Patents

Literature

64results about How to "Realize automatic feeding operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

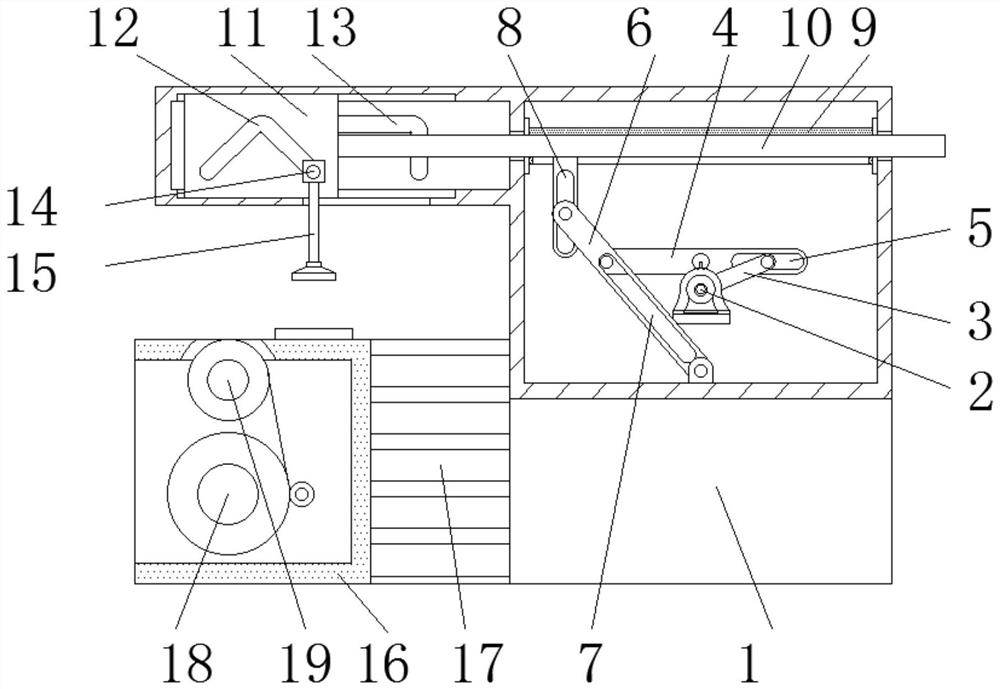

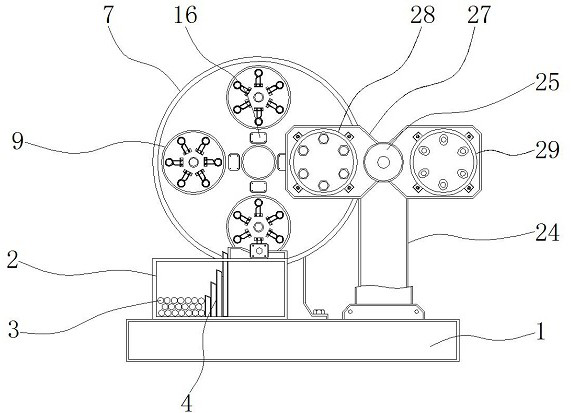

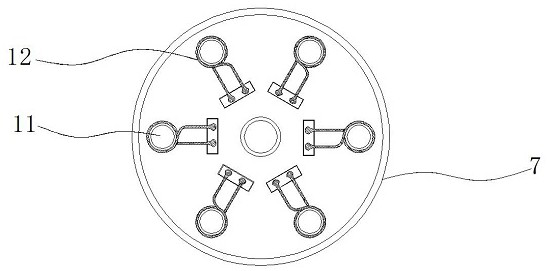

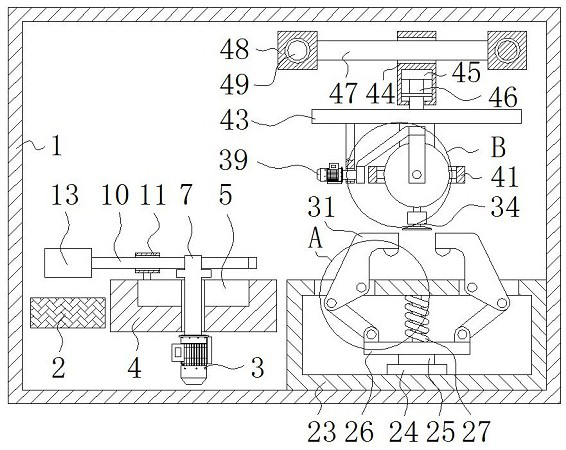

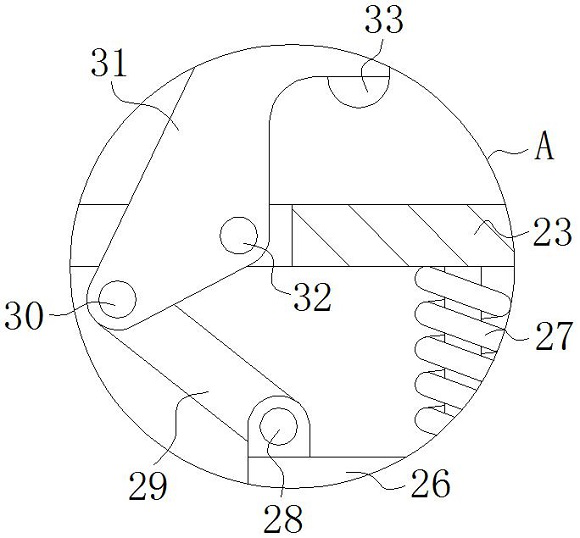

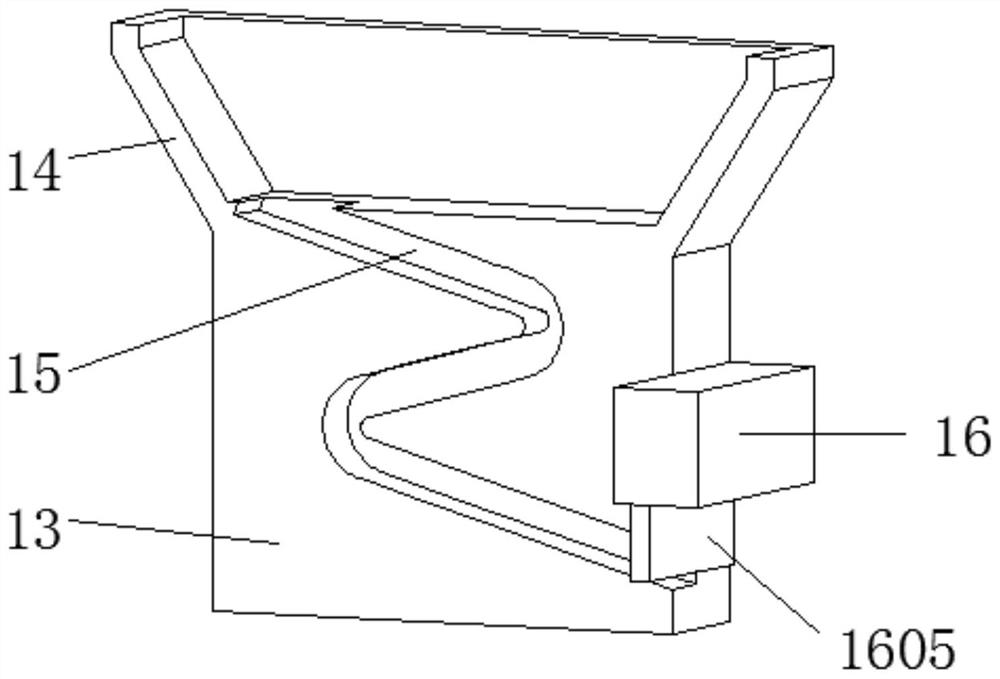

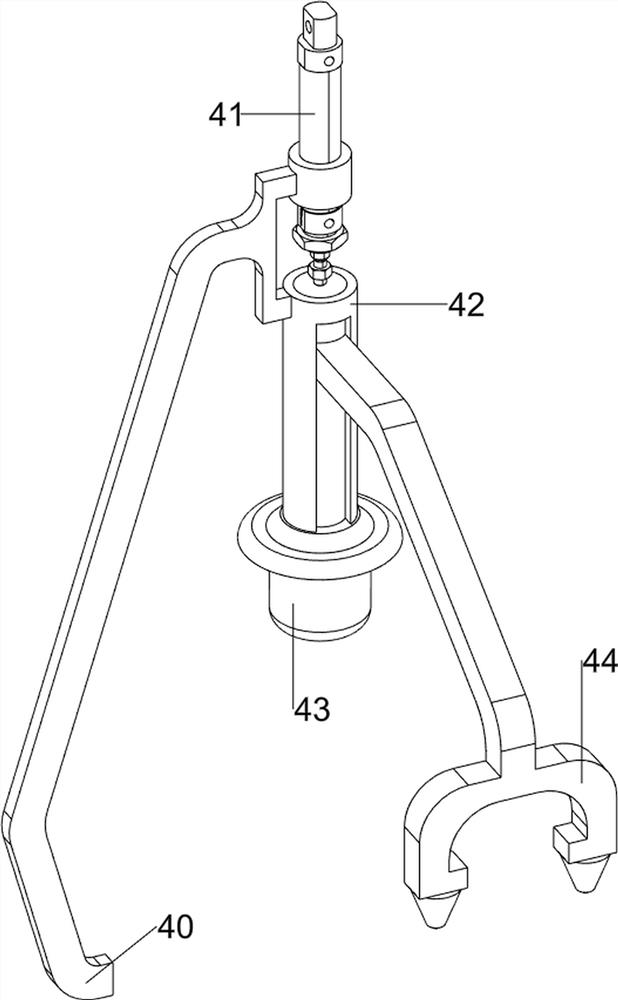

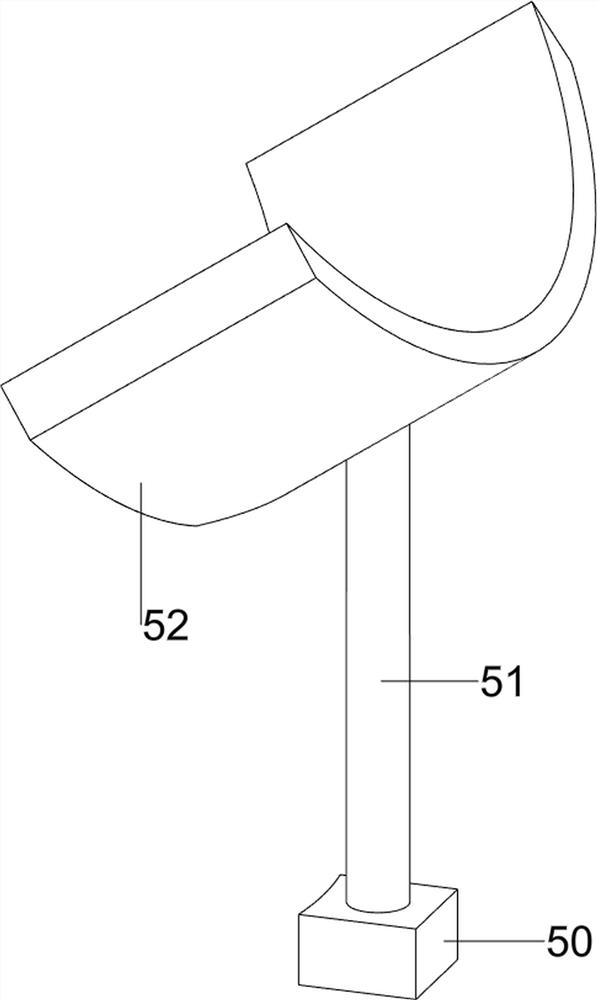

Automatic capping device for beverage processing

ActiveCN112110400ARealize automatic feeding operationRealize automatic unloadingThreaded caps applicationElectric machineryEngineering

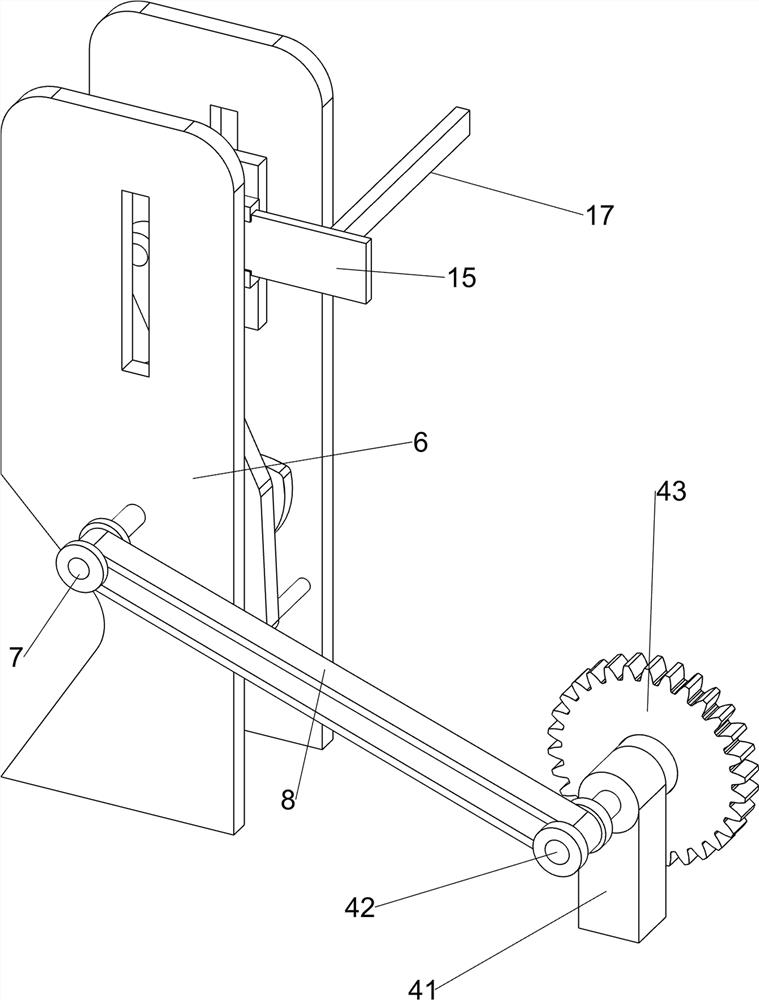

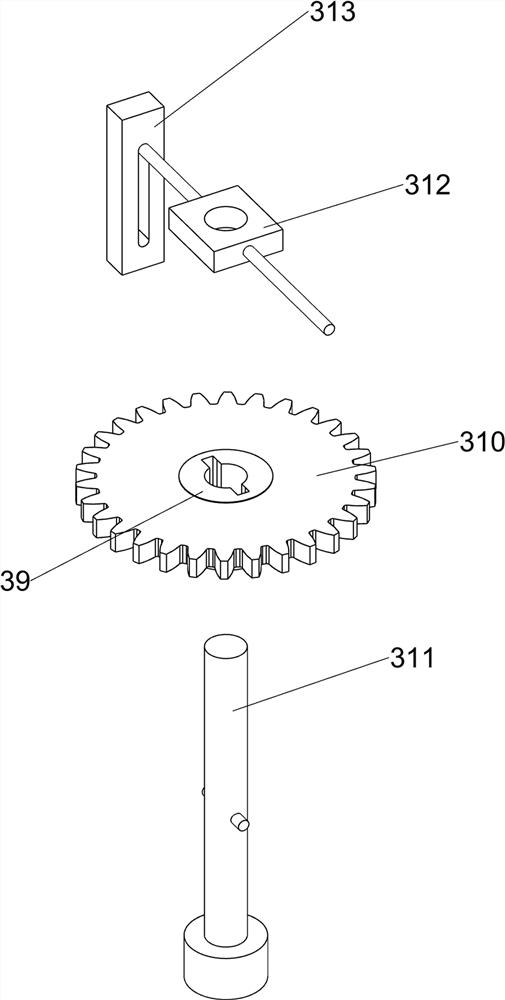

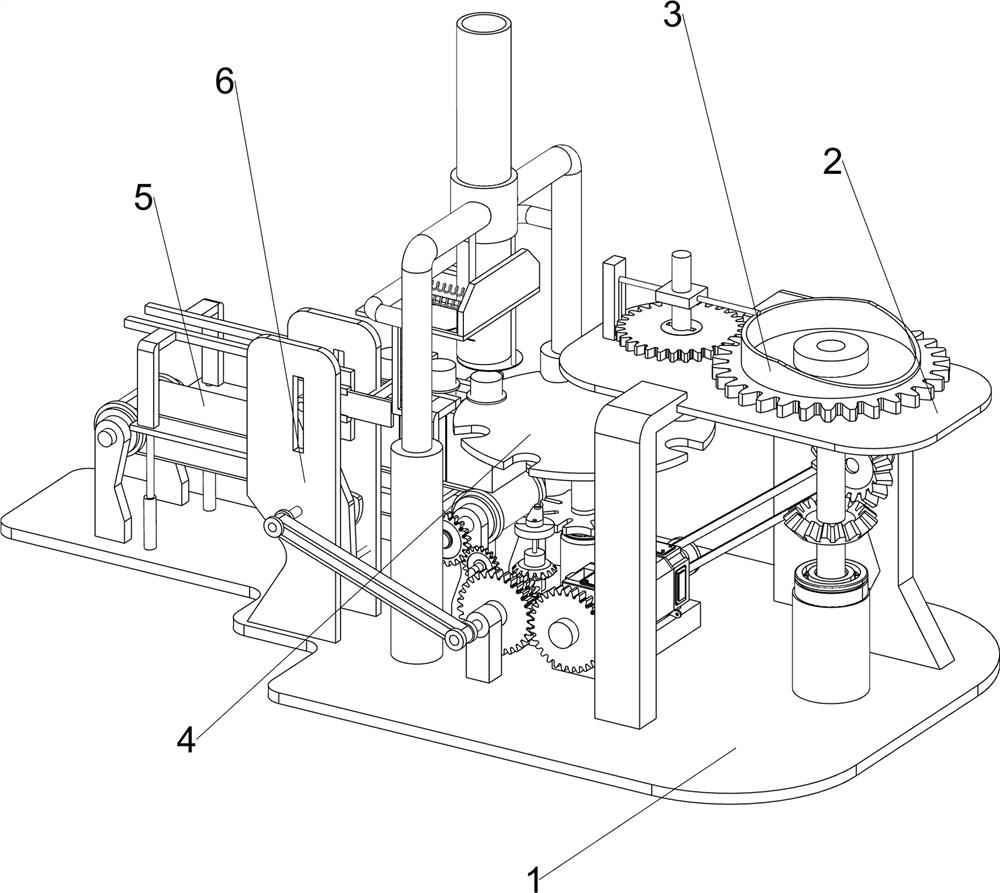

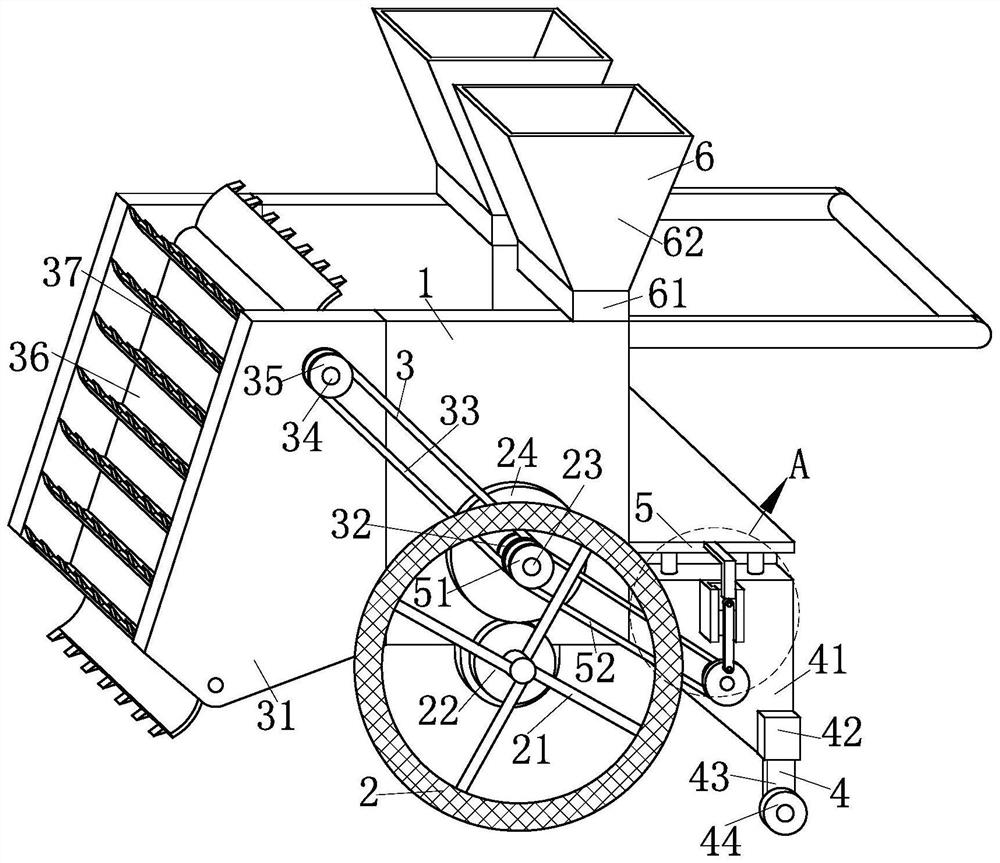

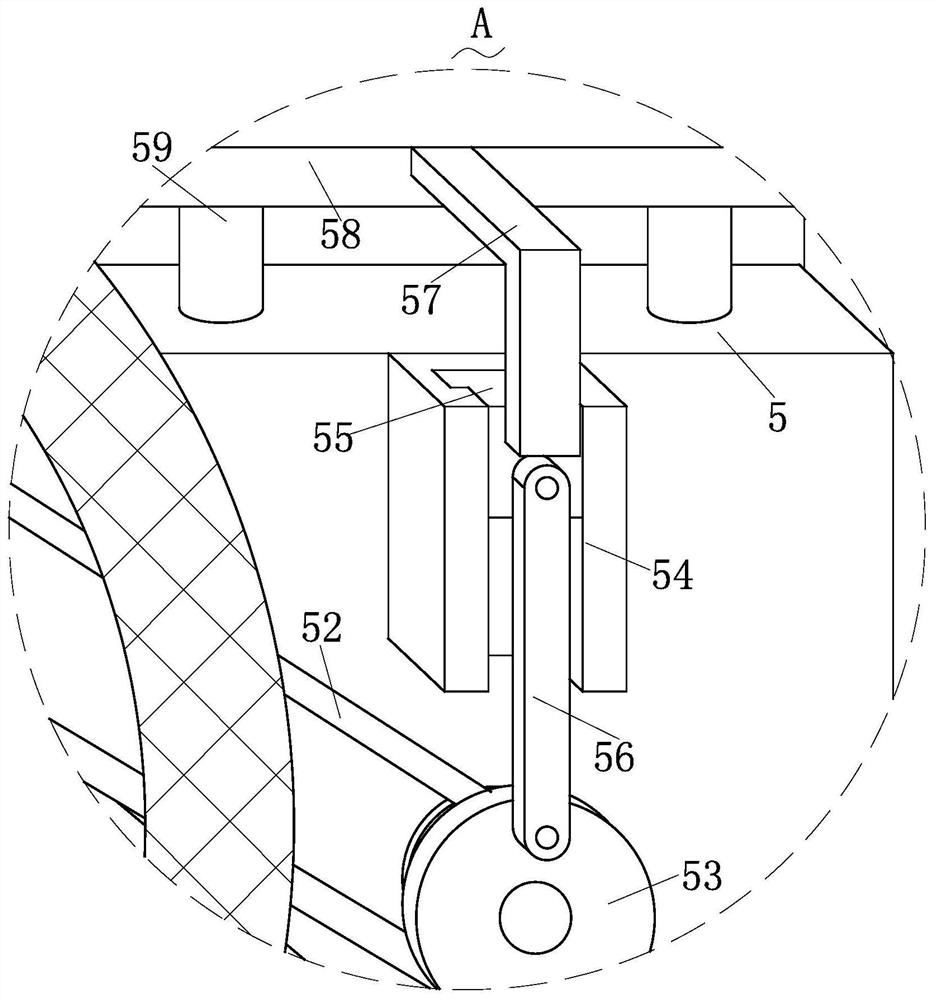

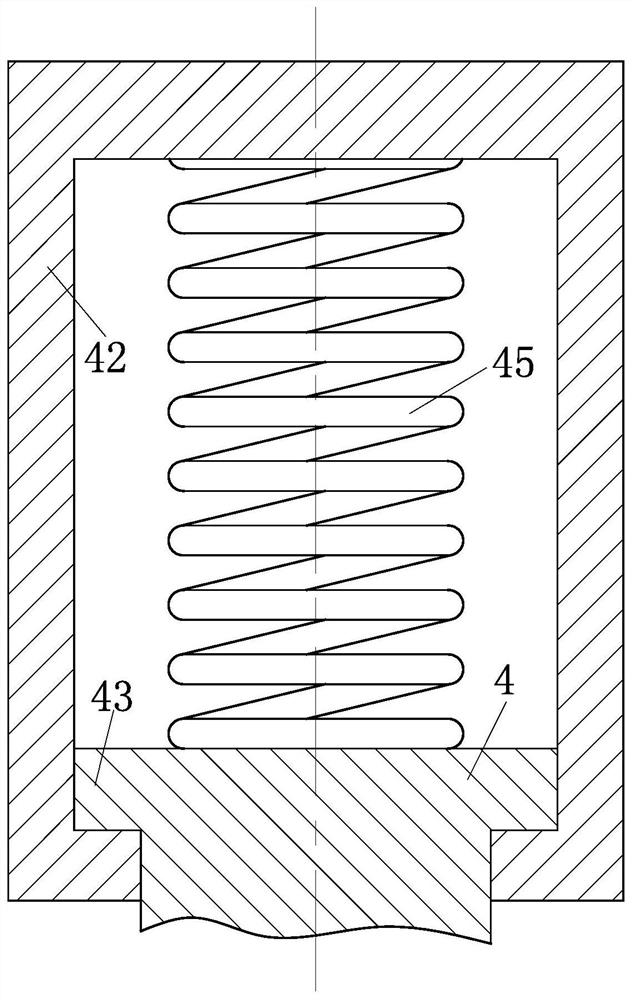

The invention relates to a capping device, in particular to an automatic capping device for beverage processing. The automatic capping device for beverage processing can conduct a large amount of capping operation and guarantee that the sealing performance of contained products in beverage bottles is good. The automatic capping device for beverage processing comprises a bottom plate, a capping mechanism, a rotating mechanism and a feeding mechanism, wherein a fixing base is arranged on one side of the top of the bottom plate, the capping mechanism is arranged between the side, close to the fixing seat, of the top of the bottom plate and the fixing seat, the rotating mechanism is arranged on the side, close to the capping mechanism, of the top of the bottom plate, and the feeding mechanismis arranged on the side, close to the rotating mechanism, of the top of the bottom plate. Workers place beverage bottles with beverage bottle caps not screwed on the top of a flat belt in sequence, adouble-shaft motor is started, the beverage bottles are conveyed to the position below a third rotating shaft through the flat belt and a second grooved wheel, and the third rotating shaft moves downwards in sliding grooves of a first shaft sleeve to screw the beverage bottle caps.

Owner:广州华农大食品科技有限公司

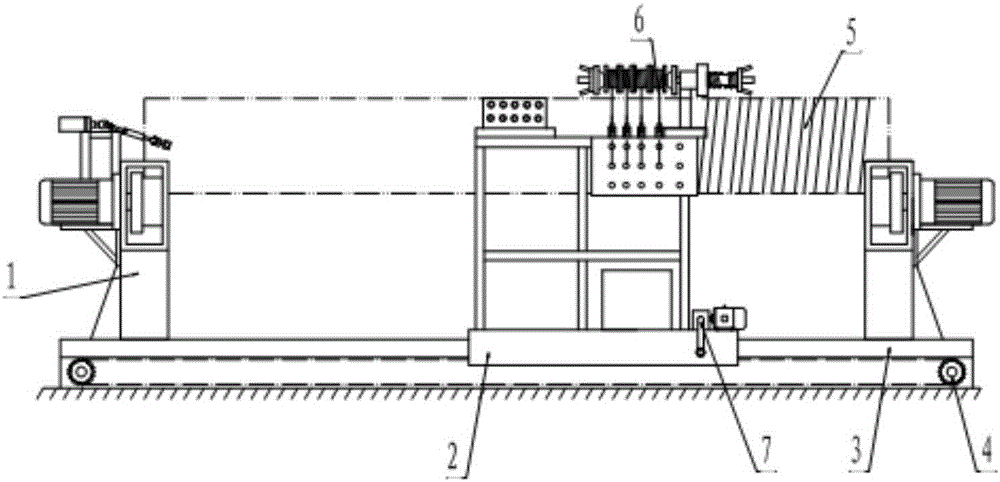

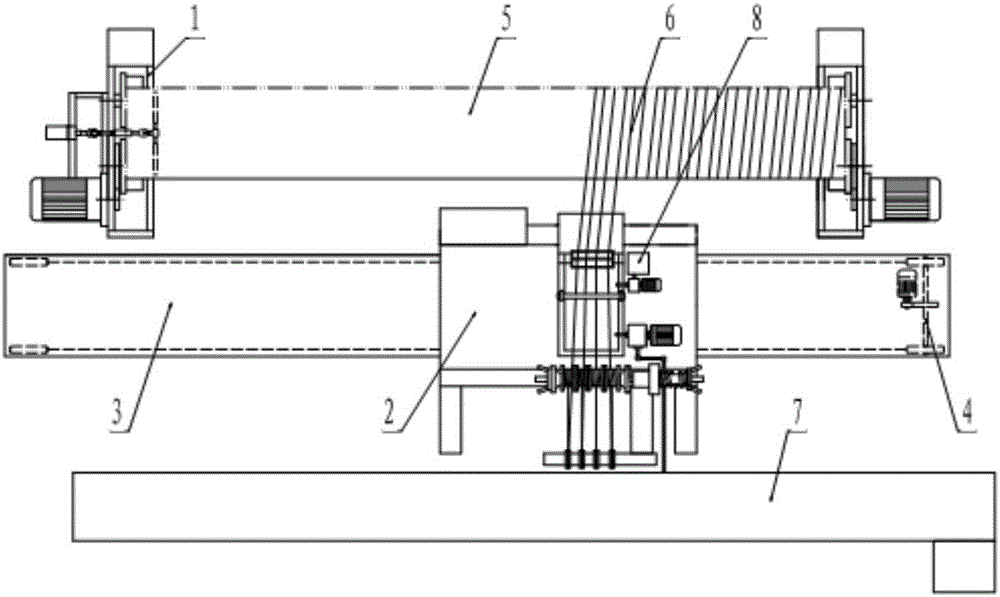

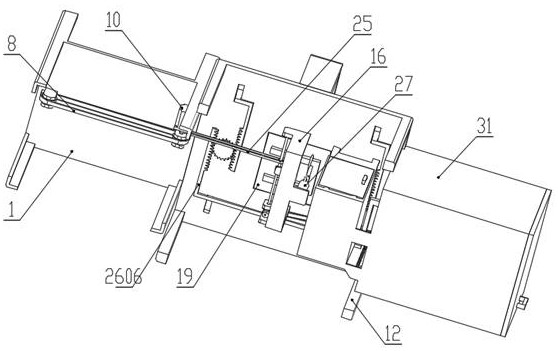

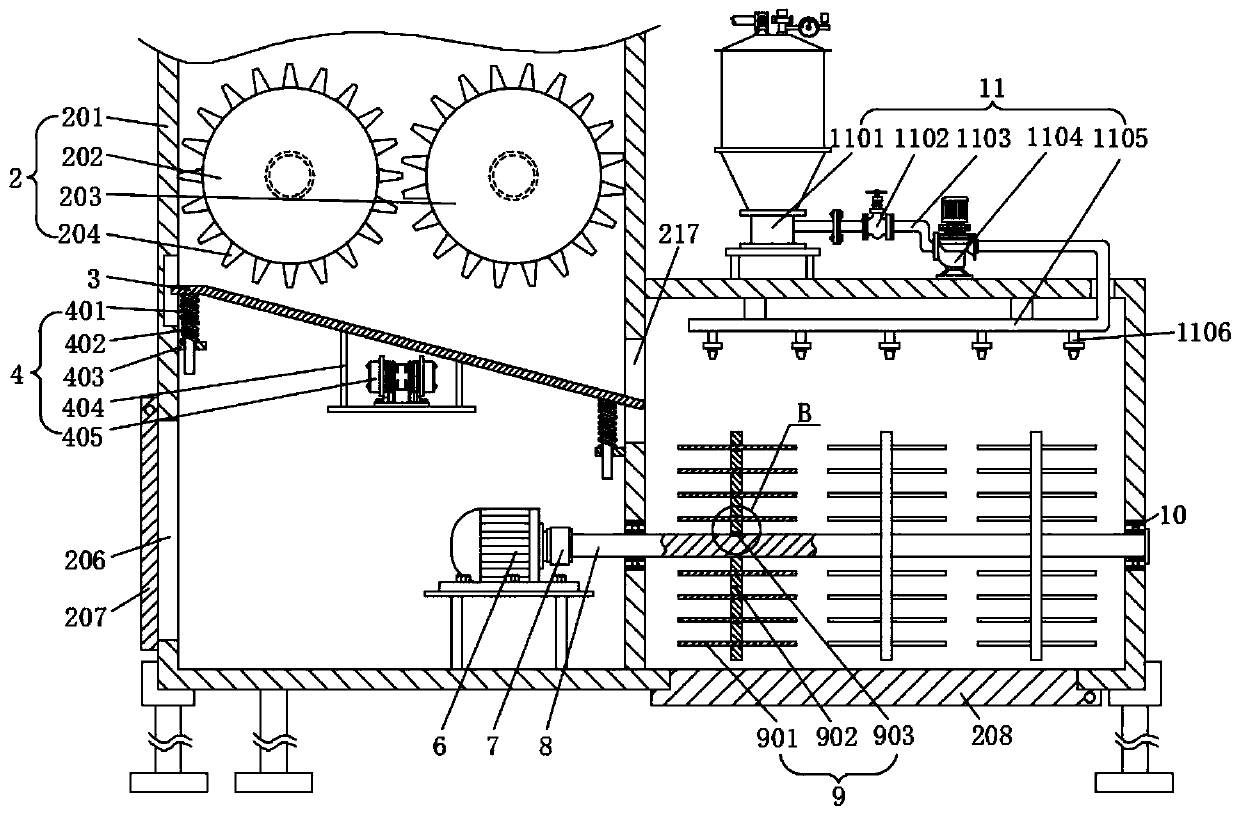

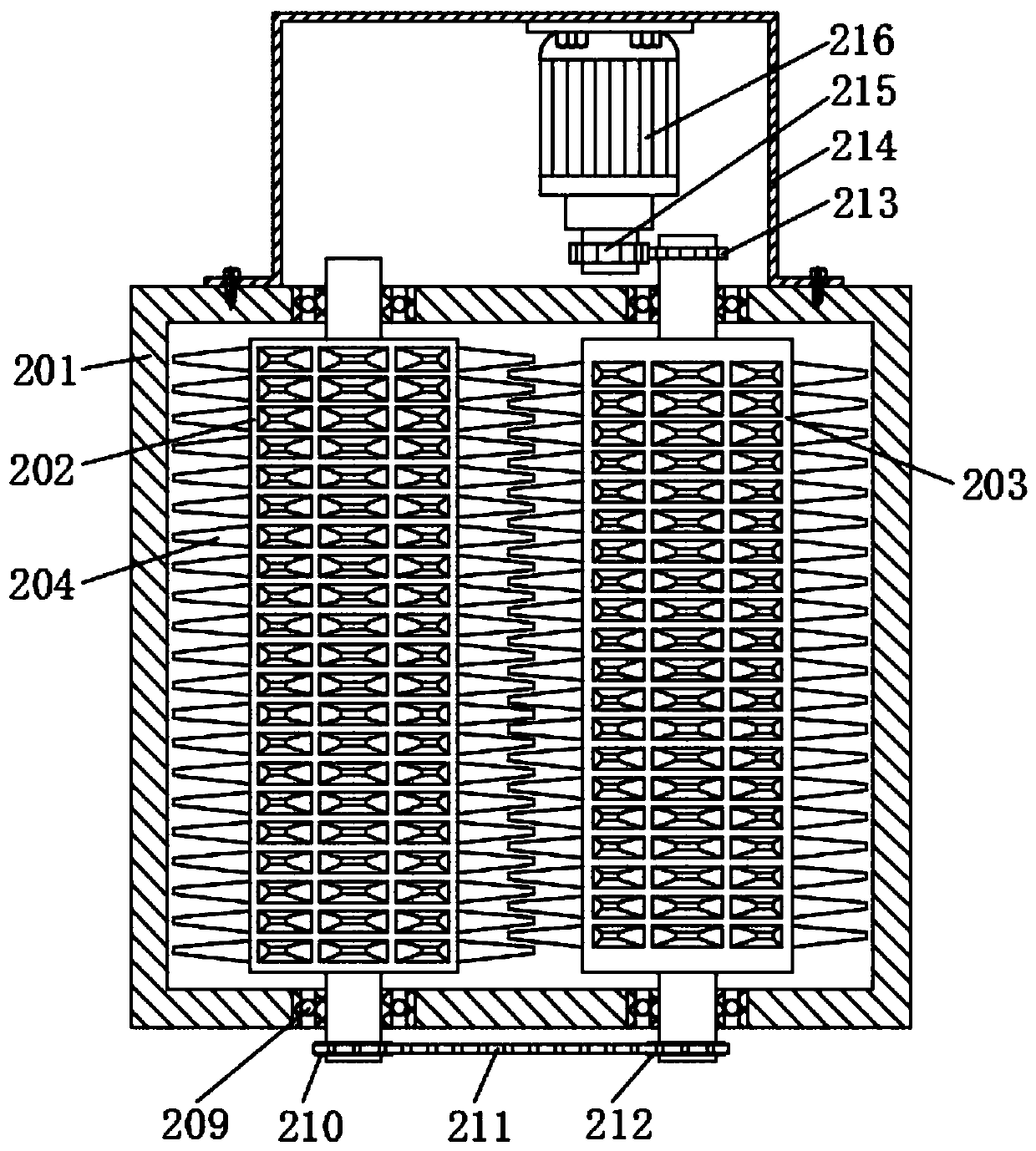

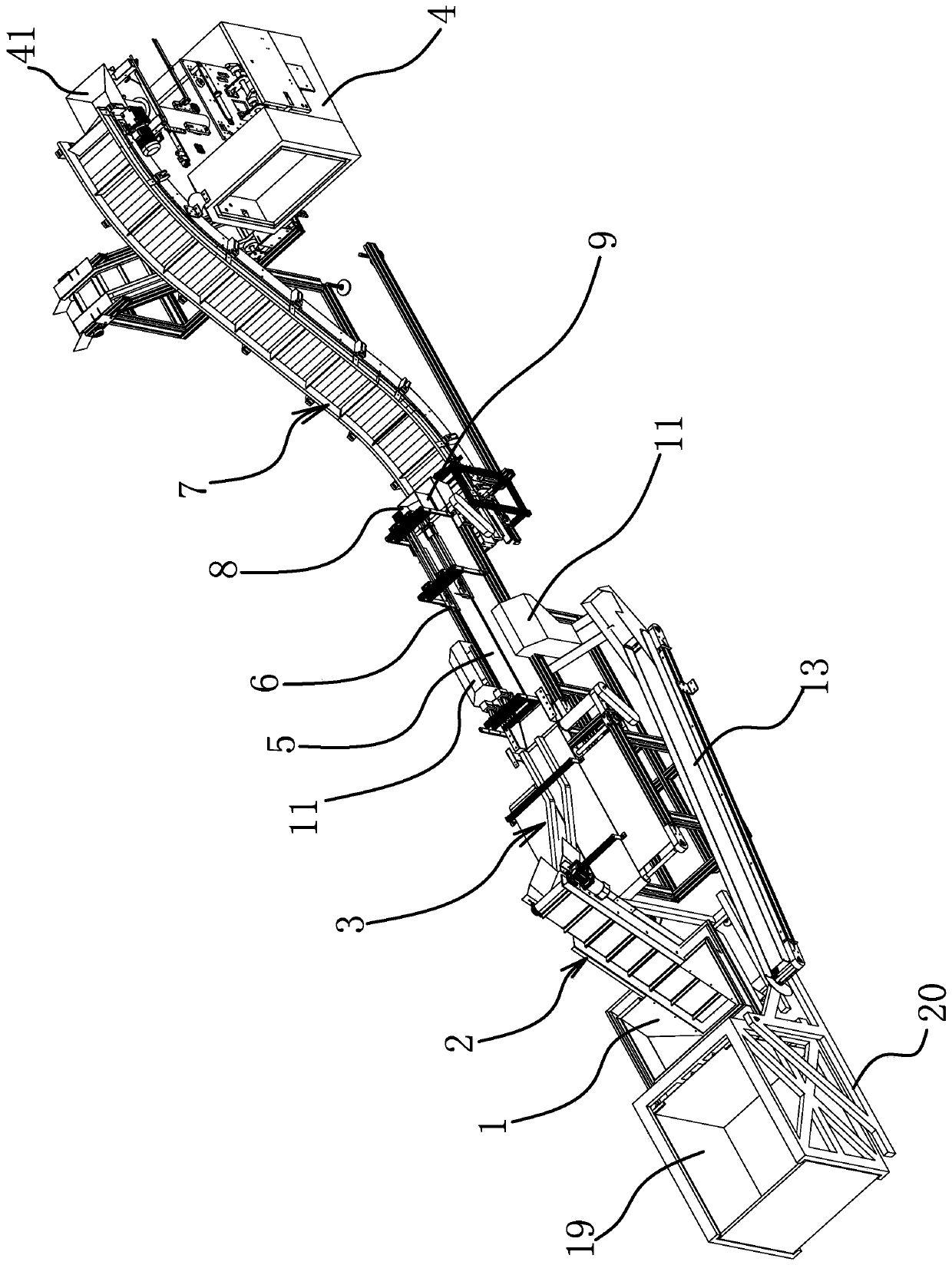

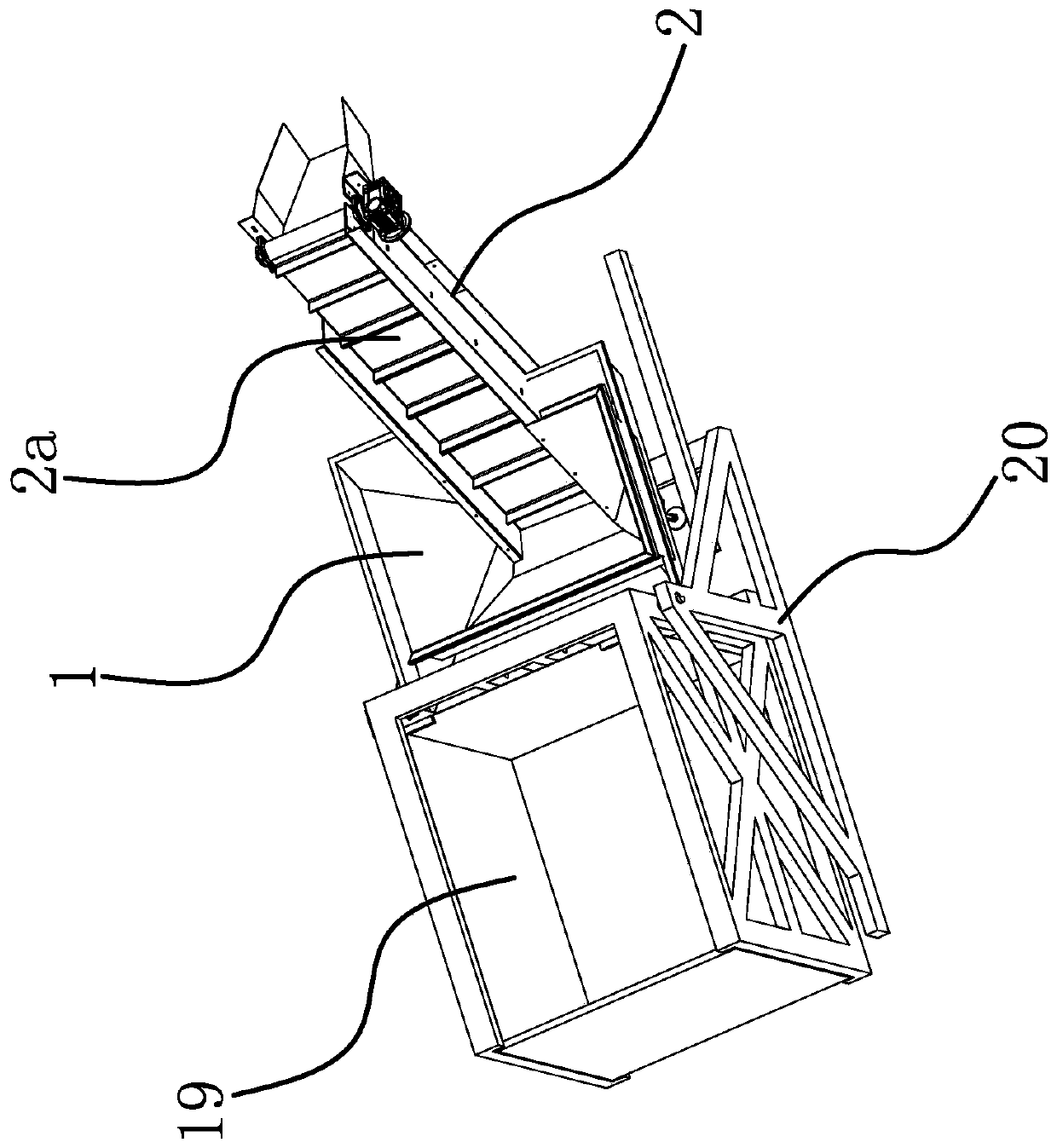

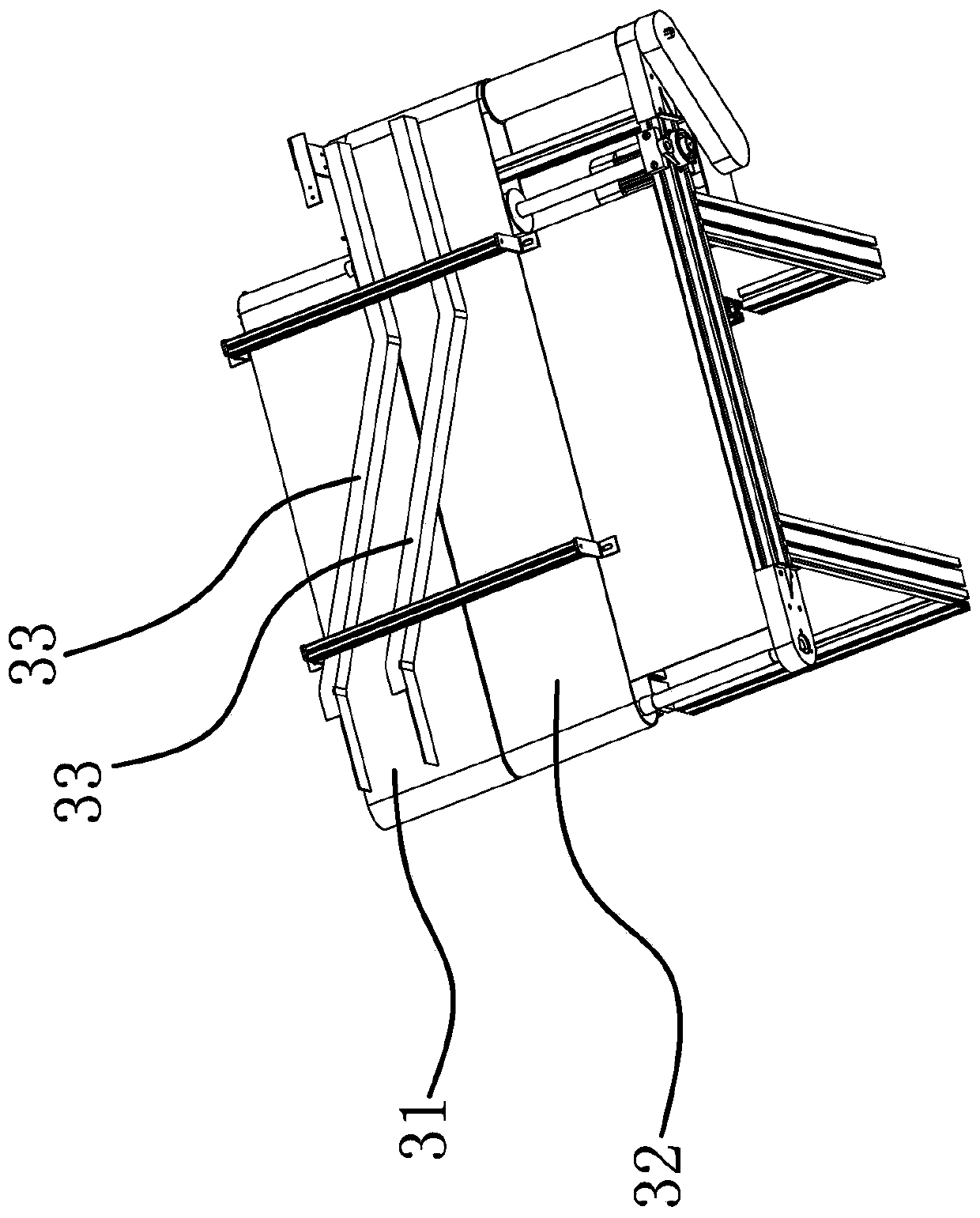

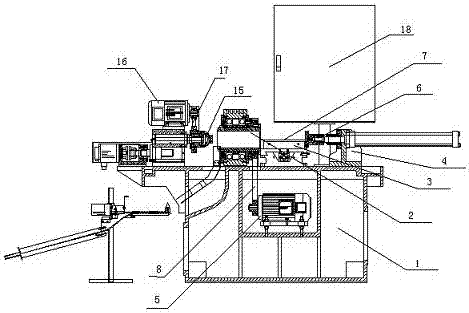

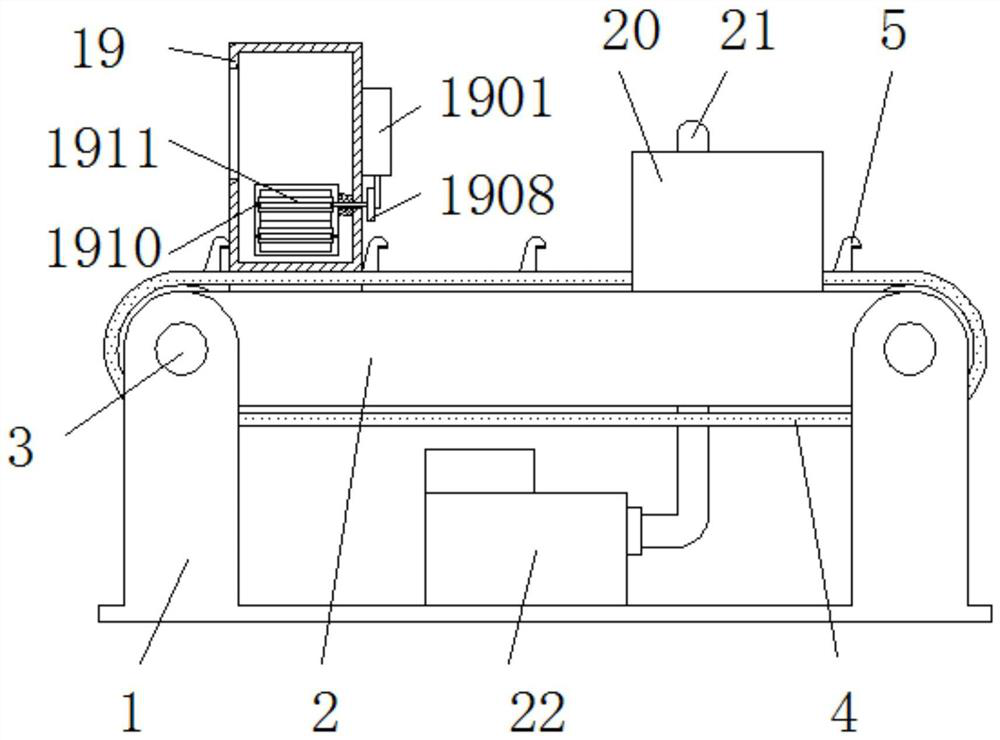

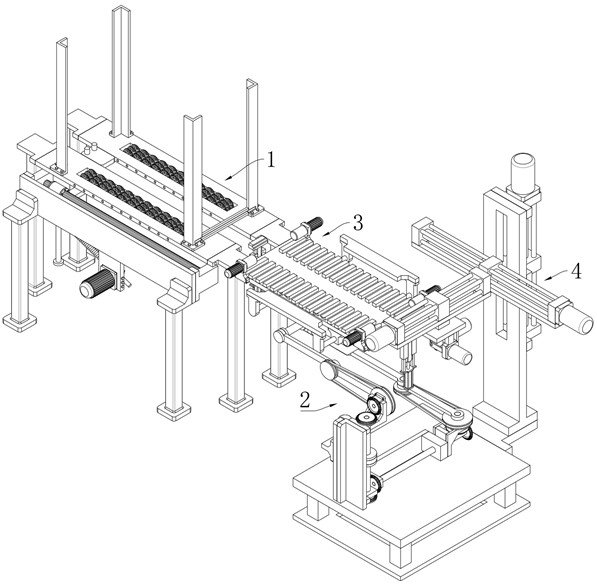

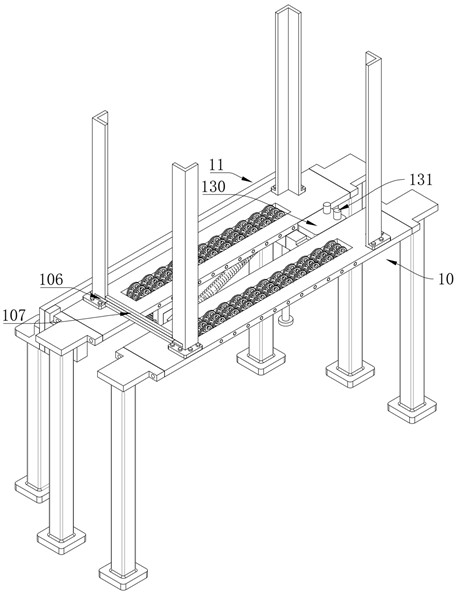

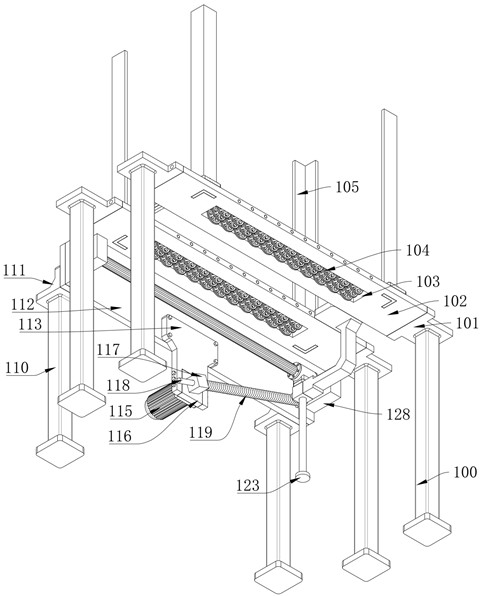

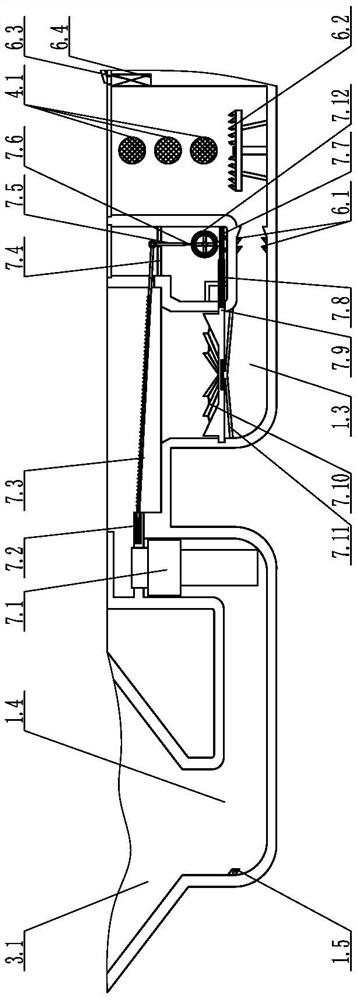

Forming equipment and process for glass steel wire outer protection anticorrosion pipe

InactiveCN106273383ARealize automatic feeding operationSolve the problem of corrosionTubular articlesGear transmissionSteel tube

The invention discloses forming equipment and a process for a glass steel wire outer protection anticorrosion pipe, and belongs to the technical field of manufacturing mechanical products. The forming equipment for the glass steel wire outer protection anticorrosion pipe comprises a workpiece supporting base, a wire winding trolley, a trolley moving guide rail and a trolley driving mechanism; the workpiece supporting base is composed of two parts arranged left and right, and each part is provided with a base, a workpiece rotating motor, a gear transmission mechanism and roller wheels, wherein the roller wheels include driving roller wheels and follow-up supporting roller wheels, and the workpiece rotating motor drives the driving roller wheels to rotate through a gear transmission mechanism to drive a steel pipe workpiece placed on the driving roller wheels and the follow-up supporting roller wheels to rotate; the trolley moving guide rail is fixed to one side of the workpiece supporting base in parallel, and the wire winding trolley and the trolley driving mechanism are assembled on the trolley moving guide rail. The working efficiency of winding glass steel wires is improved, and the winding quality of the glass steel wires is ensured.

Owner:TANGSHAN XINGBANG PIPE CONSTR EQUIP

Laser cutting device capable of conveniently and automatically separating workpieces

ActiveCN114309995AReduce labor intensityImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

The laser cutting device comprises a feeding platform and further comprises first supporting columns, limiting plates, a feeding groove and a pushing groove, the first supporting columns are fixedly connected to the periphery of the lower end face of the feeding platform, the limiting plates are connected to the periphery of the upper end face of the feeding platform, and the pushing groove is connected to the lower end face of the feeding platform. The feeding groove is formed in the right end face of the feeding platform, and the pushing groove is formed in the middle of the feeding platform. According to the laser cutting device, workpieces can be conveniently, automatically and continuously fed, so that the labor intensity of workers can be effectively reduced, the workpieces can be automatically clamped and loosened, the machining efficiency of the laser cutting device is improved, finished products and waste can be conveniently and automatically separated, the laser cutting efficiency is improved, and the production cost is reduced. And finished products and waste materials can be automatically stacked and arranged conveniently, so that the practicability of the laser cutting device is improved.

Owner:江苏天一门窗有限公司

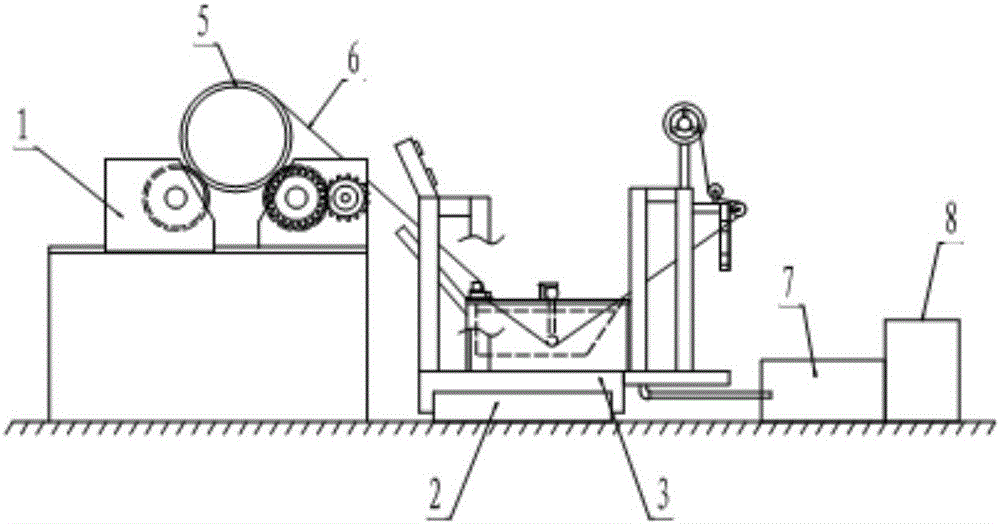

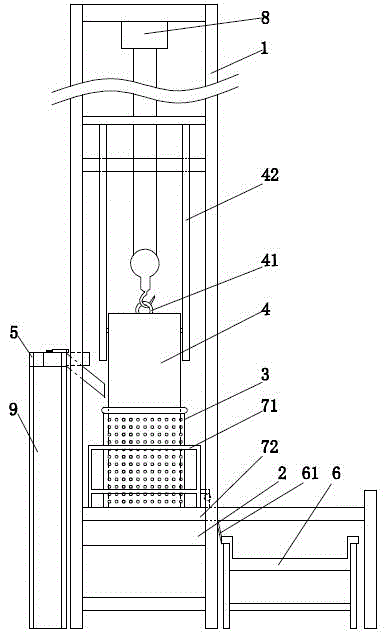

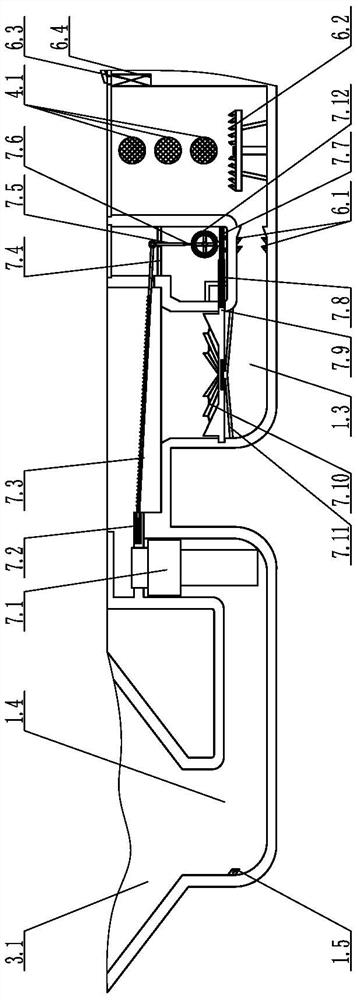

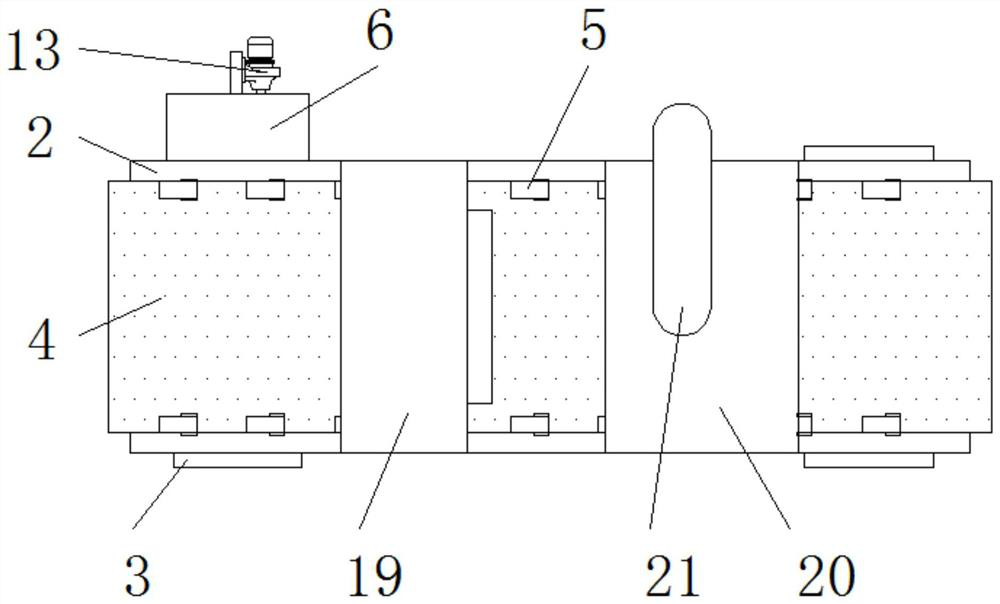

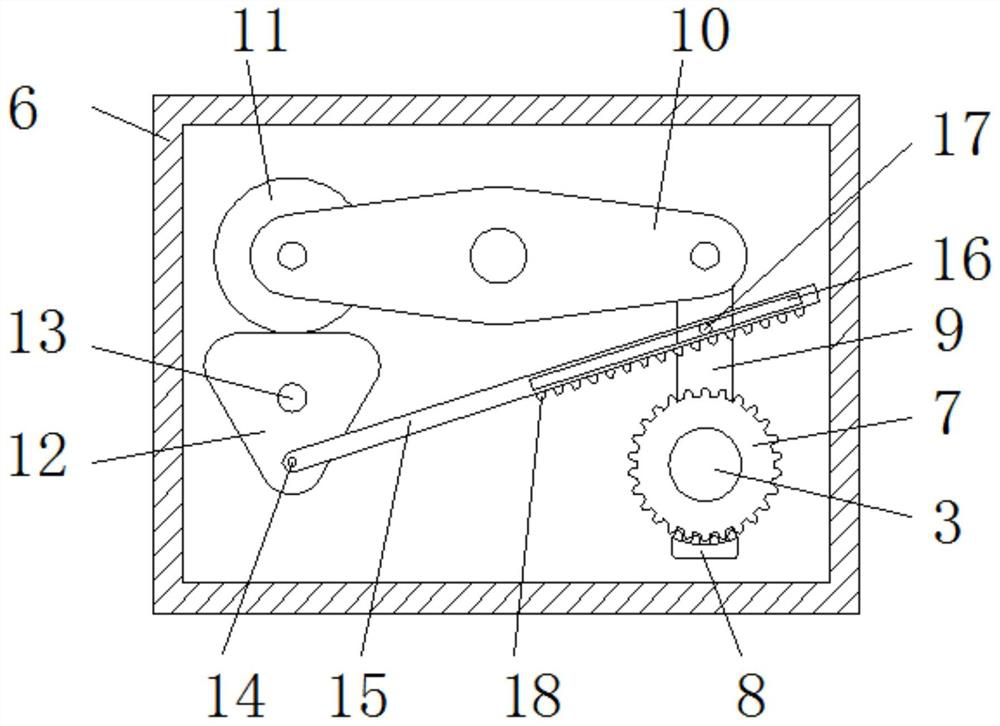

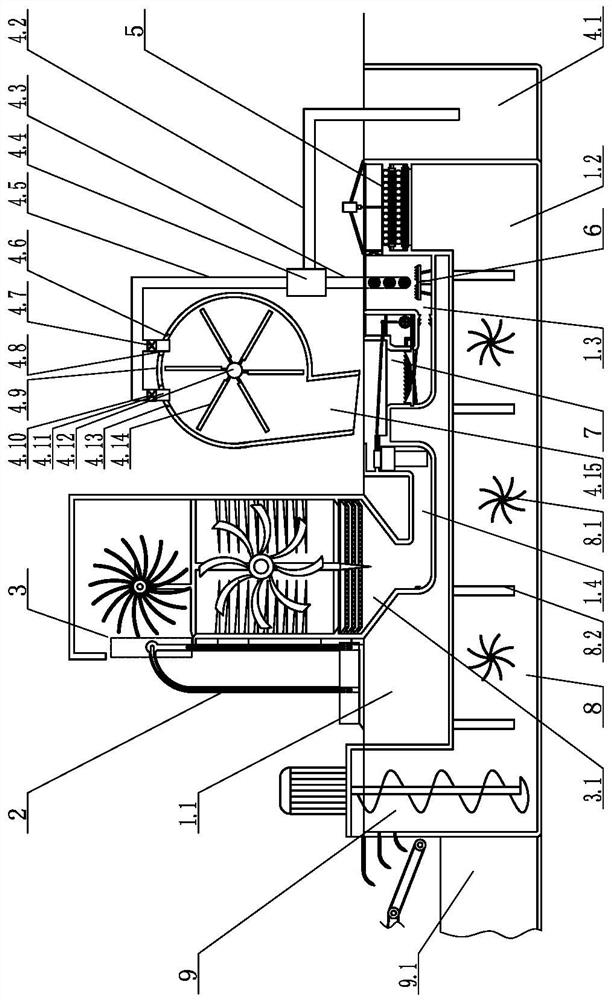

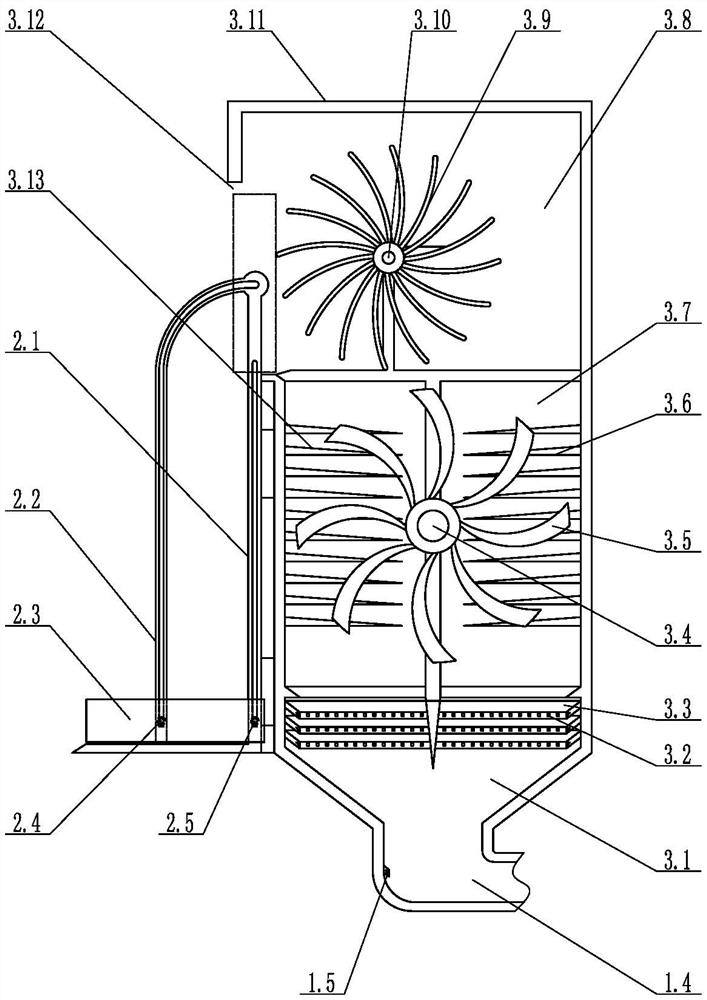

Semiautomatic settling type pickle squeezer

The invention discloses a semiautomatic settling type pickle squeezer, and belongs to the technical field of squeezing equipment. The semiautomatic settling type pickle squeezer comprises a machine frame, a squeezing platform, a bottomless filter tube, a solid squeezing tube, a feeding device, a material collecting device and a filter tube moving device, wherein the squeezing platform is arranged on the machine frame and is used for carrying the squeezing force, the bottomless filter tube is positioned on the squeezing platform, the solid squeezing tube is matched with the bottomless filter tube, the feeding device is used for feeding materials into the bottomless filter tube, the material collecting device is in seamless connection with the squeezing platform, the filter tube moving device is used for moving the bottomless filter tube to a position above the material collecting device, and the solid squeezing tube is connected with a lifting device driving the solid squeezing tube to ascend and descend. Great gravity of the solid squeezing tube per se is used for squeezing food materials and extruding water, the squeezing platform achieves a support effect on the solid squeezing tube, the pressure is greatly increased, the consumed squeezing time is short, the production efficiency is improved, the settling design is adopted, an additional pressure exertion element is not needed, and the structure is simpler and more effective.

Owner:四川红七公食品有限公司

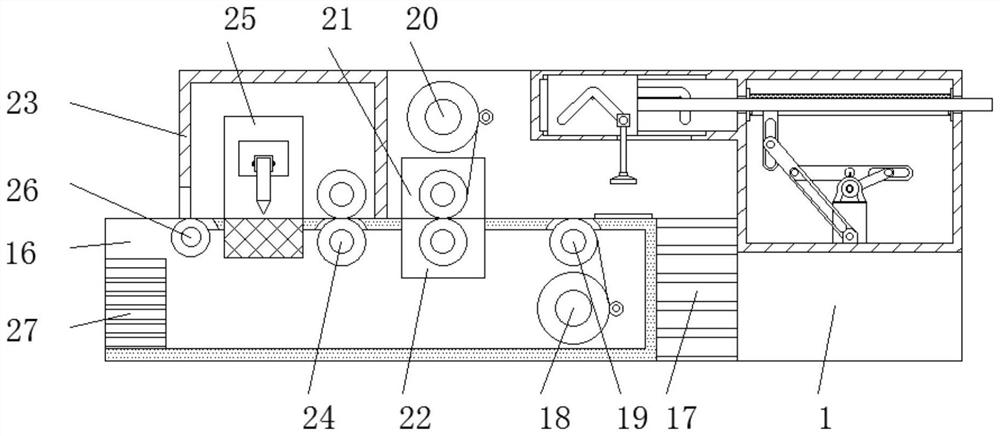

Coated paper film laminating machine auxiliary equipment

PendingCN112406257ARealize automatic feeding operationRealize lifting and calibration operationLamination ancillary operationsSpecial paperElectric machineryElectrical and Electronics engineering

The invention discloses coated paper film laminating machine auxiliary equipment which comprises a feeding frame, a motor is fixedly installed on the inner wall of the feeding frame, a first connecting rod is connected to the output end of the motor in a screwed mode, and a first rotating plate is connected to the end, away from the motor, of the first connecting rod in a screwed mode. In the coated paper film laminating machine auxiliary equipment, through arrangement of the moving plate, in the feeding frame, a motor rotates to drive a first connecting rod to rotate, the first connecting roddrives a first rotating plate to rotate through a first groove, the first rotating plate drives a second rotating plate to rotate through a second groove, the rotating angle of the second rotating plate is 120 degrees, and the second rotating plate drives a telescopic rod to slide in a telescopic cylinder barrel through a first pore plate; then the sliding length of the telescopic rod is equal tothe horizontal length of the fourth groove, the telescopic rod drives the movable plate to move, the movable plate drives the movable block to slide along the fourth groove through the third groove,wherein the third groove is in an inverted V shape and the fourth groove is in a U shape; the movable block drives the suction cup to move, and automatic feeding operation of coated paper is achieved.

Owner:华峰君

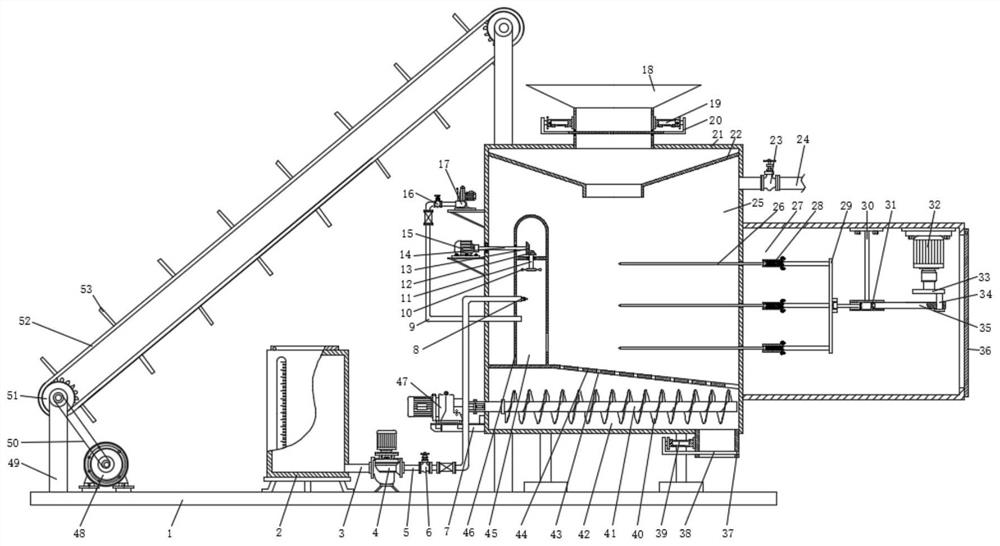

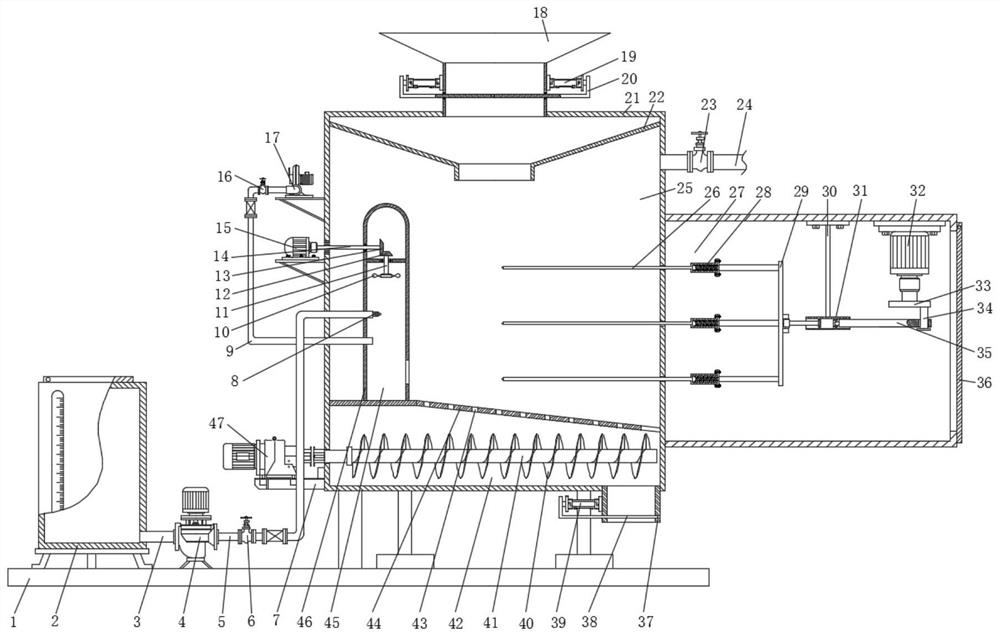

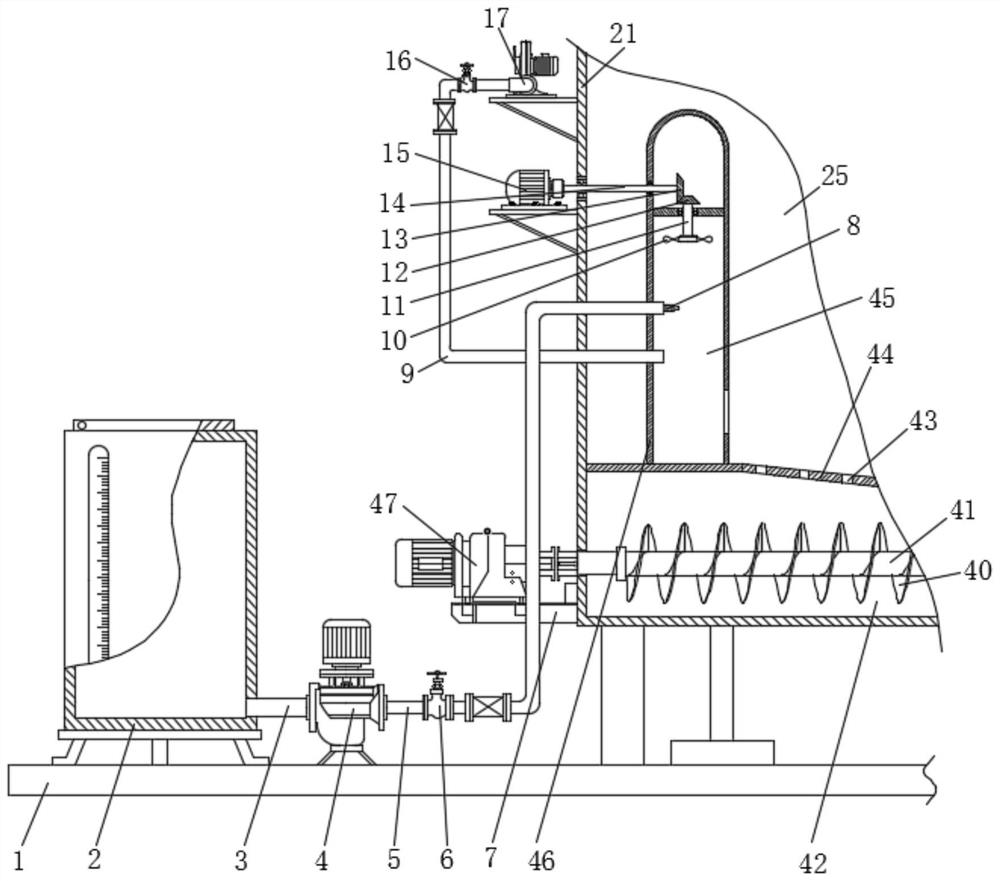

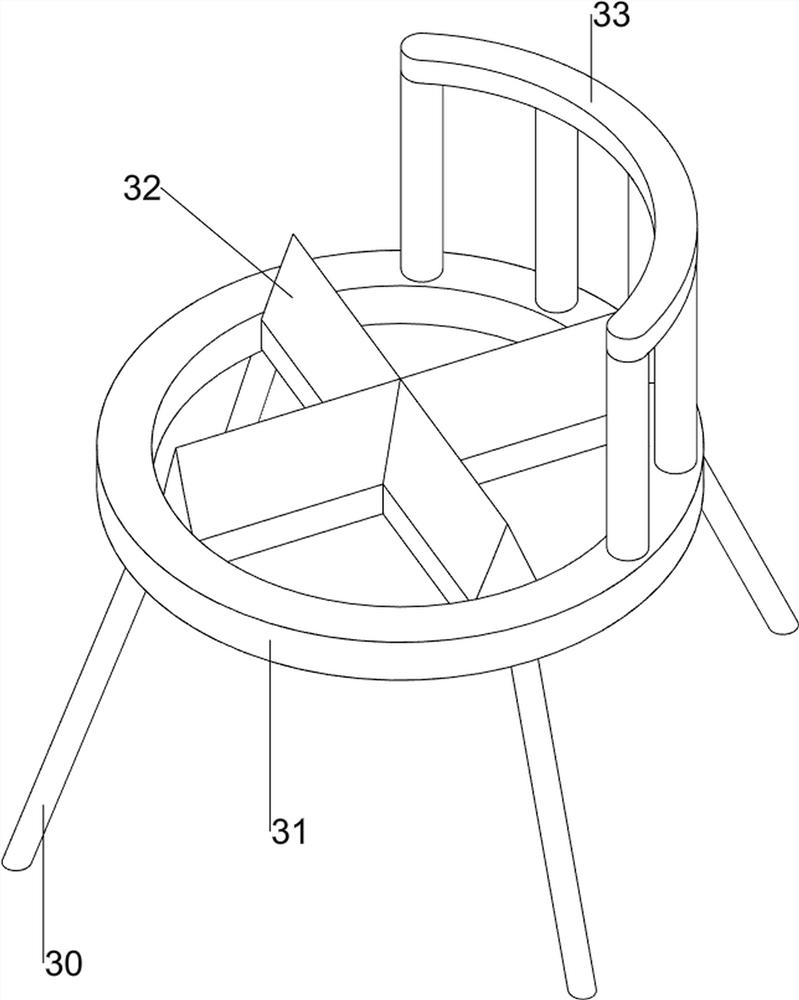

Chemical dissolving device for reduction, recycling and harmless treatment of sludge

PendingCN111453952AHigh degree of mechanizationLow costShaking/oscillating/vibrating mixersSludge treatmentSludgeProcess engineering

The invention discloses a chemical dissolving device for reduction, recycling and harmless treatment of sludge, belonging to the technical field of sludge treatment. The chemical dissolving device comprises a crushing assembly and a conveying assembly, wherein the conveying assembly comprises a feeding shell; a feeding cylinder is arranged at the upper end of the feeding shell; a discharging cylinder is arranged at the bottom of the right side of the feeding shell; the discharging cylinder is positioned right above a hopper; the hopper is arranged at the center of the top of a case body; a material stirring assembly is arranged in the hopper; a driven crushing roller and a driving crushing roller are arranged in the case body; a material guiding plate is obliquely and movably arranged below the case body; the right end of the material guiding plate is located in a discharging port; a vibration assembly is arranged at the bottom of the material guiding plate; a stirring rotating shaft is arranged on the right side of the discharging port; a combined stirring assembly is arranged on the stirring rotating shaft; and a dosing assembly is arranged above the combined stirring assembly. According to the invention, automatic feeding operation of river sludge can be realized, crushed sludge and a sludge treatment chemical are fully mixed and uniformly stirred, the waste of the sludge treatment chemical is avoided, and sludge treatment cost is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

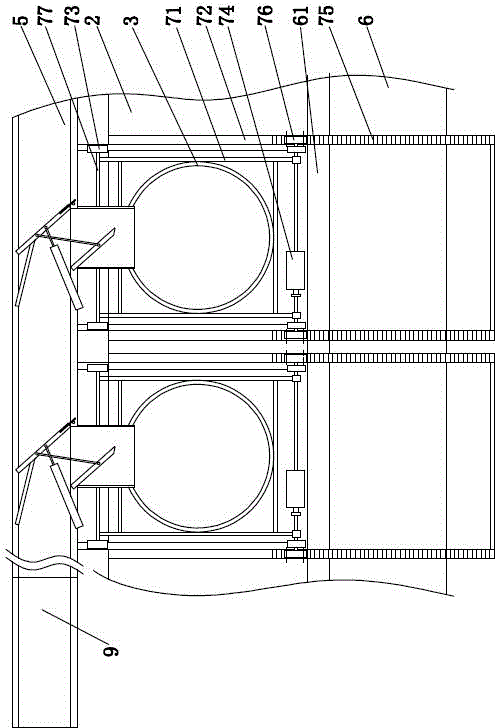

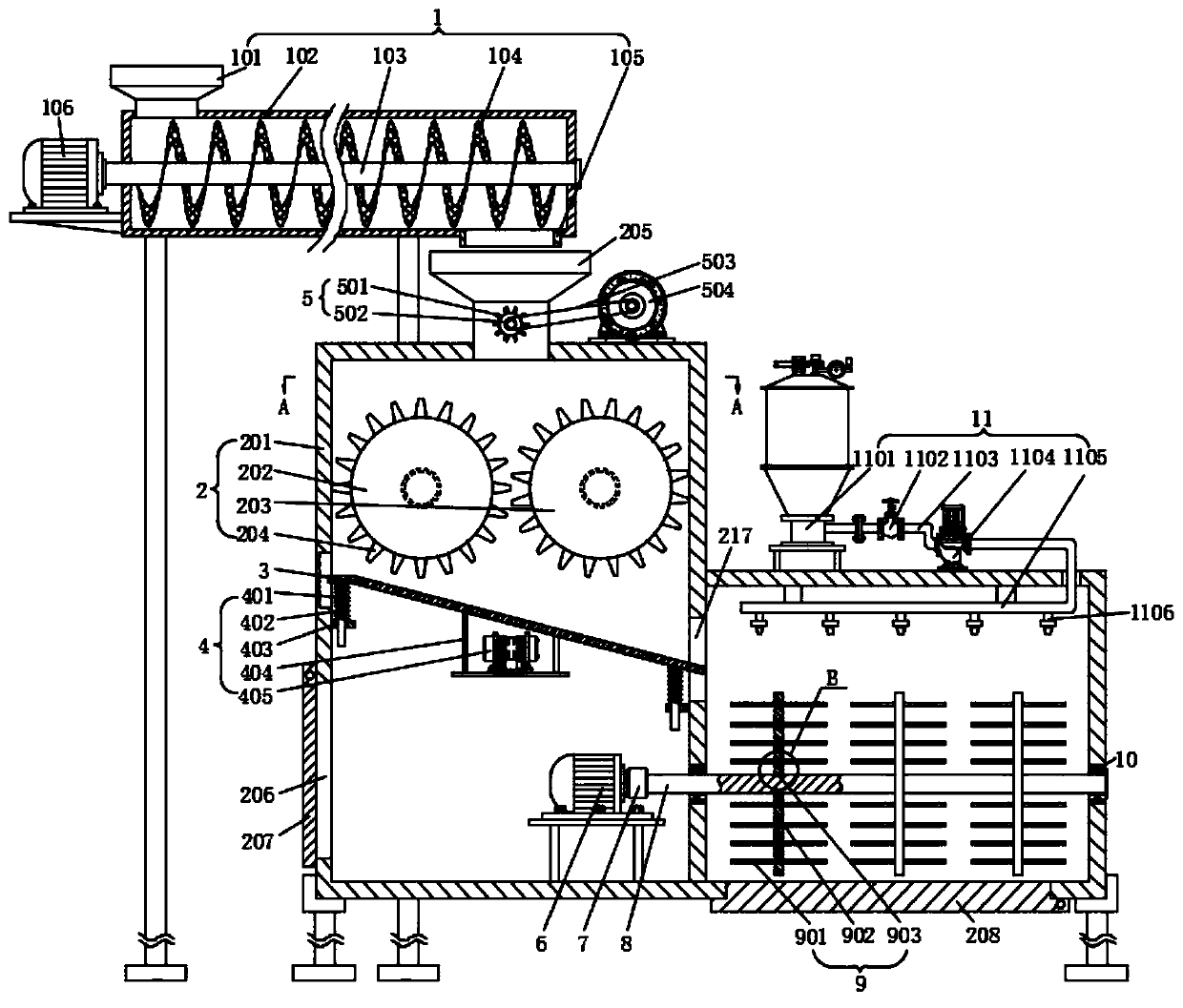

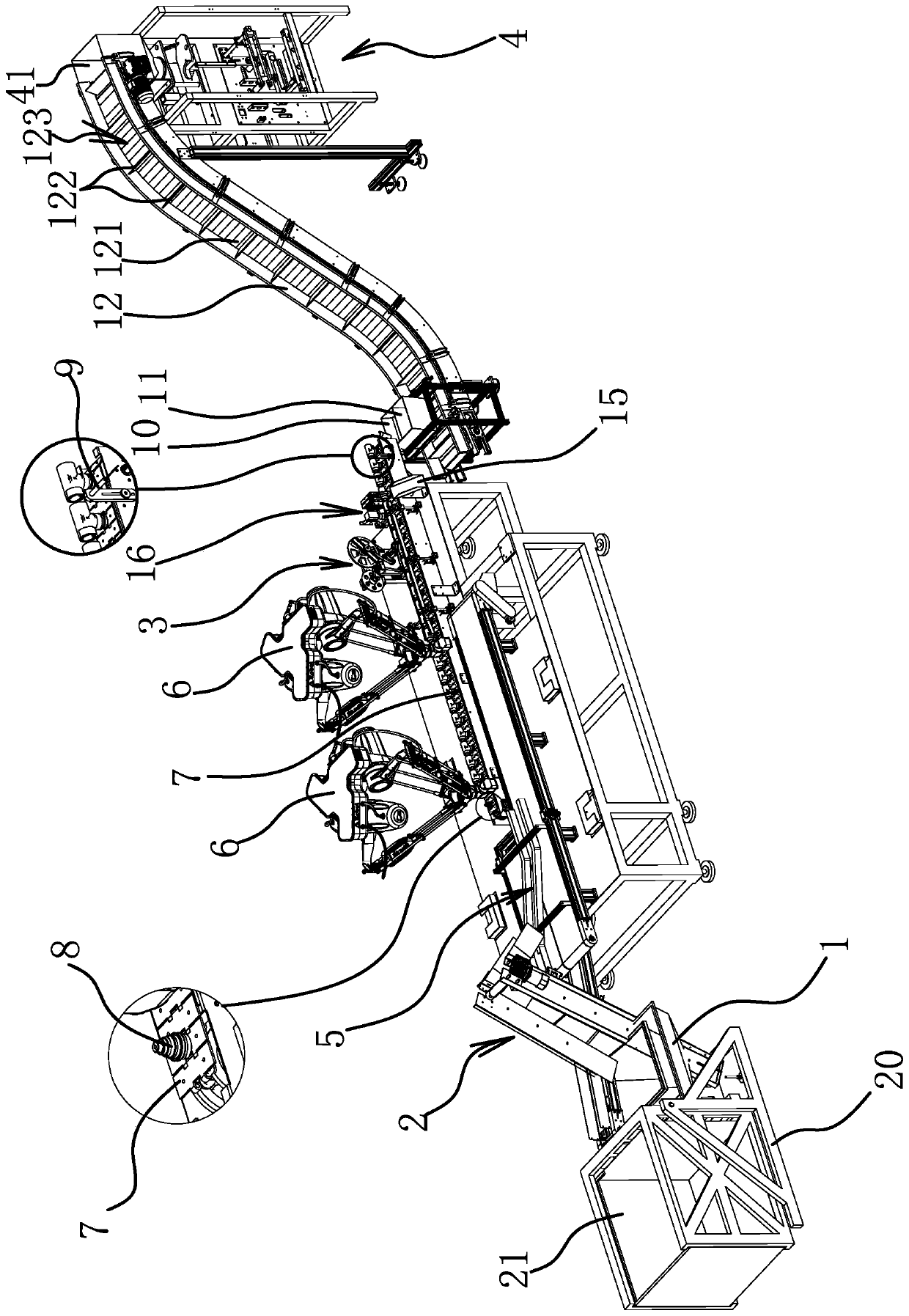

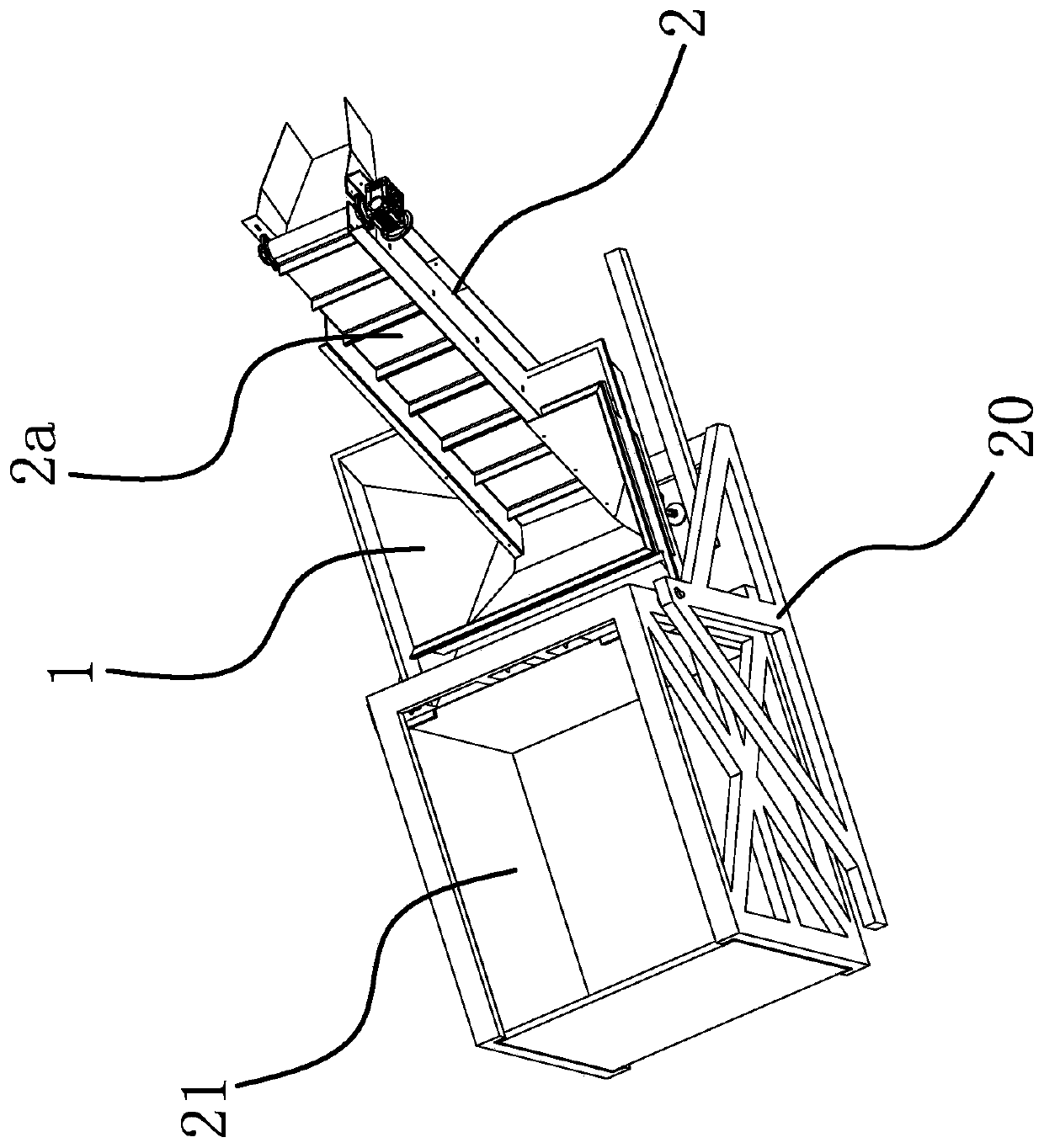

Efficient environment-friendly papermaking production line

ActiveCN112342811AQuality improvementReduce labor intensityWashing/displacing pulp-treating liquorsPaper recyclingPaper dustPapermaking

The invention relates to an efficient environment-friendly papermaking production line, belonging to the technical field of papermaking mechanical equipment. The efficient environment-friendly papermaking production line is characterized by comprising pulping equipment, wherein a feeding device of the pulping equipment can feed waste paper raw materials into a coarse crushing device; the coarse crushing device can crush the waste paper raw materials into coarse paper pulp; the coarse paper pulp is conveyed into a screening device through water flow assistance; the coarse paper pulp enters a pulp washing device after being screened and filtered by the screening device; and the pulp enters a fine grinding device after being cleaned by the pulp washing device, and enters a storage device after being finely ground by the fine grinding device. According to the invention, fine paper pulp can be finally obtained through automatic feeding, coarse crushing, paper material circulating and infiltrating, screening and paper scrap grinding and refining, and is stored for papermaking operation.

Owner:山东海天造纸机械有限公司

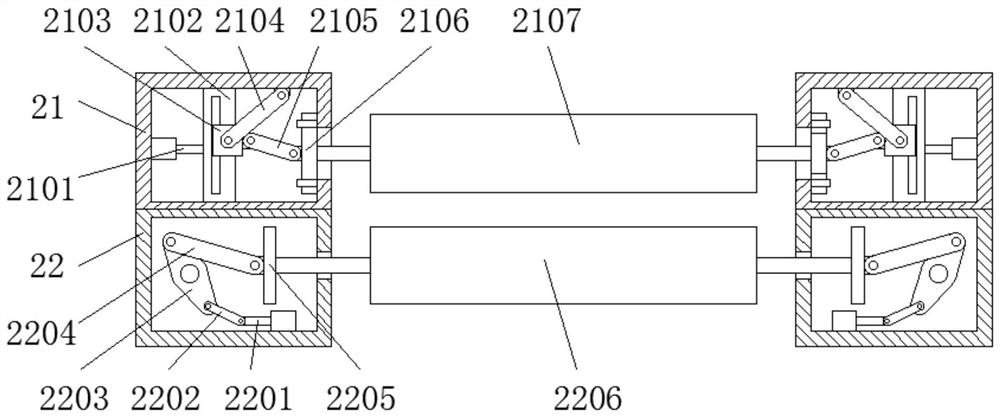

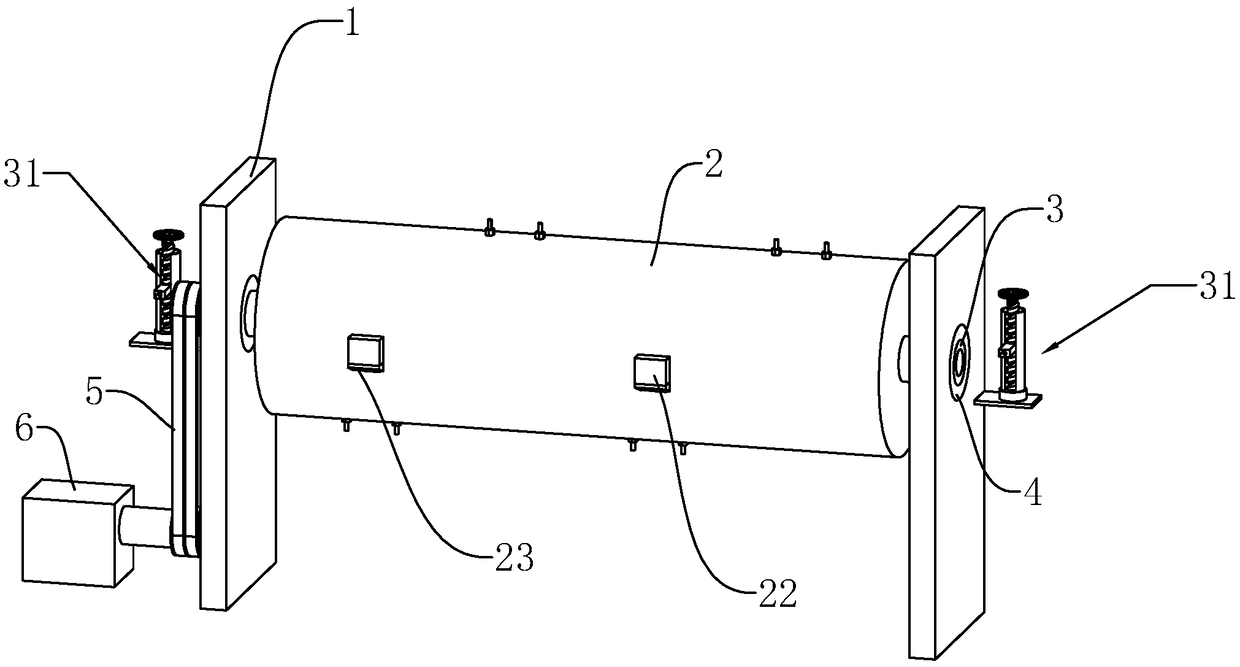

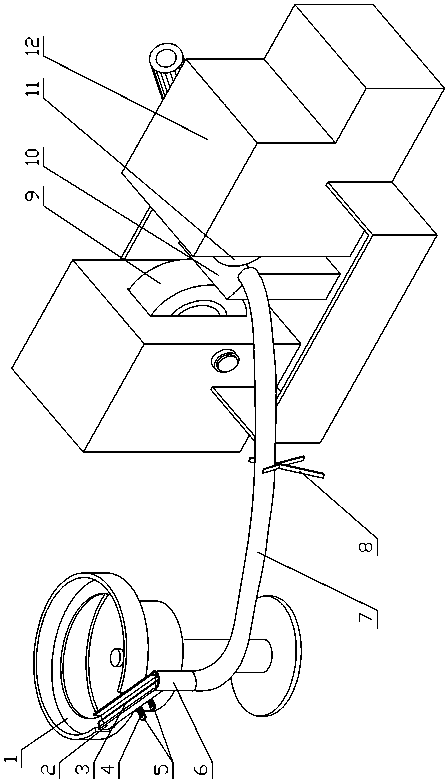

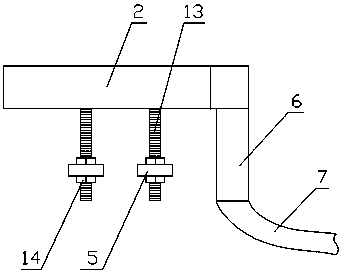

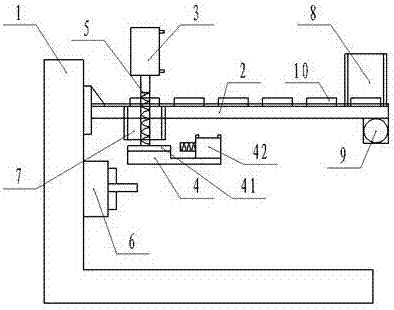

Straightening device for spring machine

ActiveCN109365679ARealize automatic feeding operationRealize the operationWire springsMetal working apparatusDrive motorEngineering

The invention discloses a straightening device for a spring machine. The straightening device comprises a rotating roller arranged between two supports, a rotating shaft with a through hole is fixedlyconnected to the two ends of the rotating roller, and a bearing base is arranged between each rotating shaft and each support, and one end of one of the rotating shafts penetrating supports is linkedwith a driving motor through a belt. The rotating roller adopts internal hollowed-out arrangement, a plurality of fixed rods which are arranged in a staggered mode are uniformly arranged on a shell of the rotating roller in a penetrating mode, two sides, on the outer shell of the rotating roller, of each fixed rod is provided with six angle nuts, a wire feeding mechanism capable of automaticallyadjusting clamping force of the steel wire spring wire is arranged at one end, in the rotating roller, of each fixing rod, the plurality of wire feeding mechanisms are located on the same plane with the through hole of the rotating shaft, and a detection mechanism for detecting and correcting precision is arranged on each support. The straightening device has the following advantage that the steelwire spring wire with large fluctuation of the outer diameter and the thickness can be automatically adjusted to clamp the force, so that wire feeding and straightening operation can be carried out at the same time.

Owner:济宁高新科达科技项目服务有限公司

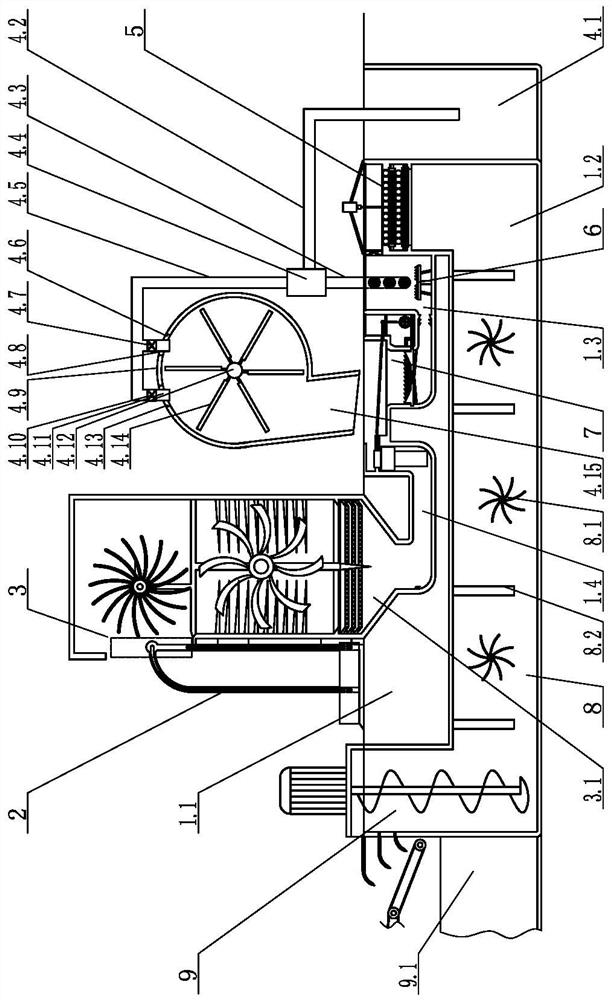

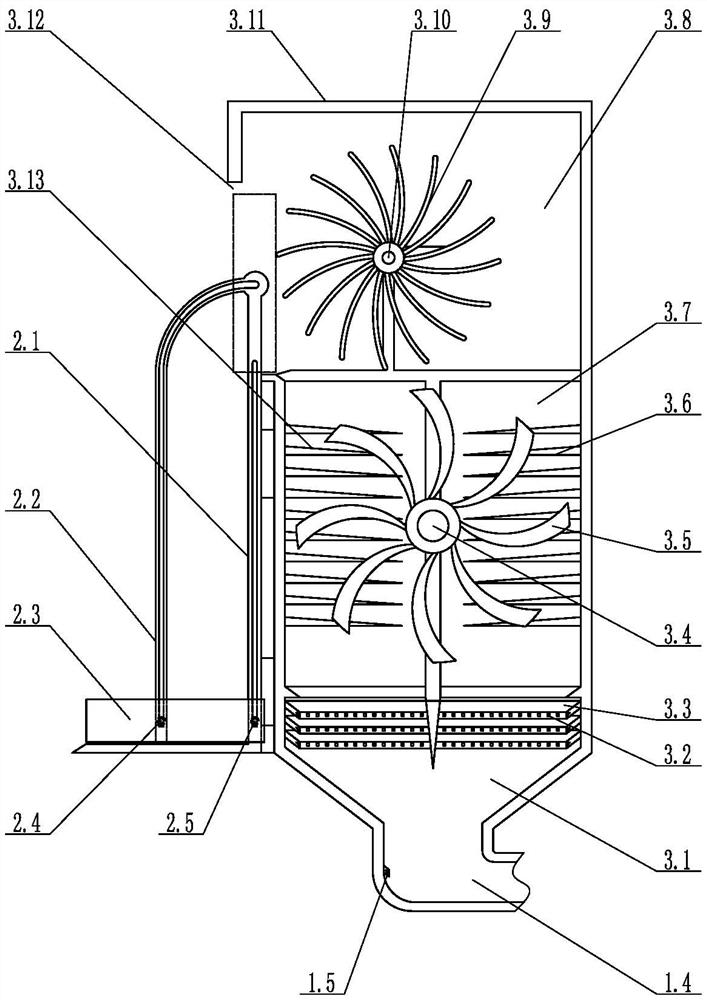

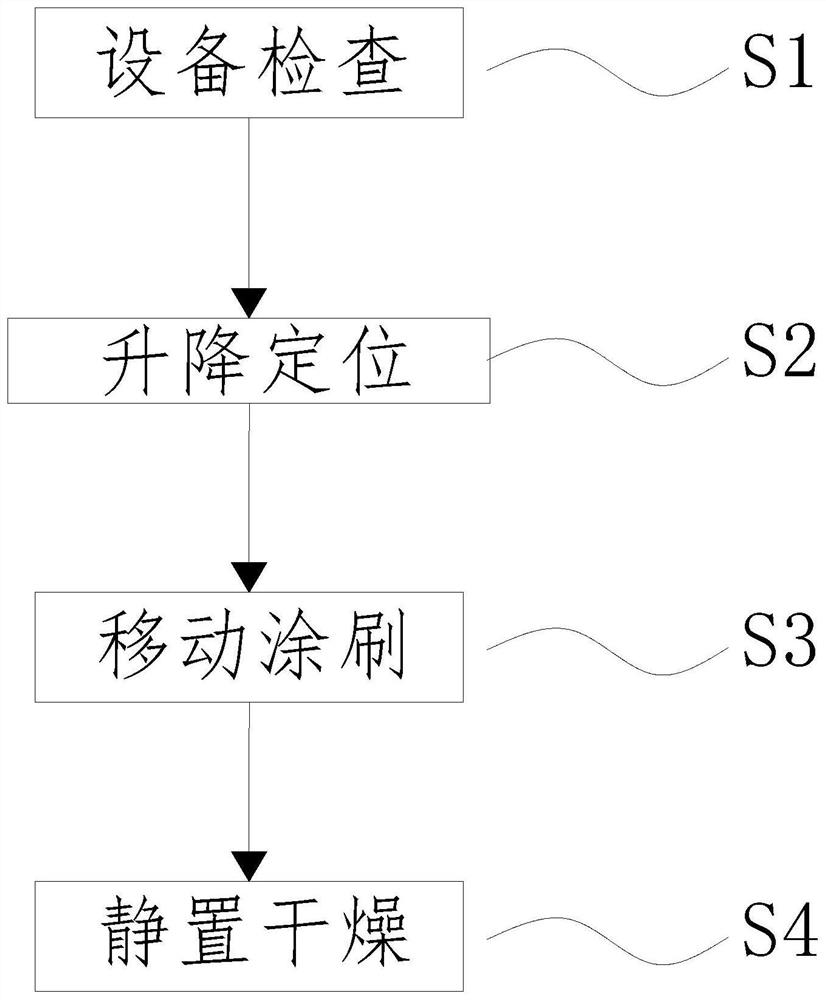

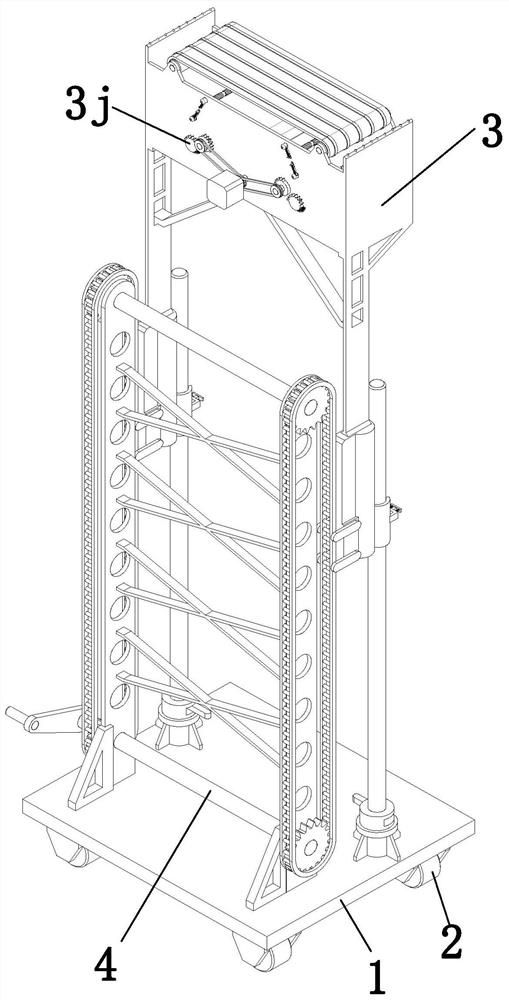

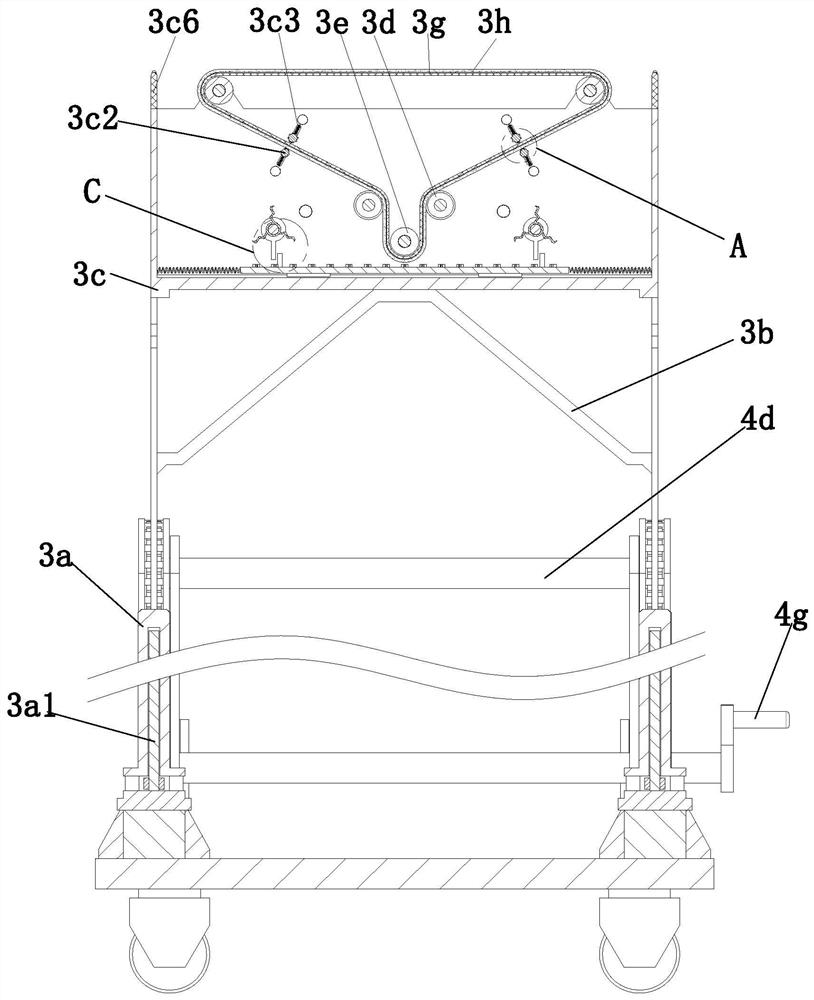

Waterproof coating brushing method for building waterproof construction

InactiveCN113235877AReduce the possibility of shakingReduce workloadRotary stirring mixersTransportation and packagingArchitectural engineeringBrush device

The invention relates to a waterproof coating brushing method for building waterproof construction. A waterproof coating brushing device for low-building waterproof construction is used, and the waterproof coating brushing device for building waterproof construction comprises a mounting bottom plate, universal wheels, a brushing mechanism and a lifting mechanism. The problems that in the waterproof coating brushing process for building waterproof construction, it is difficult to adapt to height changes of walls in different rooms, it is difficult to collect splashed and fallen waterproof coating when wall surfaces are brushed, it is difficult to keep the brushing strength of all areas uniform and consistent, it is difficult to achieve automatic feeding operation of the waterproof coating, and the stacked waterproof coating is more difficult to be continuously stirred in the brushing operation process so as to reduce deposition and condensation of the waterproof coating are solved.

Owner:高杰

Full-automatic pipe joint counting and packaging equipment

PendingCN110254866AGuaranteed accuracyFully automatedPackaging automatic controlPackaging machinesImpellerEngineering

The invention provides full-automatic pipe joint counting and packaging equipment and belongs to the technical field of machines. The equipment achieves the technical purpose that the pipe joint packaging quantity accuracy is guaranteed while the production efficiency is improved. The equipment comprises a stock bin, a feeding machine, a bagging and sealing machine and a sorting and conveying mechanism. A counting and conveying device is arranged between the bagging and sealing machine and the output end of the sorting and conveying mechanism. The counting and conveying device comprises a counting conveying belt connected with the output end of the sorting and conveying mechanism, a counting sensor arranged above the counting conveying belt, and a definite number conveyor with the output end being connected with a feeding inlet of the bagging and sealing machine. A storage chamber provided with a through cavity is arranged at the output end of the counting conveying belt. An impeller capable of blocking the through cavity is rotationally connected into the through cavity. The definite number conveyor comprises receiving grooves, wherein one receiving groove is located under the storage chamber. The counting and packaging equipment provided by the invention achieves full-automatic feeding, sorting, counting and definite number packaging, and the production efficiency is greatly improved.

Owner:ZHEJIANG YUANBANG INTELLIGENT EQUIP CO LTD

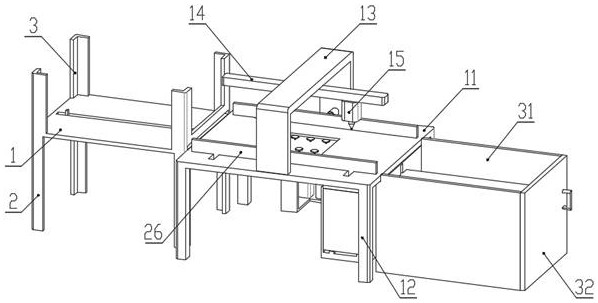

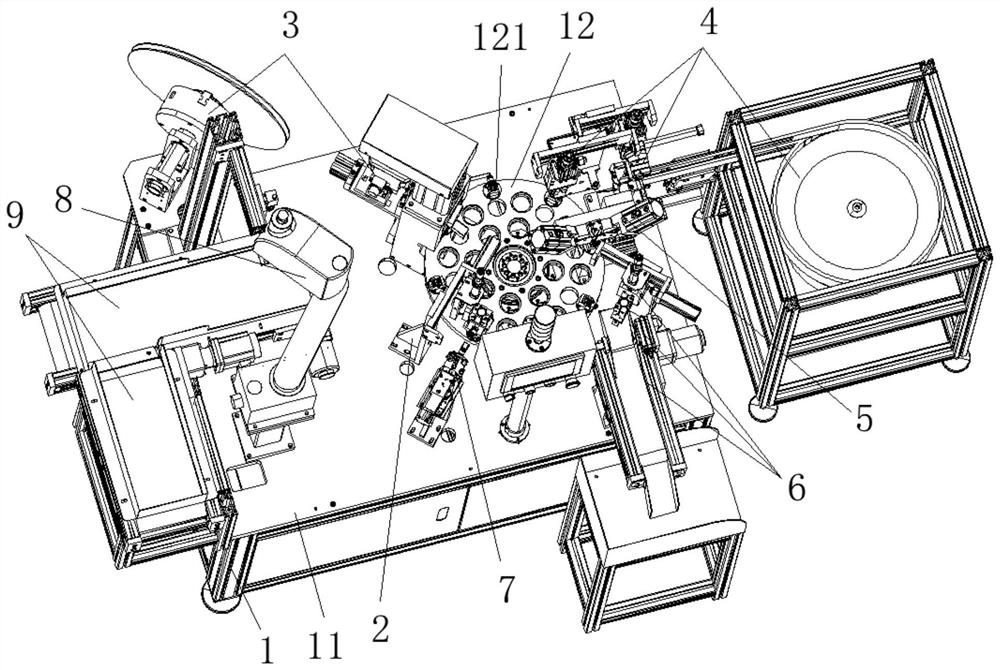

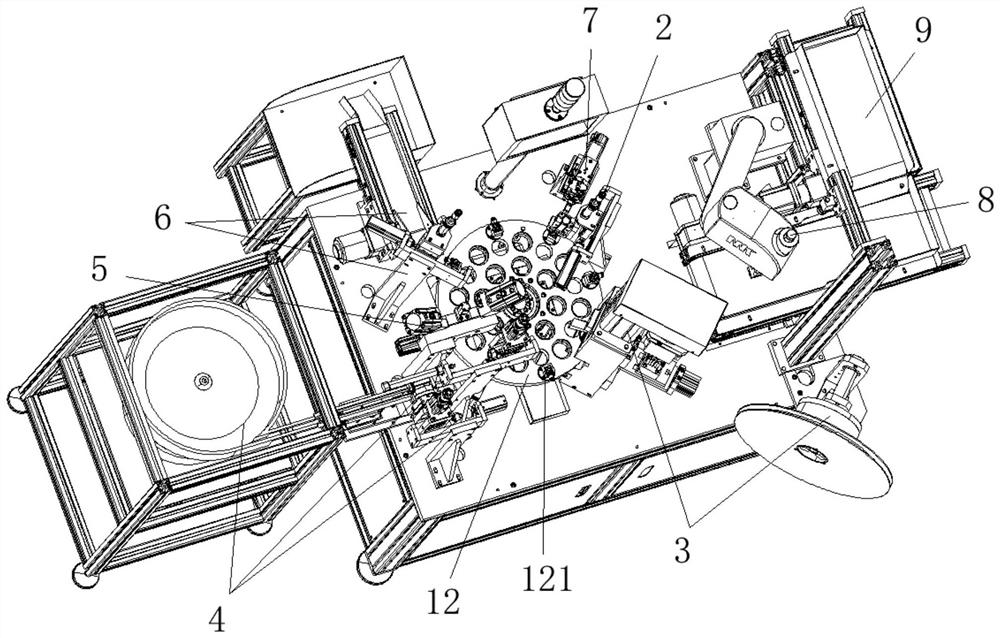

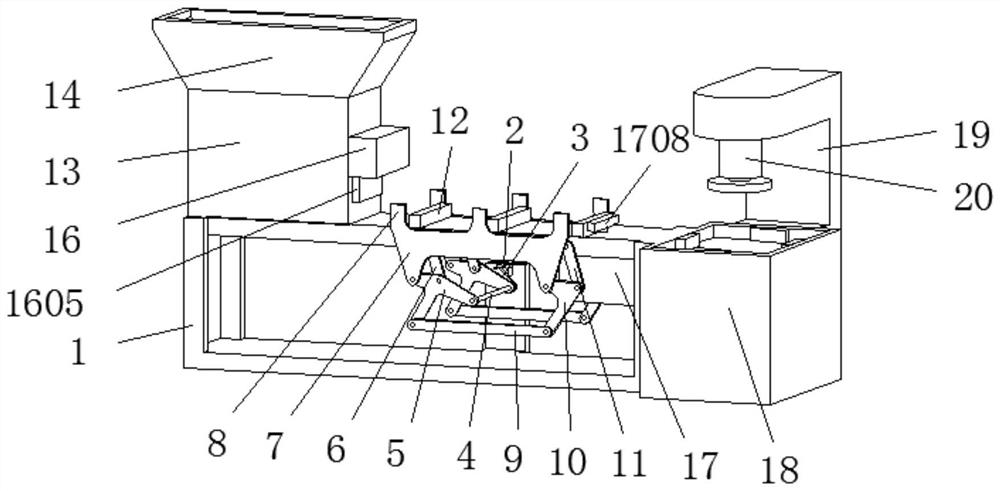

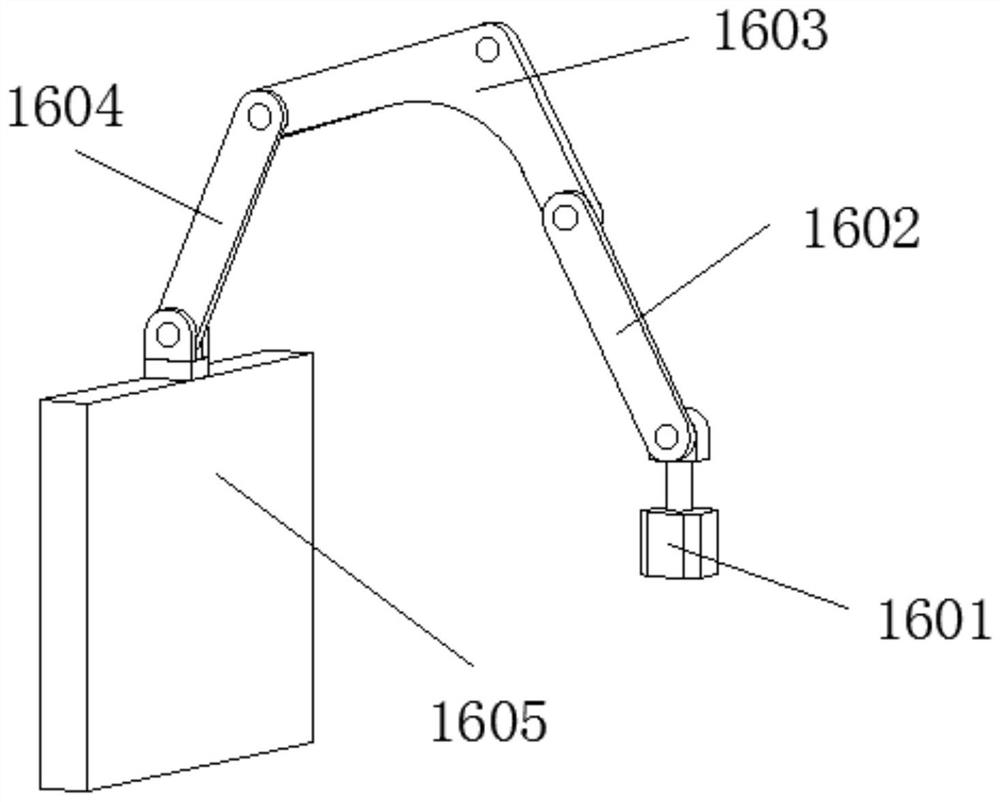

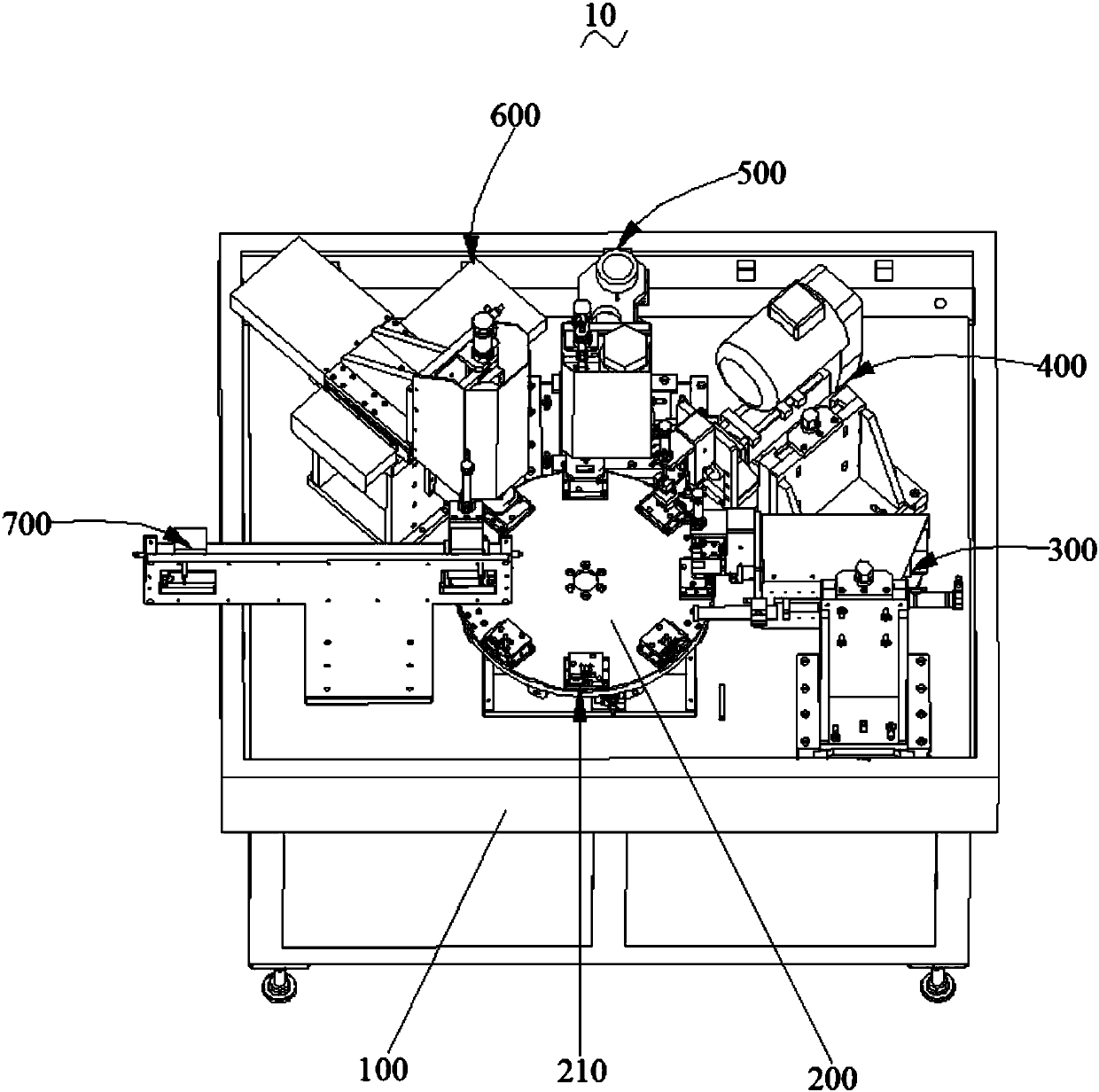

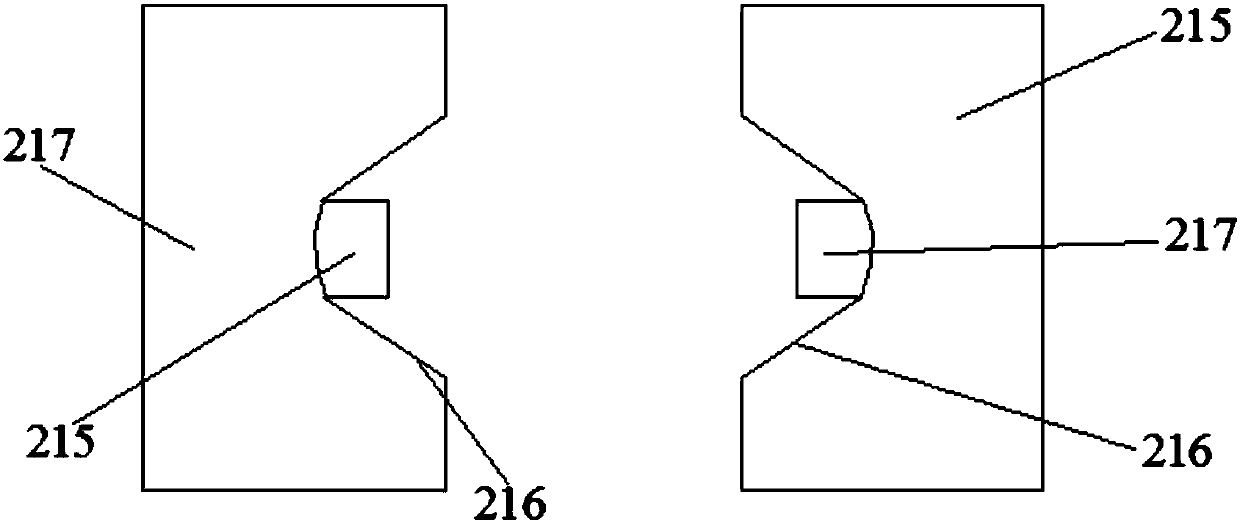

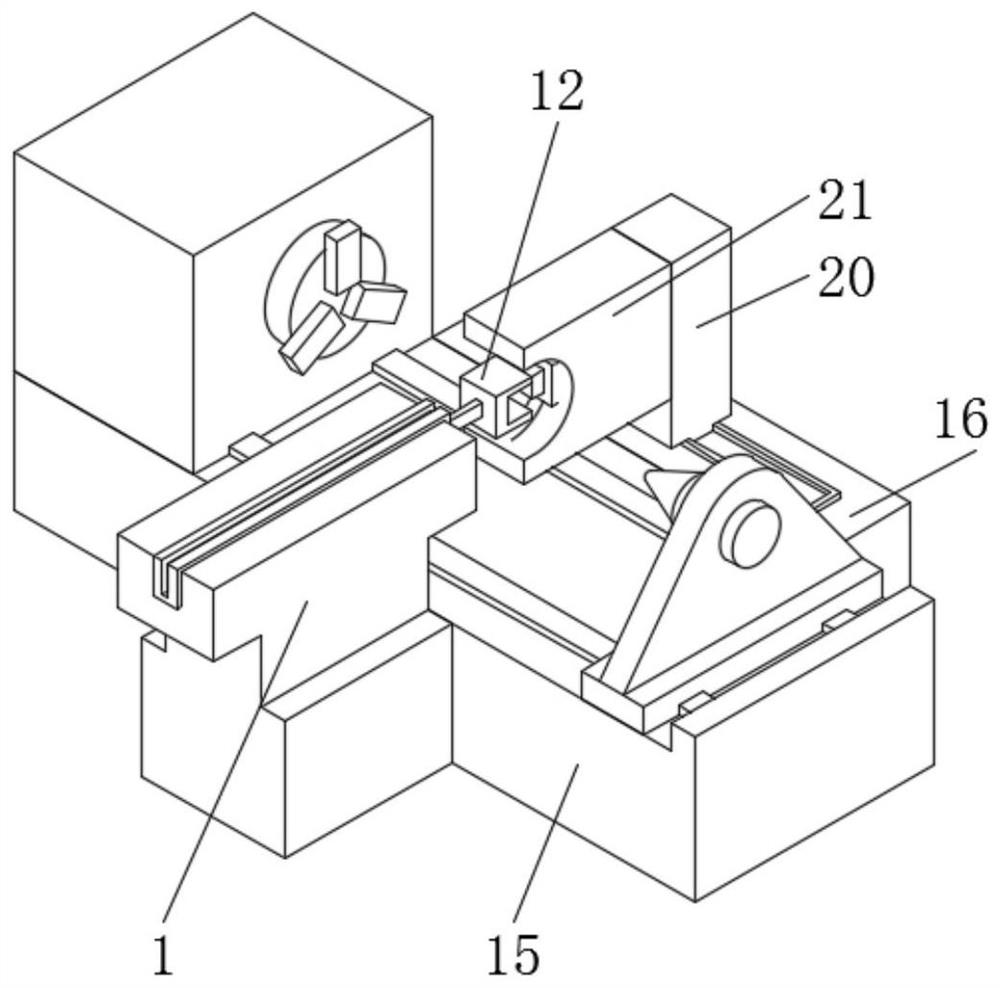

Assembling equipment for built-in soldering lug of two-way joint

ActiveCN113182740AGood for industrial processingRealize automatic feeding operationWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringManual handling

The invention provides assembling equipment for a built-in soldering lug of a two-way joint, and belongs to the technical field of metal part machining. A base feeding mechanism, a visual grabbing mechanism, a direction adjusting mechanism, an automatic base discharging mechanism, a copper ring piece machining mechanism, a bamboo joint piece placing mechanism, an assembling and pressing mechanism and an automatic discharging mechanism are sequentially arranged beside a rotary disc. Automatic feeding operation of a base and automatic adjustment of the direction of a welding hole in the base are achieved, automatic machining and installation of a copper ring piece can be achieved at the same time, the problem that machining, transferring and manual placing are needed in advance is solved, the workload is relieved, automatic feeding of a bamboo joint piece can be achieved, the base and the bamboo joint piece are automatically and temporarily fixed, automatic discharging is conducted on the base and the bamboo joint piece which are temporarily fixed, the automation degree is higher, the machining efficiency is improved, potential safety hazards caused by manual operation are avoided, and industrialization machining of the two-way joint is facilitated.

Owner:宁波亚大自动化科技有限公司

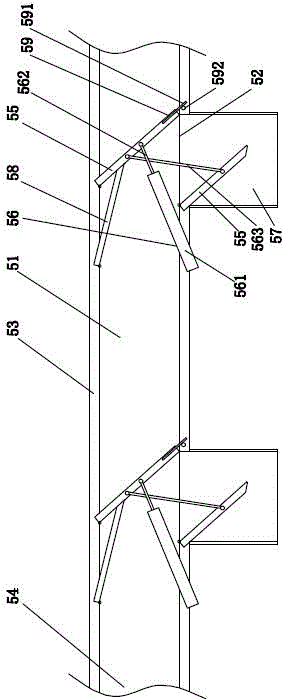

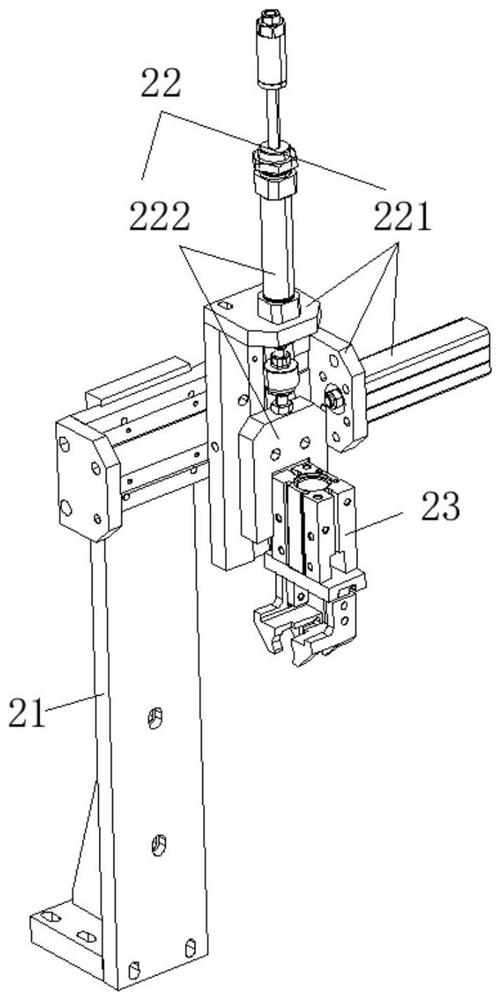

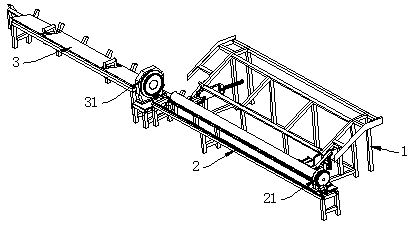

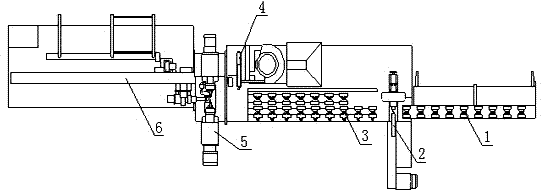

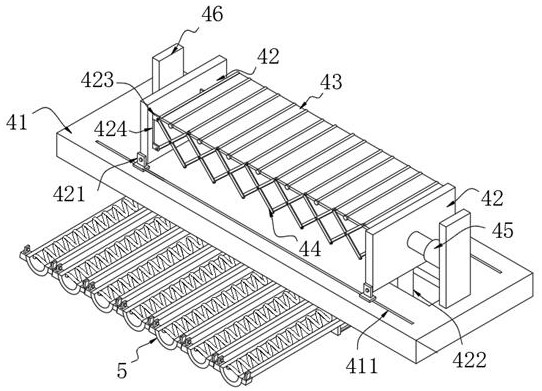

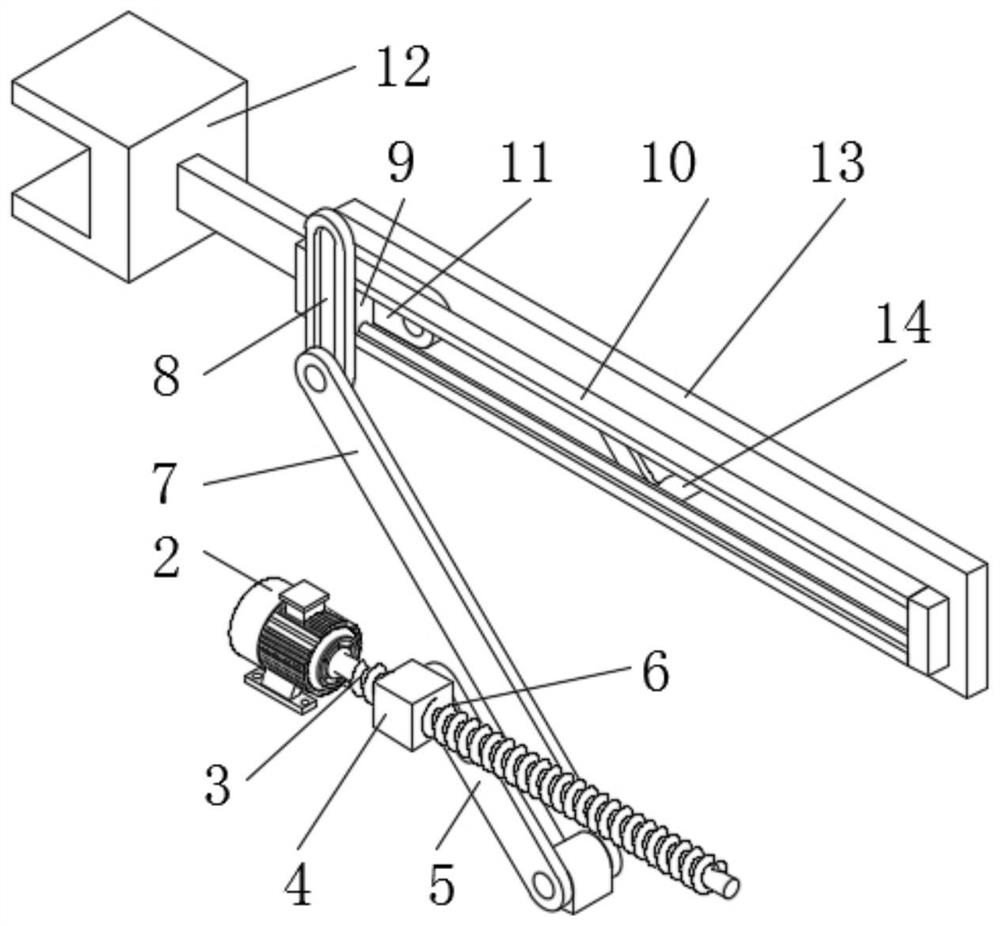

Feeding device of laser pipe cutter

PendingCN109108502ARealize automatic feeding operationSimple structureMetal working apparatusLaser beam welding apparatusSlide plateLaser

The invention provides a feeding device of a laser pipe cutter. The feeding device comprises a feeding frame, a first base and a second base, wherein the feeding frame is positioned at one side of thefirst base, and the second base is positioned at one end of the first base. The feeding mechanism comprises a sliding plate, a first support and a pushing cylinder, wherein the sliding plate is in sliding connection with the first support, and one end of the sliding plate is fixedly connected with a telescopic rod of the pushing cylinder. The sliding plate is provided with a second support, the second support is provided with a clamping jaw and an upward moving cylinder, and the clamping jaw is slidably connected with the second support and is fixedly connected with a telescopic rod of the upward moving cylinder. According to the feeding device of the laser pipe cutter, the sliding plate is driven by the pushing cylinder to realize the horizontal movement of a steel pipe, and the clampingjaw is then driven by the upward moving cylinder to realize the up-and-down movement, so that the steel pipe automatic feeding is realized, the structure is simple, and the working efficiency is high.

Owner:TIANJIN RENYIHE AUTOMATION TECH

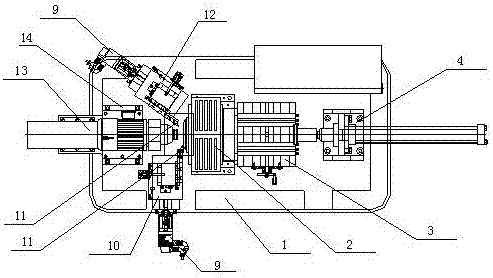

Outer circle chamfering machine tool for numerical control piston ring

InactiveCN107252900AReduce tooling operationsIncrease productivityTurning machinesMetal working apparatusNumerical controlPiston ring

The invention discloses an outer circle chamfering machine tool for a numerical control piston ring. The outer circle chamfering machine tool comprises a machine tool base, a rotary rack, a storing frame, a pushing frame, a front knife rest mechanism, a rear knife rest mechanism, a positioning mechanism and a rotary synchronous variable-frequency motor. The rotary rack, the storing frame and the pushing frame are sequentially installed on the upper surface of the machine tool base, the rotary rack is located in the middle, and the pushing frame is located on the right side; a pushing oil cylinder is installed on the pushing frame, the piston ring on the storing frame is pushed into the rotary rack, and meanwhile, the rotary rack is connected with the rotary synchronous variable-frequency motor installed below the machine tool base through a belt for transmission; the positioning mechanism is installed on the upper surface of the machine tool base and is located right behind the rotary rack; and the front knife rest mechanism is located on one side of the positioning mechanism and is arranged perpendicular to the positioning mechanism, the rear knife rest mechanism is located on the other side of the positioning mechanism, and an included angle of 45 degrees between the rear knife rest mechanism and the positioning mechanism is formed.

Owner:NANTONG DEXIN NUMERICAL CONTROL MACHINE TOOL

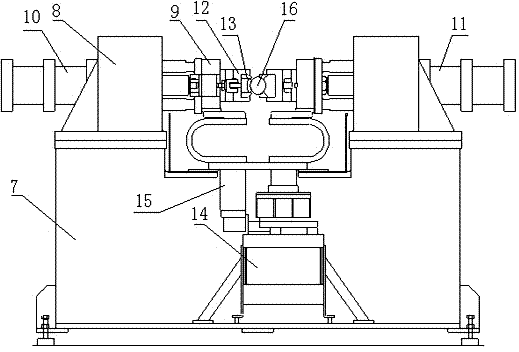

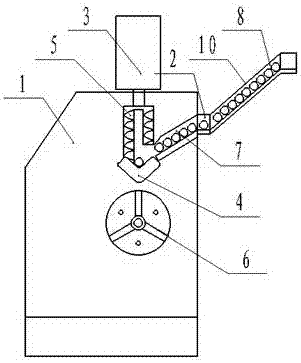

Full automatic welding machine for arc finned tubes

ActiveCN103894764ANot easy to dropSmall footprintWelding/cutting auxillary devicesAuxillary welding devicesElectrical conductorWelding power supply

The invention discloses a full automatic welding machine for arc finned tubes. The full automatic welding machine for the arc finned tubes comprises an automatic finned tube feeding mechanism, an automatic tube grinding mechanism, an automatic finned tube turnover mechanism, an automatic fin feeding mechanism, an automatic fin welding mechanism and an automatic finned tube straightening mechanism. The automatic fin welding mechanism comprises a base, two pneumatic propelling devices, two welding heads, clamping devices, a welding air cylinder, an ejecting air cylinder, a welding power source, a conductor and electrodes, wherein the two pneumatic propelling devices are symmetrically arranged on the base, the two welding heads are symmetrically arranged on the pneumatic propelling devices, the clamping devices are symmetrically arranged on the welding heads, the welding air cylinder and the ejecting air cylinder are symmetrically arranged on the pneumatic propelling devices, the welding power source is arranged on the base, the conductor is connected with the welding power source, and the electrodes are connected with the conductor and are arranged on the welding heads. The full automatic welding machine for the arc finned tubes is compact in structure, convenient to operate, accurate in control, high in production efficiency, firm in welding, stable and good in welding quality, and high in rate of finished products and automation degree, and welding pins are not prone to dropping.

Owner:QINGDAO KAINENG BOILER EQUIP

Hot pressing device with clamping structure for non-standard bolt machining

InactiveCN113695504ARealize automatic feeding operationIncrease loading capacityBoltsForging/hammering/pressing machinesElectric machineryStructural engineering

The invention discloses a hot pressing device with a clamping structure for non-standard bolt machining, and relates to the technical field of non-standard bolt machining equipment. Particularly, the hot pressing device comprises a base and a second support seat, wherein a feeding box is arranged on the upper surface of the base; bolt blanks are placed in the feeding box; a feeding plate is arranged in the feeding box; a feeding groove is formed in the upper surface of the feeding box; a feeding air cylinder is arranged at one end of the feeding groove; a machining turntable is arranged at the other end of the feeding groove; and a first motor is arranged atone side of the machining turntable. According to the hot pressing device with the clamping structure for non-standard bolt machining, the arranged rotatable carrying tray is matched with the feeding box and the feeding air cylinder for automatic feeding to achieve automatic feeding operation of a plurality of bolt blanks, and the rotatable carrying tray is matched with the rotatable machining turntable to transfer the fed bolt blanks to a forging area to be subjected to hot-pressing forging treatment, so that the load capacity of the device is greatly increased, and the machining efficiency is effectively improved.

Owner:重庆优云迪科技有限公司

LED lamp production equipment with positioning and glue pouring structure

InactiveCN112403824ARealize intermittent rotationRealize automatic feeding operationLiquid surface applicatorsCoatingsGear wheelElectric machinery

The invention discloses LED lamp production equipment with a positioning and glue pouring structure. The LED lamp production equipment comprises a base support, a supporting plate is fixedly connectedto the outer wall of the base support, rotating shafts penetrate through the two sides of the supporting plate, a conveying belt is installed on the outer sides of the rotating shafts, and a fixed positioning block is fixedly installed at the top end of the conveying belt; and material conveying working boxes are mounted on the outer wall of the supporting plate and at the ends, away from the conveying belt, of the rotating shafts. According to the LED lamp production equipment with the positioning and glue pouring structure, a rotating plate is arranged, a motor rotates to drive a rotating wheel to rotate through a special-shaped rotating wheel, the special-shaped rotating wheel is in a regular triangle shape, the rotating wheel drives a lifting plate to move through the rotating plate,the lifting plate drives a limiting gear to move, the lifting plate drives a rotating rod to move through a lifting block so as to be meshed with the rotating gear, and meanwhile the special-shaped rotating wheel drives the rotating rod to move through a guide block, so that intermittent rotation of the rotating gear is achieved.

Owner:嘉兴搁浅箱包有限公司

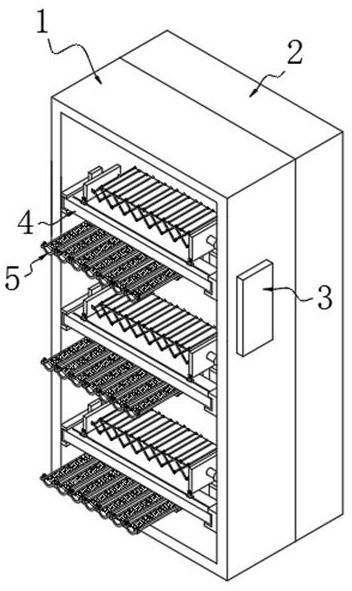

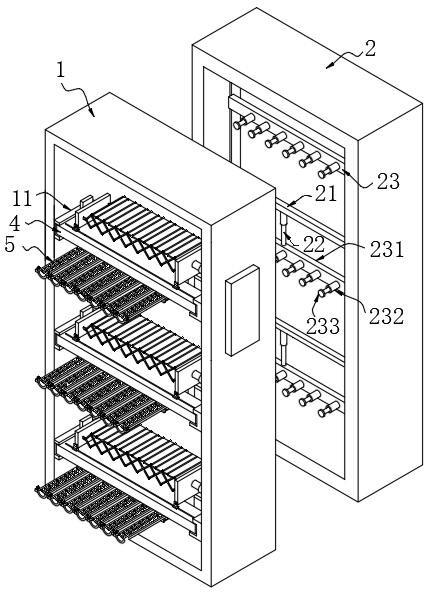

Sample storage device for product quality inspection

PendingCN114275314APlace stableAvoid unstable placementDischarging meansConveyor partsStructural engineeringMechanical engineering

The invention belongs to the technical field of sample storage, and particularly relates to a sample storage device for product quality inspection, which comprises a storage box body, and three vertically distributed storage assemblies are slidably connected in the storage box body; the multiple storage assemblies distributed up and down are slidably connected into the storage box body, the storage mechanisms capable of being unfolded and stored are arranged at the tops of the storage assemblies, and the storage mechanisms are bent and straightened under the moving action of the telescopic frame mechanisms, so that the storage mechanisms can be bent and straightened through mutual cooperation of placement plates and connecting shafts; a plurality of V-shaped containing spaces are formed and used for storing tubular or barreled samples, the barreled samples are effectively prevented from rolling on the top of the storage mechanism in the taking and containing process, the telescopic frame mechanism can be stretched, so that the storage mechanism is stretched and forms a plane state, and therefore the storage mechanism is used for containing conventional samples, and the storage efficiency is improved. And therefore, samples in various shapes can be stably placed on the device.

Owner:薛城区质量计量检测中心

Machining equipment with burr grinding function for special-shaped bolt fault diagnosis

InactiveCN111993192AEasy to sendRealize automatic feeding operationEdge grinding machinesGrinding carriagesVisual inspectionAbnormal shaped

The invention discloses machining equipment with burr grinding function for a special-shaped bolt fault diagnosis. The machining equipment with the burr grinding function for the special-shaped bolt fault diagnosis comprises a main body frame, a clamping and conveying frame and a clamping frame, and a conveying belt is arranged on the left side of the lower portion of the interior of the main bodyframe. According to the machining equipment with the burr grinding function for the special-shaped bolt fault diagnosis, compared with existing common visual inspection equipment, a first groove is formed, a first servo motor rotates to drive a first rotating shaft to rotate, the first rotating shaft drives a first sliding block to move along the first groove through a second groove in a rotatingrod, a first moving rod is driven to move along the first groove, the first groove is in a semi-closed type, and the lengths of the two sides of the first groove are equal, the distance between the conveying belt and a clamping table is equal to the distance between the clamping table and a second clamping block, the distance between the conveying belt and the clamping table is equal to the lengths of the two sides of the first groove, bolts can be conveniently clamped to the second clamping block from the conveying belt, and automatic feeding operation is achieved.

Owner:重庆数智源智能装备科技有限公司

Gear grinding device with vibration feeding mechanism

InactiveCN109202701AConvenient automatic feedingReduce labor costsRevolution surface grinding machinesGrinding feedersCenterless grindingElectromagnetic vibration

The invention relates to a gear grinding device with a vibration feeding mechanism. The gear grinding device comprises a centerless grinding machine body, and a guide wheel, a grinding wheel and a guide plate are arranged on the centerless grinding machine body, wherein the guide plate is arranged between the guide wheel and the grinding wheel, the electromagnetic vibration feeding mechanism is arranged on one side of the centerless grinding machine body, two adjusting plates are arranged below an outlet of the electromagnetic vibration feeding mechanism side by side, adjusting grooves are formed in the adjusting plates, a gear workpiece guide groove is formed above the two adjusting plates, and two screws are fixedly arranged at the bottom of the gear workpiece guide groove. A workpiece limiting rod is arranged above the gear workpiece guide groove, one end of the gear workpiece guide groove is in butt joint with the outlet of the electromagnetic vibration feeding mechanism, a cylinder is arranged on the other side of the gear workpiece guide groove in a downward butt joint mode, and a spring type material guide hose is connected to the lower end of the cylinder. By means of the gear grinding device, manpower cost is reduced, and meanwhile automatic feeding operation of a centerless grinding machine is achieved, so that high practical promotion and use value is achieved.

Owner:湖北博英精工科技股份有限公司

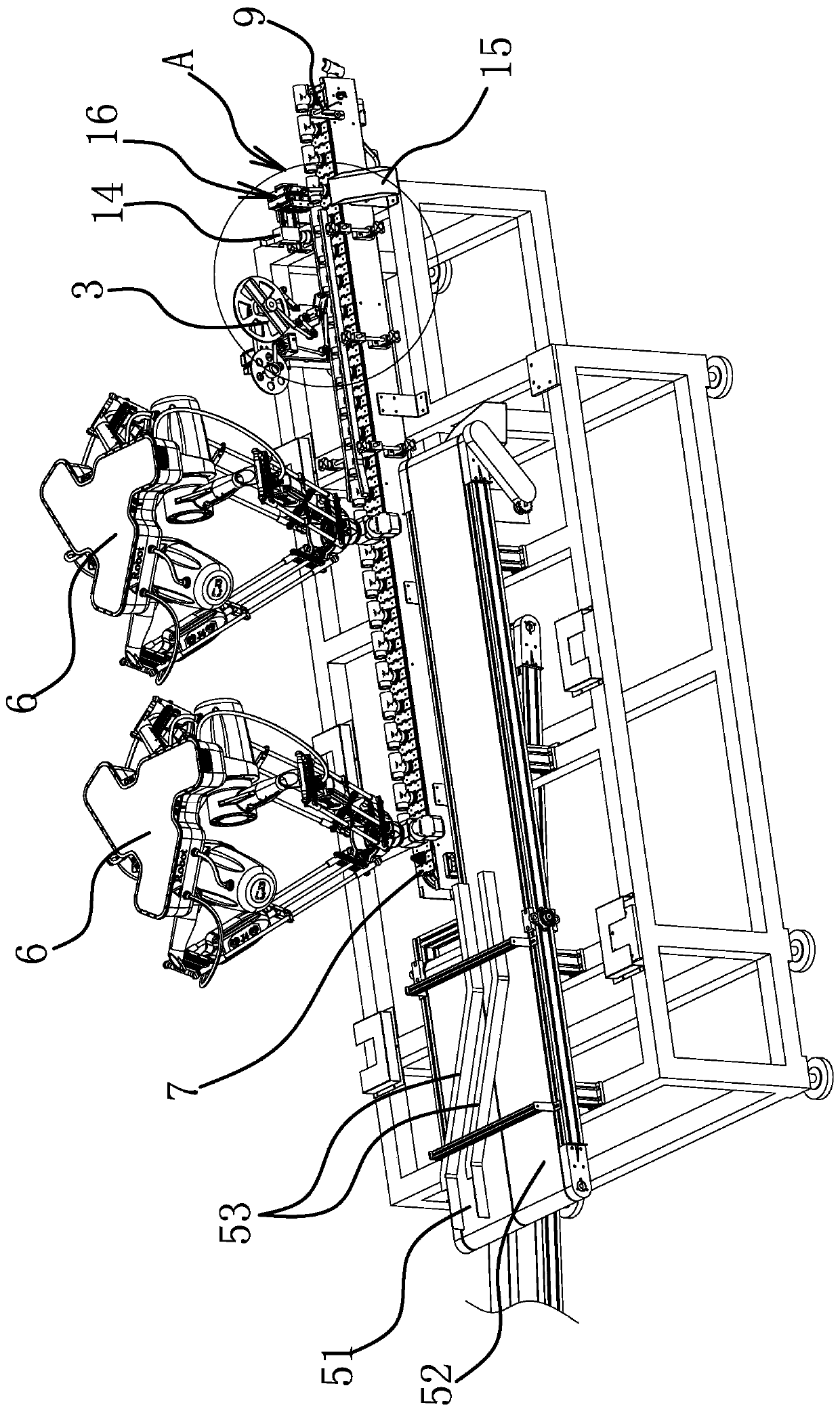

Robot-controlled pipe joint labeling and packaging device

PendingCN110282206AImprove labeling qualityGuaranteed accuracyRod-shaped articlesPackaging machinesImpellerEngineering

The invention provides a robot-controlled pipe joint labeling and packaging device, and belongs to the technical field of machines. The robot-controlled pipe joint labeling and packaging device solves the problem about how to improve the production efficiency while ensuring the accuracy of the pipe joint labeling and packaging number. The device comprises a stock bin, a loading machine, a labeling machine, a bagging and sealing machine, a material neatening and conveying mechanism, a manipulator and a labeling conveyor belt; a positioning column is fixedly connected to a belt body of the labeling conveyor belt, a labeling head of the labeling machine is located above the labeling conveyor belt, the manipulator can clamp a pipe joint and arrange the pipe joint on the positioning column in a sleeving manner, and a counting sensor is arranged between the labeling head and the output end of the labeling conveyor belt; and the output end of the labeling conveyor belt is provided with a storage chamber with a through cavity, an impeller is rotatably connected into the through cavity, a quasi-number conveyor is arranged between the storage chamber and the bagging and sealing machine, and the quasi-number conveyor comprises a receiving trough, wherein one receiving trough is located under the storage chamber. The labeling and packaging device realizes full automation of loading, material neatening, labeling, counting and quasi-number packaging.

Owner:浙江元邦智能装备有限公司

Copper ingot processing device

ActiveCN112536663AOrderly automatic feeding operationPrecise control of feeding speedEdge grinding machinesGrinding carriagesElectric machineEngineering

The invention discloses a copper ingot processing device. The device comprises a main body frame, a first motor is fixedly installed on the inner wall of the main body frame, a first rotating rod is installed at the output end of the first motor, a connecting rod is screwed to the end, away from the motor, of the first rotating rod, and a first rotating plate is screwed to the end, away from the first rotating rod, of the connecting rod. The connecting portion of the first rotating plate and the main body frame is screwed with a first connecting rod. According to the copper ingot processing device, a feeding plate is arranged, the first motor rotates to drive the first rotating rod to move, the first rotating rod drives the first rotating plate to rotate through the connecting rod, and therotating height of the first rotating plate is equal to the height of a spacing plate. The first rotating plate drives the feeding plate at one end of a working plate to move through the first connecting rod, the first rotating plate drives a second rotating plate through a second connecting rod to drive the feeding plate at the other end of a rotating working plate to move with a third connecting rod as the circle center, and orderly and automatic copper ingot feeding operation is achieved.

Owner:贵溪市正鑫铜业有限公司

Automatic feeding mechanism for numerically-controlled lathe

InactiveCN107159910AHigh degree of automationLabor savingMetal working apparatusEngineeringMaterial storage

The invention discloses an automatic feeding mechanism for a numerically-controlled lathe. The automatic feeding mechanism comprises a machine body, a conveying chain and a feeding air cylinder, wherein the conveying chain is a circulating type conveying chain mechanism and is fixedly arranged at the upper end of the machine body, and the feeding air cylinder is suspended above the conveying chain; and an air cylinder rod of the feeding air cylinder is fixedly connected with a connecting rod, a feeding seat is fixed at the bottom of the connecting rod, the feeding seat can be operated up and down and is formed by connecting a material storage seat and a material pushing air cylinder, an air cylinder rod of the material pushing air cylinder faces the interior of the material storage seat, and through cooperative use of the feeding air cylinder and the material pushing air cylinder, automatic feeding of products in a chuck is realized. According to the mode, the automatic feeding mechanism is simple in structure, convenient to operate, capable of realizing automatic feeding of the products, high in automation degree and high in production efficiency, and saving a large amount of labor.

Owner:常熟市金华机械股份有限公司

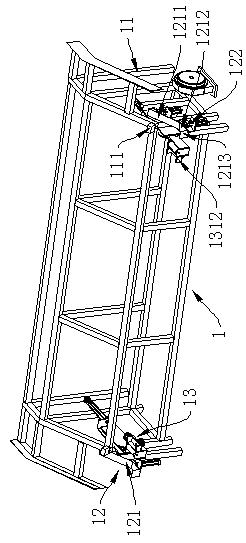

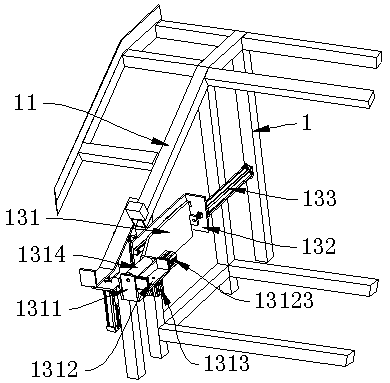

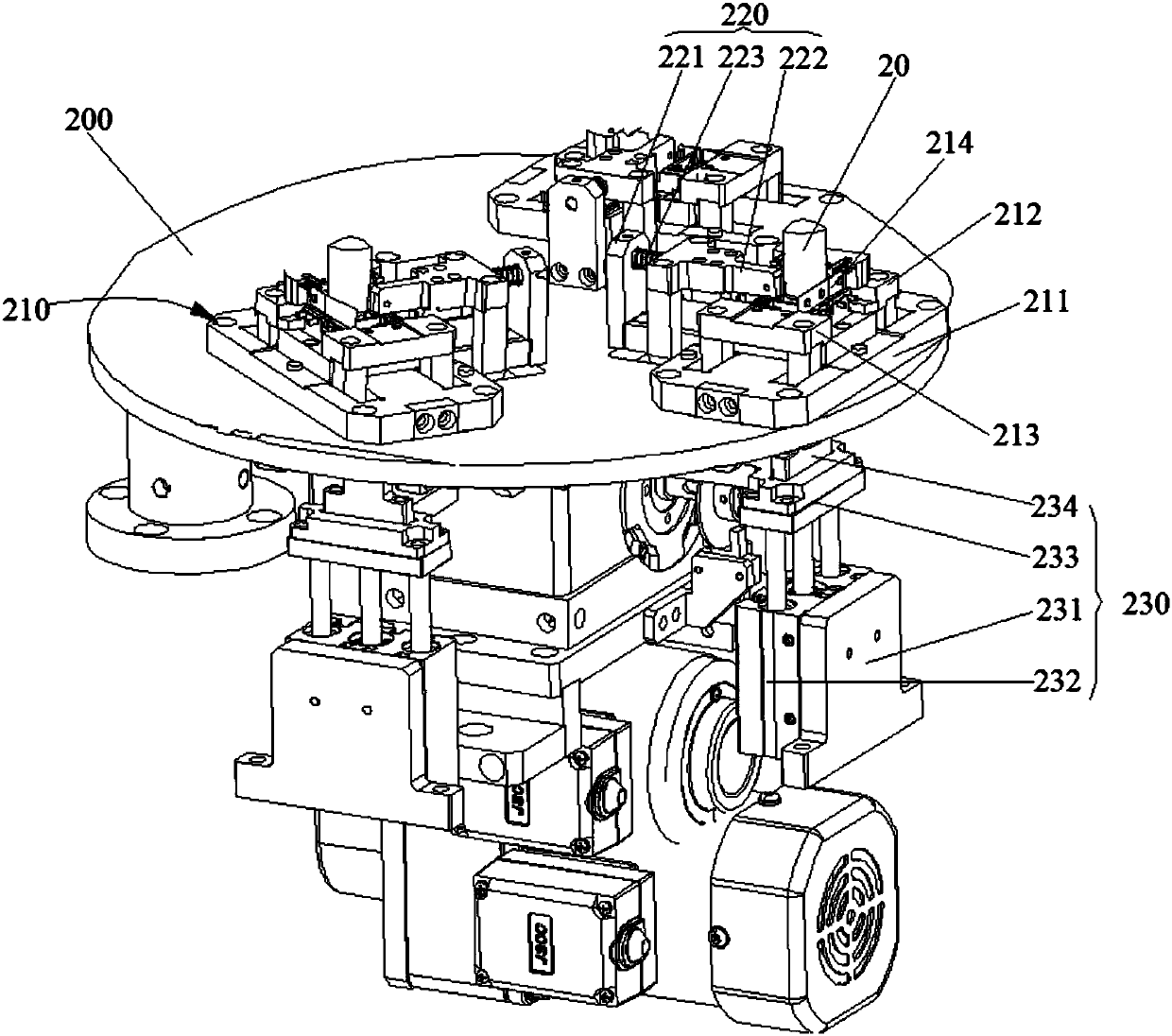

Battery carbon rod feeding mechanism and battery assembling facility

InactiveCN107808965ARealize automatic feeding operationIncrease productivityPrimary cell manufactureAssembling battery machinesElectrical batteryProduction quality

The invention discloses a battery carbon rod feeding mechanism, which comprises a battery carbon rod feeding base, an X axis driving module, an X axis moving substrate, a Y axis driving module, and abattery carbon rod placing device. The invention also discloses a battery assembling facility, which comprises the battery carbon rod feeding mechanism, a work base, a battery transmission rotary table, a battery powder feeding mechanism, a battery sealing and gluing mechanism, a battery cover feeding mechanism, and a battery discharging mechanism. The battery powder feeding mechanism, the batterycarbon rod feeding mechanism, the battery sealing and gluing mechanism, the battery cover feeding mechanism, and the battery discharging mechanism are arranged on the periphery of the battery transmission rotary table in sequence so as to carry out steps of feeding battery powder, feeding battery carbon rods, sealing and gluing batteries, feeding battery covers, and discharging batteries. The production efficiency is largely improved, the production quality is guaranteed, and the production cost is reduced efficiently.

Owner:惠州联合诚创企业管理咨询有限公司

A kind of soil purification and fertilization equipment

ActiveCN111108830BTo achieve the effect of purification and fatteningImprove purification effectSoil lifting machinesSpadesSoil scienceSoil properties

The invention relates to the field of soil purification and fertilization devices, in particular to a soil purification and fertilization equipment, including a box body, a stirring structure, a feeding structure, a stacking structure, a compacting structure and a feeding structure; The setting can automatically scoop up the soil on the field ridge and lift it to the top of the box while the stirring structure is working, so as to realize the automatic feeding operation. The setting of the feeding structure can also play the role of turning the soil, through two The setting of a feeding structure can simultaneously feed the soil purifier and soil fertilizer simultaneously, so as to achieve the effect of purifying and fertilizing the soil, and because of the single feeding structure, the feeding of a single material can be independently and accurately adjusted Speed, so that different degrees of purification and fertilization can be carried out for different soil properties, and through the use of the mixing structure inside the box, the purifier and fertilizer can be fully mixed with the soil, which can greatly enhance the soil. Purifying and fattening efficiency.

Owner:滦平新硕农业发展有限公司

A kind of cutting device for aluminum-based printed circuit board

ActiveCN113618262BEasy to cutRealize automatic feeding operationWelding/cutting auxillary devicesPCB positioning during processingEngineeringAluminum substrate

A material cutting device for aluminum-based printed circuit boards, including a conveying component, the discharge end of the conveying component is provided with a transfer component, the transfer component is provided with a positioning component, one end of the transfer component is provided with a material cutting component, and the conveying component faces the positioning component Feeding and conveying the aluminum substrate, so that the aluminum substrate moves to the positioning component, and it is positioned by the positioning component, and the transfer component drives the aluminum substrate positioned by the positioning component to move to the cutting component, so that the cutting component can carry out the aluminum substrate Cutting operation. When the present invention is processing printed circuit boards, especially when processing aluminum-based printed boards, it is convenient to cut the aluminum substrate. A certain amount of aluminum substrates can be stored, and the aluminum substrates can be automatically transferred during cutting, and the aluminum substrates can be accurately positioned to improve the accuracy of cutting and the effect of cutting.

Owner:江油星联电子科技有限公司

Full-automatic papermaking production equipment

ActiveCN112281535AQuality improvementReduce labor intensityWashing/displacing pulp-treating liquorsPaper recyclingPapermakingProcess engineering

The invention relates to full-automatic papermaking production equipment, and belongs to the technical field of papermaking mechanical equipment. The full-automatic papermaking production equipment ischaracterized by comprising pulping equipment and a pulp flowing device, the pulping equipment comprises a main rack, and a feeding device, a coarse crushing device, a screening device, a pulp washing device, a fine grinding device and a pulp storage device which are sequentially connected front and back are mounted on the main rack; the main rack comprises an overground rack body, a first underground bin body and a second underground bin body, the feeding device and the coarse crushing device are sequentially installed on the overground rack body from left to right, the screening device andthe pulp washing device are both arranged in the first underground bin body, and the fine grinding device and the pulp storage device are both arranged in the second underground bin body. Waste papercan be efficiently processed and converted into fine paper pulp in a high-quality mode, wet paper with constant uniformity and quality is produced, and the quality of manufactured paper products is effectively improved.

Owner:山东海天造纸机械有限公司

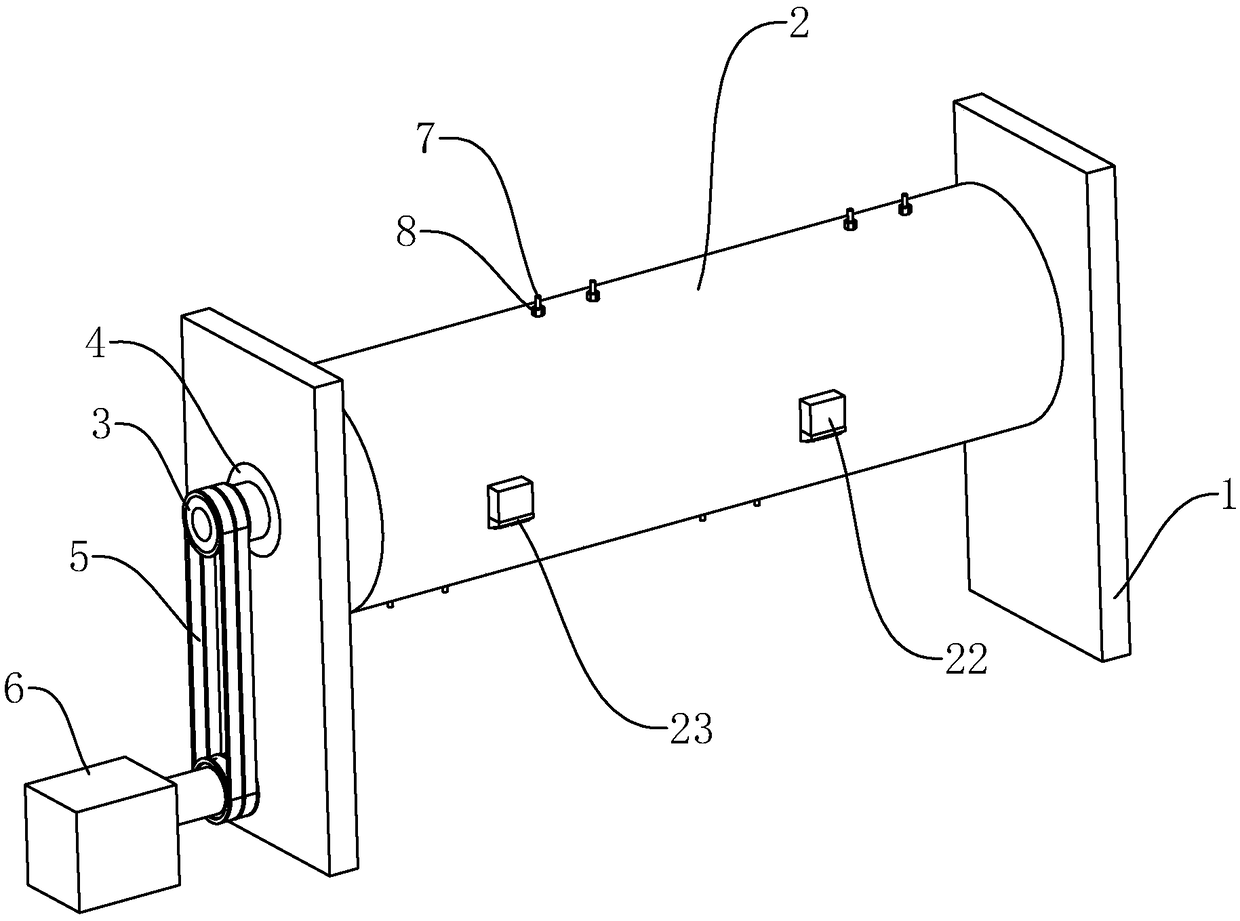

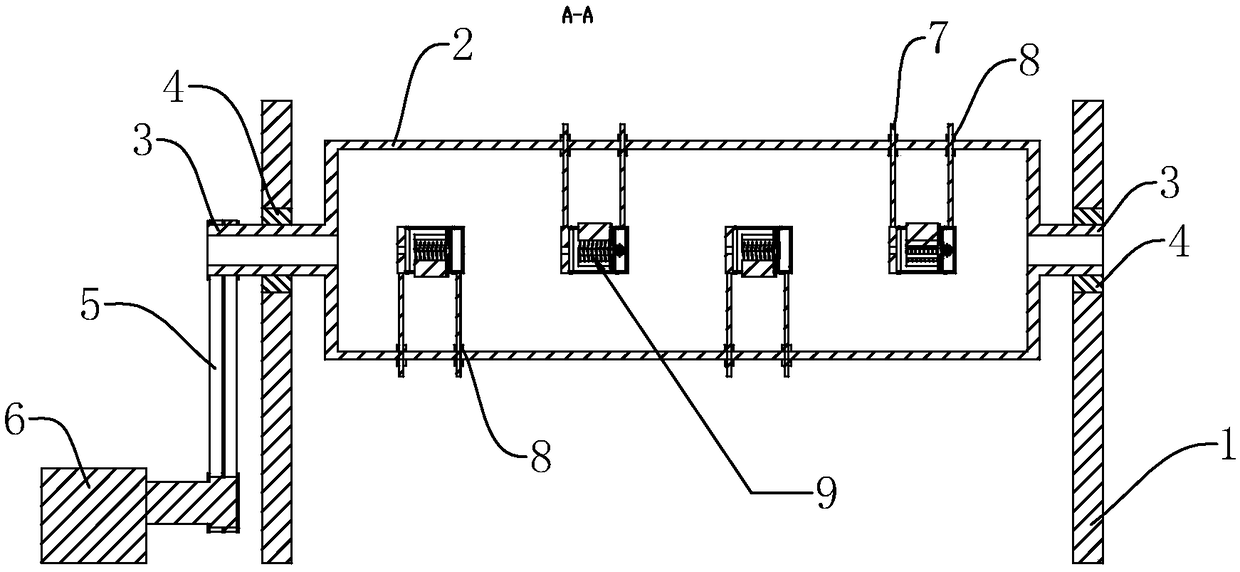

Roughness testing equipment for roll production

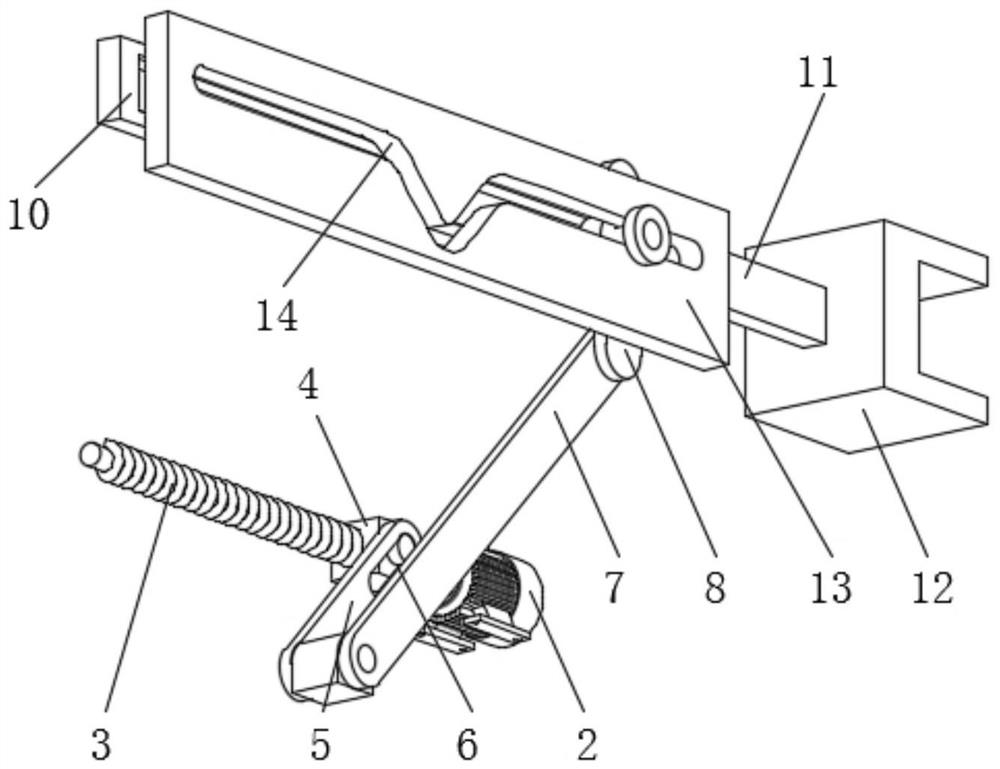

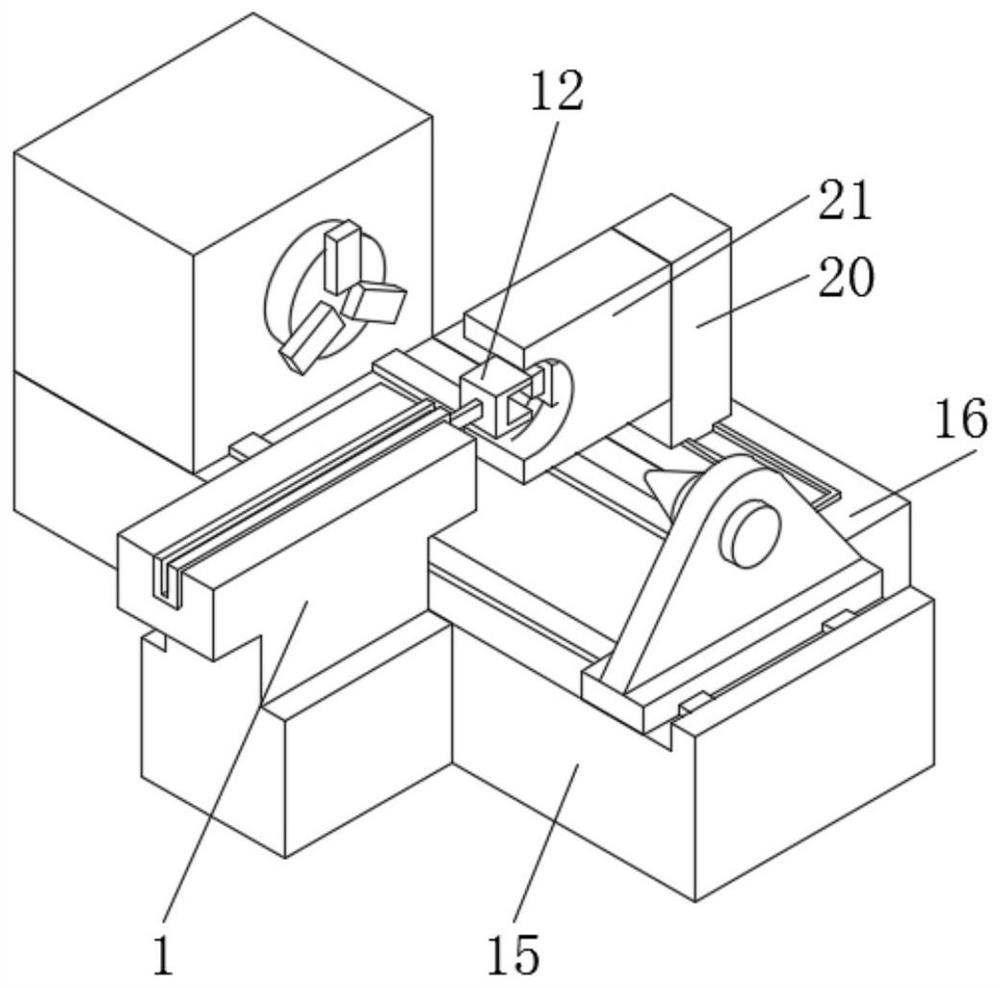

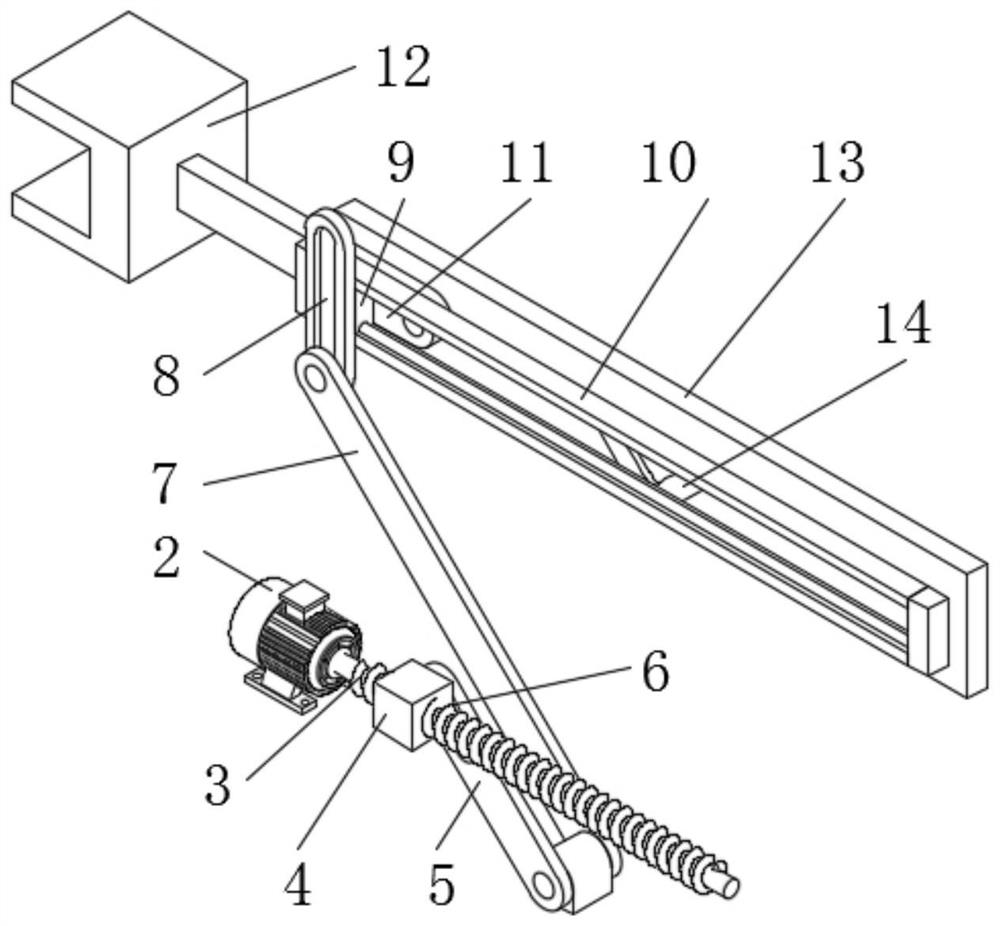

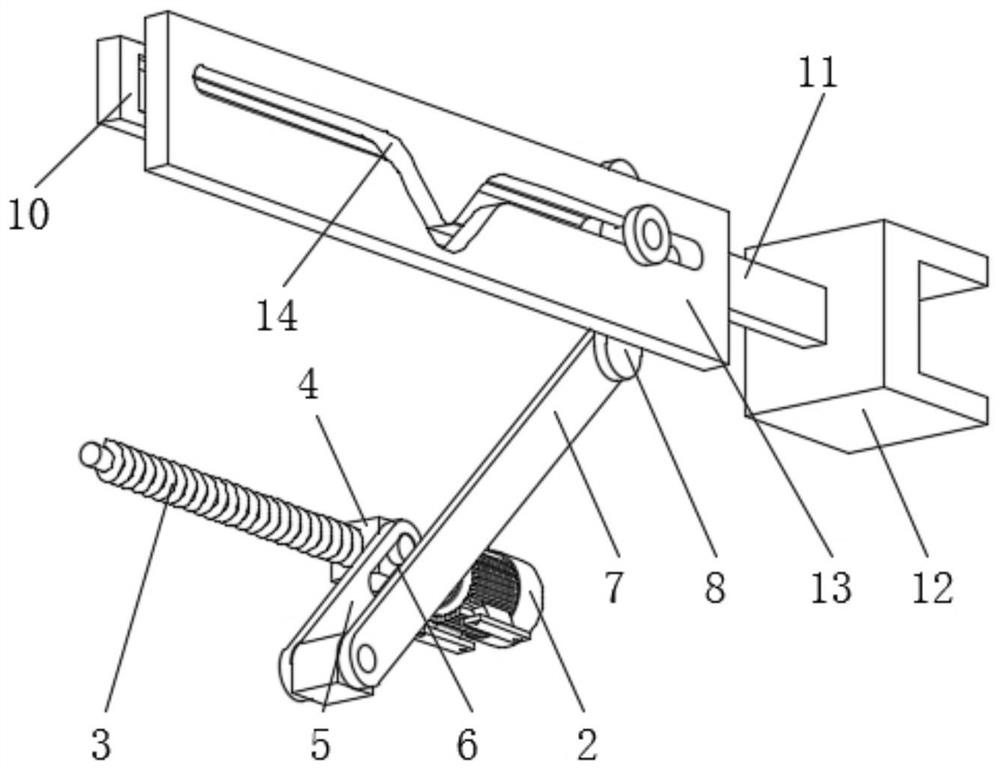

ActiveCN113701701BRealize control operationRealize automatic feeding operationMeasurement devicesConveyor partsElectric machineryScrew thread

Owner:JIANGSU GONGCHANG ROLL

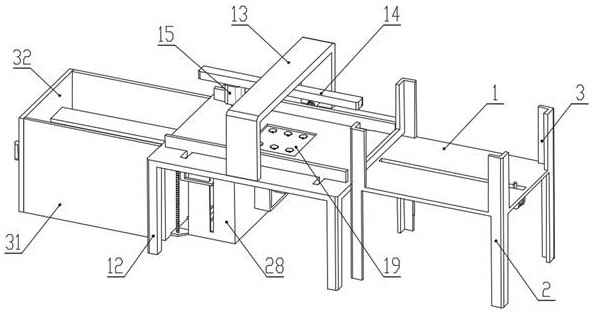

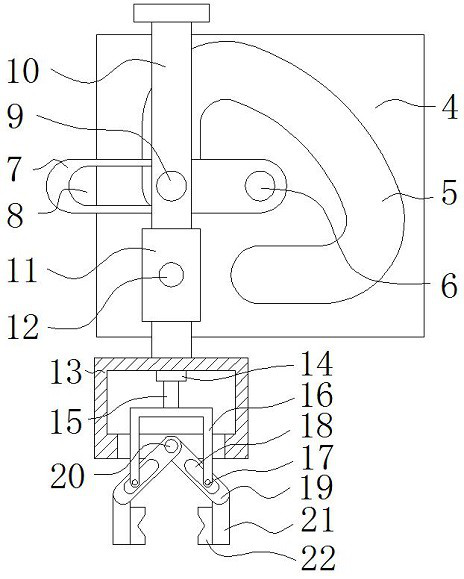

Roughness detection device for roller production and use method

ActiveCN113701701ARealize control operationRealize automatic feeding operationMeasurement devicesConveyor partsElectric machineryScrew thread

The invention discloses a roughness detection device for roller production and a using method, and belongs to the technical field of roller production. The roughness detection device for roller production comprises a feeding frame, the inner wall of the feeding frame is fixedly connected with a feeding motor, and the output end of the feeding motor is provided with a threaded rod; the outer wall of the threaded rod is in threaded connection with a threaded sliding block which is in sliding connection with the inner wall of the feeding frame, the side wall of the threaded sliding block is movably connected with a swing short plate which is in screwed connection with the inner wall of the feeding frame, and a short plate groove is formed in the connecting portion of the swing short plate and the threaded sliding block. According to the roughness detection device for roller production and the use method, by arranging a guide sliding groove, in the feeding frame, the movable sliding block moves to drive a working rod connected with a clamping claw to slide along the guide sliding groove in a guide groove plate, and due to the fact that the middle of the guide sliding groove is arranged to be a V-shaped groove, the working rod turns over the clamping claw by 180 degrees when sliding along the guide groove plate, so that the automatic feeding operation is achieved.

Owner:JIANGSU GONGCHANG ROLL

Flue gas oxidation garbage pyrolysis device with feeding function

The invention discloses a flue gas oxidation garbage pyrolysis device with a feeding function. The flue gas oxidation garbage pyrolysis device comprises a bottom plate, a machine shell, a third stop valve, a waste gas discharging pipe and a conveying motor, the inner space of the machine shell comprises a garbage pyrolysis chamber, a transmission chamber, a slag discharging chamber and a flue gas oxidation chamber, and a slag discharging plate is arranged between the garbage pyrolysis chamber and the slag discharging chamber; and slag discharging holes are formed in the slag discharging plate at intervals, material inserting rods are arranged above the slag discharging plate at intervals, the ends, penetrating through the machine shell, of the material inserting rods are connected with a connecting support through a contraction assembly, a guide cylinder assembly, a transmission connecting rod and a drawing and inserting motor are arranged on the side portion of the connecting support, the flue gas oxidation chamber is formed by isolating a flue gas oxidation shell from the slag discharging plate, and fan blades, a fuel nozzle and an oxygen supply pipe are arranged in the flue gas oxidation chamber. According to the flue gas oxidation garbage pyrolysis device, flue gas generated in the garbage pyrolysis treatment process can be subjected to secondary oxidation operation, waste residues formed after garbage pyrolysis can be subjected to drawing, inserting and scattering operation, and automatic feeding operation can be achieved.

Owner:溆浦美皇环保科技有限公司

Household wood pier breaking device

PendingCN113459217ARealize automatic collectionRealize automatic feeding operationProfiling/shaping machinesFirewoodAgricultural engineering

The invention relates to a breaking device, in particular to a household wood pier breaking device. The household wood pier breaking device can automatically break firewood, and is high in breaking speed, high in efficiency and short in consumed time. The household wood pier breaking device comprises a support, a placement assembly and a pressing mechanism, wherein the support is arranged on one side of a bottom plate, the placement assembly is arranged on the bottom plate, and the pressing mechanism is arranged on the placement assembly. Through the effect of a discharging mechanism, materials can be automatically collected, and people can conveniently collect the materials; and through the effect of an adjusting mechanism, the materials can be adjusted.

Owner:尧友娇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com