Patents

Literature

163results about How to "Speed up delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

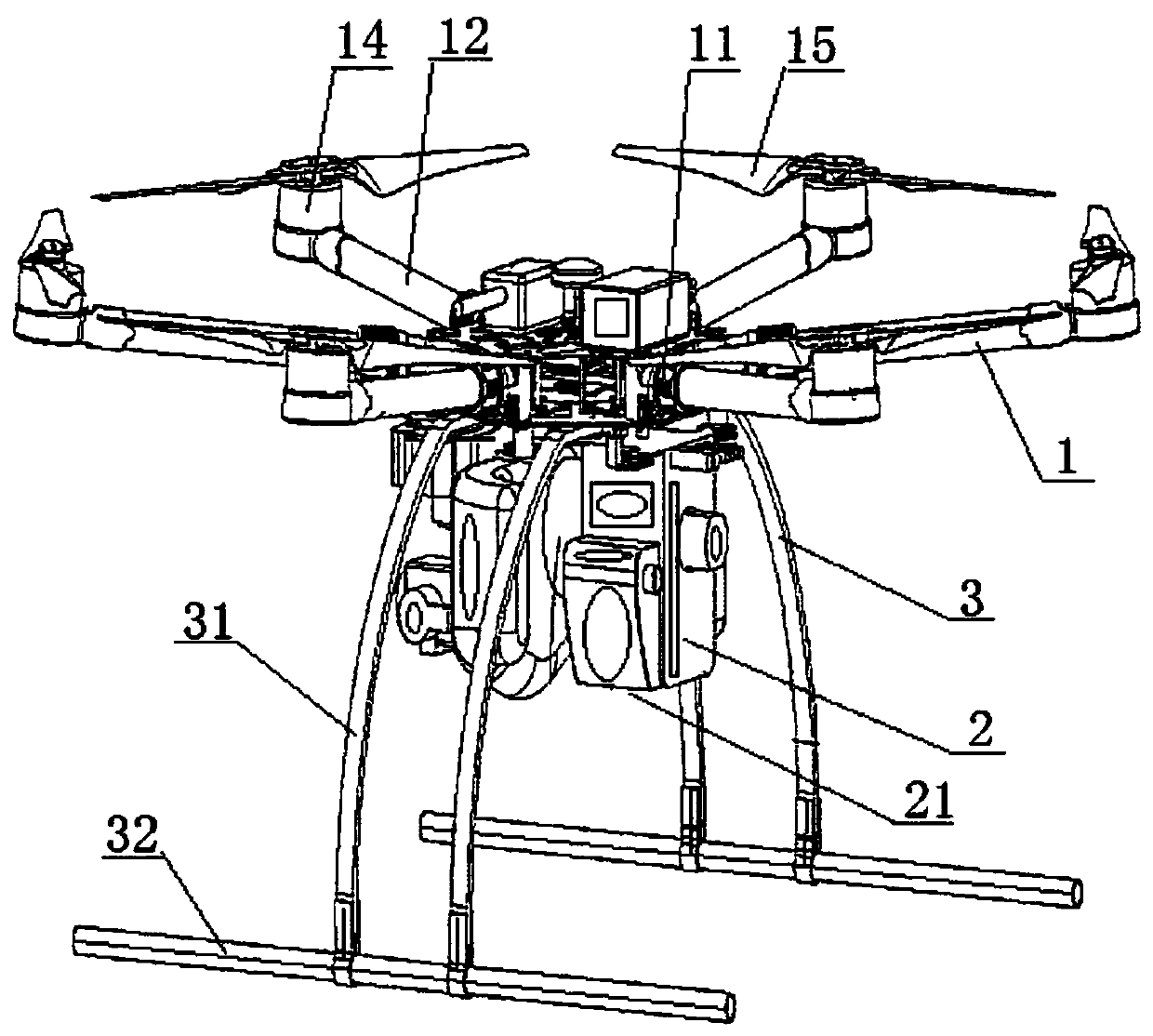

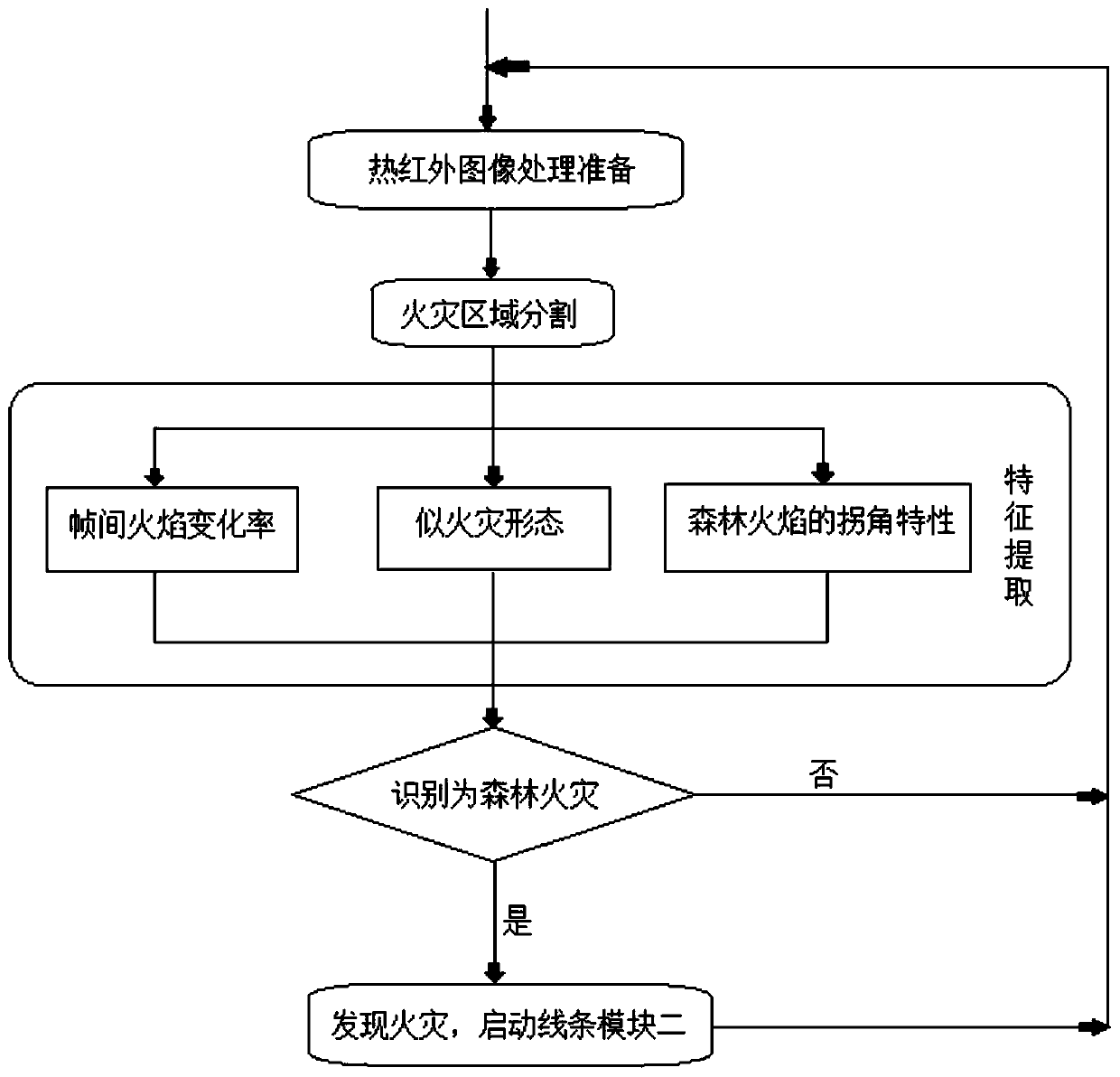

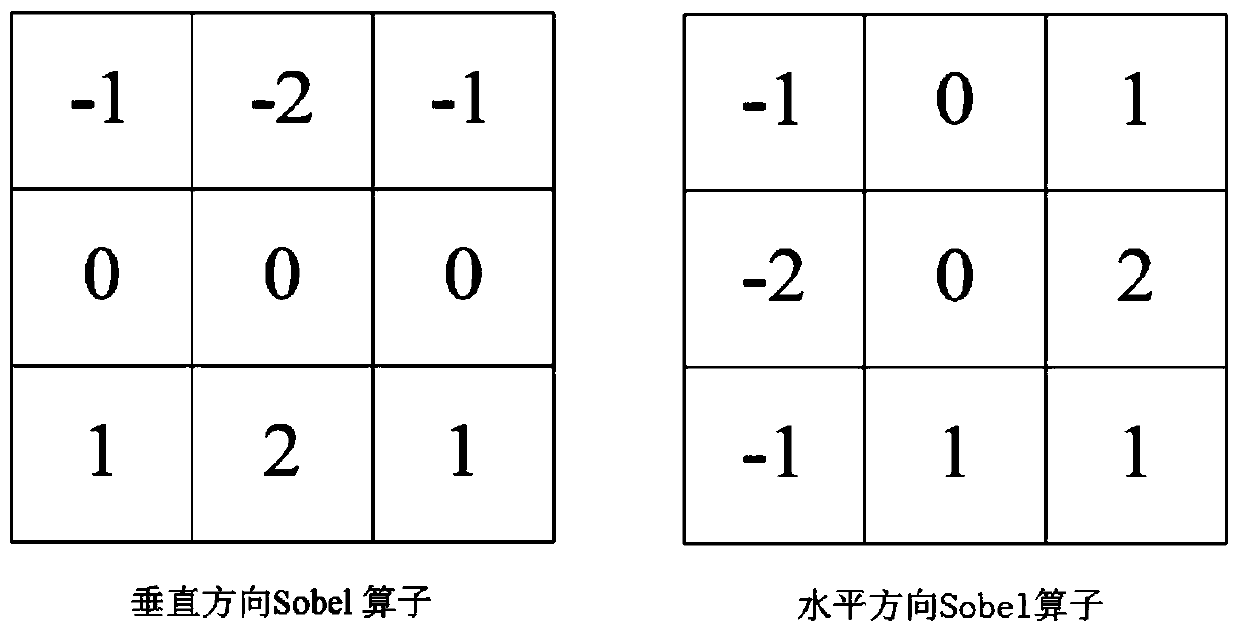

Unmanned aerial vehicle cruising and monitoring system for forest fire

PendingCN110047241AReduce weightExtended flight timeForest fire alarmsCharacter and pattern recognitionEngineeringFlight time

The invention provides an unmanned aerial vehicle cruising and monitoring system for forest fire. The weight of the unmanned aerial vehicle is reduced, flight time is prolonged, an unmanned aerial vehicle cruising range is enlarged, route planning is carried out for fire monitoring, and an unmanned aerial vehicle flight control system is combined with a geographic information system. The route planning not only guarantees monitoring quality and monitoring full coverage but also considers the hardware parameters and the flight safety of the cruising unmanned aerial vehicle, a rotary head carries a thermal infrared imager and a colorful high-definition camera, the thermal infrared characteristics of the image of the forest fire are fully utilized, and an automatic monitoring and identification method for forest fire information is designed. Even if the forest fire monitoring distance of the unmanned aerial vehicle is long, fire characteristics can be accurately captured. A colorful high-definition image is compressed and transmitted back to a ground command post, a high-definition fire video image can be quickly transmitted to the ground, a fire position can be accurately reported, so that convenience is brought to the ground command post in accurately judging a fire situation and organizing people to fight the fire, and precious fire-fighting time is saved.

Owner:刘秀萍

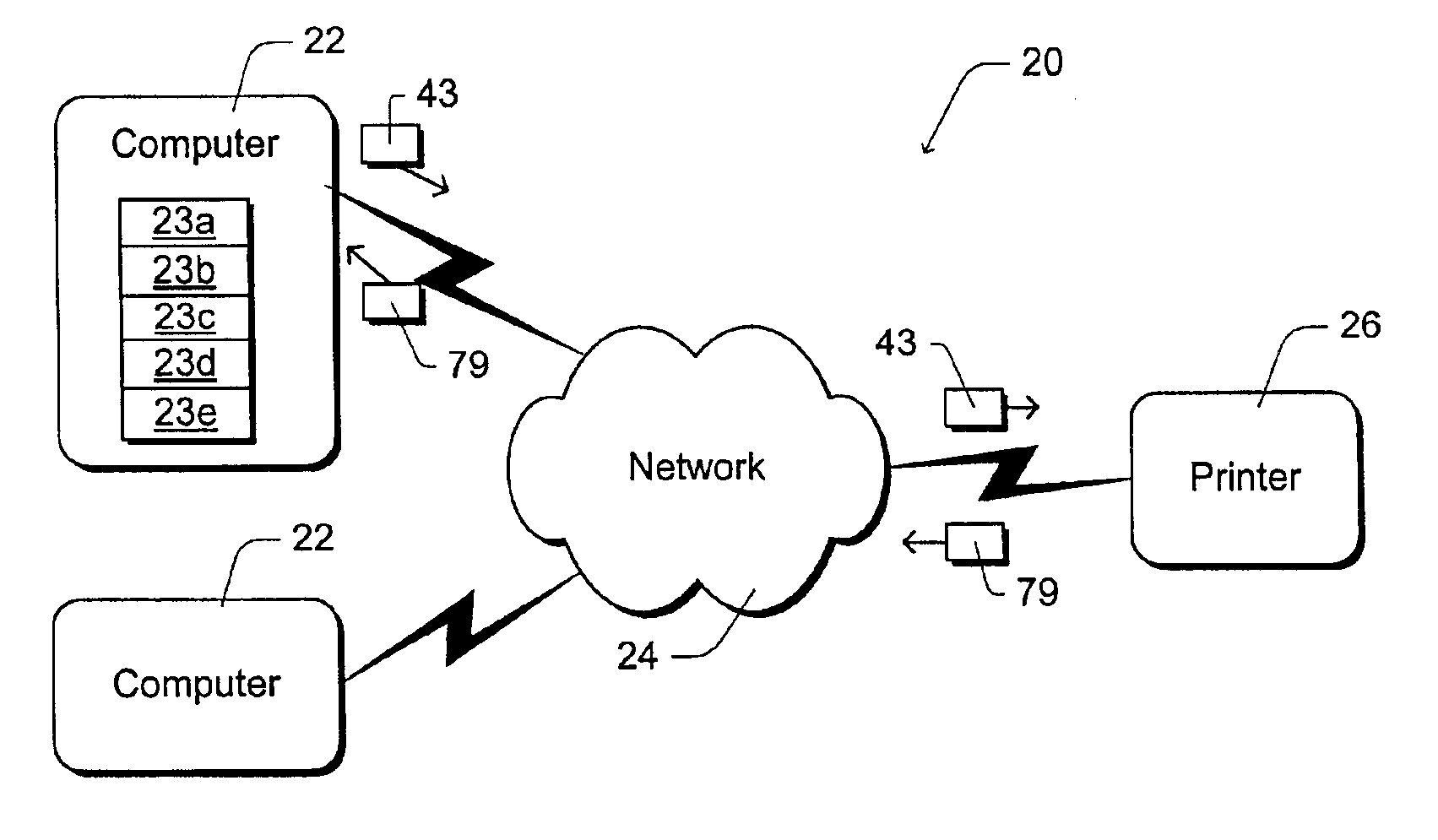

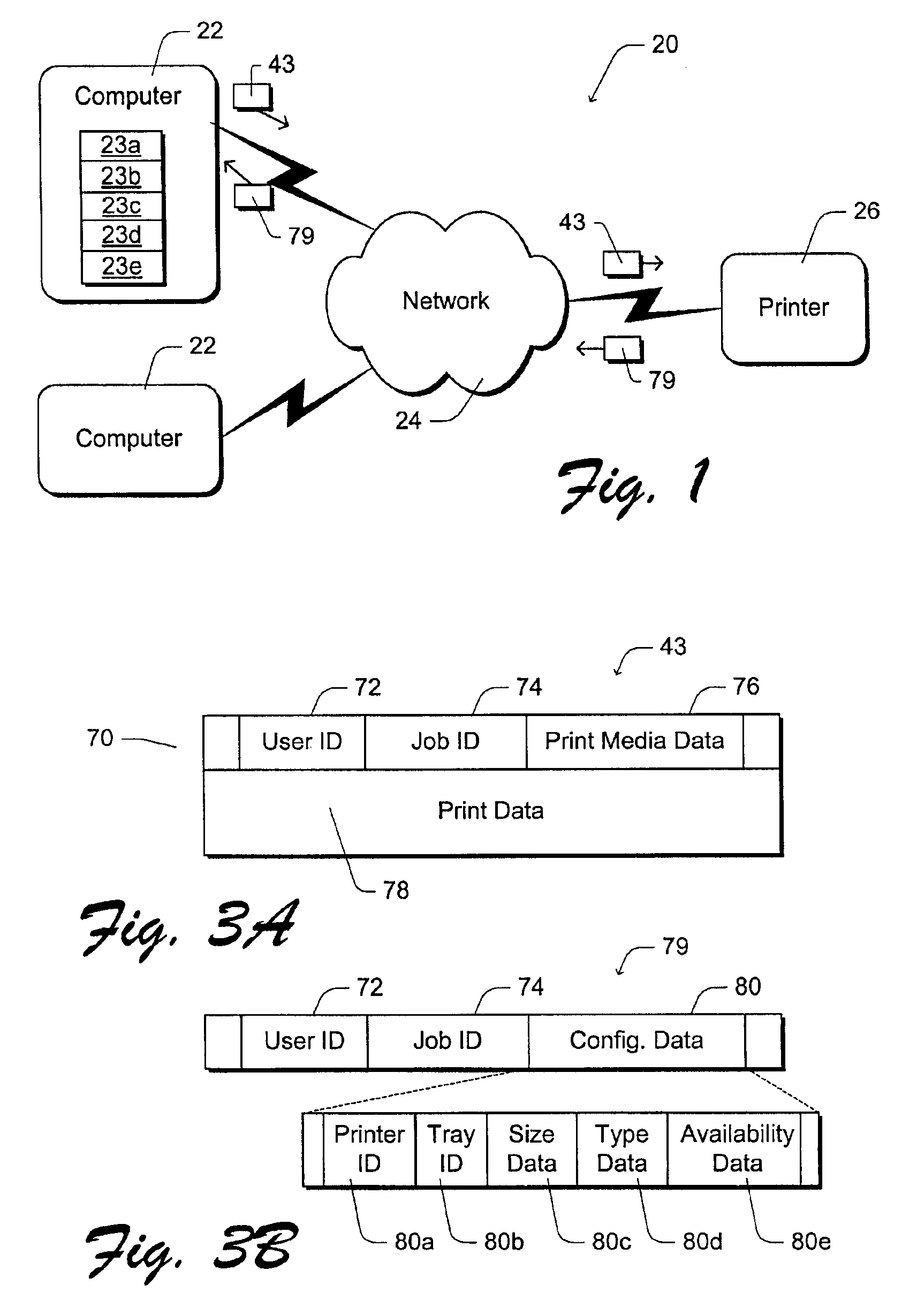

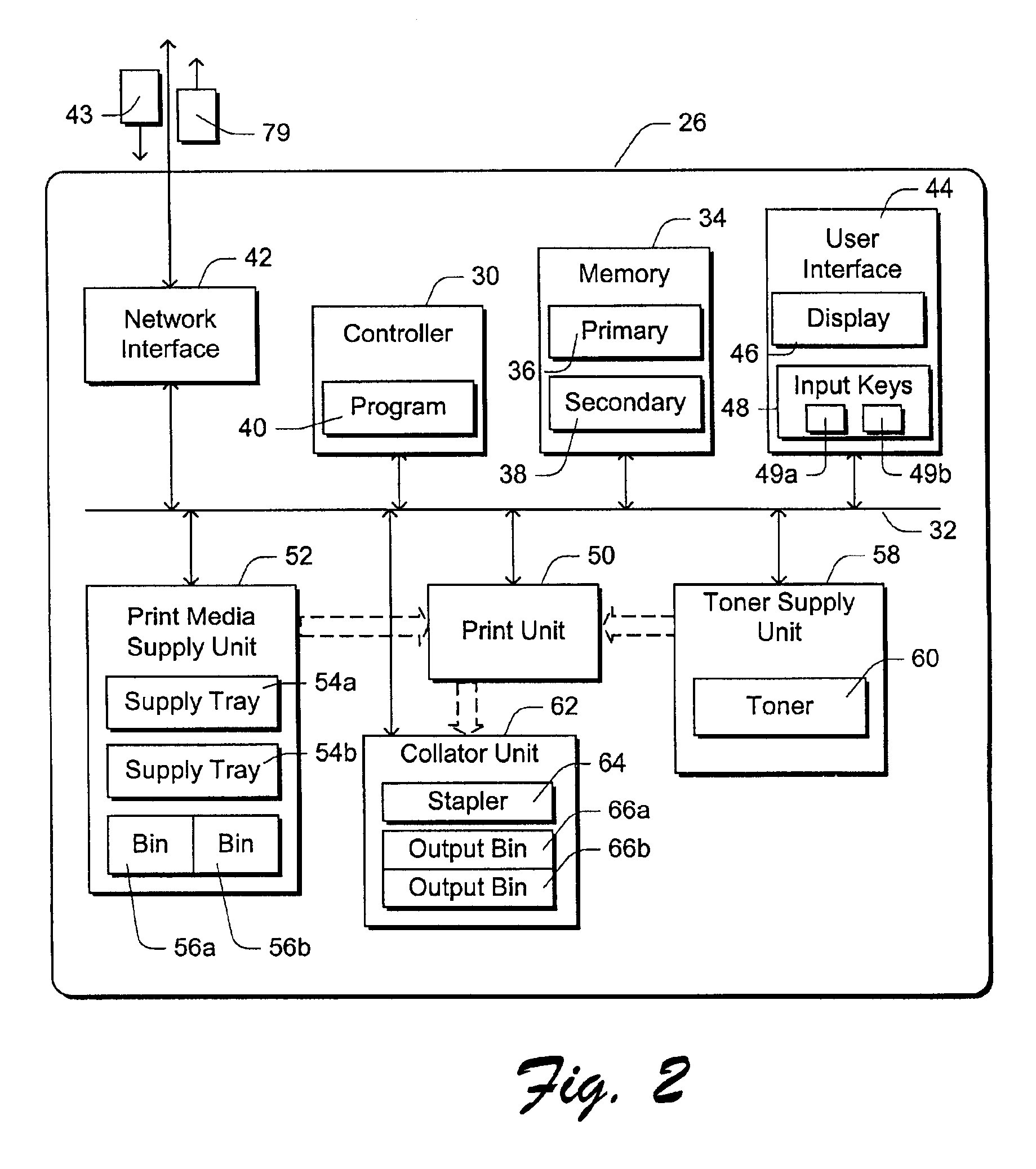

Methods and arrangement for providing and using printer configuration status information

InactiveUS6850337B1Improve productivitySpeed up deliveryVisual presentation using printersDigital output to print unitsPrint mediaGraphics

Methods and arrangements are provided for use in a printer and associated computer(s). The printer is configured to periodically and / or automatically detect when changes are being made to a print media supply tray and output / display the current configuration of the print media supply tray for use by the user and / or programs running on the computer. The current configuration of the print tray is determined using detectable mechanisms that are either hardware and / or software implemented. The configuration of the supply tray is displayed to the user via the printer display, a tray-mounted display, and / or though a graphical user interface (GUI) on the computer. The configuration is defined by at least the size and type of the print media associated with the supply tray.

Owner:HEWLETT PACKARD DEV CO LP

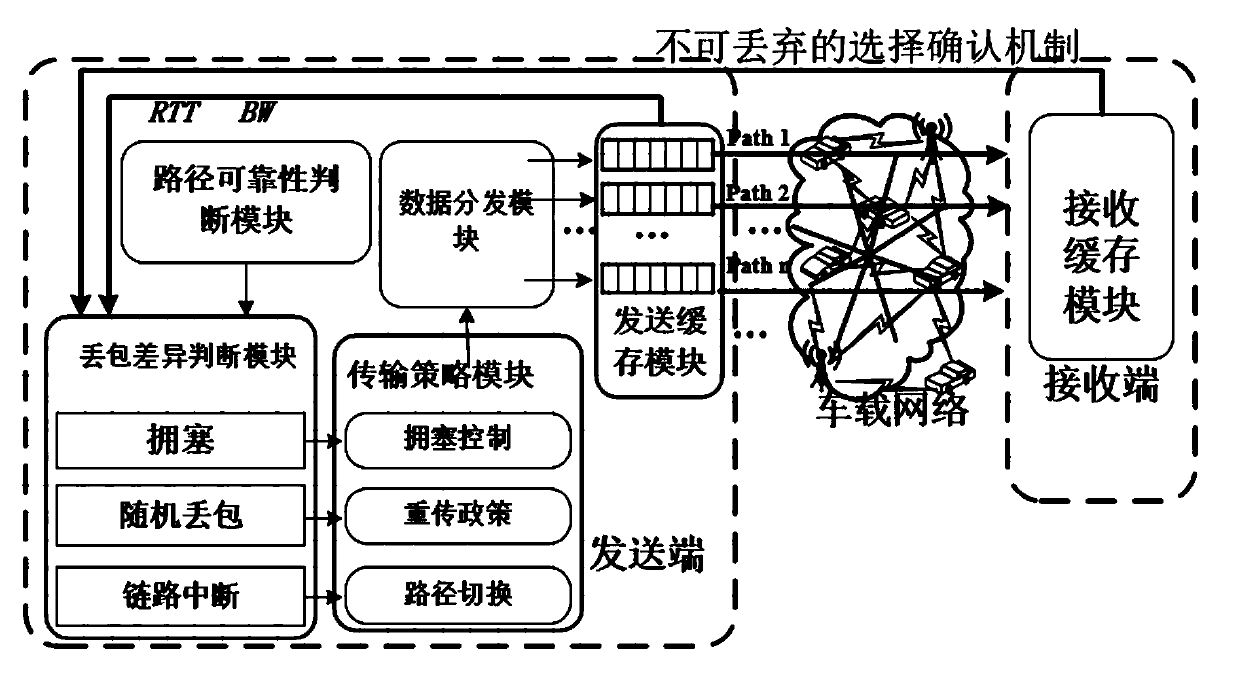

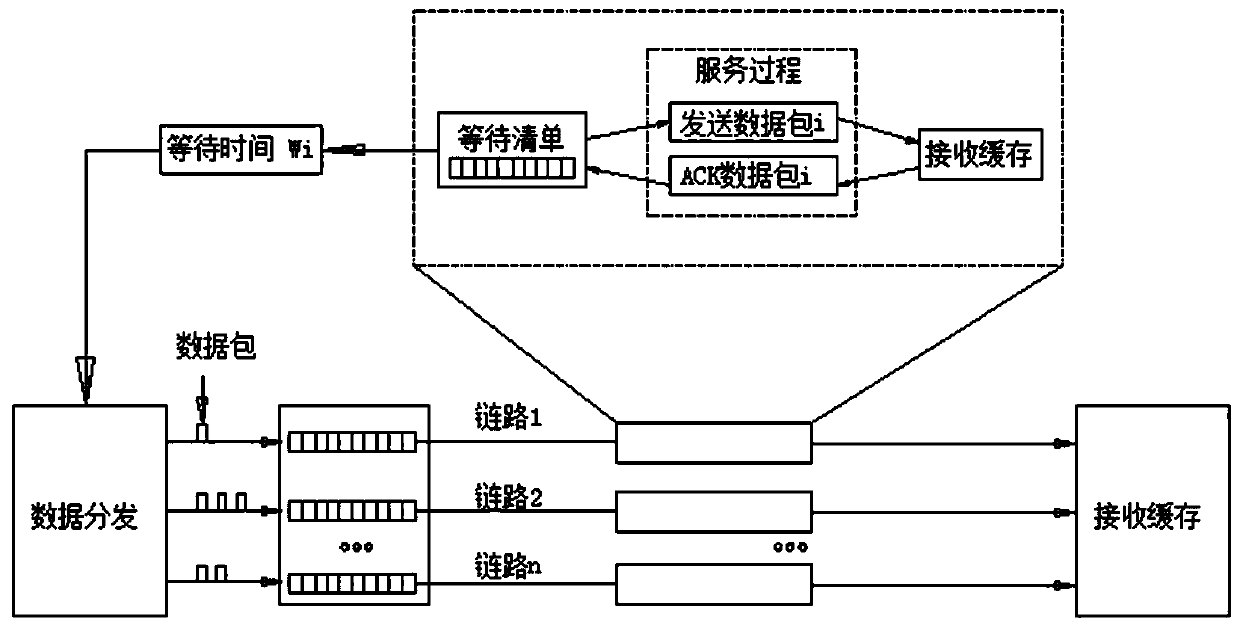

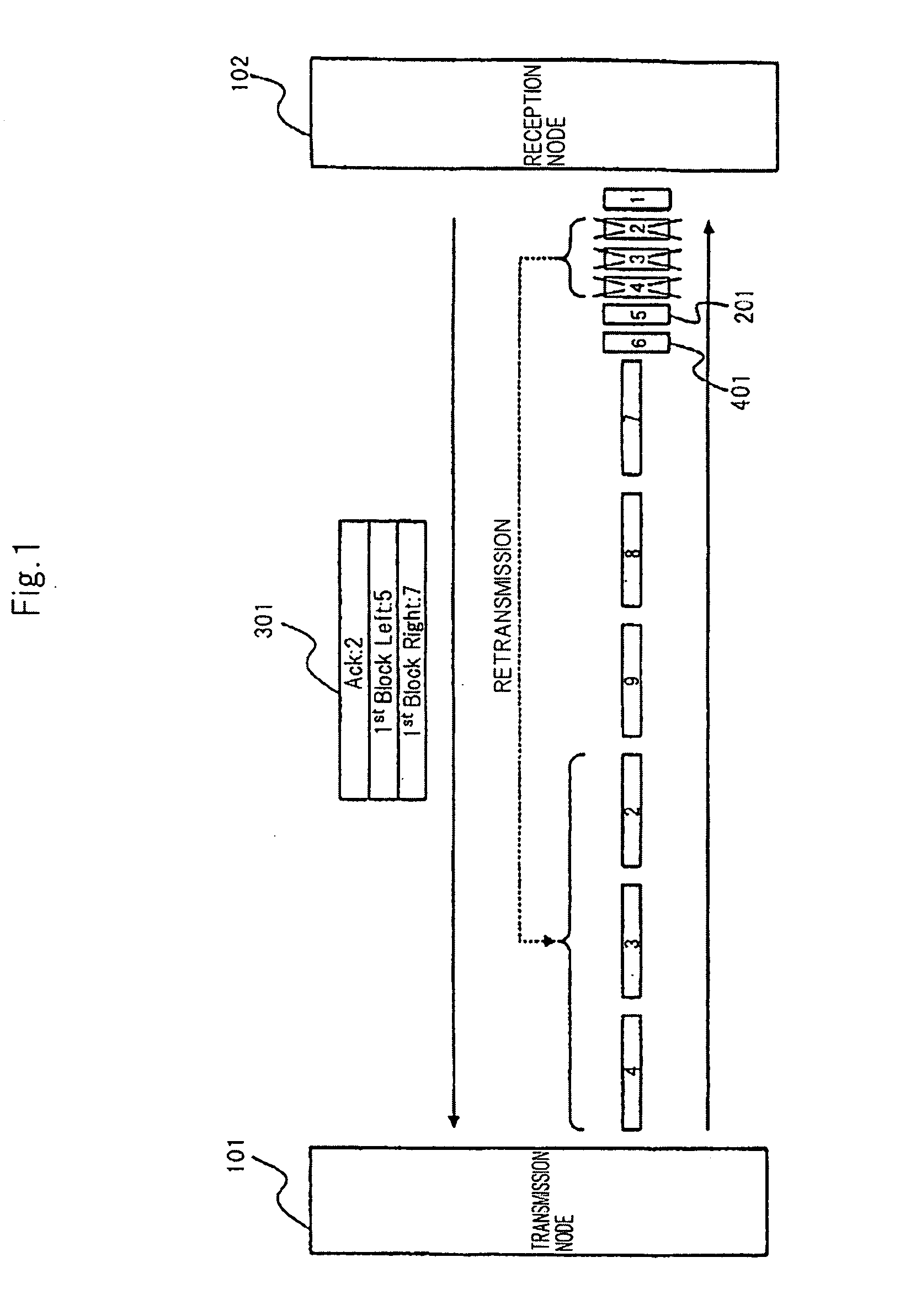

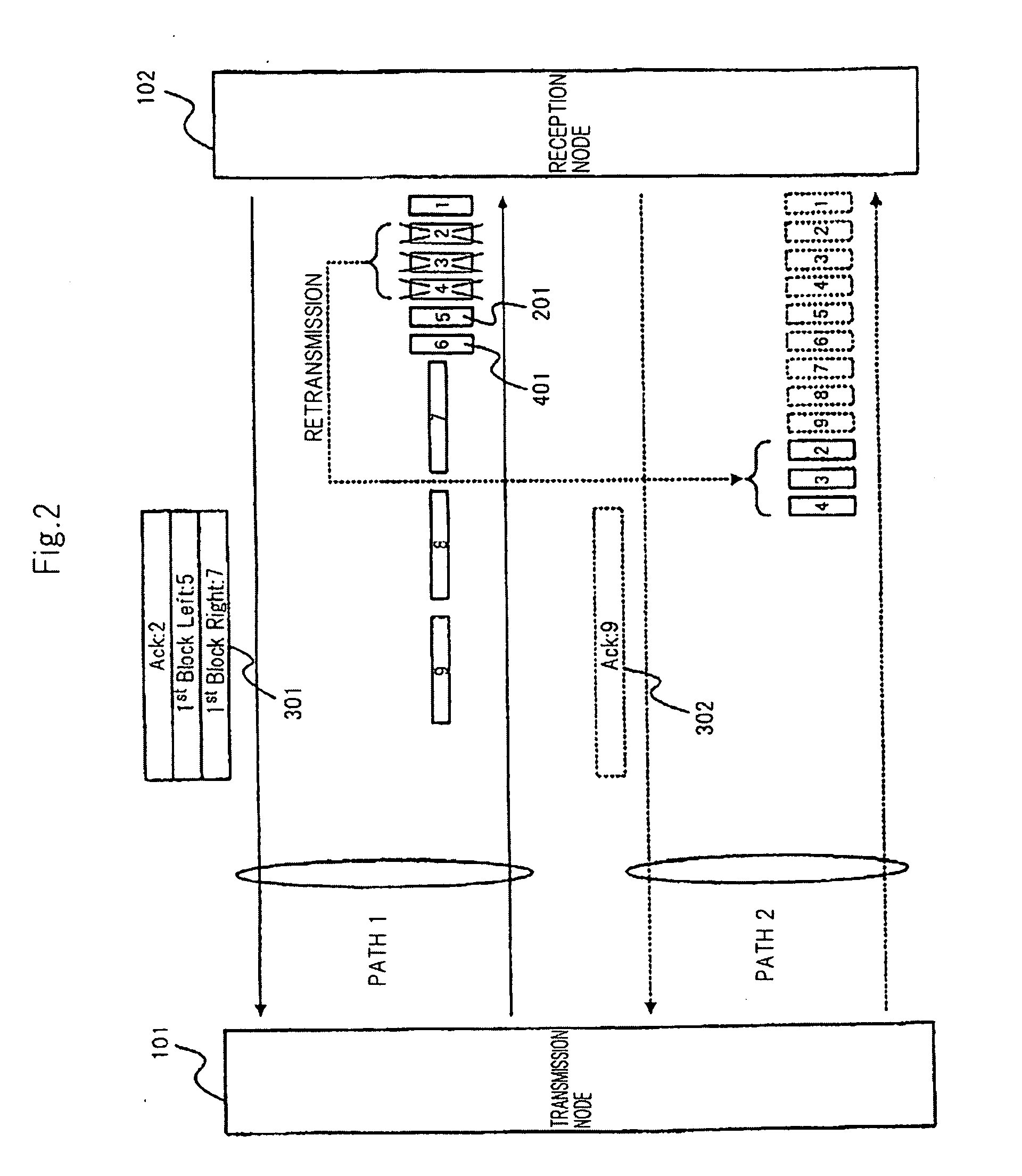

Multipath data transmission method

ActiveCN107682886ASpeed up deliveryImprove experienceError prevention/detection by using return channelNetwork traffic/resource managementPacket lossTheory model

The invention provides a multipath data transmission method comprising the steps that a queuing theory model is established for each path, the path quality of each sub-path is assessed and the data are dynamically allocated to all the paths to be transmitted according to the path quality; and the link utilization rate of the path is acquired, and packet loss distinguishing is performed according to the relationship between the link utilization rate and the preset link congestion reference threshold. Streaming media data transmission is performed by the method so that the transmission rate canbe obviously enhanced, the transmission delay can be greatly reduced and the user experience can be greatly enhanced.

Owner:BEIJING UNIV OF POSTS & TELECOMM

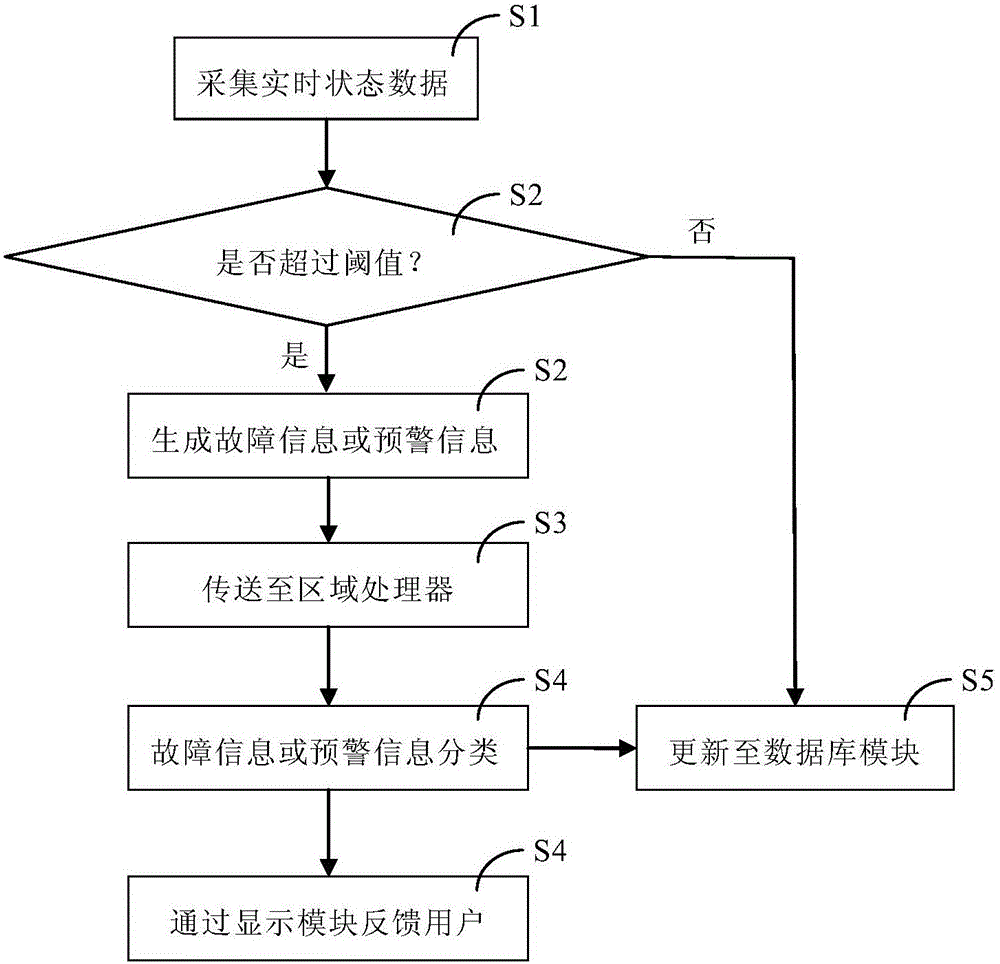

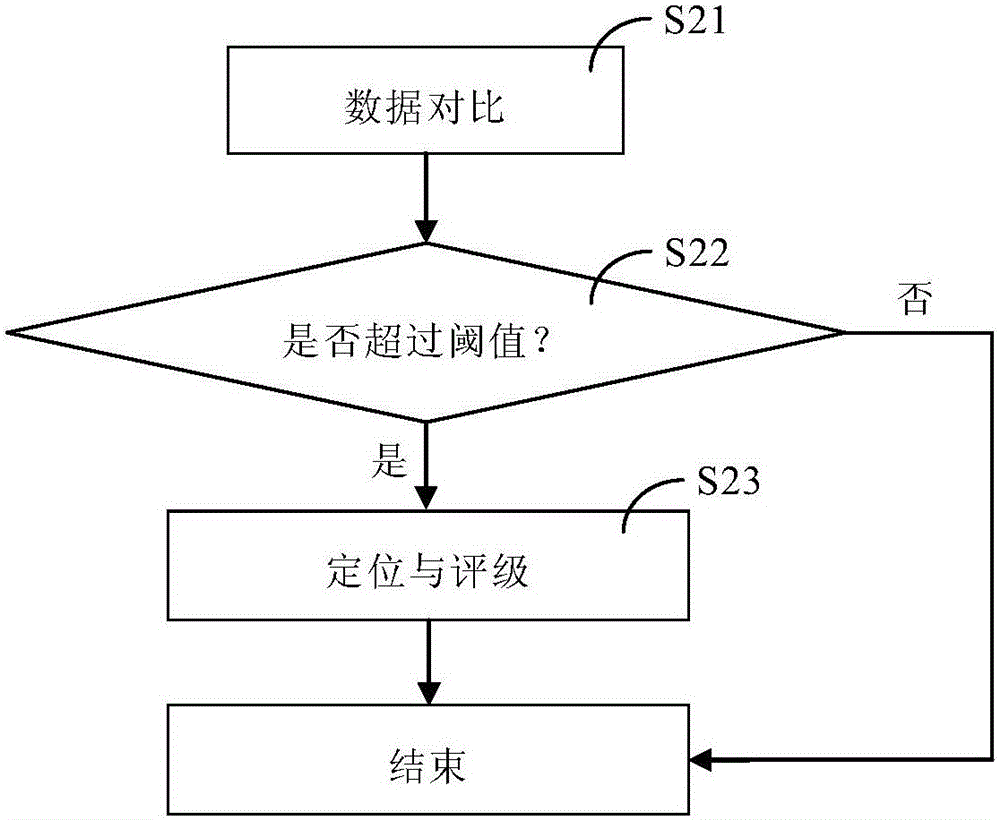

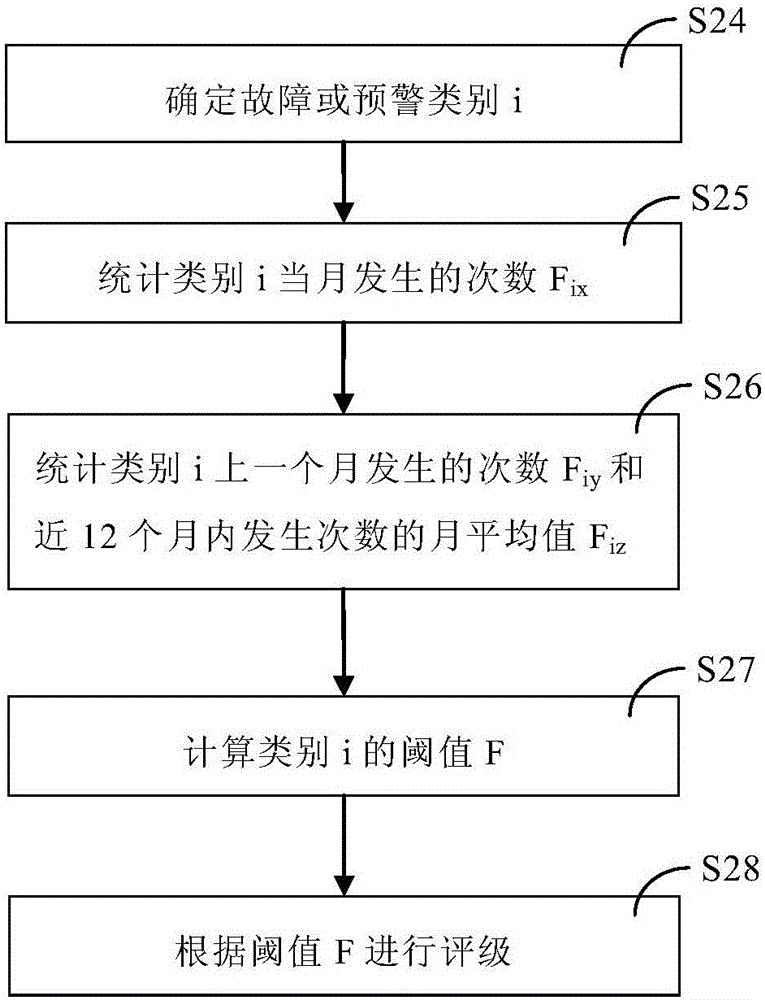

Method and system for track traffic fault monitoring and intelligent warning

ActiveCN107433962ASpeed up deliveryQuick confirmationRailway signalling and safetyClassified informationData acquisition

The invention discloses a method and system for track traffic fault monitoring and intelligent warning. The system includes a data acquisition module, a data comparison module, a data transmission module, regional processor modules, a central processor module, a database module and a display module, wherein the data acquisition module is installed on the data acquisition device and used for collecting real-time status data, comparing the collected data with corresponding data of the database module through the data comparison module, generating fault information or early warning information and feeding back classified information, location information and rating information of faults or early warning through the display module to a user; meanwhile the central processor module can intelligently update the database module by aggregating the fault information and warning information transmitted by the regional processor modules. According to the system for track traffic fault monitoring and intelligent warning, the category and the address of the faults can be determined quickly and accurately, and early warning of the foreseeable faults can be achieved in advance.

Owner:西藏谦诚信息科技有限公司

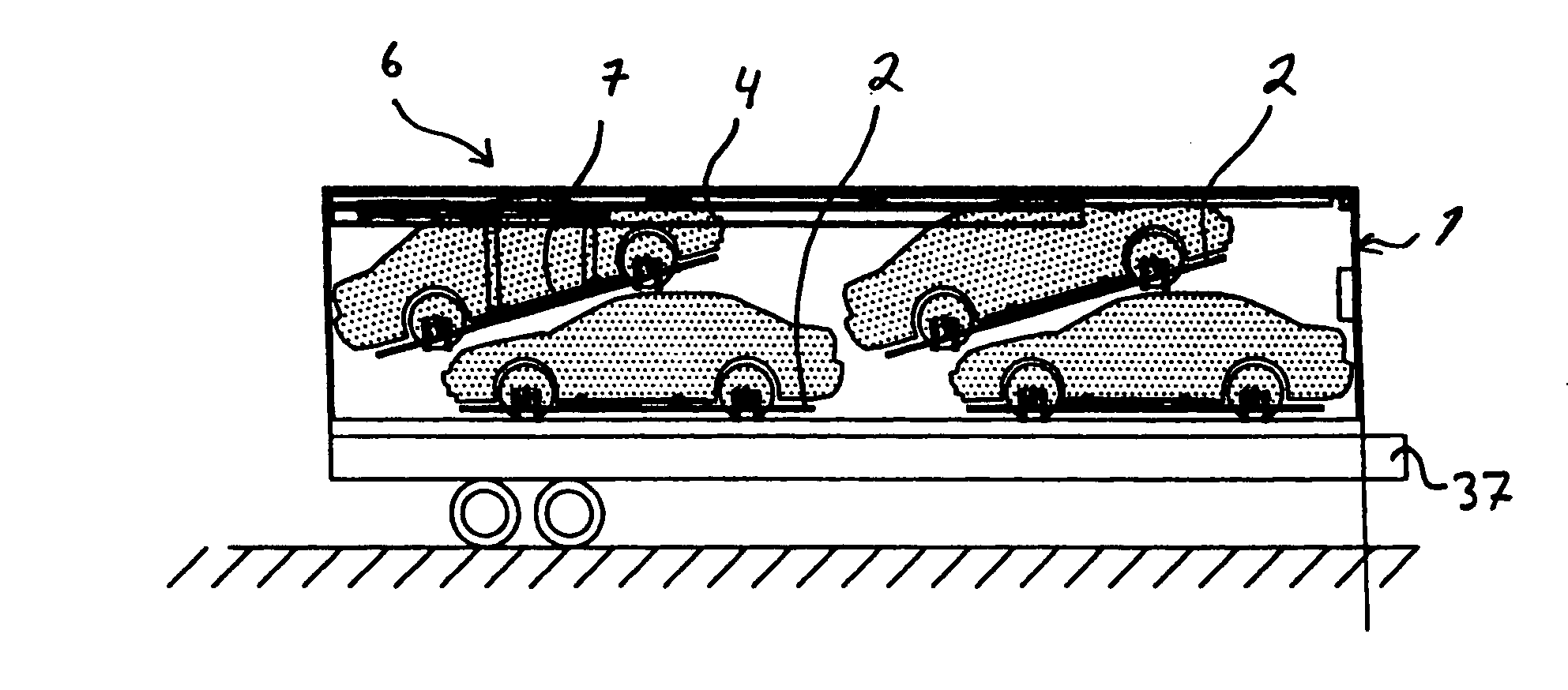

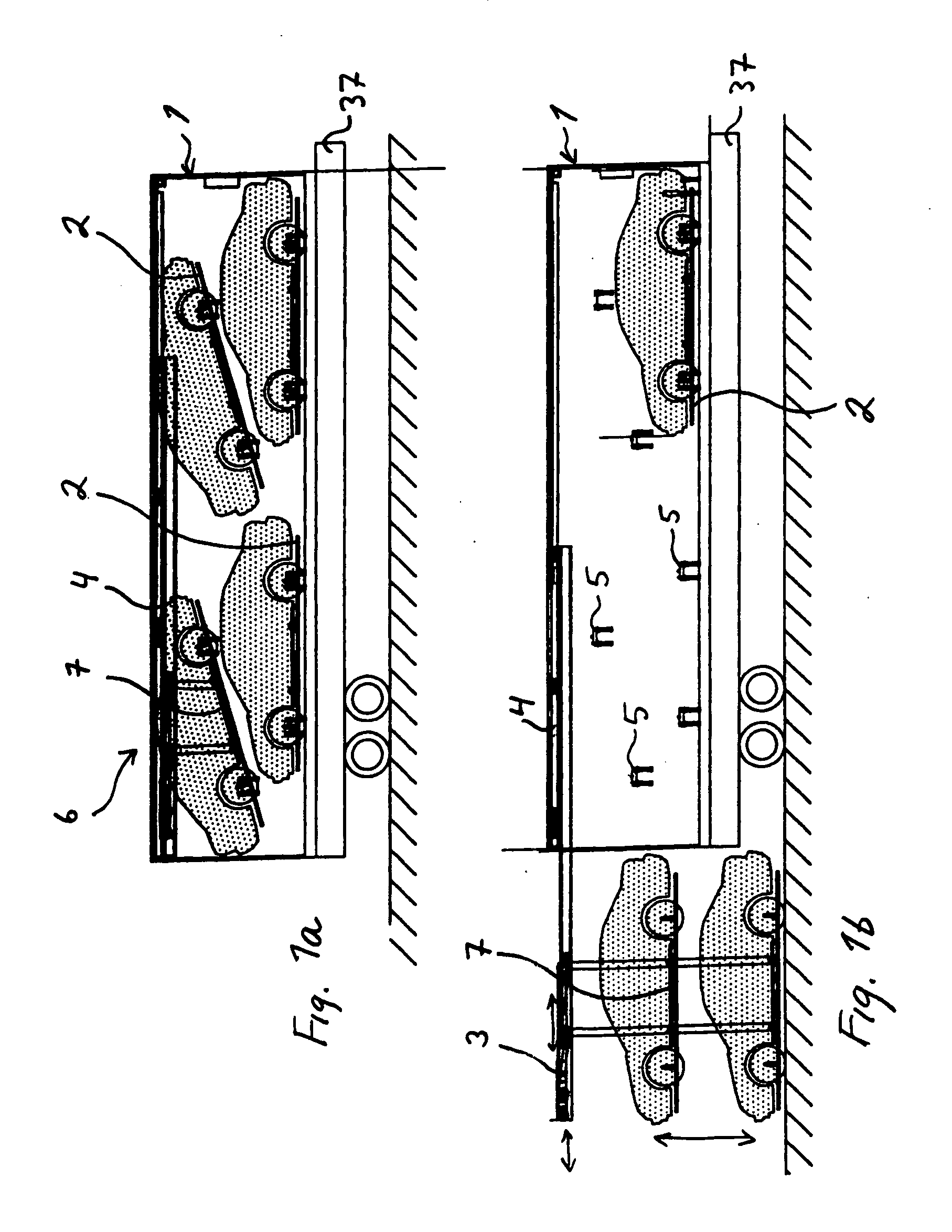

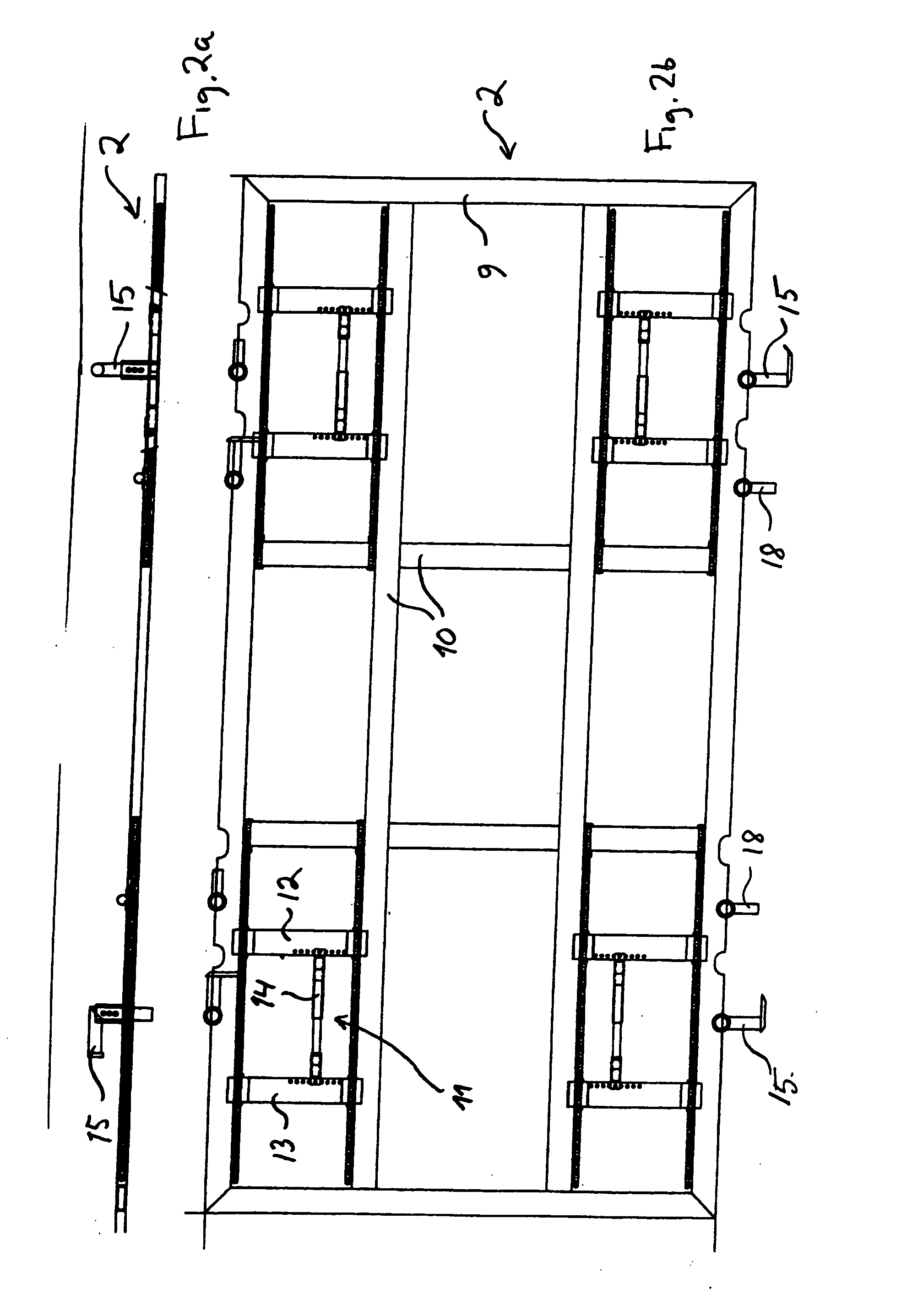

Transport unit, a transport system and a method

InactiveUS20070020059A1Decrease of equityImprove delivery securityConveyorsItem transportation vehiclesTransport systemCargo container

A transport unit for transporting cargo, which cargo is a car, a car body or other cargo. A transport unit comprises a lift and transfer apparatus, which is placed inside said transport unit, arranged during the loading of the transport unit to extend outside the transport unit, to grip to a transfer platform, on top of which the cargo is placed, to lift said transfer platform that is outside the transport unit inside the transport unit, and to transfer the transfer platform to its place in the transport unit, as well as during the unloading of the transport unit to transfer the transfer platform outside the transport unit. In an embodiment the transport unit is a cargo container, and a trailer is used for transport in an embodiment. The system utilizing cargo containers enables transporting cars from the assembly plant directly to the retail dealer.

Owner:PERMAR

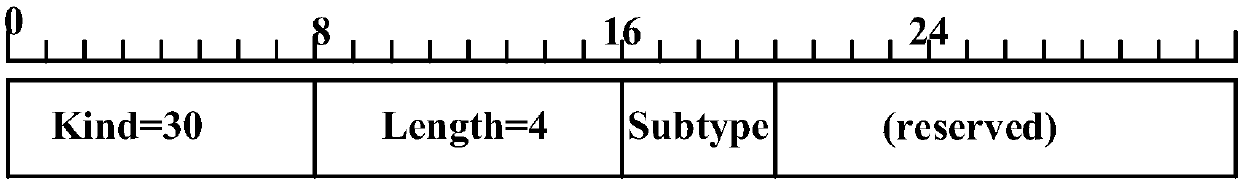

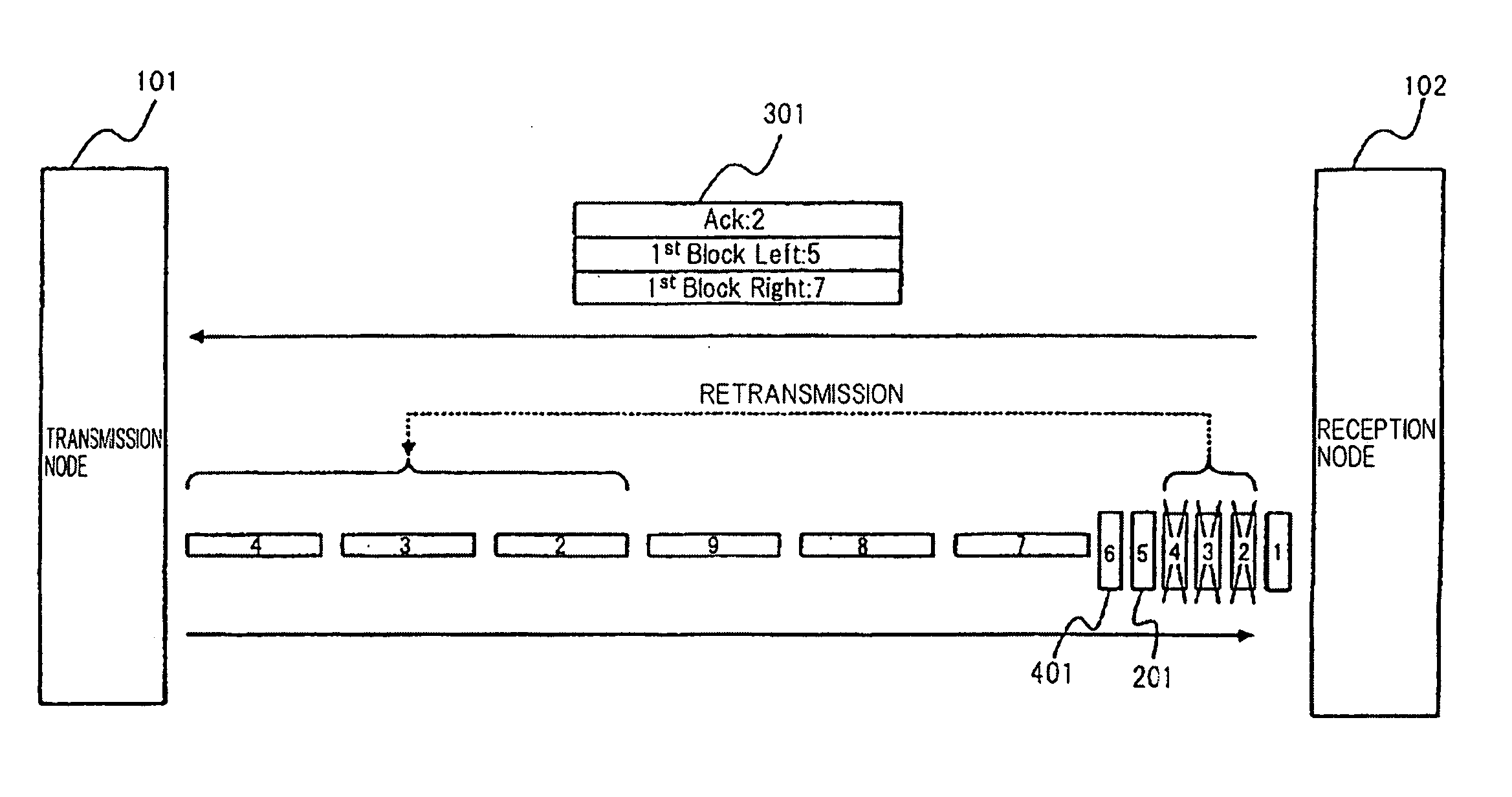

Packet recovery method, communication system, information processing device, and program

ActiveUS20100046520A1Reduce data volumePrevent redundant retransmissionsData switching by path configurationTransmission link error control systemRecovery methodInformation processing

A packet recovery method of the present invention is a packet recovery method upon loss of a plurality of packets transmitted from a first node 111 to second node 112 through a network in the order of sequence numbers assigned to each of said packets, wherein second node 112, upon detection of a loss of a packet transmitted from first node 111, transmits an acknowledgement message, including a sequence number of a packet whose receipt has been confirmed or whose loss has been detected and including information on the lost packet, to first node 111 through the network. Then, first node 111, upon receipt of the acknowledgement message from second node 112, assigns a sequence number that is different from that of any of the plurality of packets to a retransmission packet which is a packet to be retransmitted, and subsequently, transmits an acknowledgement-to-acknowledgement message attached to the retransmission packet through the network for notifying that the acknowledgement message has been received to second node 112.

Owner:NEC CORP

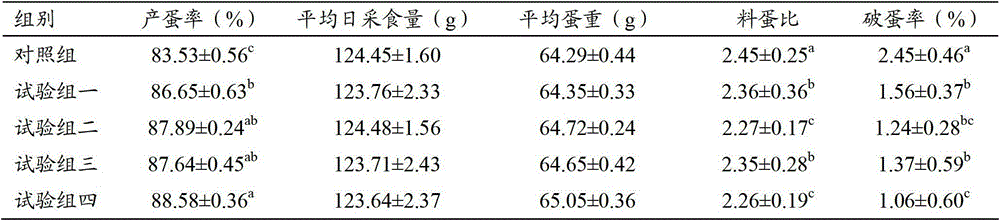

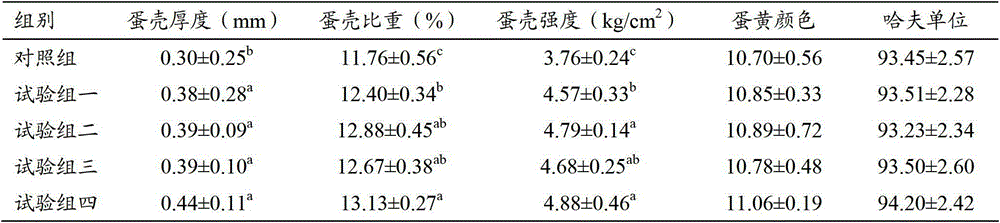

Forage for improving later-period production performance of laying hens and eggshell quality

ActiveCN103931908AIncrease egg productionImprove feed utilizationFood processingAnimal feeding stuffSodium bicarbonateAnimal Foraging

A forage for improving later-period production performance of laying hens and eggshell quality comprises, in parts by weight, 45-50 parts of corn, 10-15 parts of soybean meal, 8-12 parts of wheat, 5-10 parts of corn germ cake, 3-6 parts of alfalfa meal, 4-6 parts of calcium particles, 4-6 parts of brewer's grains, 3-5 parts of calcium powder, 2-4 parts of corn gluten meal, 0.5-1 part of calcium hydrogen phosphate, 0.1-0.2 part of bentonite, 0.2-0.4 part of plant grease, 0.0005-0.0008 part of betaine, 0.2-0.4 part of edible salt, 0.2-0.4 part of lysine, 0.1-0.2 part of composite vitamins, 0.1-0.2 part of choline, 0.1-0.2 part of composite trace elements, 0.1-0.2 part of sodium bicarbonate, 0.1-0.2 part of methionine and 0.002-0.006 part of phytase. The forage is capable of satisfying nutrition demands of laying hens at a later period, improving laying rate and eggshell thickness, and improving eggshell quality.

Owner:四川圣迪乐村生态食品股份有限公司

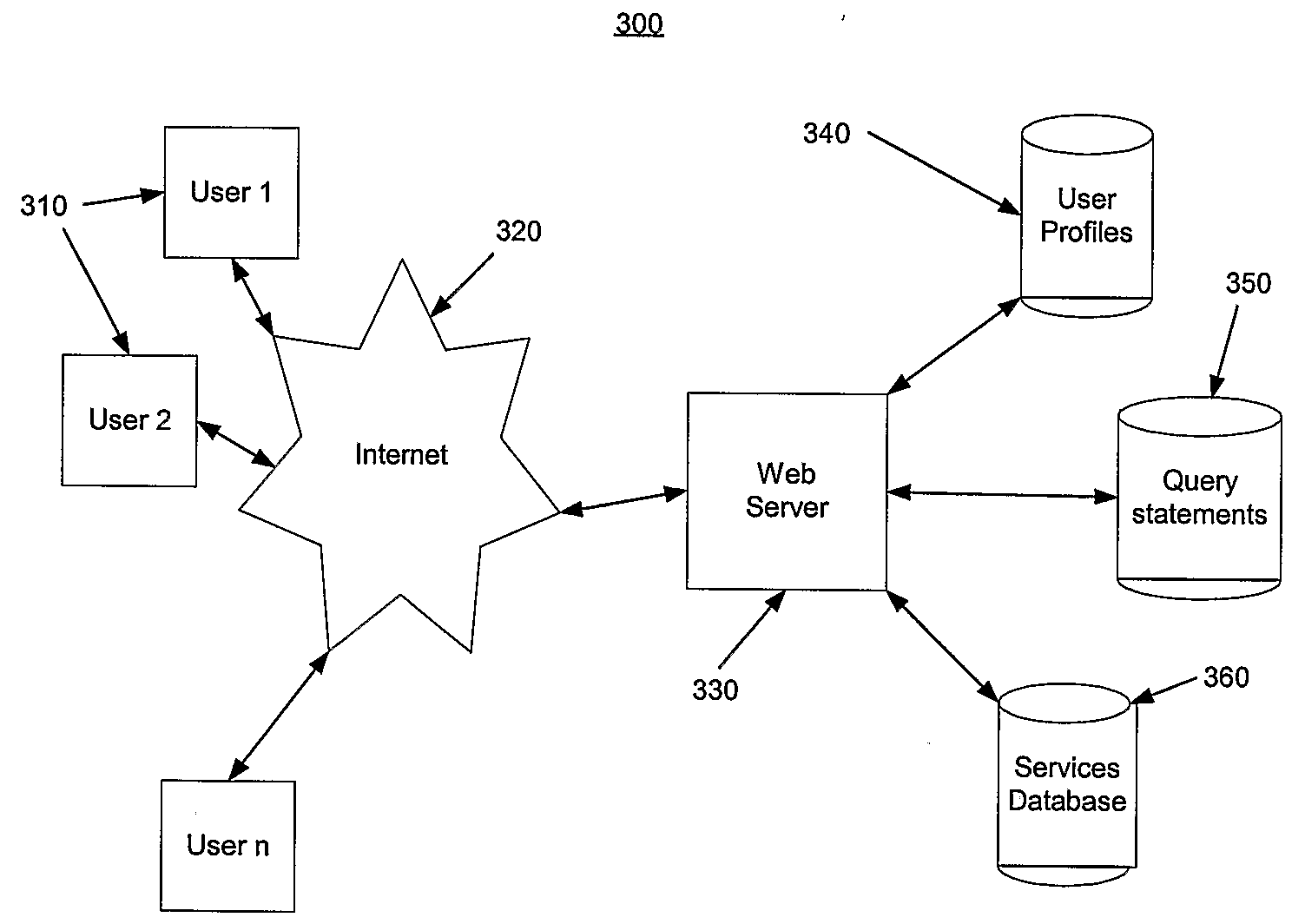

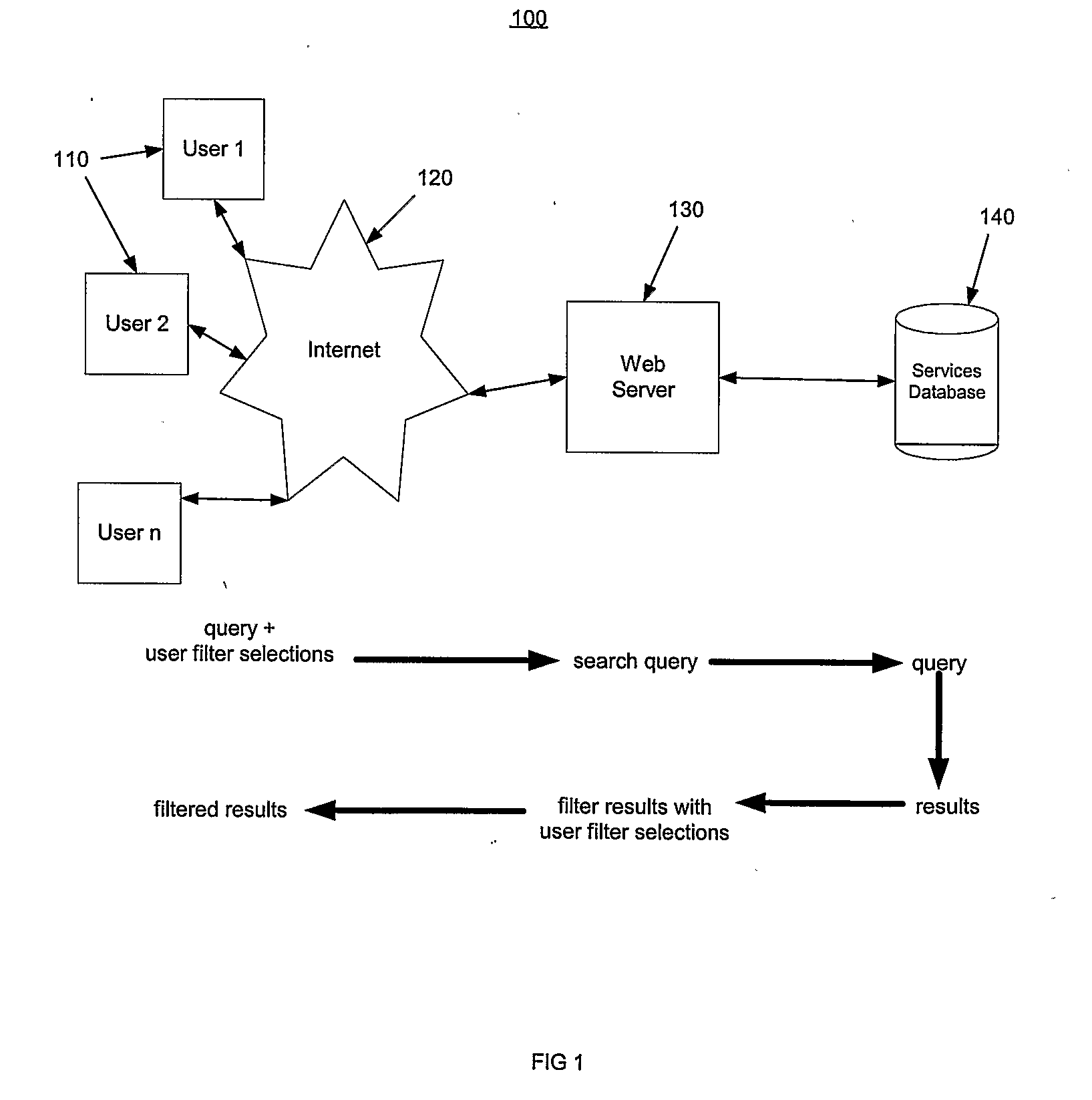

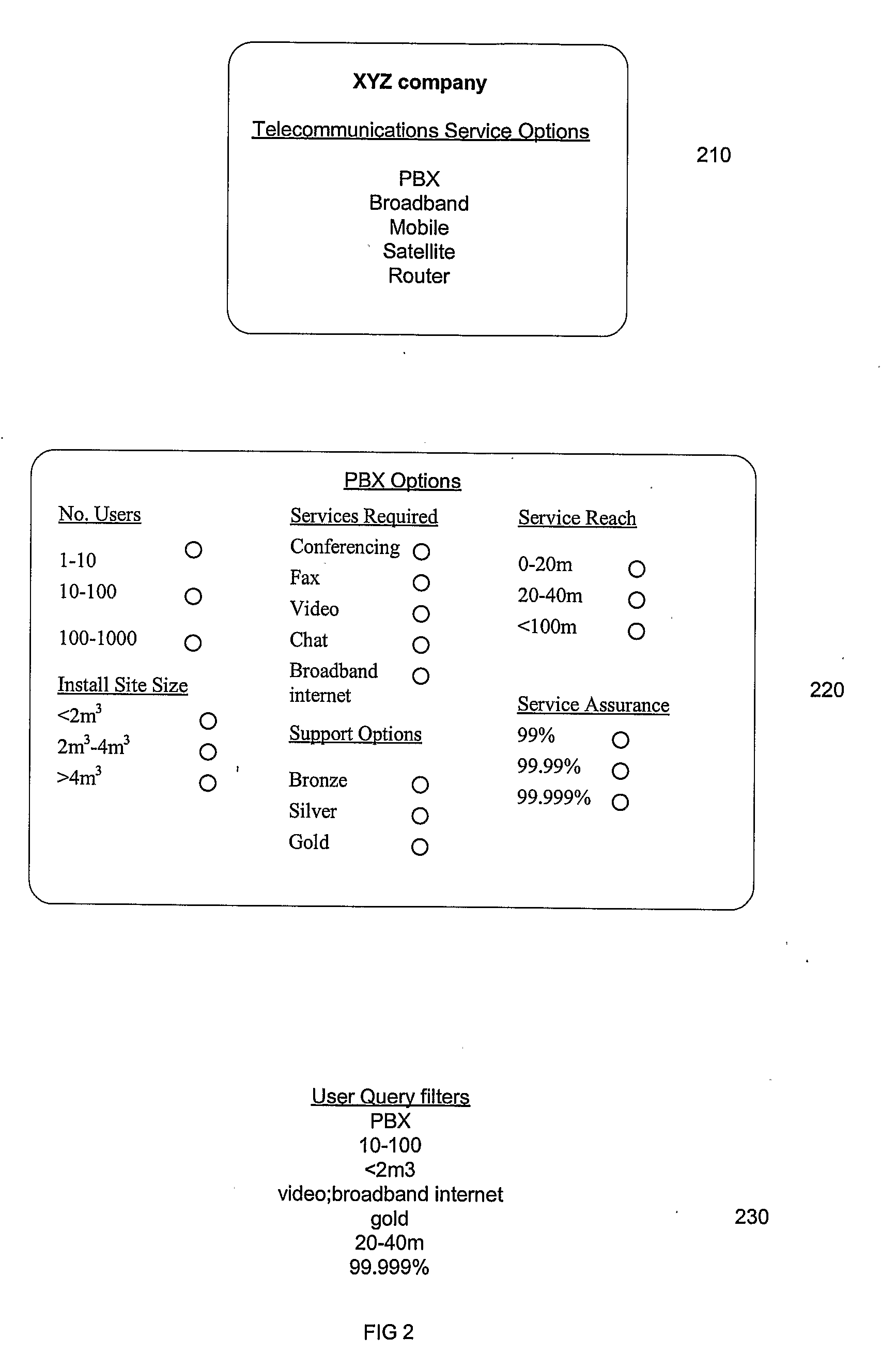

User Specific Database Querying Method and Apparatus

ActiveUS20090012949A1Good user interfaceReduce usageDigital data processing detailsSpecial data processing applicationsDatabase queryQuery statement

The present invention relates to the field of database technology, and to the automatic generation of search queries. The present invention provides a method of generating a database query, the method comprising: receiving a user selection of one of a number of predetermined generic database queries from a user; automatically identifying user specific data from user profile data corresponding to the user by applying the user profile data to a number of predetermined query statements associated with the selected generic query; automatically applying the user specific data to a number of user specific generator query statements in order to generate one or more user specific queries.

Owner:BRITISH TELECOMM PLC

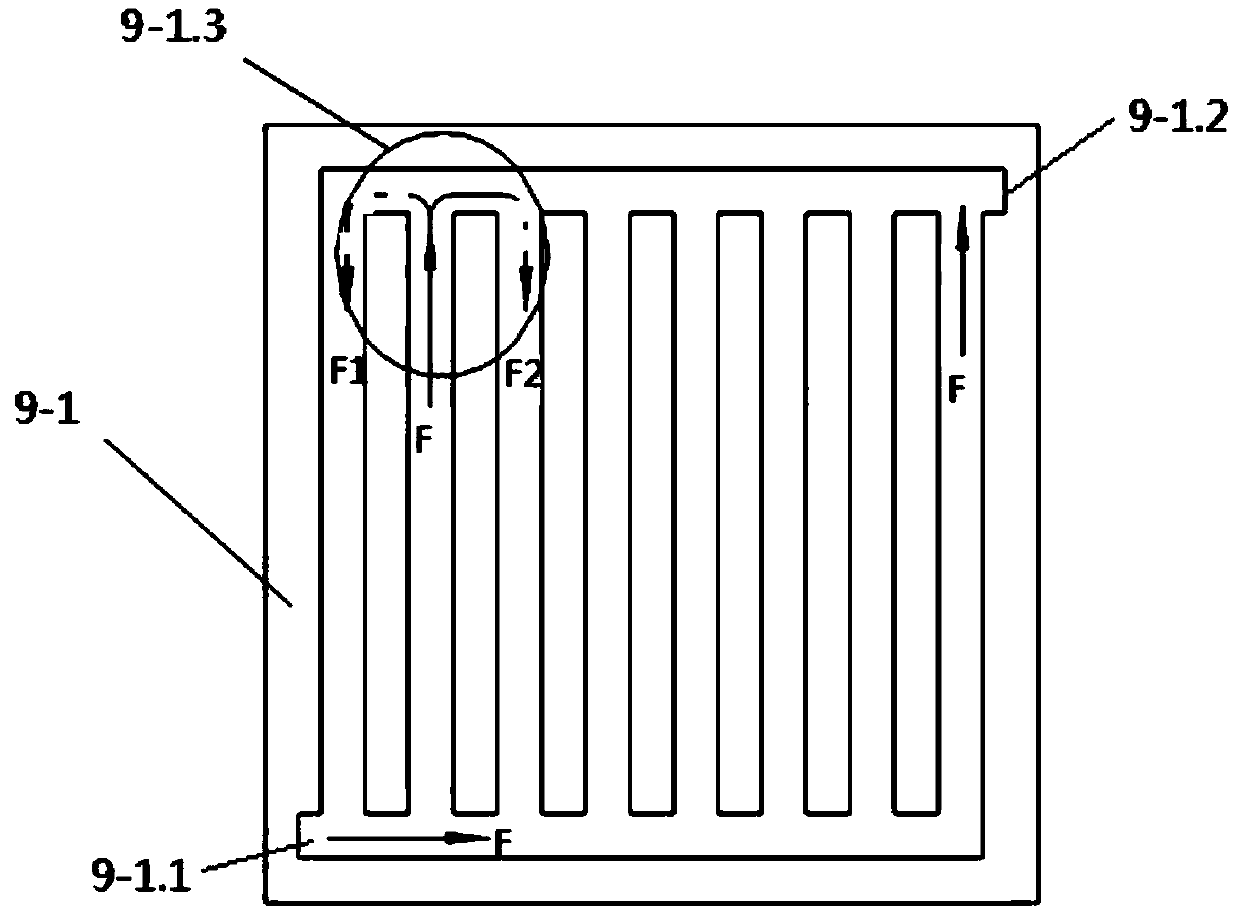

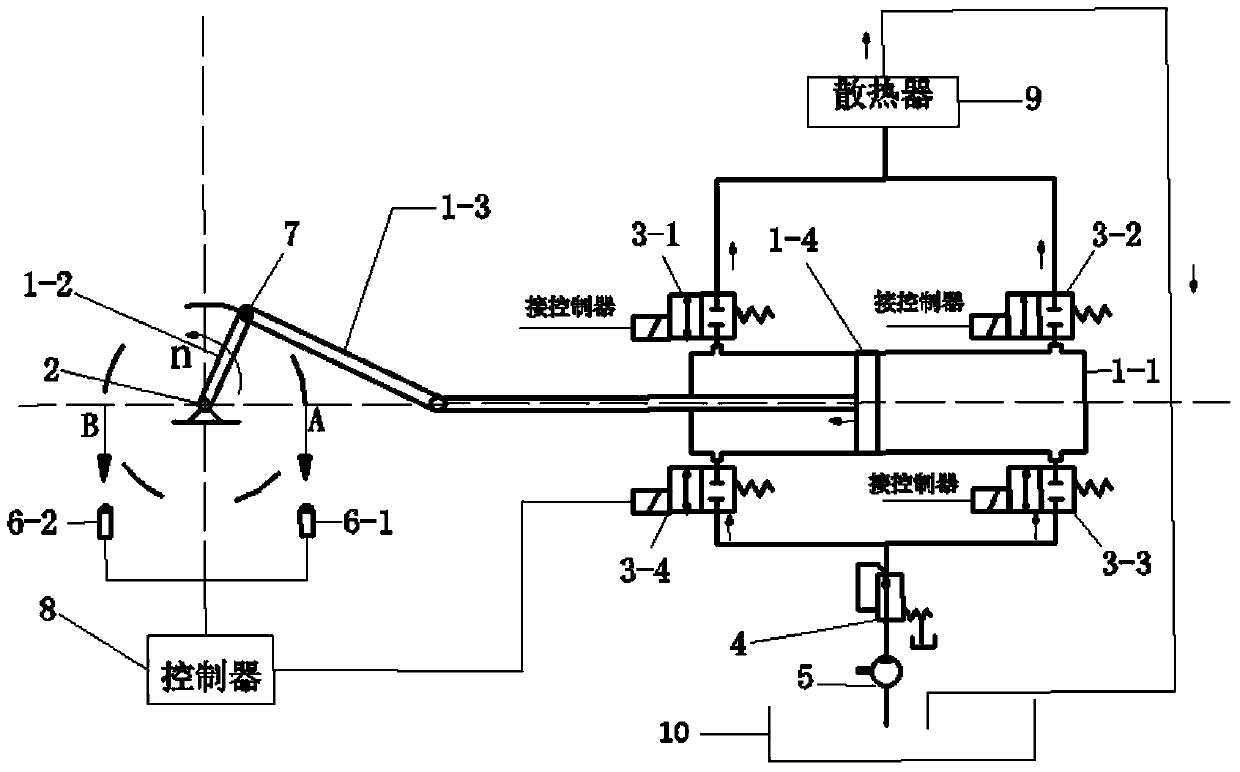

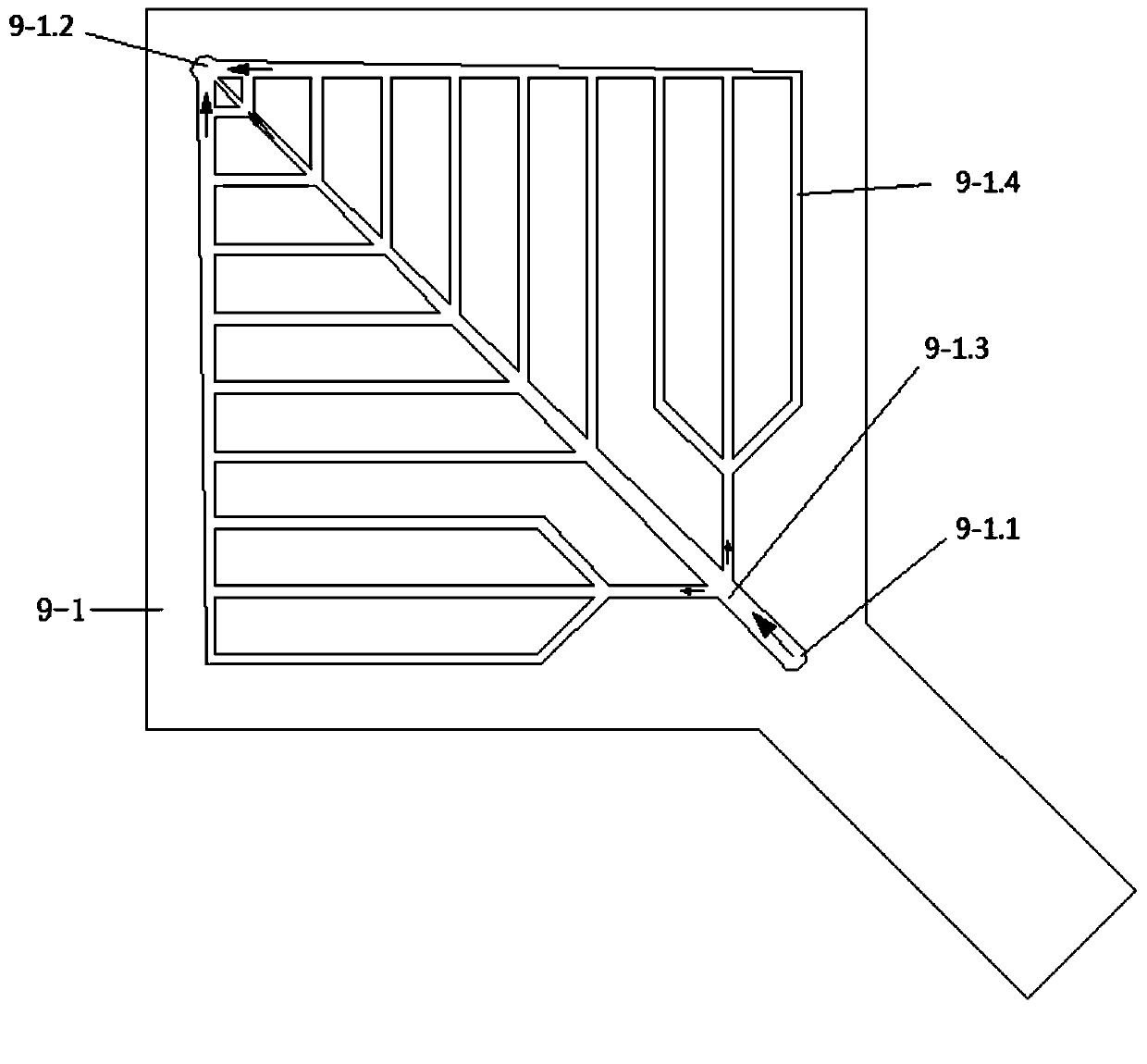

Heat radiation device with pulsating flow and leaf vein type micro channel

InactiveCN103441110AExtension of timeSpeed up deliverySemiconductor/solid-state device detailsSolid-state devicesHydraulic cylinderNuclear engineering

The invention discloses a heat radiation device with a pulsating flow and a leaf vein type micro channel. The heat radiation device is used in cooperation with an electronic element, and comprises a heat radiator, a pulsating flow generation system and a solenoid valve controller. The heat radiator comprises a micro channel heat radiation substrate or a micro channel heat radiation plate with the leaf vein type micro channel, and a cover board. The pulsating flow generation system comprises a motor, a piston type hydraulic cylinder, two liquid inlet solenoid valves and two liquid outlet solenoid valves, wherein a pair of liquid inlets and a pair of liquid outlets are formed in the front end and the rear end of a cylinder body of the piston type hydraulic cylinder respectively, the two liquid inlet solenoid valves are correspondingly connected with the two liquid inlets of the hydraulic cylinder, and the two liquid outlet solenoid valves are correspondingly connected with the two liquid outlets of the hydraulic cylinder. The solenoid valve controller comprises a signal emitter and a signal receiver. The forward travel and the back travel of the piston type hydraulic cylinder can both provide a continuous pulsating cooling medium flow for the heat radiator, the continuous and effective heat radiation time of a heat radiation cooling plate is prolonged, the mutual disturbance and mixing of a cooling medium in the micro channel are obviously strengthened, and a heat boundary layer is damaged. Therefore, the heat radiation device with the pulsating flow and the leaf vein type micro channel has the advantages of being good in heat radiation effect, high in heat radiation efficiency, good in temperature uniformity in a heat radiation area, high in reliability and stability of work of elements and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

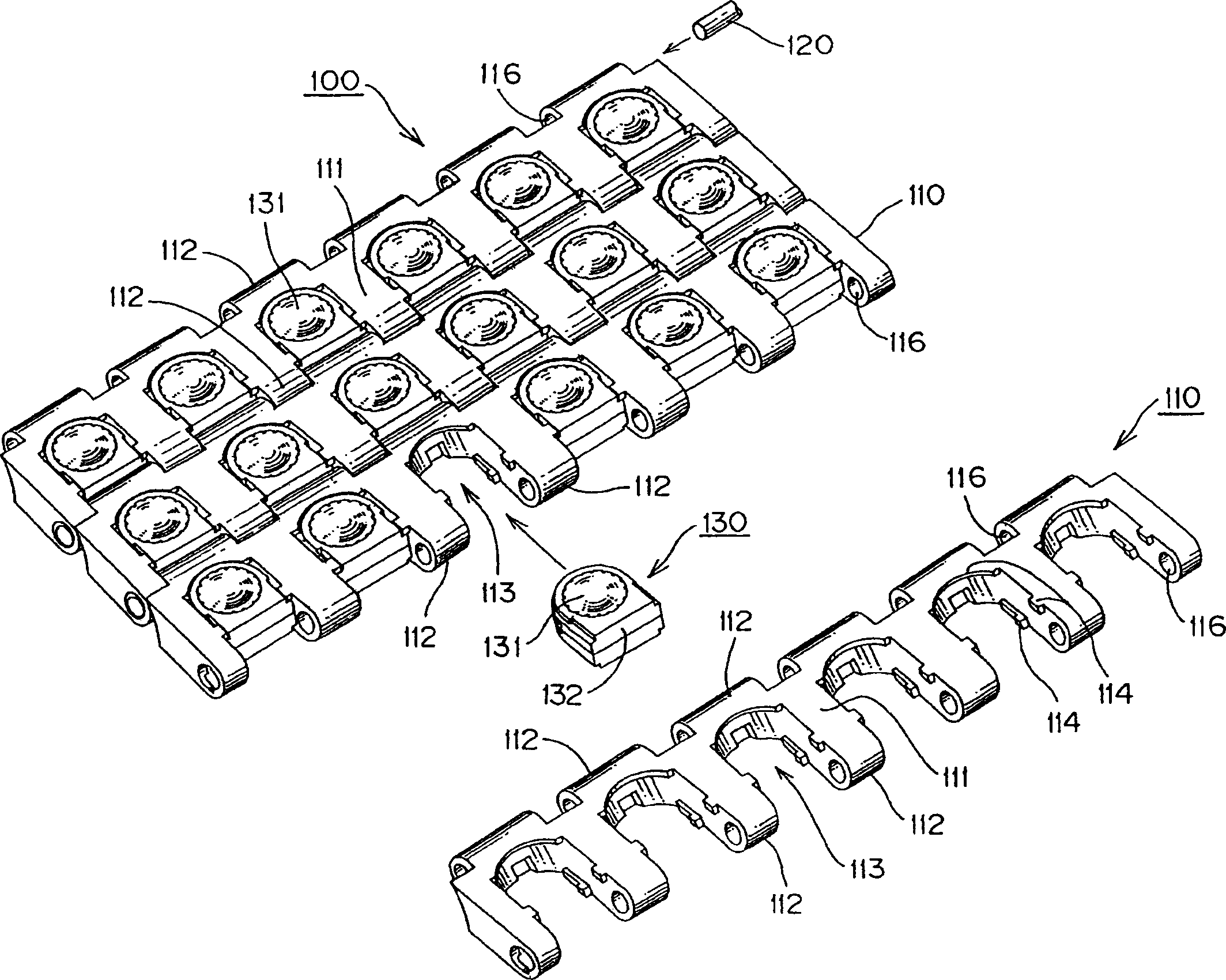

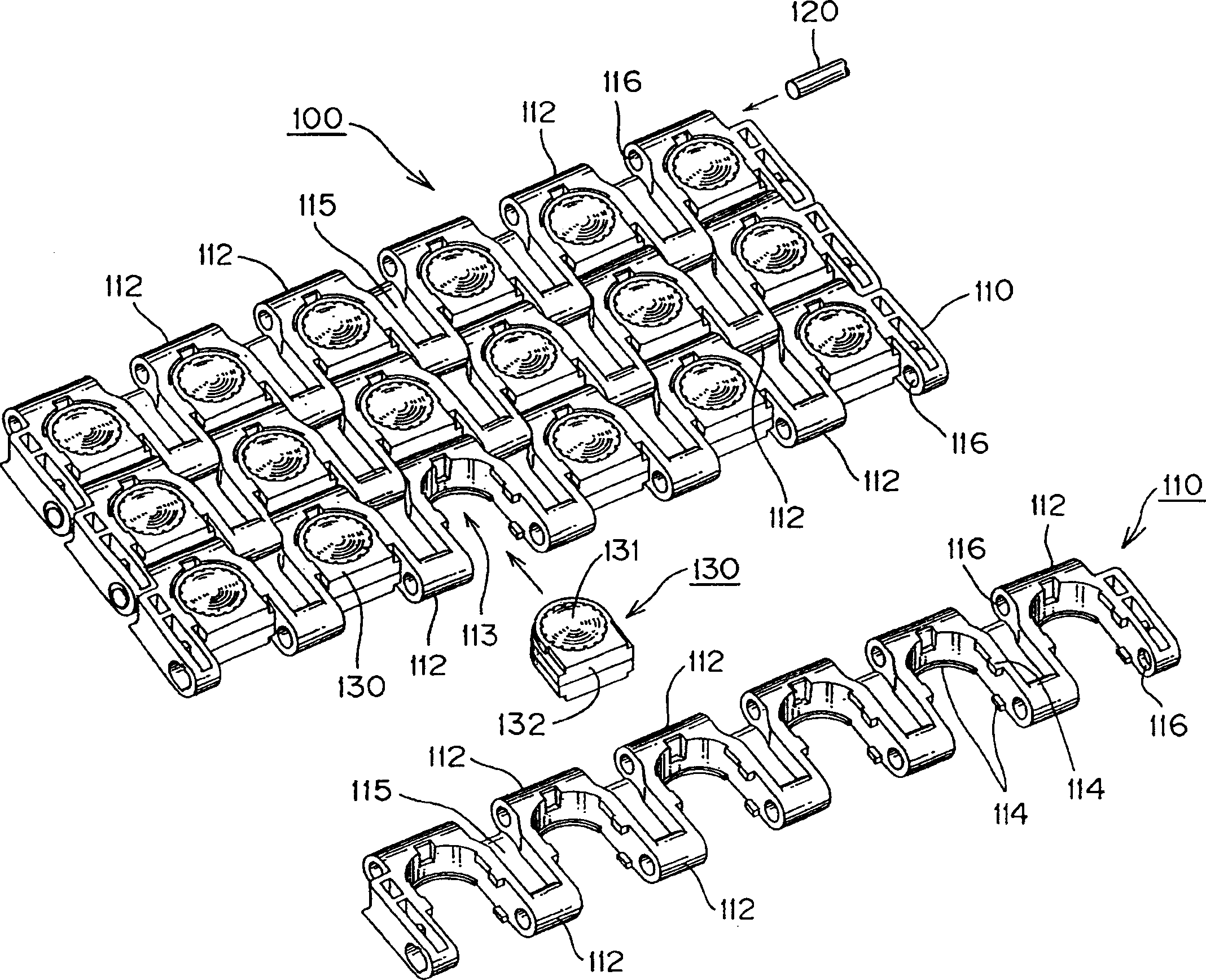

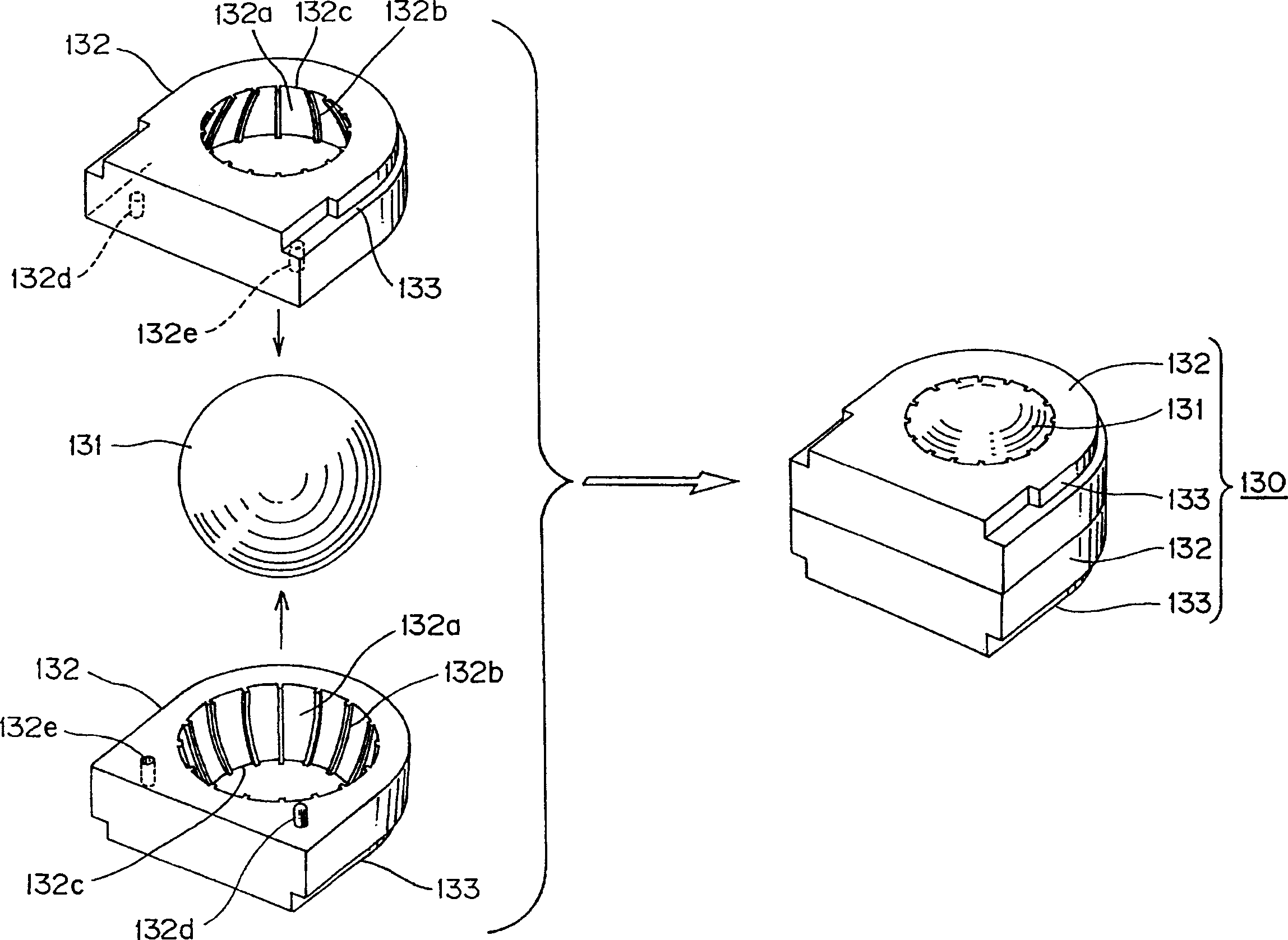

Conveyor chain

ActiveCN1868836AInhibit wearGood self-lubricating performanceConveyorsPackagingPolyesterFree rotation

Conveyor chains are provided which comprise free balls which are free to rotate in all directions thereby allowing for the stable conveyance of articles in any direction in the entire horizontal plane and at an increased speed in the direction of conveyance with reduced contamination in the conveyance environment. A conveyor chain 100 comprises a number of chain links 110 comprising a plurality of hinge portions 112 in a zigzag formation protruding from the front and rear end edges that are connected to each other in the longitudinal direction of the chain through hinge pins 120 . Free balls 131 protrude from both the surface and back sides of the chain link 110 and are free to rotate while held in the chain link 110 . Either the free balls 131 or ball holding portions 132 , which hold the free balls 131 , is made of polyacetal while the other is made of polyamide or polyester.

Owner:TSUBAKIMOTO CHAIN CO

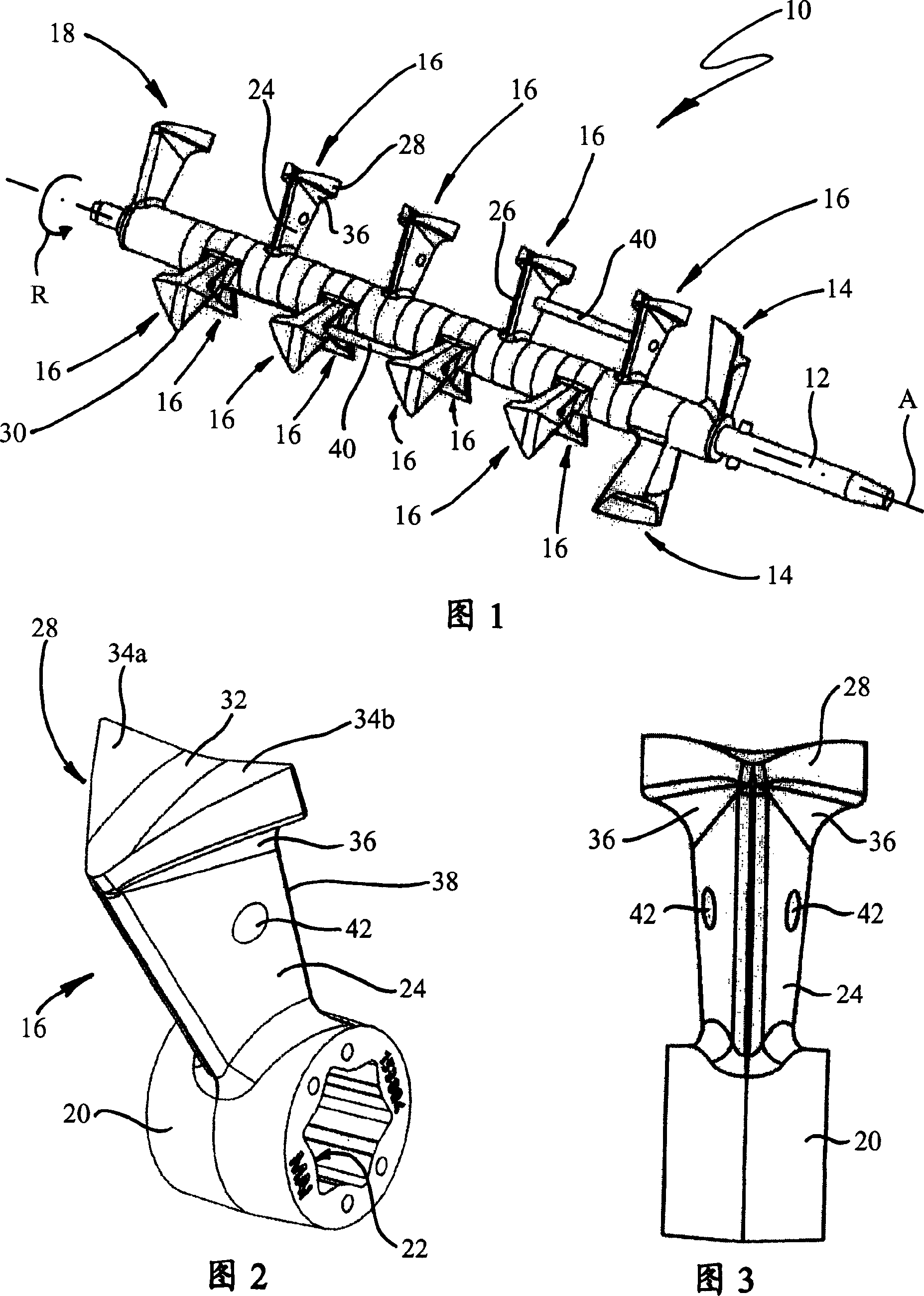

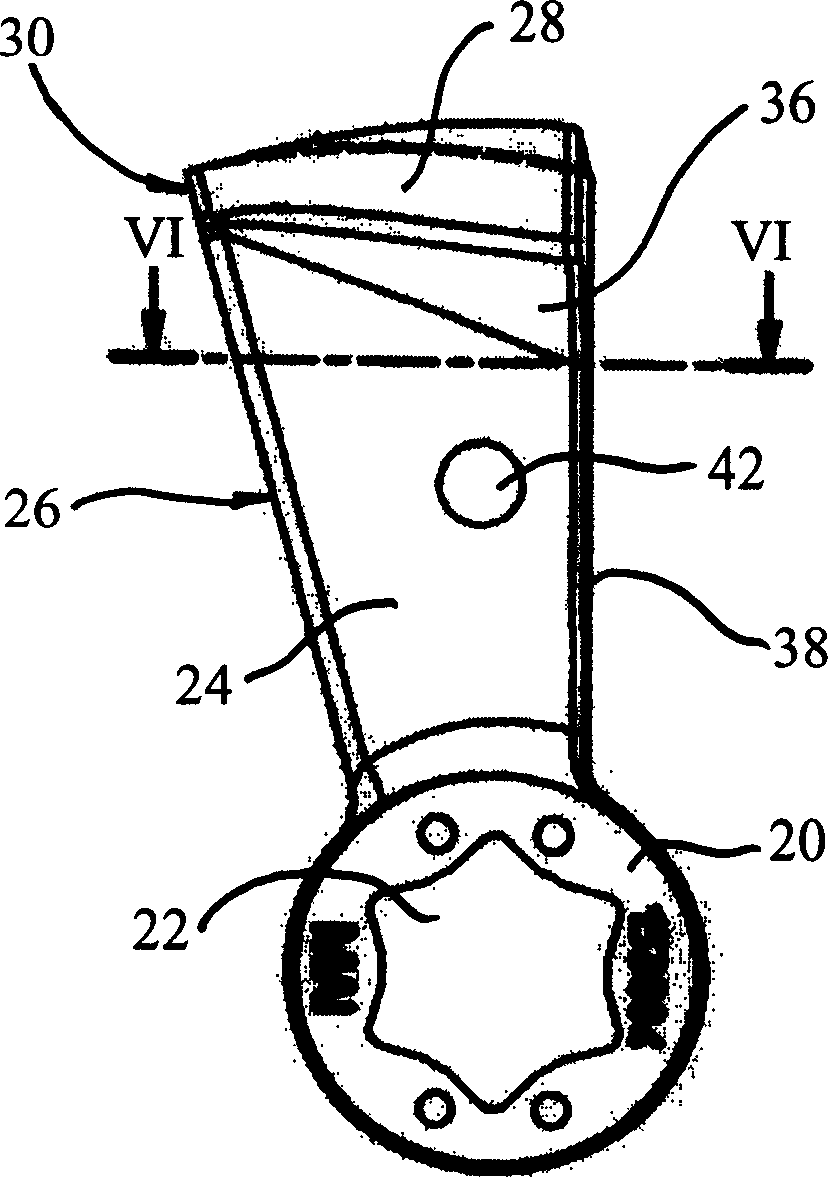

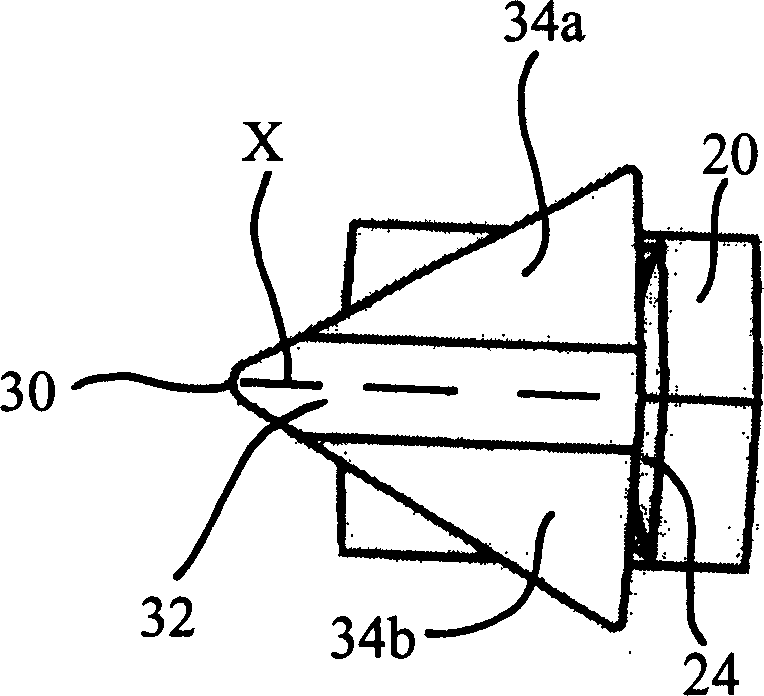

Stirring apparatus

InactiveCN1721156AMixed Strongly EffectiveWell mixedRotary stirring mixersTransportation and packagingRotational axisEngineering

A mixing mechanism (10) making suspension with liquid and solid burden includes a mixing space, a shaft (12) and a limitative axis (A). The shaft is revolved and arranged in the mixing space. The shaft is provided with vanes (16) which revolve along the rotation direction (R) of the shaft (12). At least two mixing vanes (16) include a matrix (24) with a wedgy section, which extends outwards from the axial direction of the shaft (12). The mixing vane includes a mixing vane head (28) with the wedgy section, which is connected with the free end of the matrix (24). The wedgy tips (26, 30) of the matrix (24) and the mixing vane head (28) point to the rotation direction (R) of the shaft (12). The mixing vane head (28) is wider than the matrix (24) on the axial direction. The matrix (24) has a transition region (36) on at least one side between the narrow matrix (24) and the wide mixing vane head (28). The transition region (36) is inclined relative to the shaft (12). When the rotating shaft (12) revolves along the rotation direction (R), the mixture to be mixed in the mixing space is transported inwards to the shaft (12).

Owner:MAY INT

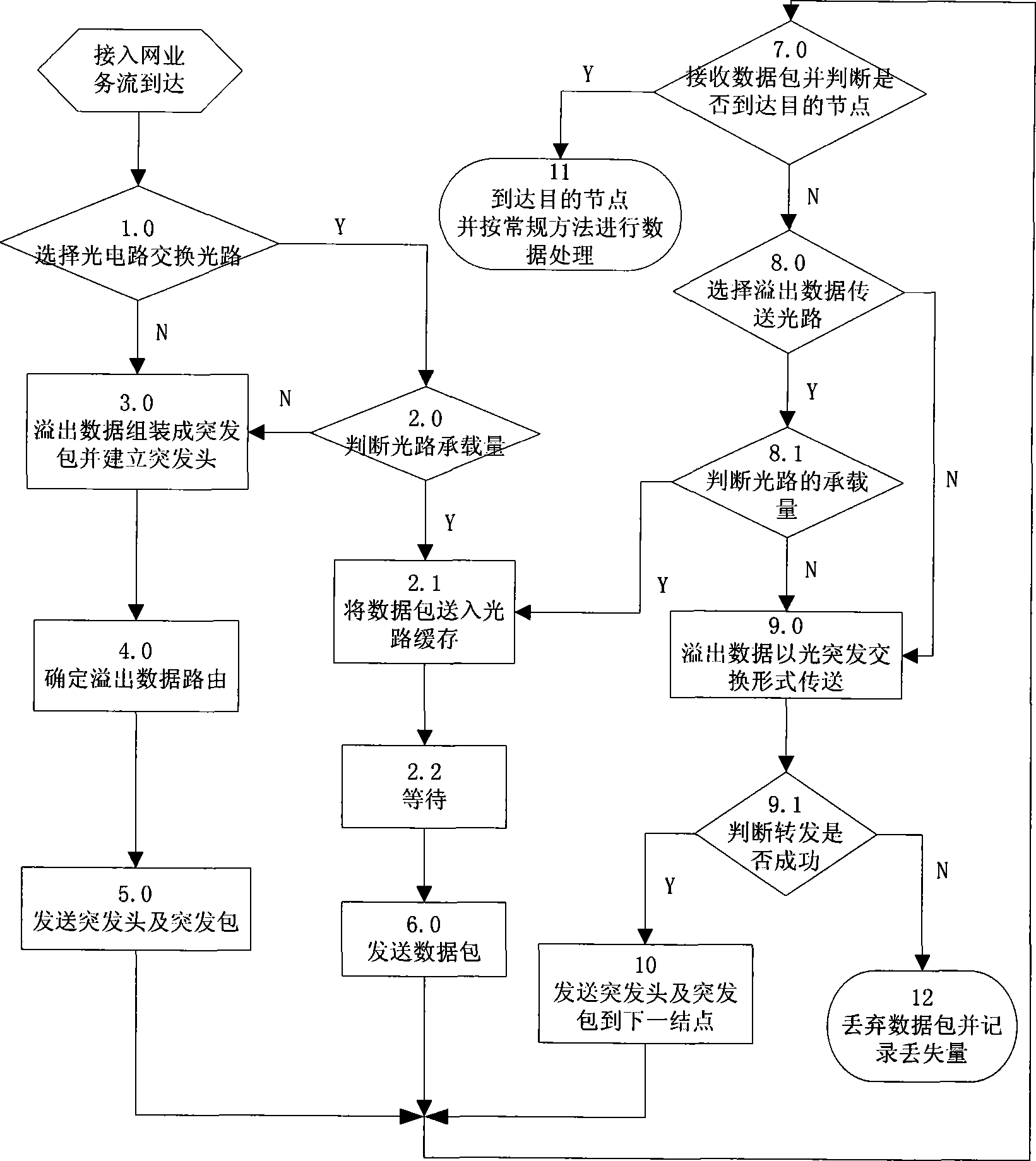

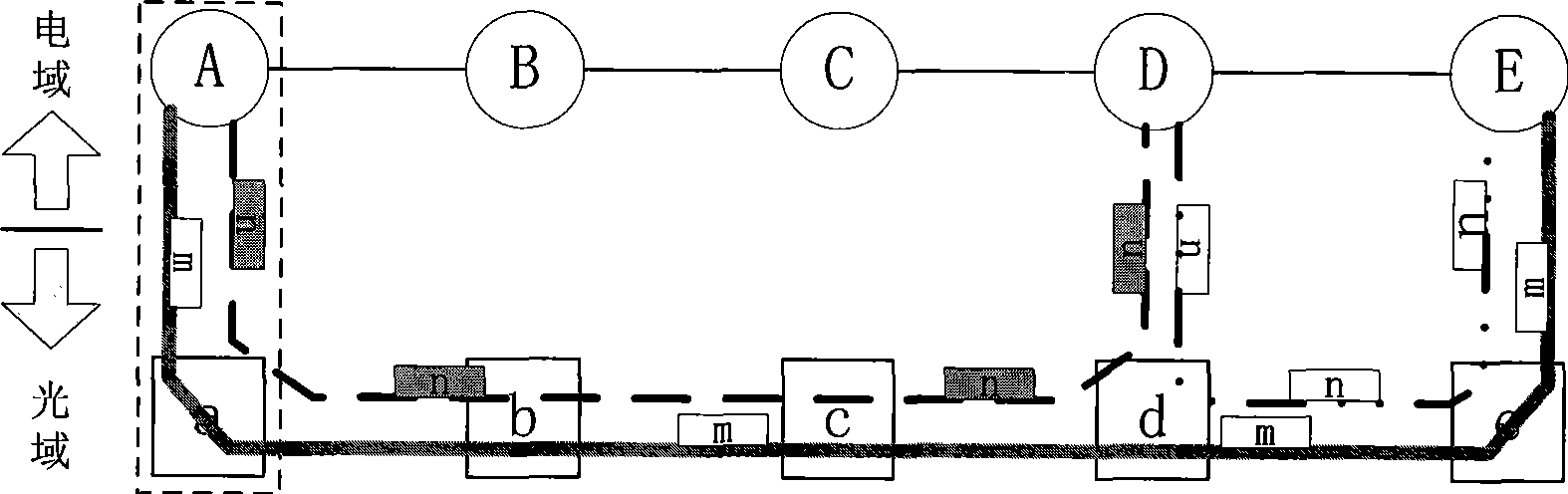

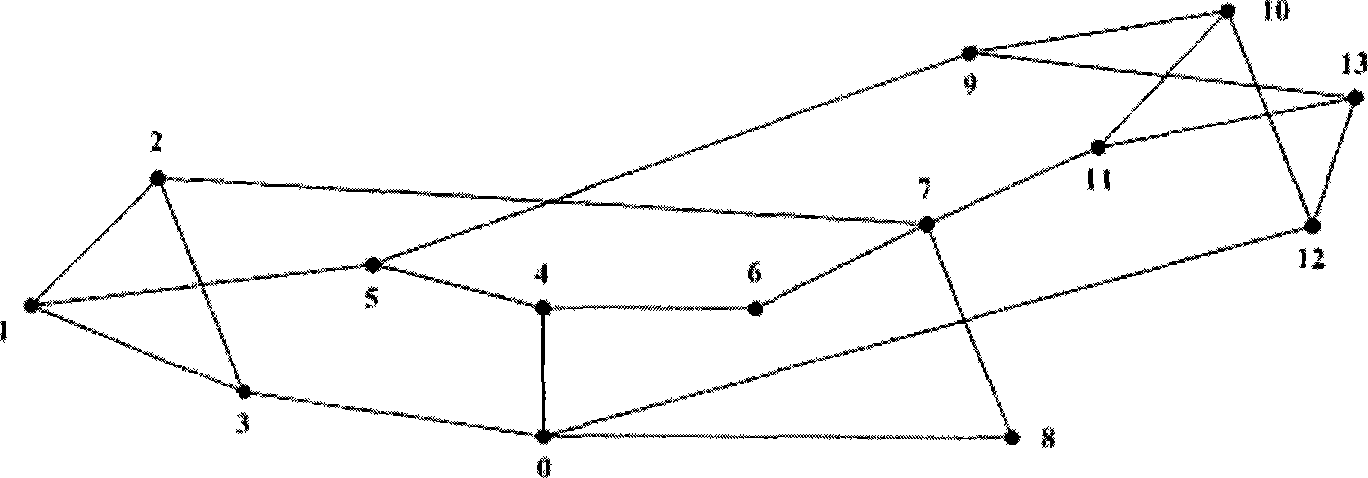

Data transmission method for integrated mixed optical network based on burst exchange

InactiveCN101426152ASpeed up deliveryImprove reliabilityMultiplex system selection arrangementsData switching networksData streamOptical burst switching

The invention pertains to a data transmission method in the optical network communication technology. The invention organically combines optical circuit switching (OCS) and optical burst switching (OBS) based on the original physical topological network, reserves wavelength in each physical link to establish an overflow transmission light path, transmits the discarded data packets of the original OBS due to booking collision into the light path to transmit continuously, accordingly resolving the problem of packet loss due to one time booking collision; most of the data packets in the network operation adopts an OCS mode transmission, and adopts an OBS mode overflow transmission light path to transmit the data packets to destination nodes when the data conveying capacity has a high a burst performance; and can switch back to the OCS mode transmission when the OCS light path is smooth, accordingly can flexibly adjust the transmission modes according to the current state of network and significantly reduce the packet loss rate. The present invention thus not only has high efficiency of OCS but also has flexibility of OBS, and has features of strong transmission capability and adaptability to burst data streams, rapid network transmission, high reliability, no additional optical devices and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

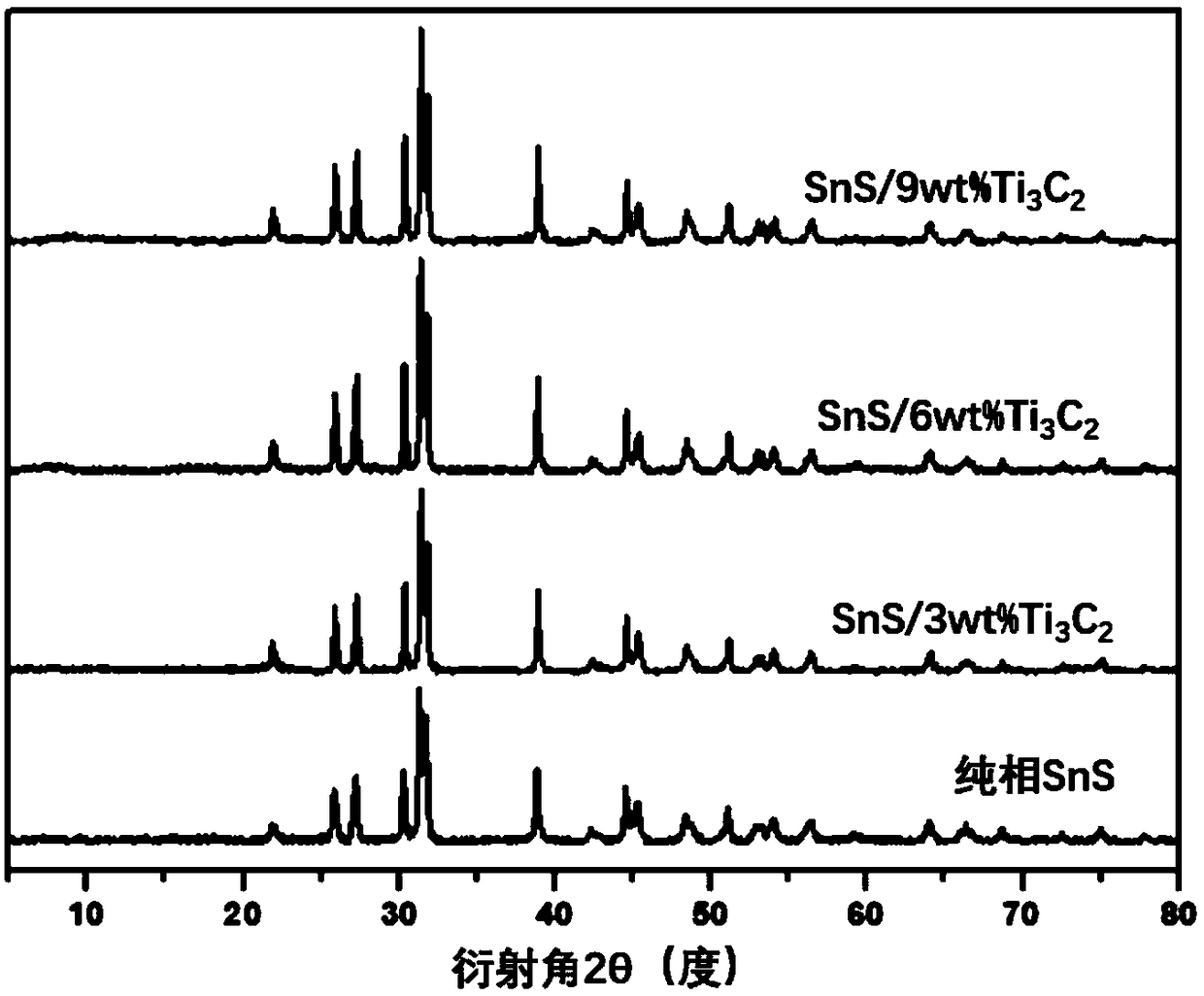

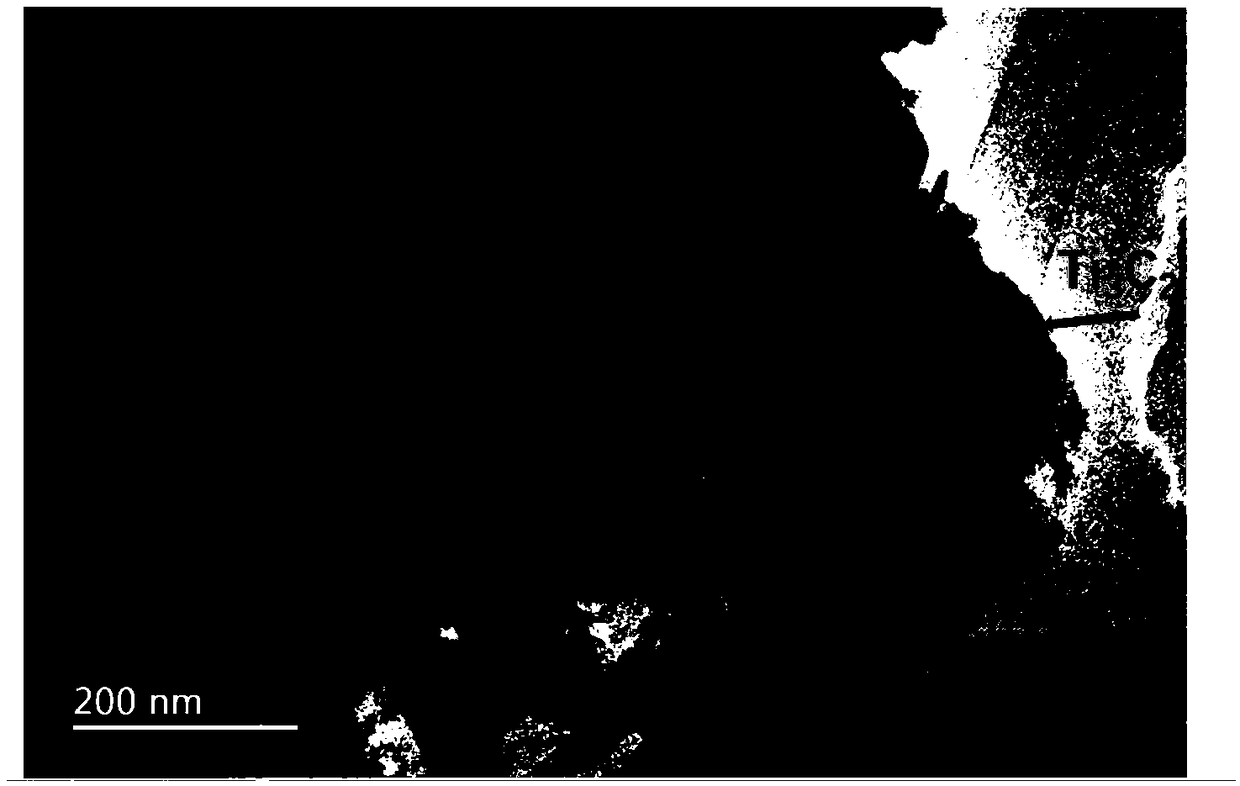

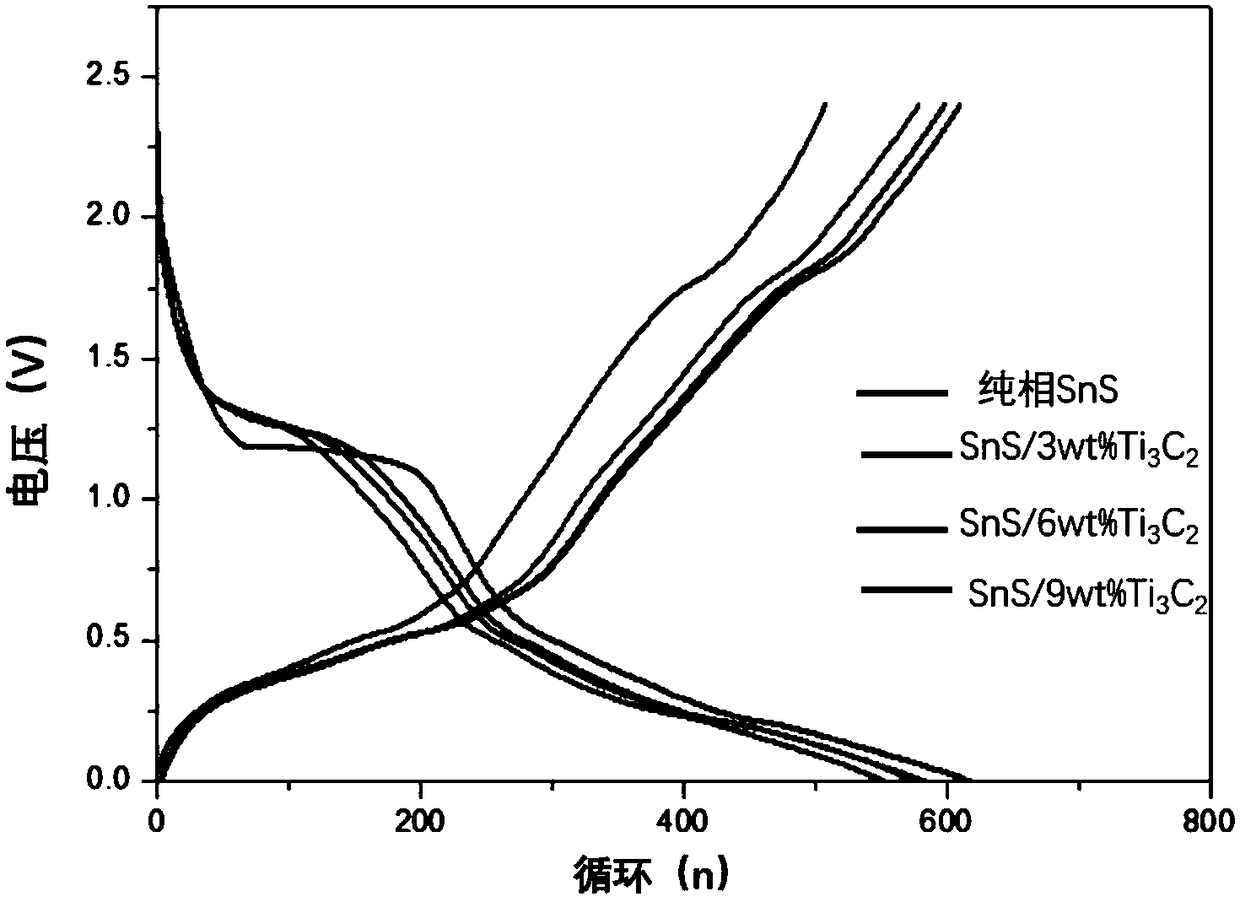

Titanium carbide-loaded stannous sulfide composite anode material

InactiveCN108963211AGood cycle performance and rate performanceImproved cycle performance and rate performanceCell electrodesSecondary cellsSolventUltrasonic oscillation

The invention relates to a titanium carbide-loaded stannous sulfide composite anode material. The composite anode material is a stannous sulfide anode material loaded with titanium carbide, wherein the loading capacity of titanium carbide is 3-9% of the mass of stannous sulfide. The composite anode material is prepared by the following specific method: mixing a sulfur source and a tin source, adding a solvent and stirring until the above substances are completely dissolved so as to obtain a sulfur-tin mixed solution; taking titanium carbide, adding a surfactant and deionized water, and carrying out ultrasonic oscillation until the substances are completely dissolved so as to obtain a titanium carbide dispersion; adding the titanium carbide dispersion into the sulfur-tin mixed solution, andtransferring the mixed solution into a reaction kettle to carry out a hydrothermal reaction; successively centrifuging, washing and drying the product after the reaction, and finally grinding to obtain a powder product; calcining the powder product in an inert gas atmosphere, cooling to room temperature with a furnace, and grinding the powder to obtain a product. This material shows better cycleperformance and rate performance than pure-phase stannous sulfide.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

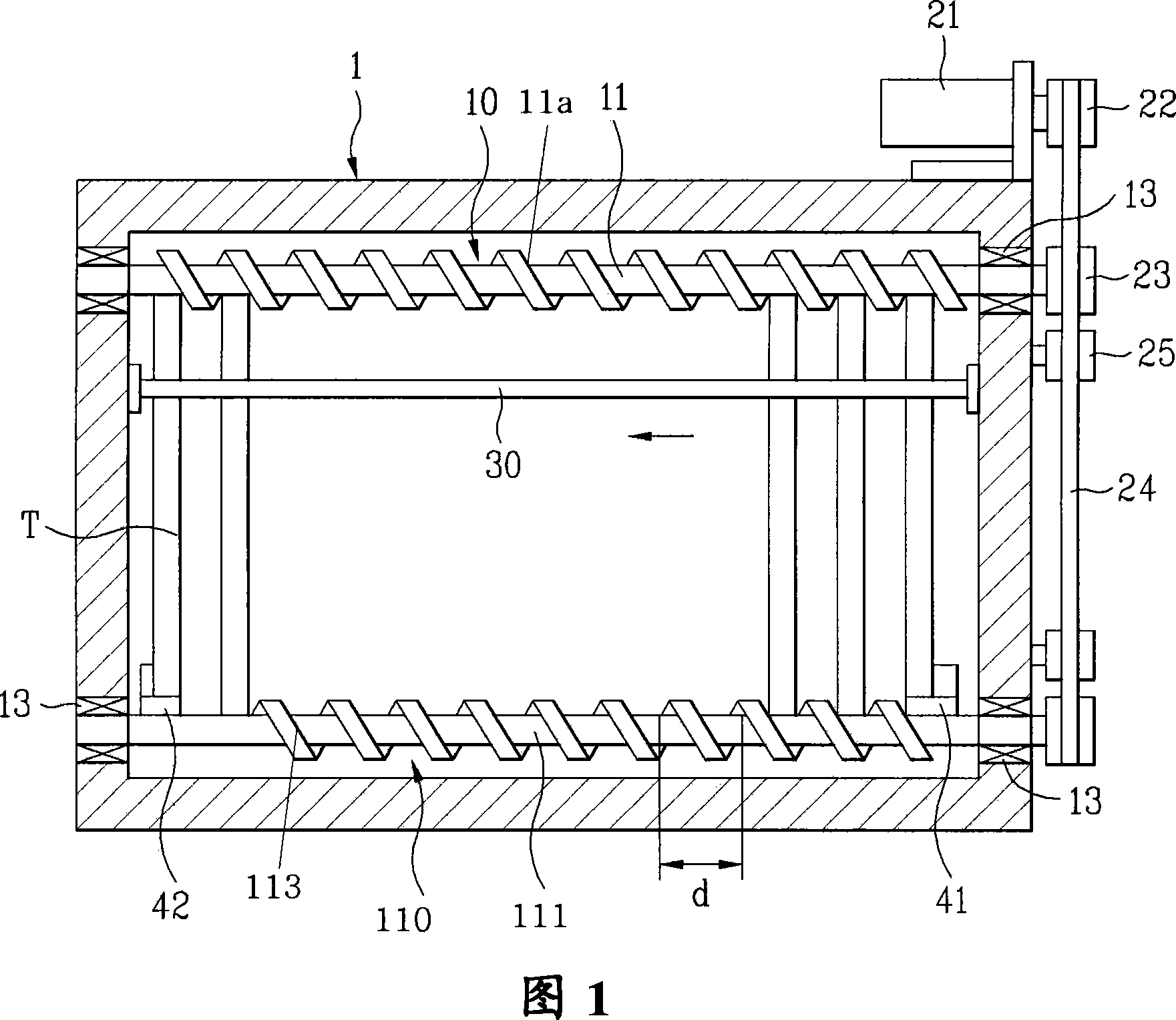

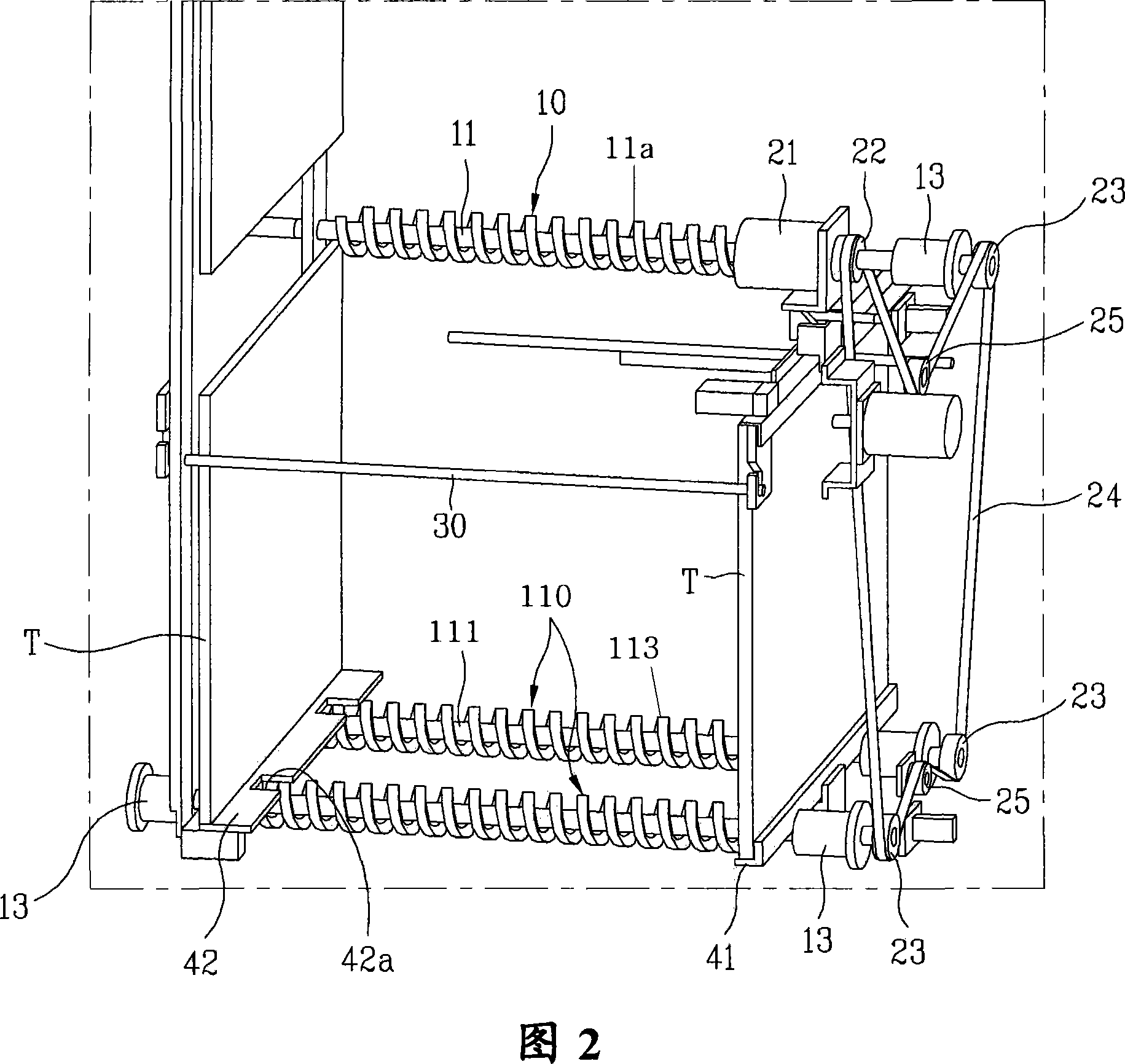

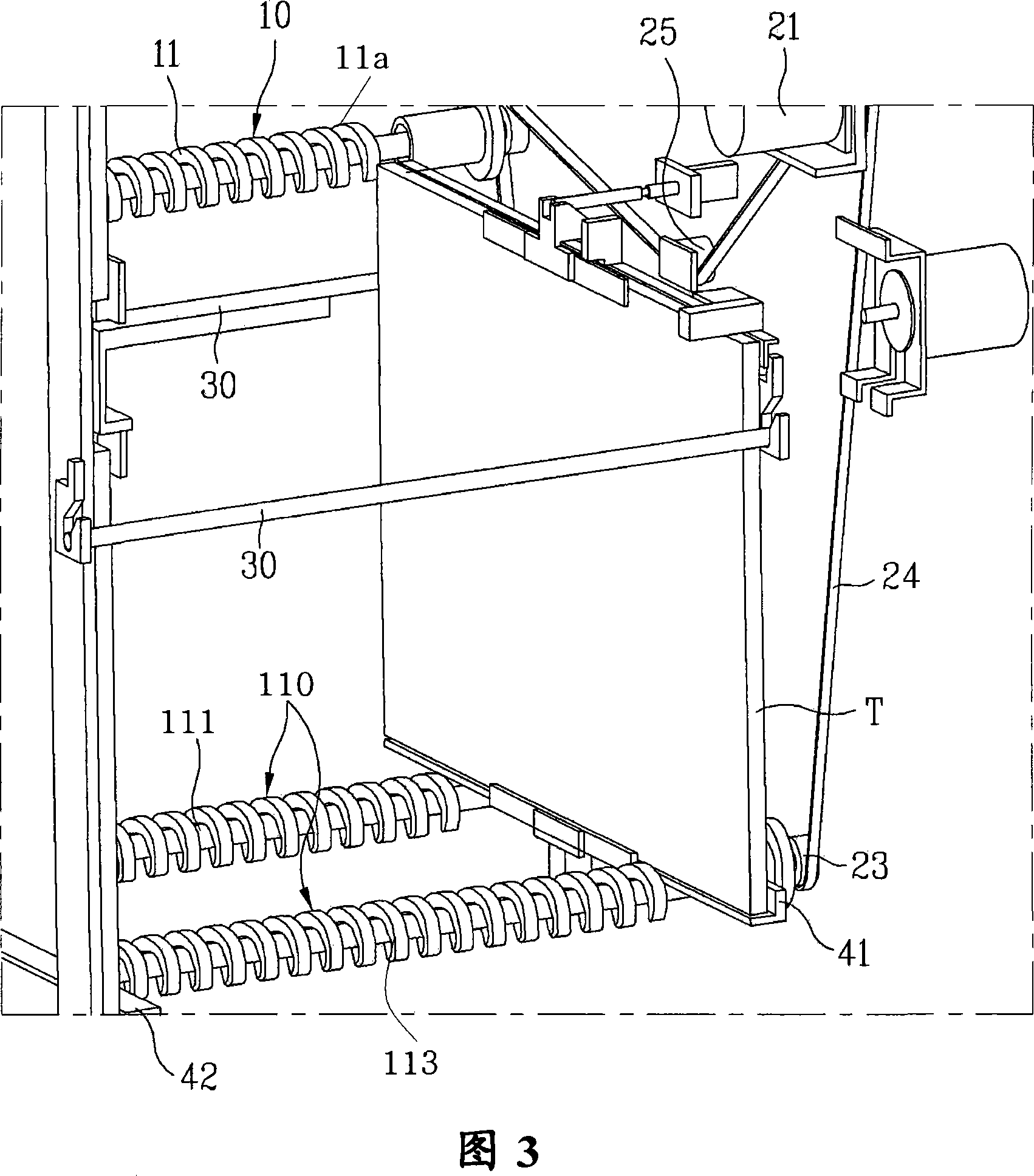

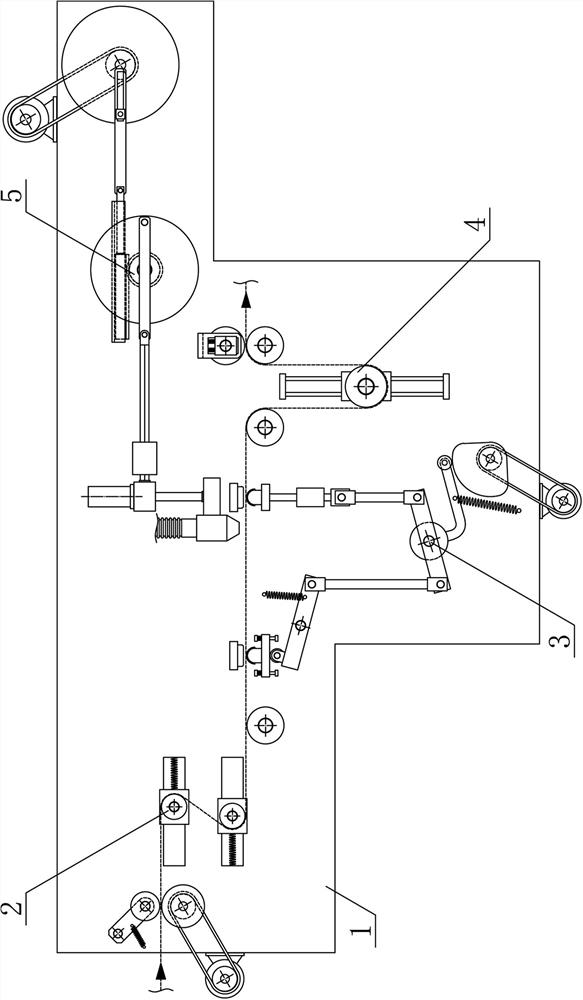

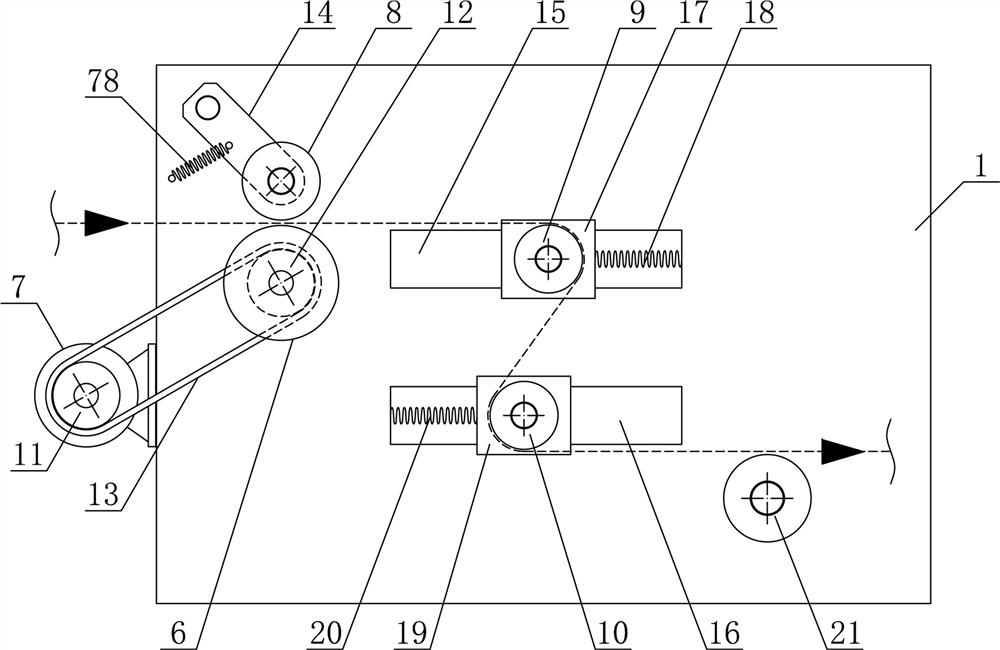

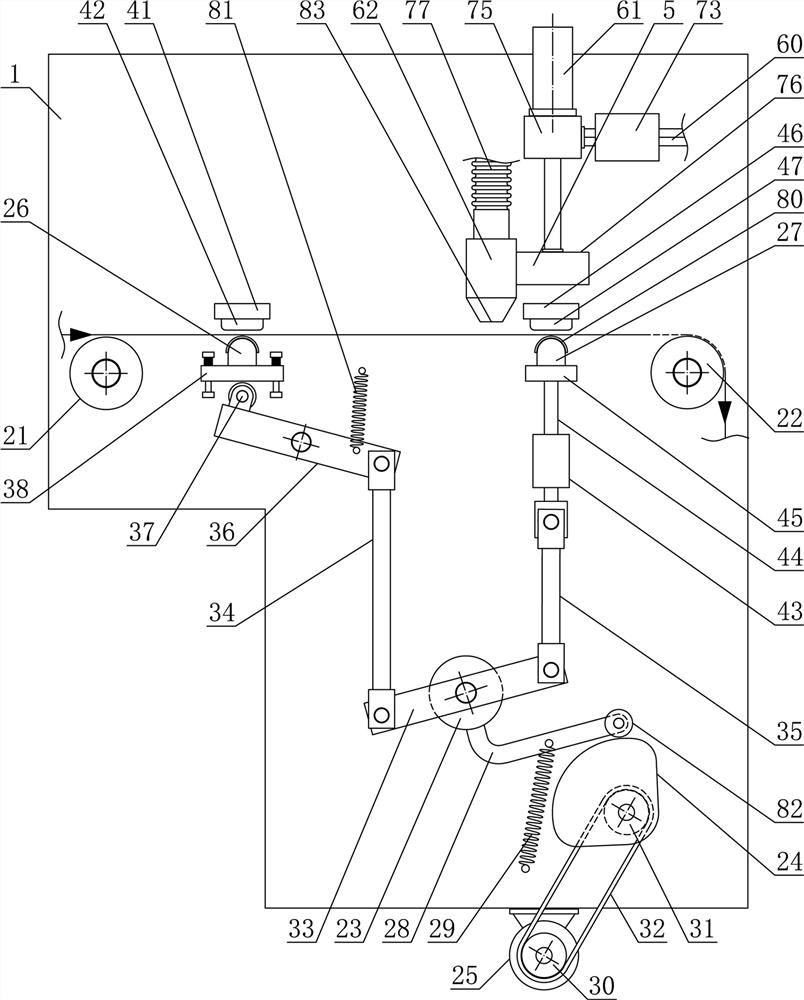

Handler for testing of packed chip

InactiveCN101079389ASmooth transmissionSpeed up deliverySemiconductor/solid-state device testing/measurementElectronic circuit testingEngineeringMechanical engineering

The present invention provides a handler for testing semiconductor equipped with a tray transfer device that has a simple structure and can safely transfer a test tray. The handler for testing semiconductors comprises a tray to which a semiconductor device is attached, a transfer member, rotating to transfer the tray, while at least one portion of the edge of the tray is being stored, and a drive unit for rotating the transfer member. The above tray is moved in the longitudinal direction of the transfer member by a force applied by the rotation of the transfer member.

Owner:MIRAE CORPORATION

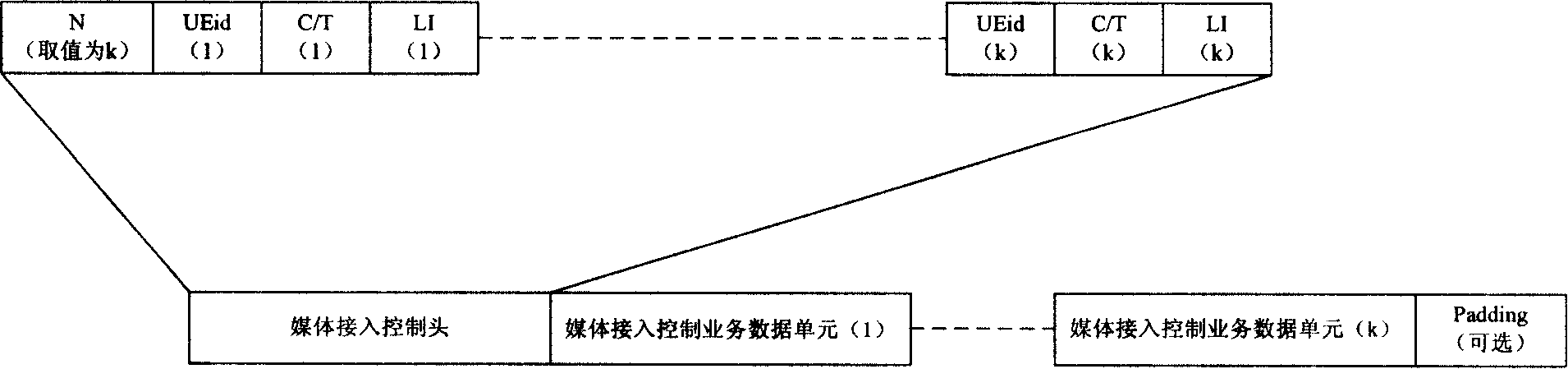

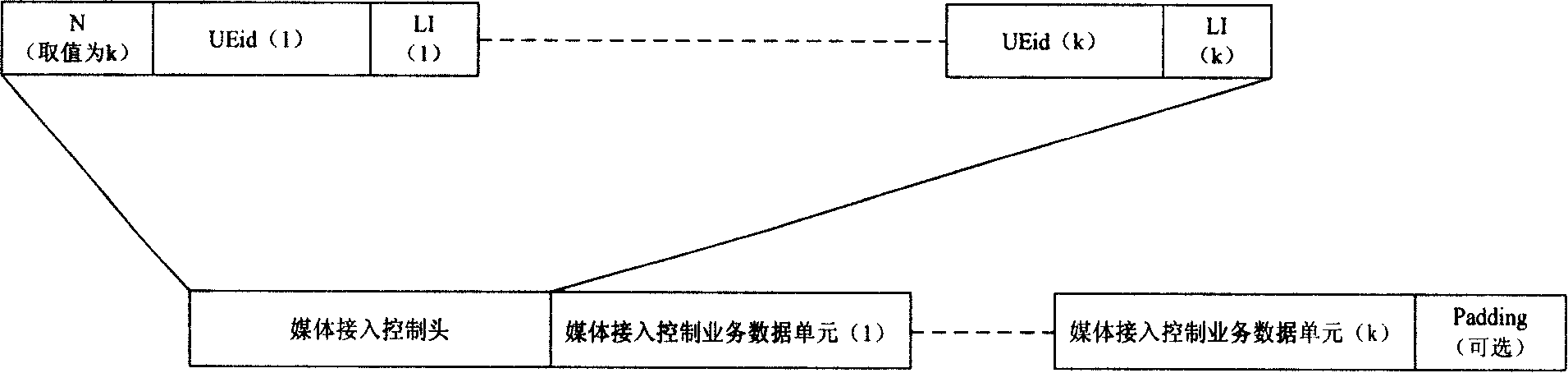

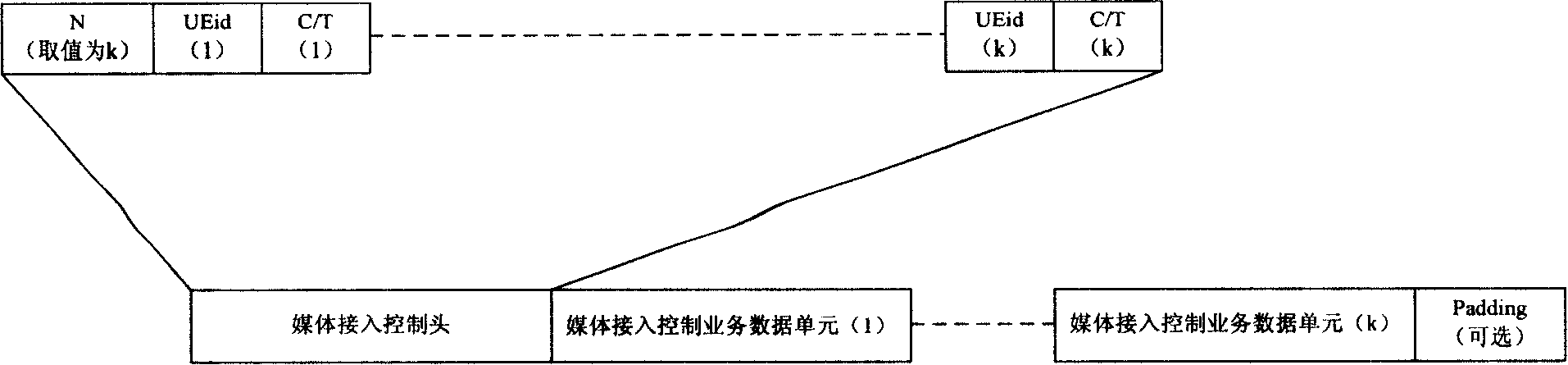

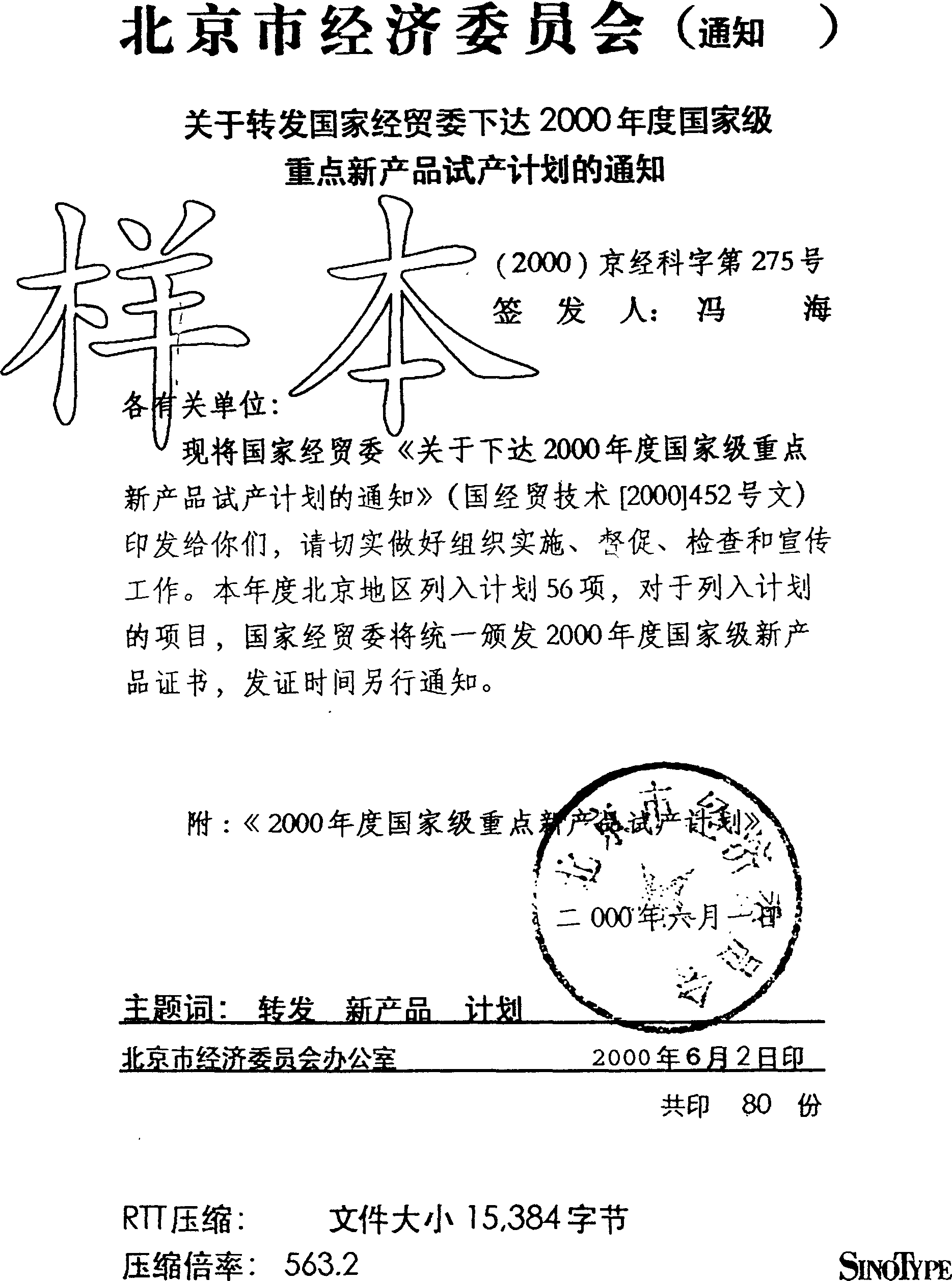

Method and apparatus for remaining always online type service

InactiveCN101175302ASpeed up deliveryImprove transmission efficiencyNetwork traffic/resource managementConnection managementTime segmentMedia access control

The present invention provides a method for preserving a permanent online service, which includes three steps. Firstly, the service data packages sent to different terminals in the same period are combined into a media access control protocol data unit; secondly, the media access control protocol data unit is transmitted via a downlink transmission channel used in the CELL-FACH state; thirdly, the different terminals respectively obtain the required service data packages from the media access control protocol data unit in order to preserve the permanent online type service. The present invention also provides a device for preserving the permanent online type service.

Owner:ZTE CORP

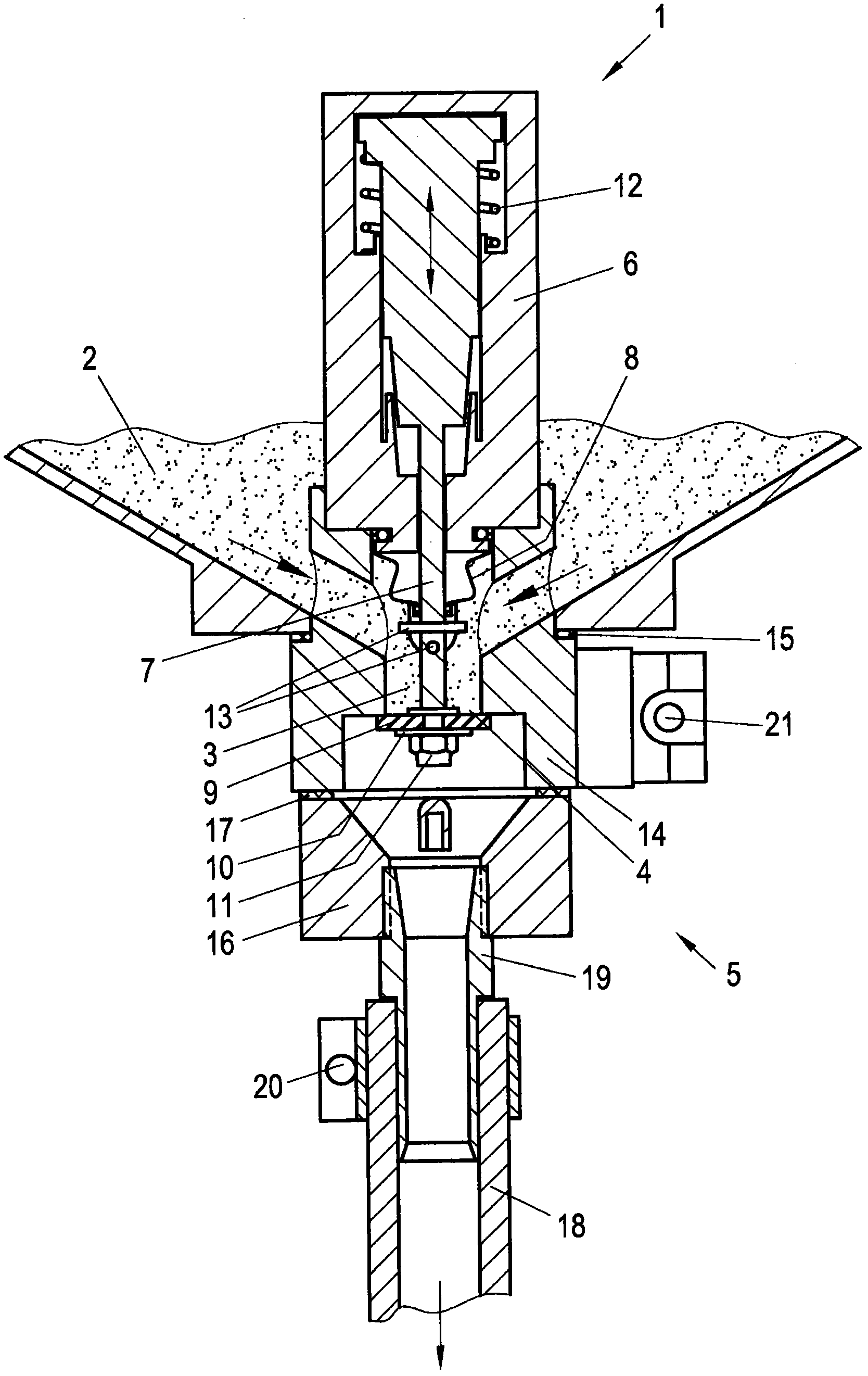

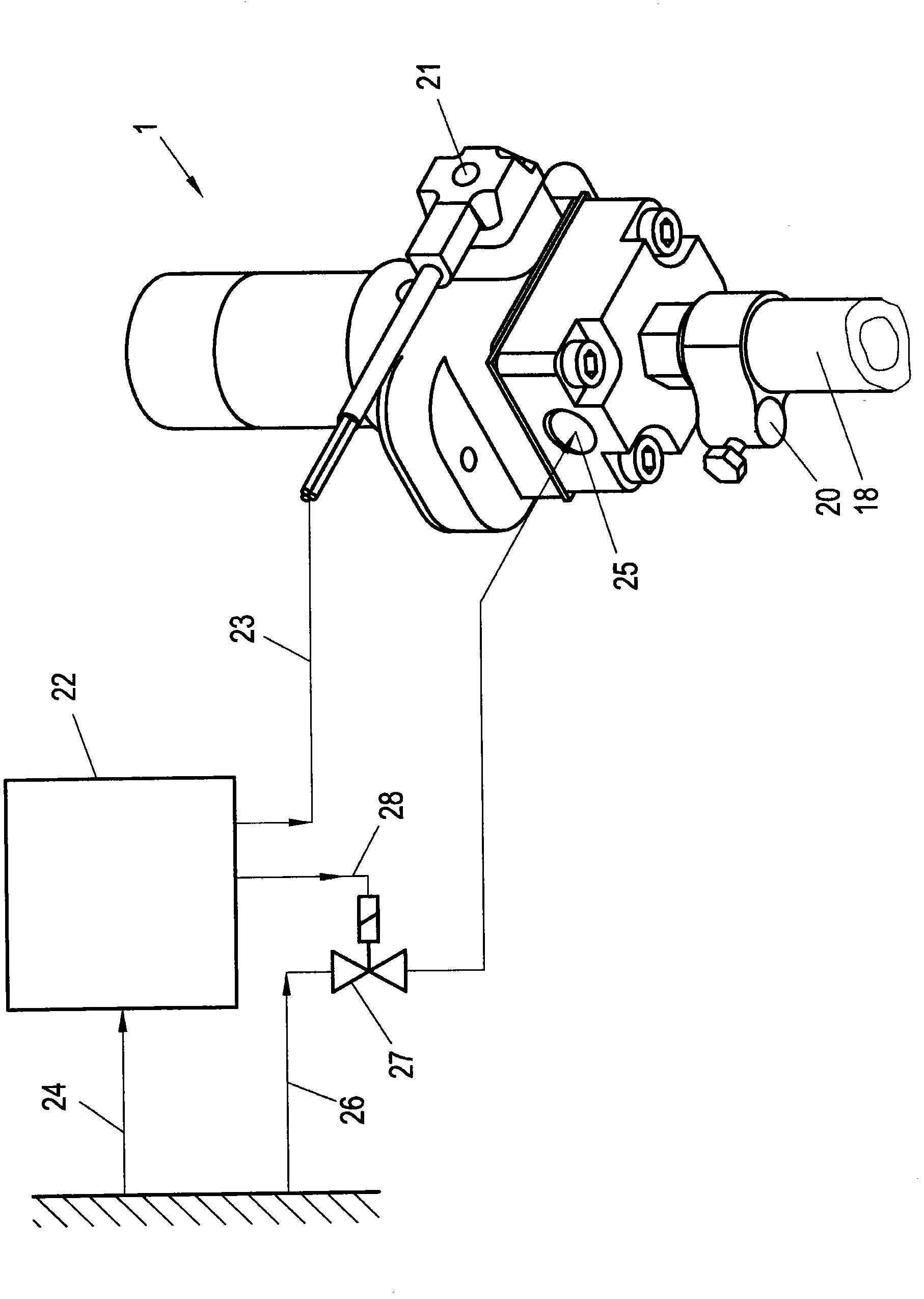

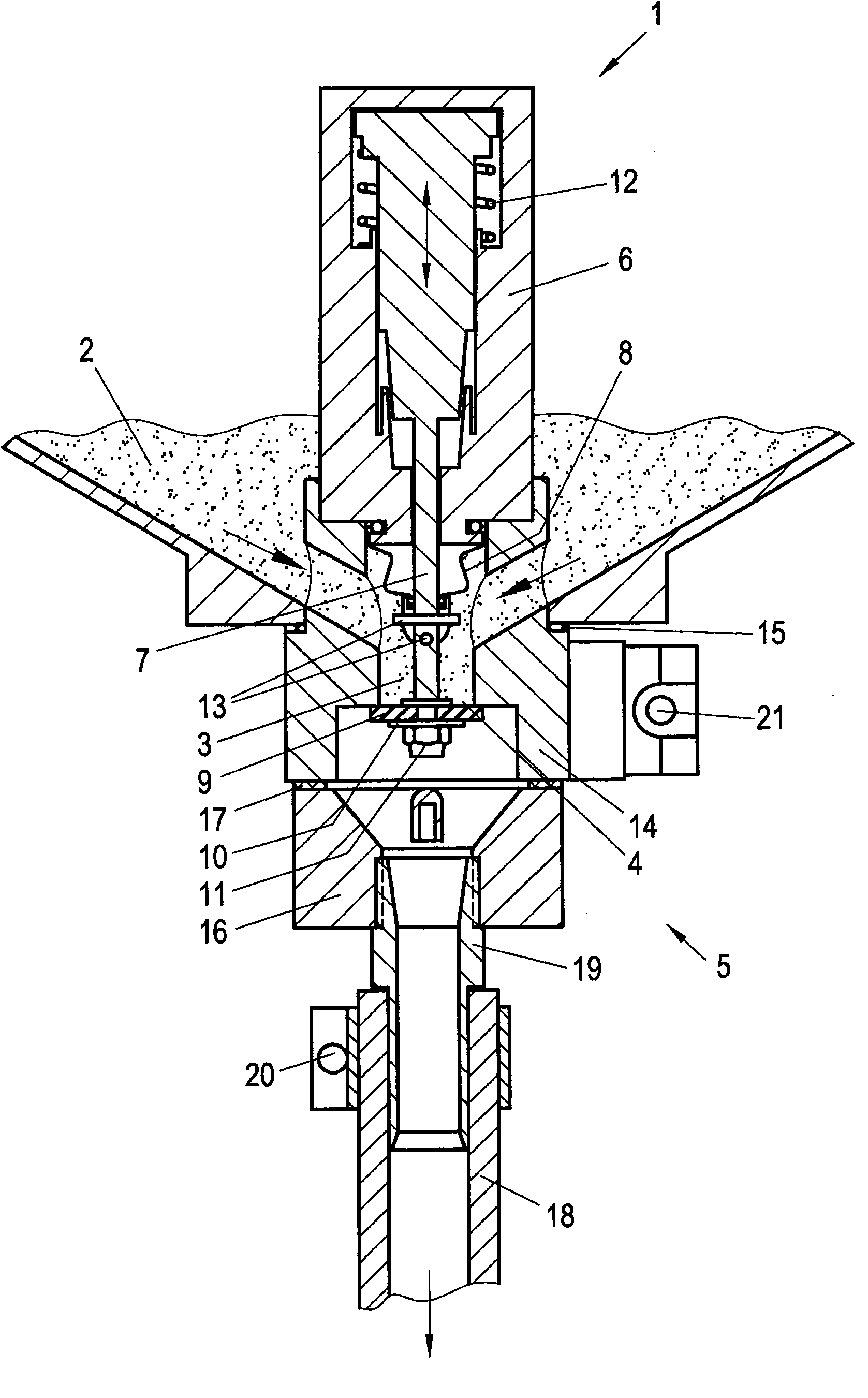

Sand dosing and blocking device

The invention relates to a sand dosing and blocking device (1) for sand spreading systems for vehicles, particularly rail vehicles with drive, the invention having a sand supply container (2) with an outlet opening (4), which can be closed by a closing element (3), for the dosed release of sand to a conveyor unit (5) which is preferably pneumatically activated, wherein the closing element (3) is formed by a lifting rod (7) of an electrically activated lifting magnet (6). According to the invention, the lifting magnet (6) is arranged inside the sand supply container (2) in the area of the outlet opening (4).

Owner:NOWE

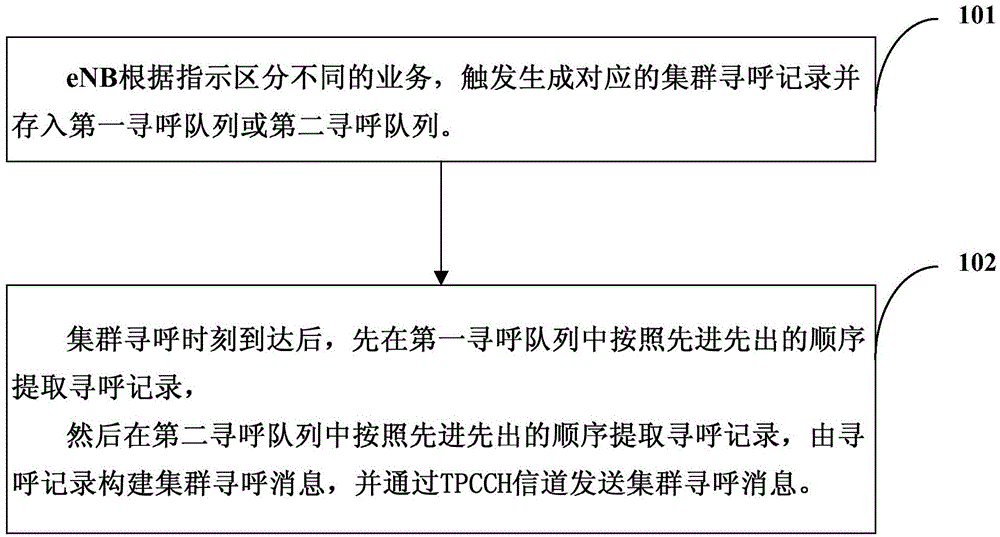

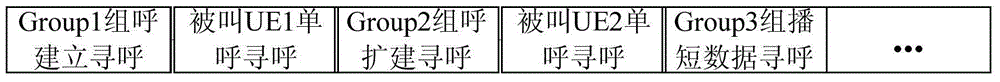

Method for sending trunking paging message

InactiveCN105792141ASpeed up deliveryQuick buildBroadcast service distributionTrunkingControl channel

The invention discloses a method for sending a trunking paging message. The method comprises the following steps that a paging message of point-to-point service about a terminal and a paging message of group service about a group are born on a trunking paging control channel TPCCH; an eNB distinguishes different services according to an indication sent by a core network or an own indication, triggers to generate corresponding trunking paging records and stores into a first paging queue or second paging queue; and after a trunking paging moment is up, the paging records are extracted in the first paging queue according to the first-in first-out order and then the paging records are extracted in the second paging queue according to the first-in first-out order, and the trunking paging message is constructed by the paging records and is sent through the TPCCH channel. After applying the embodiments of the invention, ordered sending of various service paging messages can be guaranteed, and quick call establishment and quick command issuing are realized.

Owner:POTEVIO INFORMATION TECH

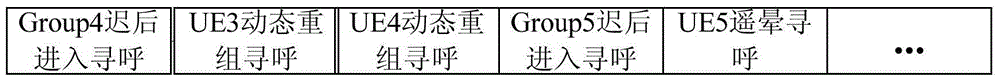

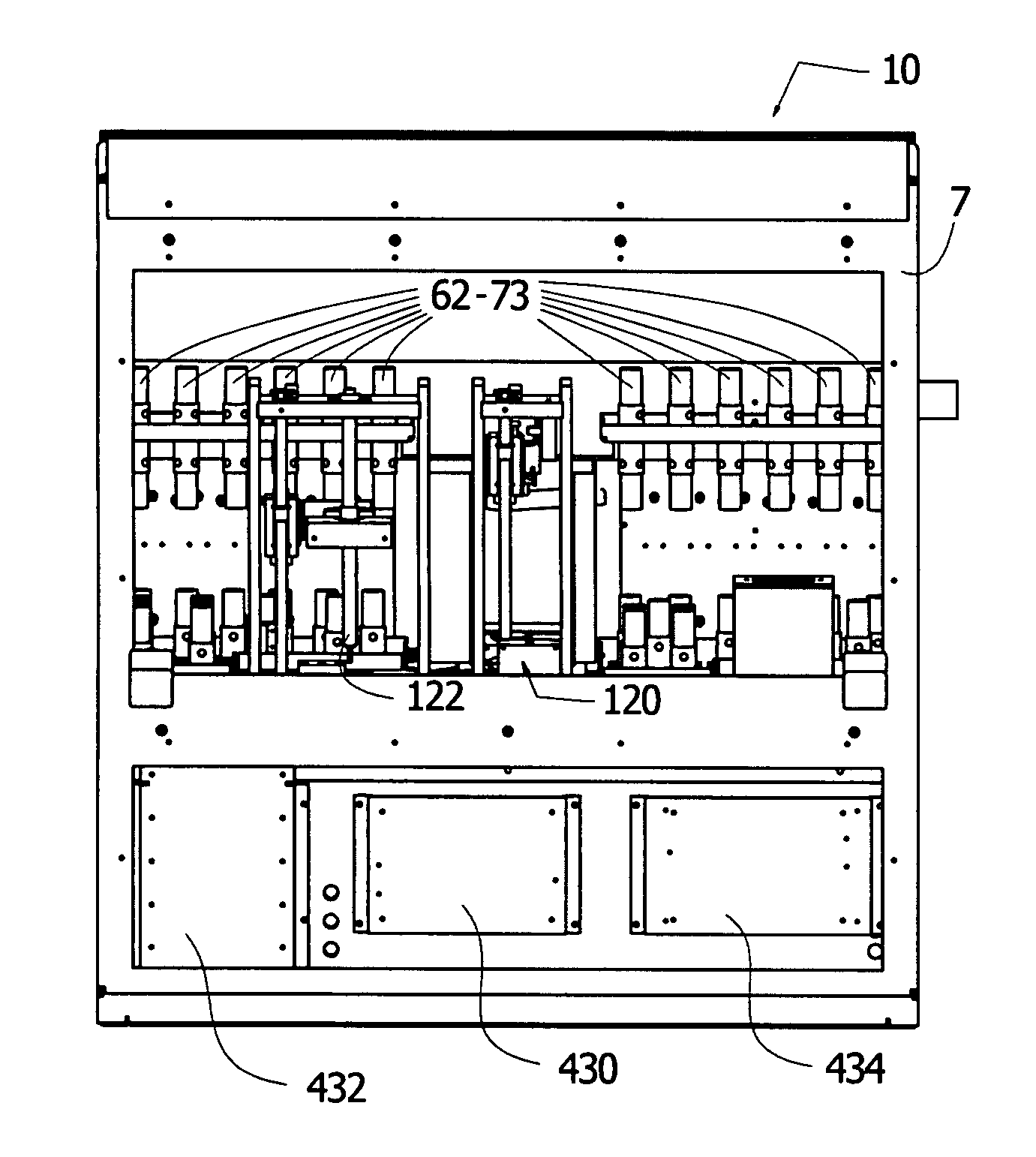

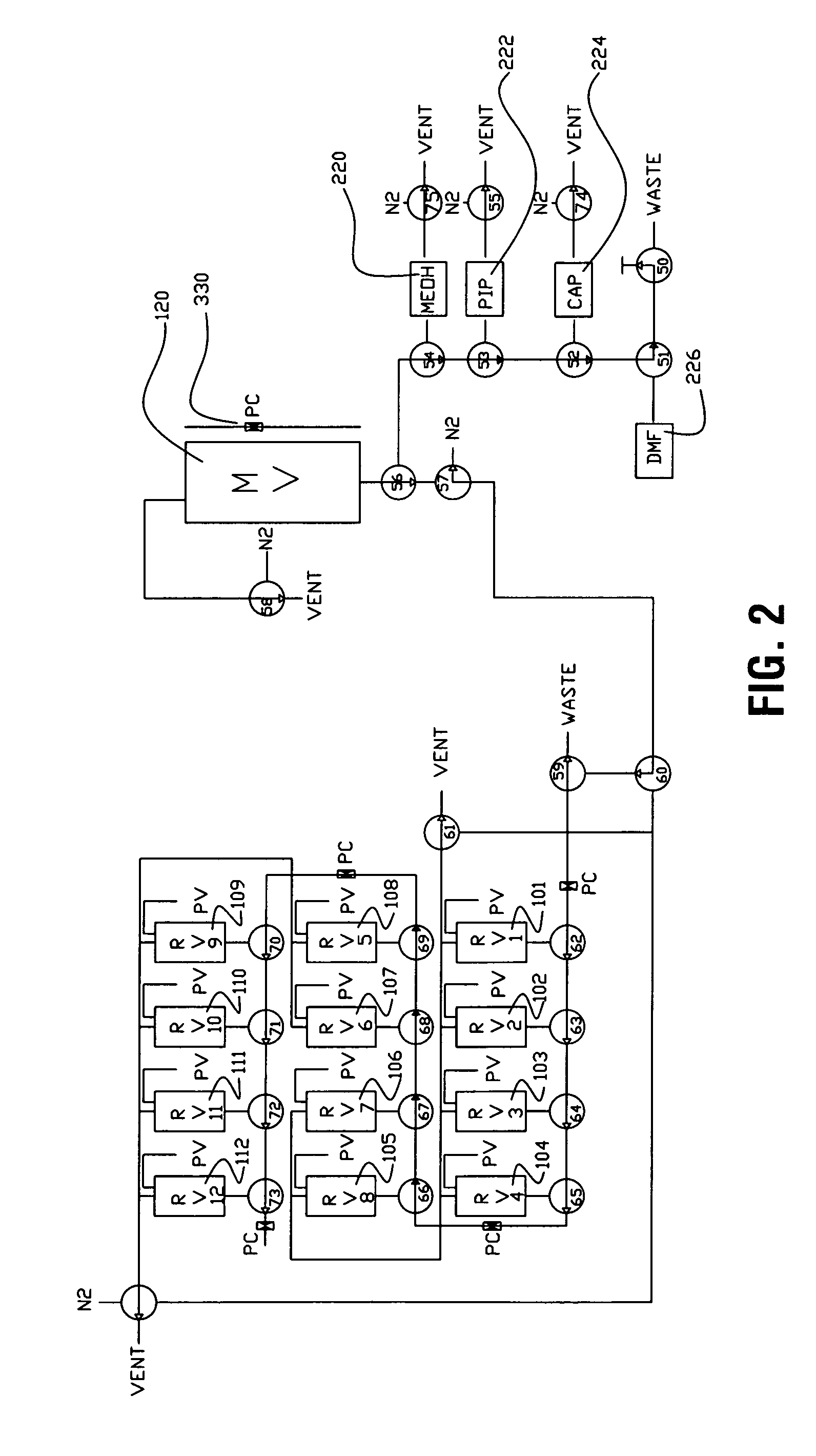

Automated peptide synthesizer

InactiveUS20150217254A1Eliminates cleaning stepSpeed up deliveryProcess control/regulationSequential/parallel process reactionsBiochemical engineeringBiology

A device capable of synthesizing a plurality of selected peptides by automatically mixing various amino acids, solvents, and activators and adding these to resins contained in a plurality of individual reaction vessels. A plurality of amino acids are contained in vessels within a carousel which is rotated into position where a needle is inserted into a selected vessel to transport the amino acid to a pre-reaction vessel for mixing with other selected amino acids which were previously drawn from the carousel. The mixture of amino acids is then transported to a reaction vessel containing the resin balls for growth of the selected peptide. A computer controls valves and pumps and is programmed to mix selected elements, apply the mixture to resins and grow peptides. A preferred method reduces cycle time and saves solvent by using the activator delivery step to simultaneously clean the needle of amino acid residue.

Owner:BOROOMAND MOHAMMAD

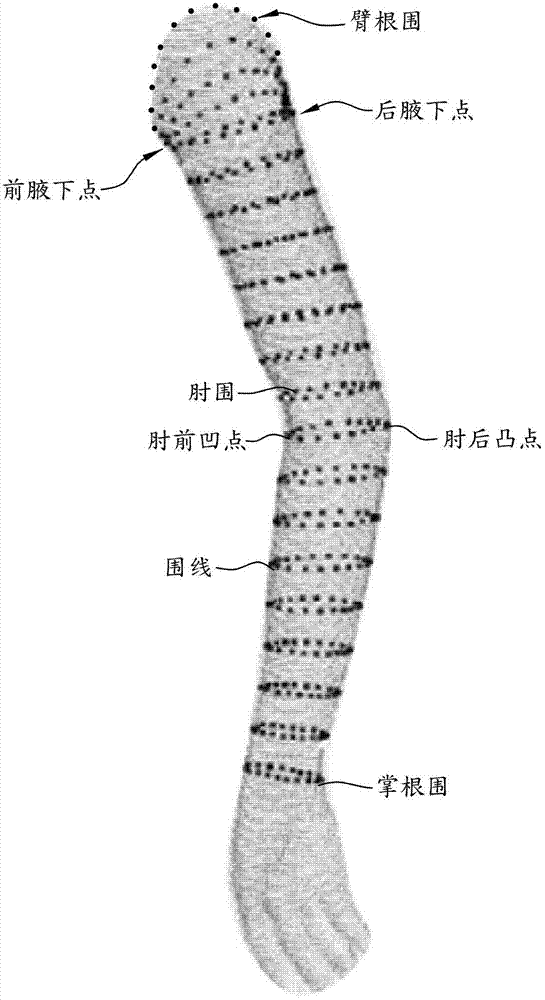

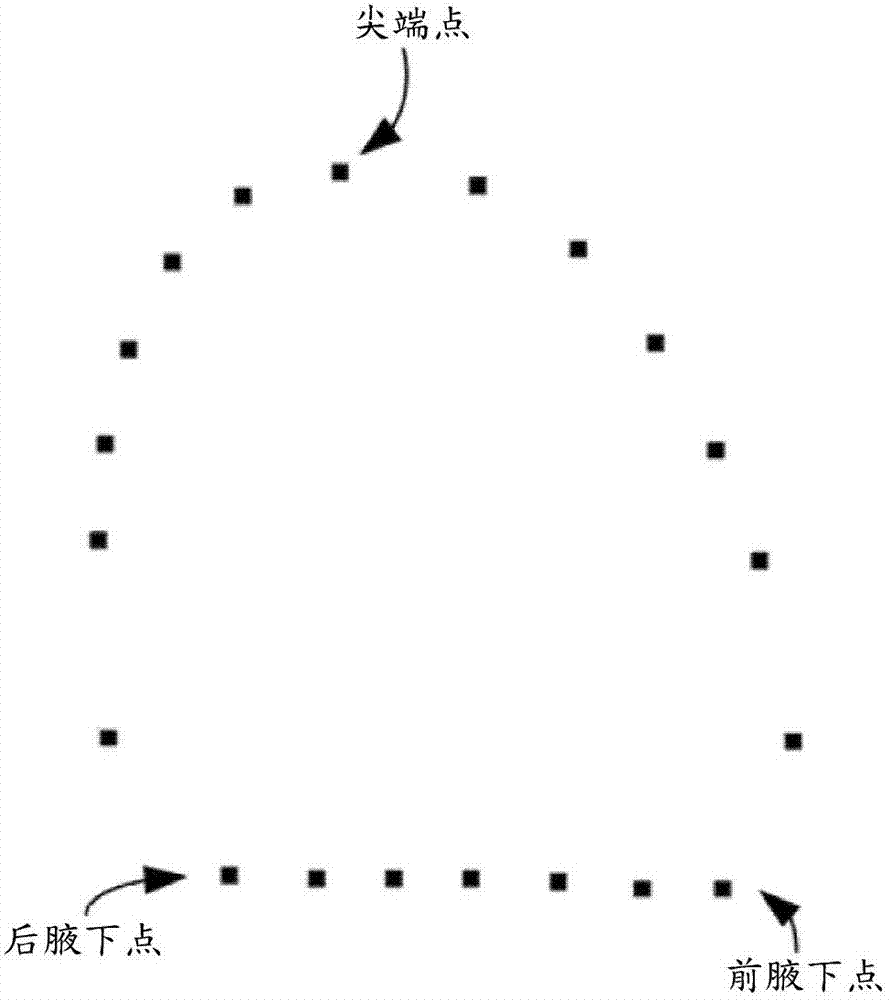

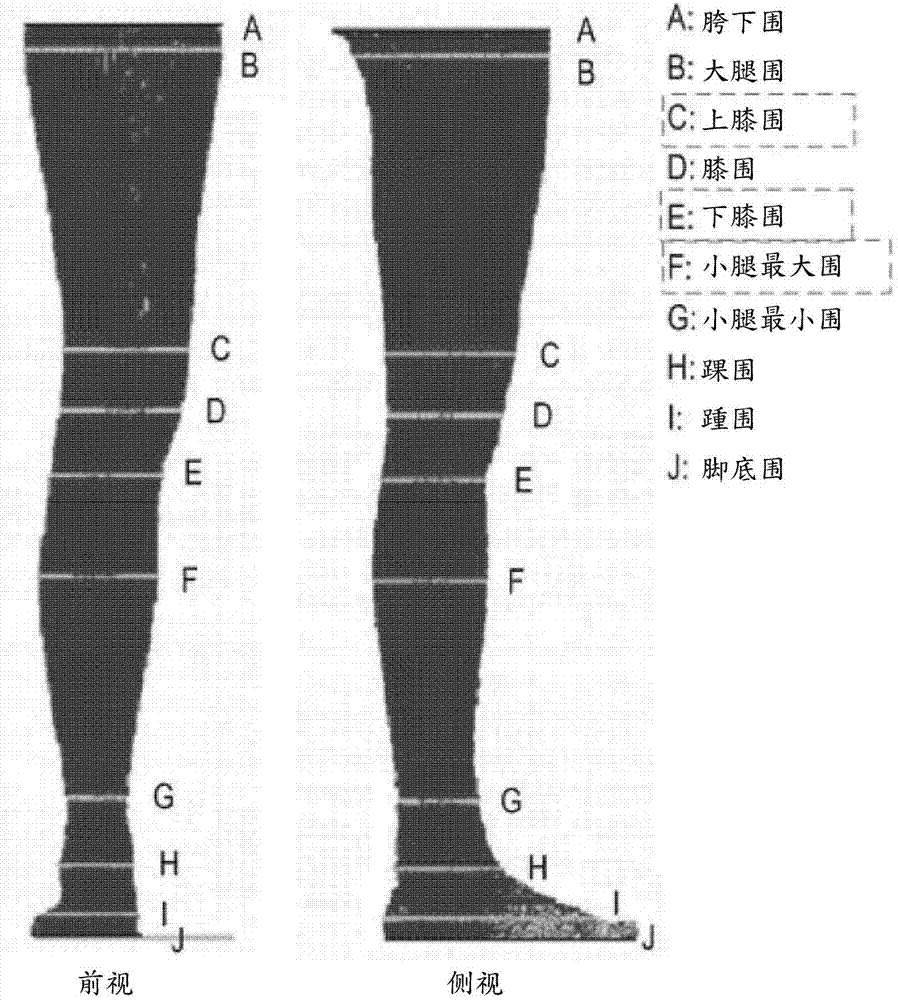

Feature-based data structure for digital manikin

InactiveCN103021027ASimplify the build processEasy to storeEducational modelsTeaching apparatusHuman bodyEngineering

A feature-based data structure of a digital manikin for describing the exterior features of a body comprises a plurality of feature points of the body, a plurality of girth lines, and a plurality of meridian lines. The girth lines pass through the feature points. Each of the meridian lines is formed by connecting the corresponding feature points respectively out of the girth lines. The girth lines of an arm of the body include an arm-hole girth, an elbow girth, and a palm base girth. The arm-hole girth passes through the shoulder end point, the front arm pit, and the rear arm pit. The elbow girth passes through the concave and convex points on the elbow girth. The palm base girth means the location where the size variation of the cross-sectional profile from the fore arm to the palm is the largest. The feature-based data structure for a digital manikin can sorts no-format cloud point data of three-dimensional human body scanning into structuralized data, faithfully describes geometrical shape of a human body in the simplest structure, simplifies human body data substantially, and can be applied to fields such as medical industry, human body measurement and costume manufacturing.

Owner:蔡明俊

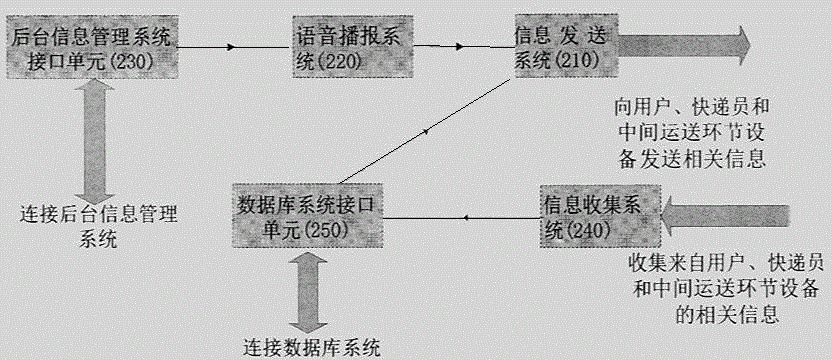

Virtual liaison based real-time express delivery information system and device

PendingCN104951915ASpeed up deliveryReduce direct contactLogisticsElectronic documentContacting Clients

An embodiment of the invention provides a virtual liaison based real-time express delivery information system and device and relevant contact rules among the virtual liaison, senders, recipients, couriers and the device of a transporting link, and provides a method based on the system for sending and receiving the express items. According to the system, the virtual liaison uses a computer program in a server in an express delivery management center to complete processes of multiple thinking, judging and contacting clients during pick-up and delivery by a courier, and pick-up and delivery electronic documents for the couriers and electronic receipts for the recipients are utilized to ensure legality of the couriers and the recipients during mailing and receiving. The system also introduces an evidence analysis and problem processing module, and uses relevant evidences collected during all links to analyze problems occurred during the express delivery, determine accountabilities and provide determining evidences to relevant people.

Owner:桂林 +1

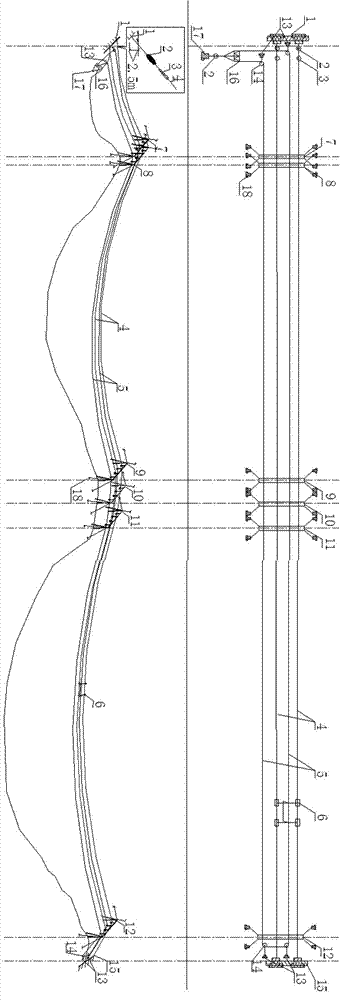

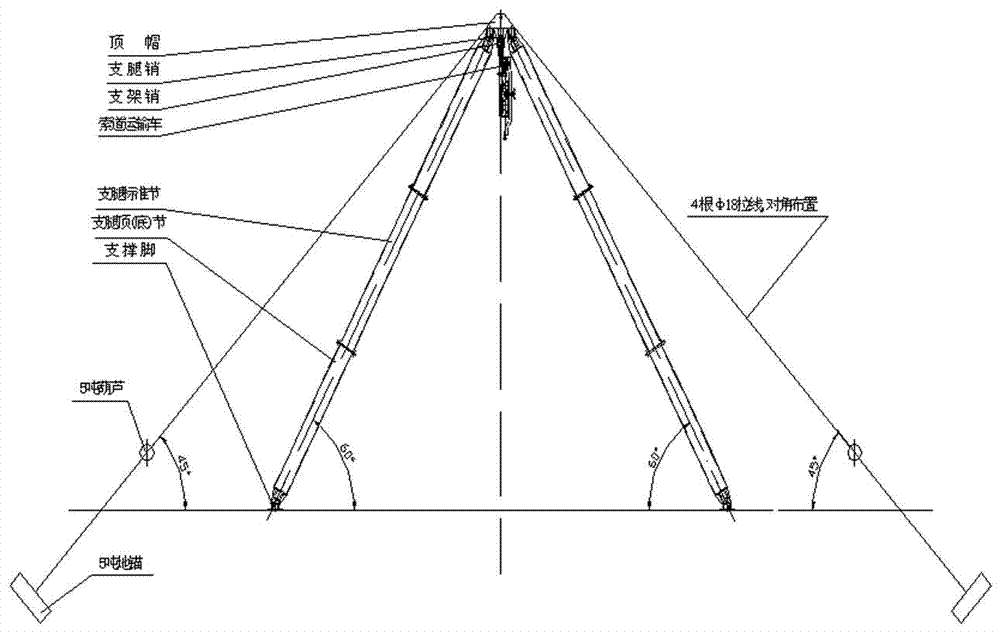

Construction method for transmission line project material transport by prefabricated cableway

The invention relates to a construction method for transmission line project material transport by a prefabricated cableway. The construction method includes the steps of S01, supporting pillar mounting, S02, pulling cable erection and driving device mounting, S03, driving device mounting, S04, carrying cable erection, S05, traveling trolley selection, and S06, cableway operation test. The construction method has the advantages of applicability to material transport in mountainous areas and hilly grounds, high applicability, simplicity in application, convenience in maintenance, high working efficiency, little environmental destruction and the like.

Owner:STATE GRID CORP OF CHINA +2

Conveying and impurity suction device for melt-blown cloth production

ActiveCN111826920ASmooth and smooth pressing and fixingPress and fix evenlyMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention discloses a conveying and impurity suction device for melt-blown cloth production, and belongs to the field of melt-blown cloth production equipment. A melt-blown cloth pressing rotary roller is arranged on the upper side of a cloth feeding and conveying rotary roller, a front material guide rotating roller and a rear material guide rotating roller are rotationally connected to a cloth conveying machining bracket in sequence, a front positioning cloth pressing plate is fixedly arranged on the upper side of a front lifting guide plate, a rear positioning cloth pressing plate is fixedly arranged on the upper side of a rear lifting guide plate, a cloth discharging and conveying rotary roller is rotationally connected to the cloth conveying machining bracket on one side of the rear material guide rotating roller, a lifting material guide rotating roller is rotationally connected to a lifting reciprocating guide plate, a reciprocating impurity suction material pipe is arrangedbetween the front positioning cloth pressing plate and the rear positioning cloth pressing plate, and an impurity suction connecting hose is arranged in the middle of the upper side of the reciprocating impurity suction material pipe in a communicating mode. The conveying and impurity suction device for melt-blown cloth production is reasonable in structural design, melt-blown cloth can be pressed and fixed intermittently, efficiently and stably in the conveying process, then the melt-blown cloth can be subjected to segmented impurity suction machining conveniently and smoothly, the automation degree of melt-blown cloth production and machining is improved, and the requirements of production and use are met.

Owner:桐乡市中瑞环保科技有限公司

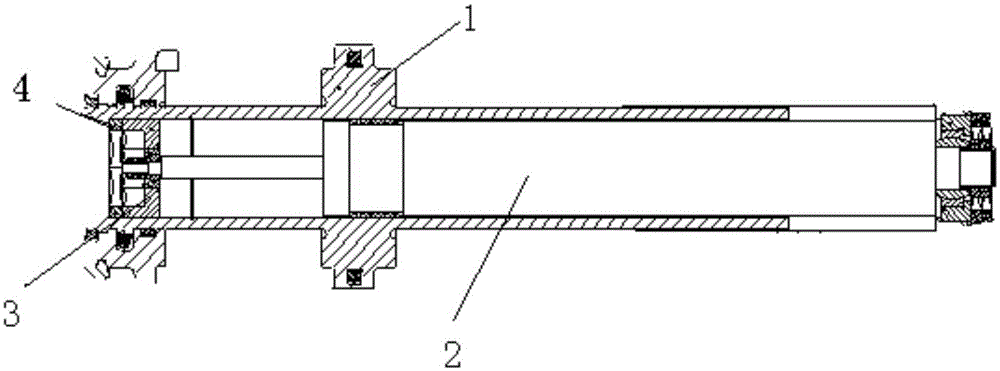

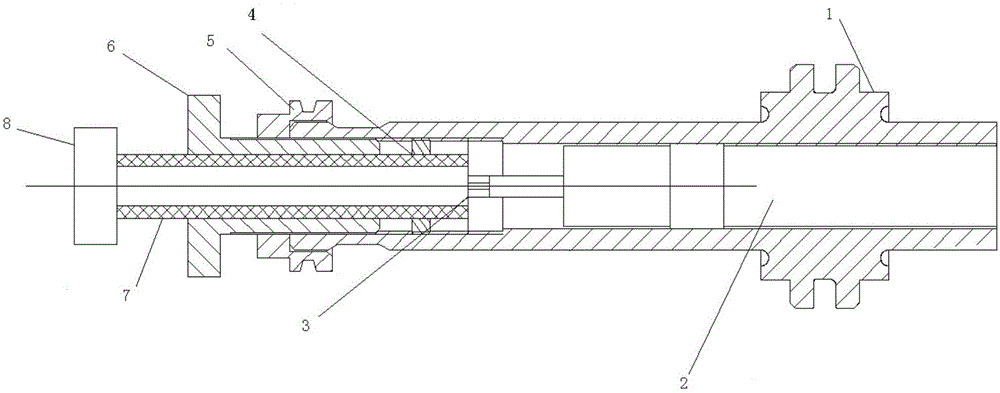

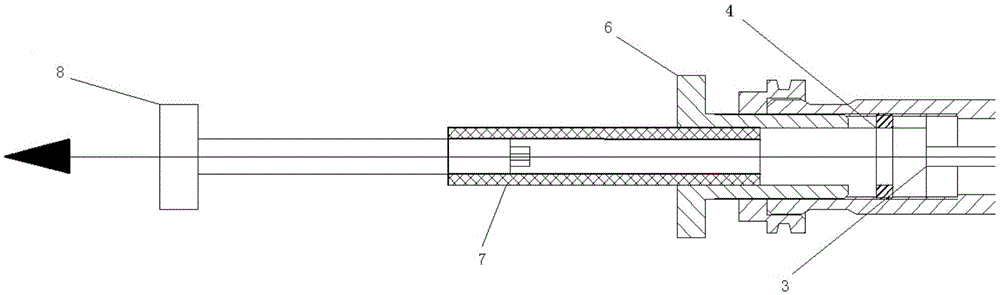

Zero adjustment device for servo actuator

ActiveCN105041761AAvoid Zero Position OffsetReduce the number of repeated debuggingFluid-pressure actuatorsServo actuatorEngineering

The invention discloses a zero adjustment device for a servo actuator. The zero adjustment device comprises a piston rod, a displacement sensor and an adjustment component, wherein the adjustment component comprises a piston rod fixing part, a guide rod nut locking part and a zero adjustment part; outer threads of the hollow piston rod fixing part are connected with inner threads of a locking nut, and then are connected with inner threads of the piston rod, so that the piston rod cannot do lateral rotation; the hollow guide rod nut locking part penetrates through the hollow part of the piston rod fixing part and is arranged in a front-end nut so as to adjust the axial movement of the front-end nut; the zero adjustment part penetrates through the hollow part of the guide rod nut locking part, and one end of the zero adjustment part is arranged in a guide rod nut to adjust the guide rod nut, so that the axial movement of the displacement sensor is further controlled. According to the zero adjustment device disclosed by the invention, during a zero adjustment process, the zero position offset of a product is effectively avoided; the frequency of repeated debugging is reduced; the delivery schedule of the product is accelerated; and the labor cost is reduced.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

Rabbit excrement organic-inorganic compound fertilizer and production method thereof

InactiveCN102491817AIncrease vitalityImprove the soilFertiliser formsFertilizer mixturesFertilizerNutrient

The invention discloses a production method of a rabbit excrement organic-inorganic compound fertilizer. The compound fertilizer is prepared by the following procedures of: fermenting rabbit excrement serving as an organic component, drying and smashing; and mixing with nitrogen, phosphorus and potassium serving as raw materials, granulating, drying, spraying a moisture-proof anti-blocking agent, and the like. After the compound fertilizer is applied, the physical and chemical properties of soil can be improved, the absorption of nutrients by crops is promoted, crop plants develop robustly, crop yield is increased, product quality is improved, and the aims of high yield and high quality are fulfilled. When the compound fertilizer is applied to garlic planting, the yield of garlics can be increased by 12-25 percent, and the yield of garlics per mu is increased by 96-200 kilograms; and when the compound fertilizer is applied to apple production, the yield is increased by 34 percent. As proved by tests, the rabbit excrement organic-inorganic compound fertilizer has a good yield increasing effect.

Owner:邳州市东方养殖有限公司

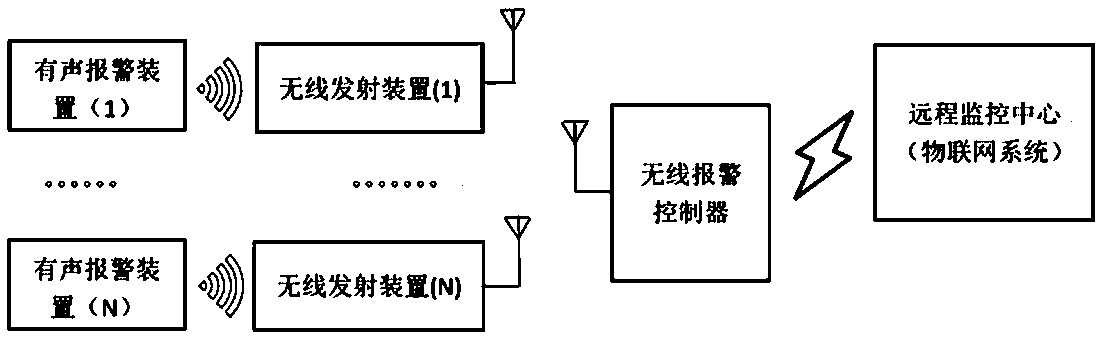

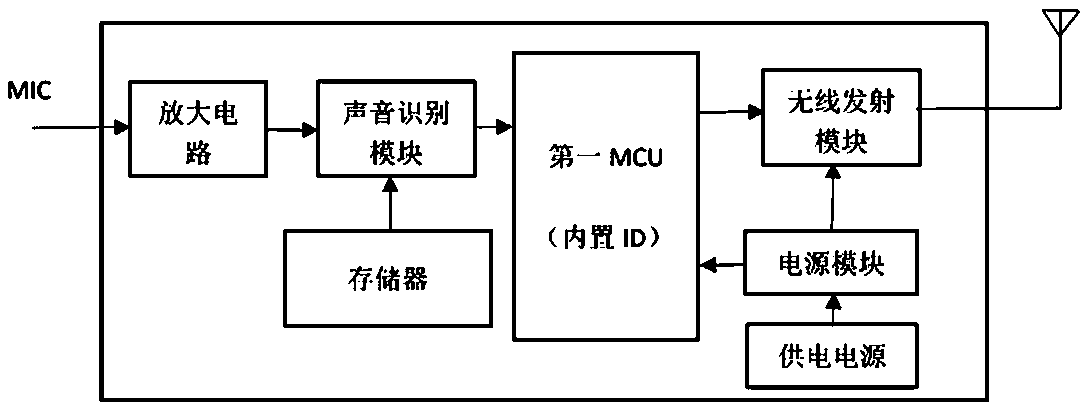

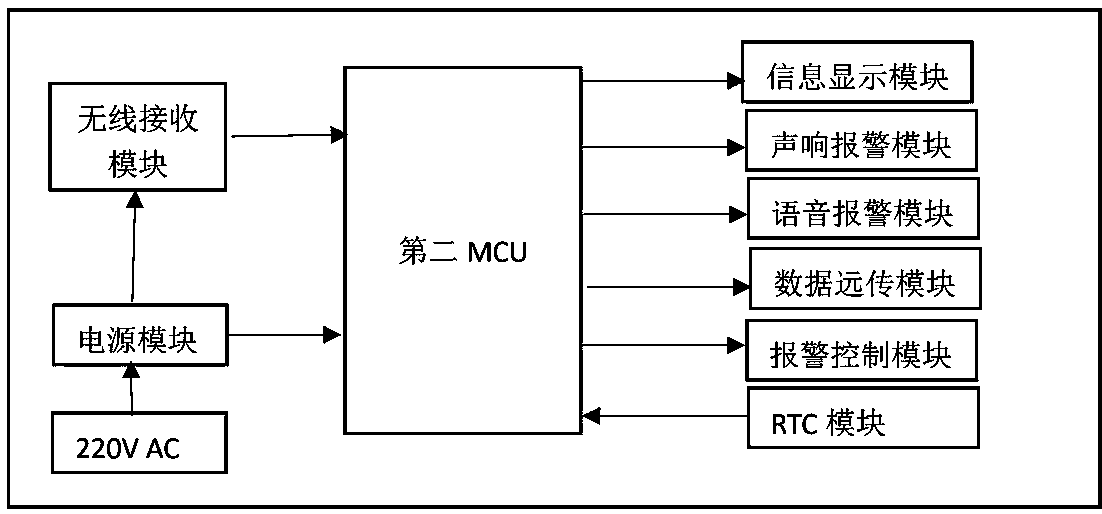

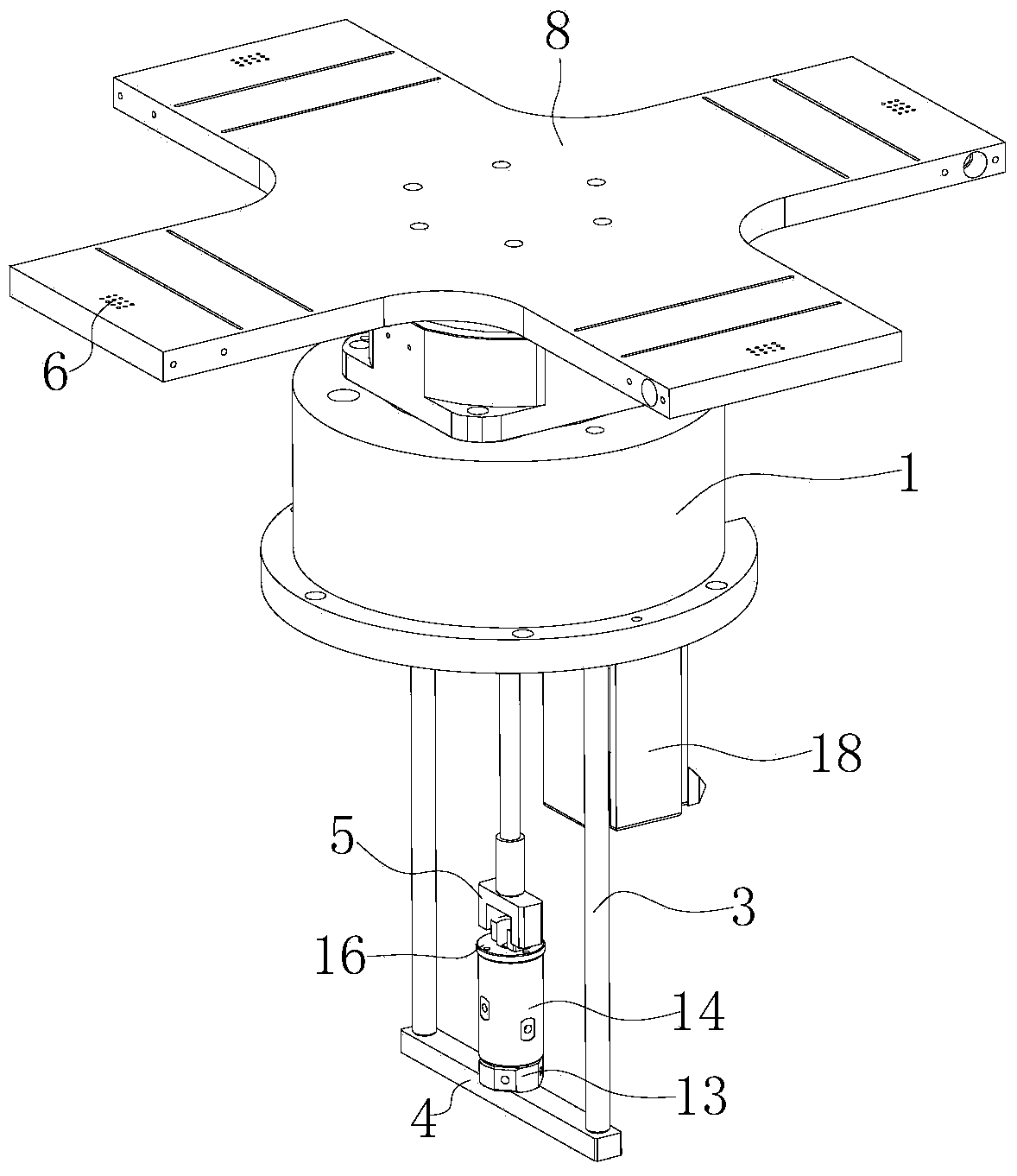

Sound connection-based wireless alarm system

The invention discloses a sound connection-based wireless alarm system comprising a number of acoustic alarm devices, a number of wireless transmission devices having sound recognition functions and awireless alarm controller; the acoustic alarm devices are connected with corresponding devices, equipment or systems; when abnormal events or faults occur in the devices, equipment or systems, different alarm sound is sent out according to categories of the events or faults; the wireless transmission devices are used for collecting alarm sound of the acoustic alarm devices, alarm categories can be identified, corresponding alarm information can be generated and then sent out wirelessly, the wireless alarm controller is used for receiving and analyzing the alarm information of the wireless transmission devices having the sound recognition functions, and analysis results can be uploaded to a remote monitoring center or an Internet-of-Things system. The sound connection-based wireless alarmsystem can be used for unified networked management of all independent acoustic alarm devices, and alarm information can be rapidly processed and comprehensively analyzed.

Owner:深圳市赋安安全系统有限公司

Rotating disc type multi-station automatic dispensing mechanism

ActiveCN103464345AAvoid complex wiring problemsSmall footprintLiquid surface applicatorsCoatingsEngineeringElectromagnetism

The invention discloses a rotating disc type multi-station automatic dispensing mechanism which comprises a rotating disc base, a transmission device installed on the rotating disc base, a negative pressure shunt rotary base connected with the transmission device, and a rotating disc upper board fixed to the negative pressure shunt rotary base. The rotating disc upper board is provided with at least one set of negative pressure holes. Compared with the prior art, the rotating disc type multi-station automatic dispensing mechanism has the advantages of solving the problem of complex wire arrangement caused by respective control of electromagnetism, being small in occupied space, simple in structure, accurate in locating, stable in transmission and simple and rapid in action, achieving rapid transmission locating with 360 degrees, improving the efficiency of construction operation, and effectively improving the overall production efficiency of equipment.

Owner:李志强

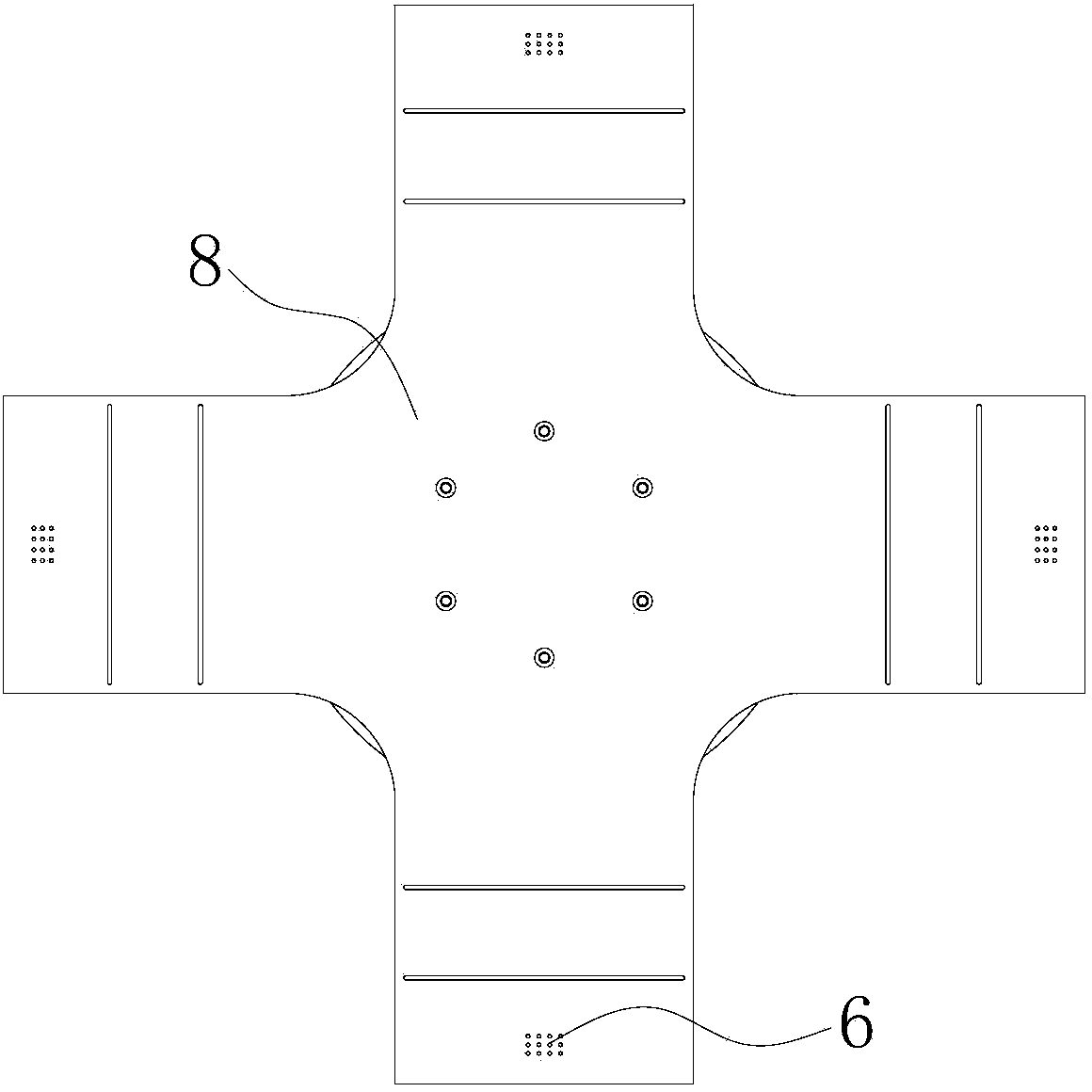

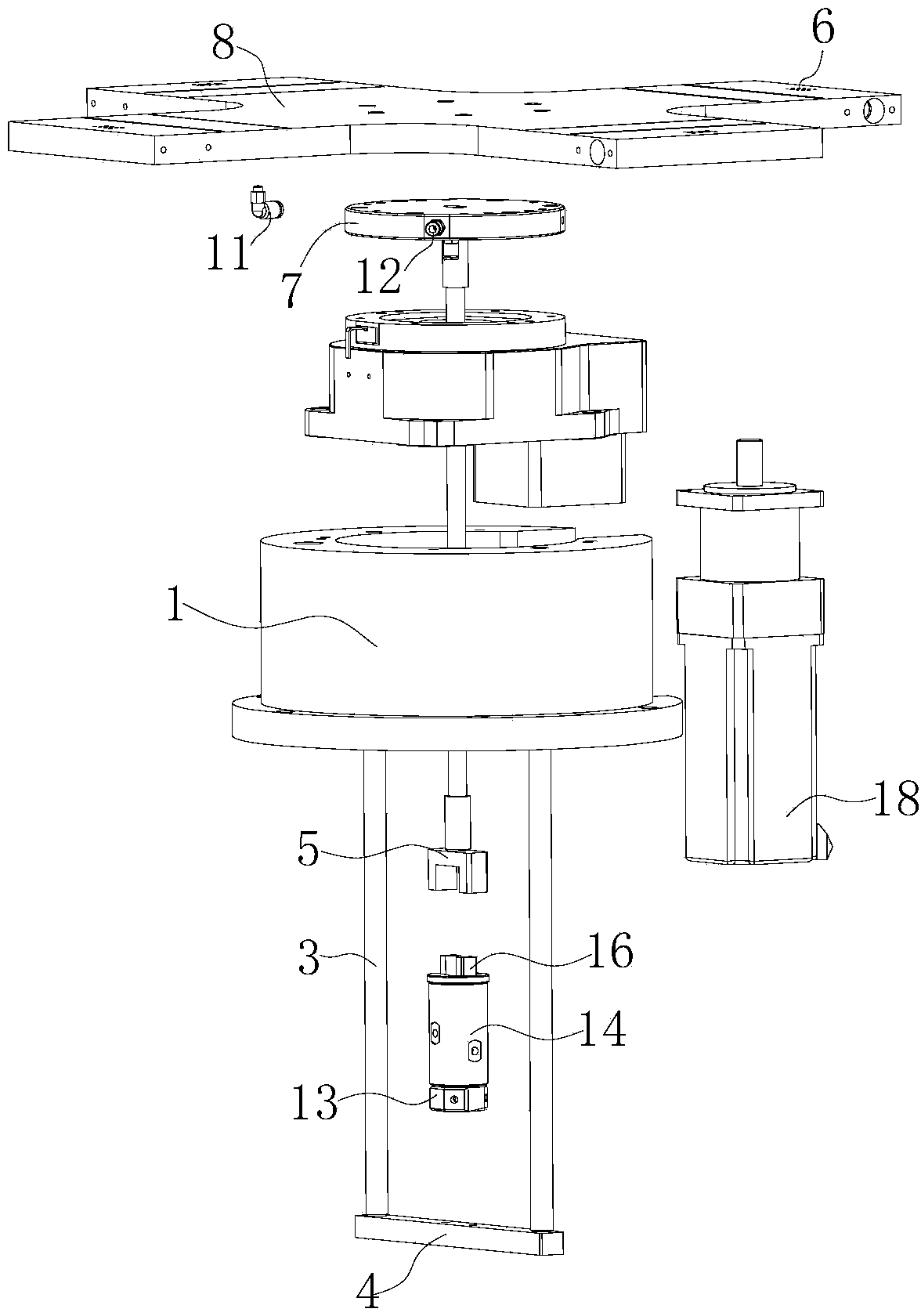

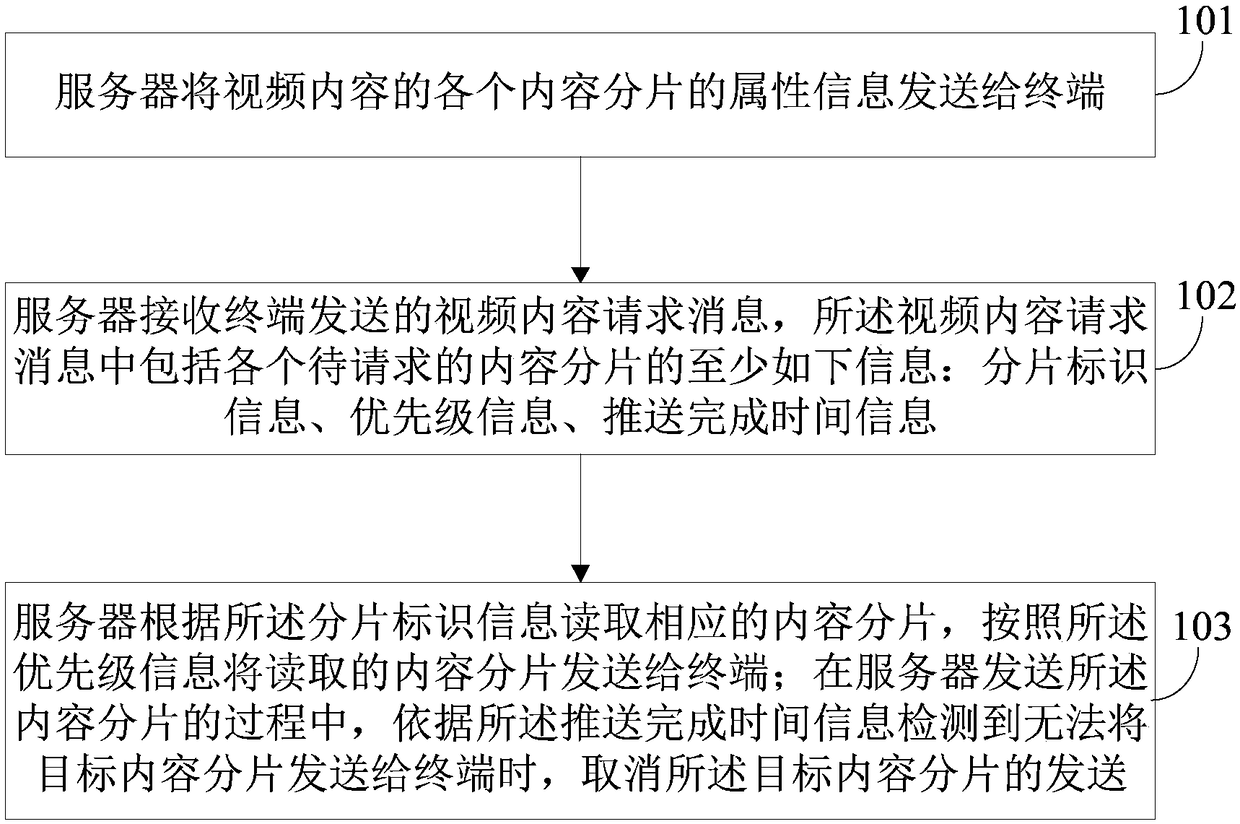

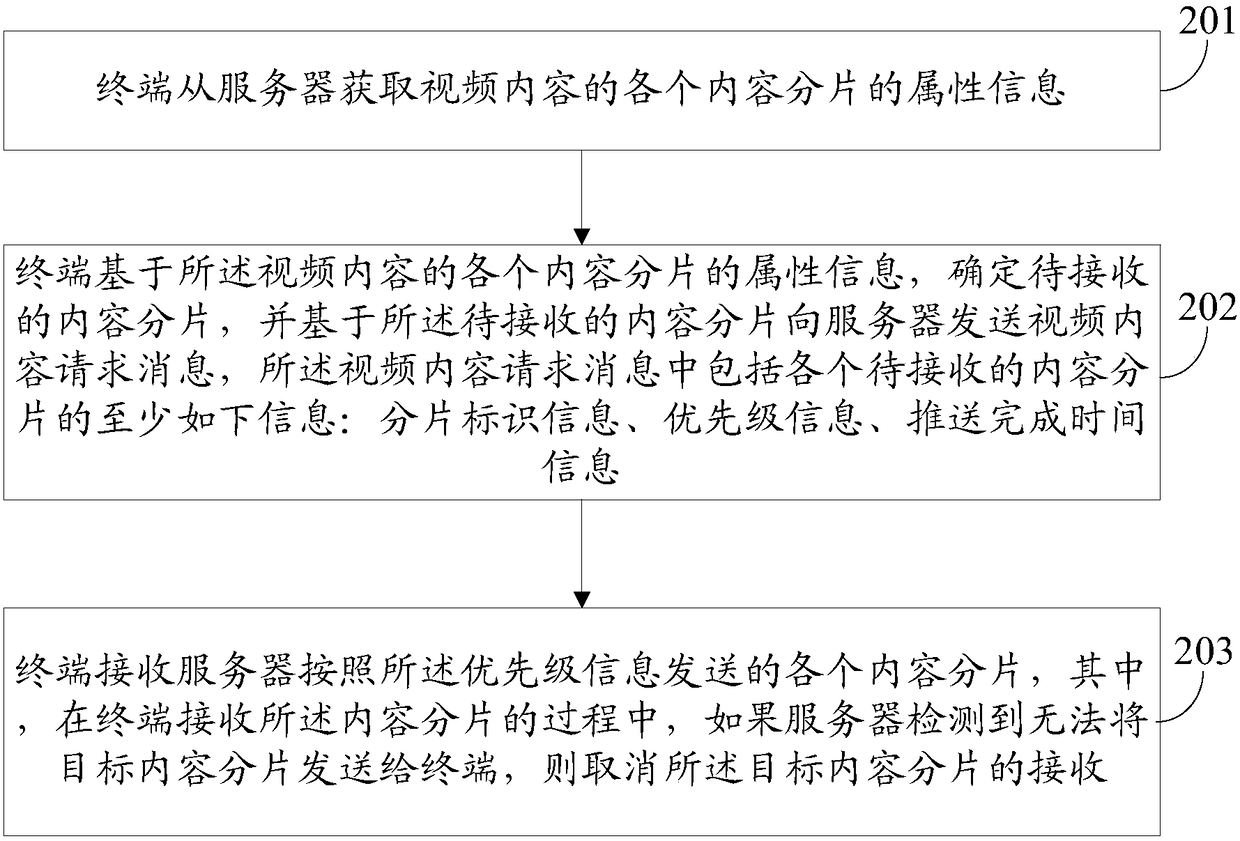

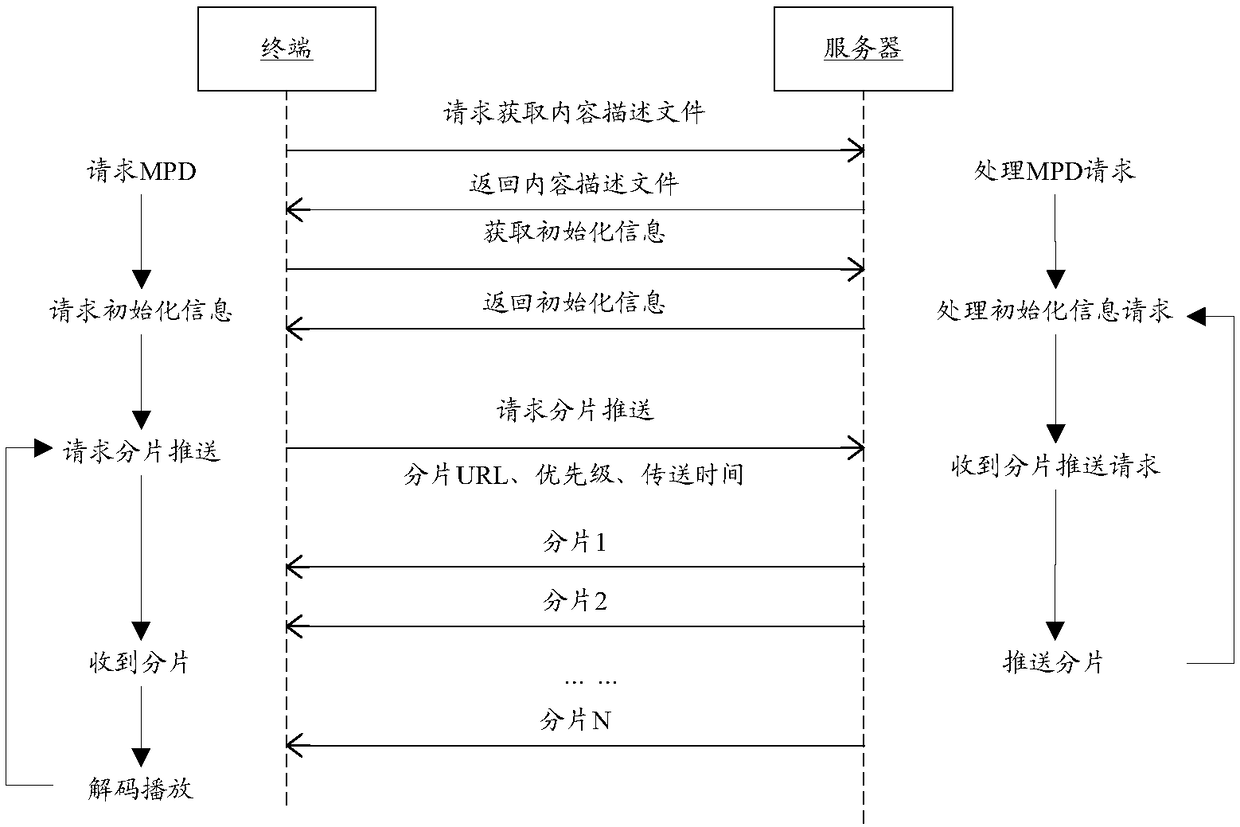

Streaming media transmission method, device and system, server and terminal

InactiveCN108337574AStable deliverySpeed up deliveryDigital video signal modificationSelective content distributionCompletion timeComputer network

The invention discloses a streaming media transmission method, device and system, a server and a terminal. The server sends attribute information of each content fragment of a video content to the terminal; the server receives a video content request message sent by the terminal, the video content request message comprising at least the following information of each content fragment to be requested: fragment identification information, priority information, and push completion time information; the server reads the corresponding content fragments according to the fragment identification information, and sends the read content fragments to the terminal according to the priority information; and in the process of sending the content fragments, when a target content fragment cannot be sent tothe terminal according to the push completion time information, the server cancels sending of the target content fragment.

Owner:ZTE CORP

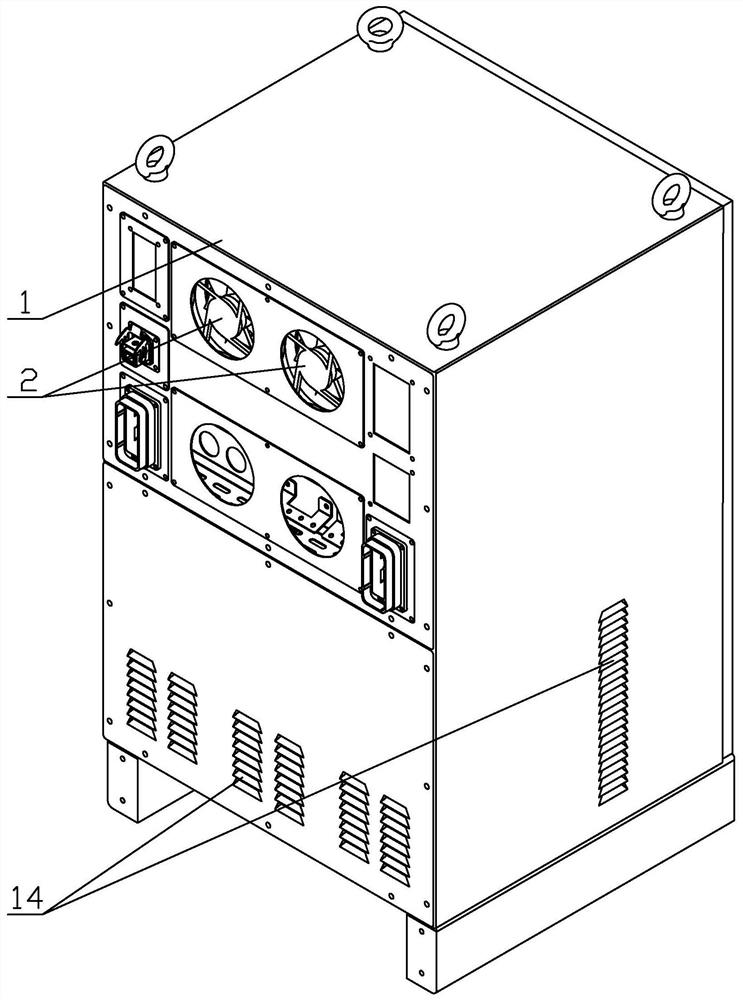

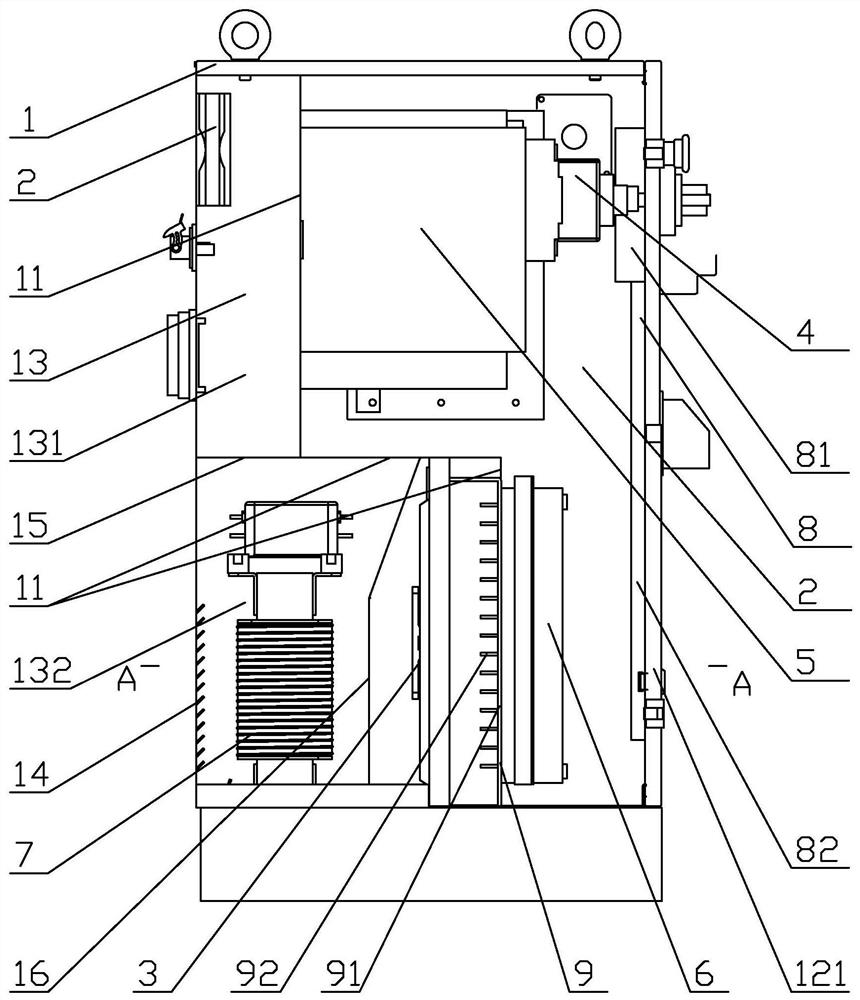

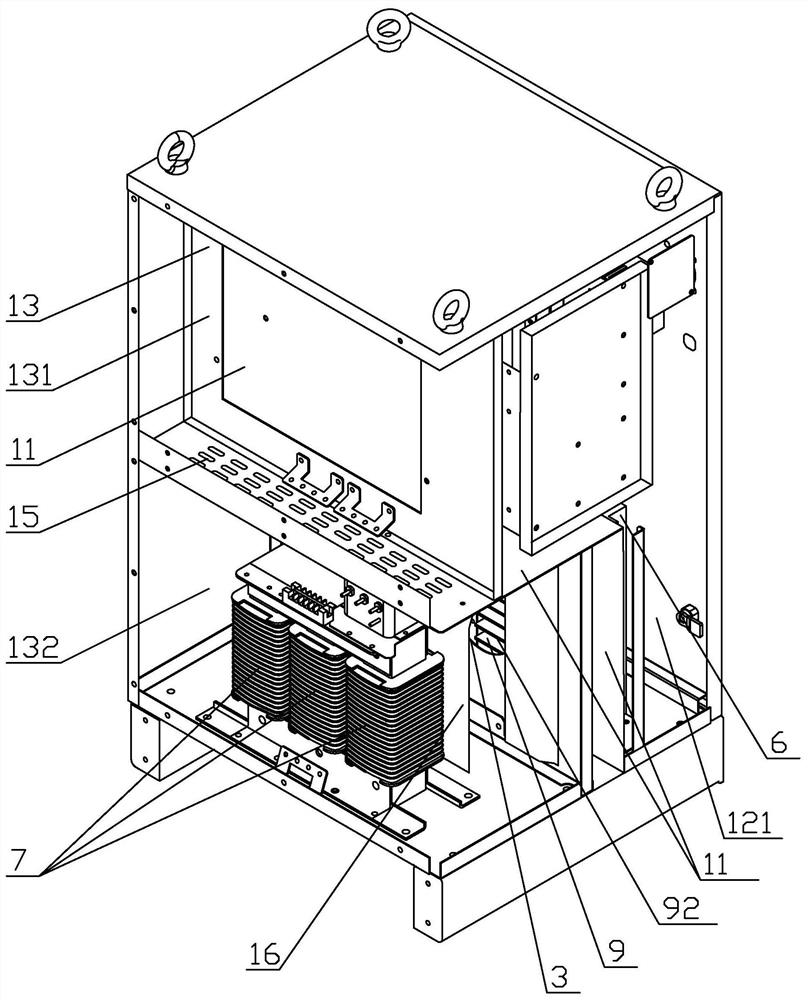

Robot control cabinet

PendingCN111901988AImprove dustproof effectImprove and meet dust resistanceClosed casingsCasings/cabinets/drawers detailsSemi openEngineering

The invention discloses a robot control cabinet which comprises a cabinet body, a partition plate and an air inlet fan. The partition plate is arranged in the cabinet body and divides the cabinet bodyinto two spaces, namely a closed space and a semi-open space; the closed space is not communicated with the outside; the air inlet fan is arranged at the semi-open space, is arranged on one plane ofthe cabinet body, and conveys air outside the cabinet body into the semi-open space of the cabinet body; a ventilation hole for air in the semi-open space to flow out of the semi-open space is formedin the cabinet body at the semi-open space; and the partition plate is positioned on one side of the closed space and is used for mounting an electrical element. According to the robot control cabinet, the partition plate with dust prevention and heat dissipation functions is used, the robot control cabinet is divided into the closed space used for dust prevention and the semi-open space used forheat dissipation, and the heat exchange performance of equipment is guaranteed while the dust prevention performance of the device is improved and met.

Owner:HANGZHOU KAIERDA ROBOT TECH CO LTD

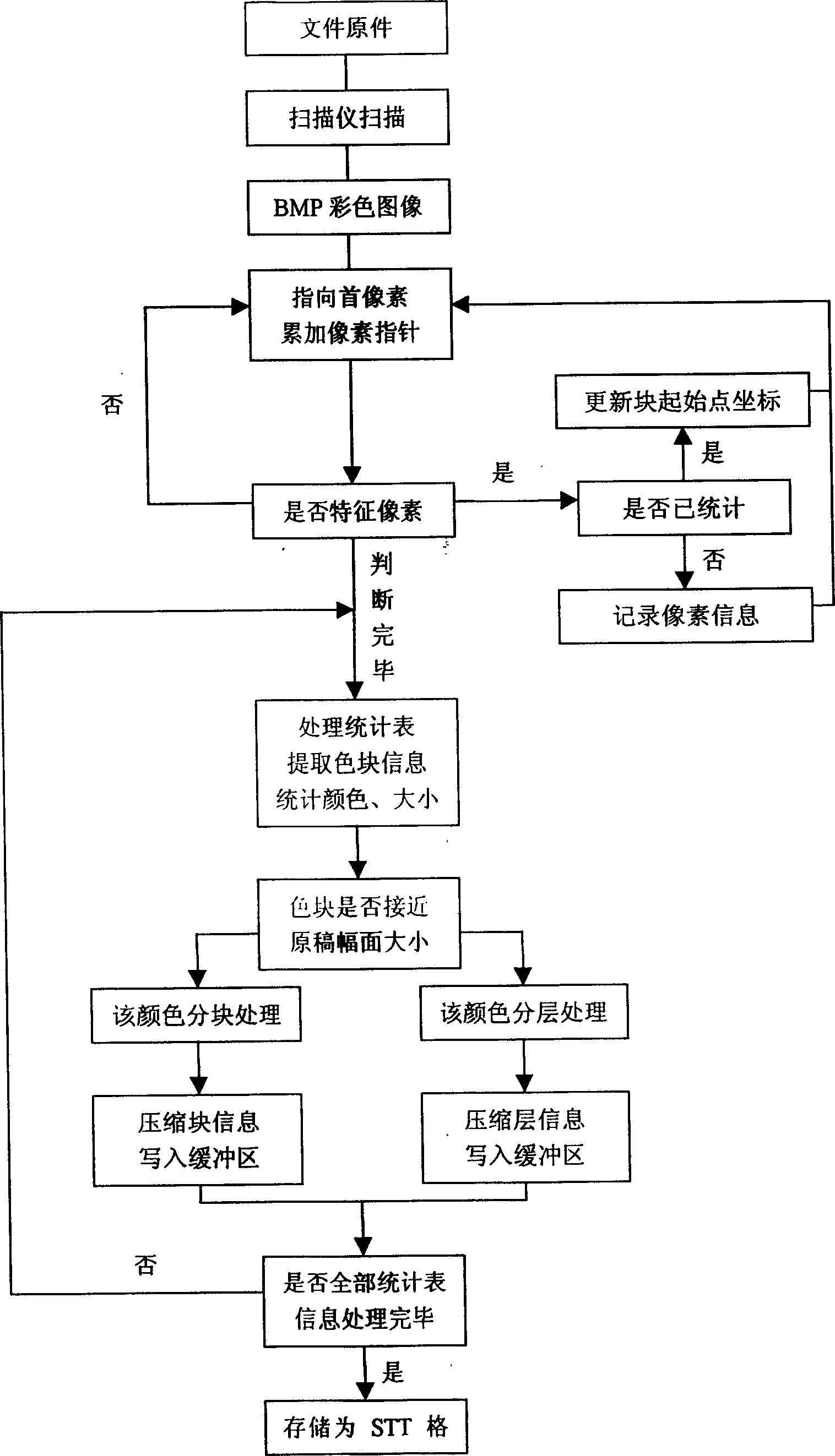

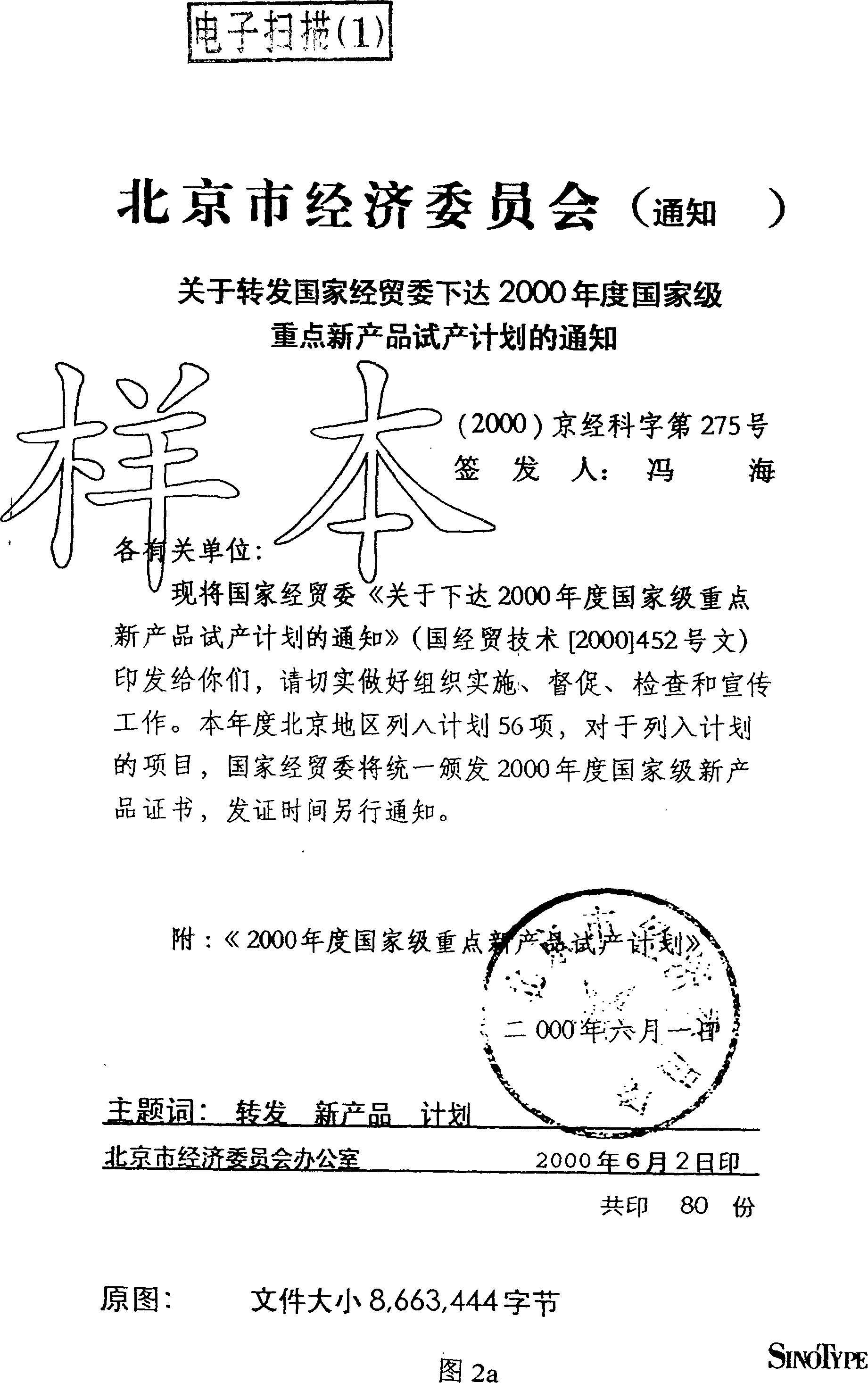

Image datamation storaging method

InactiveCN1425985ASpeed up deliveryQuality assuranceMemory systemsComputer graphics (images)Monochrome Image

The image datamation storming includes image data processing and data storing process, in which the special colors of the original image are counted and each specific color part in the image are stored in monochromic image data. To color image, especially image with relatively simple color composition, the said method has less file number formed and can ensure the quality of the restored image.

Owner:CHANGZHOU HUAWEN WRITING TECH

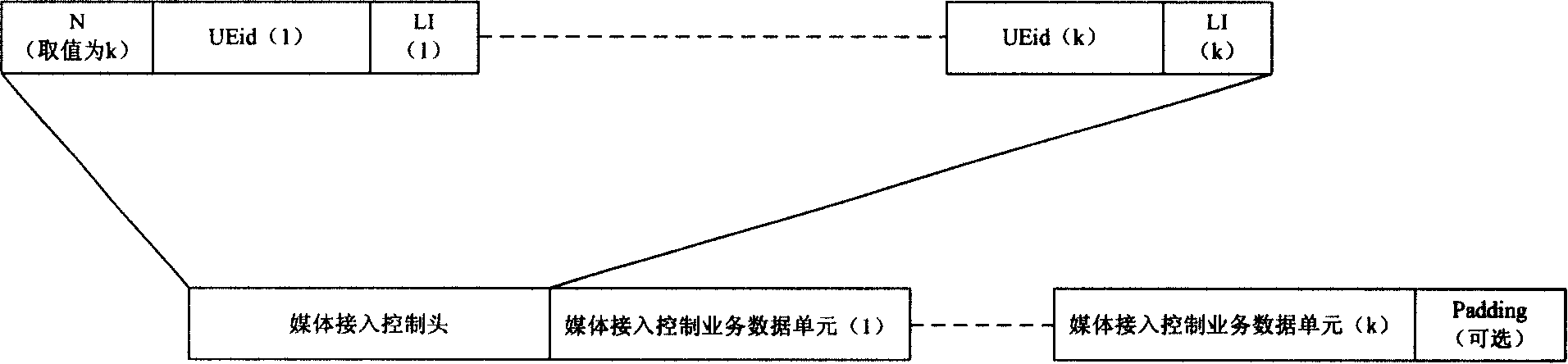

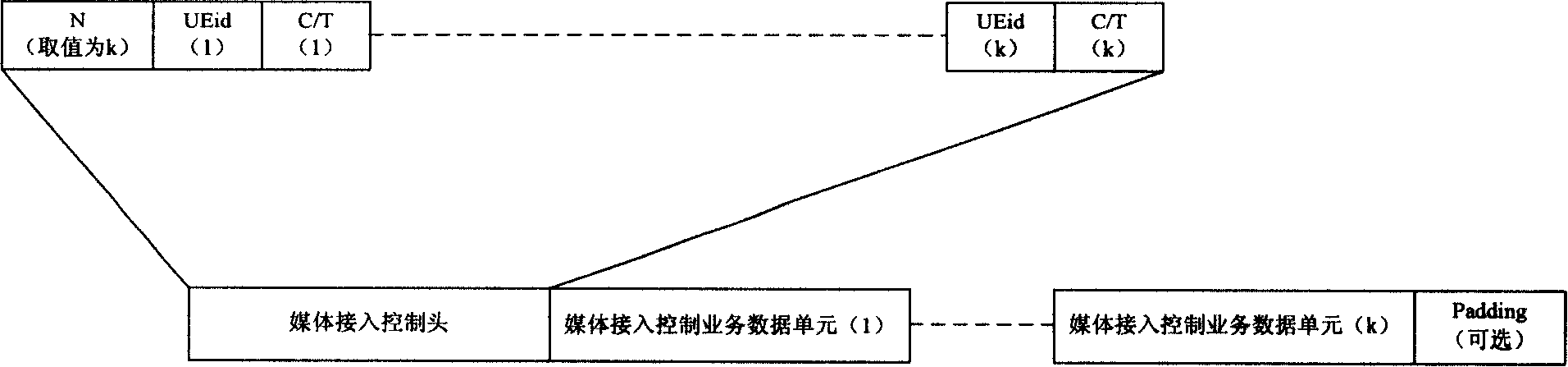

MAC protocol data unit construction device

InactiveCN101175072ASpeed up deliveryIncreased Chances of SchedulingNetwork traffic/resource managementRadio/inductive link selection arrangementsMedia access controlProtocol data unit

The invention provides the structure device of the media access control protocol data unit of downlink transfer channel used under CELL-FACH state, which comprises a merging module and a sending module. The merging module is used for merging the data packets sending to different terminals at the same time into a media access control protocol data unit; the sending module, is used for sending a media access control protocol data unit through downlink transfer channel which is used under CELL-FACH state.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com