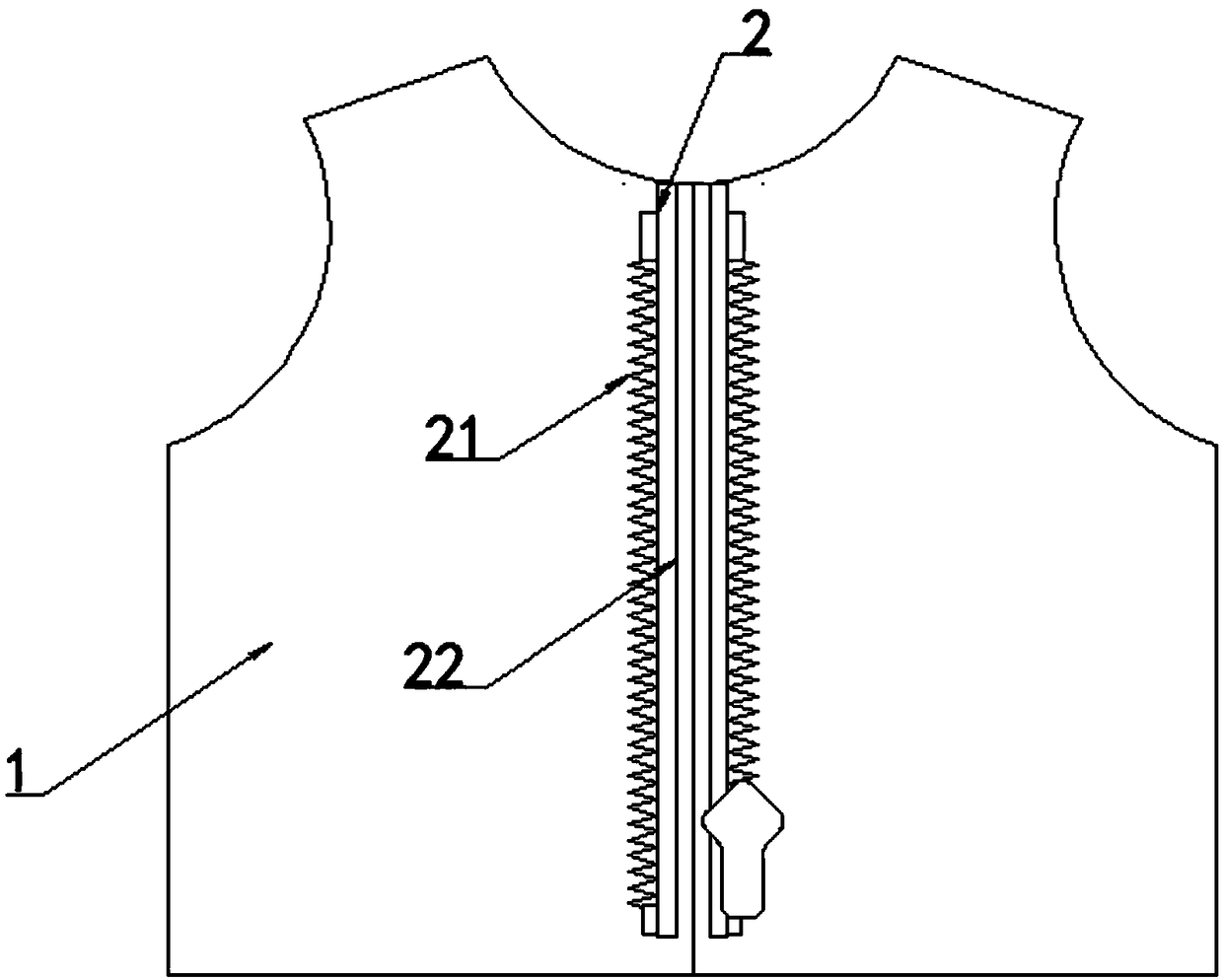

[0040] 3, on the zipper, such as figure 2 As shown, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com