Patents

Literature

383results about How to "Pressure is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

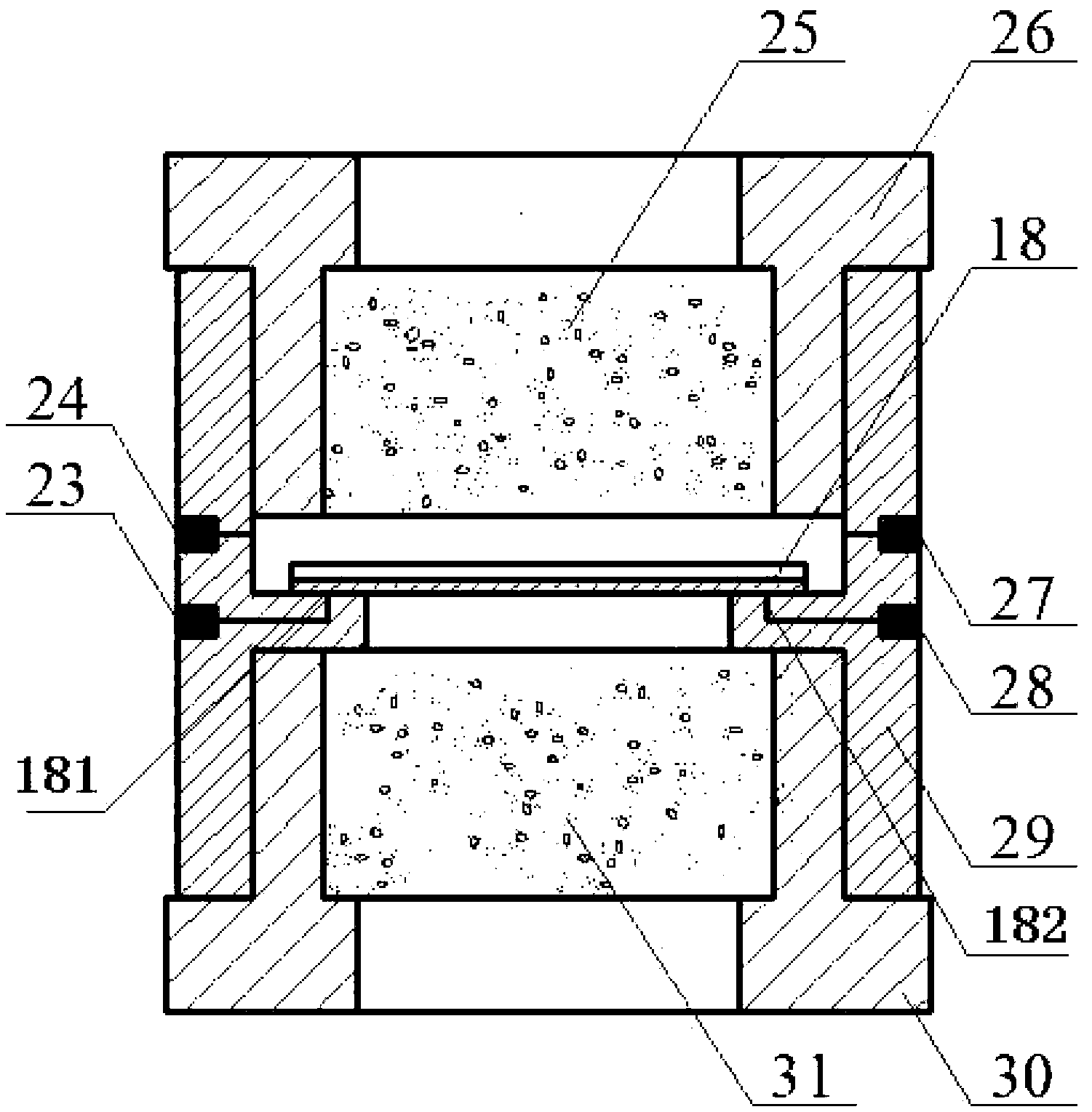

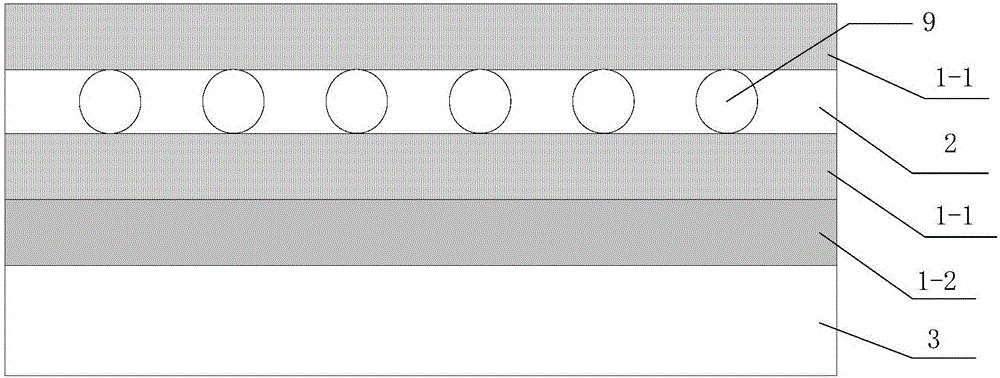

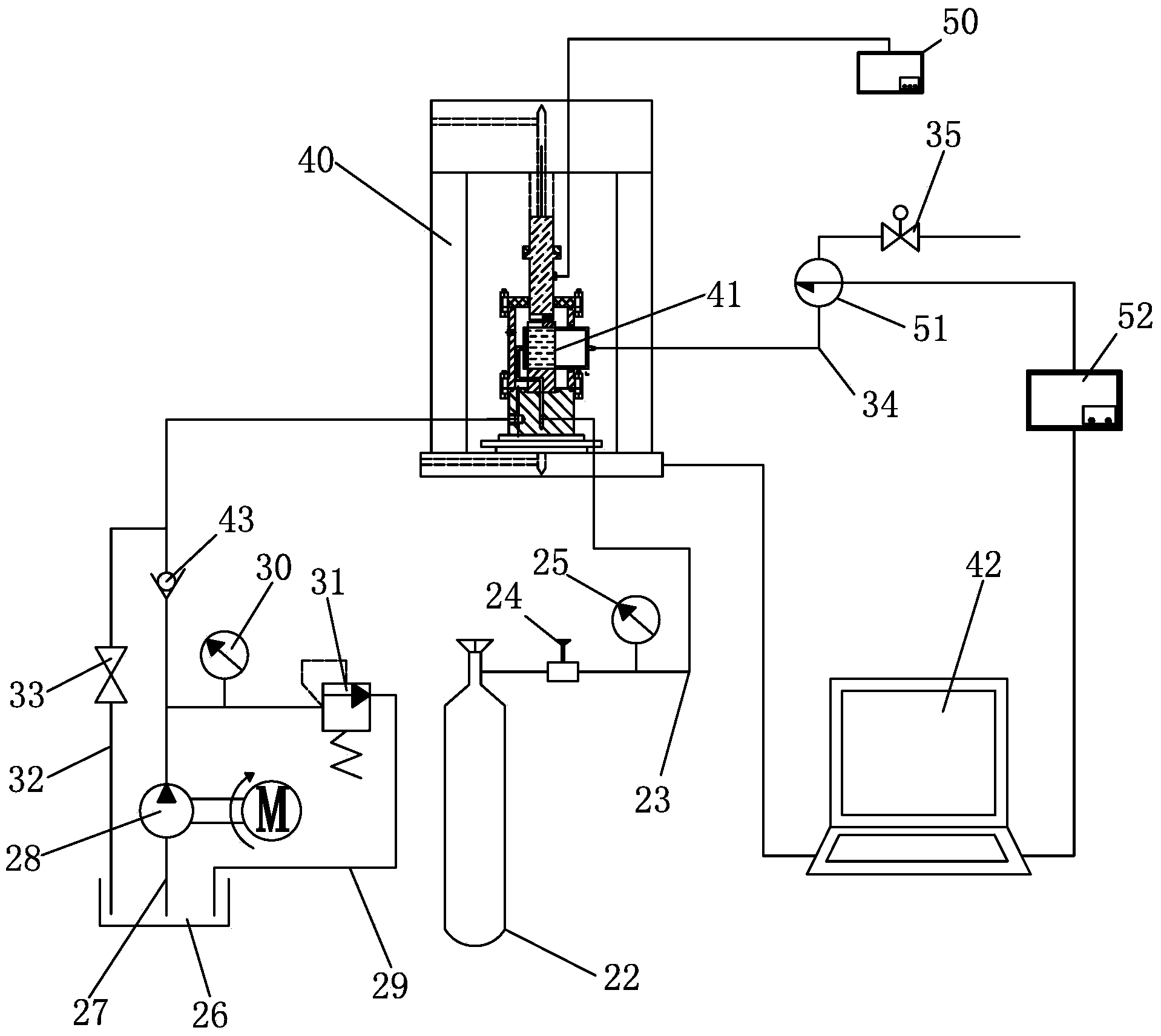

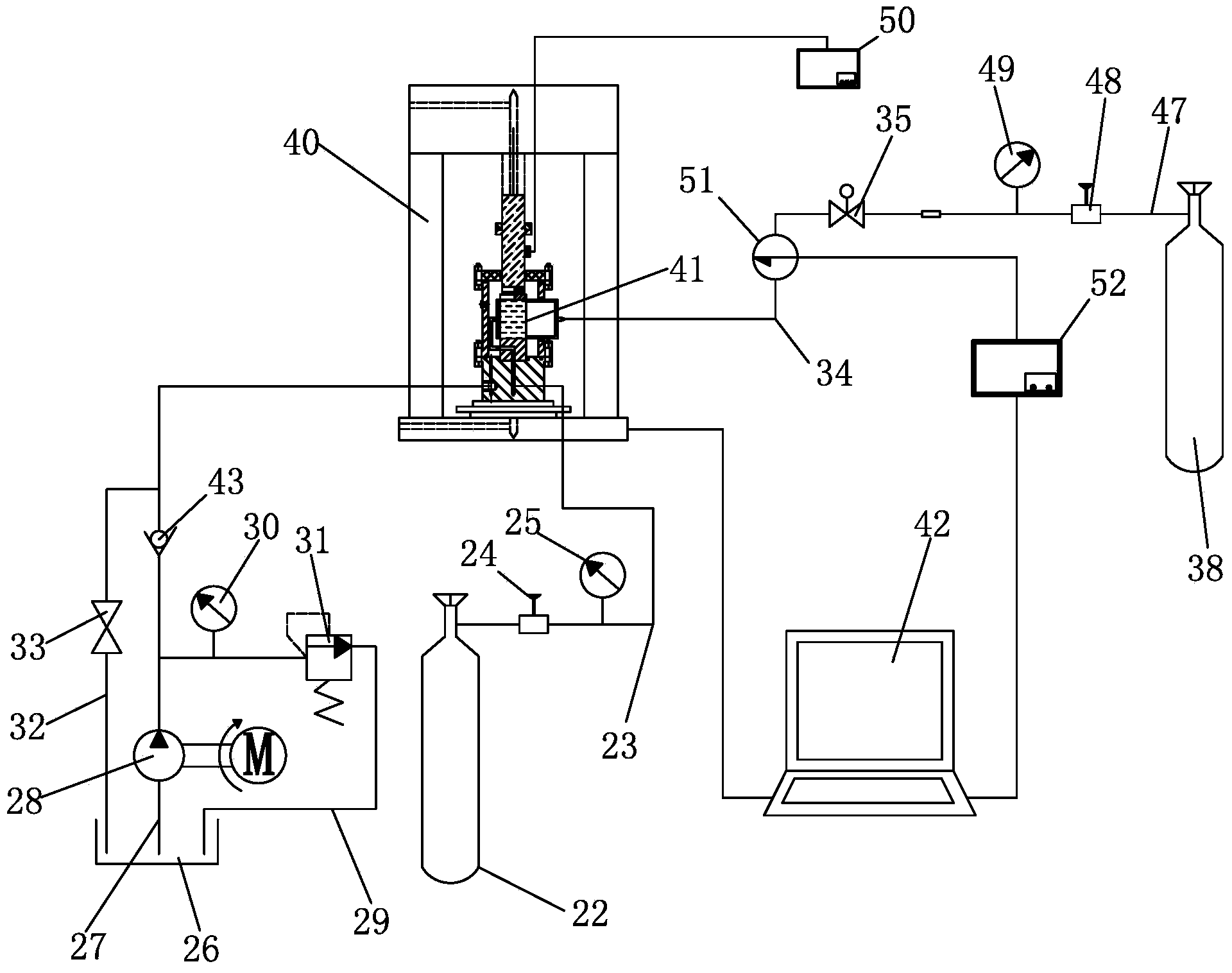

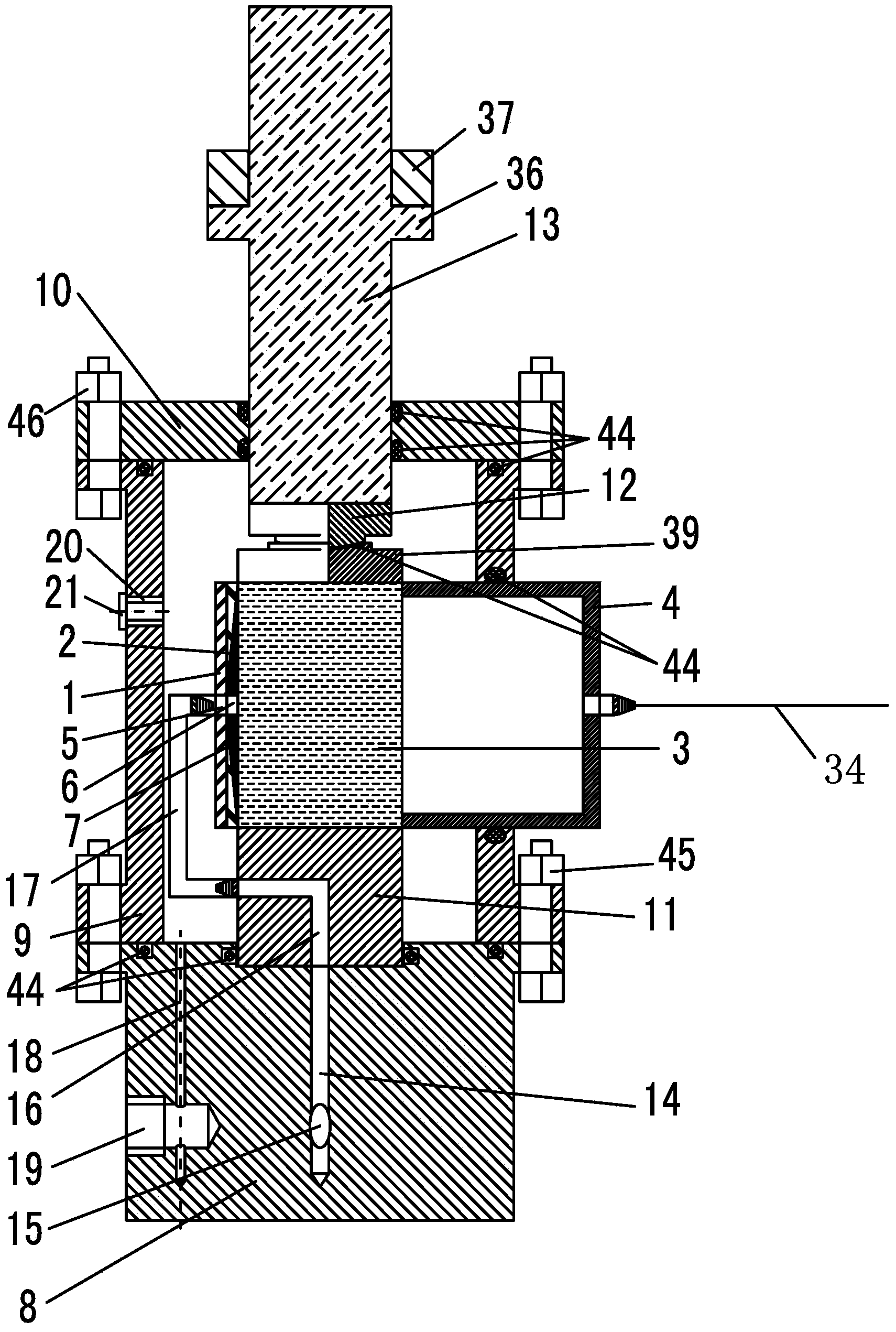

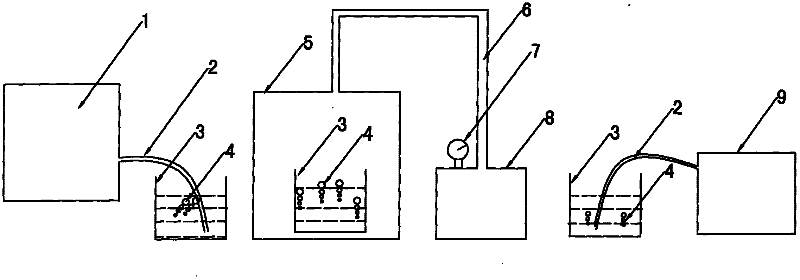

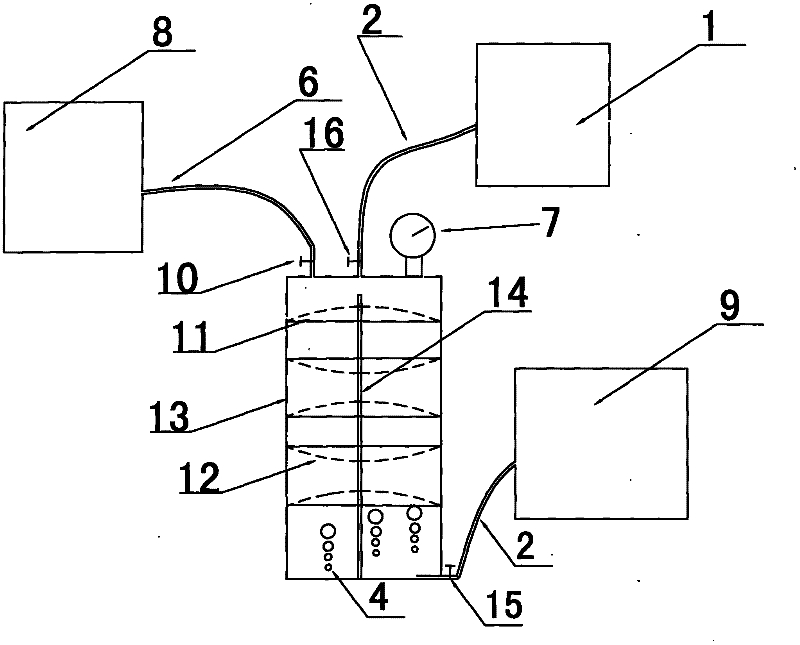

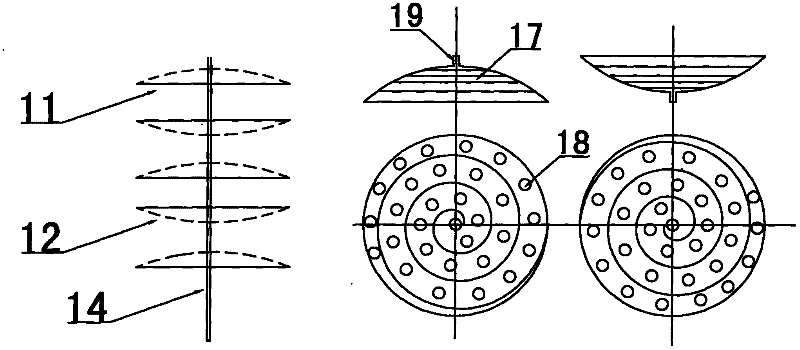

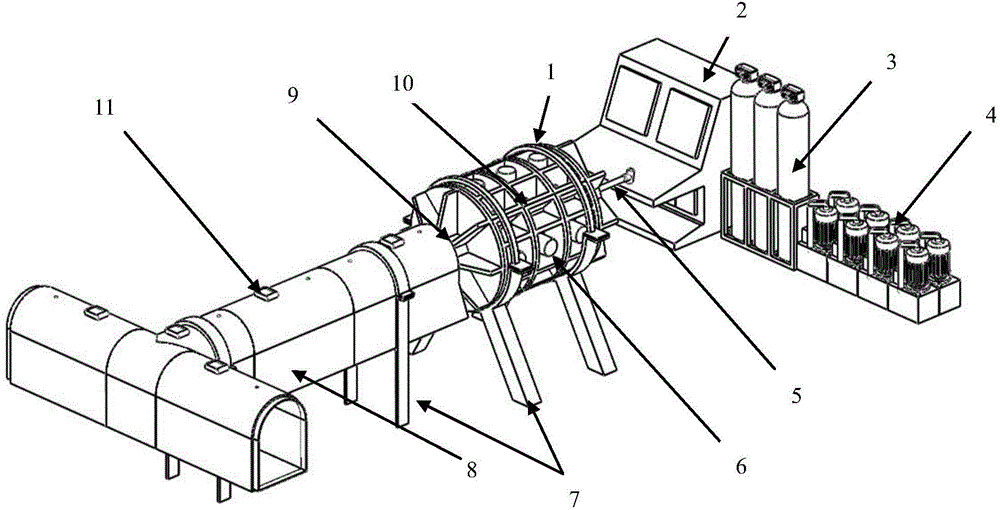

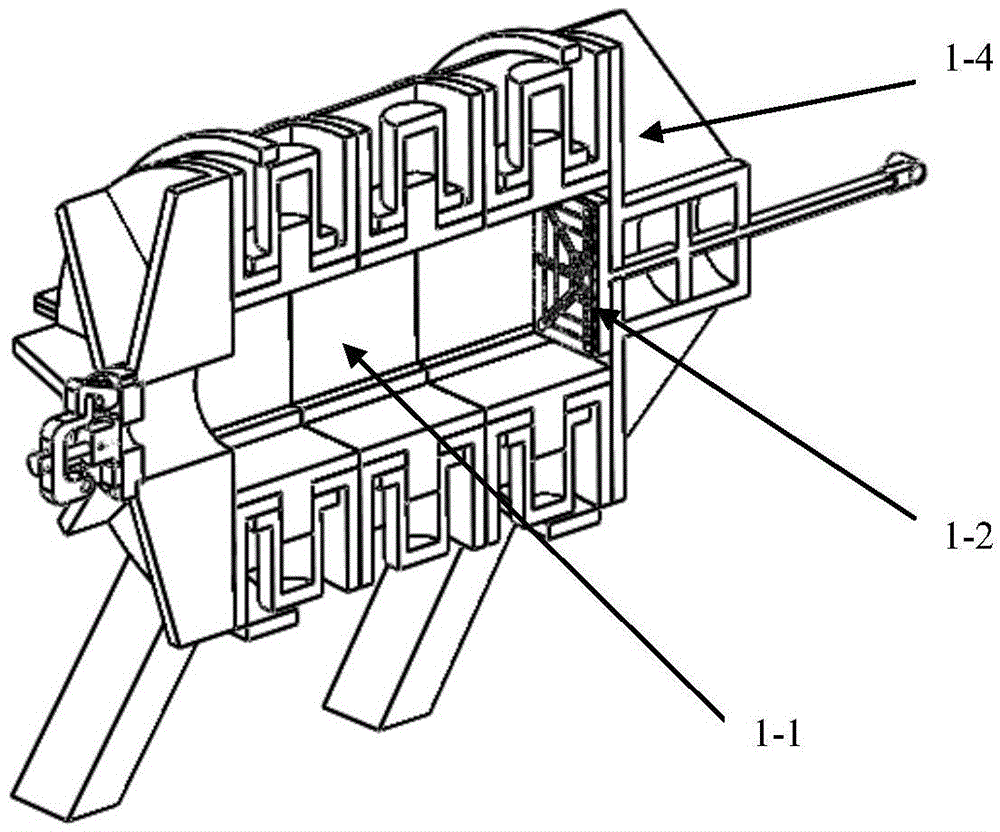

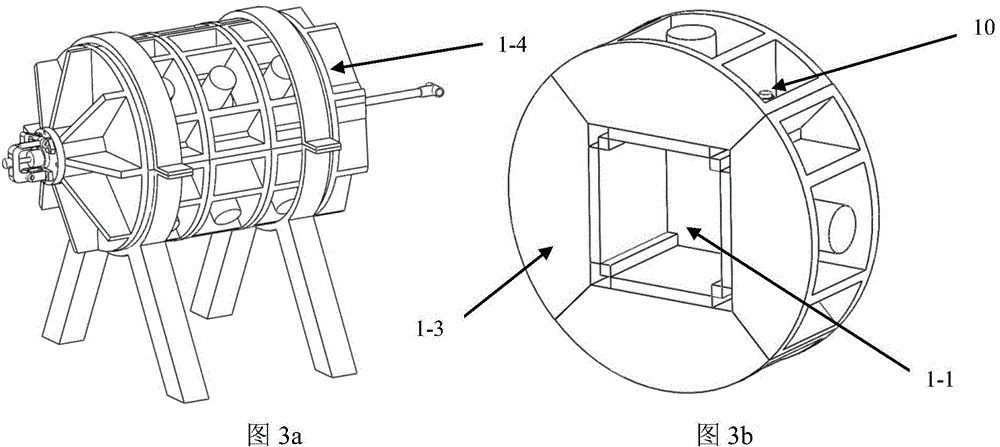

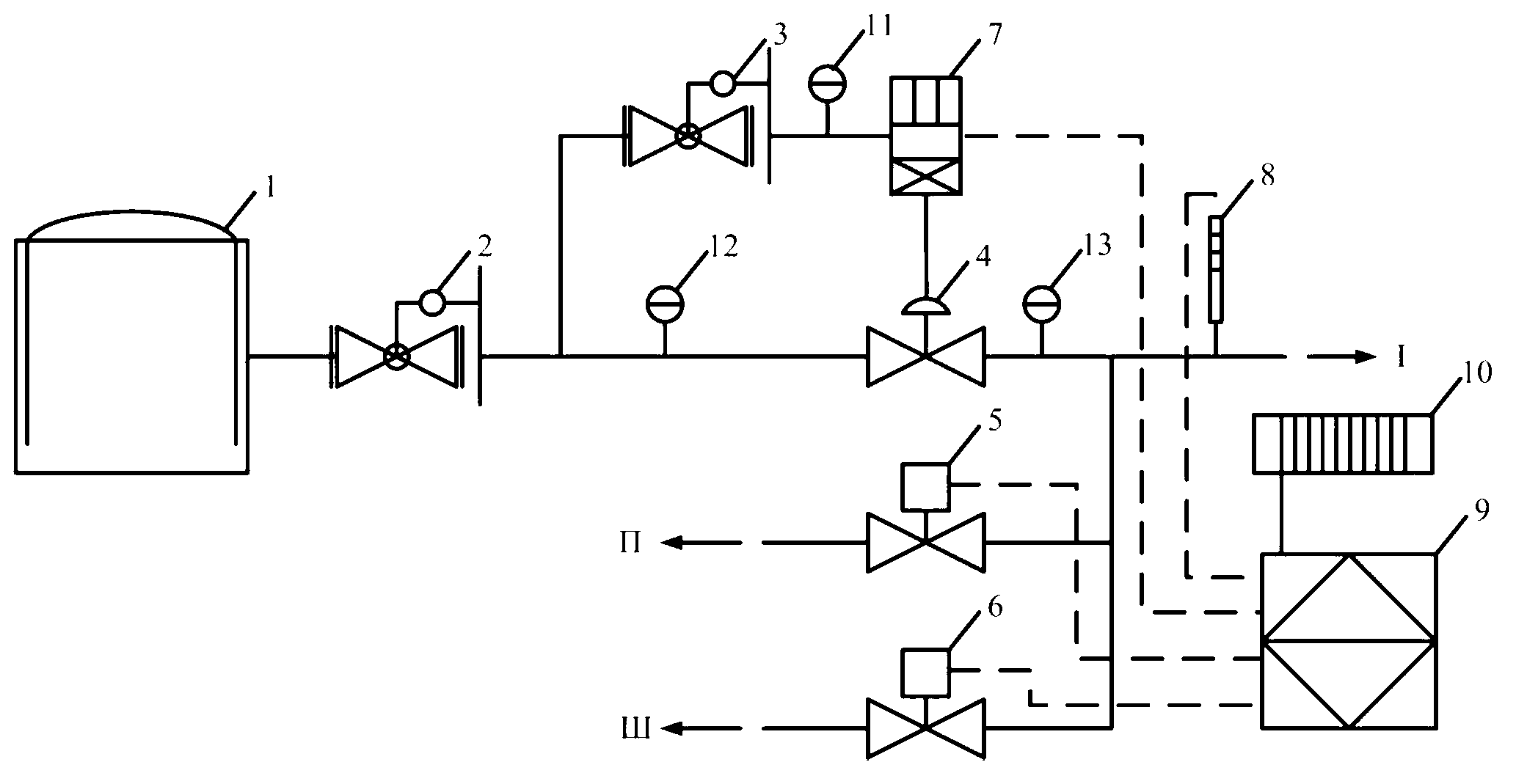

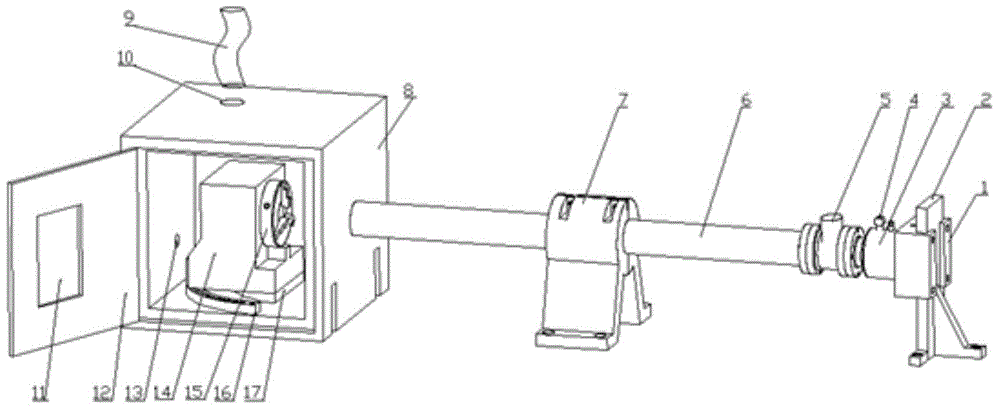

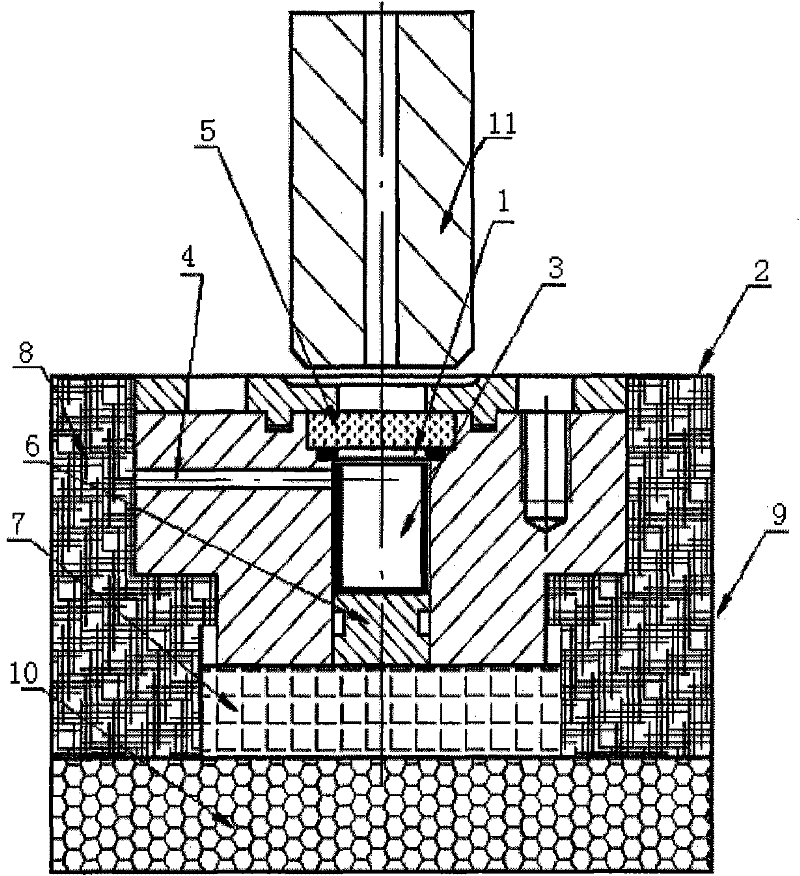

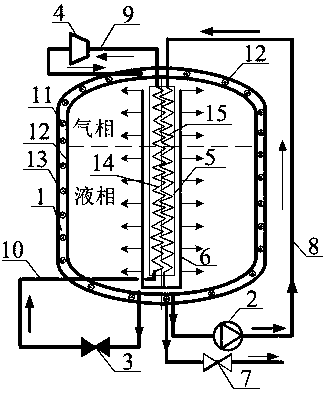

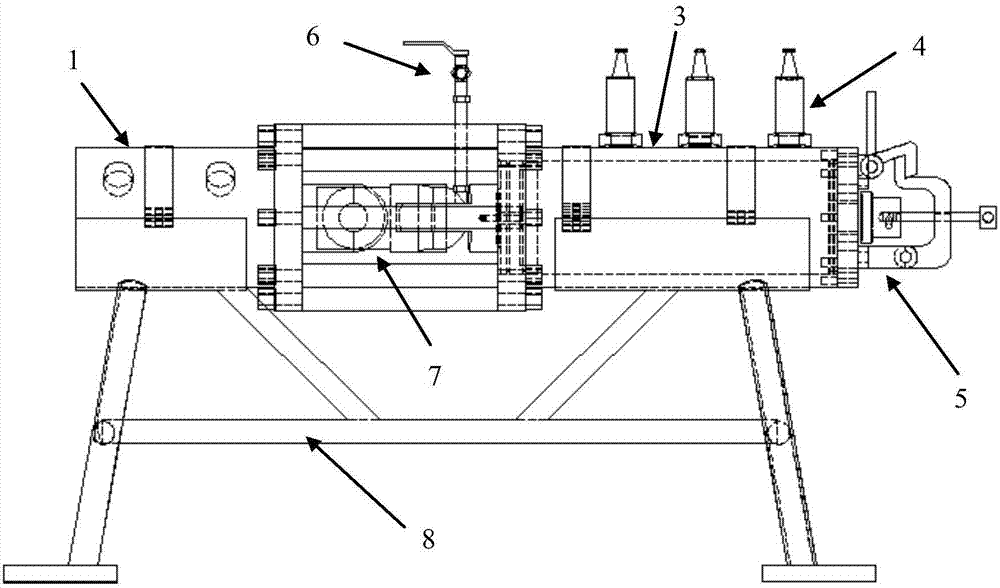

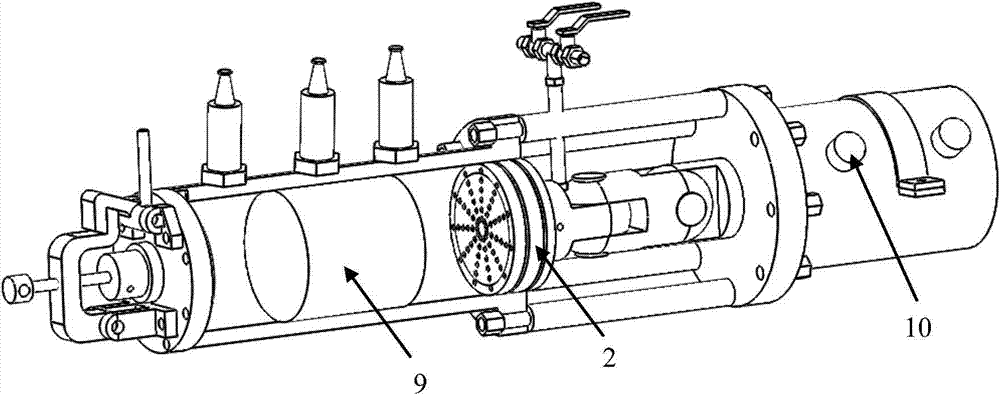

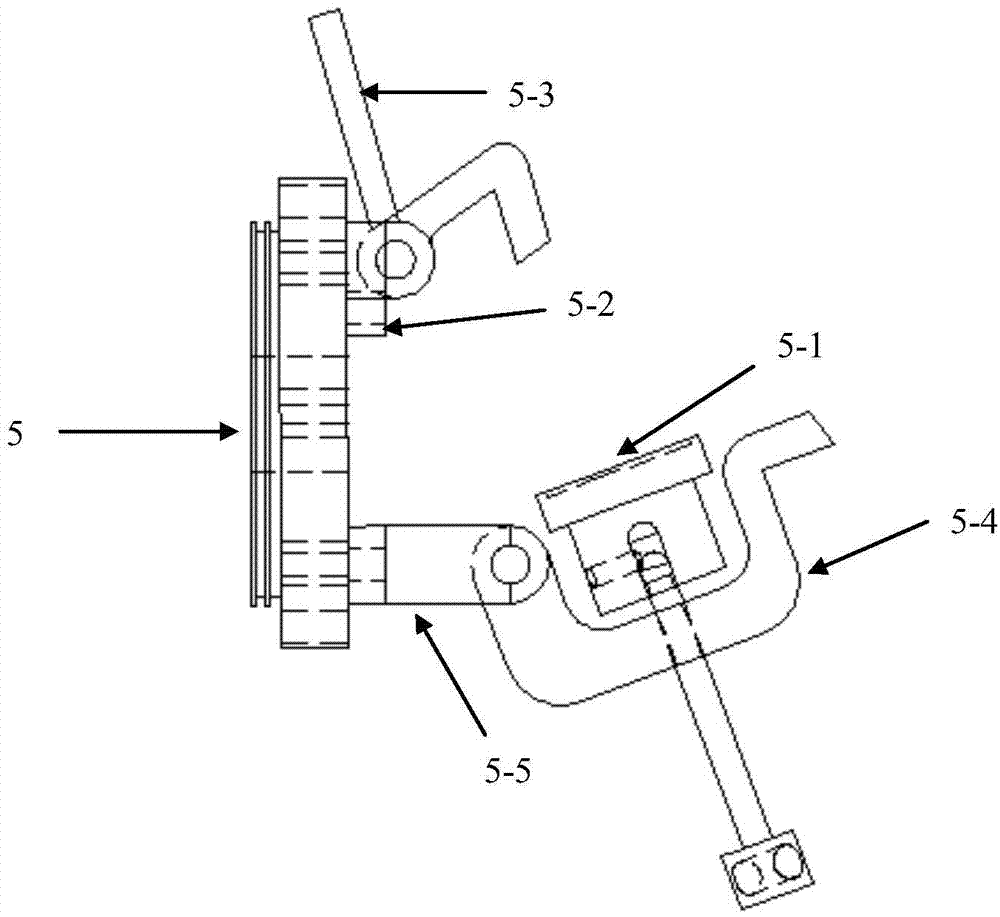

High temperature and high pressure visual device for simulating microorganism oil displacement and simulating method thereof

ActiveCN103216222AConvenient and effective temperatureConvenient and effective ring pressure sizeConstructionsFluid removalMicroorganismTemperature control

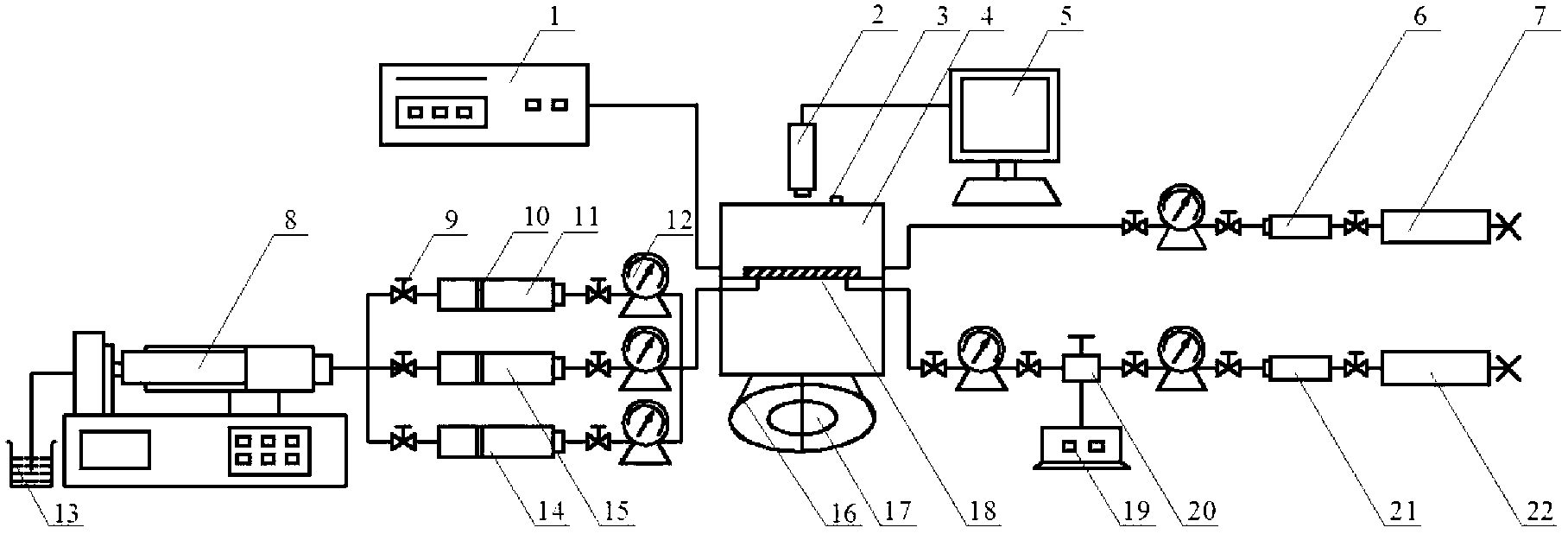

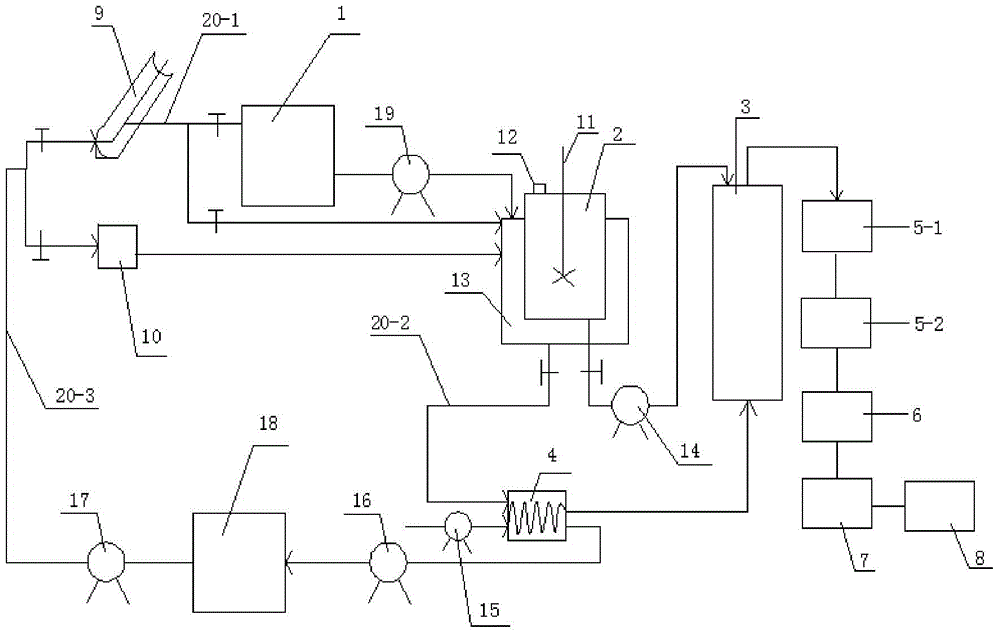

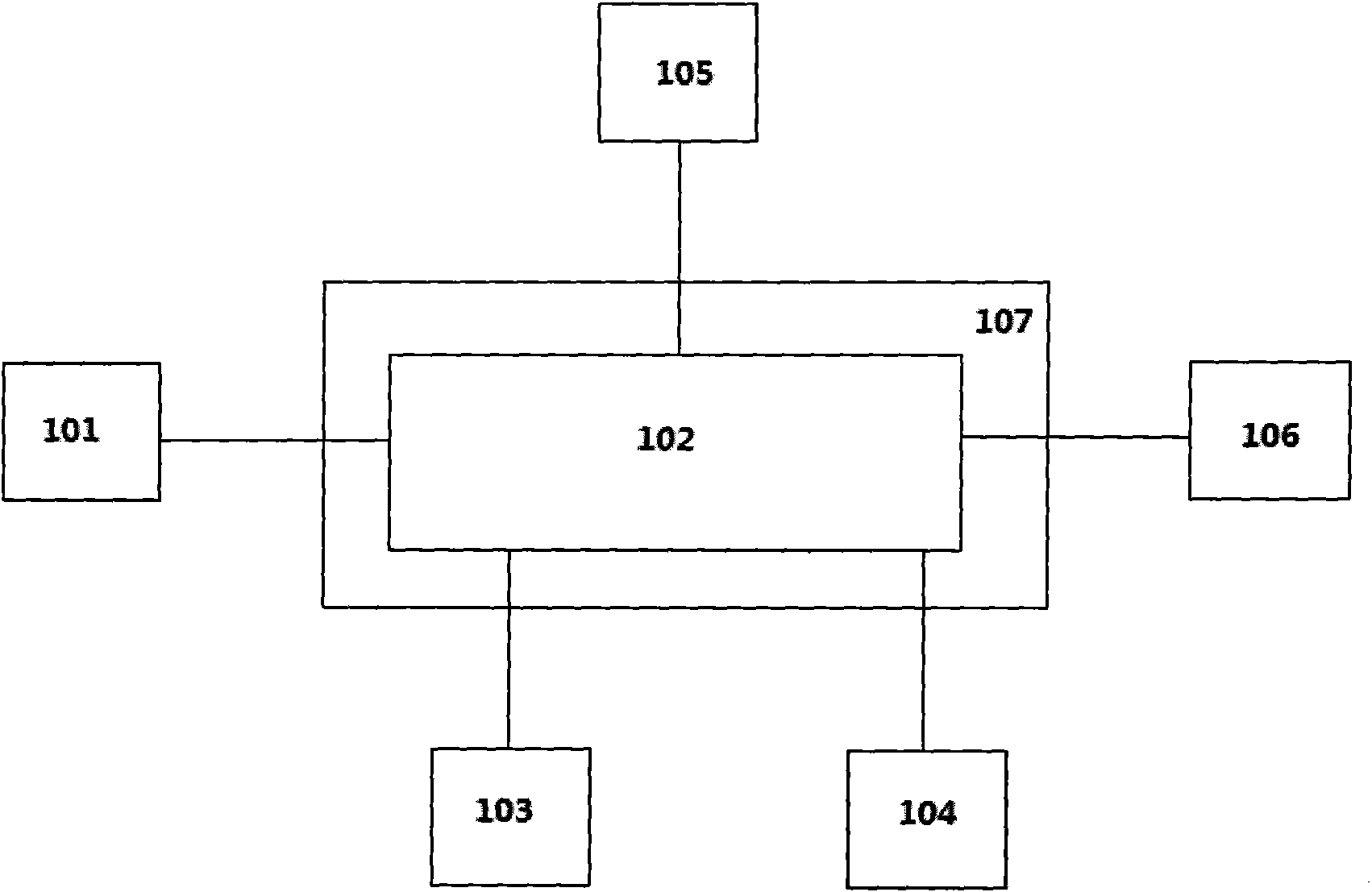

The invention relates to an experimental method and a device for simulating the process that microcosmic remaining oil is extracted in a microcosmic simulation model under the condition of oil deposit high temperature and high pressure, researching feasibility of microorganism oil displacement technology in improving enhanced oil recovery after water drive, and carrying out visualized microcosmic oil displacement experimental research under the high temperature and high pressure experimental conditions, in particular to a high temperature and high pressure visual device for simulating microorganism oil displacement and a simulating method thereof. The device comprises a model clamp clamping a microcosmic visual model, a displacement system, a back pressure system, an annular pressure system, a pressure monitoring system, a temperature control system and an image collecting system. According to the device, temperature and pressure can be controlled easily, used space is small, safety performance is excellent, operation is simple, action mechanism of microorganism and petroleum hydrocarbon and starting mechanism of the microorganism on the remaining oil can be conveniently observed in a visualized condition, and the device has important significance on wide application and popularization of microcosmic experiments in oil industries.

Owner:UNIV OF SCI & TECH BEIJING

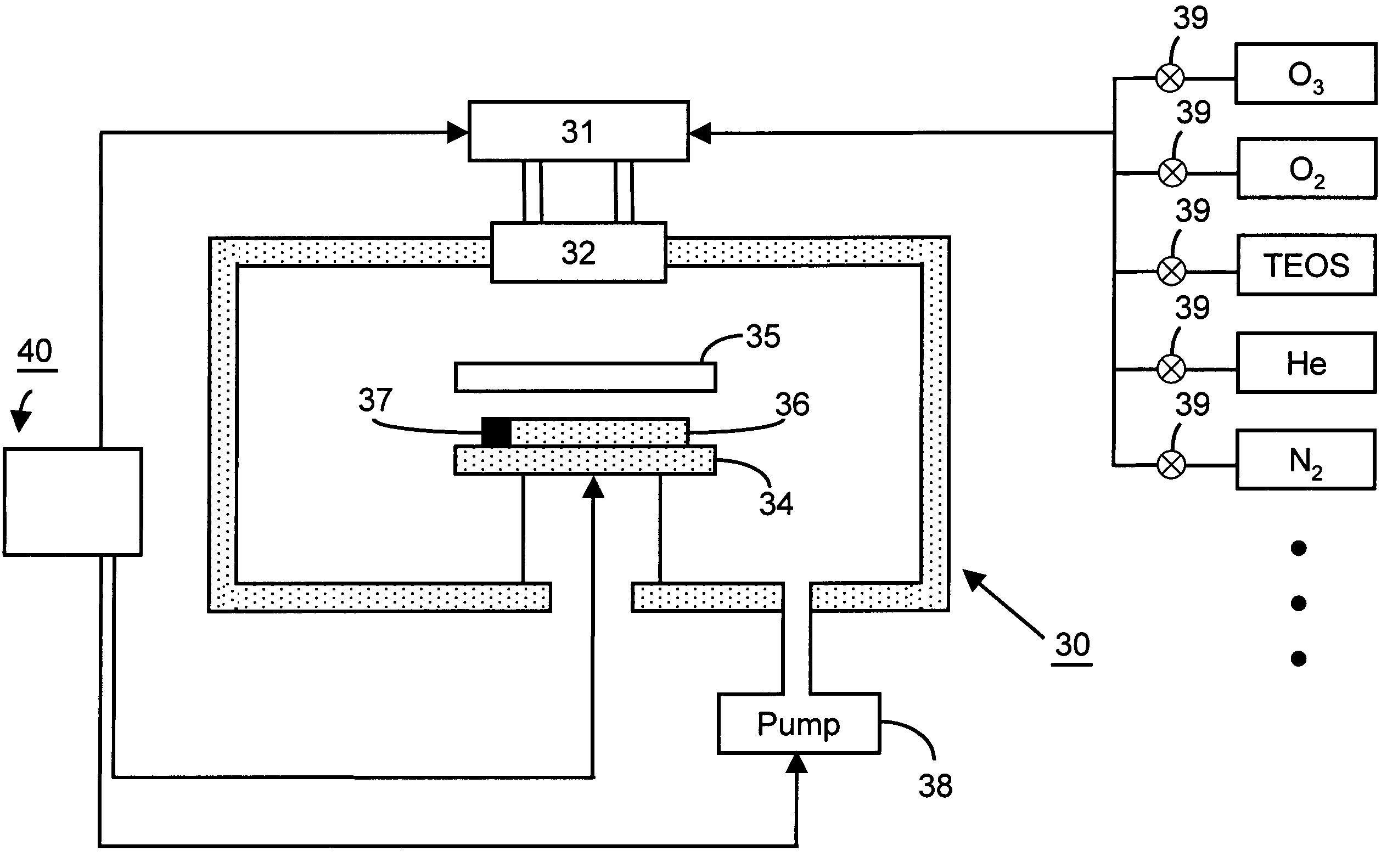

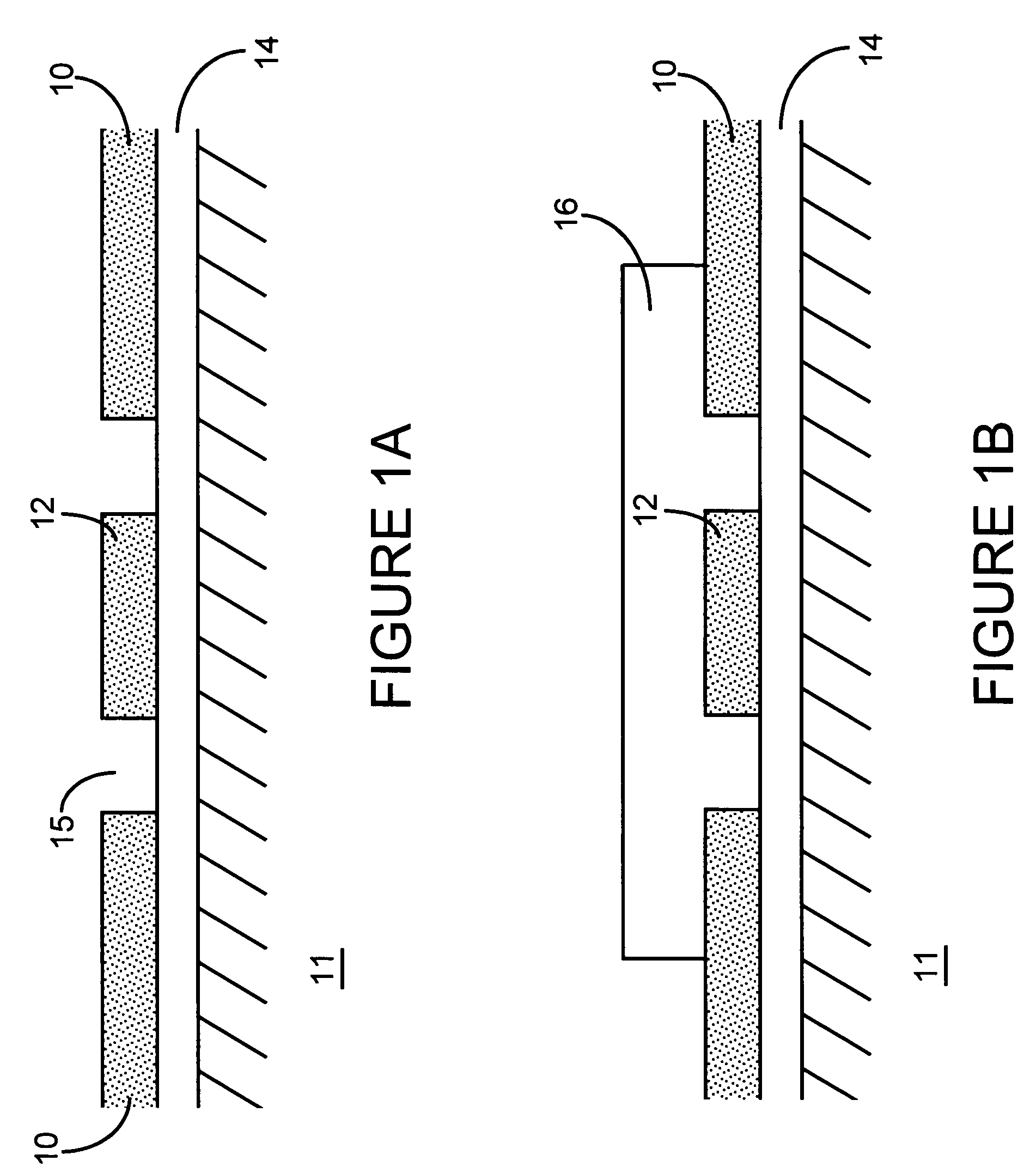

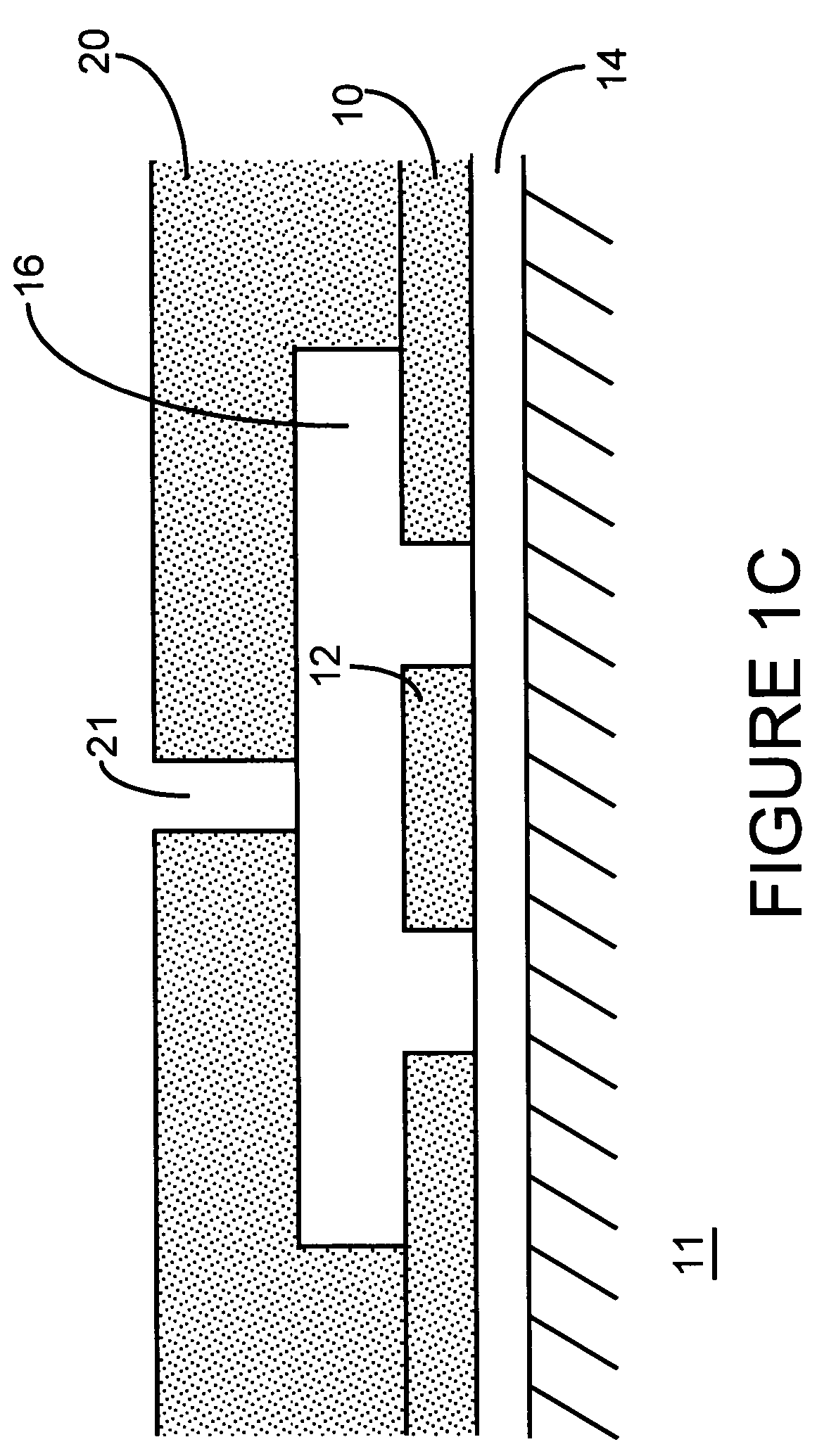

Crack and residue free conformal deposited silicon oxide with predictable and uniform etching characteristics

ActiveUS20050106318A1Pressure is easy to controlReduce inclusionsDecorative surface effectsVacuum evaporation coatingCrazingDecomposition

A silicon oxide layer is formed by oxidation or decomposition of a silicon precursor gas in an oxygen-rich environment followed by annealing. The silicon oxide layer may be formed with slightly compressive stress to yield, following annealing, an oxide layer having very low stress. The silicon oxide layer thus formed is readily etched without resulting residue using HF-vapor.

Owner:ROBERT BOSCH GMBH

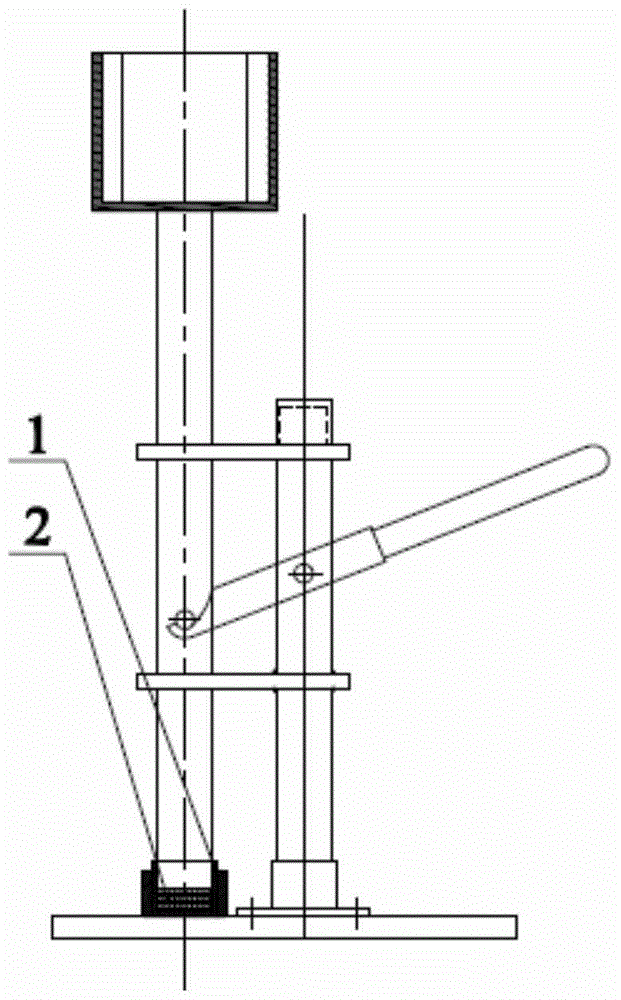

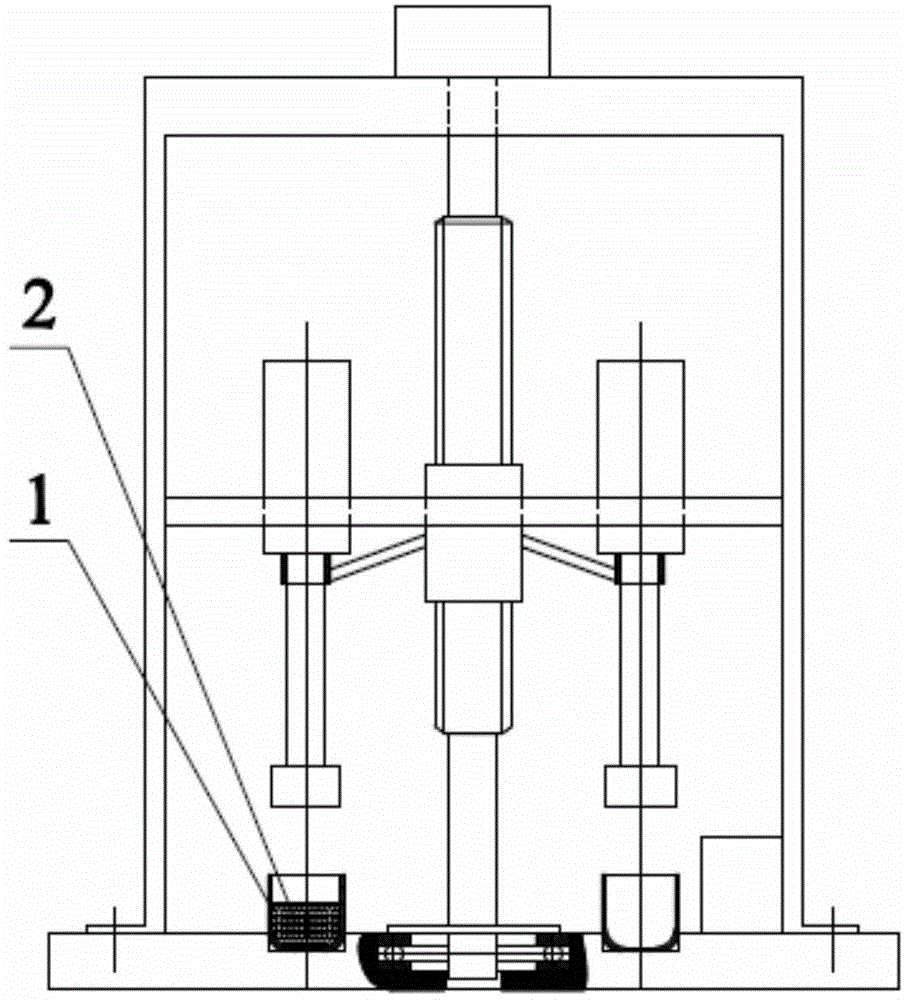

Simple production equipment for bituminous coal sample block

ActiveCN104792590AIncrease or decrease stressSimple structurePreparing sample for investigationCrucibleBituminous coal

The invention discloses simple production equipment for a bituminous coal sample block, and relates to the field of automatic equipment for manufacture of bituminous coal samples. The simple production equipment comprises a T-shaped frame, a motor rack, a lower bearing bracket, an upper bearing bracket, guide rails, two sliders, a T-shaped crucible holder, a T-shaped pressure plate frame, a two-way screw, a pressure applying plate and a spring, wherein the two-way screw is used for changing the distance between a crucible and the pressure applying plate for pressure applying; the spring is sued for controlling the pressure accurately. The equipment for automatically producing the bituminous coal sample block is simple and compact in structure and convenient to operate, and the pressure is controllable.

Owner:上海屹苒自动化设备有限公司

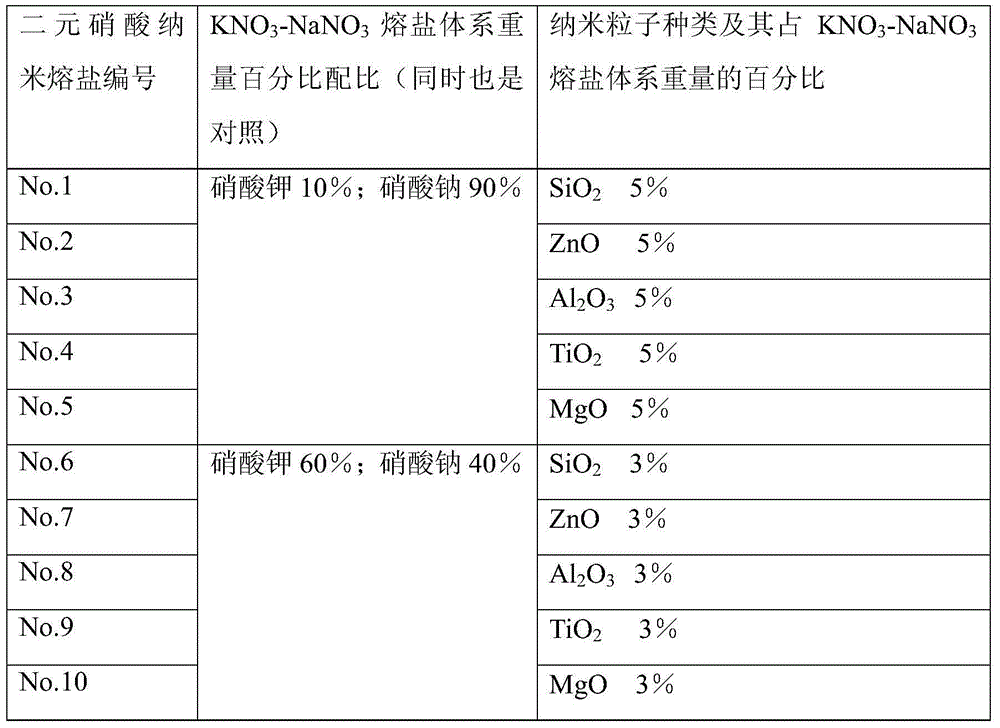

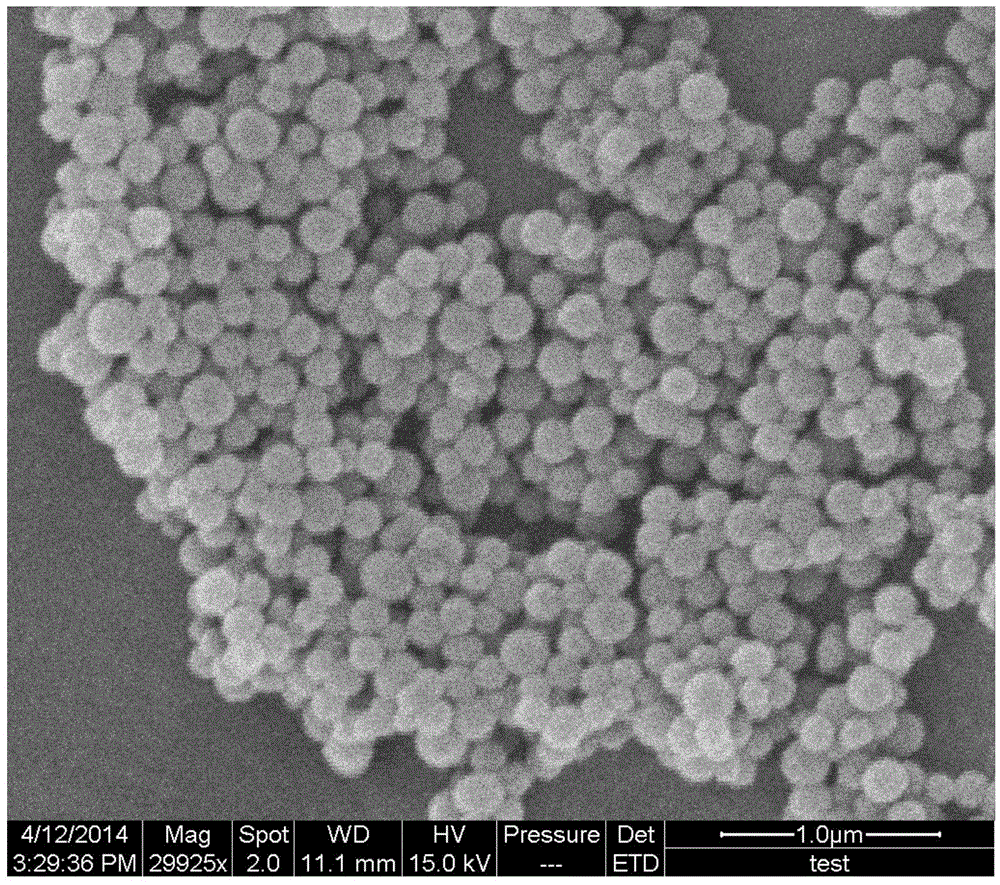

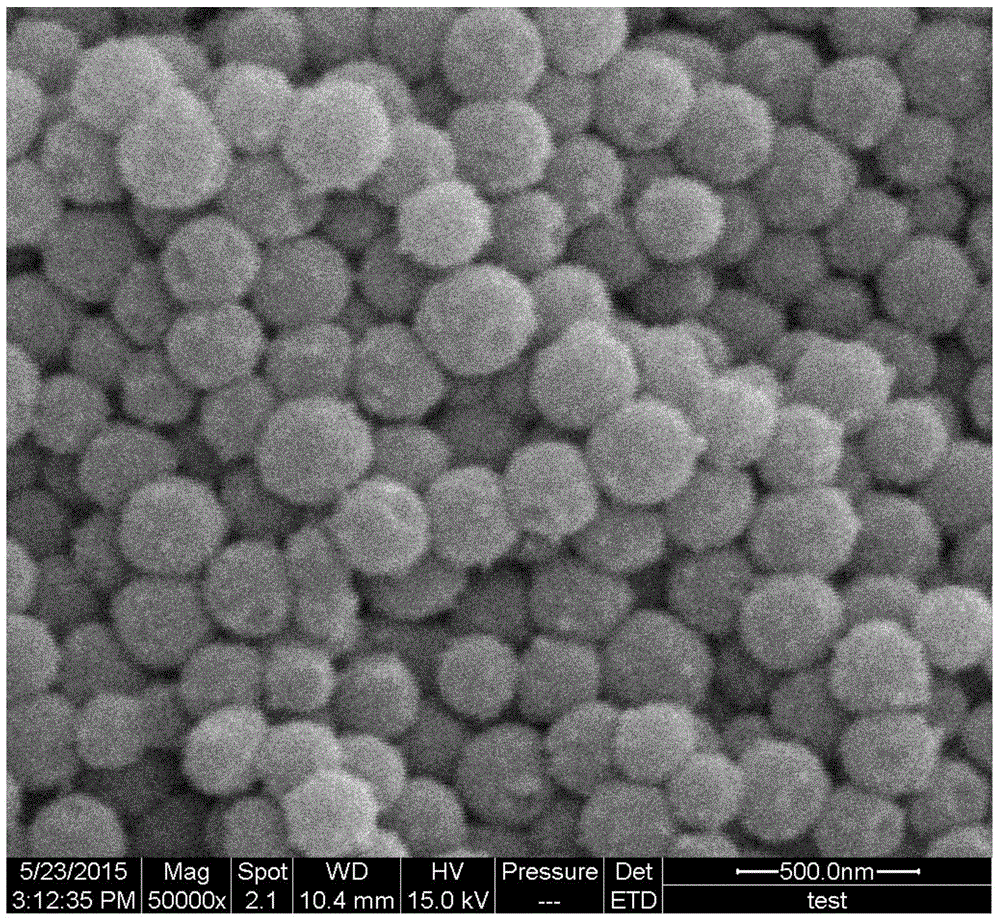

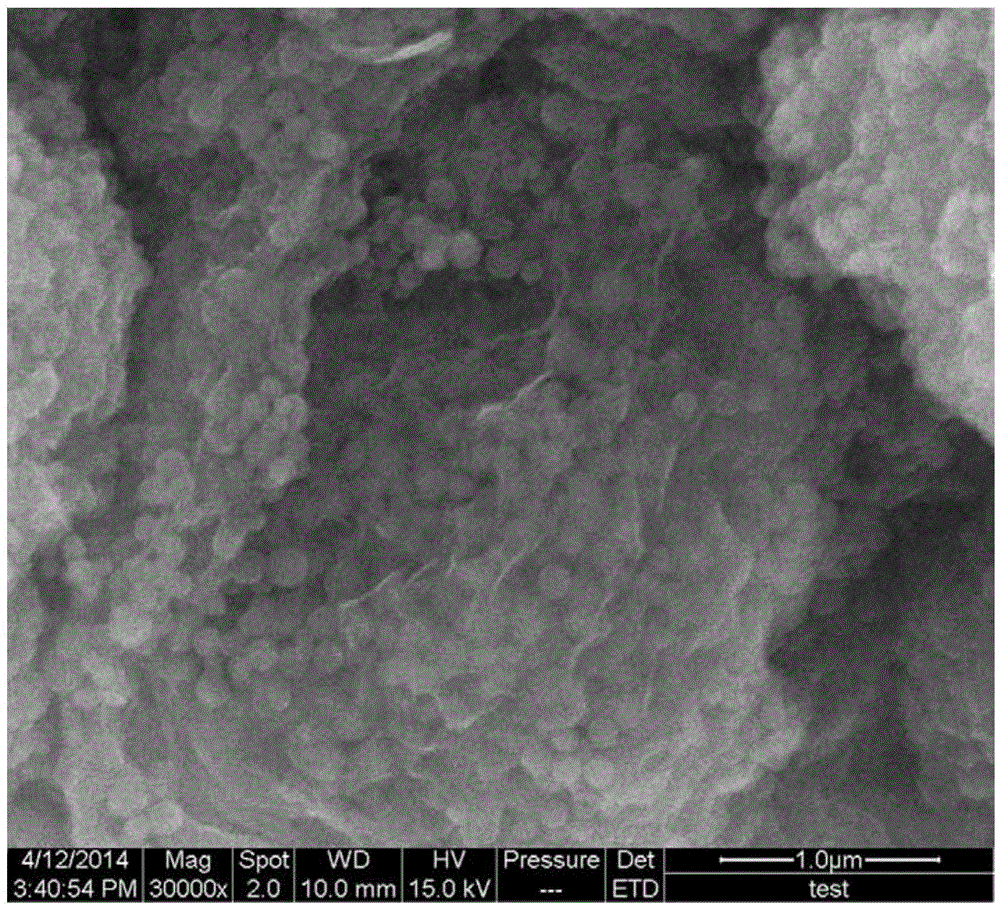

Nanometer molten binary nitrate heat-transfer heat-storage medium and preparation method thereof

ActiveCN103911121AImprove thermal conductivityImprove thermal stabilityFrom solar energySolar heat devicesMolten saltHeat stability

The invention relates to a nanometer molten binary nitrate heat-transfer heat-storage medium and a preparation method thereof and belongs to the field of solar photo-thermal electricity generation. The nanometer molten binary nitrate heat-transfer heat-storage medium is characterized in that nano-particles are dispersed in a KNO3-NaNO3 and KNO3-NaNO2 solid-liquid phase-change molten binary nitrate system at a high temperature so that the nanometer molten binary nitrate heat-transfer heat-storage medium is compounded, and the nano-particles comprise SiO2, ZnO, Al2O3, TiO2, CaO and / or MgO nanoparticles. The nanometer molten binary nitrate heat-transfer heat-storage medium solves the problem that the existing nanometer molten binary nitrate system has a low heat conductivity coefficient, poor heat stability and a narrow use temperature scope and can be widely used in the technical field of solar photo-thermal electricity generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

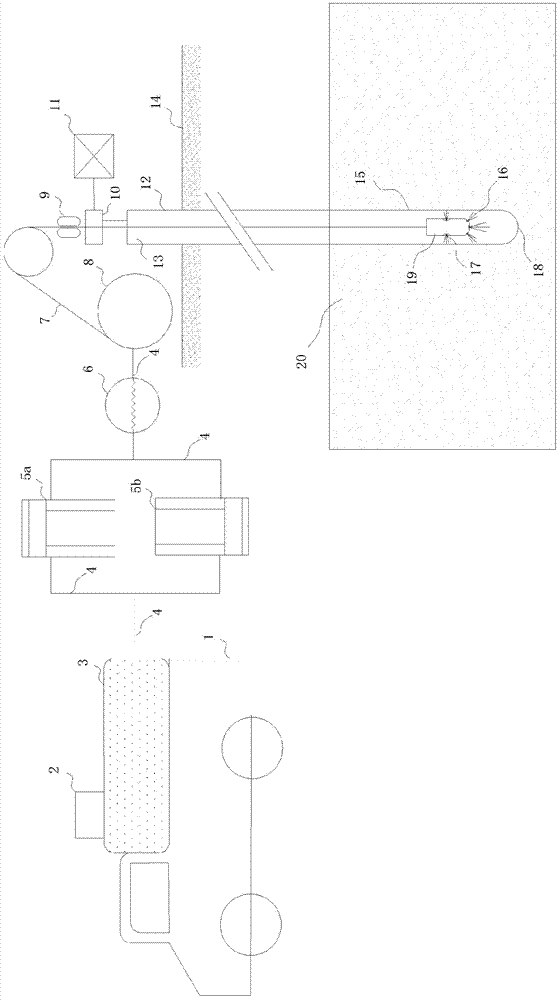

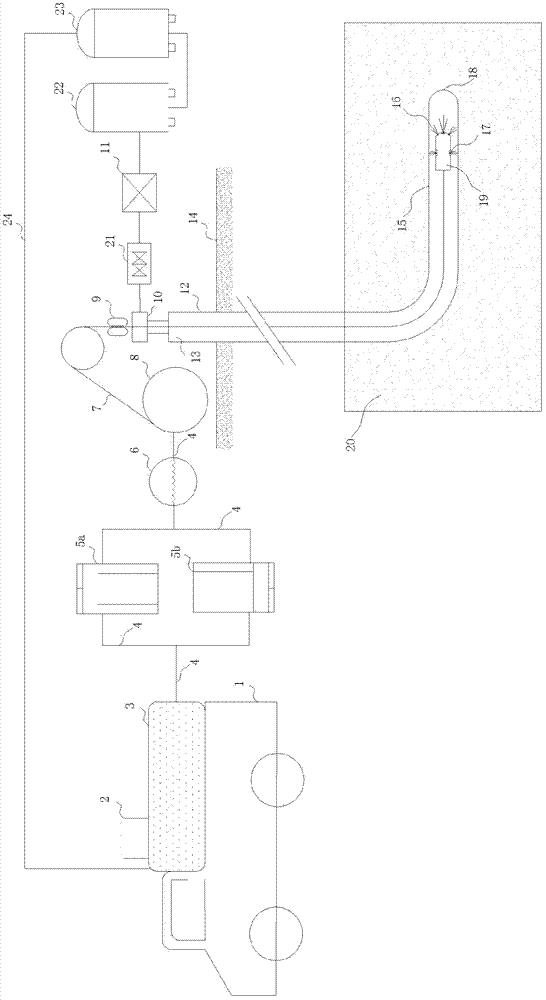

Method combining coiled tubing with supercritical CO2 for jet-flow sand washing plugging removal

The invention relates to a method combining coiled tubing with supercritical CO2 for jet-flow sand washing plugging removal. The method uses the supercritical CO2 as flushing fluid to carry out jet-flow sand washing plugging removal for a shaft or an oil casing. When a supercritical CO2 jet-flow is combined with the coiled tubing to carry out supercritical CO2 jet-flow sand washing plugging removal, pressure relief is not needed in the trip process, the coiled tubing can directly work with pressure, and the working procedure and the time are saved. The fluid viscosity of the supercritical CO2 is low, the surface tension of the supercritical CO2 is close to zero, and the diffusion coefficient of the supercritical CO2 is large, so that the supercritical CO2 can easily enter into tiny pores and cracks to dissolve polymer organic matters and other impurities, and the cleaning is more thorough. And, above all, the supercritical CO2 does not have any pollution to a reservoir, the viscosity of crude oil can also be reduced after the supercritical CO2 enters into the reservoir, the permeability of the reservoir is increased, and the yield and the recovery ratio are increased. Thus, the supercritical CO2 is especially suitable for downhole plugging removal working of unconventional oil-gas reservoirs such as low permeability oil-gas reservoirs, pressure-depleted oil-gas reservoirs, coal gas reservoirs, shale gas reservoirs, tight sandstone gas reservoirs, heavy oil reservoirs and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Active evaporation control method applicable to long-term on-orbit storage of cryogenic propellant

The present invention relates to an active evaporation control method applicable to long-term on-orbit storage of a cryogenic propellant. According to the method, an active evaporation control device that comprises a composite thermal insulating layer, a steam cooling shield, a heat exchanger, a throttling assembly, a circulating pump, a bypass valve and a steam cooling shield exhaust valve is installed for a propellant storage tank. According to the present invention, with the developed active evaporation control method for a cryogenic propellant, discharge of a small amount of simple gaseous propellant can be achieved under the circumstance of uncertain gas-liquid position under microgravity condition, and pressure control on the cryogenic propellant storage tank and control on evaporation of the cryogenic propellant may be effectively realized under dual action by fully using thermodynamic enthalpy of the discharged cryogenic propellant after being throttled; and the method can allow effective reduction of evaporation loss of the cryogenic propellant in on-orbit use, thus prolonging the on-orbit mission time of a spacecraft.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Coal body permeability characteristic testing system and method

InactiveCN103940719ASimple structureEasy to assemblePermeability/surface area analysisAxial pressureHydraulic pump

The invention discloses a coal body permeability characteristic testing system. The coal body permeability characteristic testing system comprises an electronic universal testing machine, a permeability characteristic testing device, a vibration detecting device, a first gas system, a confining pressure hydraulic system and a computer, wherein the permeability characteristic testing device consists of a lane simulating mechanism and a lane ambient environment simulating mechanism; the lane simulating mechanism comprises a baffle, a breathable plate, a coal rock sample and a U-shaped clamping sleeve; the lane ambient environment simulating mechanism comprises a base, a cylinder tube, a lower pressing head, an upper half concave surface pressing head, an upper half convex surface pressing head and a piston; the first gas system comprises a first gas tank, a first pressure reduction valve and a first gas pressure meter; the confining pressure hydraulic system comprises a confining pressure liquid tank, a hydraulic pump, a unidirectional valve, a confining pressure hydraulic meter and a confining pressure liquid overflow valve. The invention also provides a coal body permeability characteristic testing method. According to the coal body permeability characteristic testing system and method, the axial pressure, the confining pressure and the methane gas pressure are controllable, the gas permeability characteristics influenced by disturbance of a lane coal rock body and a coal mine deep part coal rock body can be tested, and the testing precision is high.

Owner:XIAN UNIV OF SCI & TECH

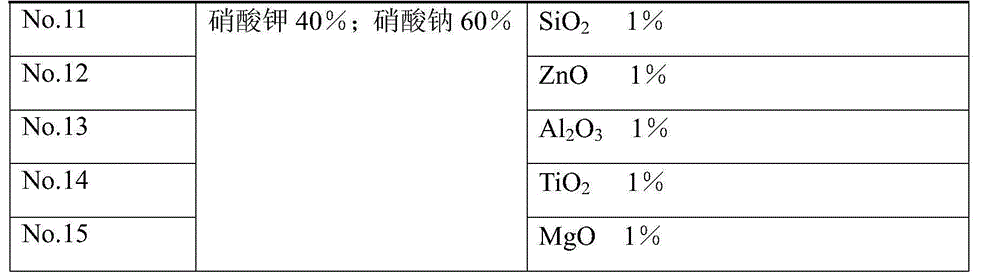

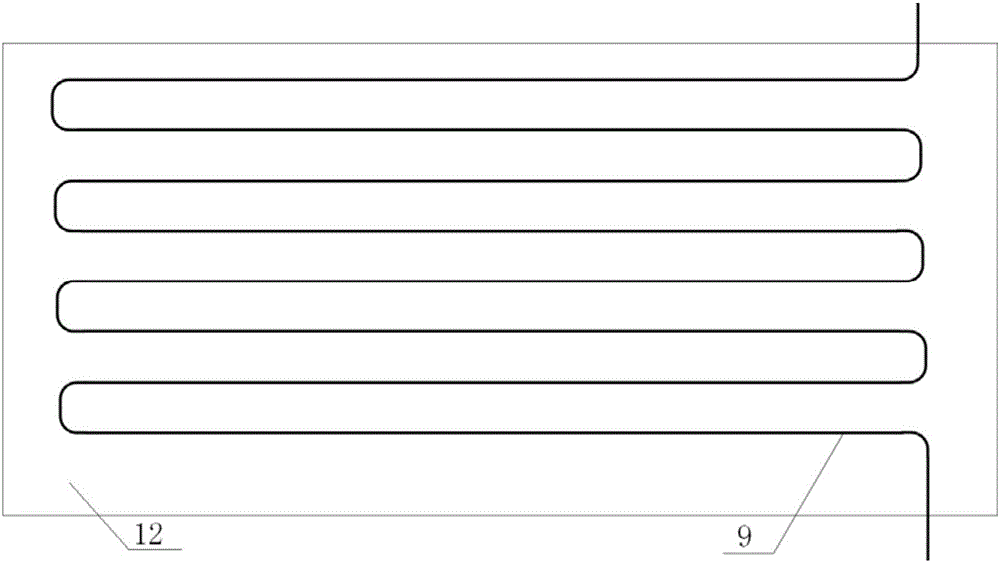

Liquid resin defoaming method and device for vacuum infusion forming of composite material

ActiveCN102173061AEnables continuous production applicationsDegassing method is simple and easyThin layerPressure difference

The invention belongs to the field of composite material forming technology and mainly relates to a liquid resin defoaming method and device for vacuum infusion forming of composite material. In the defoaming method, mixed liquid resin enters a defoaming device (13) and continuously flows over a plurality of layers of spiral laminar flow plates of the defoaming device; the defoaming device (13) is in a continuous vacuum state to increase the surface area of the liquid resin, even if the liquid level of the liquid resin becomes a thin layer with extremely small thickness, the pressure difference of the defoaming device instantaneously amplifies the volume of bubbles in the liquid resin, and the bubbles are removed quickly under the continuous vacuum state; and the liquid resin which is defoamed is directly connected to the vacuum infusion forming site of the composite material to carrying out infusion forming of a composite material product (9) in a vacuum state, and thus, the integration of defoaming and infusion of the liquid resin is realized.

Owner:LUOYANG SUNRUI WIND TURBINE BLADE

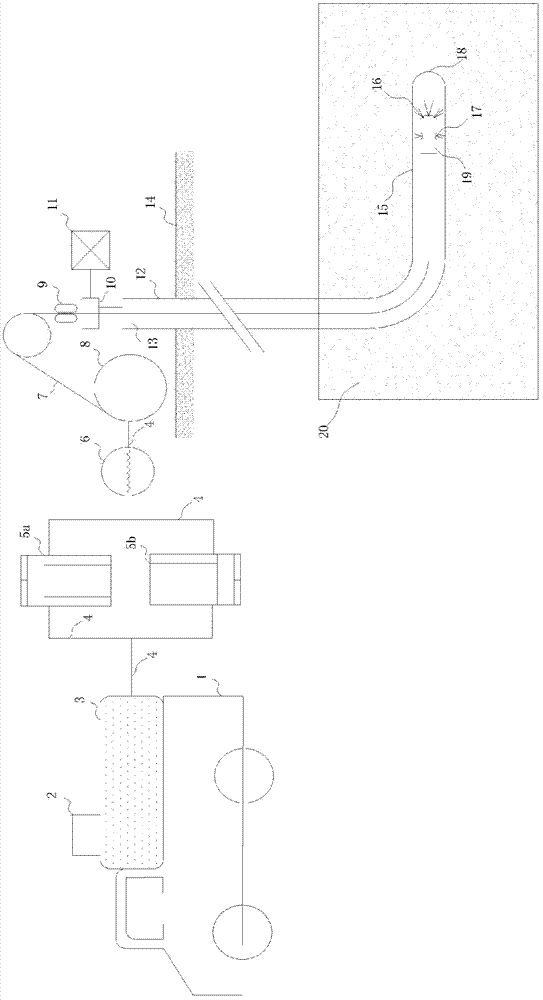

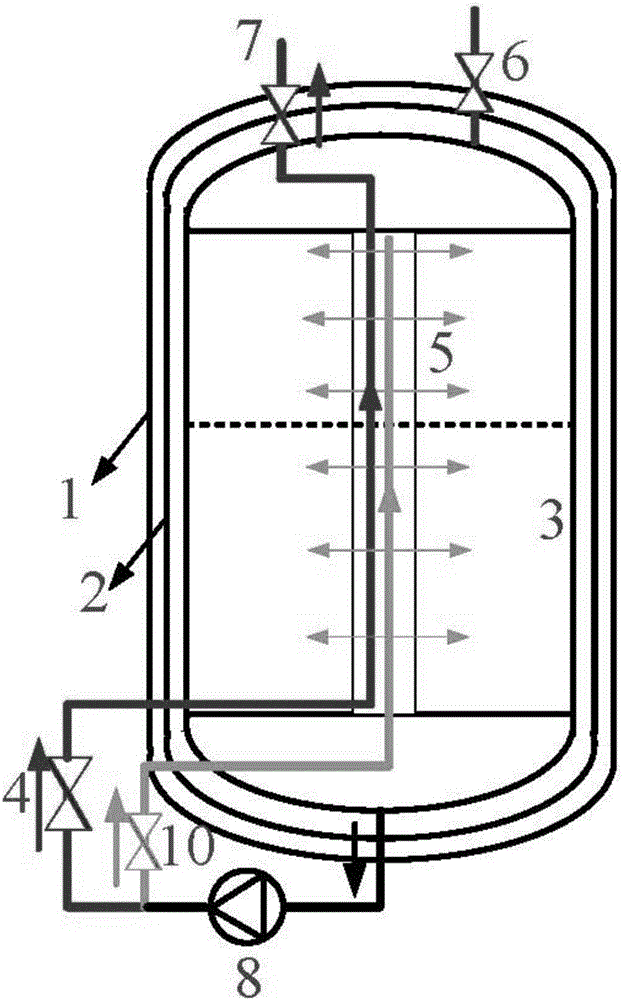

Oil-gas mixed transportation pipeline device and method for simulating formation, blocking and melting of hydrates

ActiveCN105510529ANo production impactEasy to control temperatureMaterial analysisData processing systemTemperature control

The invention discloses an oil-gas mixed transportation pipeline device and a method for simulating formation, blocking and melting of hydrates. The device comprises a reaction kettle I and a reaction kettle II, wherein the reaction kettle I and the reaction kettle II are connected with the same gas supplying system; a grouting port is formed in the reaction kettle I; the top of the reaction kettle II is communicated with the bottom of the reaction kettle II through a circulation pipeline, and a liquid injection port is formed in the circulation pipeline; each of the reaction kettle I and the reaction kettle II is provided with a temperature control device for adjusting the temperature; a detection device for detecting the reaction state of the natural gas hydrates in a pipeline is further mounted on the circulation pipeline and connected with a data processing system. The oil-gas mixed transportation pipeline device and the method for simulating formation, blocking and melting of the hydrates have a very good effect on controlling loss caused by long-time production suspension as a result of blocking of the pipeline in a high-risk blocking state.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

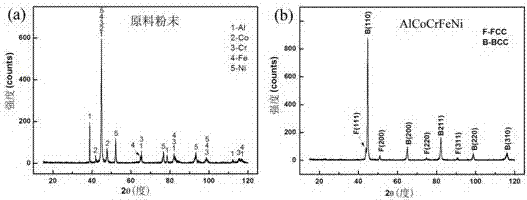

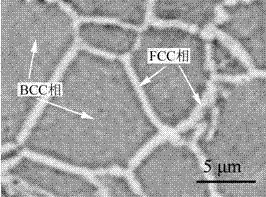

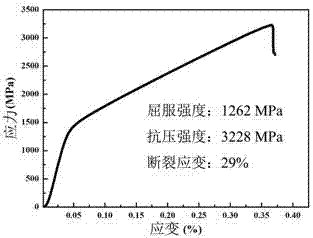

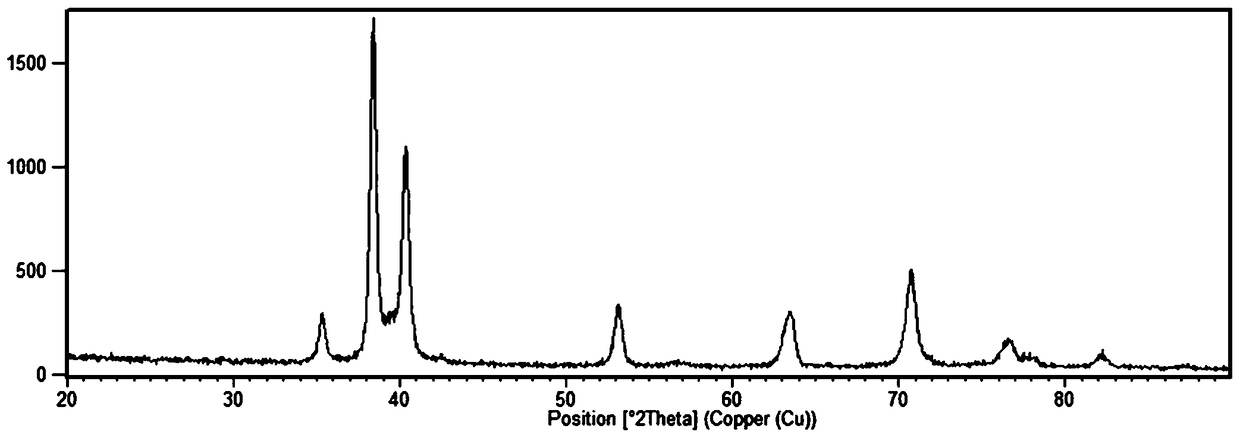

Preparation method for high-entropy alloy

InactiveCN107130125AGood mechanical propertiesRealize dense integrationMetallic material coating processesPowder mixtureHigh entropy alloys

The invention discloses a preparation method for a high-entropy alloy. A pure element or master alloy powder mixture is adopted as a raw material and is directly put into discharge plasma sintering (SPS) equipment, a vacuum hot pressing reaction is conducted, and the bulk high-entropy alloy is fast sintered and synthesized; and the integration of the densification of the alloy bulk material and the solid solution phase of the high-entropy alloy is achieved through the precise control over the SPS sintering parameters, and the dense high-entropy alloy bulk material is obtained at a time. The high-entropy alloy prepared through the technology is high in densification, uniform in structure and excellent in mechanical performance. The preparation method has the outstanding beneficial effects that the equipment and process are simple, the efficient and fast functions are achieved, the production cost is low, and the reliability is high and is suitable for the industrial production of the high-entropy alloy.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

True-triaxial coal and gas adsorption-desorption and outburst test device system and test method

ActiveCN104458490ATrue adsorption stateAchieve adsorptionFuel testingMaterial strength using tensile/compressive forcesAxial pressureSurface type

The invention discloses a true-triaxial coal and gas adsorption-desorption and outburst test device system. The true-triaxial coal and gas adsorption desorption and outburst test device system comprises a cylindrical coal sample chamber structure which is formed by sequentially connecting a plurality of cylindrical units, wherein a plurality of pressure and temperature sensors are uniformly arranged on the outer circumference of each cylindrical unit, four loading devices are symmetrically arranged on the outer circumference of each cylindrical unit, the loading devices stretch into an inner cavity of each cylindrical unit along the radial direction of the cylindrical unit to be connected with loading plates, and lateral stress is applied to briquette coal in the inner cavity of each cylindrical unit by the loading plate; two ends of the cylindrical coal sample structure are respectively provided with a counterforce cover, a surface-type inflating loading disc with the inner side surface being communicated with the inner cavity of the cylindrical coal sample chamber structure is arranged in the counterforce cover on one end and is used for applying the axial pressure, a coal and gas outburst opening is formed in the other end, and an instantaneous release mechanism is arranged in the coal and gas outburst opening. The invention also discloses a test method utilizing the device. By adopting the test device and the test method, the adsorption-desorption characteristics of briquette coal to the gas and the gas outburst mechanism under the condition of different ground stress and different gas pressure can be researched.

Owner:SHANDONG UNIV

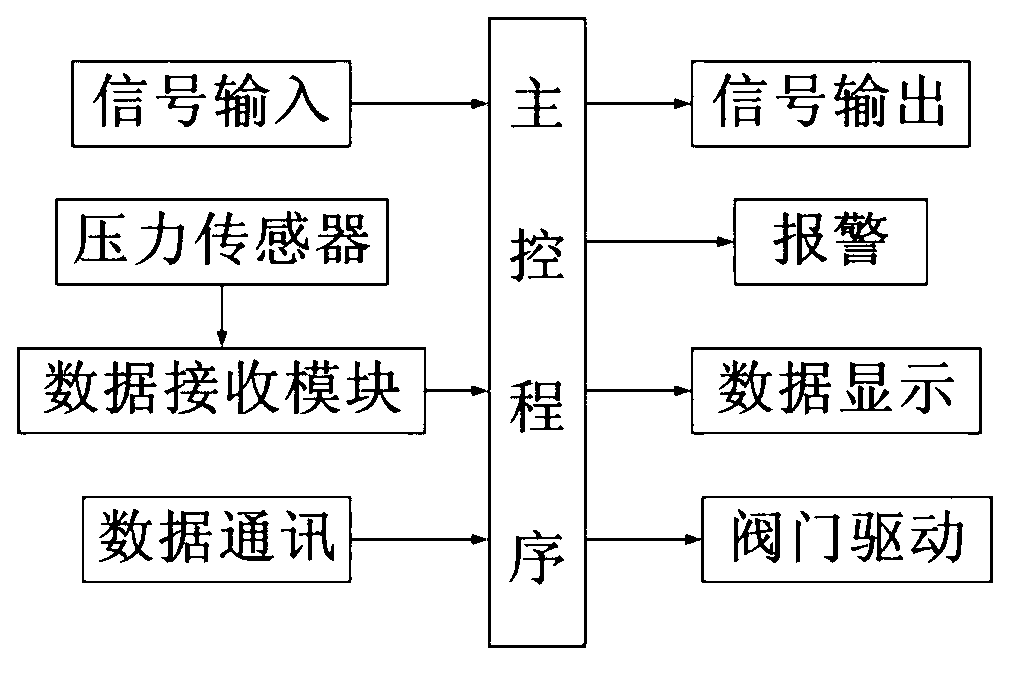

Injection mold cavity pressure control system and method

The invention discloses an injection mold cavity pressure control system and method. The injection mold cavity pressure control system comprises a high-pressure nitrogen source, wherein the high-pressure nitrogen source is connected with a mould air inlet through a pipeline, a first pressure reducing valve is arranged on the part, which is close to the high-pressure nitrogen source, of the pipeline, the pipeline is divided into two paths after passing through the first pressure reducing valve, one path is connected with an air control regulating valve through a second pressure reducing valve, a first pressure meter and an electronic pressure controller, the other path is connected with the air control regulating valve through a second pressure meter, the outlet of the air control regulating valve is connected with the mould air inlet, a third pressure meter, a pressure sensor and a pressure relieving pipeline unit are sequentially arranged on the pipeline, the electronic pressure controller, the pressure relieving pipeline unit and the pressure sensor are connected with a data processing and controlling system, and the data processing and controlling system is connected with an injection molding machine signal unit. The invention also discloses a control method of the injection mold cavity pressure control system. The injection mold cavity pressure control system has the characteristics of high pressurizing rate and pressure relieving rate of a mould cavity, capabilities of maintaining high pressure of the mould cavity and controlling the acting time of the high pressure of the mould cavity, and the like.

Owner:SHANDONG UNIV

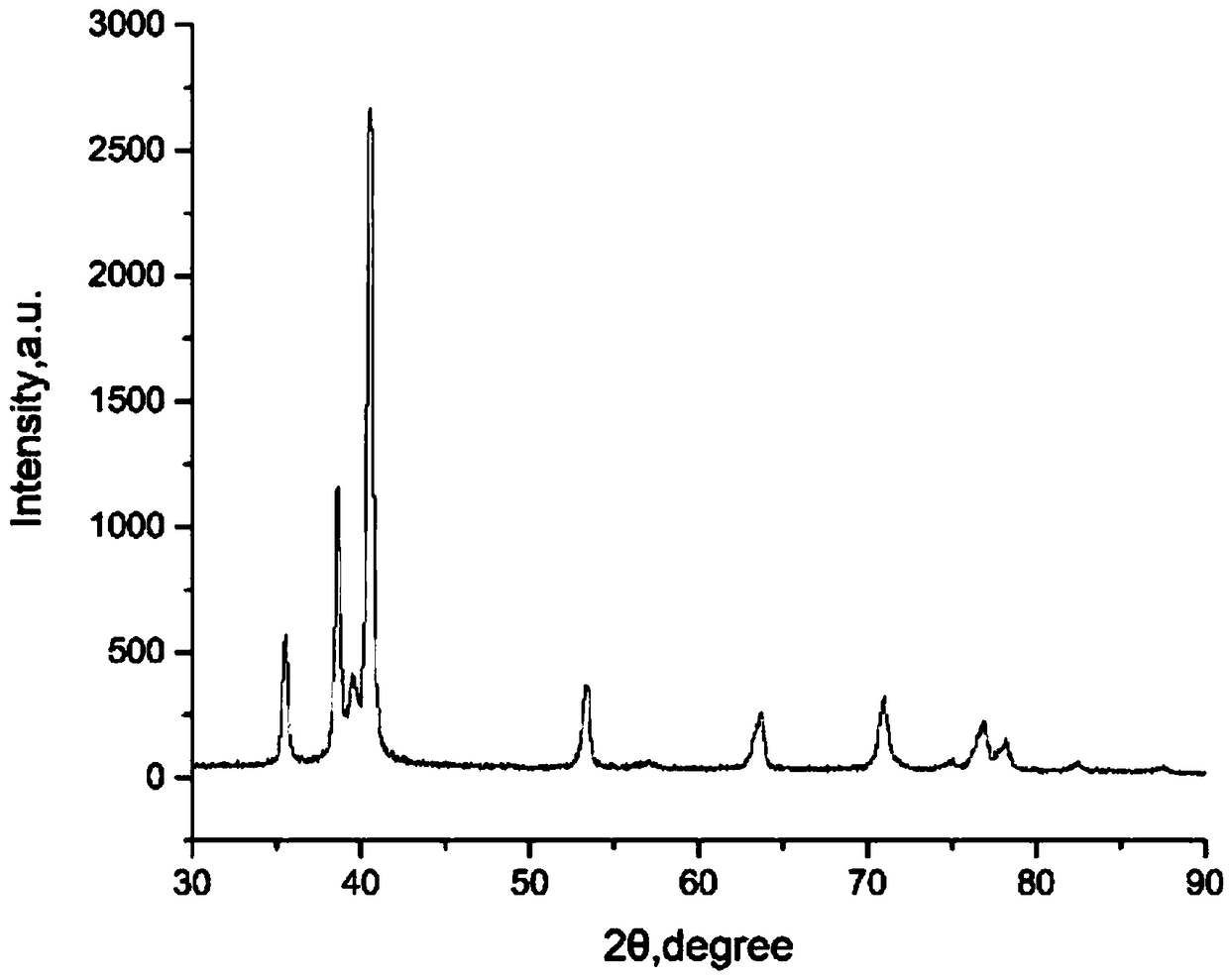

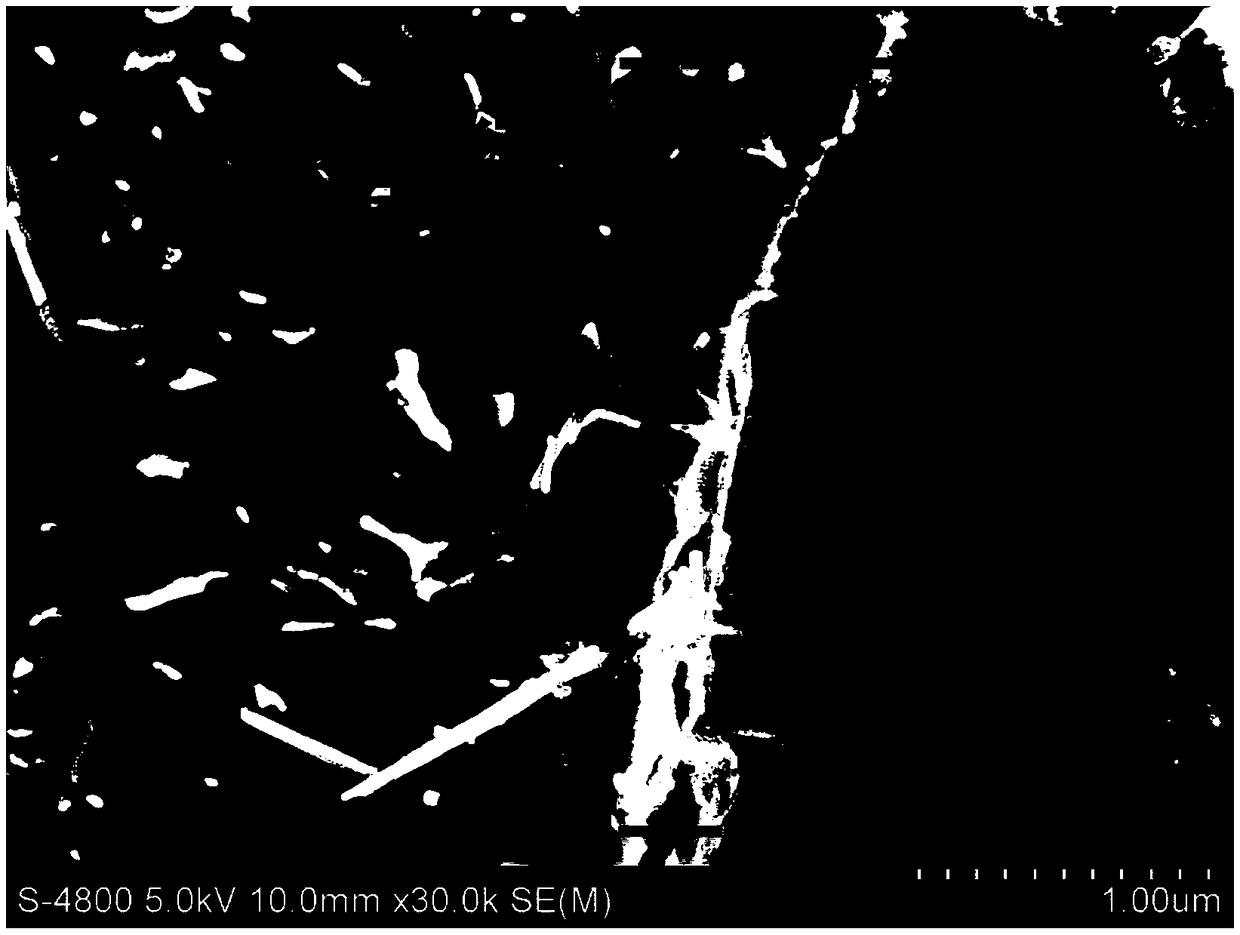

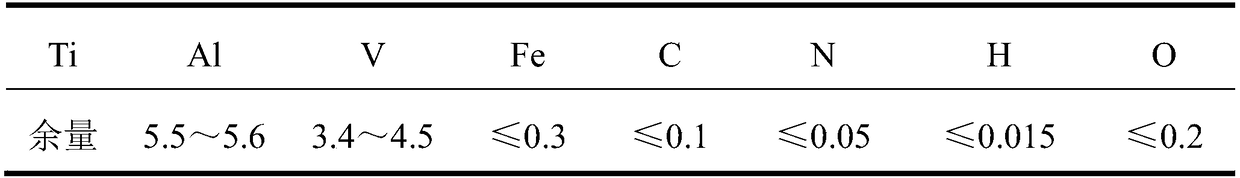

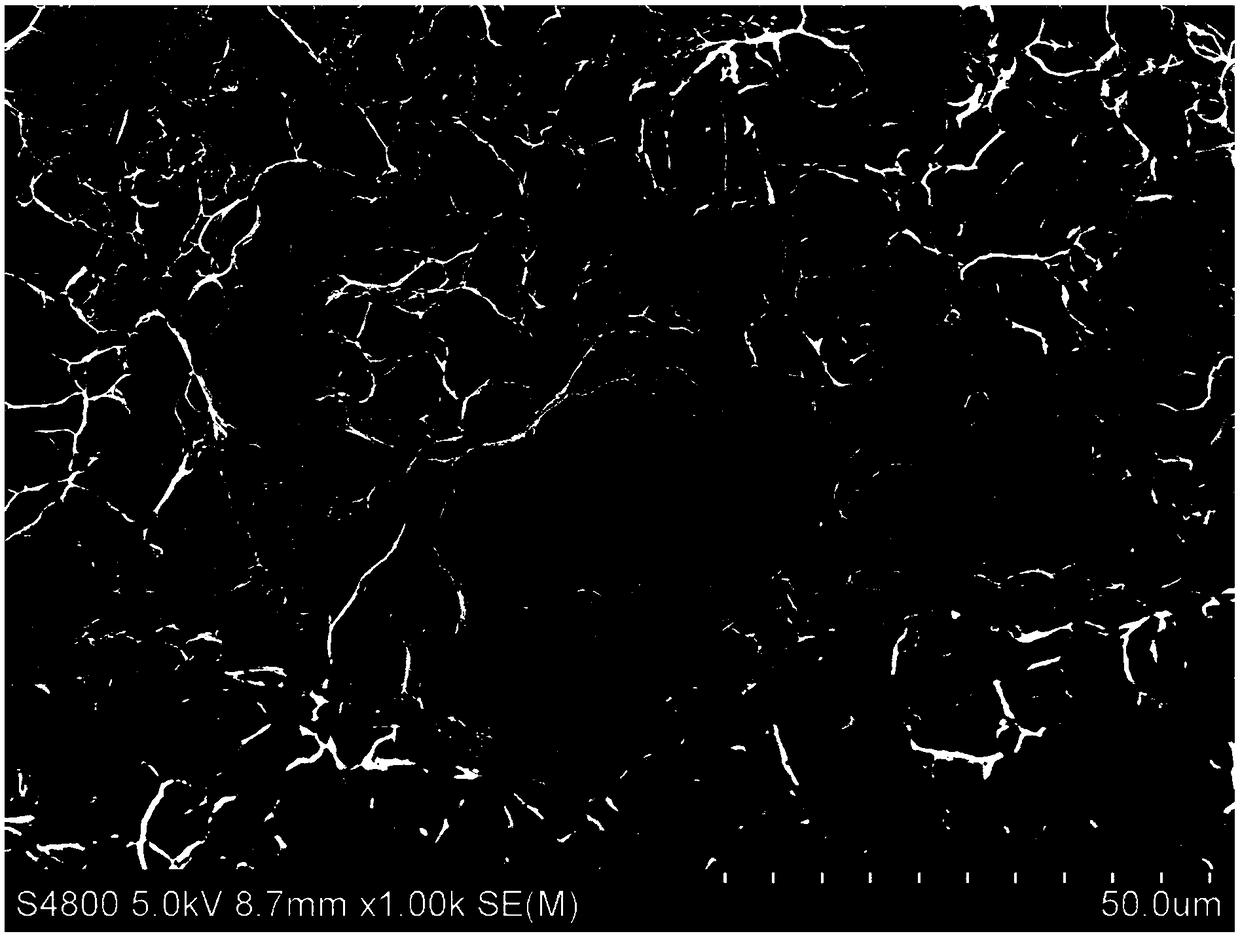

Preparation method of directionally-distributed TiB whisker reinforced titanium-based composite material

ActiveCN108796264AEffectively regulate organizational evolutionSolve problems such as a sharp drop in aspect ratioTitanium matrix compositesThermal deformation

The invention relates to a preparation method of a directionally-distributed TiB whisker reinforced titanium-based composite material, and belongs to the field of metal-based composite materials. Thepreparation method comprises the following steps that nano TiB2 powder and titanium powder, or nano TiB2 powder and titanium alloy powder are uniformly mixed; sintering treatment is carried out on themixed powder by adopting a discharge plasma system to obtain a composite material block body; and the dried composite material block body is packaged in a quartz tube in a vacuum mode, heat treatmentis carried out in a heat treatment furnace, and then the composite material is obtained by step-by-step cooling. The method can effectively regulate and control the organization evolution of a TiB whisker in the titanium-based composite material, the problem that the orientation regulation and control means of the TiB whisker is single is fully solved, a thermal deformation means is used for regulating and controlling the crystal whisker form, and the crystal whisker length-diameter ratio is greatly reduced and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of TiB nano-reinforced titanium-based composite material

The invention relates to a preparation method of a TiB nano-reinforced titanium-based composite material, and belongs to the field of metal-based composite materials. According to the method, the composite material is prepared through ball milling, spark plasma sintering and hot rolling. The original powder is prepared through ball milling, the advantages that the sintering efficiency of the discharge plasma is high, and the external pressure and the sintering atmosphere can be controlled are utilized, so that under the low sintering temperature and the high pressure, and on the premise that the TiB2 particles and the surrounding titanium or titanium alloy matrix do not generate in-situ reaction, a sintering block body with high compactness is prepared; and finally, the TiB2 particles in the sintered block body are subjected to in-situ reaction with the surrounding titanium or titanium alloy matrix through hot rolling to form whiskers, and meanwhile, the crystal grains of the matrix are deformed, the porosity in the structure is reduced, and the strength and the plasticity of the composite material are improved. The TiB nano crystal whisker generated in situ in the method is cleanin surface and is uniformly distributed in a matrix and free of agglomeration, has good interface bonding and lattice relationship with the titanium matrix, and can effectively refine matrix crystal grains.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-speed collision experiment testing device for vehicle power battery

ActiveCN104655388AAcquire detonation propertiesEasy to control speedMaterial exposibilityShock testingPower batteryMeasurement device

The invention discloses a high-speed collision experiment testing device for a vehicle power battery. A high-pressure air tank, a solenoid valve and an acceleration pipe are connected sequentially in a sealed manner and then are fixed by a fixing device; the other end of the acceleration pipe is in sealed connection with an explosion-proof box body; the central line of the acceleration pipe is perpendicular to the side wall of the explosion-proof box body; a mass block is arranged in the acceleration pipe; a worktable is mounted in the explosion-proof box body; a three-claw chuck is fixedly arranged on the worktable; a pressure sensor is arranged in the worktable; a rail and an index plate are mounted at the bottom of the worktable; the worktable can rotate along the rail around the center of the index plate; a protection box is mounted at the corner of the inner part of the explosion-proof box body; a temperature detection device and an image acquisition device are mounted in the protection box; a battery parameter measurement device is arranged at the outer part of the explosion-proof box body and is connected with battery negative and positive electrode connection electrode pieces on the three-claw chuck by connection wires; and a detection door is formed in the front side of the explosion-proof box body. The device can be used for realizing controllable speed, controllable pressure and controllable collision angle, and can be used for measuring parameters at the collision moment of the battery.

Owner:固安海高汽车技术有限公司

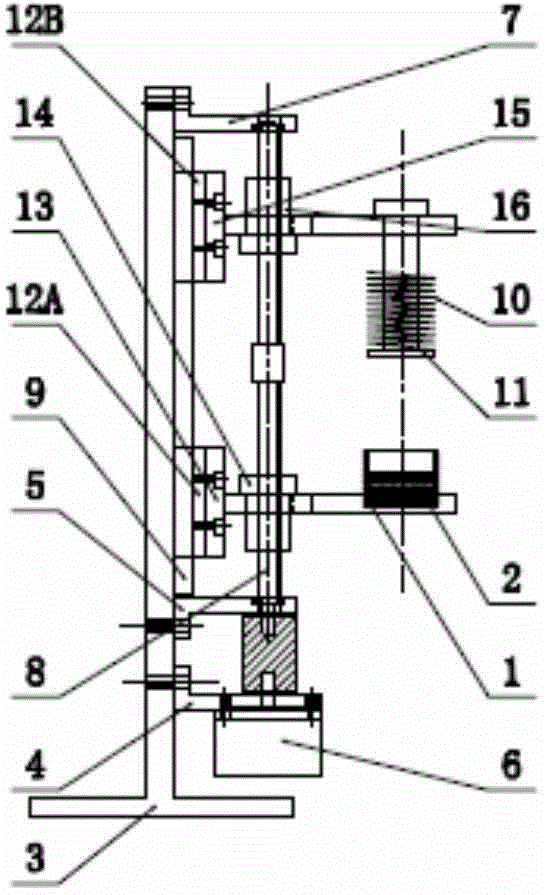

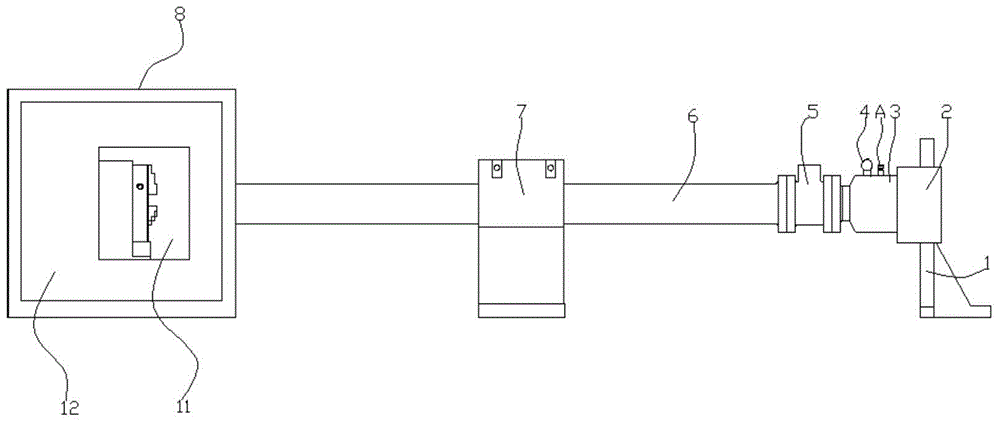

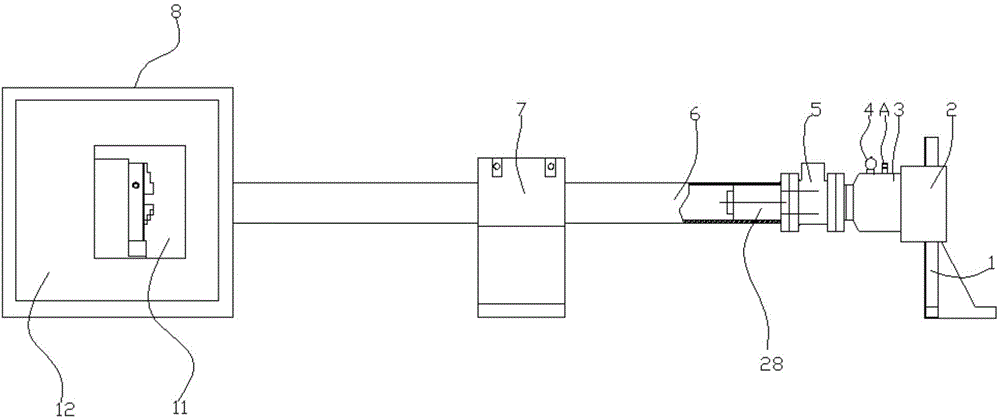

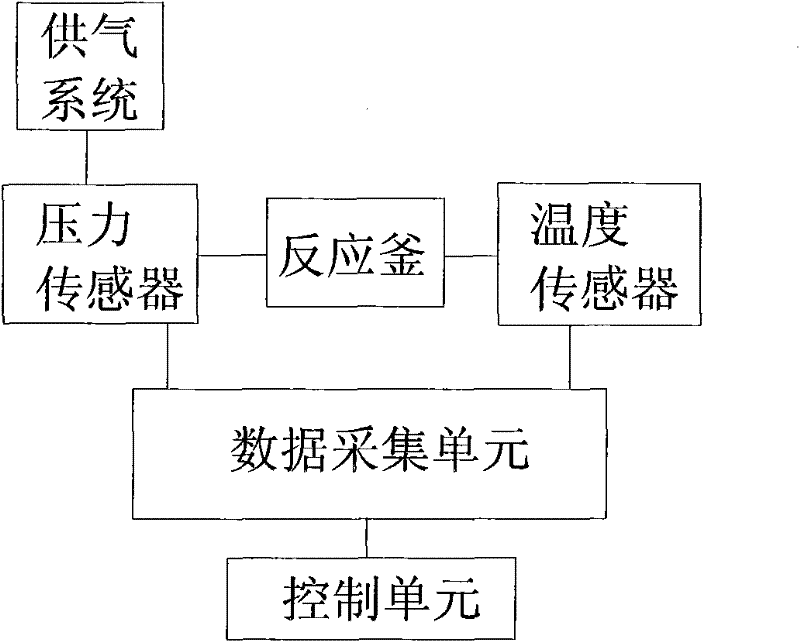

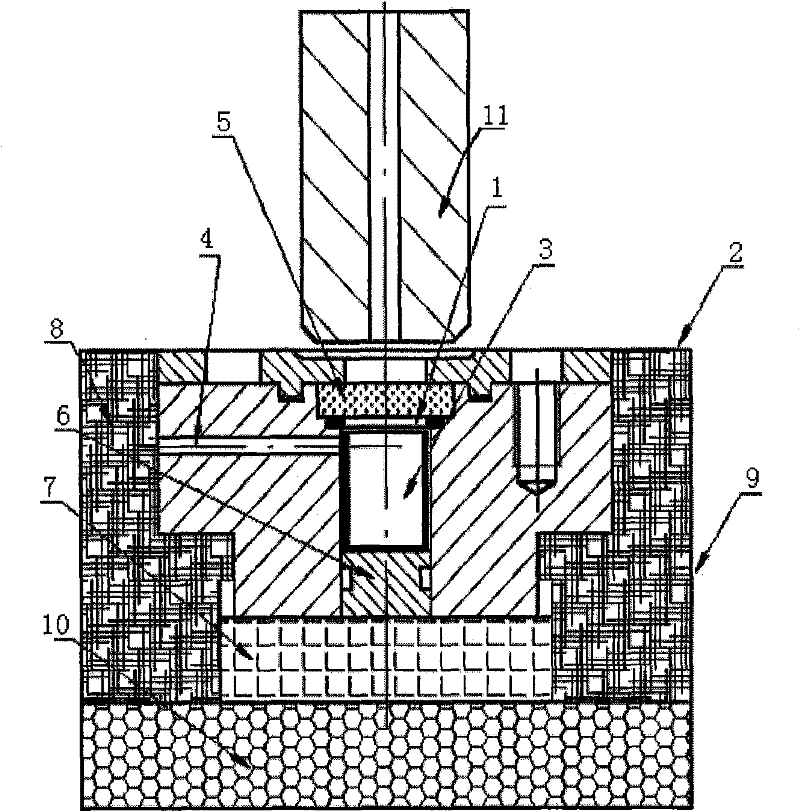

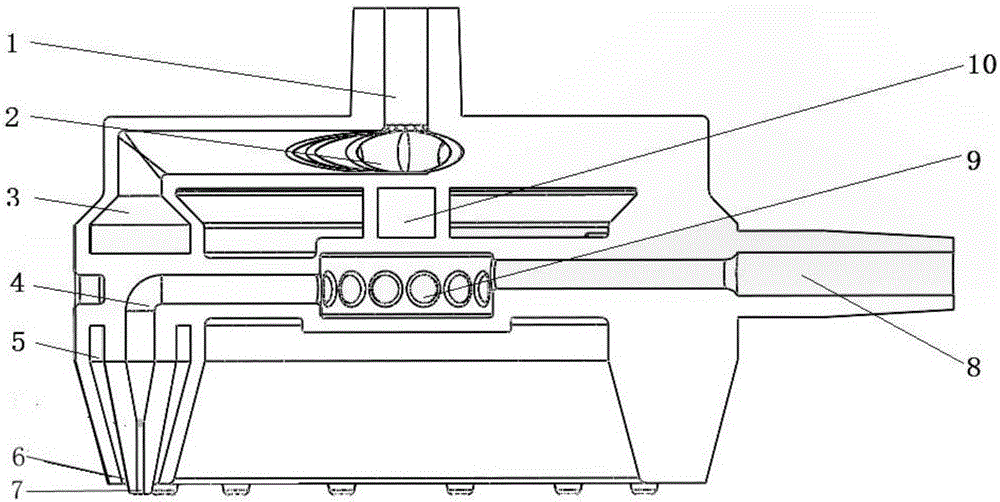

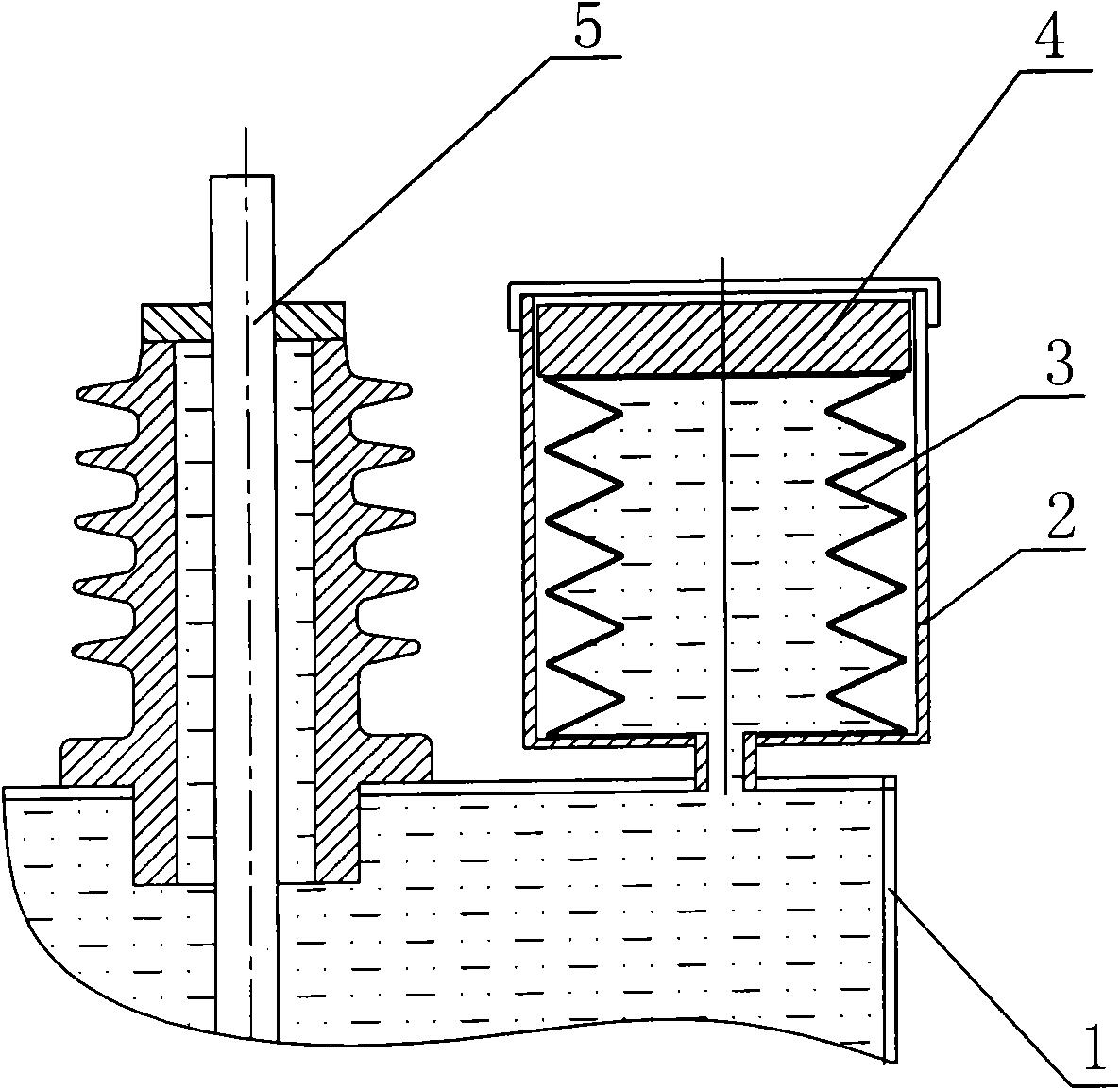

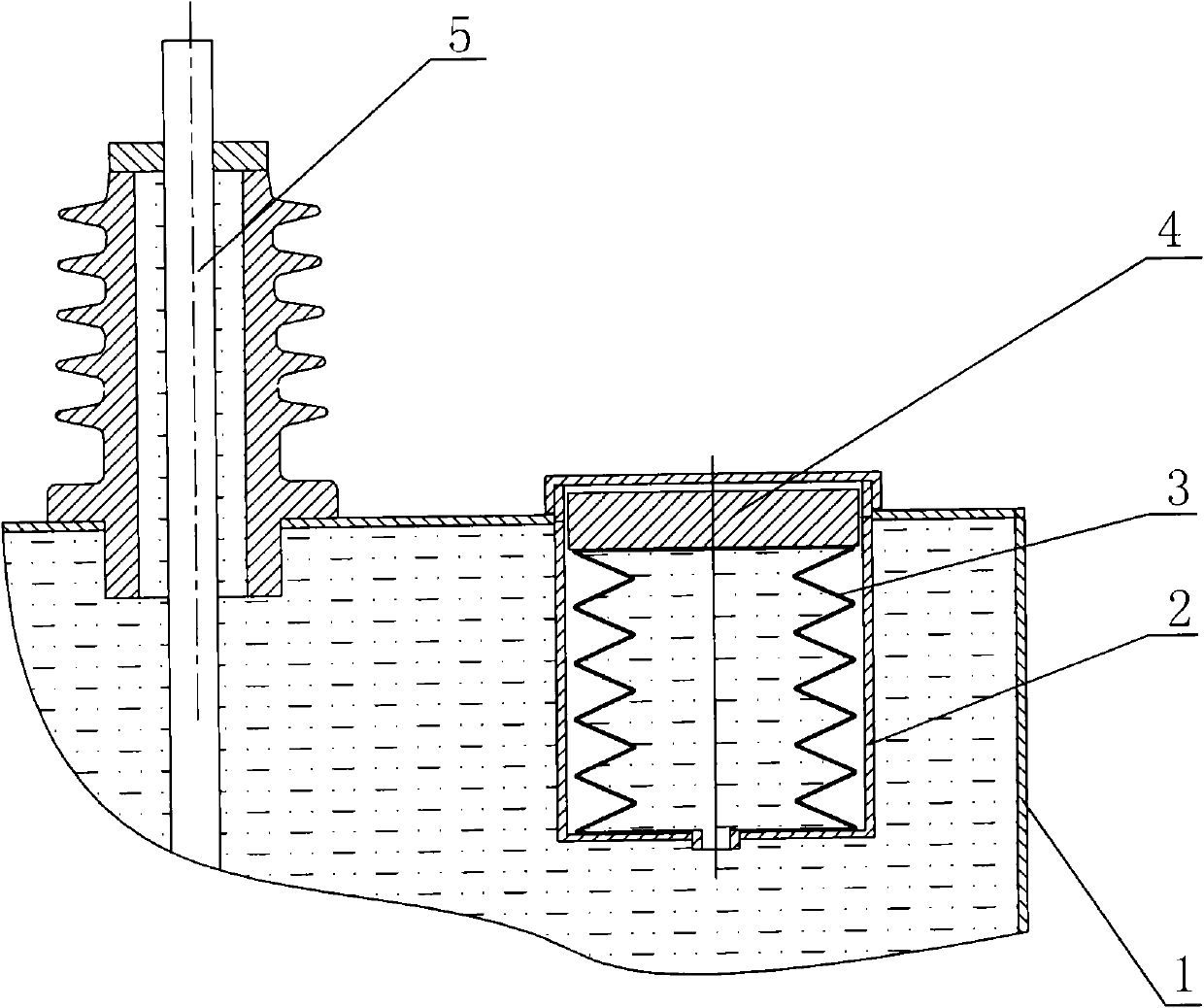

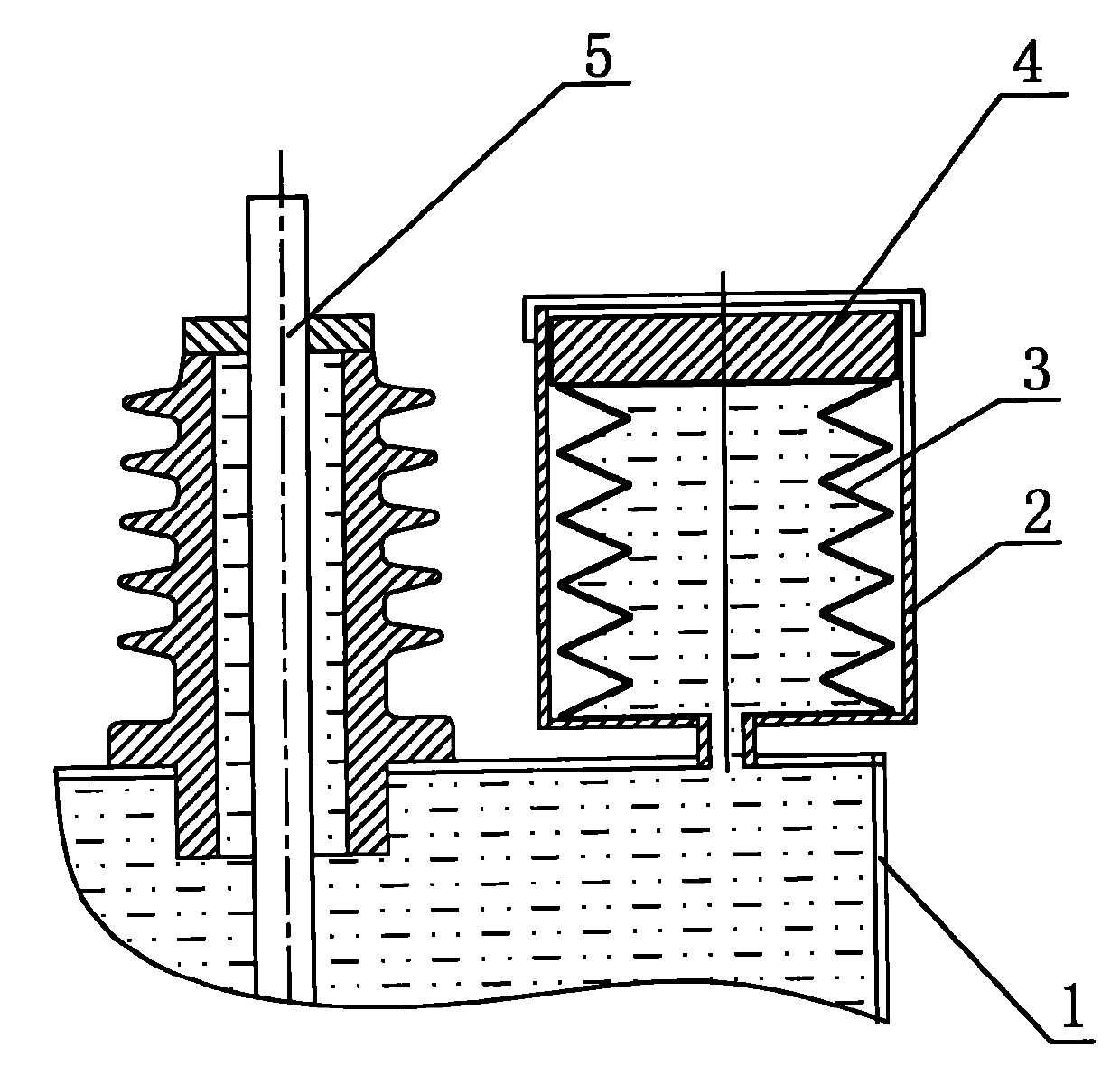

High-pressure temperature control experiment device for micro laser-Raman spectrum

InactiveCN102053081AEasy to control temperaturePressure is easy to controlRaman scatteringLaser raman spectroscopyEngineering

The invention relates to an experiment device, in particular to a high-pressure temperature control experiment device for a micro laser-Raman spectrum, comprising an air supply device, a pressure sensor, a temperature sensor, a reaction kettle, a data acquisition unit and a control unit, wherein the air supply unit is connected with the reaction kettle through the pressure sensor; the temperature sensor is arranged on the reaction kettle; and the pressure sensor and the temperature sensor are respectively connected with the data acquisition unit which is connected with the control unit. The high-pressure temperature control experiment device takes a small-sized high-pressure reaction kettle as a core, is suitable for the in situ observation of the micro laser-Raman spectrum, can control the temperature and the pressure, can be used for in situ observation of hydrates of depositions in different types and overcomes the defects of the current existing device.

Owner:QINGDAO INST OF MARINE GEOLOGY

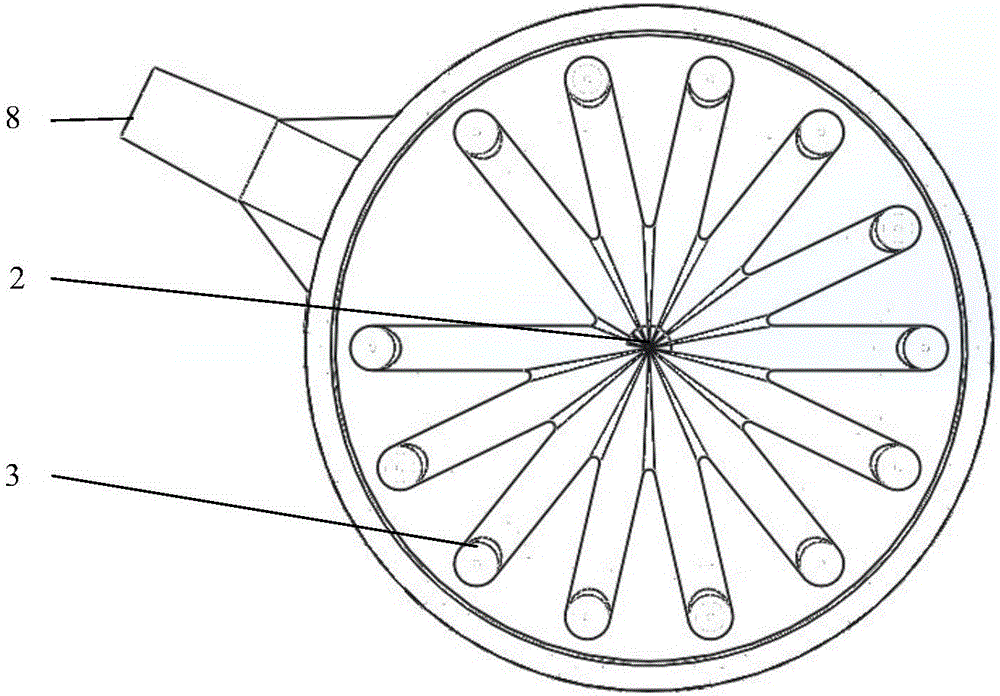

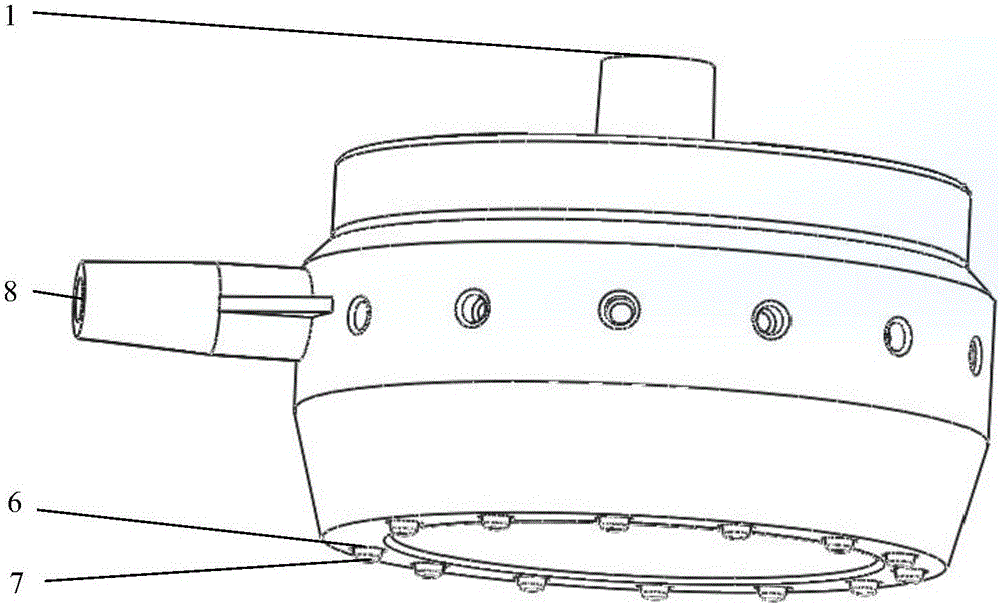

Multi-nozzle module based on 3D (three-dimensional) printing and device and technique for large-scale production of particles

InactiveCN106622413AEvenly distributedReduce the difficulty of printingAdditive manufacturing apparatusLaboratory glasswaresEnvironmental resistanceEngineering

The invention discloses a technical method for large-scale production of particles by a multi-nozzle module based on a 3D (three-dimensional) printing technique and application of the technical method. The technical method is characterized in that a single nozzle is of a coaxial annular gap air blowing structure, the middle part is provided with a fluid channel, and the coaxial annular gap is an air channel; on the basis of a two-phase flow cutting principle, liquid-phase liquid is cut by air, and liquid droplet particles are produced; by controlling air and liquid outlet pressures and flow rates, the liquid droplets with different particle sizes can be obtained; the number of nozzles can be designed according to the requirement of droplet output, and liquid and air are uniformly distributed by a distributor, so as to obtain higher droplet production efficiency. The technical method has the advantages that the preparation of 3D printing nozzle modules is simple, the material cost is low, and other complicated mechanical processing methods are not required; the prepared particles are free from the pollution by poisonous matters, such as a continuous phase and surfactants; the technical method is especially suitable for preparing high-viscosity solution and suspension droplets containing insoluble particles, is widely applied to the fields of medical care, petroleum, biology, environment protection and the like, and is suitable for large-scale industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

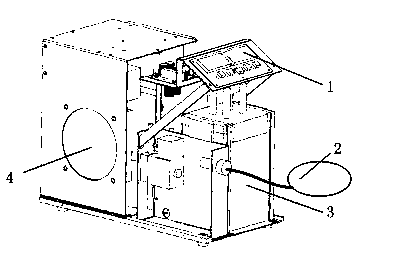

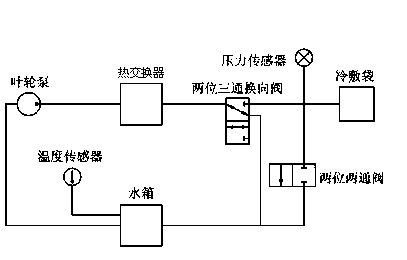

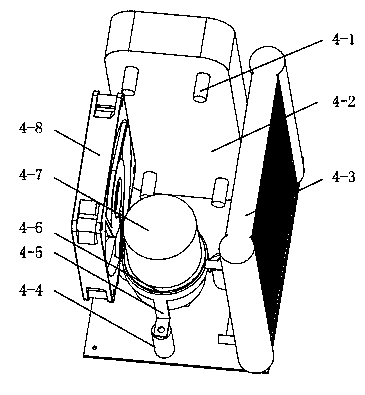

Portable medical cold compress device

InactiveCN103735349AFast coolingPressure controllableTherapeutic coolingTherapeutic heatingHospital treatmentWater circulation

The invention relates to a portable medical cold compress device which comprises a host and a cold compress bag, wherein a water circulating module, a refrigerating module and a detection control module are arranged in the host; the water circulating module comprises a water tank, a heat exchanger, an impeller pump, a three-way reversing valve and a two-way valve; the refrigerating module mainly comprises a micro compressor, a condenser, a throttle valve, an evaporator and a fan; the detection control module mainly comprises a temperature sensor, a pressure sensor, a power supply and a control circuit on the basis of ATmega32; the detection control module detects the temperature and the pressure inside a liquid circuit of the water circulating module, compares the detected temperature and pressure with set cold compress temperature and pressure, enables the water circulating module to operate in different modes and controls the refrigerating module to be started or shut down. The portable medical cold compress device is rapid to refrigerate, is controllable in the cold compress temperature, time and pressure, can implement multi-parameter regulation and is suitable for treatment in hospitals and outdoor on-site rescue.

Owner:HARBIN INST OF TECH AT WEIHAI

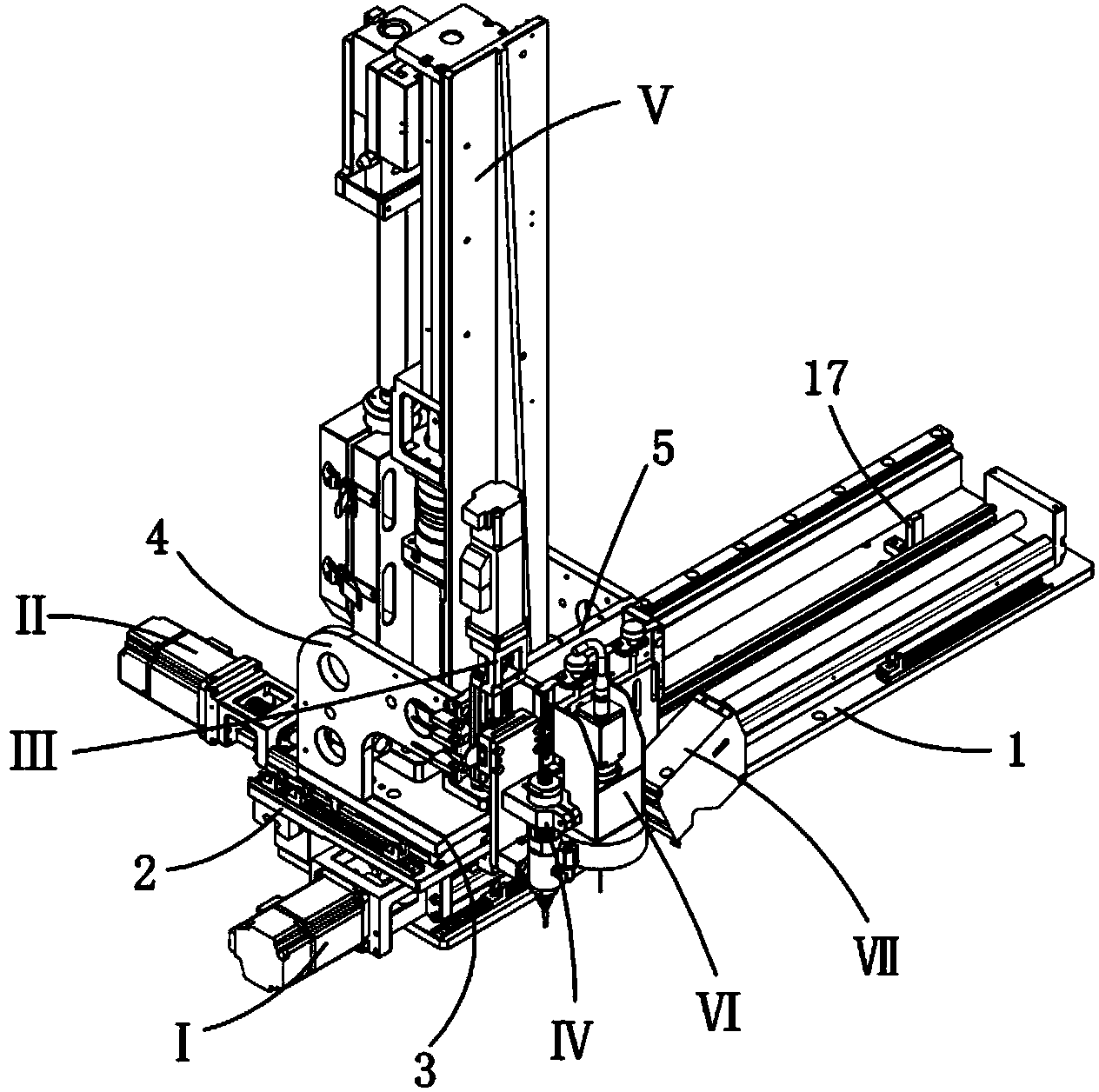

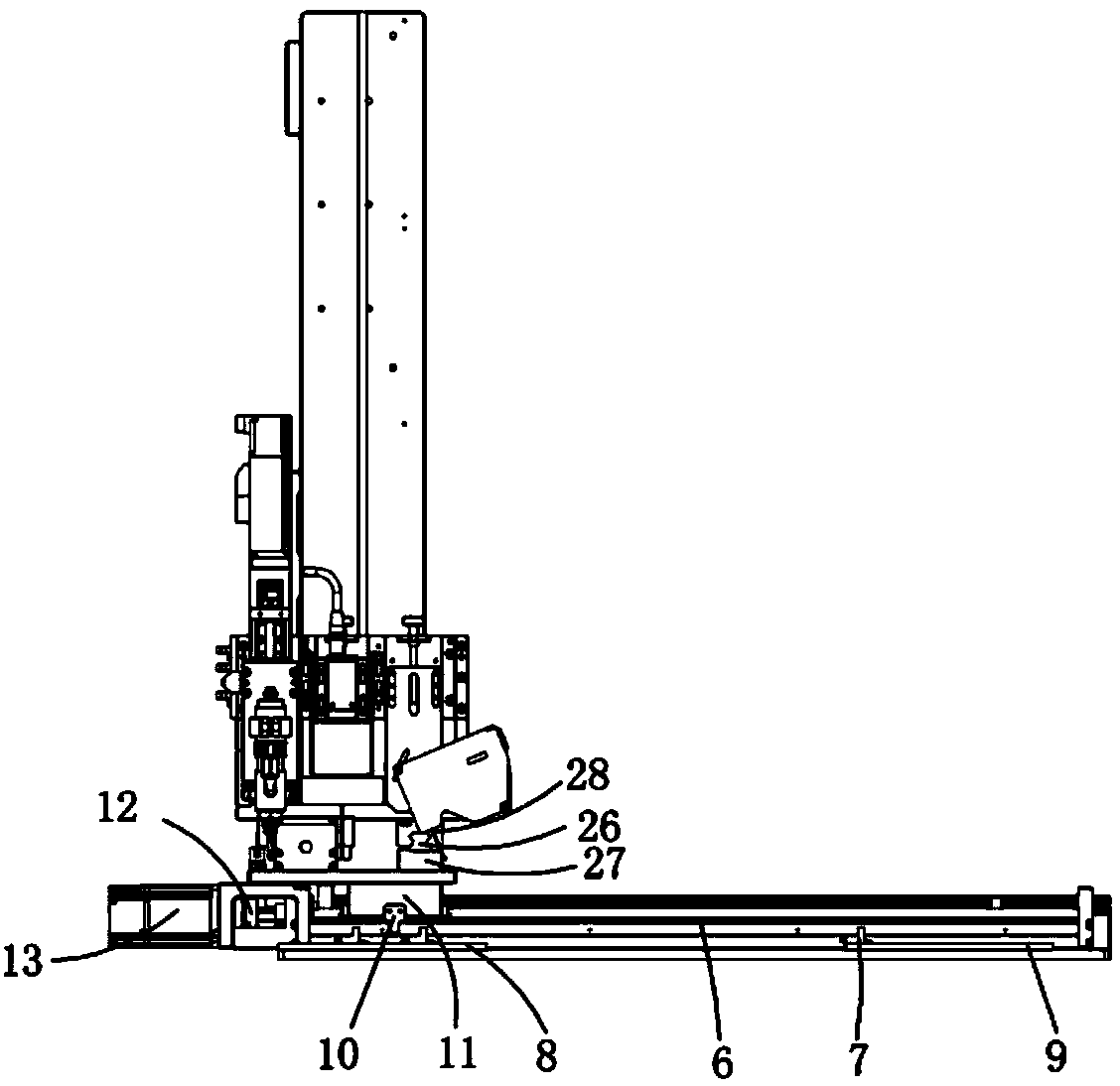

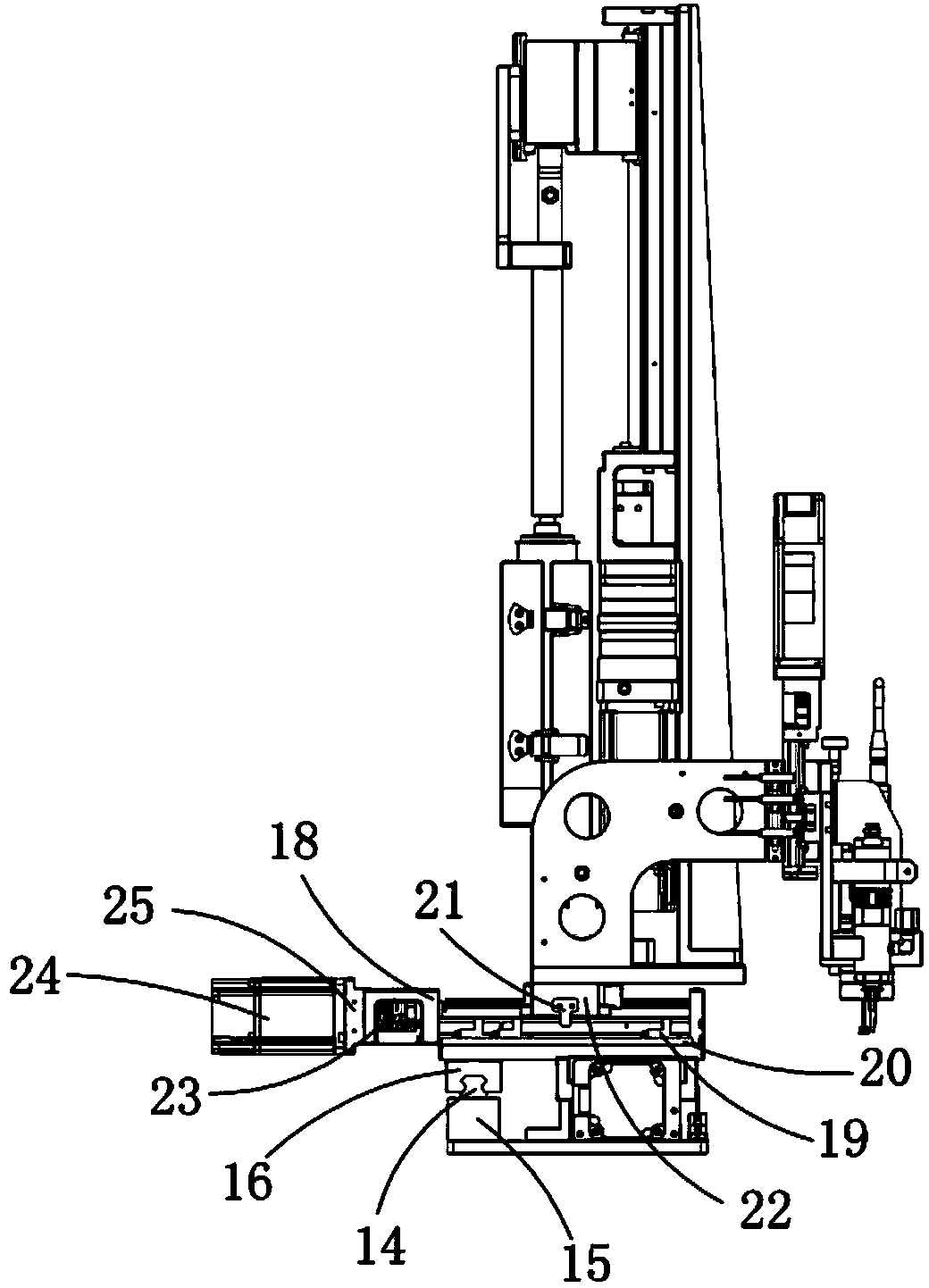

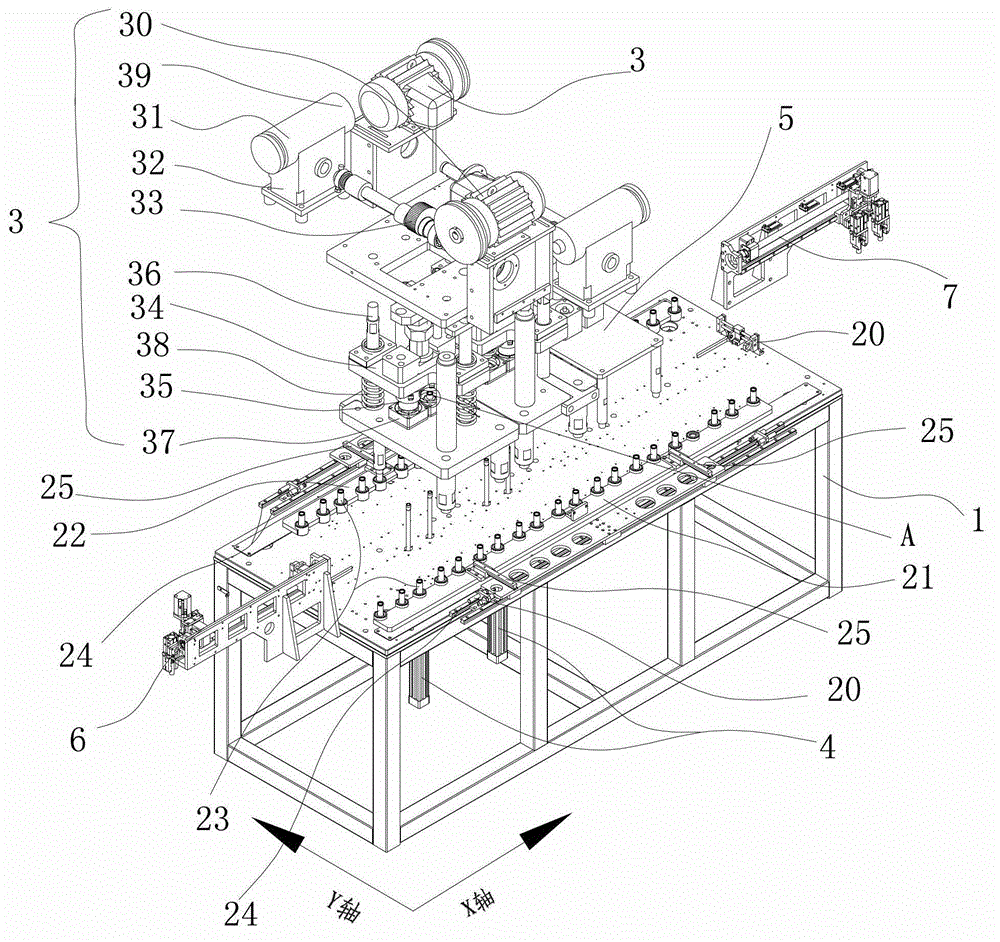

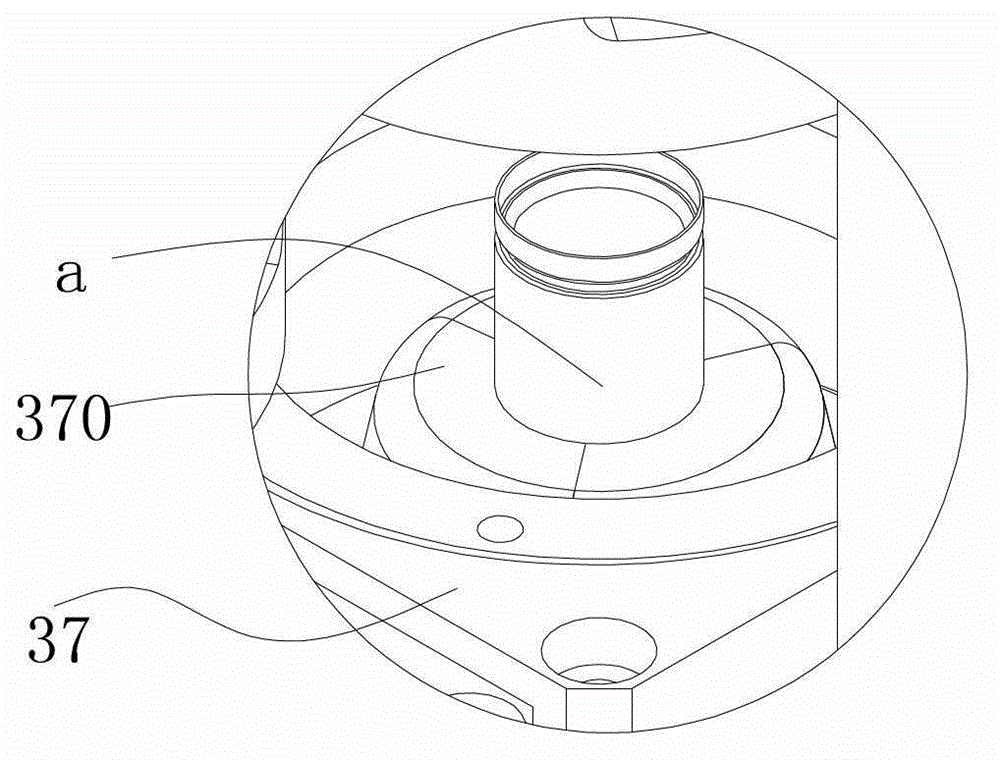

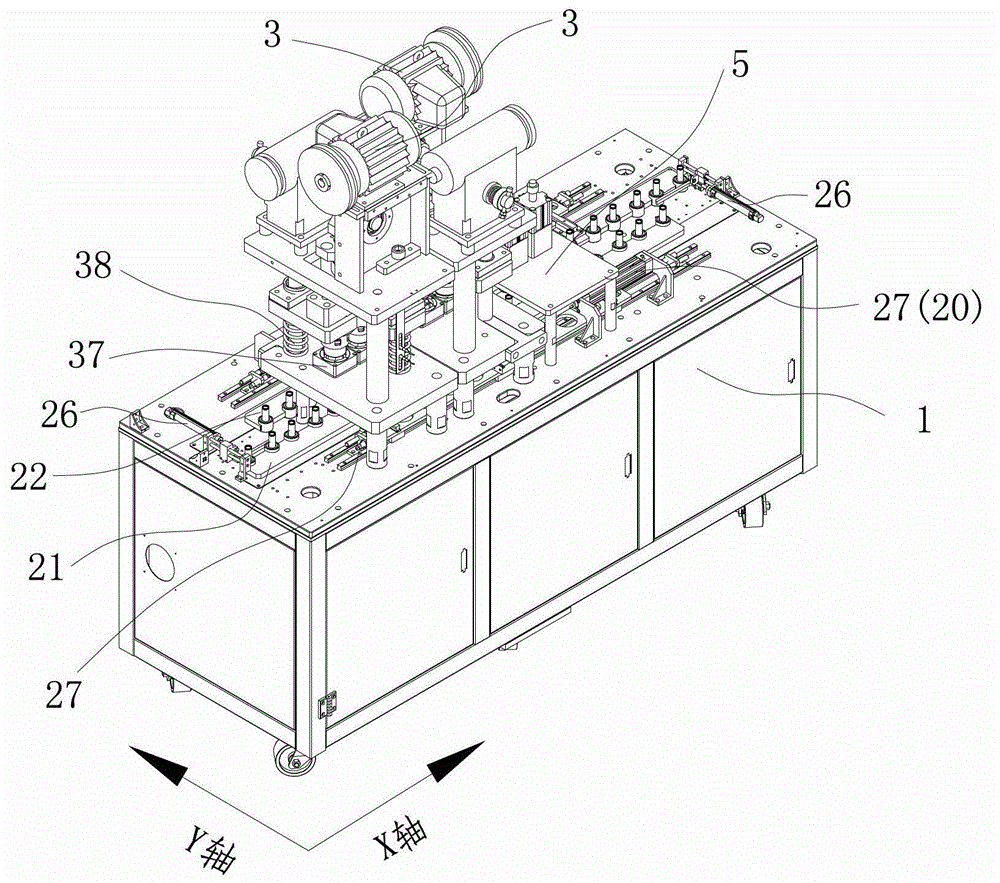

Full-automatic quantitative glue dispensing mechanism

ActiveCN104307699APrecise dispensing positionHigh precisionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a full-automatic quantitative glue dispensing mechanism. An X-axis mechanism is mounted on a base plate. A Y-axis mechanism is mounted on the X-axis mechanism through an XY connecting plate. A mounting plate is mounted on the Y-axis mechanism. The number of Z-axis installation connecting plates is two. The two Z-axis installation connecting plates are mounted on the two sides of the mounting plate respectively. A Z-axis mounting plate is mounted on the two Z-axis installation connecting plates. A Z-axis mechanism is mounted on the Z-axis mounting plate. A glue dispensing mechanism body is mounted on the Z-axis mechanism. A glue dispensing pressurization mechanism is mounted on the mounting plate and located on the rear side of the mounting plate. A CCD mechanism is mounted on the Z-axis mounting plate. A laser mechanism is mounted on a CCD mounting plate of the CCD mechanism. According to the full-automatic quantitative glue dispensing mechanism, the X-axis mechanism, the Y-axis mechanism and the Z-axis mechanism are used for transporting the glue dispensing mechanism body to a standard operation position; the glue dispensing pressurization mechanism is used for adjusting appropriate glue dispensing pressure to ensure an appropriate glue output amount; the CCD mechanism is used for calibrating the glue dispensing position; the laser mechanism is used for collecting the volume of glue and calculating the glue output amount. The full-automatic quantitative glue dispensing mechanism can accurately control the glue dispensing position and the glue dispensing amount and improve the accuracy of the glue dispensing process.

Owner:BOZHON PRECISION IND TECH CO LTD

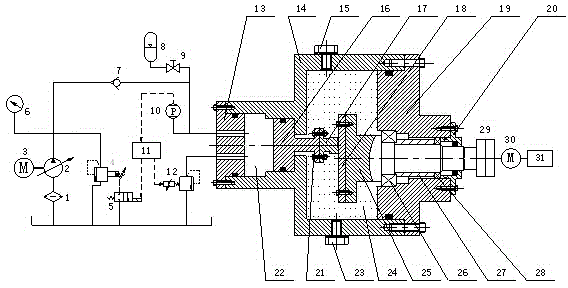

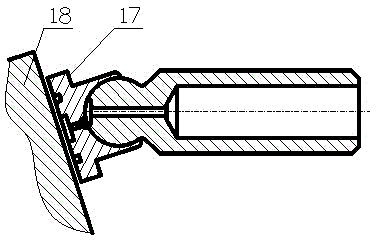

Friction performance testing device for slipper pair of high-pressure axial plunger pump

InactiveCN104458466AThe experimental setup is simpleAdjustable pressure and speedInvestigating abrasion/wear resistanceElectric machineryPlunger pump

The invention discloses a friction performance testing device for a slipper pair of a high-pressure axial plunger pump. The left and right sides of a box body are respectively provided with a high-pressure oil chamber and a sealed experiment chamber; the left and right ends of the box body are respectively provided with a left end cover and a right end cover of the box body; the high-pressure oil chamber is internally provided with a thrust piston; the end part of a piston rod of the thrust piston is arranged in the sealed experiment chamber and is connected with a slipper for testing through a connecting bolt; a swash plate stationary shaft is arranged on the right end cover of the box body; one end of the stationary swash plate shaft is arranged in the sealed experiment chamber, and a swash plate for testing is connected to the end through a bolt; and the other end of the swash plate stationary shaft is connected with a variable-frequency motor through a shaft coupling, and the variable-frequency motor is controlled by a frequency converter. By using the friction performance testing device, not only can the dry friction performance of the slipper pair of the high-pressure axial plunger pump be tested, but also different working states can be simulated to test. The friction performance testing device has the advantages of simple structure, convenience in use, accuracy in testing, low manufacturing and using costs and the like.

Owner:GUIZHOU UNIV

Expansion protecting device

InactiveCN102568762APositive pressure controllablePrevent expansion and deformationTransformers/inductances coolingTransformerPositive pressure

The invention discloses an expansion protecting device, which belongs to the technical field of expansion protecting devices of electric oil storage equipment. The expansion protecting device comprises an elastic body communicated with an inner cavity of an electric equipment sealed oil tank, and a pressure block is arranged on the upper surface of the elastic body. When in use of the expansion protecting device, oil is filled into the oil tank and the elastic body, the pressure block presses the elastic body, so that oil in the elastic body and the oil tank is applied with positive pressure, and leakage of external rainwater, air and the like to the oil tank is avoided. When the electric equipment is heated during running, the temperature of oil in the oil tank rises and the oil expands. Since the elastic body is communicated with the inner cavity of the sealed oil tank, the elastic body can expand along with expansion of the oil, and deformation of the oil tank is avoided effectively. Meanwhile, positive pressure in the oil tank can be controlled by utilizing different elastic bodies and pressure blocks, and the service life of the electric equipment can be prolonged. The expansion protecting device can be used on electric equipment with oil, such as transformers, reactors, mutual inductors and the like.

Owner:周玉春

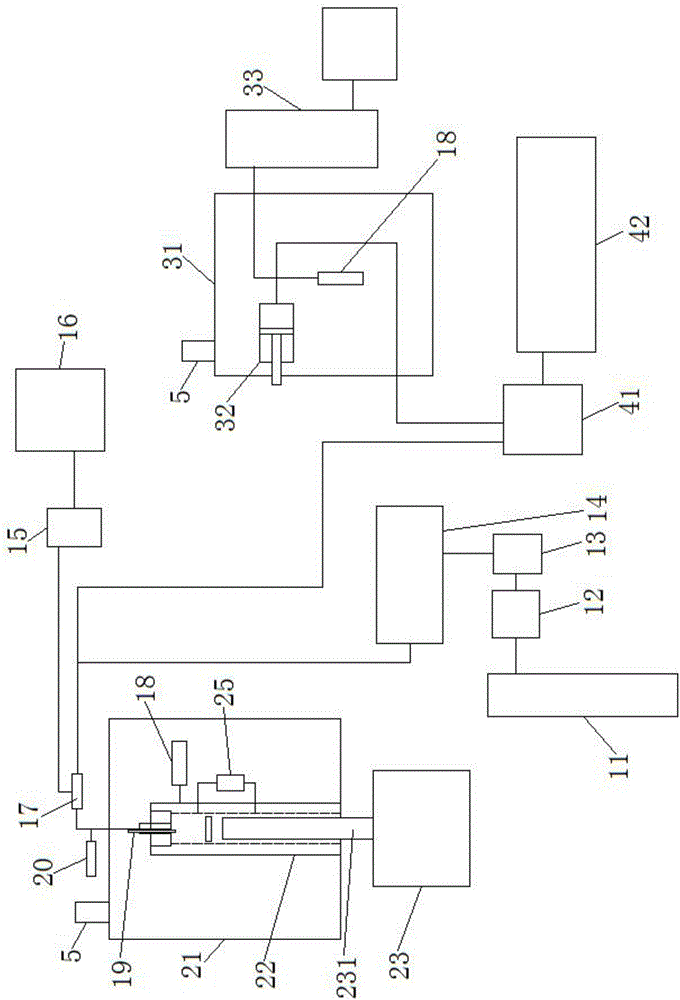

High temperature and high pressure multiphase fluid comprehensive tester

InactiveCN106596802ASimple structureImprove test accuracyComponent separationCombined testData collector

The invention relates to a high temperature and high pressure multiphase fluid comprehensive tester, which comprises a fluid storage and output system, a high temperature and high pressure simulation system, a fluid solubility analysis and testing system, a sampler, a data collector and a computer host machine, wherein a reaction chamber is arranged in the high temperature and high pressure simulation system, the fluid storage and output system is communicated to a gas inlet, the communicated pipeline is provided with a gas mass and flow rate meter, the gas mass and flow rate meter is sequentially connected to the data collector and the computer host machine, the high temperature and high pressure simulation system is provided with a temperature sensor and a pressure sensor, the temperature sensor and the pressure sensor are respectively connected to the data collector, the sampler is used for sampling a fluid to be detected in the reaction chamber, and the fluid to be detected can be subjected to solubility analysis and testing in the fluid solubility analysis and testing system. According to the present invention, the high temperature and high pressure multiphase fluid comprehensive tester has advantages of simple structure, high test precision, controlled experiment temperature, controlled experiment pressure and controlled experiment volume, can stably work for a long time under the high temperature and high pressure conditions, and is used for the accurate testing of the fluid phase, the fluid property and the solubility.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

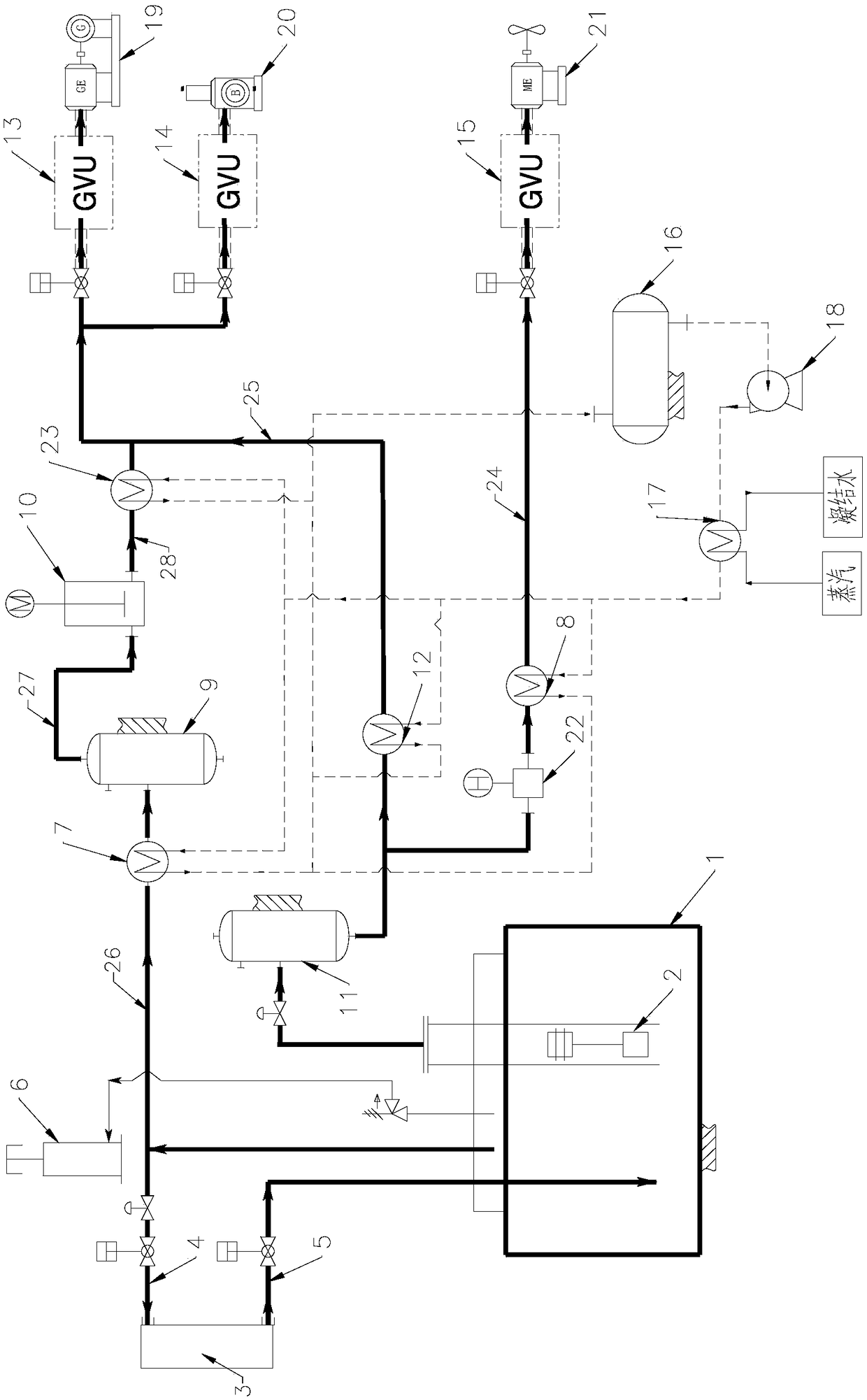

Natural gas high and low pressure integrated gas supply system for large dual-fuel power ship

InactiveCN109185693ASolve different needsChanging complex processesPropulsion based emission reductionPower plants using propulsion unit combinationsProcess engineeringHigh pressure

The invention discloses a natural gas high and low pressure integrated gas supply system for a large dual-fuel power ship. The natural gas high and low pressure integrated gas supply system comprisesa liquid natural gas (LNG) fuel bin, a high-pressure gas supply system and a low-pressure gas supply system. The LNG fuel bin is an IMO B-type thin film bin. The high-pressure gas supply system boostsLNG through an LNG booster pump, the LNG is gasified and heated through an LNG high-pressure gasifier, and the fuel gas with the pressure, temperature and flow meeting the requirements of a ship mainengine is provided. The low-pressure gas supply system comprises an LNG gasification unit and a BOG processing unit. The LNG gasification unit gasifies and heats the LNG through an LNG low-pressure gasifier, and the fuel gas with the pressure, temperature and flow meeting the requirements of a generator and / or a boiler is provided. The BOG processing unit is pressurized by a normal-temperature BOG compressor, then the temperature is adjusted through a BOG heater and an outlet heat exchanger of the BOG compressor, and the fuel gas with the pressure, temperature and flow meeting the requirements of a dual-fuel generator and / or the boiler is provided. The gas supply system is simpler and more reliable.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

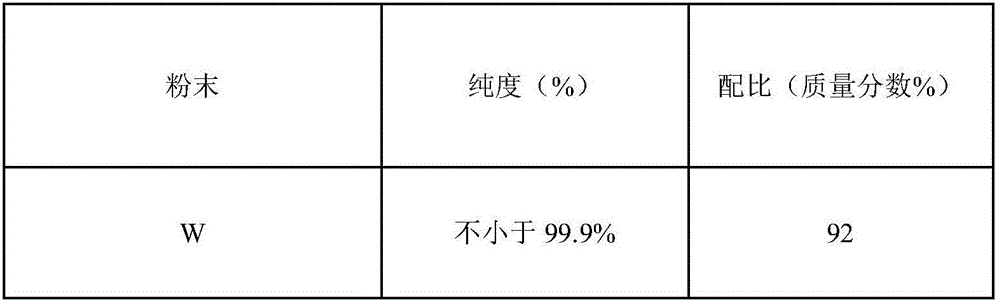

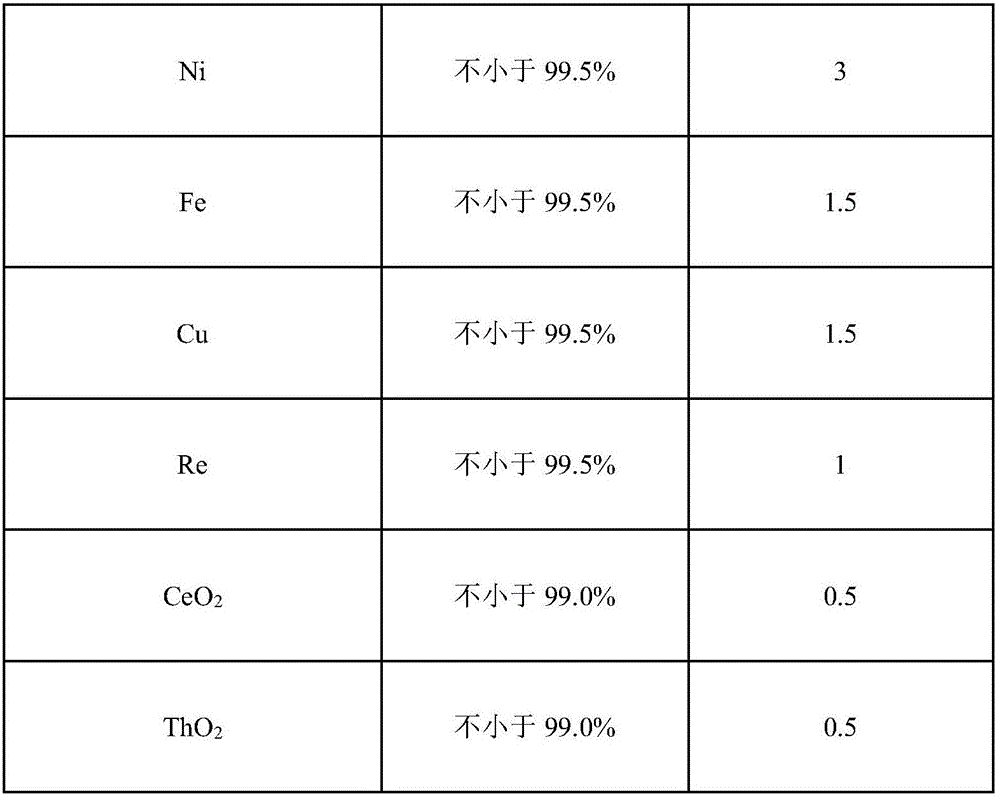

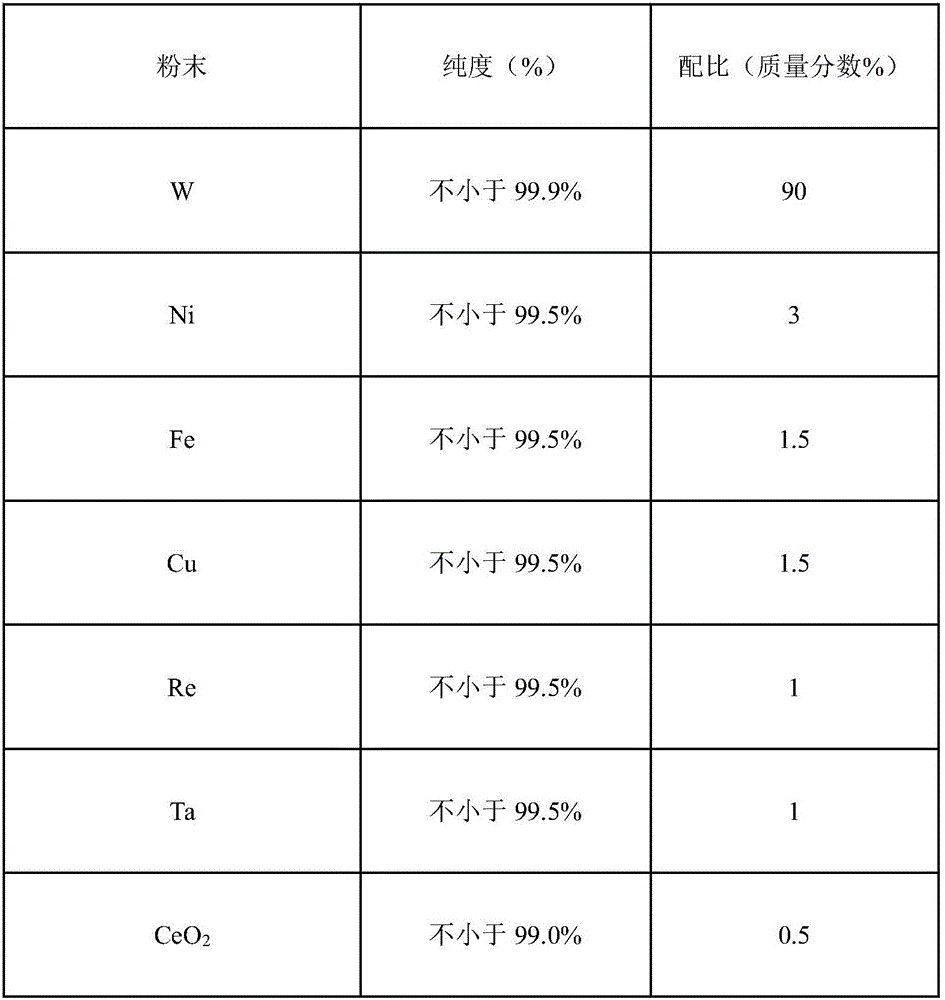

Tungsten alloy material and preparation method thereof

The invention discloses a tungsten alloy material and a preparation method thereof and belongs to the technical fields of non-ferrous metal smelting and rolling. The tungsten alloy material comprises the following metallic elements of, by mass, 85-92% of W, 3-7% of a metallic element a, 1-5% of a metallic element b and 0.5-1% of a rear earth oxide, wherein the metallic element a is one or more of Ni, Fe and Cu; the metallic element b is one or more of Mo, Zr, Hf, Re, Nb, V and Ta; the rear earth oxide is one or more of rear earth oxides; the mass percent of Re of the metallic element b is no less than 1%; and the mass percent of CeO2 is no less than 0.5%. According to the tungsten alloy material and the preparation method thereof provided by the invention, raw materials in the tungsten alloy formula are easy to obtain, the process is simple, and the prepared tungsten alloy material has the advantages of small grain size, high density, strength and hardness, good ductility and machinability and the like.

Owner:深圳市威勒科技股份有限公司

Edge-bottom water heavy oil reservoir steam-drive two-dimensional proportion physical simulation device and application method thereof

ActiveCN103452541AOriginal thermal insulation structureHeat and mass transfer simulationFluid removalBottom waterHeavy oil reservoir

The invention discloses an edge-bottom water heavy oil reservoir steam-drive two-dimensional proportion physical simulation device and an application method thereof. The device comprises an injection unit, a model body, an edge-bottom water temperature control unit, an edge-bottom water pressure control unit, a model insulation unit, a yield metering unit, a data acquisition and image processing unit and the like. The device is used for exploring the edge-bottom water oil reservoir steam driving mechanism, understanding the influence of edge-bottom water of oil reservoirs upon steam flooding effect and the development features and production features of a temperature field of edge-bottom water heavy oil reservoir steam driving, and guiding the development of edge-bottom water heavy oil reservoir steam driving.

Owner:PETROCHINA CO LTD

Low-temperature propellant storage tank with pressure control device

ActiveCN107726040AImprove heat transfer efficiencyReduce heat leakageContainer filling methodsFluid handledInsulation layerExhaust valve

The invention discloses a low-temperature propellant storage tank with a pressure control device. The low-temperature propellant storage tank comprises a low-temperature propellant storage tank body,a low-temperature circulation pump, a throttling valve, an expansion machine, a double-pipe heat exchanger, an exhaust cooling coil and an exhaust valve. In order to improve the heat exchange efficiency of the heat exchanger, the reverse-flow double-pipe heat exchanger is adopted, and more cooling capacity can be generated. Meanwhile, fluid passing through the throttling valve absorbs heat and becomes saturated gas or superheated gas which is expanded and cooled through the expansion machine after being discharged out of the tank body, the low-temperature gas forms a cold shield through the cooling coil wound in an insulation layer outside the tank body, external leakage is reduced to the greatest extent, and the exhaust cooling capacity is fully used. The low-temperature propellant storage tank is simple in structure and high in heat exchange efficiency, the cooling capacity is fully used, the tank body pressure is effectively controlled, and effective guarantee is provided for long-term storage of a low-temperature propellant and the tank body pressure.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of double-modified SnO<2>@C/graphene nano composite anode material

ActiveCN105609722ANanoscale smallGood dispersionCell electrodesSecondary cellsHigh current densityLithium

The invention provides a preparation method of a double-modified SnO<2>@C / graphene nano composite anode material, relates to the preparation method of the anode material, and aims at solving the problems of poor cycle performance and lithium storage property of SnO<2> and graphene composite prepared by an existing method when used as the anode material at high current density. The preparation method comprises the following steps: (1) preparing nano carbon spheres; (2) preparing SnO<2>@C through a two-step method to obtain an SnO<2>@C composite material; and (3) carrying out microwave hydrothermal reaction to obtain SnO<2>@C / graphene composite material solid powder, namely double-modified SnO<2>@C / graphene nano composite anode material. The preparation method is mainly used for preparing the double-modified SnO<2>@C / graphene nano composite anode material.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

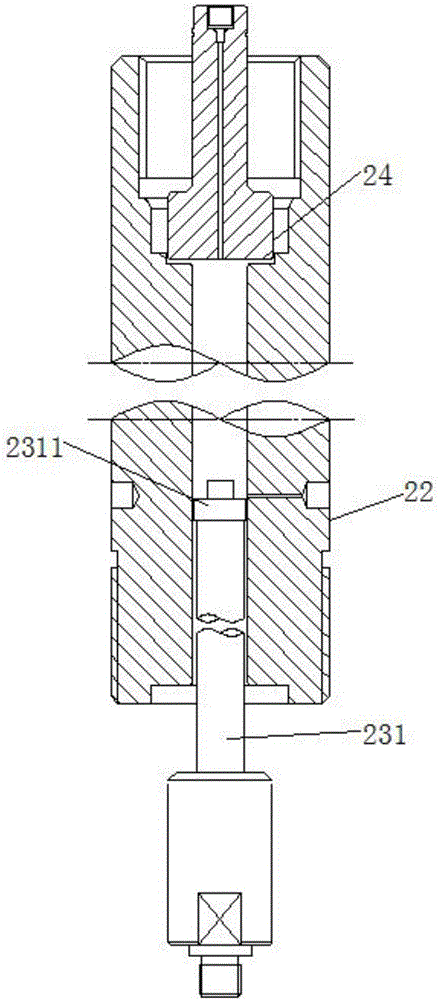

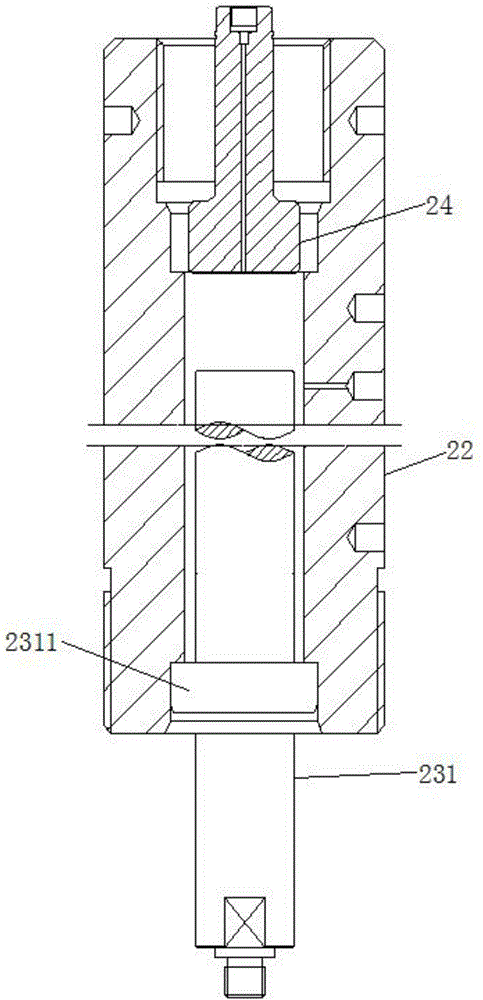

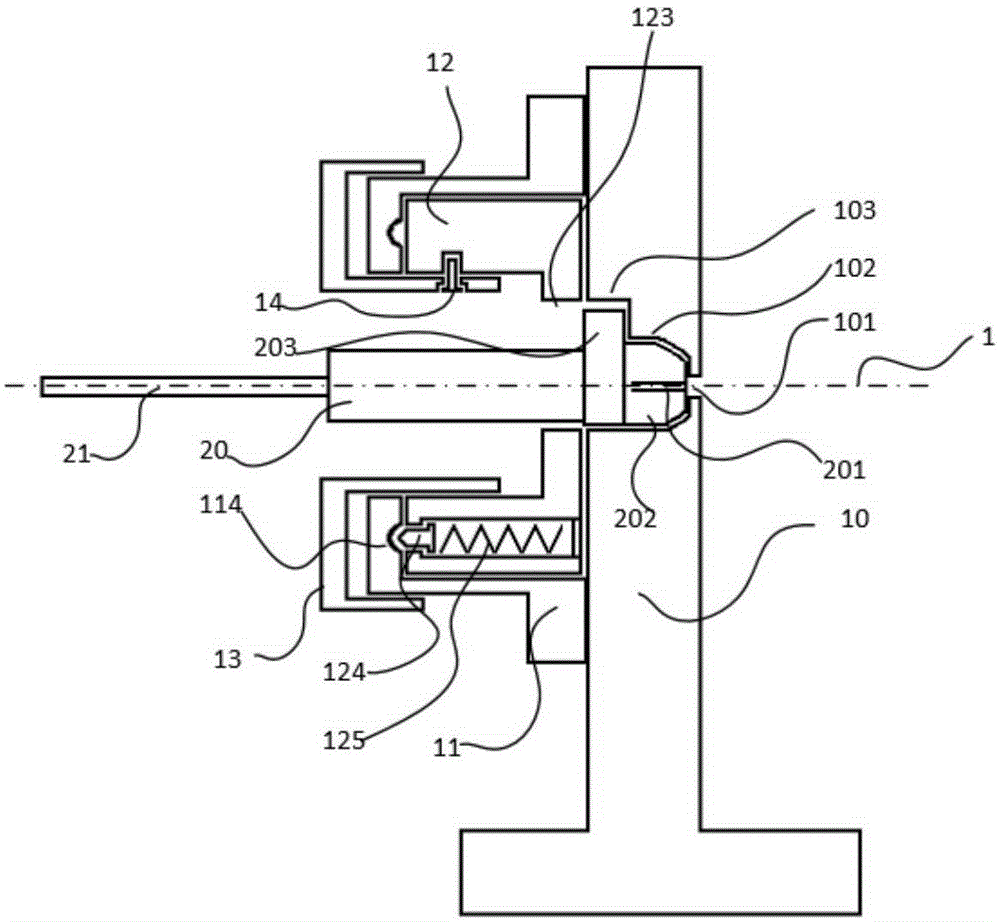

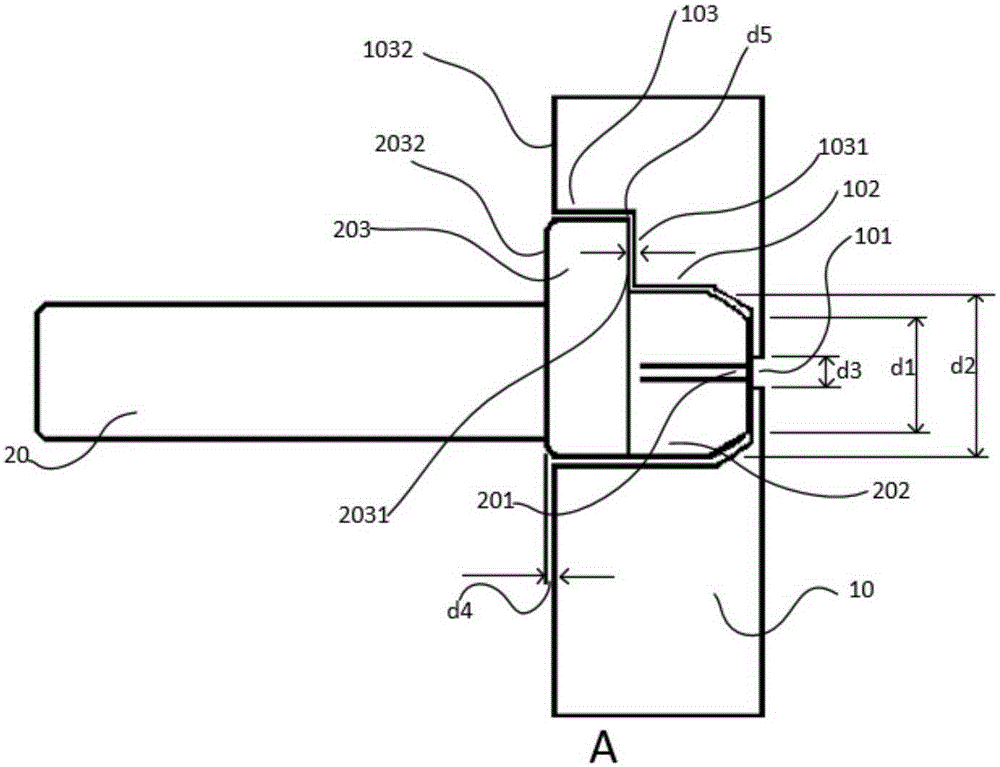

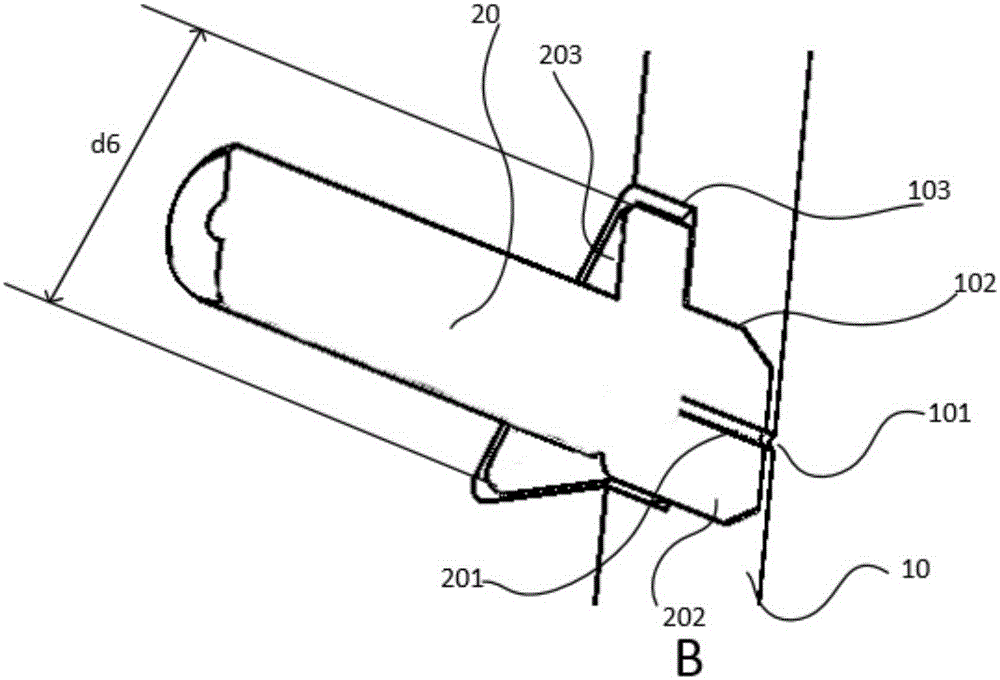

Cam-type sealing machine for cylindrical batteries

ActiveCN102916215AEasy to shapePressure is easy to controlFinal product manufacturePrimary cellsHand PlateDrive motor

The invention relates to a cam-type sealing machine for cylindrical batteries. The cam-type sealing machine comprises a baseframe, a track delivery device and at least one set of sealing mold device, wherein linear transfer tracks of the track delivery device are arranged on the platform of the baseframe; the track delivery device comprises a delivery driving device, as well as a front transfer clamping plate and a rear transfer clamping plate which form a pair, a plurality of clamping pillars for clamping and sending the cylindrical batteries to achieve transverse shift are respectively arranged at the joint between the front transfer clamping plate and the rear transfer clamping plate, transverse linear slide rails facilitating transverse reciprocating movement of the front transfer clamping plate and the rear transfer clamping plate are respectively arranged on the platform of the baseframe, and longitudinal linear slide rails are respectively arranged on the front transfer clamping plate and the rear transfer clamping plate; the transfer driving device comprises an X-axis power source and a Y-axis power source; and the sealing mold device comprises a driving motor, a clutch, a reducing mechanism, a cam mechanism, a slide block mechanism, a sealing die, a sliding pole and a lower die, the lower die is mounted on the transfer tracks on the platform of the baseframe, the slide block mechanism and the sealing die are mutually connected and slide along the sliding pole, and the sliding pole is equipped with a return spring.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

Optical fiber connector capable of accurate positioning

ActiveCN105242358AImprove axial positioning accuracyLimited rotationCoupling light guidesEngineeringConfocal imaging

The invention discloses an optical fiber connector capable of accurate positioning, which comprises a connector socket and a connector plug, wherein the connector socket comprises a connector socket base, a locking wheel pressure ring, a locking wheel and an operating handle, and the connector socket base is fixed to an optical bottom plate of a confocal imaging system in a rigid manner; the locking wheel pressure ring, the locking wheel and the operating handle form a locking and limiting mechanism of the connector socket; the head part of the connector plug is provided with an axial positioning head, a rotary positioning head is arranged behind the axial positioning head, an optical fiber bundle passes through a hollow hole, and the optical fiber bundle and the connector plug are fixed to each other after being leveled; and the hollow hole faces just to a circular light passing hole when connector plug is inserted to the bottom part of a positioning groove of the connector socket base, and focused laser is injected into the optical fiber bundle through the circular light passing hole. The optical fiber connector adds a rotary positioning function, limits the optical fiber to rotate around the axis, achieves positioning in the rotational direction, applies a pressure on the connector through a spring, ensures stable and reliable locking of the connector, and can control the pressure.

Owner:精微致远医疗科技(武汉)有限公司

Split type coal-gas adsorption desorption and outburst test device and test method

InactiveCN104515716ARealize quasi-3D stress loadingTrue adsorption stateMaterial analysisUniversal jointSurface type

The invention discloses a split type coal-gas adsorption desorption and outburst test device, which comprises a cylindrical coal sample chamber. The coal sample chamber is provided with several pressure temperature sensors able to detect molded coal temperature and gas pressure. Hydraulic loading equipment able to stretch into the coal sample chamber and apply axial ground stress is fixedly mounted at one end of the coal sample chamber, the other end is provided with a coal-gas blowout port communicated with the coal sample chamber during work, and a quick release mechanism is disposed at the coal-gas blowout port to control the blowout port breakover. The hydraulic loading equipment is connected to a piston rod through a universal joint, and the tail end of the piston rod is connected to a surface type inflation loading disc in contact with a coal sample placed in the coal sample chamber during test. The invention also discloses a test method using the device. The device and the method provided by the invention can research the adsorption desorption characteristics of coal to gas and the coal-gas outburst mechanism when molded coal is under different ground stress and gas pressure conditions.

Owner:SHANDONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com