Automobile battery box air tightness automatic detection device

An automatic detection and automotive battery technology, which can be used in the use of liquid/vacuum for liquid tightness measurement, and by measuring the acceleration and deceleration rates of fluids. Time-consuming and other problems, to achieve the effect of saving material costs and labor costs, high detection accuracy and stability, and reducing the generation rate of waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

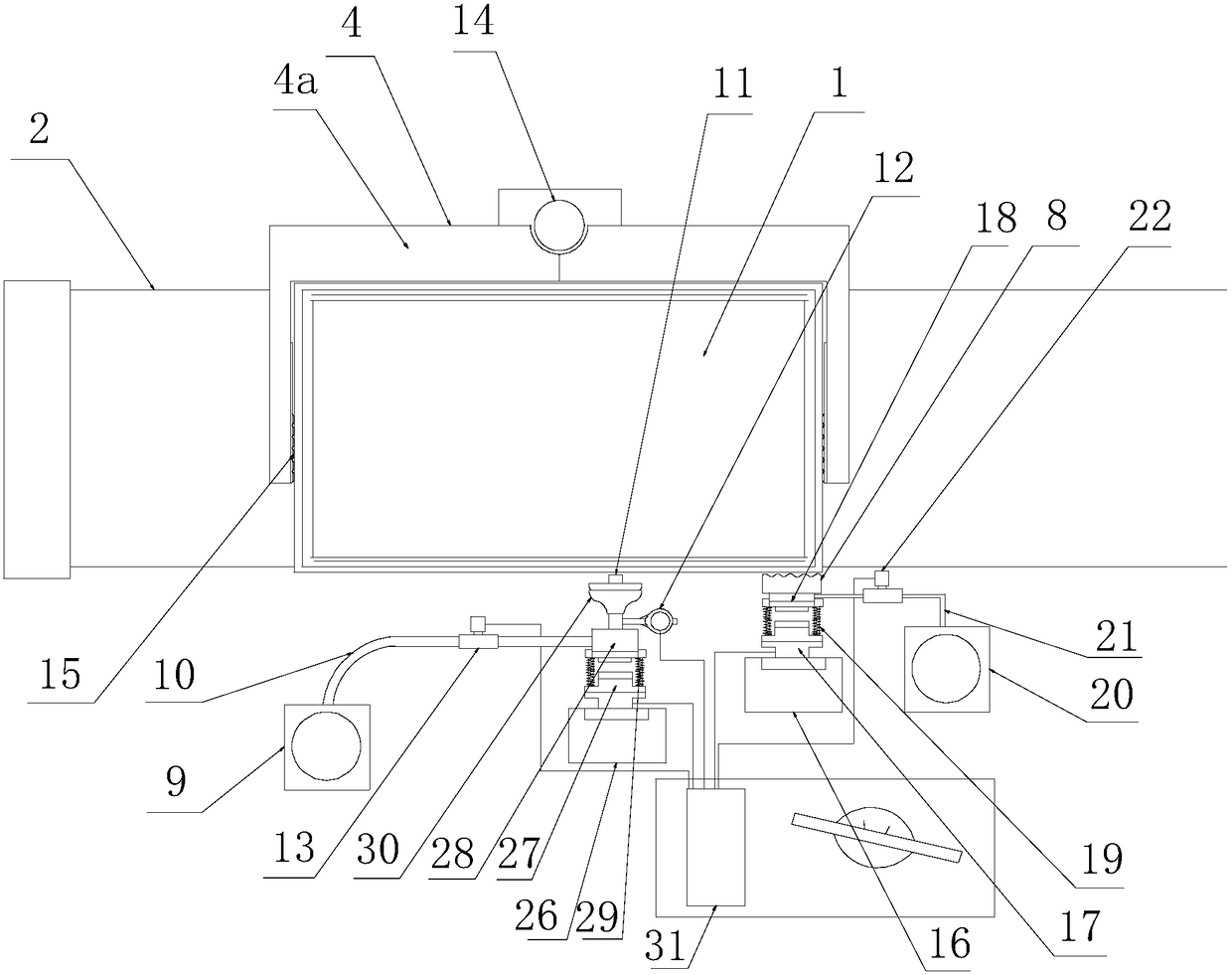

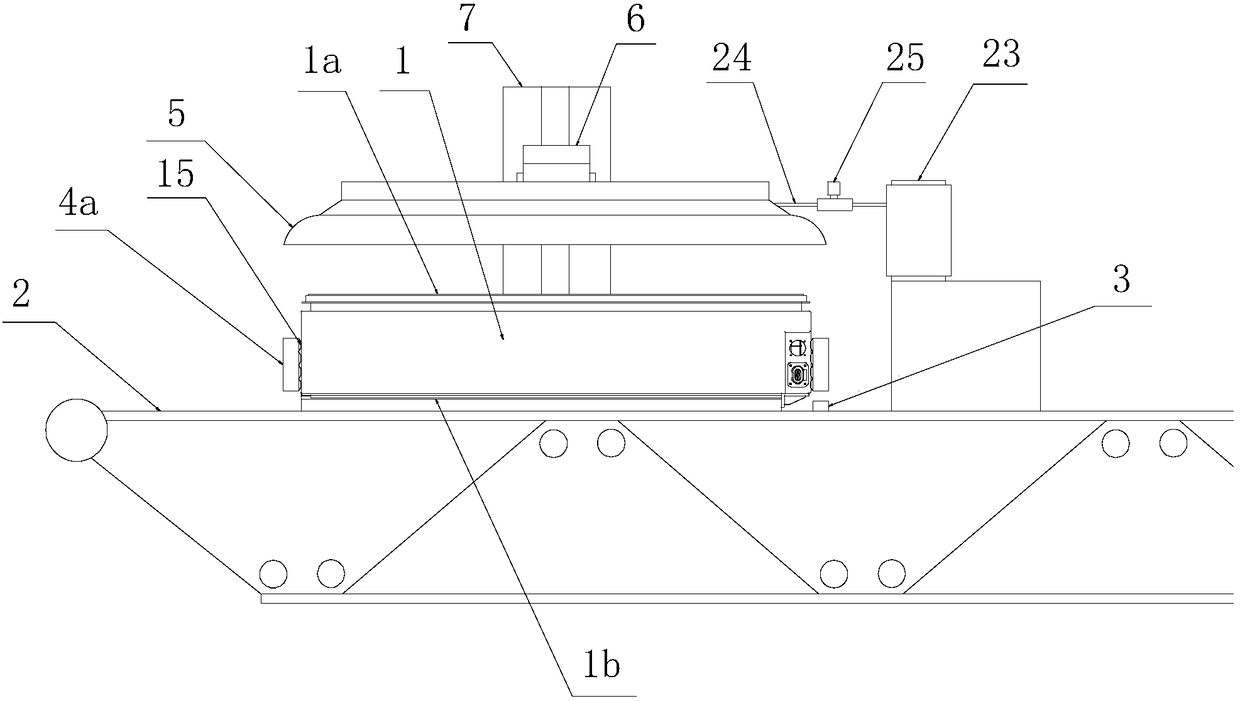

[0041] Example: Combine figure 1 with figure 2 As shown, it is a specific embodiment of the airtightness automatic detection device of the automobile battery box of the present invention, which has a line body 2 for transporting the automobile battery box 1, an airtightness detection station located beside the line body 2, and used for The brake line body 2 is controlled by a controller 31 that stops the car battery box 1 on the station and a position signal switch 3 that gives the controller 31 a braking signal. The position signal switch 3 described in this embodiment is an infrared position signal switch located on one side of the line body 2. For details, see figure 2 shown.

[0042] The air tightness detection station is provided with the following mechanism:

[0043] Automotive battery box positioning mechanism: it has a mechanical pliers clamping mechanism 4 and a driving device for driving the mechanism to open and close, and the driving device is electrically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com