Circulating tea-flatting machine

A circulating, tea machine technology, applied in the direction of tea processing before extraction, can solve the problems of easily broken tea leaves, easy burns on hands, and difficult to master the frying method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

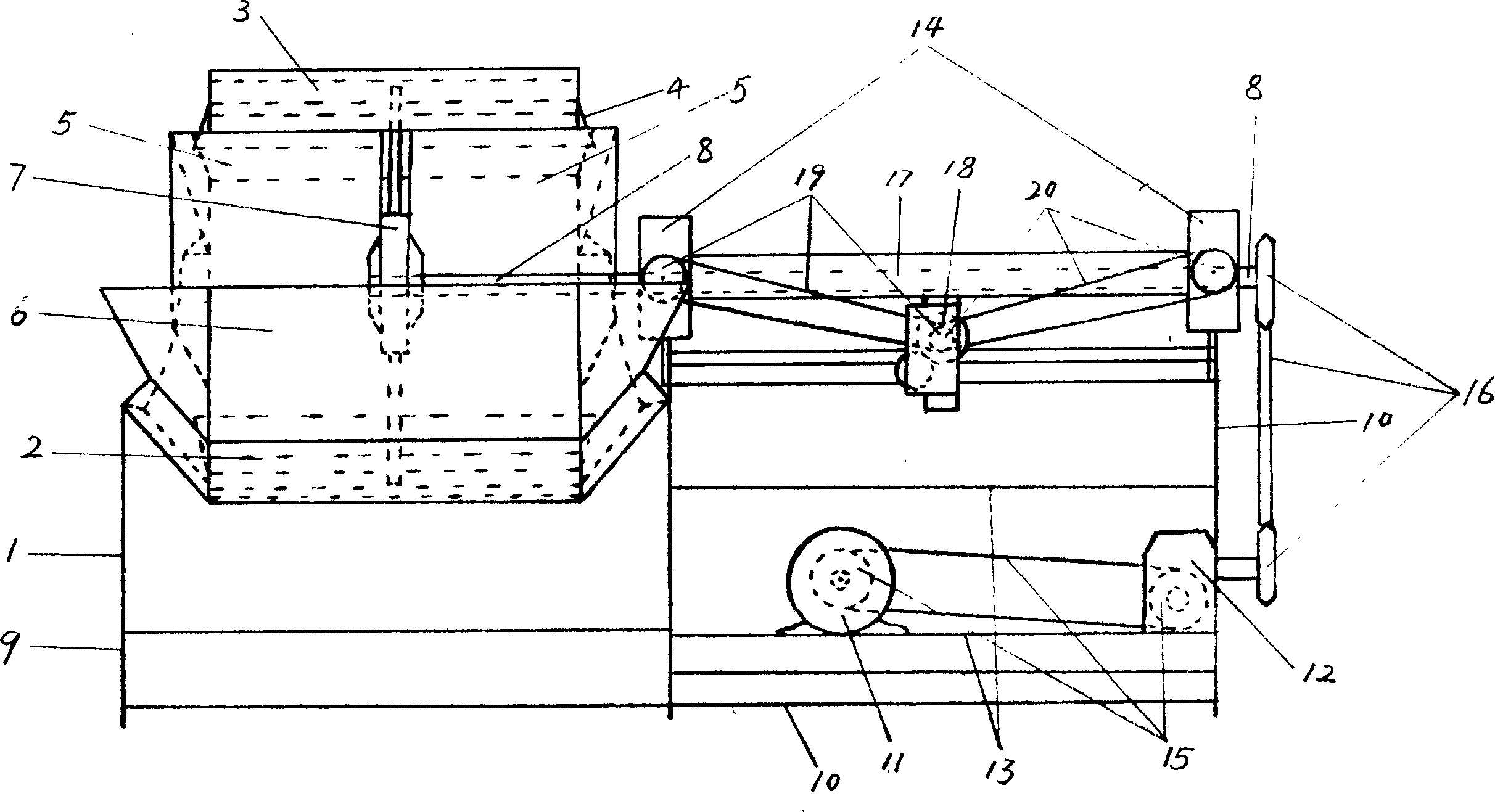

[0031] The circulating flat tea frying machine includes four parts: the main machine, the heat source, the transmission mechanism and the control mechanism.

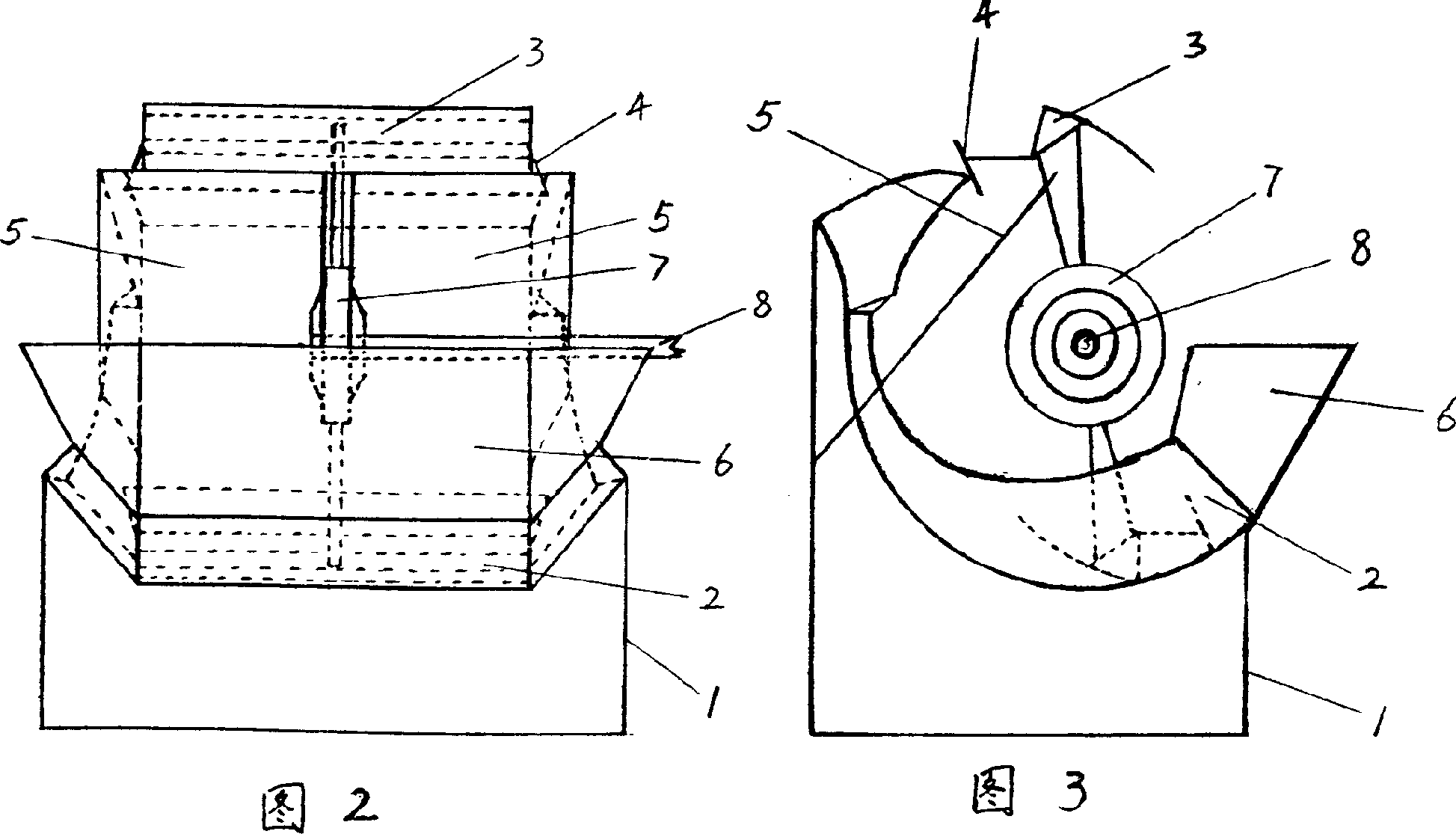

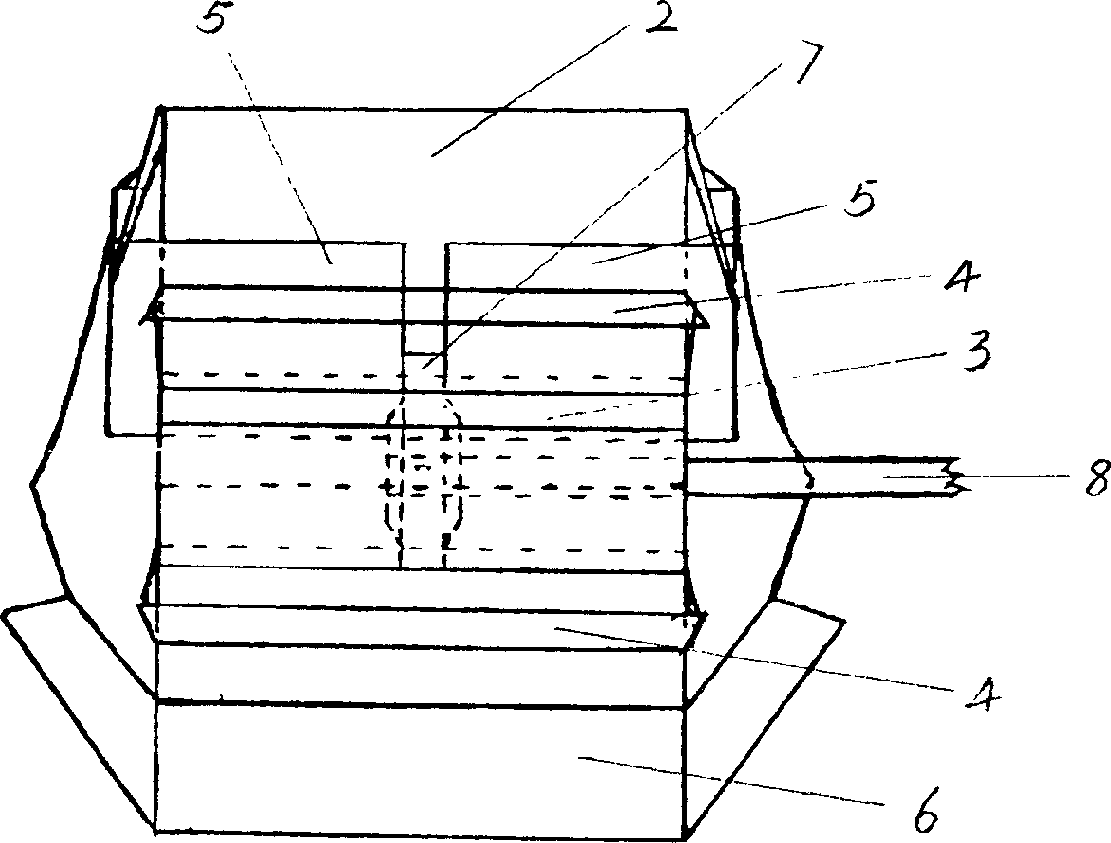

[0032] The main engine includes the main engine bracket 1, the semi-circular grooved pot 2, two pressing plate assemblies 3, two supporting plate assemblies 4, two strip plate assemblies 5, pressing plate frame assembly 7, baffle plate assembly 6 and shaft 8 .

[0033] Main engine support 1 is corresponding with pot 2, is welded with angle iron.

[0034] The semi-circular trough-shaped pot 2 is close to a semi-circle, and the upper port has a section that turns outwards, and both sides are welded with pot pages of certain size, curvature, and inclination. The pot is installed on the host frame according to a certain inclination.

[0035] The pressing plate assembly 3 includes a plurality of pressing plates 21 with a certain degree of curvature, which are movably connected with the pressing plate support plate 22 by a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com