Assembly tooling for annular net cabinet

A technology for assembling tooling and ring network cabinets, which is applied to assembly machines, workbenches, manufacturing tools, etc., can solve the problems of inability to realize the rotating production line of the air box, unstable support of the air box, and unfavorable assembly efficiency of the ring network cabinet, so as to avoid The effect of reducing operating efficiency, avoiding inconvenient operation, and avoiding waste of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

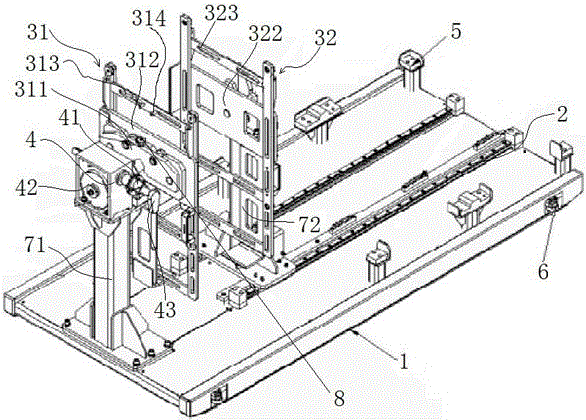

[0019] Embodiment of assembly tooling for ring main unit:

[0020] The specific structure of the assembly tooling for the ring network cabinet is as follows: figure 1 As shown, it includes a base 1 and a stand arranged on the base 1. The stand includes a front column 71 and a rear column 72 which are fixedly arranged on the base 1 and arranged at intervals along the front-to-back direction, and are respectively rotatably mounted on the front column 71 and the rear column. The front swivel clamp 31 and the rear swivel clamp 32 on the column 72 . The front column 71 is also provided with a drive mechanism 4 for driving the front rotary fixture 31 to rotate. The front rotary fixture 31 is an active rotary fixture, and the rear rotary fixture 32 is a driven rotary fixture that is driven to rotate by an air box installed between the front and rear rotary fixtures. . The base 1 extends along the front-to-back direction, and two racks 2 extending along the front-to-back direction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com