Simple production equipment for bituminous coal sample block

A technology for sample block and bituminous coal is applied in the field of simple production equipment for bituminous coal sample block, and achieves the effects of simple structure, controllable pressure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

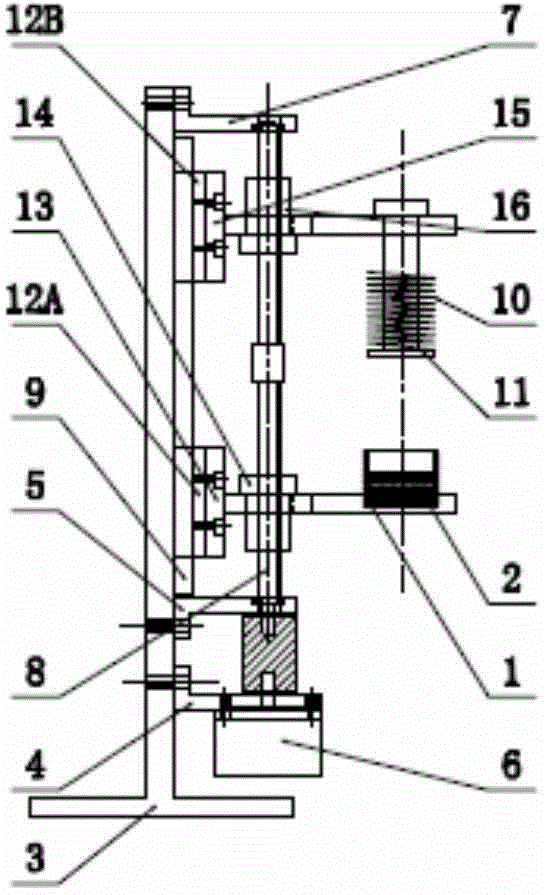

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

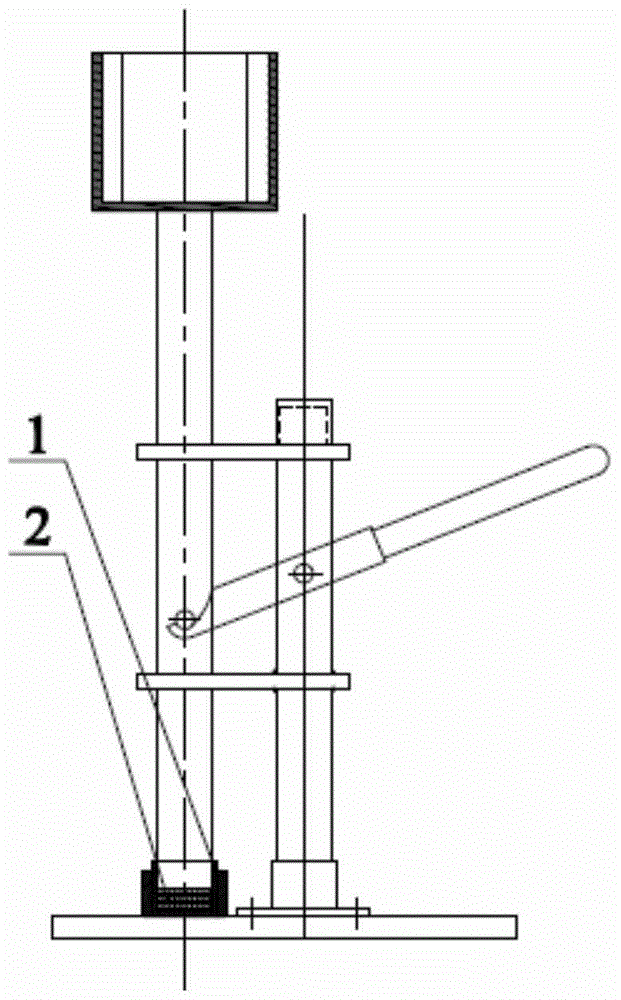

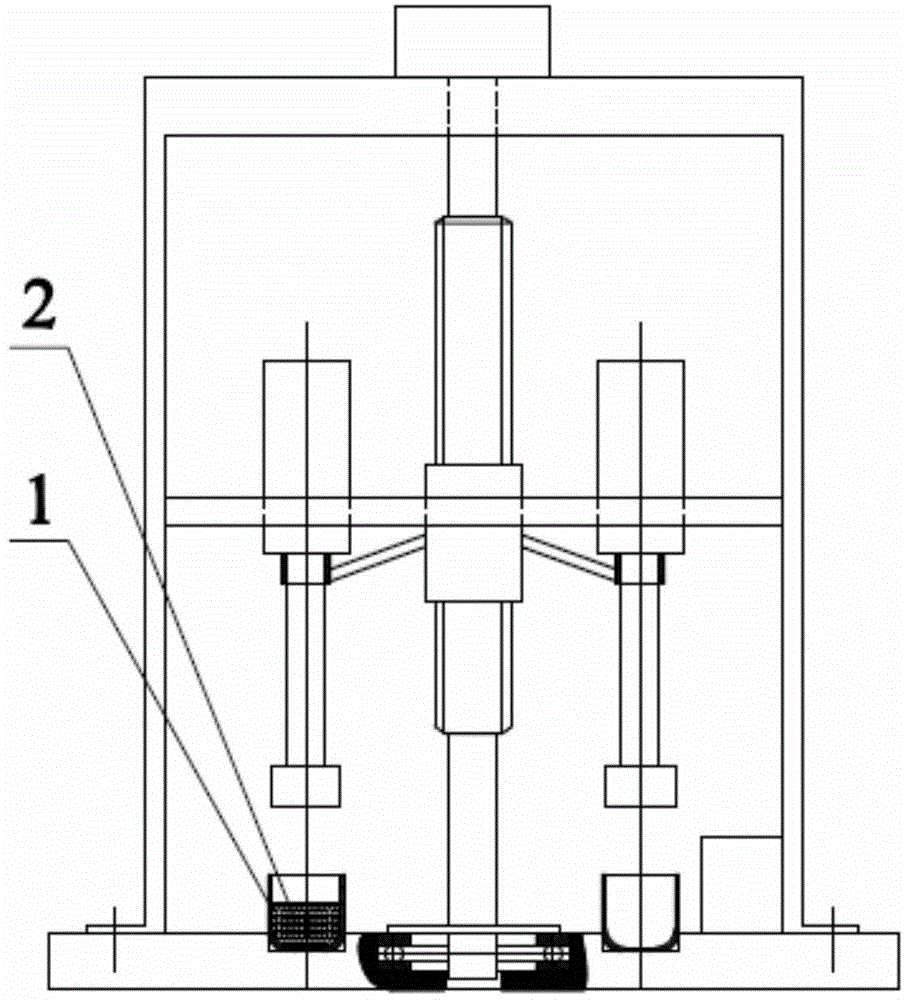

[0014] see image 3 and Figure 4 As shown, the forward rotation of the motor 6 drives the forward rotation of the two-way lead screw 8, and the T-shaped crucible frame 13 moves upward along the guide rail 9 under the joint action of the left-hand nut 14 and the slider 12A. The right-hand nut 16 and the slide block 12B jointly move down along the guide rail 9, and the distance between the T-shaped crucible frame 13 and the T-shaped platen frame 15 becomes smaller; when the motor 6 reversely rotates, the T-shaped crucible frame 13 and the T Type platen frame 15 moves downwards and upwards along guide rail 9 respectively, and the distance between T-shaped crucible frame 13 and T-shaped platen frame 15 becomes larger; The distance between T-shaped crucible frame 13 and T-shaped platen frame 15 becomes smaller During the process, as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com