Heat radiation device with pulsating flow and leaf vein type micro channel

A technology of heat dissipation device and micro flow channel, which is applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc. problem, to achieve the effect of good heat dissipation, strengthening the transmission of heat energy, and prolonging the time of continuous effective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

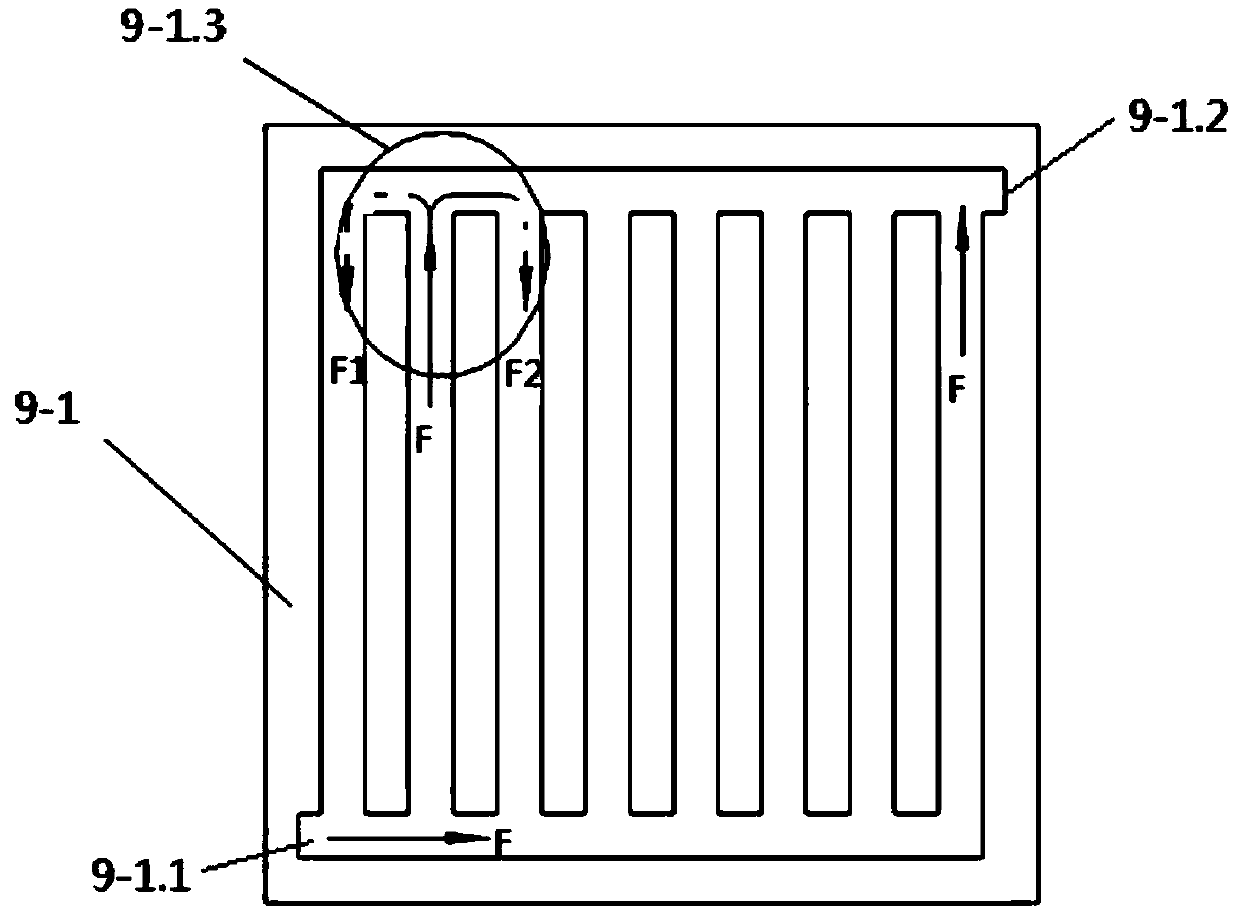

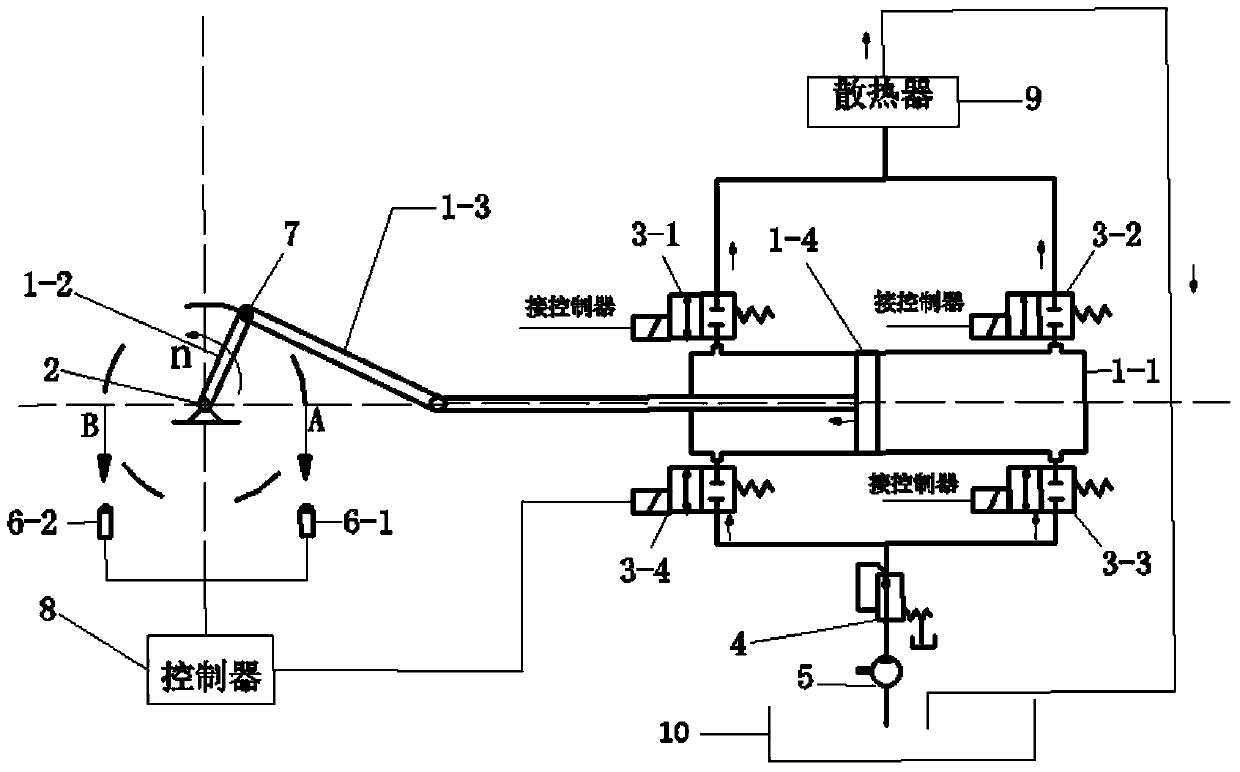

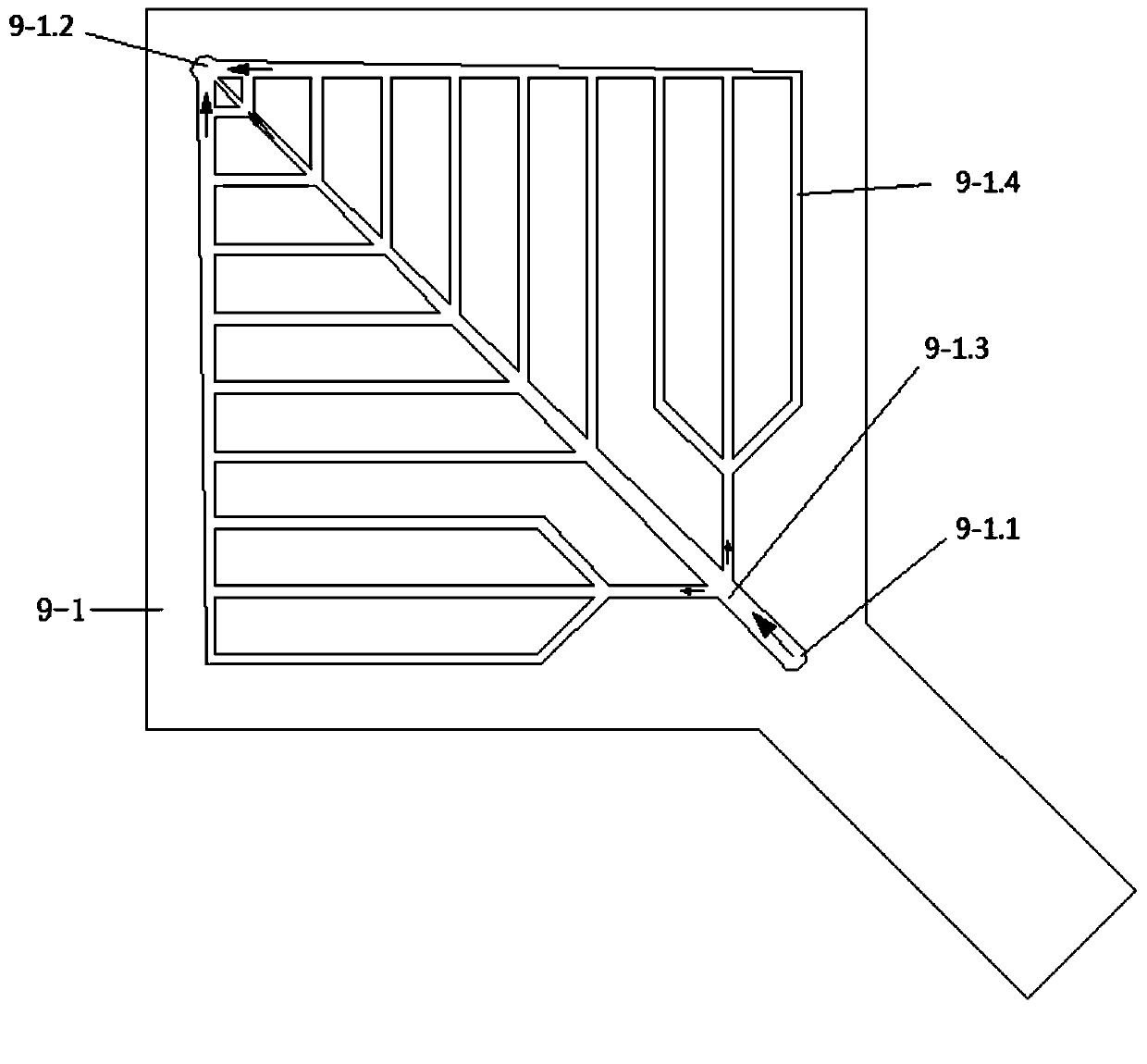

Embodiment 1

[0022]Embodiment 1: The radiator 9 in this embodiment is composed of a microchannel substrate 9-1 and a (radiator) cover plate 9-2. The main body of the microchannel heat dissipation substrate 9-1 (length×width×thickness) is 100×100× 3.0mm, the depth of each flow channel is 2mm, the size of the handle is (length×width×thickness) 50×20×3.0mm, and the total heat dissipation area is 5357.7042mm 2 , wherein: main channel 9-1.3 long? , The width of the water inlet is 3.54mm, and the width of the water outlet is 0.5mm. The width of each branch channel 9-1.4 is 1.5mm. The length of the branch channel is 51.3mm, the length of the third branch channel is 42.1mm, the length of the fourth level branch channel is 32.8mm, the length of the fifth level branch channel is 23.5mm, the length of the sixth level branch channel is 14.2mm, and the seventh level branch channel The length of the channel is 4.8mm, and the branch channels at all levels are symmetrically arranged on both sides of the ...

Embodiment 2

[0026] The main body and pulsating flow generation system of the microchannel substrate 9-1 in this embodiment are the same as those in Embodiment 1, and the structure of the microchannel cooling plate 9-3 is also the same as that of the microchannel substrate 9-1. Each branch channel (leaf vein) 9-3.4 on the heat dissipation plate 9-3 is provided with (upper and lower branch channel) communication ports 9-3.5 as the cooling medium (water) inlet and the corresponding branch flow on the vein-type micro-channel heat dissipation substrate The outer end of the road 9-1.4 is connected, and the cooling medium outlet 9-3.2 on the vein type microchannel cooling plate 9-3 is located on the main channel 9-3.3 of the vein type microchannel cooling plate shank (i.e. the main channel 9 -3.3 wide mouth end) and communicate with the cooling medium outlet 9-2.2 on the radiator cover plate; the cooling water (medium) in this embodiment is passed through the micro-channel substrate by the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com