Split type coal-gas adsorption desorption and outburst test device and test method

A technology of adsorption, desorption, and test equipment, which is applied in the direction of measuring equipment, analysis materials, instruments, etc., can solve problems such as complex operation, easy stress concentration at the corners of the model, and inability to collect coal and gas transient changes at one time. Achieve the effect of convenient operation, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

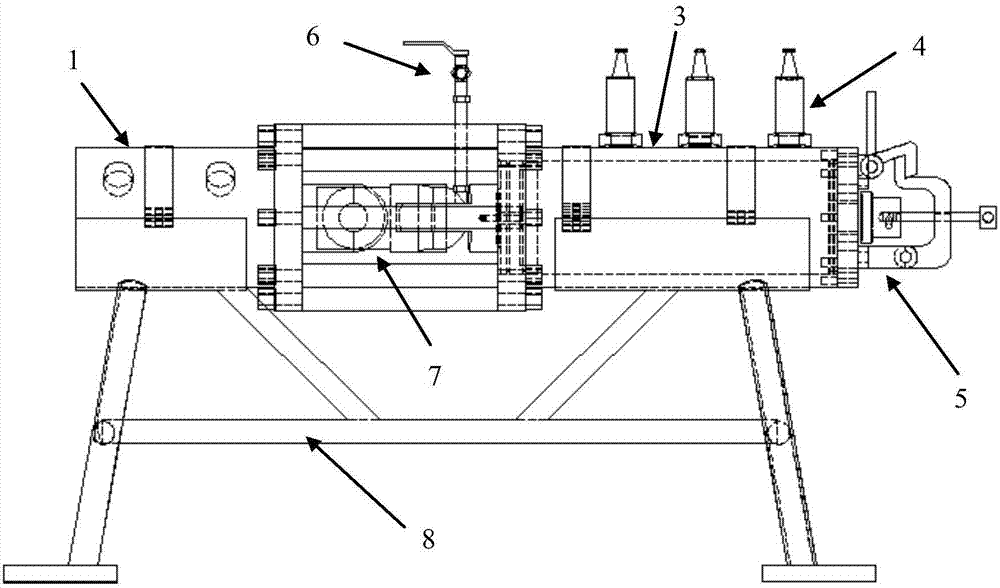

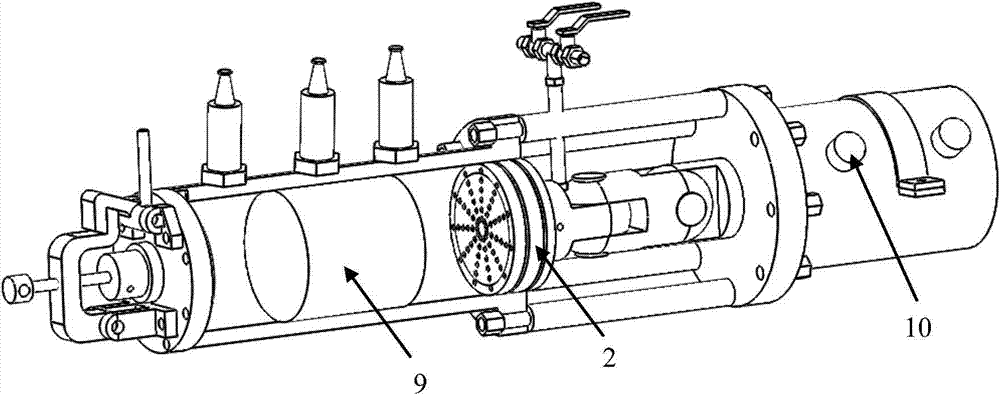

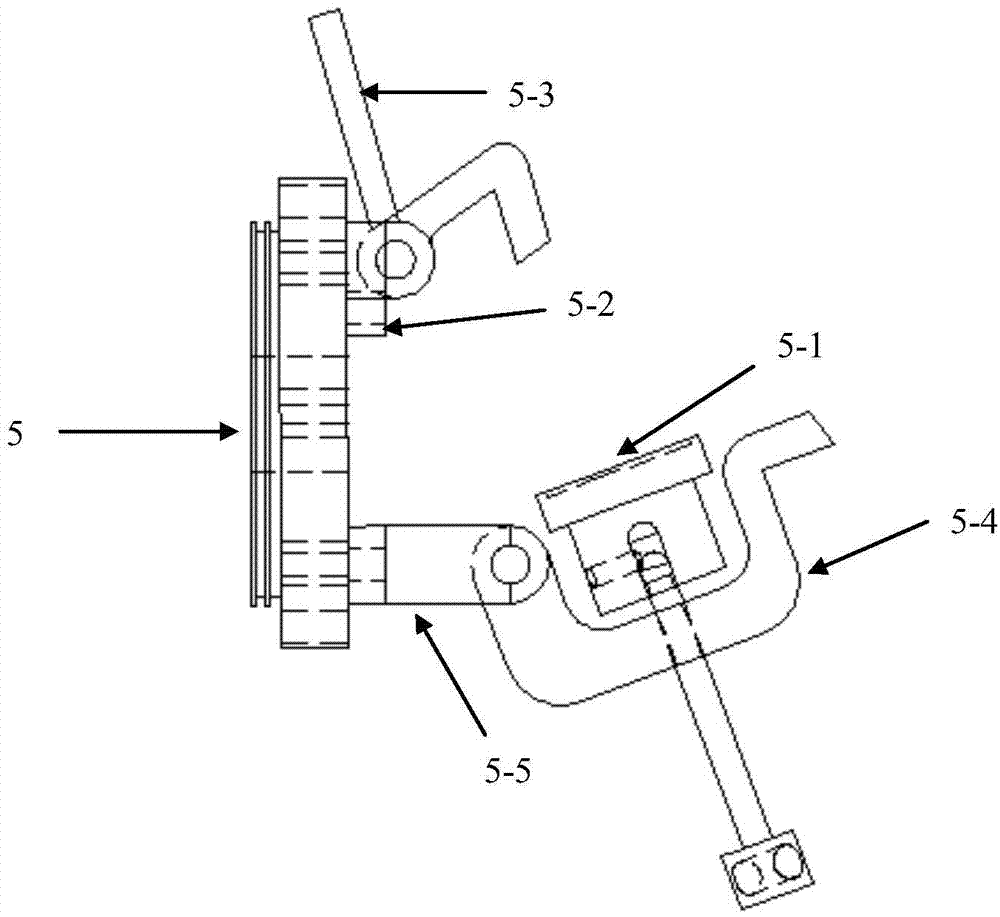

[0054] Such as figure 1 , figure 2 As shown: Coal and gas adsorption, desorption and outburst test device 13 includes hydraulic loading equipment 1, coal sample chamber 3, quick release mechanism 5, surface-type inflatable loading plate 2, pressure and temperature sensors 4 and structural support 8. The coal sample chamber 3 , the hydraulic loading device 1 , the surface-type inflatable loading plate 2 and the quick release mechanism 5 are all fixed on the structural support 8 . The coal sample chamber 3 is provided with a coal sample cavity for placing coal samples, and a gas channel is left on the surface-type inflatable loading plate 2 to connect the tee 6, and the two outlets of the tee 6 are respectively equipped with control switches. The coal sample chamber is provided with a collection device 4 for detecting the internal pressure and temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com