High-speed collision experiment testing device for vehicle power battery

A power battery and crash test technology, which is applied in the direction of measuring devices, impact tests, and machine/structural component testing, can solve the problems that it is difficult to reach the level of collision accidents, and it is impossible to simulate the impact conditions of vehicle power batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

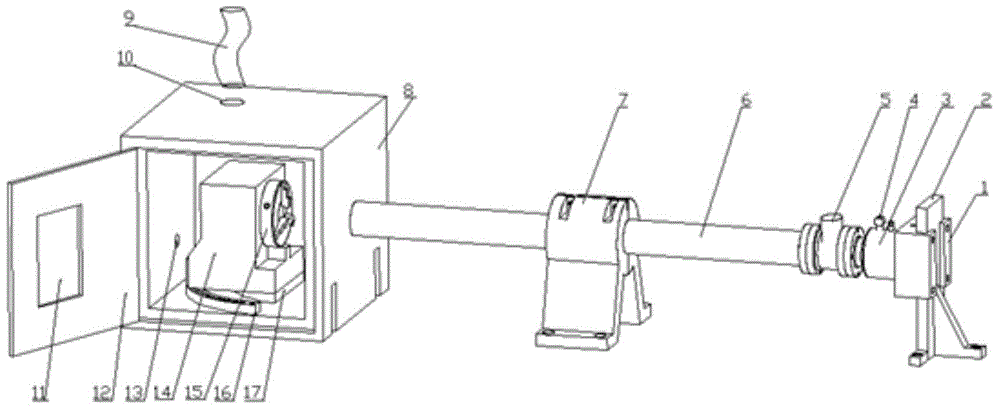

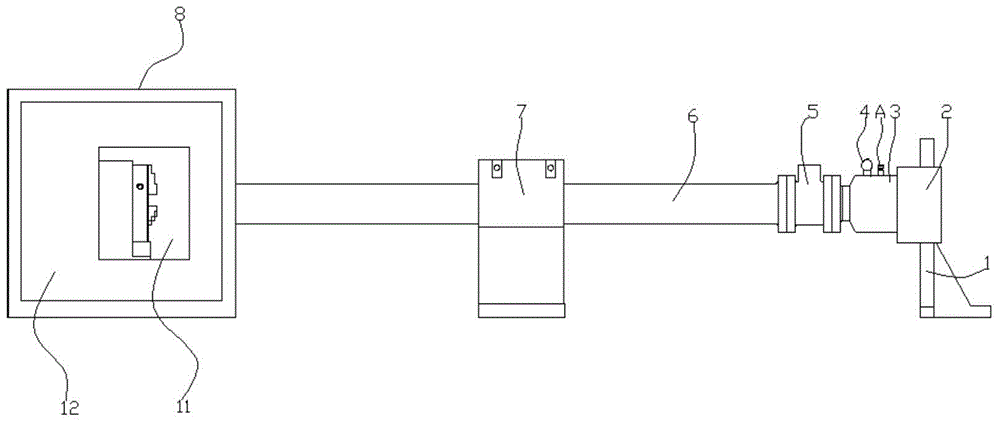

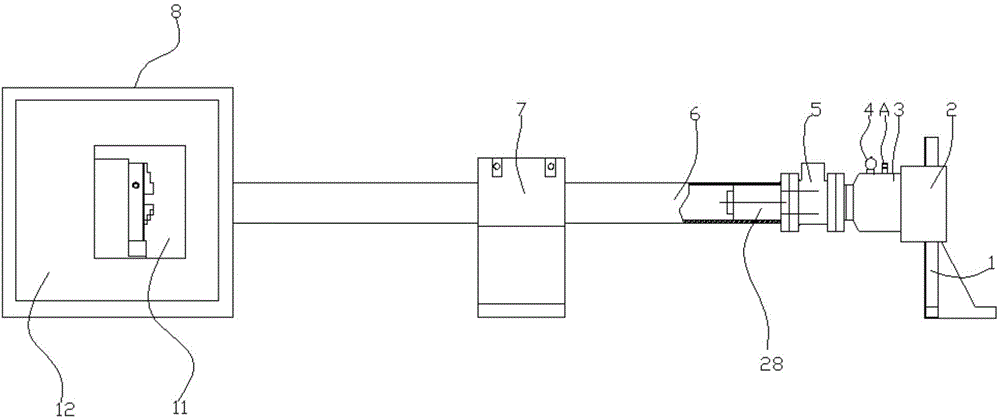

[0027] Such as figure 1 , 2 , 6, a vehicle power battery high-speed crash test device, including high-pressure gas tank 3, solenoid valve 5, acceleration tube 6, workbench 14, indexing plate 17, track 16, fixing device, explosion-proof box 8 , temperature detection device, pressure sensor, image acquisition device and battery parameter measurement device. The fixing device includes a middle fixing seat 7 and an end fixing seat composed of a support 1 and a clamping plate 2 . The high-pressure gas tank 3 is embedded in the clamping plate 2 and tightened with bolts, and the clamping plate 2 and the support 1 are clamped and fixed on the ground. The high-pressure gas tank 3 is provided with an inflation nozzle A and a barometer 4 capable of displaying internal pressure, and the high-pressure gas tank 3 is inflated through the inflation nozzle A. One end of electromagnetic valve 5 is connected with high-pressure gas tank 3 with bolts, and is sealed with a sealing ring to preven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com