Patents

Literature

70 results about "Environmental destruction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

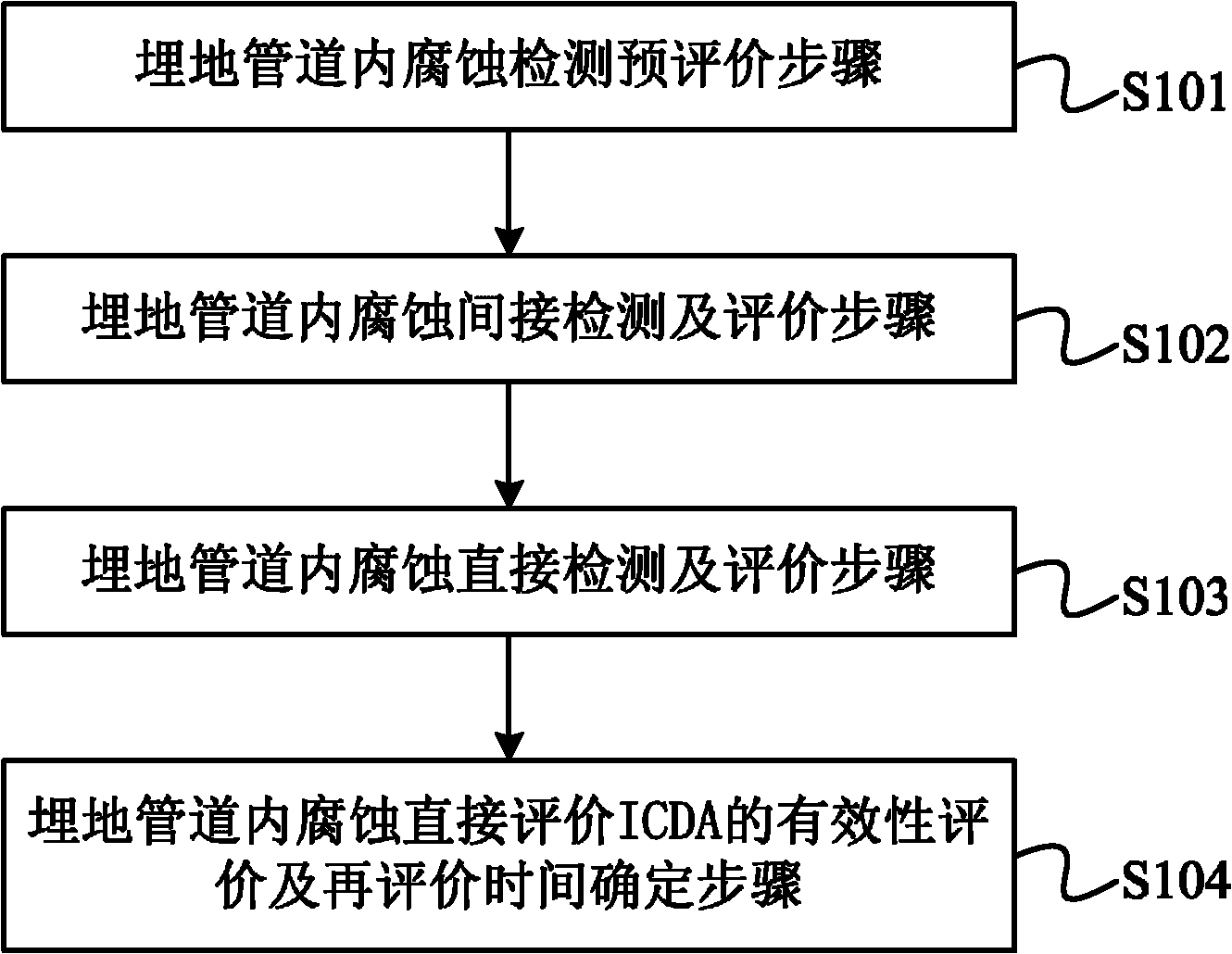

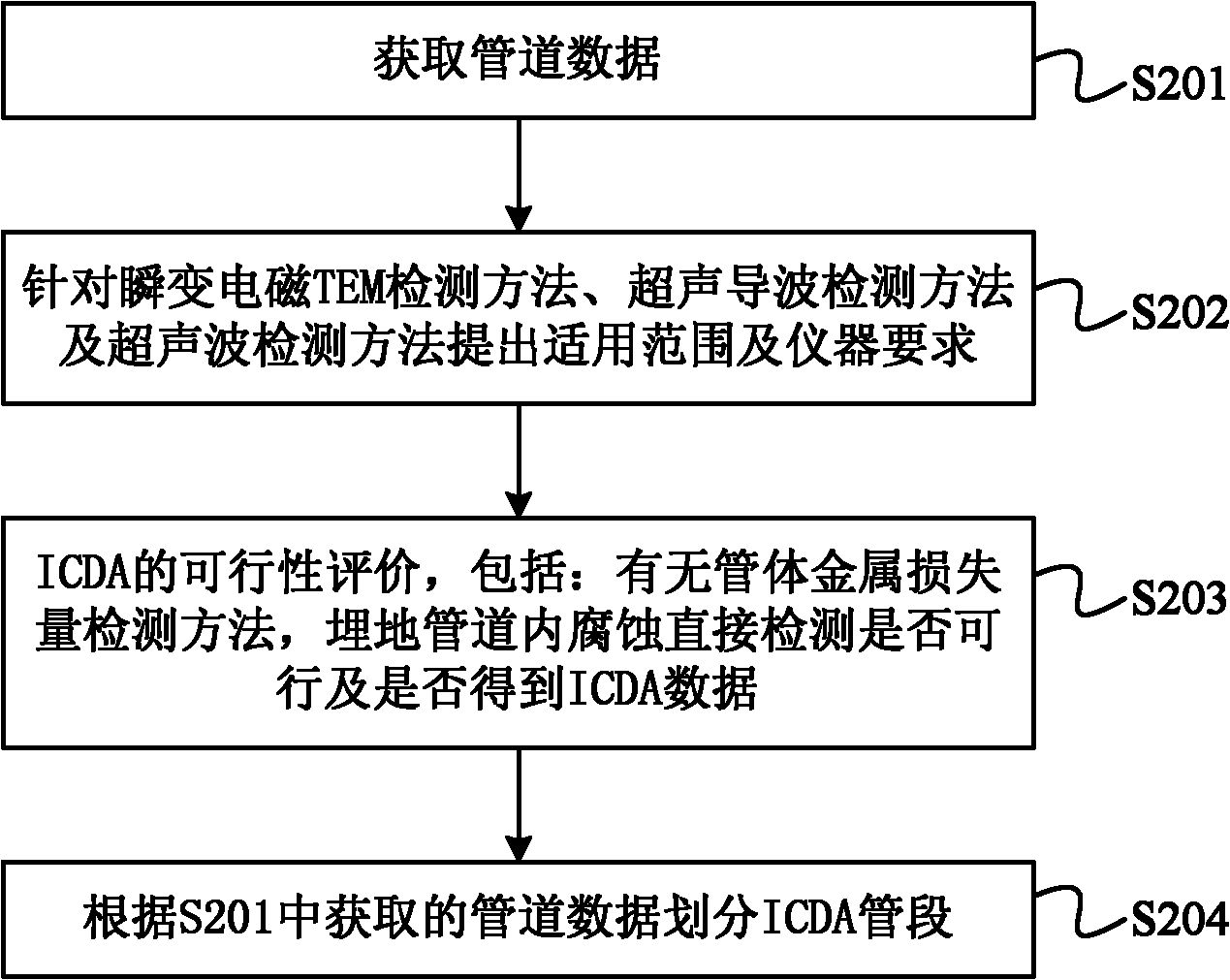

Method for evaluating corrosion in buried pipeline

ActiveCN102156089AReduce economic lossUnleash the full potential of your applicationWeather/light/corrosion resistanceDirect evaluationSafe operation

The invention provides a method for evaluating corrosion in a buried pipeline. The method for evaluating the corrosion in the buried pipeline comprises the following steps of: preliminary evaluation of corrosion detection in the buried pipeline, indirect detection and evaluation of the corrosion in the buried pipeline, direct detection and evaluation of the corrosion in the buried pipeline, and validity evaluation of direct evaluation ICDA of the corrosion in the buried pipeline and reevaluation time determination. At present, many in-service pipelines of petroleum enterprises sequentially enter a frequent accident period and an important stage of maintenance and update. By the method for evaluating the corrosion in the buried pipeline, levels of safe operation management and technology of the buried pipeline are improved, economic loss of personnel and facilities due to sudden accidents can be reduced, and safe production is ensured; the application potential of the in-service old pipelines is fully exerted, and the service life of the pipelines is prolonged; reliability and economical efficiency of pipeline engineering construction and operation are improved, and petroleum production and engineering costs are reduced; and environmental destruction caused by the sudden accidents is slowed down.

Owner:PETROCHINA CO LTD +1

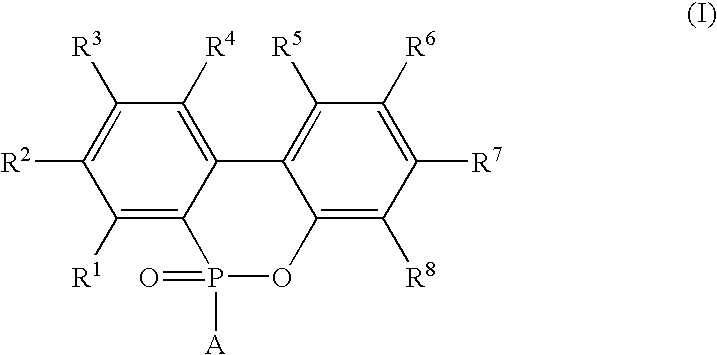

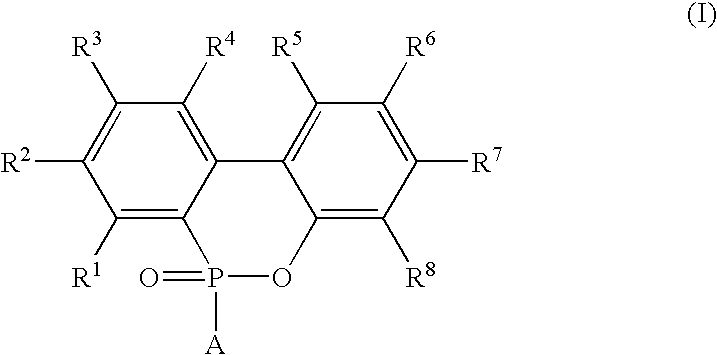

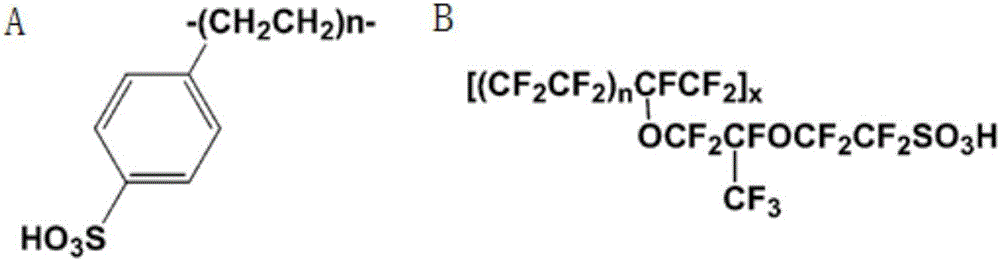

Water-soluble flame-retardant polyester resin, resin composition containing the resin, and fiber product treated with the resin composition

InactiveUS7358323B2Improve flame retardant performanceEliminate the problemSynthetic resin layered productsHeat resistant fibresSolubilityFiber

A water-soluble, flame retardant polyester resin is obtained by a condensation reaction or a polycondensation reaction of a dicarboxylic-acid component, a glycol component, a water-solubility imparting component and a reactive phosphorus-containing compound such that a ratio of the water-solubility imparting component in a total of the dicarboxylic-acid component and the water-solubility imparting component is in a range of 1 to 60 mol %. Since this polyester resin can be dissolved in a solvent by allowing a halogen-free, phosphorus-containing polyester with excellent flame resistance to have water solubility, it is possible to improve applicability and eliminate problems of working environment and environmental destruction resulting from organic solvents. In addition, even when treating substrates such as fibers and PET films with the polyester resin, there is no deterioration of these substrates.

Owner:GOO CHEM IND

Operation method for confirming cold regeneration mix mixing proportion of emulsified asphalt

The invention relates to a working method for determining the combining ratios of cold recycled mixtures of emulsified asphalts and comprises the following aspects: (1) the performance evaluation of old asphalt mixtures; (2) the design of the combining ratio of cold recycled mixtures of the emulsified asphalts; (3) the performance tests of the performance of the cold recycled mixtures of the emulsified asphalts. The working method has the advantages of releasing the unavoidable reflective cracking problem of a semi-rigid base, improving the water temperature environment, reducing the tensile stress at the bottom of the semi-rigid base and prolonging the service life of the semi-rigid base asphalt pavement, thus providing effective measure of settlement for newly built pavements, more particularly for the maintenance and transformation of old roads; the working method can save a plurality of construction and maintenance funds as well as reducing the resource waste and environmental destruction.

Owner:TIANJIN GUOSHENG CONSTR COST CONSULTATIVE

Water-soluble flame-retardant polyester resin, resin composition containing the resin, and fabric product treated with the resin composition

InactiveUS20050261461A1Improve flame retardant performanceImprove fire resistanceHeat resistant fibresThin material handlingFiberSolubility

A water-soluble, flame retardant polyester resin is obtained by a condensation reaction or a polycondensation reaction of a dicarboxylic-acid component, a glycol component, a water-solubility imparting component and a reactive phosphorus-containing compound such that a ratio of the water-solubility imparting component in a total of the dicarboxylic-acid component and the water-solubility imparting component is in a range of 1 to 60 mol %. Since this polyester resin can be dissolved in a solvent by allowing a halogen-free, phosphorus-containing polyester with excellent flame resistance to have water solubility, it is possible to improve applicability and eliminate problems of working environment and environmental destruction resulting from organic solvents. In addition, even when treating substrates such as fibers and PET films with the polyester resin, there is no deterioration of these substrates.

Owner:GOO CHEM IND

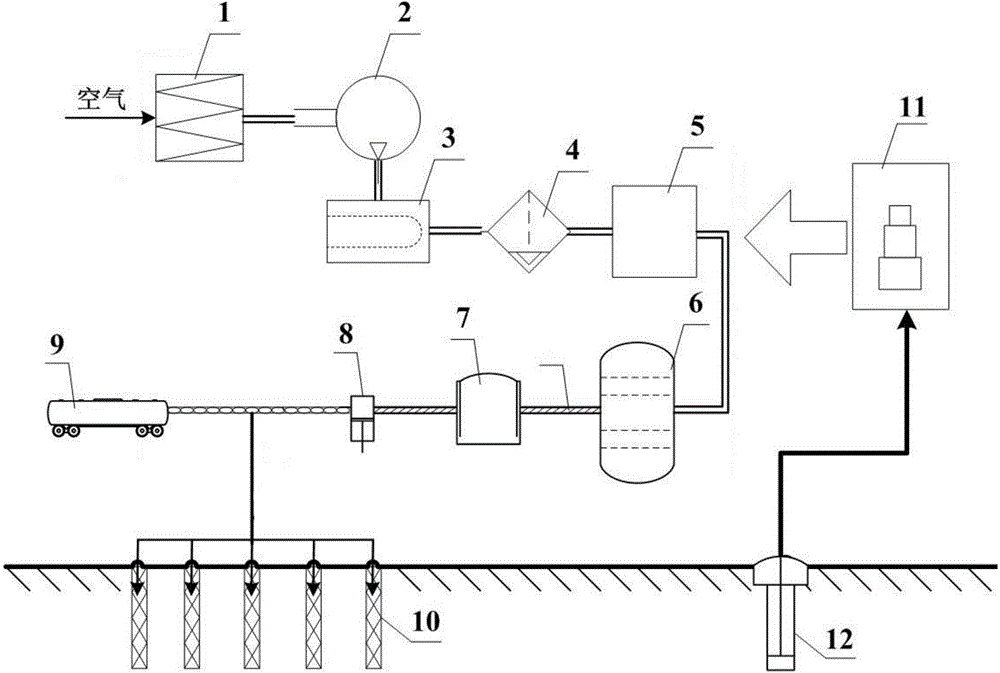

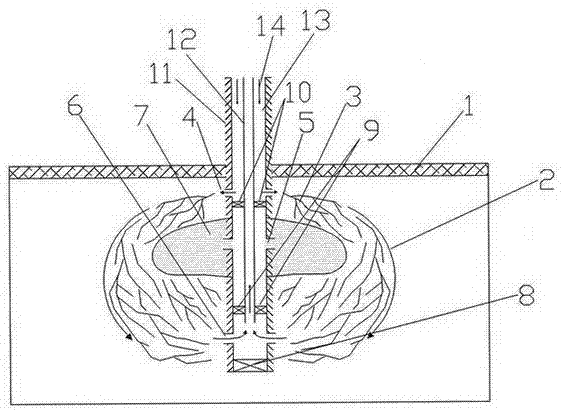

Liquid nitrogen system and method for nondestructively governing fire area in coal field

ActiveCN104912585AReduce water consumptionAvoid destructionDust removalFire preventionThermal energyAir filter

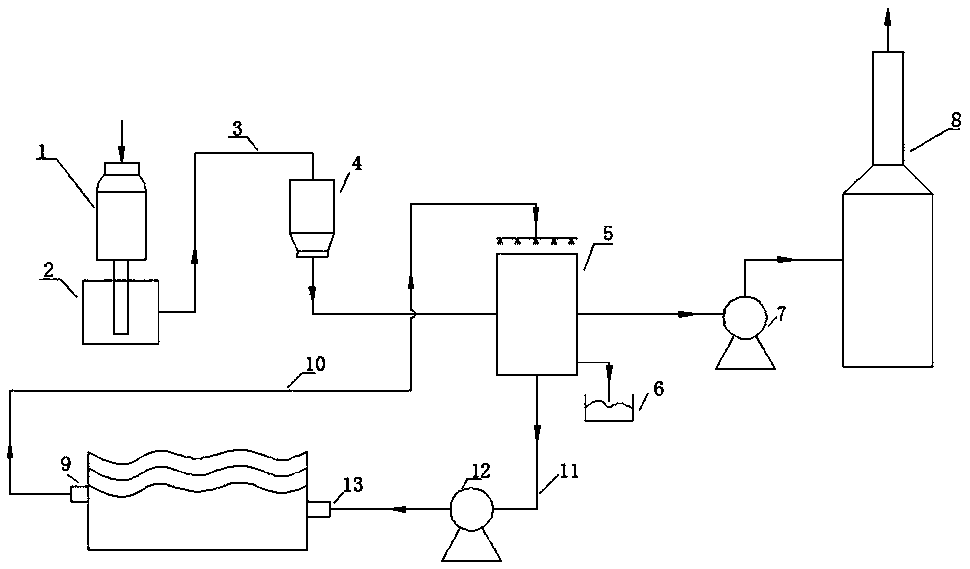

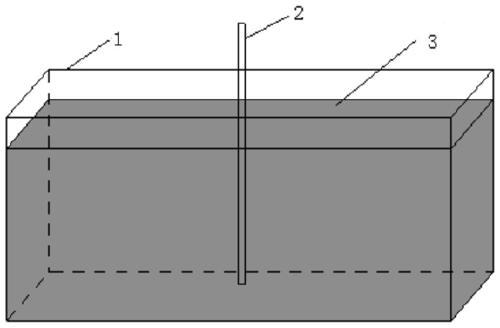

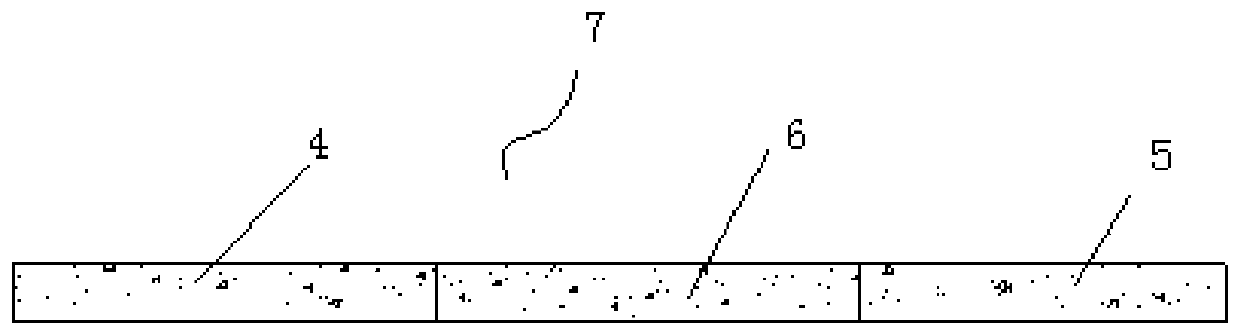

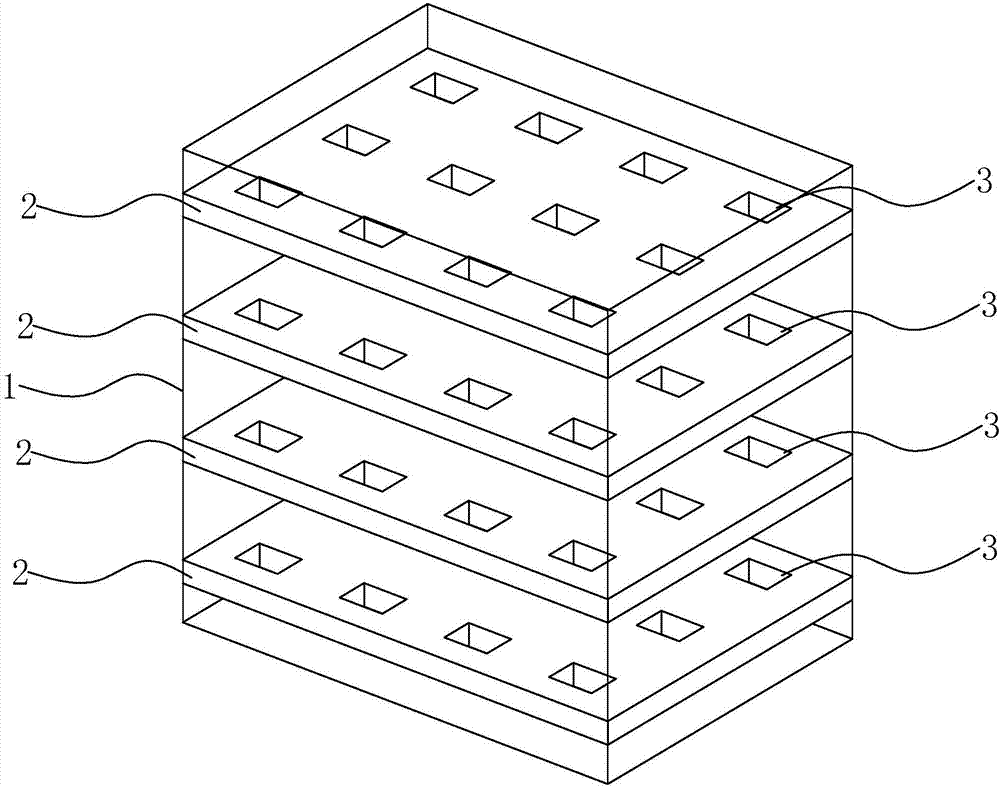

The invention discloses a liquid nitrogen system and a method for nondestructively governing a fire area in a coal field. An air filter (1), an air compressor (2), an air cooler (3), an oil-water separator (4), an air drying purifier (5), an air separation tower (6), a liquid nitrogen storage slot (7) and a booster pump (8) are sequentially connected by a pipeline; a liquid nitrogen tank car (9) and an access end of a surface borehole (10) are connected with an output end of the booster pump (8); a bottom surface borehole (10) and a geothermal well (12) are positioned in the fire area in the coal field; and geothermal power generation equipment (11) generates power to supply to the equipment by virtue of high-temperature steam provided by a geothermal well (12). According to the liquid nitrogen system and the method disclosed by the invention, waste heat energy generated by the fire area in the coal field is utilized to carry out geothermal power generation, so that energy waste is reduced; a liquid nitrogen fire preventing and extinguishing technology is adopted to govern coal field fire, so that cooling and inerting are quickly carried out on the fire area; the liquid nitrogen is from nitrogen gas in air, and quickly returned into air for being recycled for preparing liquid nitrogen, so that not only is environmental destruction not caused, but also cycling and reutilization of resources are realized.

Owner:CHINA UNIV OF MINING & TECH

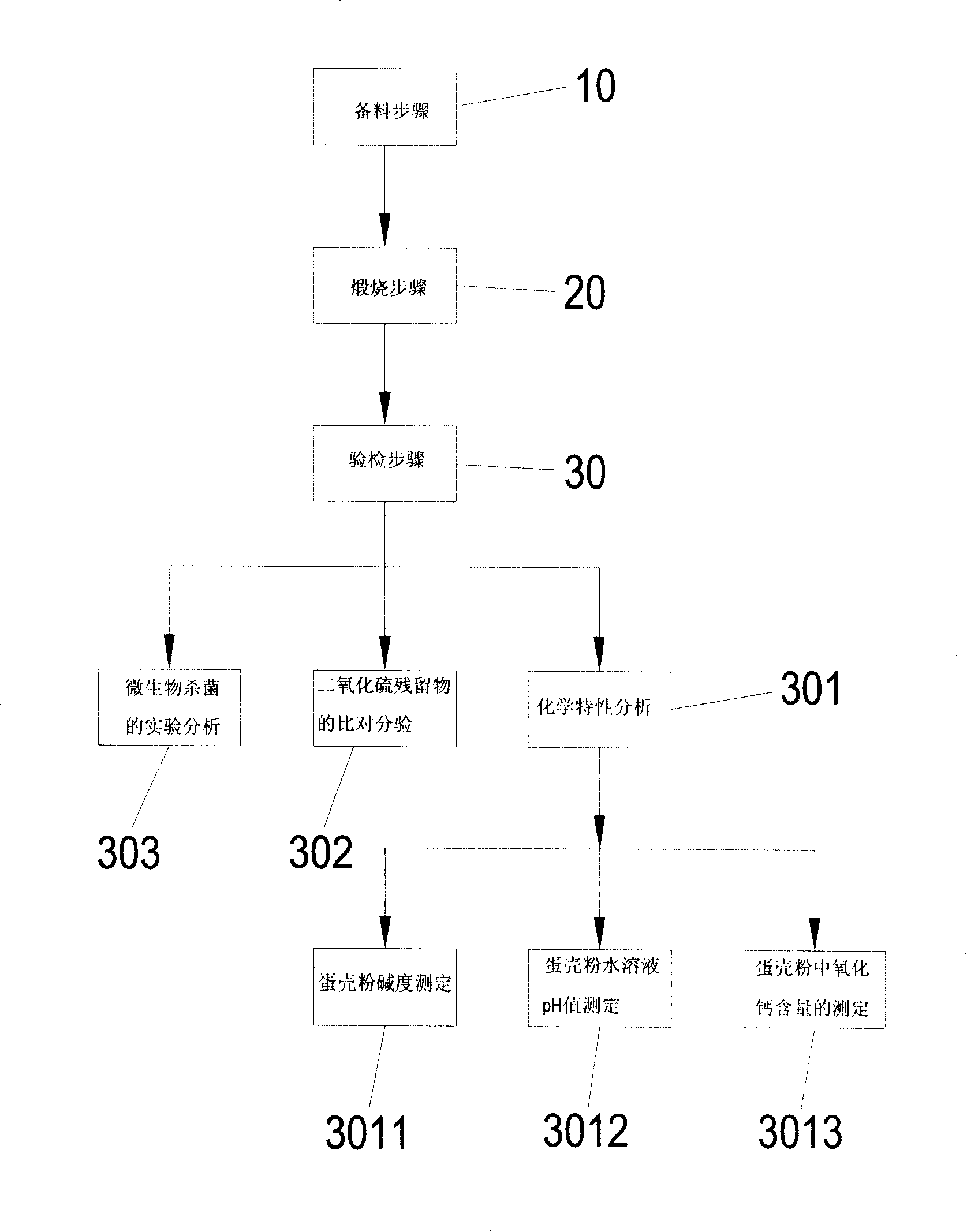

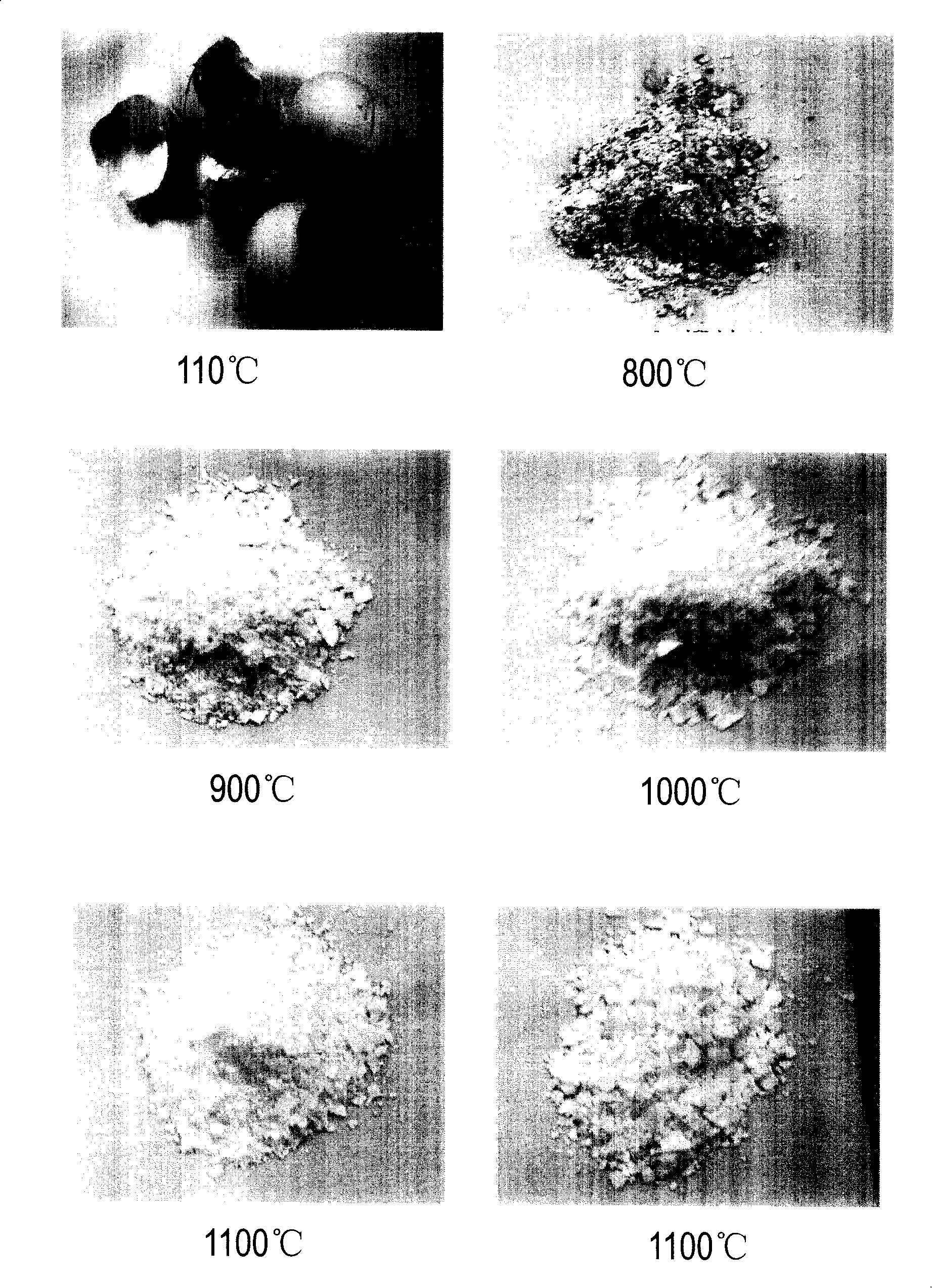

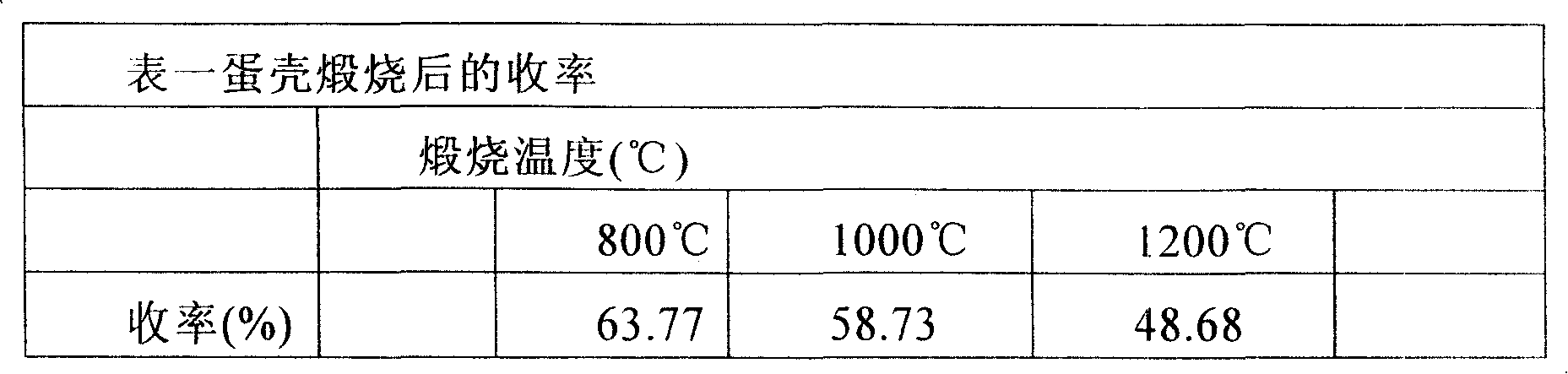

Eggshell calcium oxide powder and preparation and application thereof

InactiveCN101209112AEnhanced inhibitory effectEfficient removalFruit and vegetables preservationEdible seed preservationEggshellRenewable resource

The invention discloses a preparation method of eggshell calcium oxide powder and a product which is prepared by the method, the method of the invention includes the following steps that: the inside and outside surfaces of the eggshell are dried after cleaning the eggshell; the eggshell after the drying is calcined to get the eggshell ash powder, and the eggshell ash powder is smashed into the fine powder after the cooling, so as to get the product. The invention has the release effect, the method of the invention utilizes the wasted eggshell as the renewable resource, which can not only reduce the environmental damage from pollutants, have the excellent inhibition effect on E.coli of the prepared eggshell calcium oxide powder and have good effects of sterilization, corrosion protection, fresh keeping and so on, but also highly efficiently remove the residual pesticides and sulfur dioxide on vegetables, fruits or grains.

Owner:刘发勇

Method of improving heat exchanging efficiency after fracturing of dry hot rock

ActiveCN107989589AOptimize circulation pathExpand flow areaFluid removalSealing/packingSuction forceHeat conducting

The invention discloses a method of improving the heat exchanging efficiency after fracturing of dry hot rock, and belongs to the field of geothermal energy development. According to the method, a single well fracturing technology is used; high temperature resistant heat-conducting cement is poured into the hydraulic fracturing position of dry hot rock reservoirs, so that sheeted fissure in the hydraulic fracturing near-well area are closed, and only fissure in the far-well area are reserved. The purposes of improving the flowing path of heat carrying fluid and improving the heat exchanging efficiency are achieved. Distribution and arrangement of upper circulating holes and lower circulating holes can enlarge the flowing area of the heat carrying fluid to a maximum extent, and promote heatexchanging of the heat carrying fluid and the dry hot rock reservoirs. Under the action of ground suction force, the heat carrying fluid passes through the upper circulating holes, fissures producedby fracturing, the lower circulating holes and heat insulation oil pipes and then returns to the ground, in this way, the heat exchanging efficiency after fracturing of the dry hot rock can also be improved. Though application of the single well technology and the method of improving the heat exchanging efficiency after fracturing of the dry hot rock, the dry hot rock development cost can be reduced, environmental destruction can be reduced, and the single well fracturing technology and the method of improving the heat exchanging efficiency after fracturing of the dry hot rock play a positiverole in widespread use of geothermal energy.

Owner:青海九零六工程勘察设计院有限责任公司 +1

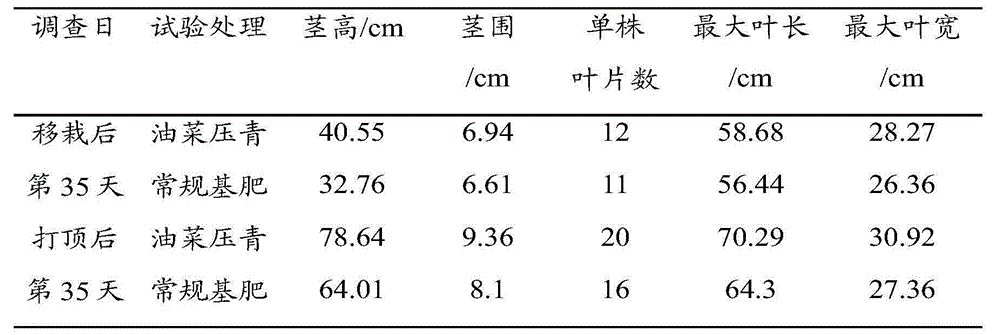

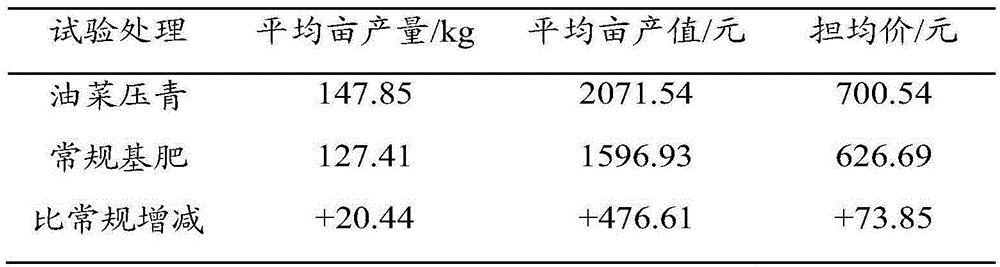

Method for planting tobacco

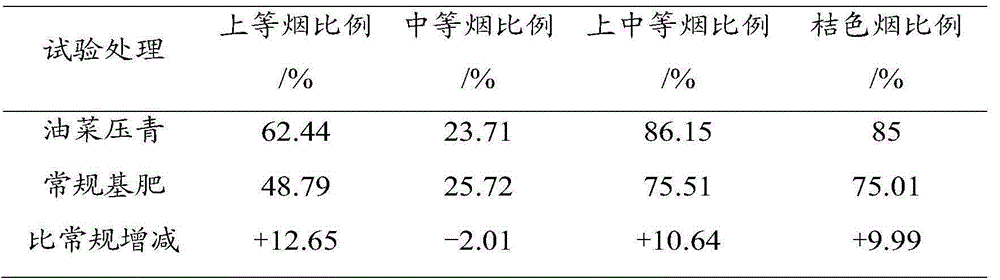

InactiveCN105052441AHelps growQuality improvementSuperphosphatesPlant cultivationSoil propertiesNicotiana tabacum

The present invention provides a method for planting tobaccos. The method includes the steps of planting rapes in a tobacco field, when the rapes enter into a green ripe stage, turning over rape stalks and rapeseeds integrally, and transplanting cultivated tobacco seedlings in a green manured field. The organic oil content of rapes is high, the most nutrient and organic matters that the rapes contain can be achieved in the green ripe stage, and base fertilizers obtained by turning over the rapes can evenly supply adequate nutrients for the growth of the tobaccos for a long term, so that chemical fertilizers can be greatly decreased in the process of planting tobaccos, the soil properties can be improved, and the soil environmental destruction and nutrient imbalance of tobaccos caused by single cropping of tobaccos can be avoided. The method also can improve the yield of tobacco leaves, greatly improve the aroma substance content of tobacco leaves, and improve the quality of tobacco leaves. According to the method, the yellowing speed of tobacco leaves and the single leaf mass can be increased, the proportion of superior and medium leaves, and the aroma substance content of tobacco leaves, the per mu yield, and the per mu value can be increased.

Owner:贵州省烟草公司黔南州公司

Method for restoring petroleum-polluted wetland by using carex phacota Spr. and microorganisms

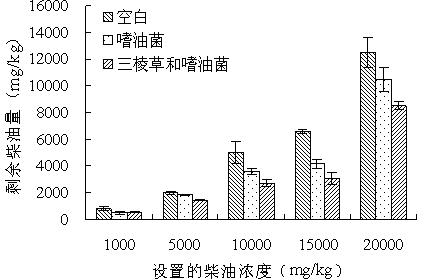

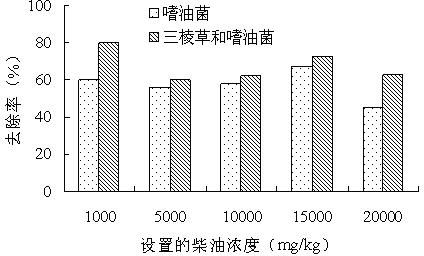

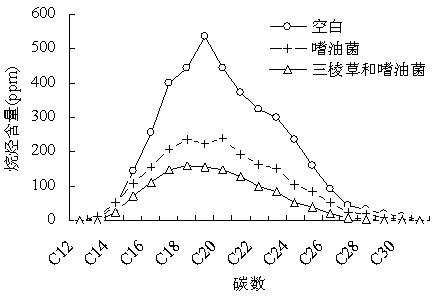

InactiveCN102172612AWon't breakLess investmentClimate change adaptationContaminated soil reclamationPlant rootsPetroleum

The invention relates to a method for restoring a petroleum-polluted wetland by using carex phacota Spr. and microorganisms. The method comprises the following specific steps of: planting carex phacota Spr. in soil of the petroleum-polluted wetland; adding a bacterial suspension of an oil-degraded microorganism into the soil after adaptation; and removing petroleum oil stains from the soil under the coordination of the oil-degraded microorganism and a plant root system, wherein the density of the planted carex phacota Spr. is 300-800 plants / m<2>, 10 milliliters of bacterial suspension are added into every kilogram of soil, and the volume weight ratio of the added bacterial suspension to the soil is generally (1-5):100 ml / g. By adopting a degrading bacteria consortium obtained by screening, the degradation of a carex phacota Spr. rooting zone on oil pollutants can be enhanced. By adopting the method, a large number of petroleum organic matters can be removed from soil, so that the effect of quickly and completely removing a large number of petroleum organic matters from the soil is achieved. The method has the advantages of small environmental destruction, no damage to the physicochemical property of soil, low cost and the like.

Owner:SHANGHAI UNIV

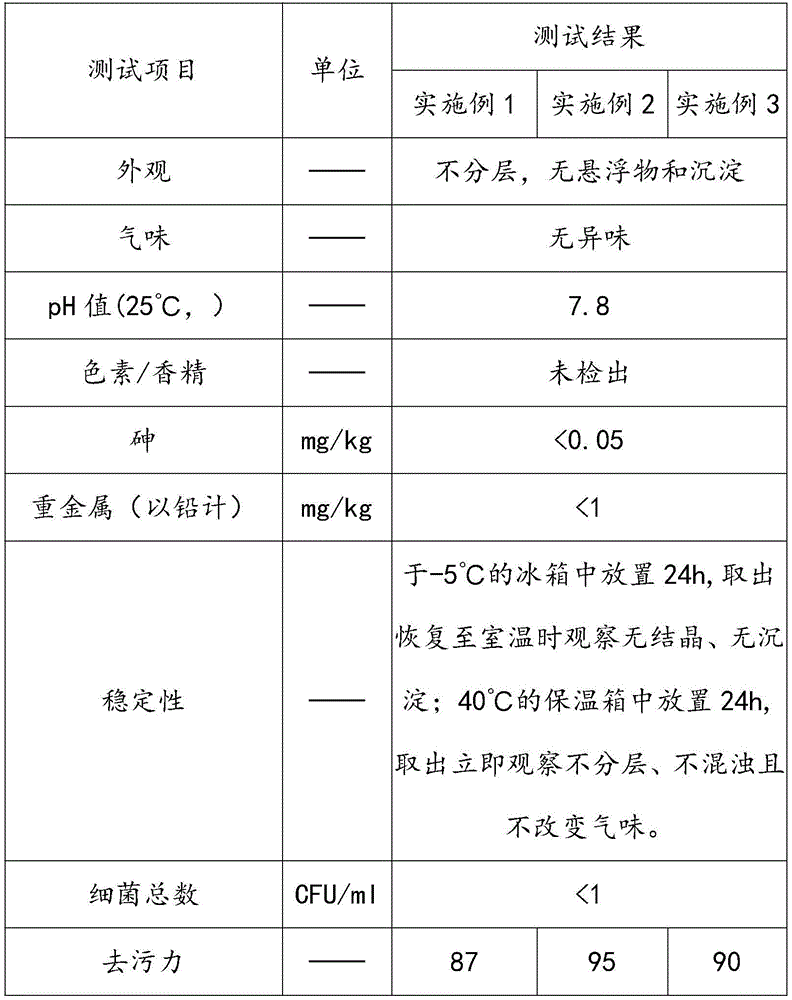

Multifunctional, efficient and environmentally friendly heavy oil contamination detergent

ActiveCN105802755ADecontamination without residueNo health hazardInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsTriclosanFatty alcohol

The invention discloses a multifunctional, efficient and environmentally friendly heavy oil contamination detergent. The multifunctional, efficient and environmentally friendly heavy oil contamination detergent is prepared from, by weight, 6-9 parts of fatty acid methyl ester ethoxylate sulfonate, 4-6 parts of fatty alcohol polyoxyethylene ether sulfate, 4-6 parts of polyoxypropylene-poly-oxyethylene blocked polyether, 3-5 parts of isomeric polyoxyethylene ether, 3-5 parts of isomeric tridecan fatty alcohol ether, 2-4 parts of a low-foaming wetting agent, 1-3 parts of sodium lauryl alcohol polyether ester, 0.5-1 part of sodium benzoate, 0.5-1 part of 1-hydroxy ethylidene-1,1-diphosphonic acid, 0.5-1 part of aminotrimethylene phosphonic acid, 1-2 parts of sodium carbonate, 0.5-1 part of sodium silicate, 0.3-1 part of hydroxypropyl methyl cellulose, 0.1-0.5 part of triclosan, 0.05-0.1 part of essence and 60-70 parts of water. The multifunctional, efficient and environmentally friendly heavy oil contamination detergent has strong detergency, is friendly to the human skin, does not contain organic solvents and does not cause environmental destruction.

Owner:FUJIAN JIAFENG BIOCHEM

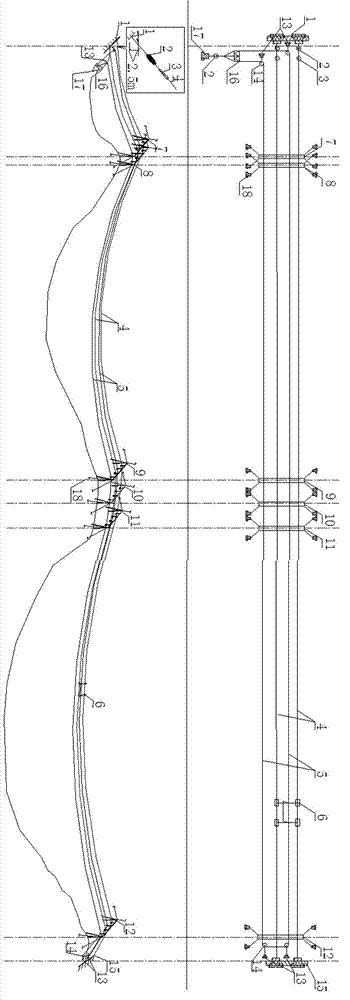

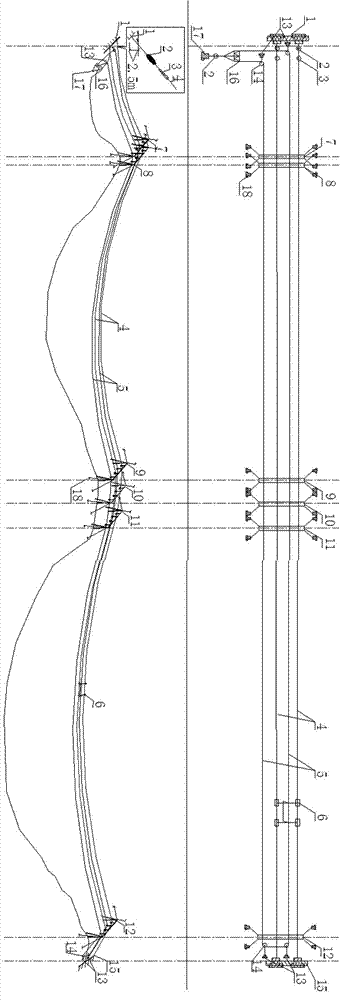

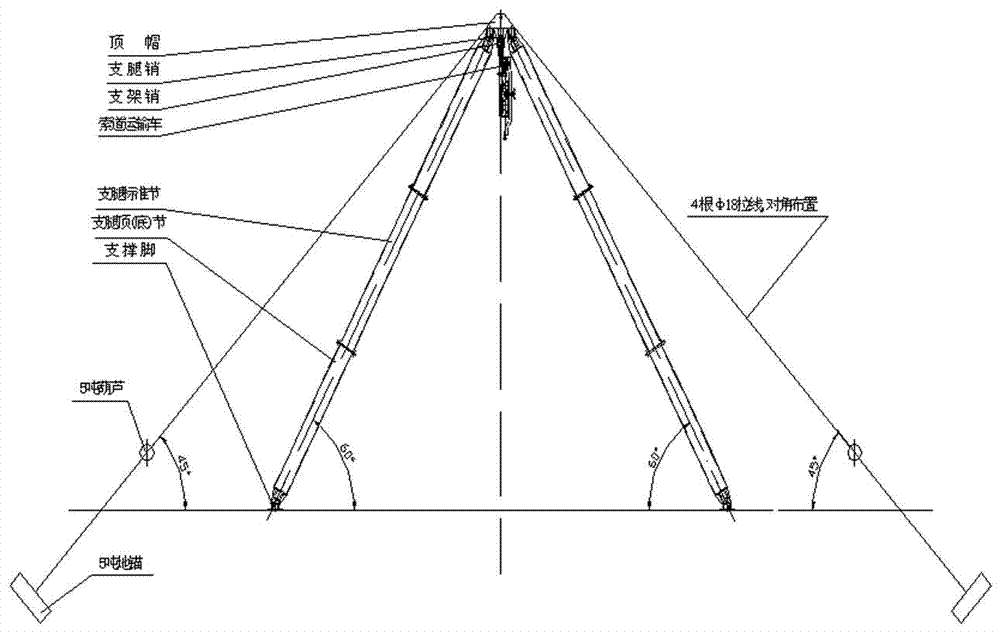

Construction method for transmission line project material transport by prefabricated cableway

The invention relates to a construction method for transmission line project material transport by a prefabricated cableway. The construction method includes the steps of S01, supporting pillar mounting, S02, pulling cable erection and driving device mounting, S03, driving device mounting, S04, carrying cable erection, S05, traveling trolley selection, and S06, cableway operation test. The construction method has the advantages of applicability to material transport in mountainous areas and hilly grounds, high applicability, simplicity in application, convenience in maintenance, high working efficiency, little environmental destruction and the like.

Owner:STATE GRID CORP OF CHINA +2

Method for producing flower and plant nutrient soil

InactiveCN103360148AFull of nutritionImprove physical and chemical propertiesBio-organic fraction processingOrganic fertiliser preparationEnvironmental resistanceNormal growth

The invention discloses a method for producing flower and plant nutrient soil. Gramineous straws are utilized as basic raw materials, the raw material source is wide, the time for producing the nutrient oil is greatly shortened through microorganism fermentation, the soil production process can be generally finished within 20 days, the nutrient soil contains comprehensive nutrients, and the production process and the raw materials are environment-friendly, pollution-free, free from any side effect, and capable of effectively improving physical and chemical properties of soil and a living environment of microorganisms, guaranteeing normal growth and development of flowers and plants, and avoiding environmental destruction caused by digging mountain forest soil and peat soil.

Owner:邹飞剑

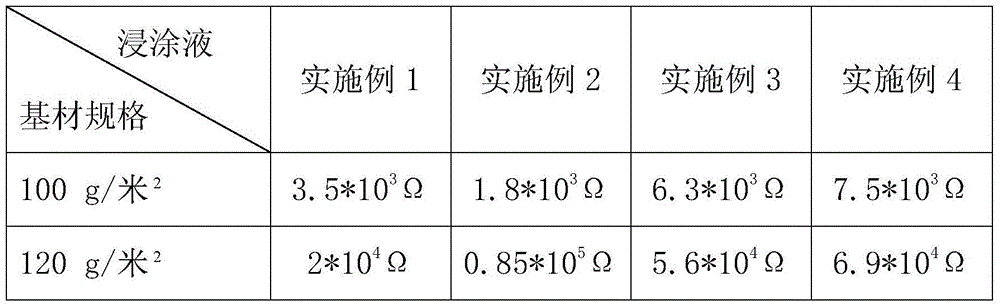

Anti-static dip-coating liquid and anti-static non-woven fabric using same

InactiveCN104631100ANot easy to harmLess destructiveFibre typesNon-woven fabricsPolyesterElectrical resistance and conductance

The invention relates to the technical field of fabric production, and in particular relates to an anti-static dip-coating liquid and an anti-static non-woven fabric using the same. The anti-static dip-coating liquid comprises a certain amount of aluminum powder, graphite powder, a dispersing agent and an acrylic adhesive; the anti-static dip-coating liquid has the characteristics of being lower in cost, stable in formulation and hardly harmful to the environment; the invention also relates to the anti-static non-woven fabric; the anti-static non-woven fabric is prepared by needling polyester fibers to form a needled felt, carrying out dip-coating on the needled felt by upper dip-coating liquid and drying. The anti-static non-woven fabric is formed by needling the non-woven fabric, coating and then drying, has the surface specific resistance of 103-105 omega, has a good anti-static function, and has the characteristics of being low in production cost, less in environmental destruction, firm and durable in use.

Owner:DONGGUAN KEDI IND CO LTD

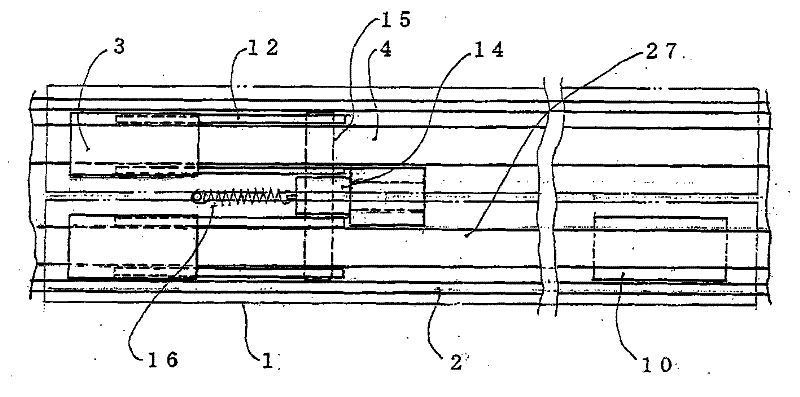

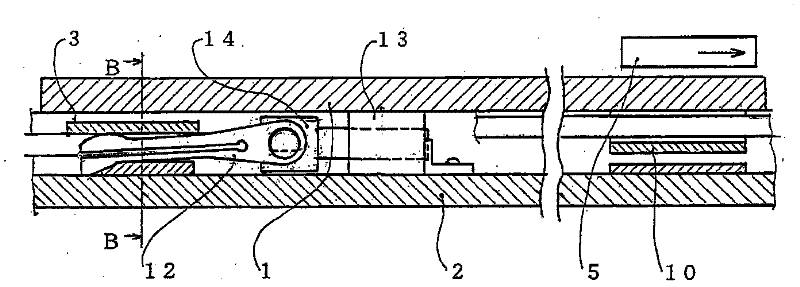

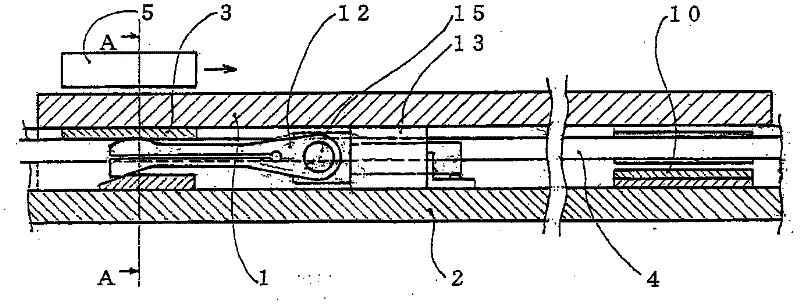

Transportation systems that charge vehicles while they are in motion

InactiveCN102271961AEmission reductionHigh penetration rateRail devicesBatteries circuit arrangementsElectricityGasoline

Provide an electric vehicle transportation system that reduces CO 2 emissions and also enables automatic driving to prevent accidents caused by the driver dozing off or losing attention, in light of the situation of late where reduction of CO 2 emissions has become critical to one of the greatest problems causing environmental destruction and where vehicles that use gasoline, diesel oil and other fossil fuels are among the various things that generate a lot of CO 2 . This vehicle transportation system promotes a widespread use of storage-cell-powered vehicles by minimizing the number of storage cells installed on them and thereby reducing their cost. The system involves laying rails that carry current on roads, where only the rails that are passed by vehicles carry current. In addition, the system releases earth leakage current by means of grounding to ensure safety even during rain, so that even storage-cell-powered vehicles can drive long distances by recharging themselves while traveling. Since this is a single-rail system, driving a vehicle becomes much easier and there is also peace of mind because the vehicle can be driven by using the electricity received from the rail to drive the motor, turn on the lights at night, and heat the cabin in winter or cool it in summer, without worrying about electricity running short. At the same time the storage cells are constantly charged to allow for continuous driving as long as there is a rail, and thereby reducing CO 2 generated from such continuous driving.

Owner:北口弘正

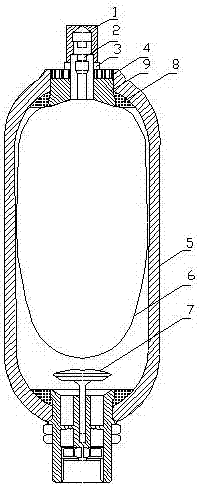

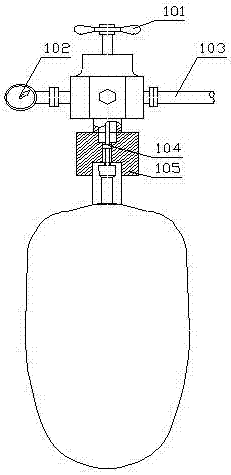

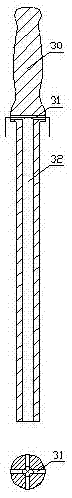

Energy accumulator leather bag on-line replacing device and method

The invention relates to an energy accumulator leather bag on-line replacing device which is characterized in that the energy accumulator leather bag on-line replacing device comprises an air extracting and inflating device, an energy accumulator assembly, a guiding rod, bag edges and a rope; and the air extracting and inflating device is arranged on the energy accumulator assembly, and the guiding rod is used for guiding radial penetrating of the rope. According to the technical scheme, the use effect is good, safety and reliability are achieved, the environmental destruction accidents such as leather bag bursting and hydraulic oil leakage cannot occur, and energy conservation and environmental friendliness are achieved accordingly.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

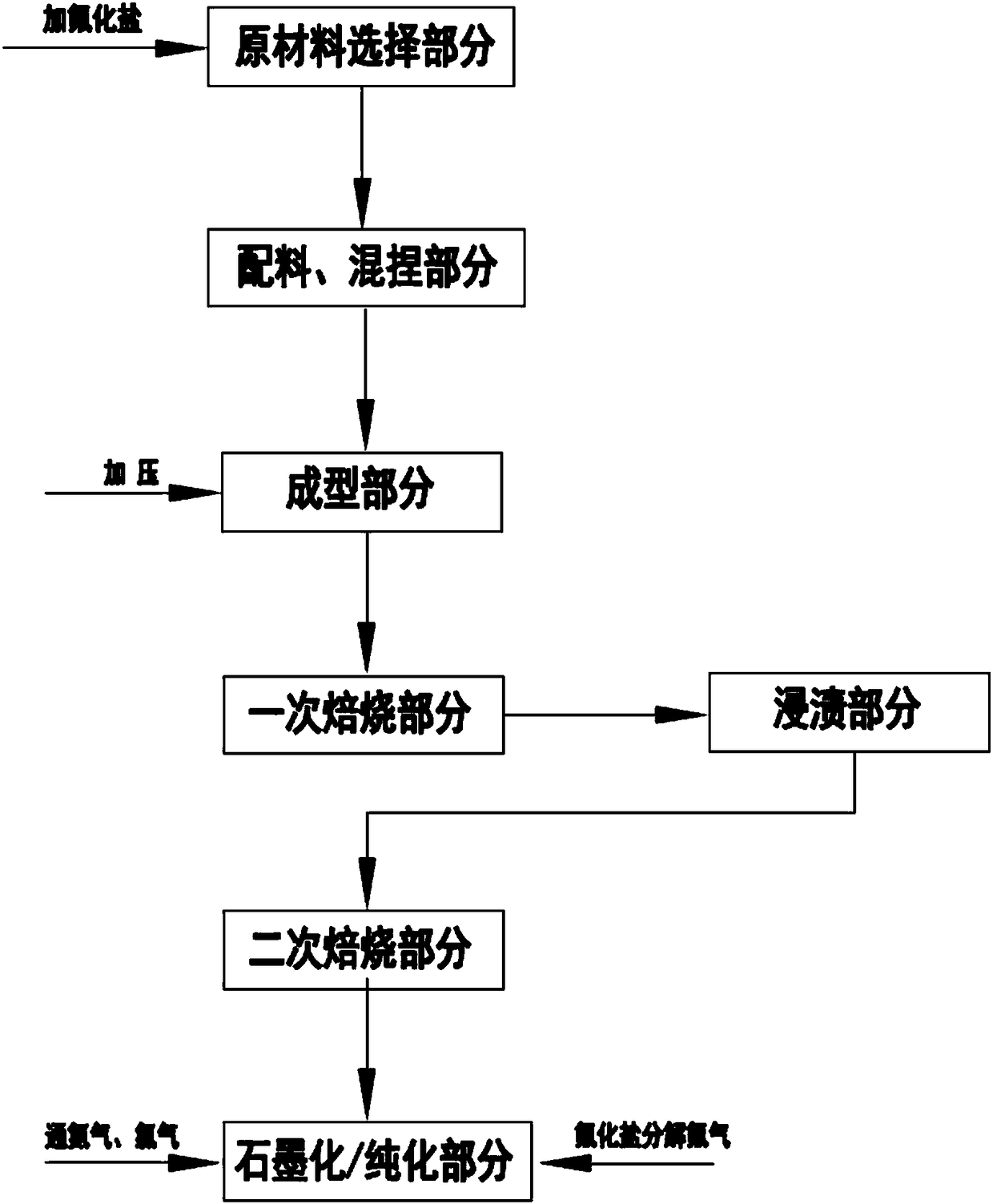

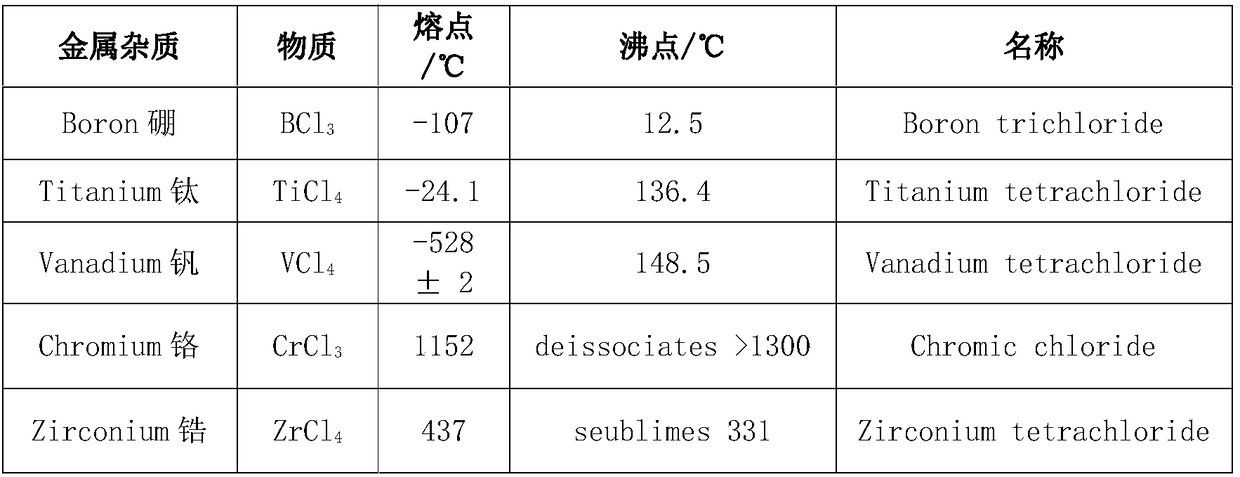

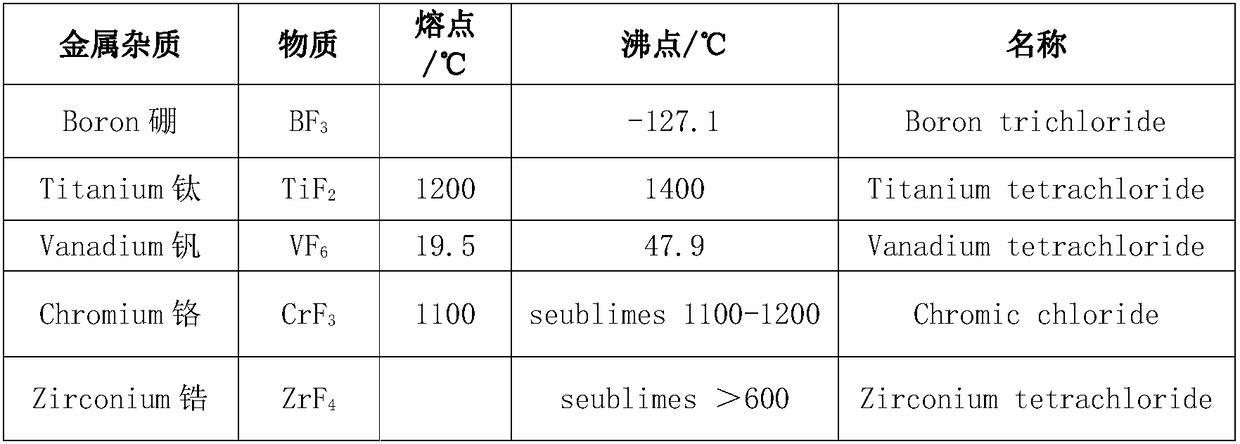

Graphite purification method with adding fluoride salt in formula

InactiveCN108545736AGuaranteed purification effectAvoid destructionCarbon compoundsPurification methodsAdhesive

The invention relates to a graphite purification method with adding fluoride salt in a formula. The graphite purification method comprises the following production steps of selecting cokes and an adhesive as raw materials, adding the fluoride salt with a certain ratio in the adhesive, milling and crushing the raw materials to enable the average particle size not to exceed 50 microns, performing mixing kneading on the 65-80 parts of the cokes and 35-20 parts of adhesive, performing formation on an obtained product, performing roasting after formation, and dipping a graphite product after beingroasted with an impregnant; introducing nitrogen for exhausting air when a temperature of a furnace body is raised to 1800-1900 DEG C, and stopping introduction of the nitrogen and changing to introduce chlorine when the temperature is 1900-2000 DEG C; and when the temperature reaches 2200 DEG C, enabling the fluoride salt to start to decompose to produce fluorine gas. The graphite purification method provided by the invention solves the problems that Freon is used to perform purification to cause environmental destruction, multi-step gas introduction needs to be performed, the technology is tedious, and the cost is high in the prior art.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Method utilizing buoyant rafts to breed big oysters

InactiveCN107581116ASufficient nourishmentClimate change adaptationPisciculture and aquariaOysterSalinity

The invention relates to a method utilizing buoyant rafts to breed big oysters. The method comprises the following steps that 1, an offshore sea area with the water depth of 10-20 meters, the salinityof 0.9% or below, the lowest water temperature of 5 DEG C or above and the dissolved oxygen greater than 5 mm / L is selected as a breeding sea area, and buoyant rafts are erected in the breeding sea area; 2, attachment bases where big young oysters attach are suspended under the buoyant rafts by suing ropes of 1-4 meters, and the attachment bases are suspended on the ropes at intervals to be immersed in seawater; 3, the total breeding time is three years, big young oysters with the length of 10-20 mm are suspended for breeding in the first year, the buoyant rafts are fixed in the sea area withthe salinity of 0.9%-1.5% for culture, the buoyant rafts are transferred and fixed to the sea area with the salinity of 1.5%-2% for culture in the second year, and the buoyant rafts are transferred and fixed to the sea area with the salinity of 2-3% for culture in the third year, and big oysters can be collected after the body length of the big oysters exceed 10 cm. By adopting the method, sufficient nutrients can be provided in the breeding process, and environmental destruction can be also reduced.

Owner:浦北县德海种养农产品加工专业合作社

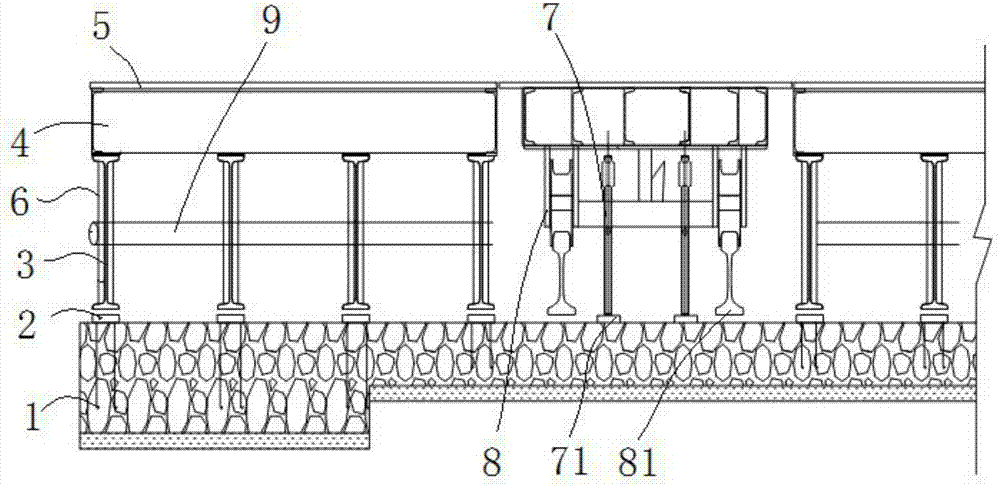

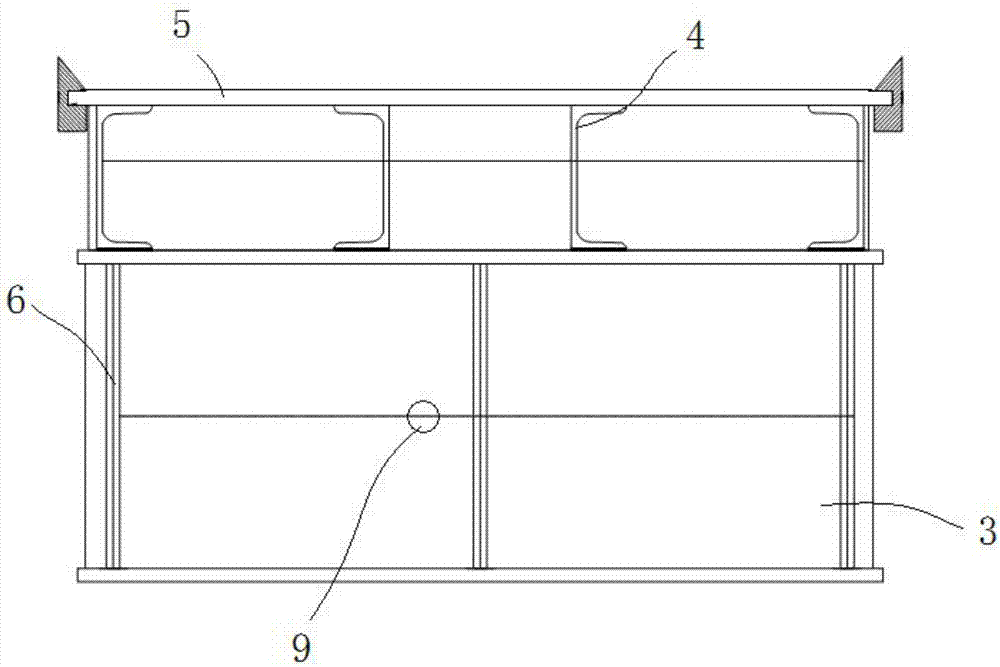

Beam fabricating pedestal

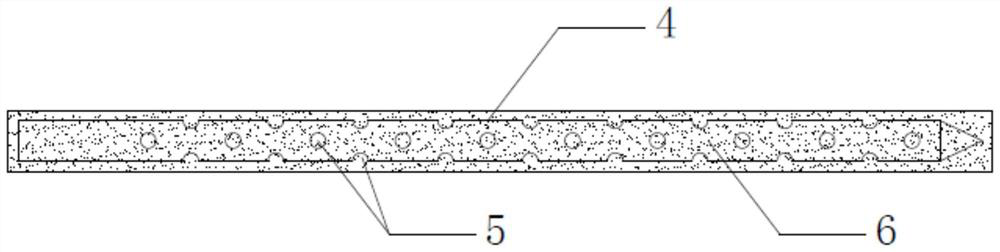

PendingCN107336346AReduce demolitionReduce wasteAuxillary shaping apparatusShaped beamReinforced concrete

The invention discloses a beam fabricating pedestal. The beam fabricating pedestal comprises a pedestal foundation formed by pouring of concrete, steel plate assemblies embedded in the pedestal foundation and I-beams fixedly connected with the steel plate assemblies. The upper surface of each I-beam is fixedly provided with a steel channel. The upper surfaces of the steel channels are fixedly provided with a bottom block steel plate. By adopting the beam fabricating pedestal provided by the invention, dismantling of concrete projects of later period can be reduced; land waste and environmental destruction can be reduced; the prefabrication cycle of T-shaped beams is shortened; the construction progress is accelerated; and the production efficiency is improved.

Owner:3TH ENG CO LTD OF CHINA RAILWAY CONSTR 11TH BUREAU GRP +1

Exhaust purifying agent

InactiveCN103045314AExtended service lifeDecrease riseLiquid carbonaceous fuelsFuel additivesOctadecaneDodecylbenzenesulfonic acid

The invention discloses an exhaust purifying agent, which aims to solve the problems that the conventional additive using plenty of aromatic hydrocarbon as a solvent is high in toxicity and seriously pollutes the environment at the same time. The exhaust purifying agent comprises the following components in parts by weight: 50 to 80 parts of cetyl palmitate, 30 to 50 parts of methyl behenate, 5 to 8 parts of stearyl stearate, 2 to 4 parts of dodecyl phenyl amine sulfonate, 1 to 3 parts of octadecyl amine sulfonate, 2 to 5 parts of sulfo-benzene and 1 to 3 parts of pentaerythritol. The prepared purifying agent has a good effect and low toxicity, and can effectively reduce environmental destruction.

Owner:CHENGDU SHENGERJIA SCI & TECH

Medicinal composition for aerosol

ActiveCN101721368AAvoid rising costs and complex processing techniquesPressure is easy to controlAerosol deliveryOrganic non-active ingredientsDichlorodifluoromethaneMedicine

Owner:YANGTAI PHARMA SHANDONG

Process and system for eliminating industrial discharge gas white smoke pollution

InactiveCN107606632AAchieve the purpose of condensationWill not polluteCombustion technology mitigationStationary plate conduit assembliesCooling towerPlate heat exchanger

The invention relates to a process and a system for eliminating industrial discharge gas white smoke pollution. The system comprises a quenching tank, a washing tower, a water spraying-glass plate heat exchanger, a condensed water collecting tank, a chimney, a seawater taking pipe and a seawater return pipe; the quenching tank is connected to the washing tower through a pipe; a smoke outlet of thewashing tower is connected to an inlet of a hot side runner of the water spraying-glass plate heat exchanger through a pipe; an outlet of the hot side runner is connected to the chimney through a pipe; an inlet of a cold side runner is connected to a sea through the sweater taking pipe; and an outlet of the cold side runner is connected to the sea through the seawater return pipe. A cold source of the method is not directly contacted with smoke without polluting the cold source; the extracted seawater quantity is lower compared with the total quantity of surrounding seawater; the heat carriedby seawater heated after heat exchange with the smoke is naturally dissipated into the environment after returning to the sea; and such other cooling measures as a cooling tower are not needed to cool without causing environmental destruction.

Owner:瑞切尔石化工程(上海)有限公司

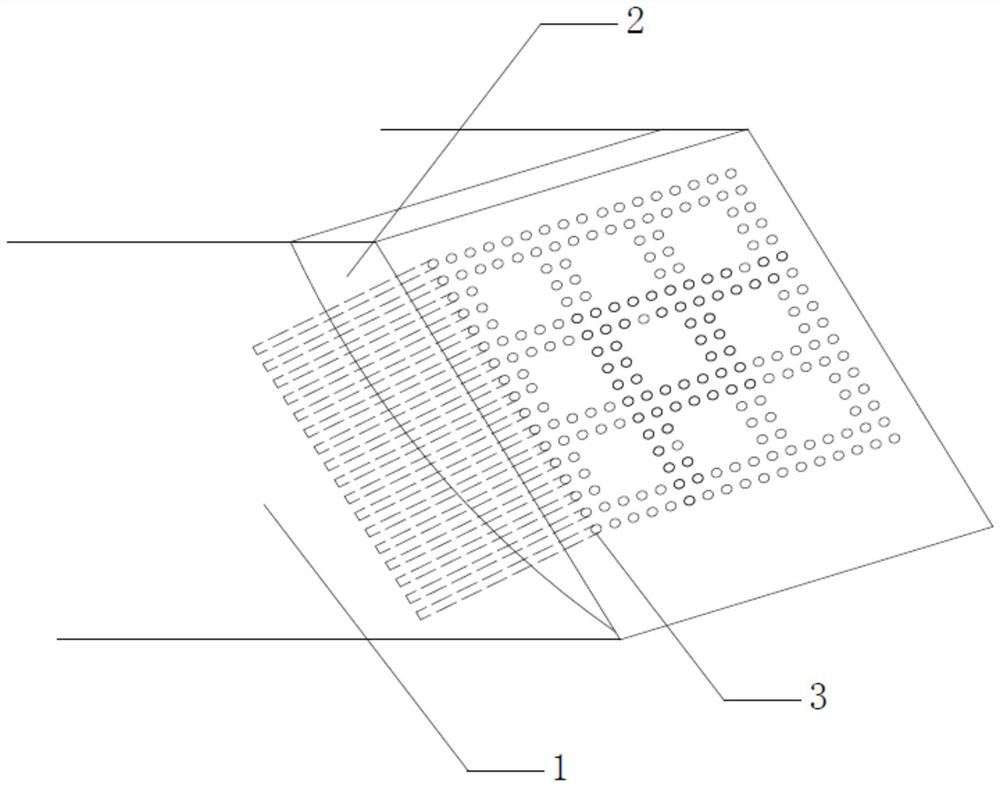

Anti-seepage cut-off underground curtain wall coal ash based impermeable material and construction method

The invention provides an anti-seepage cut-off underground curtain wall coal ash based impermeable material and a construction method. The impermeable material needs no sands and stones, coal ash serving as a power plant waste can be used, solid waste emission and environmental destruction can be reduced, and the impermeable material is green and environmentally friendly. The impermeable materialis used for casting and forming an underground curtain wall and has the advantages of convenience in construction and simple casting technological process, and the formed underground continuous wall is high in adaptability and good in impermeability. The anti-seepage cut-off underground curtain wall coal ash based impermeable material comprises, by weight, 40 parts of cement, 50-70 parts of coal ash, 5-10 parts of silica fume, 2-4 parts of bentonite, 2-3 parts of sodium chloride, 1.5-3 parts of calcium lignosulphonate and 60-70 parts of water.

Owner:DAYAN MINE IND NEIMENGGU +1

Machine-made sand bare concrete and construction technology thereof

InactiveCN108358558AEliminate surface air bubblesAvoid damageEnvironmental destructionDefoaming Agents

The invention discloses machine-made sand bare concrete and a construction technology thereof, and specifically relates to the machine-made sand bare concrete. According to the machine-made sand bareconcrete disclosed by the invention, high-quality limestone is adopted for preparing machine-made sand and stones are used as coarse and fine aggregates, and natural river sand and pebbles are replaced, so that the resource of the river sand can be effectively saved, and environmental destruction can be reduced. The invention also provides the construction technology of the machine-made sand bareconcrete. Compared with a traditional method of mixing a defoaming agent into concrete after stirring, a method of painting the defoaming agent on the surface of a template release agent is adopted, surface bubbles of the concrete can be more directly and effectively removed, the surface of the concrete can be flat and smooth, the smooth finish can be up to 95 percent or above, the cost for carrying out engineering decoration on the outer surface again is saved, and the construction cost is reduced.

Owner:贵阳城市建设工程集团有限责任公司 +1

Waste water afterheat recovery device

InactiveCN107990764AReduce the temperatureEfficient recyclingStationary plate conduit assembliesWastewaterProduct gas

The invention discloses a waste water afterheat recovery device. The waste water afterheat recovery device comprises a device body; multiple heat exchange plates are fixed in the device body; the internals of the heat exchange plates are hollowed for enabling high-temperature waste water to flow through; heat exchange through holes for enabling gas to be heated to pass through are formed in the externals of the heat exchange plates; the high-temperature waste water transversely penetrates through the device body; and the gas to be heated vertically penetrates through the device body. Four heatexchange plates are fixed in the device body. Each heat exchange plate is provided with twelve heat exchange through holes. The waste water afterheat recovery device can effectively recover heat in the waste water to reduce the temperature of the waste water, recovers the heat to reduce the energy consumption, and can reduce environmental destruction.

Owner:JIANGMEN XIANCHENG ENVIRONMENTAL PROTECTION ENERGY SAVING EQUIP CO LTD

Siliceous sandstone artificial sand and preparation method thereof

InactiveCN102173623ASolve pollution damage and save immeasurable energy problemsSlagUltimate tensile strength

The invention provides a siliceous sandstone artificial sand and a preparation method thereof. The invention is characterized in that the siliceous sandstone artificial sand is prepared by pulverizing siliceous sandstone, of which the SiO2 content is at least 60%, the clay content is at most 2%, the density is at least 2.4 g / mm<3> and the saturated compression strength is at least 5.0 Mpa. The preparation method of the siliceous sandstone artificial sand comprises the following steps: (1) selecting materials: selecting satisfactory siliceous sandstone from sandstone: the SiO2 content is at least 60%, the density is at least 2.4 g / mm<3> and the saturated compression strength is at least 5.0 Mpa; (2) removing clay until the clay content is at most 2%; and (3) pulverizing the satisfactory siliceous sandstone to obtain the artificial sand. The invention overcomes the technical defect that people can not make machined sand to replace natural sand; in the regions with abundant siliceous sandstone resources, satisfactory siliceous sandstone (including waste siliceous sandstone in earthwork) can be made into machined sand to replace natural sand and artificial sand made of hard limestone, thereby solving the problems of natural sand / artificial sand resource shortage, high cost, difficulty in use of sand, environmental destruction and waste of energy resources in part of regions, also solving the problem of environmental pollution and destruction caused by waste slag in earthwork in part of regions and providing imponderable energy resources.

Owner:CHONGQING TECHEMCO

2-branch acylation method of solid acid continuous loaded catalyzed aromatic heterocyclic compound

ActiveCN106397295AAvoid harmEasy to separateOrganic chemistryMolecular sieve catalystsChemical compoundSolid acid

The invention relates to the technical field of chemical compounds, in particular to a 2-site acylation method of solid acid continuous loaded catalyzed aromatic heterocyclic compound. The method comprises the following steps: filling a continuous reaction device with solid acid catalyst, and continuously adding aromatic heterocyclic compounds and acylating agents to trigger the Friedel-Crafts acylation. The method is a highly efficient green synthesis process which applies heterogeneous catalysis to make the products easily separable, thereby avoiding the use of Lewis acid such as AlCl3 and eliminating the environmental destruction; the method uses continuous operation with mild reaction conditions and short reaction time. The catalyst does not have to be separated and can be recycled. The reaction recovery rate can reach 95% or above. The reaction selectivity is superior. The purity of the product can reach 92% or above. The method is simple in operation, and has obvious advantages especially in enlarged production.

Owner:ASYMCHEM LAB TIANJIN +4

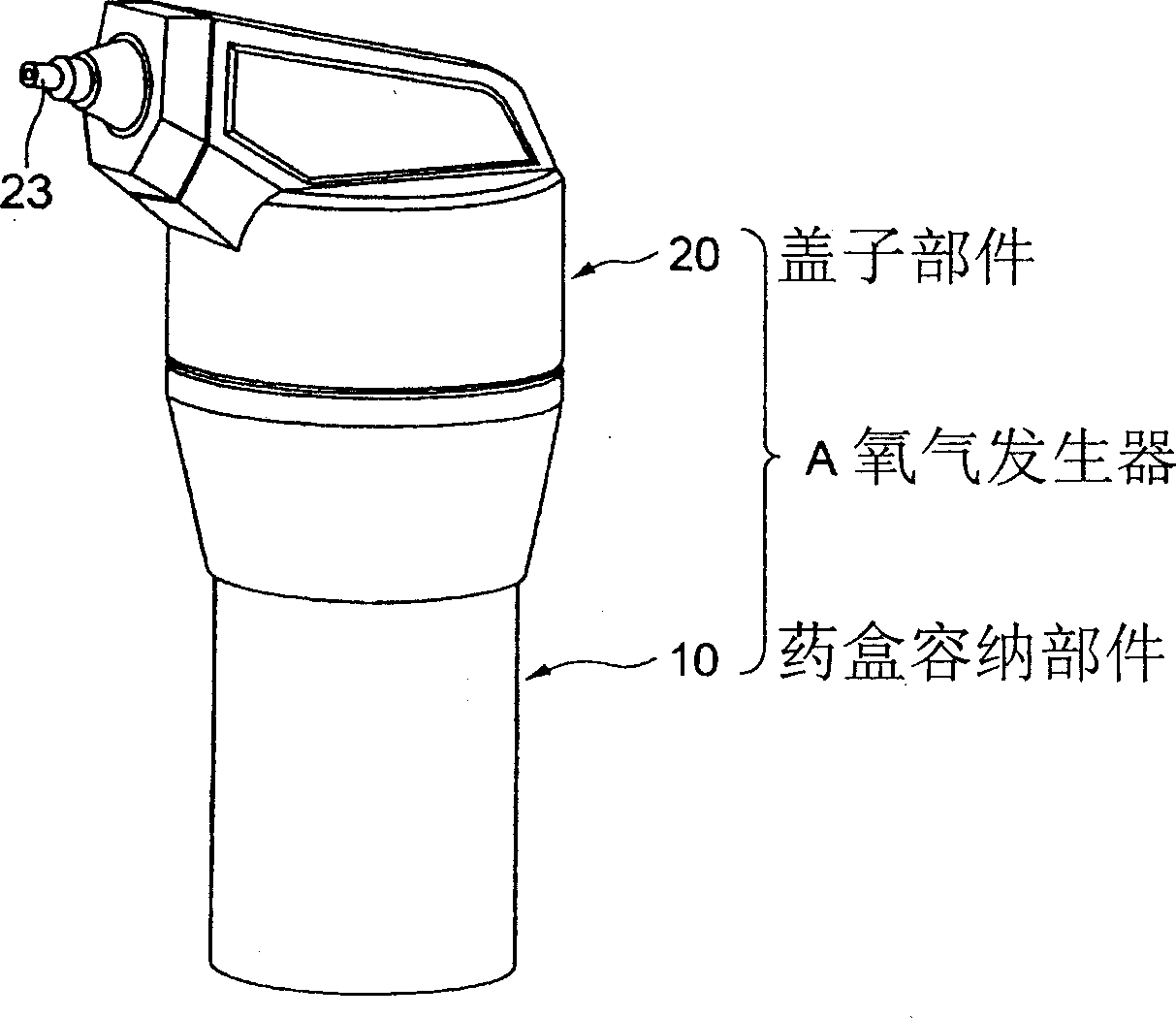

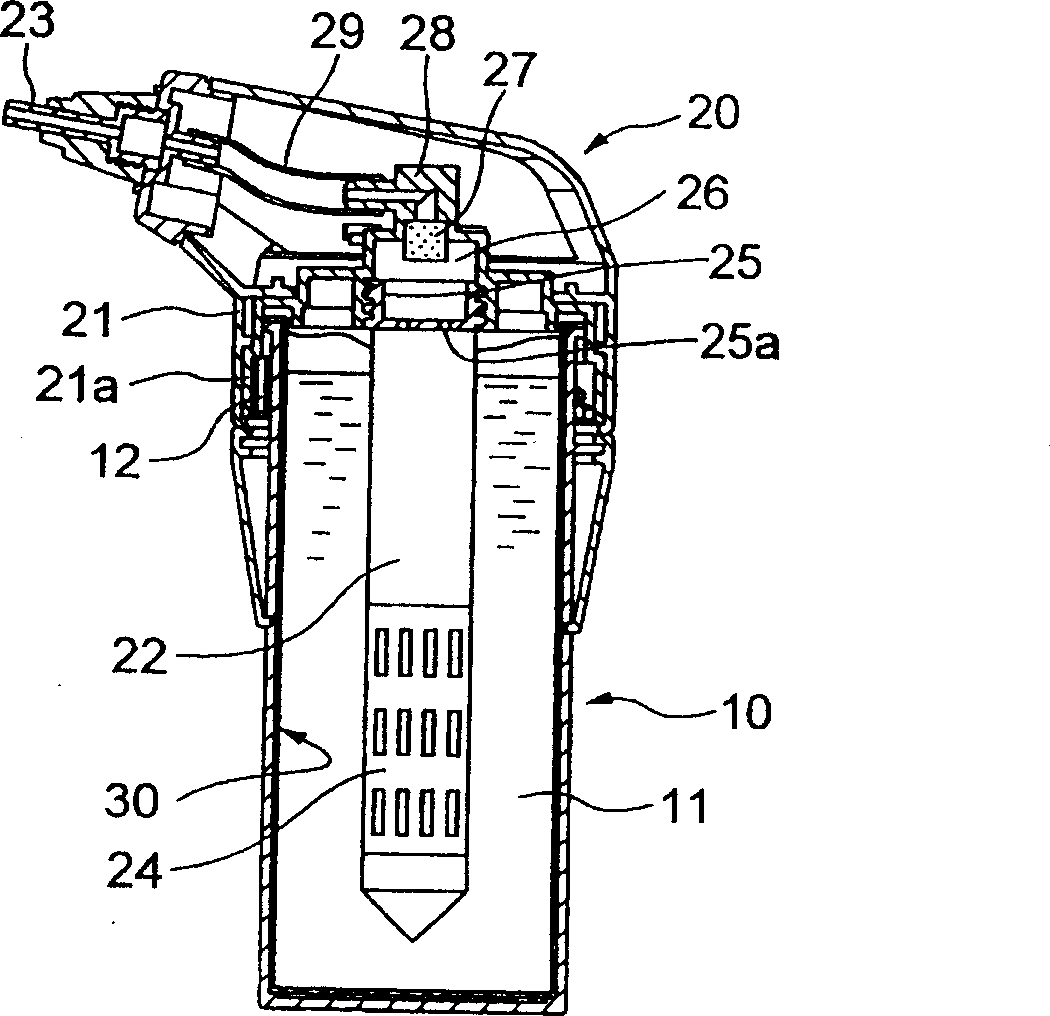

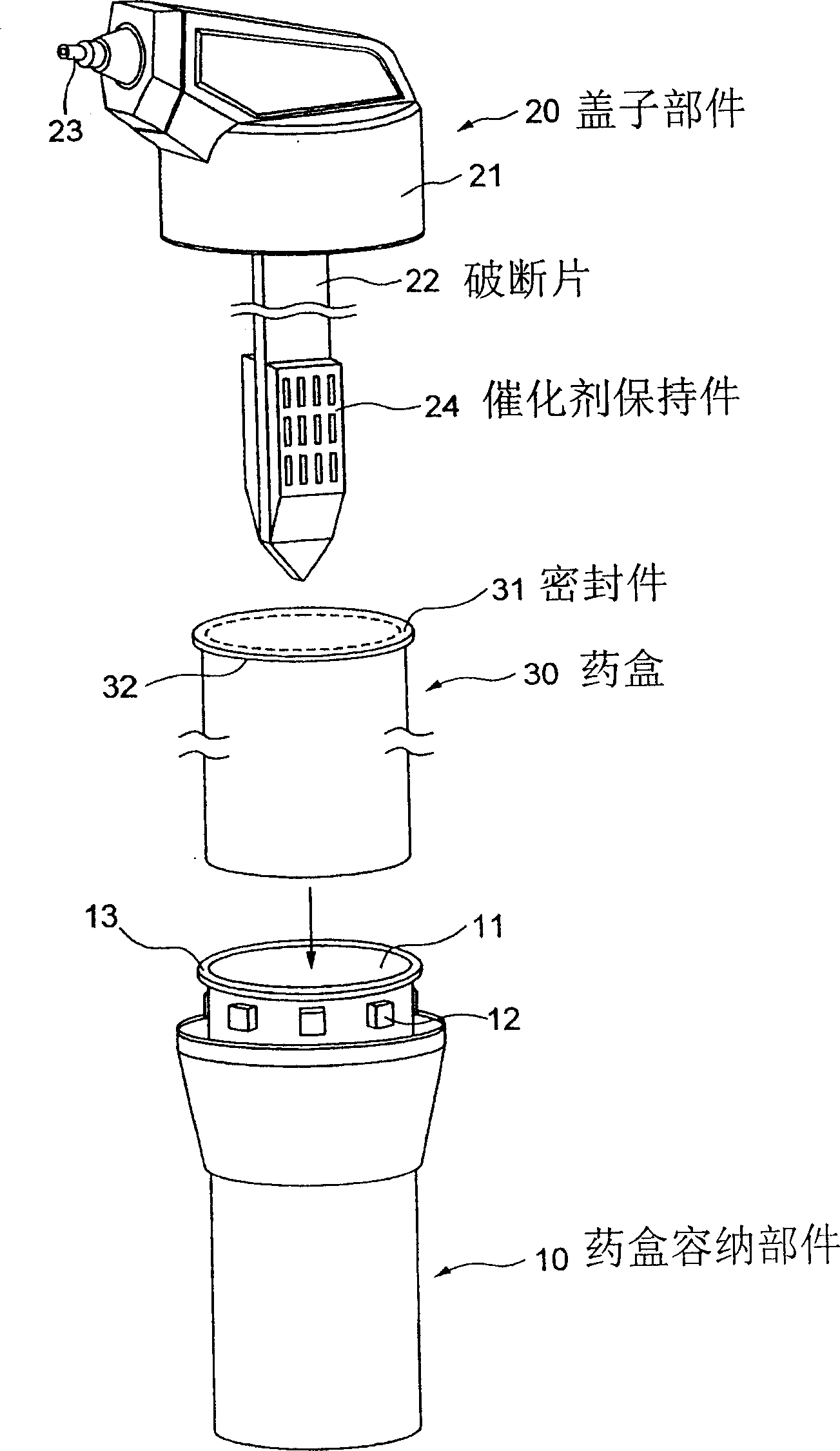

Oxygen generator and drug case thereof

The present invention provides an oxygen generator and a cartridge for oxygen generator, the oxygen generator is composed of a cartridge container and a lid, the cartridge container has a space containing the cartridge container with a opening on the top, and containing the cartridge container in changable way, the cartridge container is seal by the sealer, and filled with aqueous hydrogen peroxide; and the lid provided with a fracture part removably connected to close an opening surface of the cartridge storing space of the body, and holding metal catalyst, which breaks the seal of the cartridge stored in the cartridge storing space when it is mounted and enters the aqueous hydrogen peroxide to generate oxygen due to contact with the aqueous hydrogen peroxide, and a nozzle for jetting oxygen collected on the upper part of the cartridge. This oxygen generator is simple handle, causing no problem in environmental destruction, and inhaling oxygen at low cost.

Owner:DREAM WORKSHOP

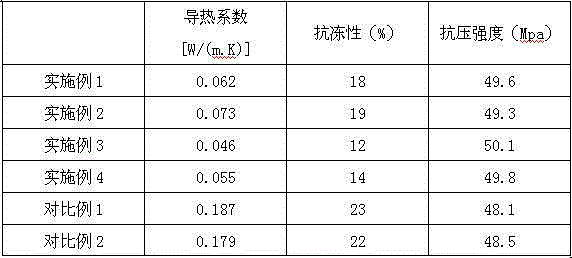

Building external wall fireproof and thermal insulation material and preparation method thereof

The invention provides a building external wall fireproof and thermal insulation material and a preparation method thereof. The material is composed of the following components by weight: 70-90 parts of Portland cement, 30-50 parts of a waste molecular sieve catalyst, 8-15 parts of nano calcium carbonate, 5-8 parts of carbon fiber, 10-15 parts of water glass, 1-3 parts of a water reducing agent and 18-36 parts of water. The building external wall thermal insulation material provided by the invention can save cement consumption and reduce the engineering cost, also can reduce environmental destruction, and improves the compressive strength and fireproof and thermal insulation performance of the material.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

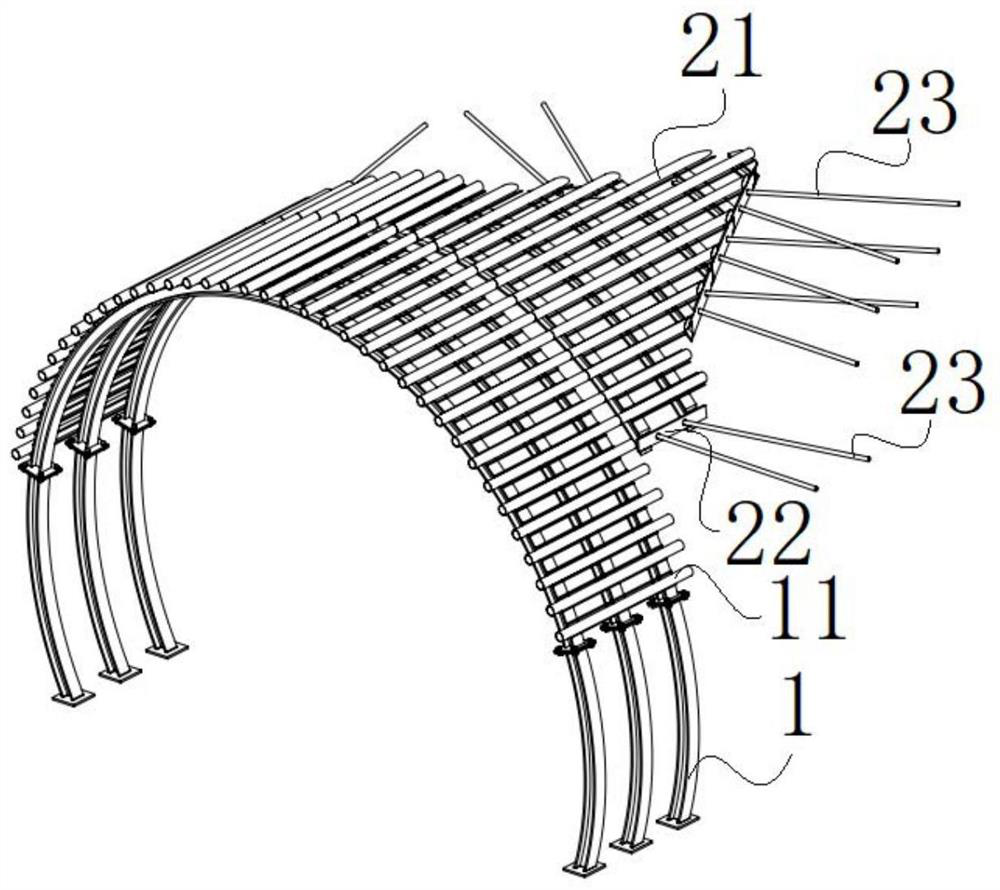

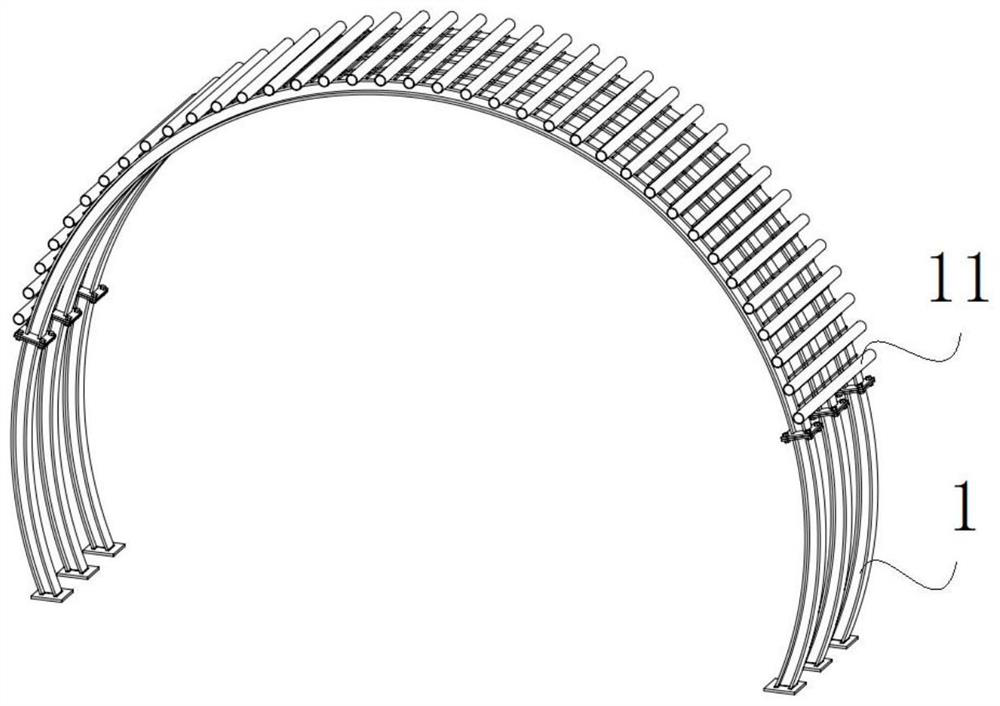

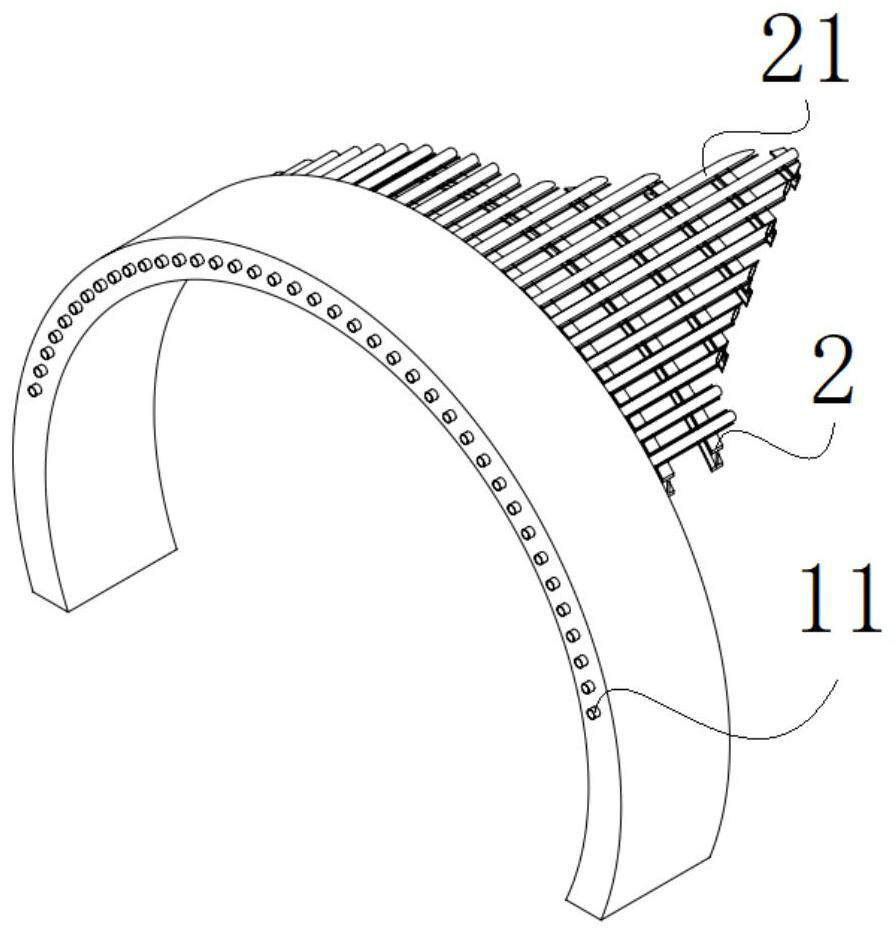

Slope superficial loose body natural lattice reinforcing structure and reinforcing method

InactiveCN112376586AReduce economic investmentSignificantly strengthenedExcavationsSoil preservationStructural engineeringSurface water

The invention discloses a slope superficial loose body natural lattice reinforcing structure and reinforcing method, and relates to the technical field of geological disaster prevention and control. The slope superficial loose body natural lattice reinforcing structure and reinforcing method are mainly used for solving the problems that an existing slope lattice project is damaged due to the effect of surface water, and the environment is greatly damaged in the construction process. The slope superficial loose body natural lattice reinforcing structure comprises a plurality of rows of transverse grouting body sets and a plurality of rows of longitudinal grouting body sets, wherein the transverse grouting body sets and the longitudinal grouting body sets are arranged in a crossed mode to form a reinforcing frame; and the transverse grouting body sets and the longitudinal grouting body sets each comprise grouting bodies which are sequentially arranged, and the grouting bodies penetrate through superficial loose bodies and extend to a sliding bed. The slope superficial loose body natural lattice reinforcing structure and reinforcing method have the advantages of being good in reinforcing effect, convenient to construct and small in damage to the environment.

Owner:INST OF EXPLORATION TECH OF CHINESE ACAD OF GEOLOGICAL SCI

Tunnel entrance protection structure for V-shaped terrain and construction method of tunnel entrance protection structure

PendingCN111794773AAvoid damageReduced excavation constructionUnderground chambersTunnel liningShotcreteTerrain

The invention discloses a tunnel entrance protection structure for V-shaped terrain and a construction method of the tunnel entrance protection structure. The method comprises the following steps of S1, construction preparation; S2, tunnel top intercepting ditch excavation; S3, side and upward slope excavation and supporting; S4, sleeve arch and pipe shed construction; S5, special-shaped section sleeve arch construction; S6, advanced large pipe shed construction; and S7, dark tunnel construction. According to the V-shaped terrain underground cave entering construction method, special-shaped sleeve arch supporting is adopted, so that a tunnel enters underground excavation construction in advance, excavation and protection of a high-side upward slope of a cave entrance are reduced, potentialsafety hazards and environmental damage of the cave entrance are reduced, time and labor are saved, the special-shaped sleeve arch is constructed by spraying concrete, a certain support formwork is saved, and the modulus is reduced; moreover, the solidification time of the sprayed concrete is short, so that the structure enters a stressed state in advance, the construction time is saved to a great extent, the environmental damage and unnecessary excavation construction before entering a hole can be reduced, the construction cost is reduced, and meanwhile, the safe and rapid construction in the hole can be achieved.

Owner:YUNNAN CONSTR INVESTMENT HLDG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com