Patents

Literature

148results about How to "Solve the problem of corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Black organic-silicon heat-resisting paint and preparation method thereof

InactiveCN101550315ASelf-drying at room temperaturePrevent oxidationCoatingsWeather resistanceFilling materials

The invention discloses a black organic-silicon heat-resisting paint comprising 45-65 percent of organic silicon resin, 10-25 percent of high-temperature resisting pigment, 3-8 percent of talc powder, 5 percent of weather-resistance filling materials, 5-15 percent of mica powder, 8-15 percent of mixed glass powder, 5-10 percent of Kaolin, 2-5 percent of cosolvent and 10-20 percent of solvent. A preparation method of the black organic-silicon heat-resisting paint comprises the steps of firstly, weighing the above materials; secondly, putting the high-temperature resisting pigment, the talc powder, the mica powder, the mixed glass powder and the kaolin into a mixing tank, putting part of the organic silicon resin, cosolvent and solvent firstly and then stirring for fully mixing; thirdly, pressing the mixed materials after stirring into a sand mill for full sanding; and fourthly, according to the requirements of glossiness, putting the mixed materials after sanding into a paint formulation kettle, then adding the residual organic silicon resin, cosolvent and solvent in the mixed materials, stirring, mixing, then testing, filtering and packaging.

Owner:TAIZHOU QUAD CHEM

Method for deep enzymolysis of low value fish protein with rotten inhibiting function

InactiveCN1561788AAvoid inhibition of protease activityPrevents fish protein hydrolysis efficiencyProtein foodstuffs working-upFisheryAnaerobic bacteria

An erosion-suppresisng deep enzymolyzing process for low-value fish features that said low-value fish is enzymolyzed by endoproteinase and exoproteinase under 0.1-0.3 MPa while filling clean air or O2 to kill or suppress the anaerobic bacteria.

Owner:SOUTH CHINA UNIV OF TECH

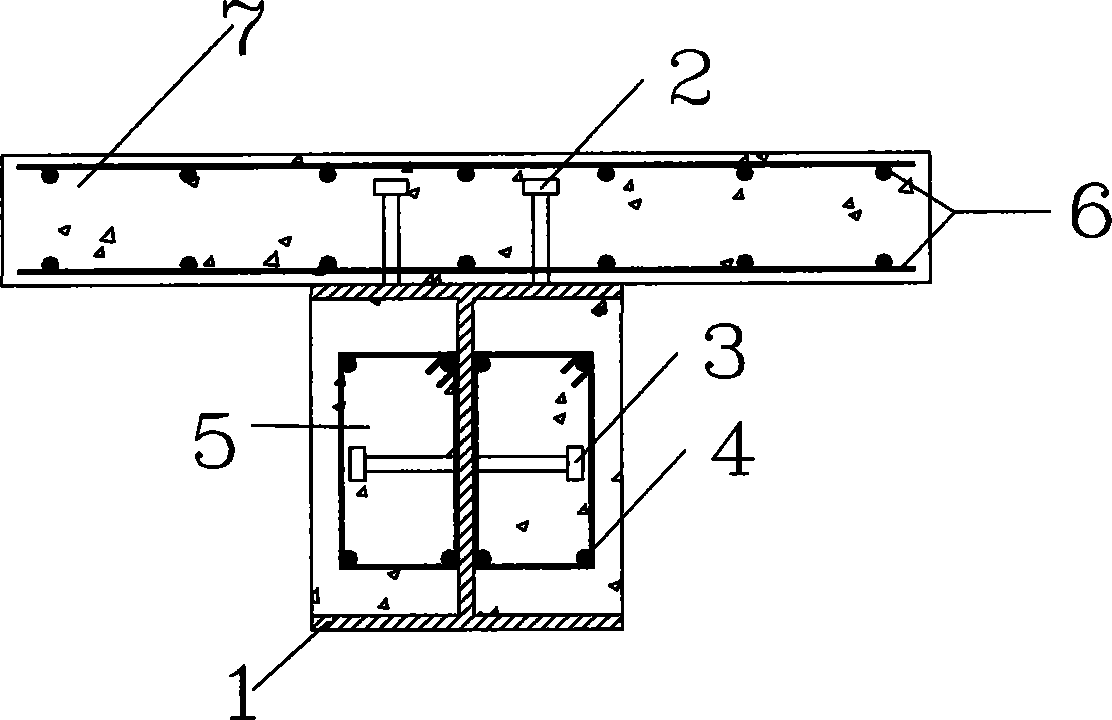

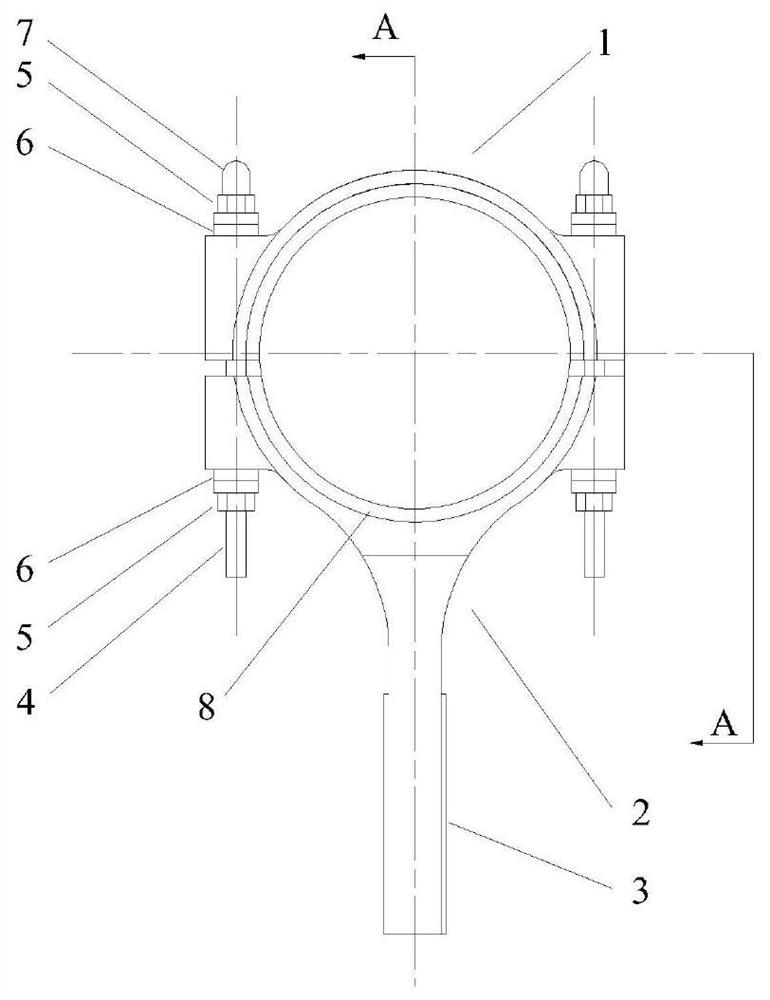

Composite beam comprising steel beam with concrete at abdomen

InactiveCN103266720AImprove fire resistanceImprove efficiencyLoad-supporting elementsMaterials scienceComposite beams

The invention discloses a composite beam comprising a steel beam with concrete at the abdomen. The composite beam comprises a steel beam (1) and a floor plate (7), wherein the concrete (5) is poured at the abdomen of the steel beam (1); the outer wall of the concrete (5) is flush with the outer sides of an upper flange and a lower flange of the steel beam (1); a steel reinforcement cage (4) is embedded at the abdomen of the steel beam (1); an abdomen shearing force connecting piece (3) is welded at the abdomen of the steel beam (1); reliable bonding and joint working of the concrete at the abdomen of the steel beam and the steel beam (1) are ensured through the abdomen shearing force connecting piece (3); outer shearing force connecting pieces (2) are welded at the outer side of the upper flange of the steel beam (1); and combination and joint working of the steel beam (1) and the floor plate (7) are realized through the outer shearing force connecting pieces (2). Compared with the prior art, the combination with the floor plate is taken into account, the whole bearing capacity and rigidity are improved, the section height of a member is decreased, and the building clearance is increased, so that the economic performance is greatly improved.

Owner:NANJING UNIV OF TECH

Plunger for high abrasion-proof displacement pump

ActiveCN101403381ASmall coefficient of frictionImprove wear resistancePositive displacement pump componentsPlungersGas phaseMetallic materials

The invention provides a plunger used for a positive-displacement pump, which is formed by embedding metallic and non-metallic materials and has good wear-resisting property. The plunger comprises a plunger core body which is manufactured by Ni-Cr stainless steel and provided with a connecting end head; the plunger core body is coated with a shell prepared by a SIC material; a sealing adhesive layer is arranged between the connecting end head of the plunger core body and the contacting surface of the shell; the end head of the plunger core body is also provided with a plug to plug the end head. The surface of the plunger adopts a gas-phase permeation SIC shell with high hardness, and has very small friction coefficient and good wear-resisting property and good self-lubricity; after being used by the positive-displacement pump, the wear-resisting property of the plunger is higher than the metallic plunger by more than 5 times, thereby being applicable to be used by the positive-displacement pump with high reciprocating frequency and short stroke; simultaneously, the anti-corrosion property of gas-phase permeation SIC material also solves the anti-corrosion property of the plunger, thereby prolonging the service life of the plunger, guaranteeing that the plunger can operate normally in any serious environment and being applicable to be used in highly corrosive mediums.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

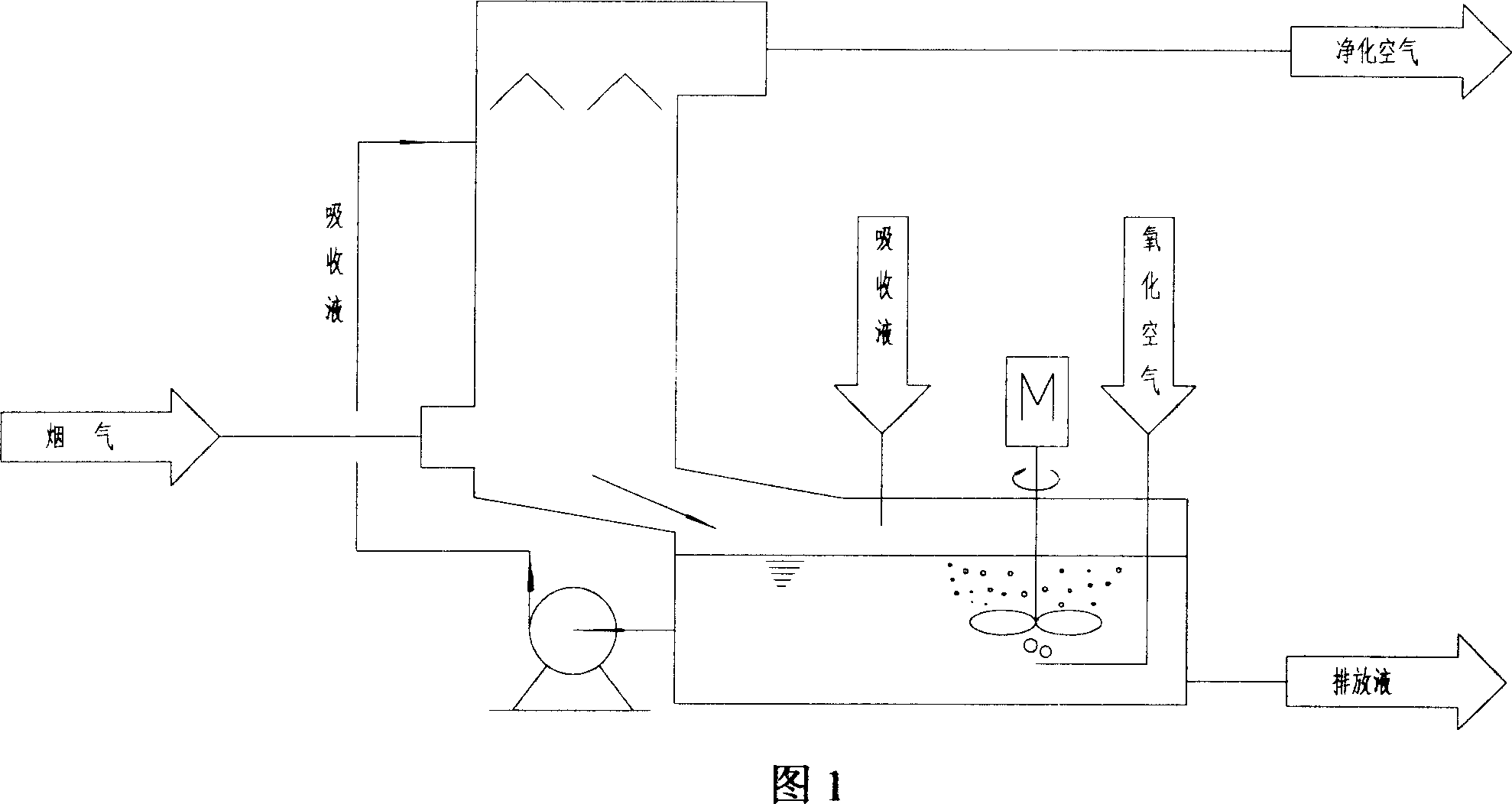

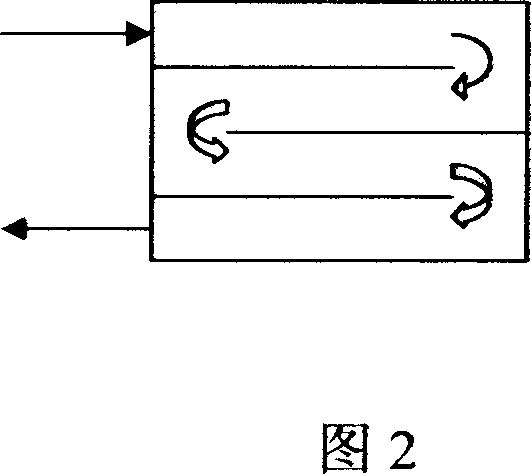

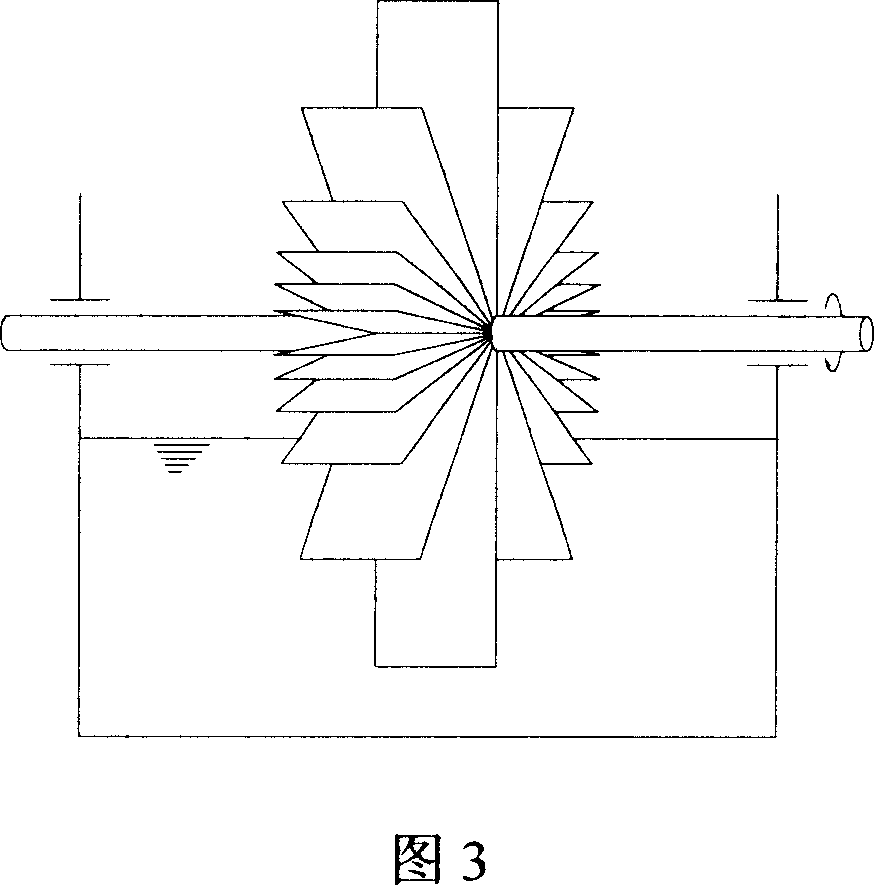

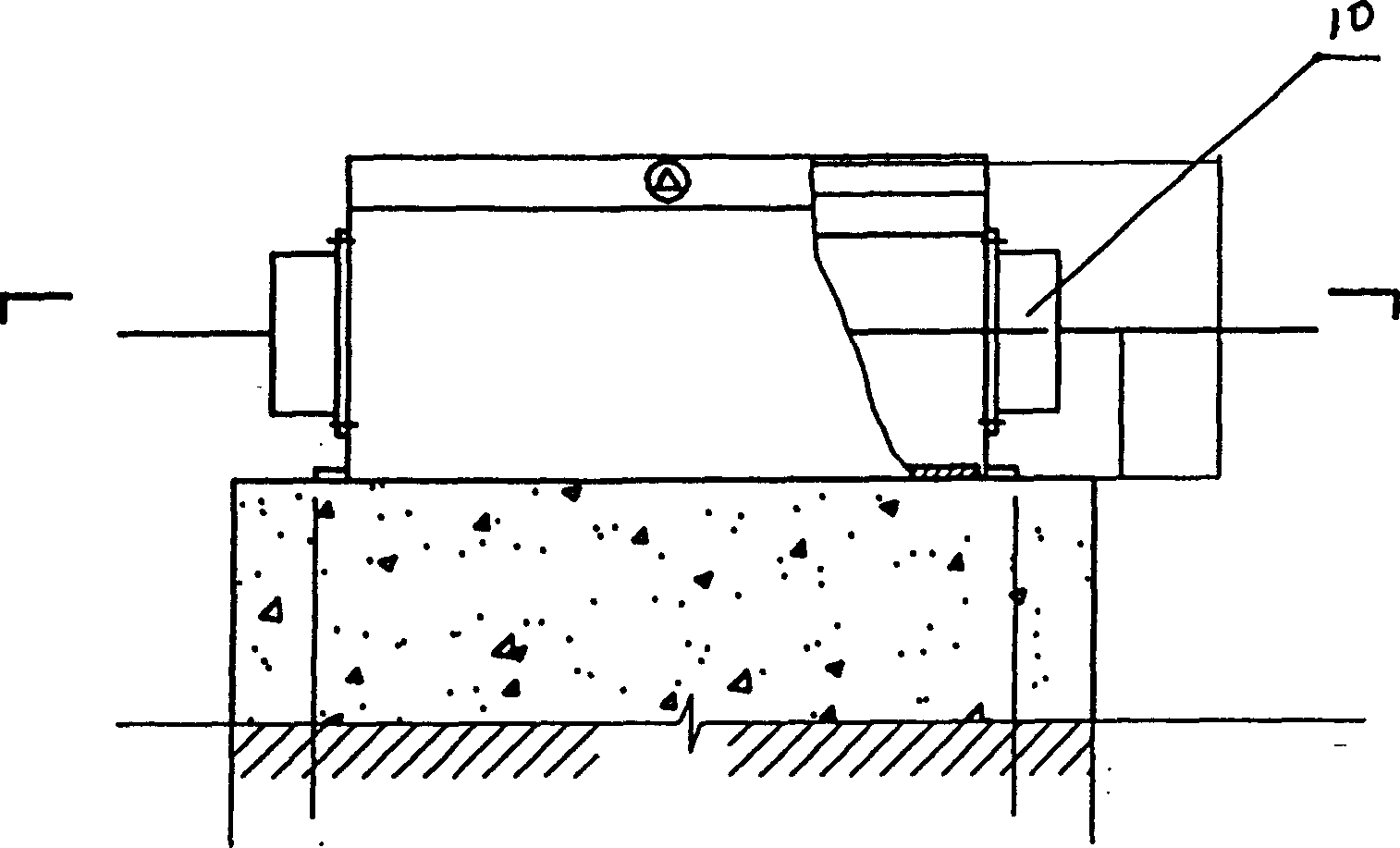

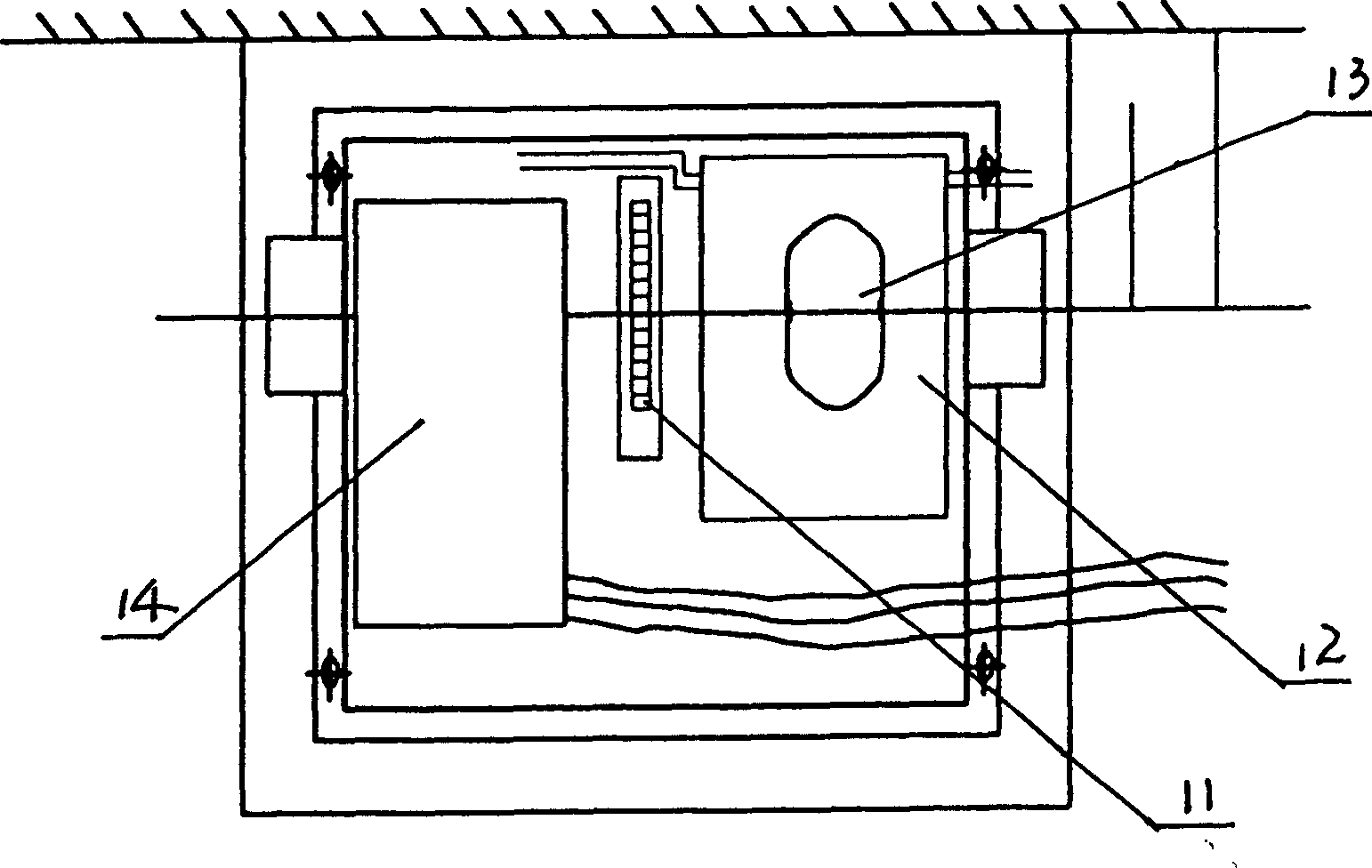

Liquid holding bath side-placed smoke gas desulfurization unit

ActiveCN101062462AIncrease volumeLower the altitudeDispersed particle separationParticulatesProduct gas

The invention relates to a liquid holdup side set flue gas desulfurization device made of gas desulfurization and side holding liquid slot. The smoke going into the bottom of the desulfurization section, contact with the top spraying absorption counter current to be removed by SO2 in the smoke, absorption liquid falling to the bottom of the desulfruization flowing back to the liquid holdup slot without liquid storing at the bottom, installing mixer on the top of the liquid holding slot, preventing the deposit of floating grains, blowing into oxidization air from the liquid holdup slot, with the oxidized gas emitted together with the purified smoke. The space right under the smoke desulfurization section is the circulating pump house.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-way lead wire device

InactiveCN1560558AAutomatic cycleResolve Level VariationsHydrostatic levellingMechanical measuring arrangementsMetallic LeadStatic force

The invention discloses a two-way bracing wire device, which belongs to a measuring device in water conservation, communication and rock and soil field. It includes a fixing end, suspending end, bracing wire body, two-way measuring box, automatic water filling device, liquid storage barrel and connecting pipe, the two-way measuring box has a water box, floating bracket, manual measuring meter and two-way bracing wire device; the water box, liquid storage barrel and the automatic liquid filling device are connected together through the connecting pipe, the bracing wire is leaded in through the fixed end to the suspending end through each measuring bracket, and the wire are winded on the heavy wheel. The invention changes the single measuring aim of the single way bracing wire device and static force level device, realizes two functions with one wire.

Owner:NANJING AUTOMATION INST OF WATER CONSERVANCY & HYDROLOGY MINIST OF WATER RESOURCES

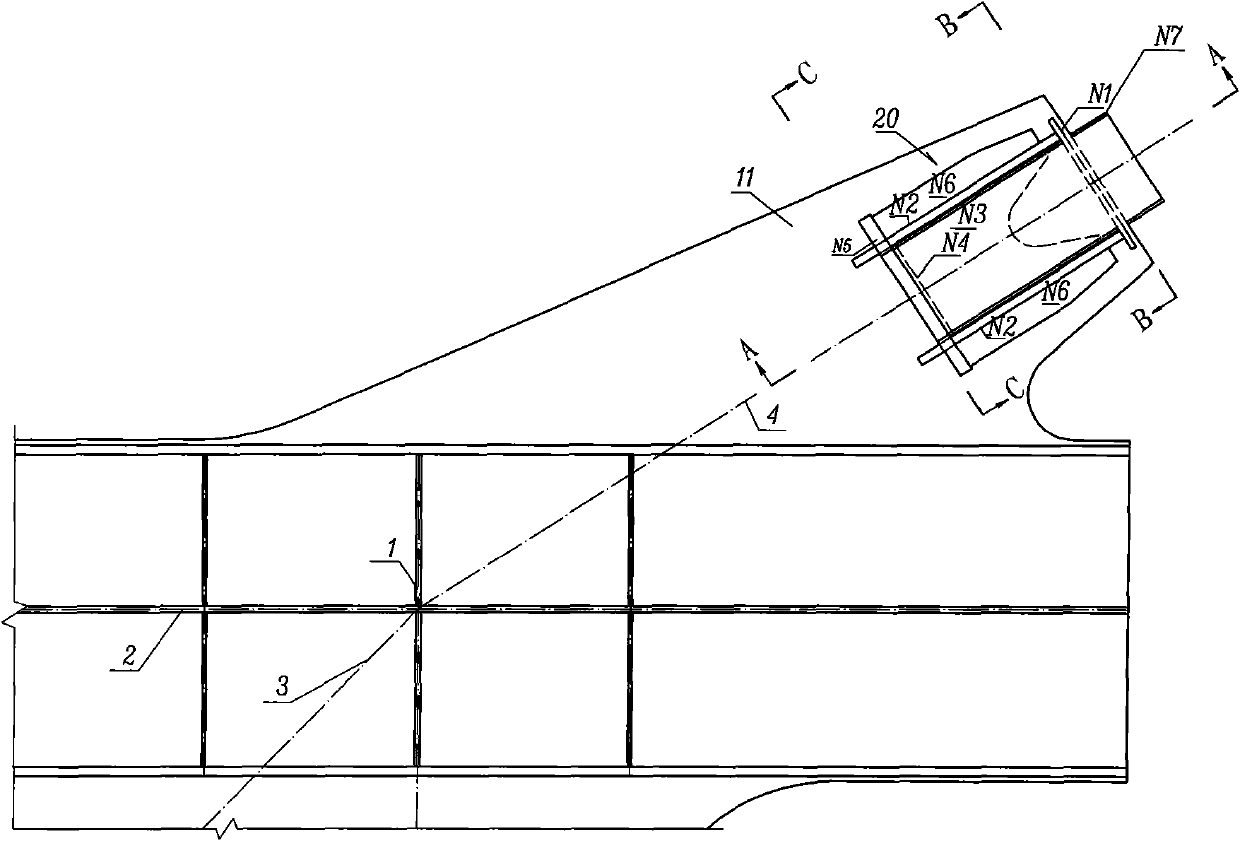

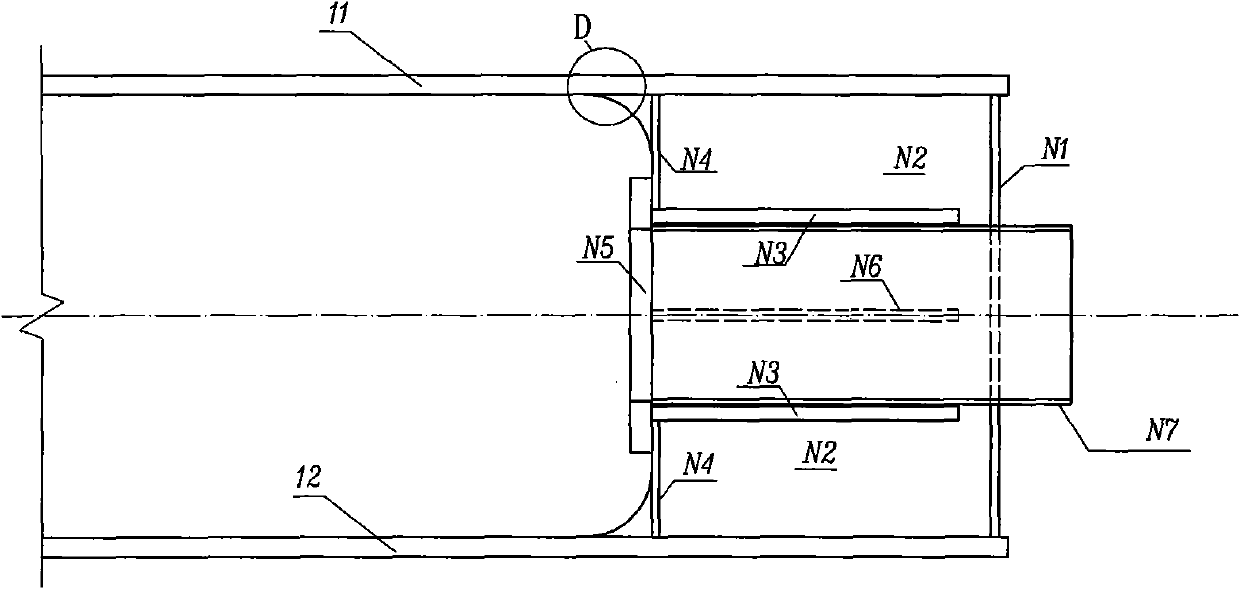

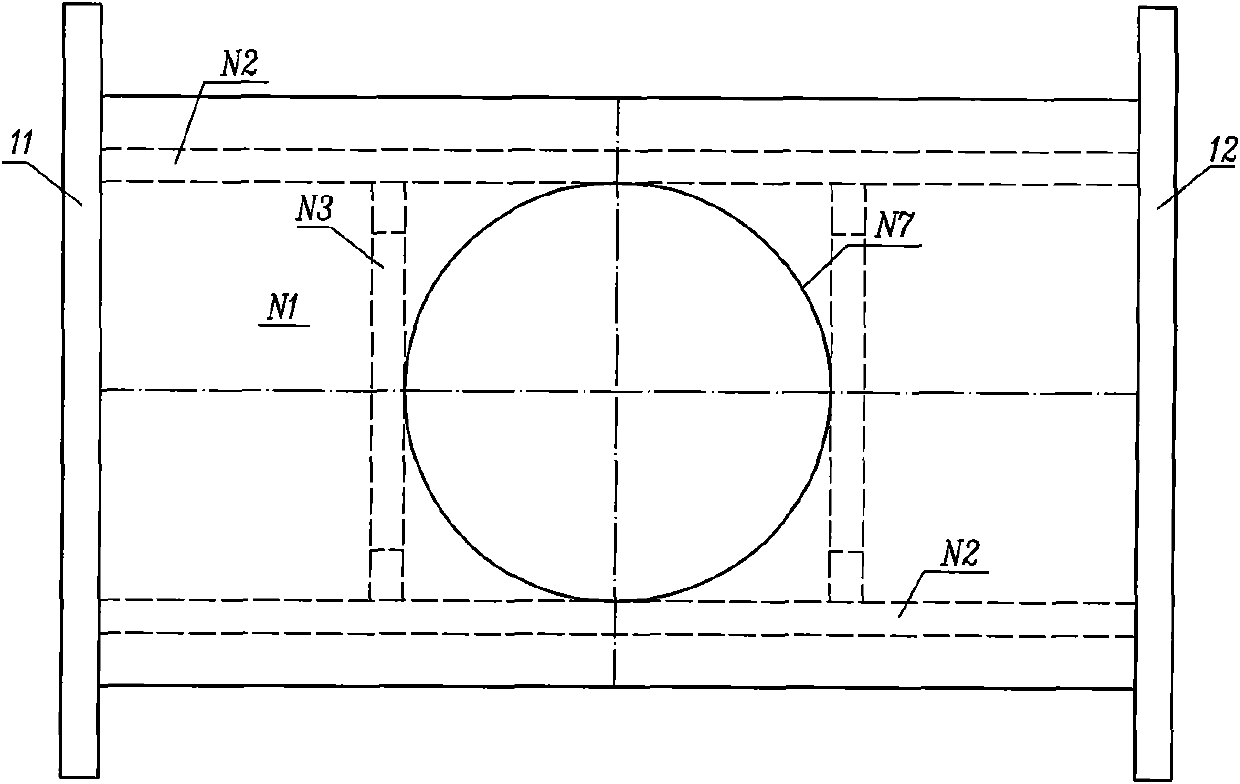

Overall composite towing beam arching structure for railway steel truss girder cable-stayed bridge

ActiveCN101793002AAvoid defectsTightly boundCable-stayed bridgeBridge structural detailsStress concentrationCable stayed

The invention discloses an overall composite towing beam arching structure for a railway steel truss girder cable-stayed bridge, which aims to uniformly transfer a cable force to a main truss structure, has high integrity without generating greater stress concentration phenomenon at key parts such as a welding seam and the like, and improves the anti-fatigue performance of the structure. The structure comprises a pair of overall arch plates (11 and 12) and a steel anchor box (20), wherein the pair of overall arch plates (11 and 12) are formed by extending upwards directly from node plates on the two sides of the top chord of a main truss; the steel anchor box (20) is arranged between the upper parts of the pair of overall arch plates (11 and 12) and is fixed with the upper parts of the overall arch plates (11 and 12); a steel sleeve tube (N7) through which a stayed-cable can pass is fixedly arranged in the steel anchor (20); and the stayed-cable axis of the steel sleeve tube (N7) is crossed with the central line (1) of a node of the main truss, an upper chord system line (2) and a diagonal web member system line (3).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

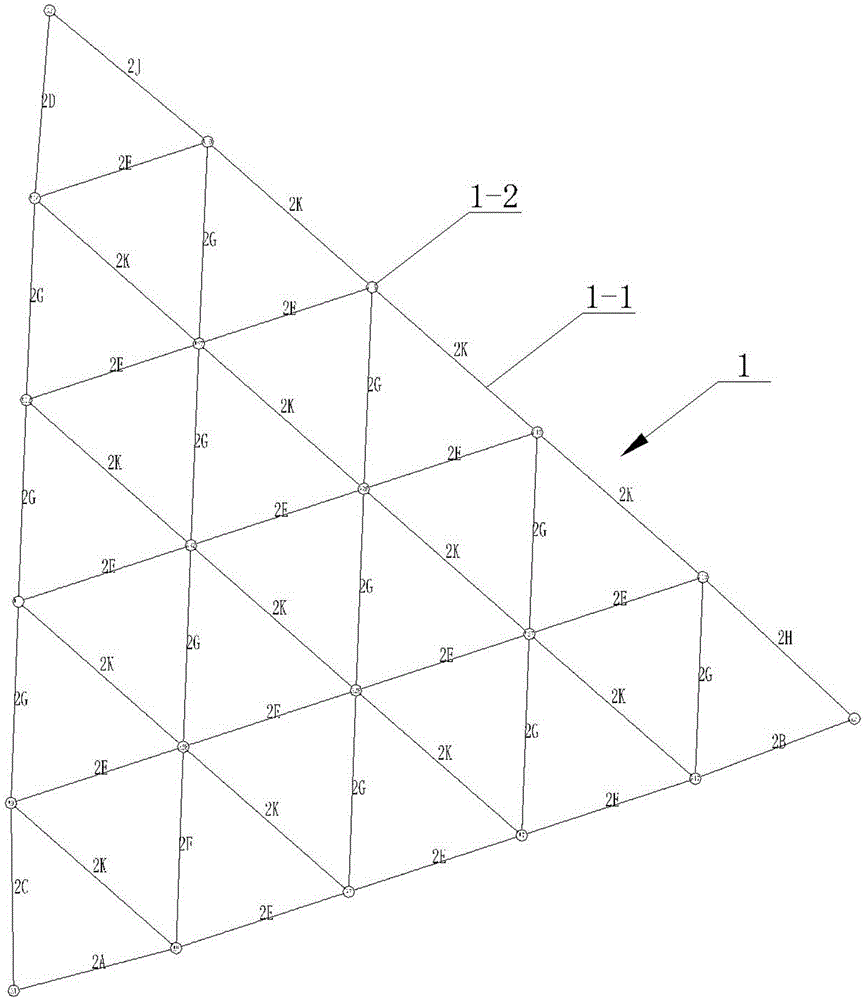

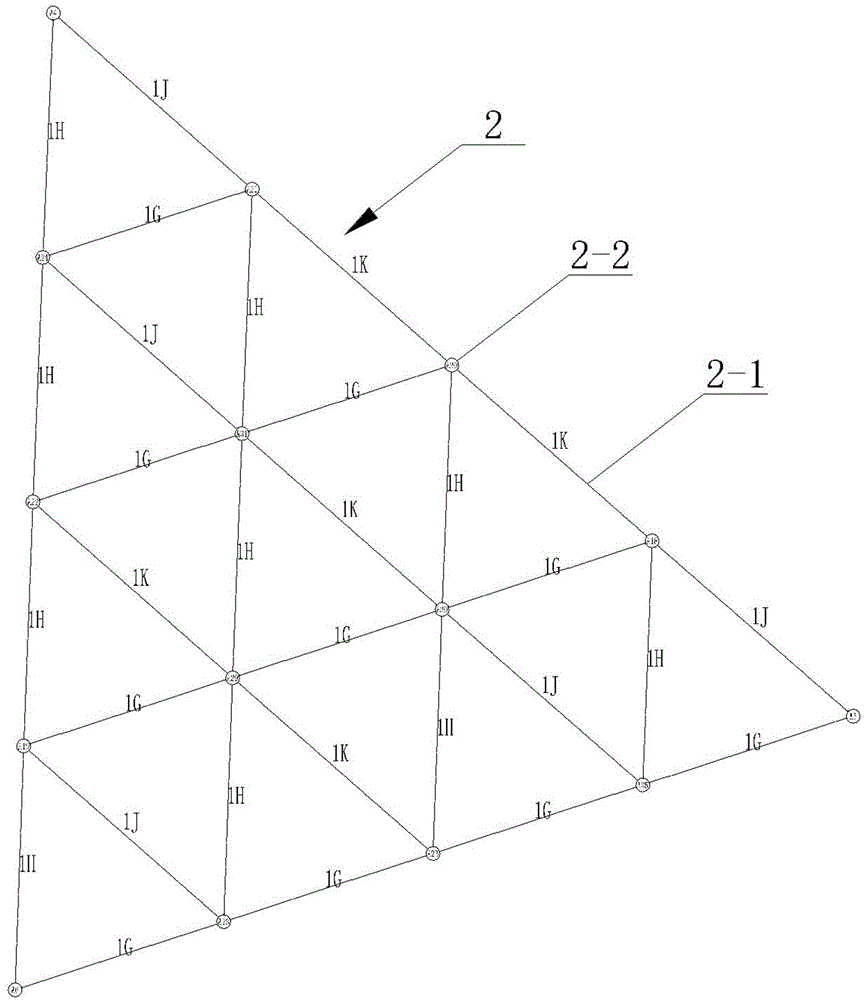

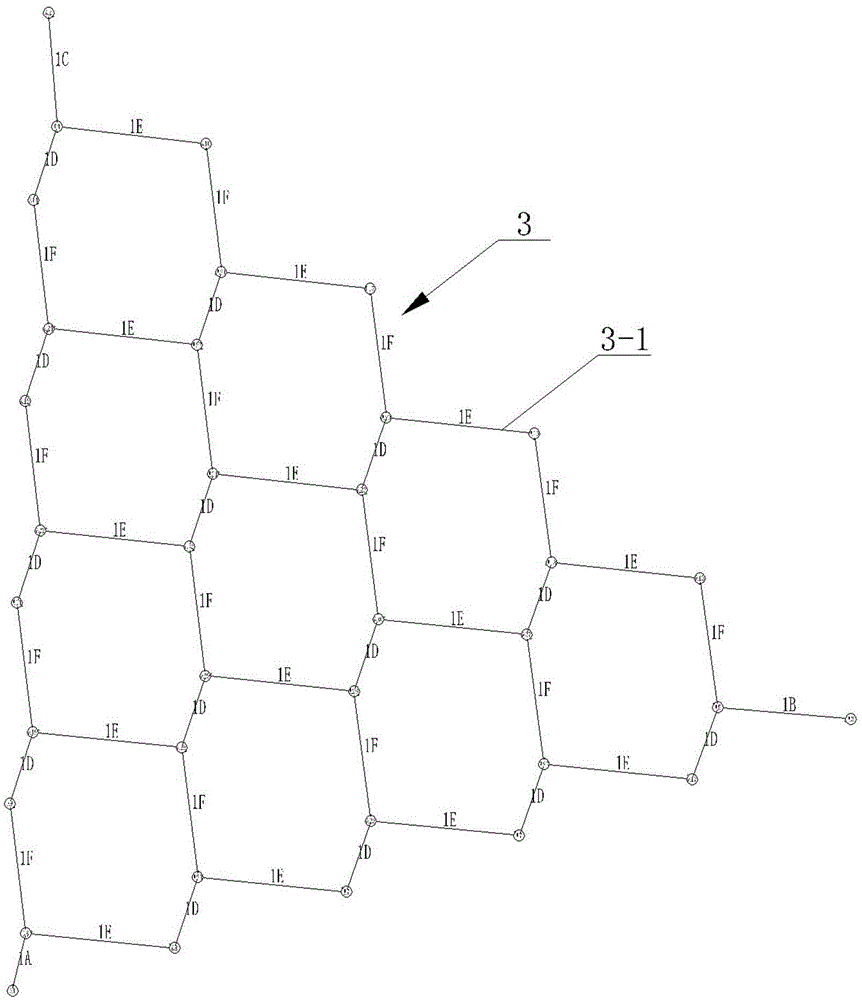

Spatial five-equal partition reflecting face unit of FAST (five-hundred-meter aperture spherical radio telescope)

The invention discloses a spatial five-equal partition reflecting face unit of an FAST (five-hundred-meter aperture spherical radio telescope). The spatial five-equal partition reflecting face unit of the FAST comprises a double-layer frame carrier. The double-layer frame carrier is integrally shaped in a triangle. Each layer of the frame carrier is formed by a plurality of triangular structure units. The triangular structure units are formed by connecting support rods via joint balls. Every edge of an upper layer of the frame carrier is partitioned into five equal partitions. Every edge of a lower layer of the frame carrier is partitioned into four equal partitions. Web diagonal bracings are arranged between the two layers and are connected to the joint balls. The upper layer of the frame carrier serves as a base seat and is provided with a plurality of triangular panel subunits. The panel subunits are fixedly mounted on the support rods and the joint balls of the upper layer of the frame carrier via joint support devices. Support heights of the panel subunits can be adjusted by the joint support devices. The support rods, the joint balls, the web diagonal bracings and the panel subunits are made of aluminum alloy.

Owner:NAT ASTRONOMICAL OBSERVATORIES CHINESE ACAD OF SCI

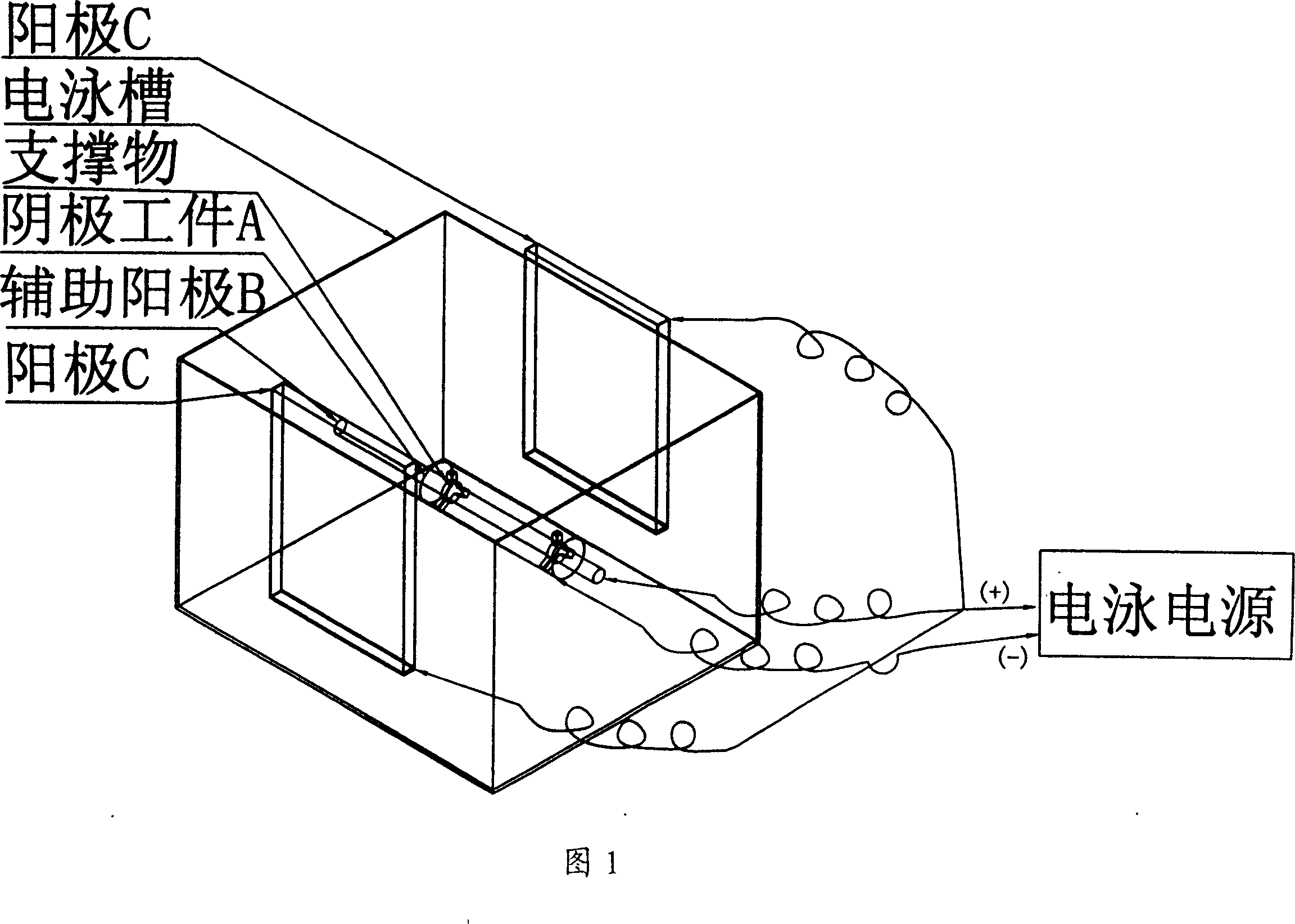

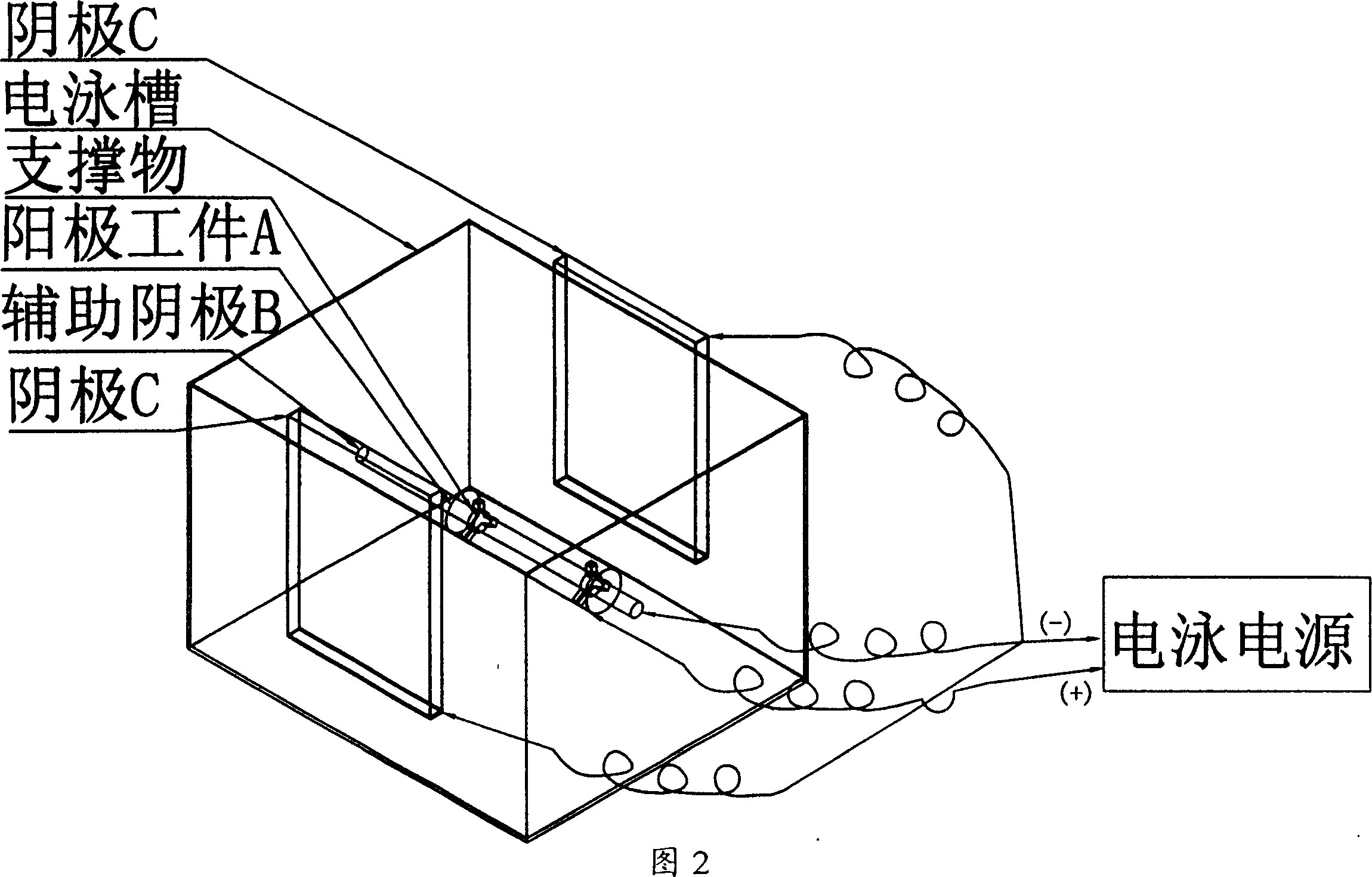

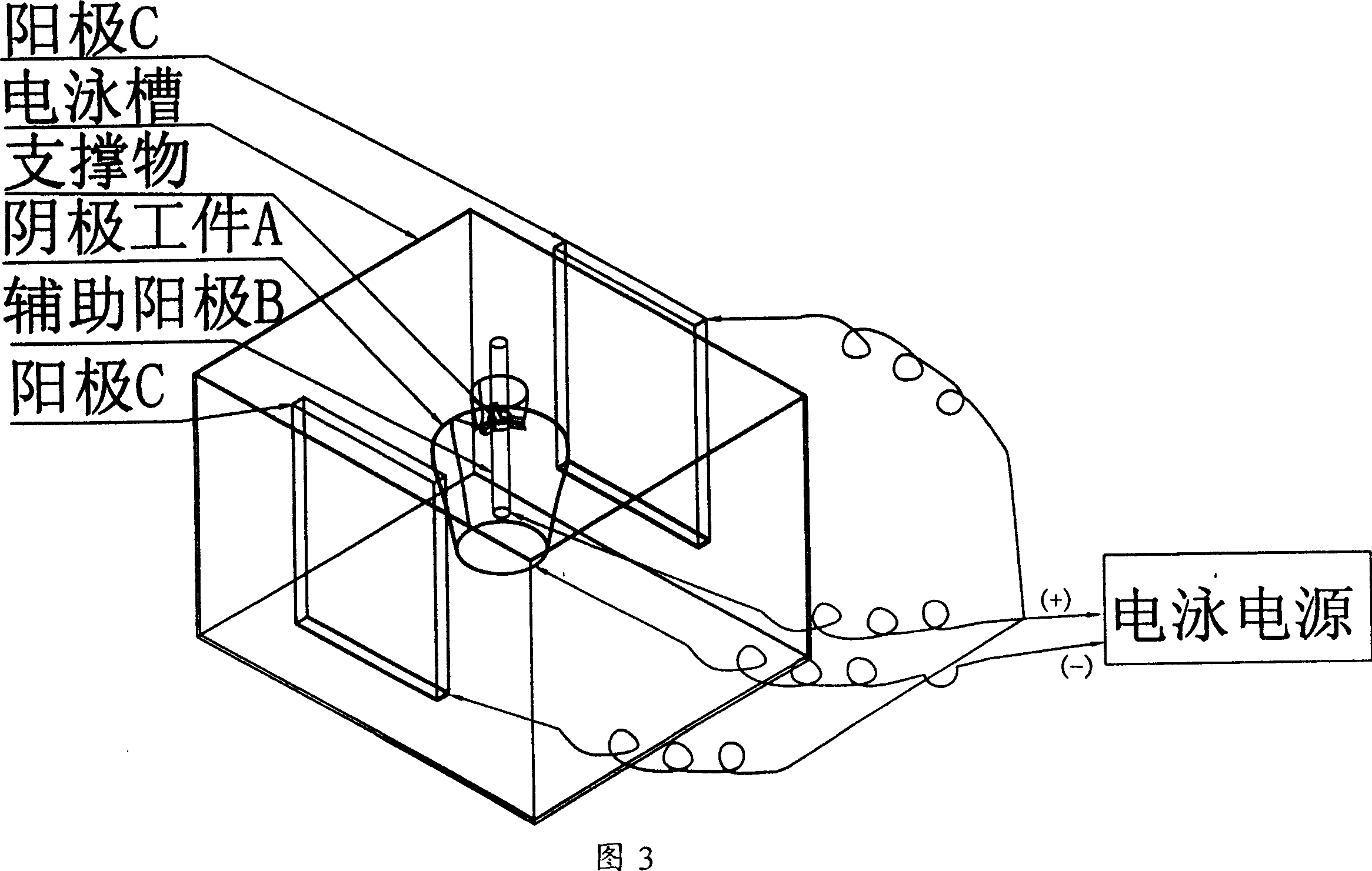

Electrophoresis painting dressing technical method for pipe fitting type metal, and metal piece with deep hole, and deep concave

InactiveCN101003908ASolve the problem of corrosionSimple processElectrophoretic coatingsPipe fittingElectrophoresis

This invention relates to a method for metal surface electrophoretic coating, more specifically, a method for electrophoretic coating of tube-shaped, deep-hole-shaped or concave-shaped metal surface. The method comprises: putting an auxiliary cathode into the deep hole of the metalwork during anode electrophoresis process. The method has such advantages as simple process and wide applications. The method can realize electrophoretic treatment of inner and outer wall as well as inner and outer chamber of tube-shaped, deep-hole-shaped or concave-shaped metals thus can completely solve the preservative problem of inner and outer wall as well as inner and outer chamber.

Owner:李再亮

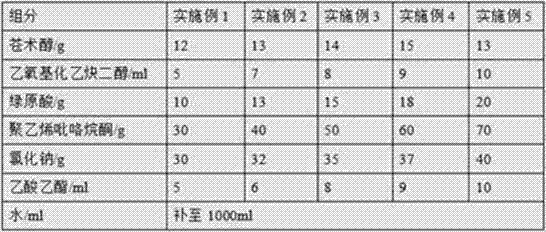

Pathological specimen processing method

InactiveCN106908294ABroad antimicrobial effectAntioxidantPreparing sample for investigationChlorogenic acidSpecimen Handling

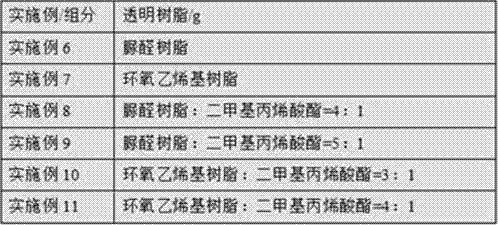

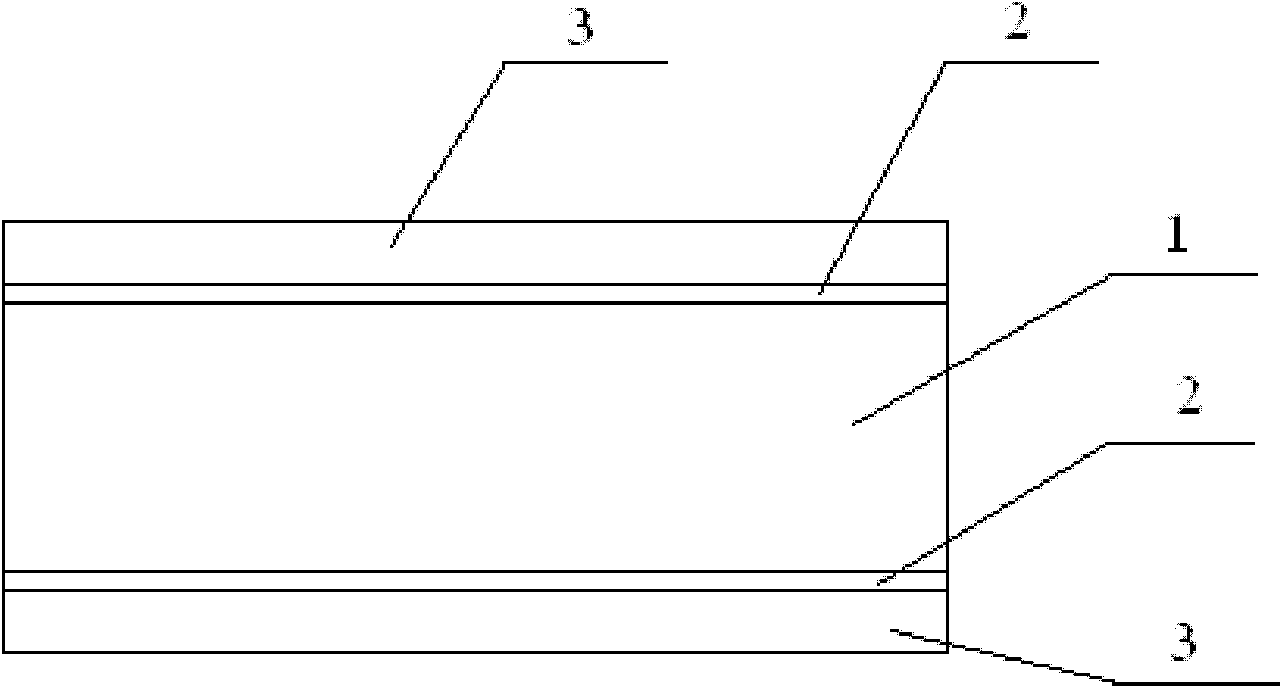

The invention discloses a pathological specimen processing method and belongs to the field of specimen processing technology. According to the processing method, sampled pathological tissues successively undergo fixation, dehydration, transparency, wax impregnation, embedding, slicing, staining and mounting so as to obtain a pathological specimen. The fixation is to fix the pathological tissues by the use of a fixative for 4-15 h. The fixative is composed of atractylol, ethoxylated acetylenediol, chlorogenic acid, polyvinylpyrrolidone, sodium chloride, ethyl acetate and pure water. The mounting is to carry out mounting on the stained pathological tissues by the use of a mixture of polyacrylamide, polyvinylpyrrolidone and xylene. According to the invention, toxicity of reagents used in the invention is obviously reduced, the fixation effect is good, degradation and transparency degree are easy to control. Then, the tissues are not easy to deform, embrittle or harden, and mounting is complete and staining is remarkable.

Owner:LUOHE MEDICAL COLLEGE

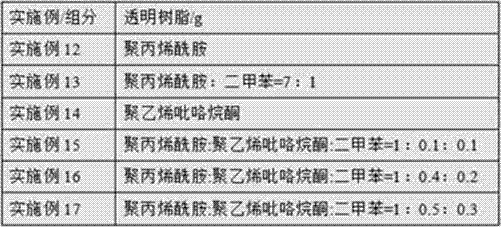

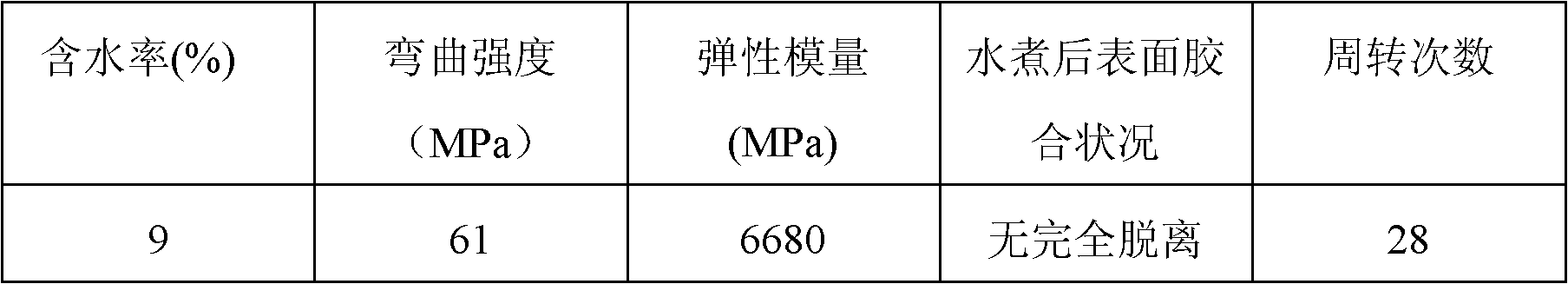

Plastic overlaid plywood building template with large turnover number and preparation method thereof

InactiveCN102425295AEasy to demouldReduce use costLaminationLamination apparatusTurnover timeAdhesive

The invention relates to a plastic overlaid plywood building template with a large turnover number and a preparation method thereof, in particular to a building template and a preparation method thereof. Due to the adoption of the plastic overlaid plywood building template with the large turnover number, the technical problems of the present wooden template or the overlaid plywood building template that a mould is difficult to remove and the turnover number is small during the application process can be solved. The plastic overlaid plywood building template with the large turnover number is characterized in that: a layer of polyolefine laminated surface is adhered on the upper surface and the lower surface of the wooden plywood template. The preparation method comprises the following steps that: after polyolefine material is extruded by a vertical-type three-roller plastic sheet machine set to obtain sheets, a layer of non-woven fabric covers the sheet to be extruded again to obtain the polyolefine laminated surface which is covered by the non-woven fabric; and adhesive is smeared onto the non-woven fabric, then the non-woven fabric which is smeared with the adhesive covers the upper surface and the lower surface of the polished wooden polywood to be pressed so as to obtain the plastic overlaid polywood building template with lage turnover number. The surface of the template is free from being adhered by the cement, the turnover times of the template are 25 to 30 times, and the template can be used for construction engineering.

Owner:卜凡华

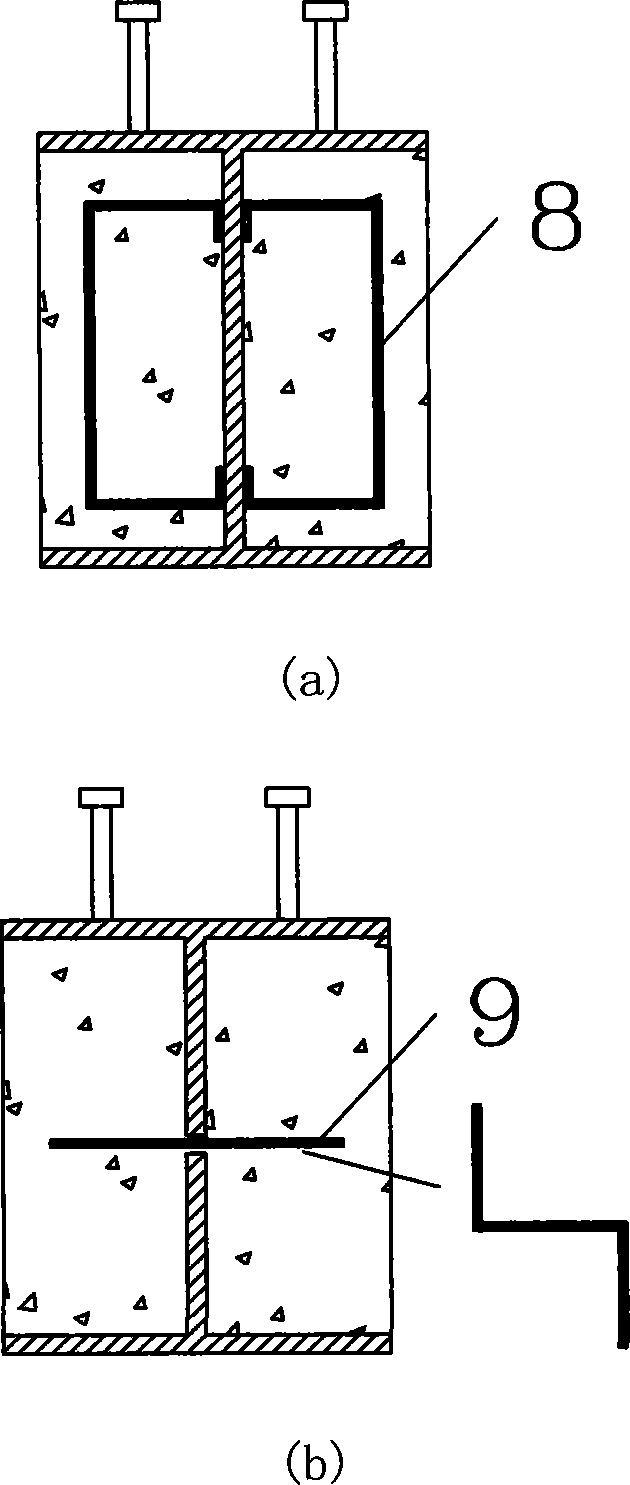

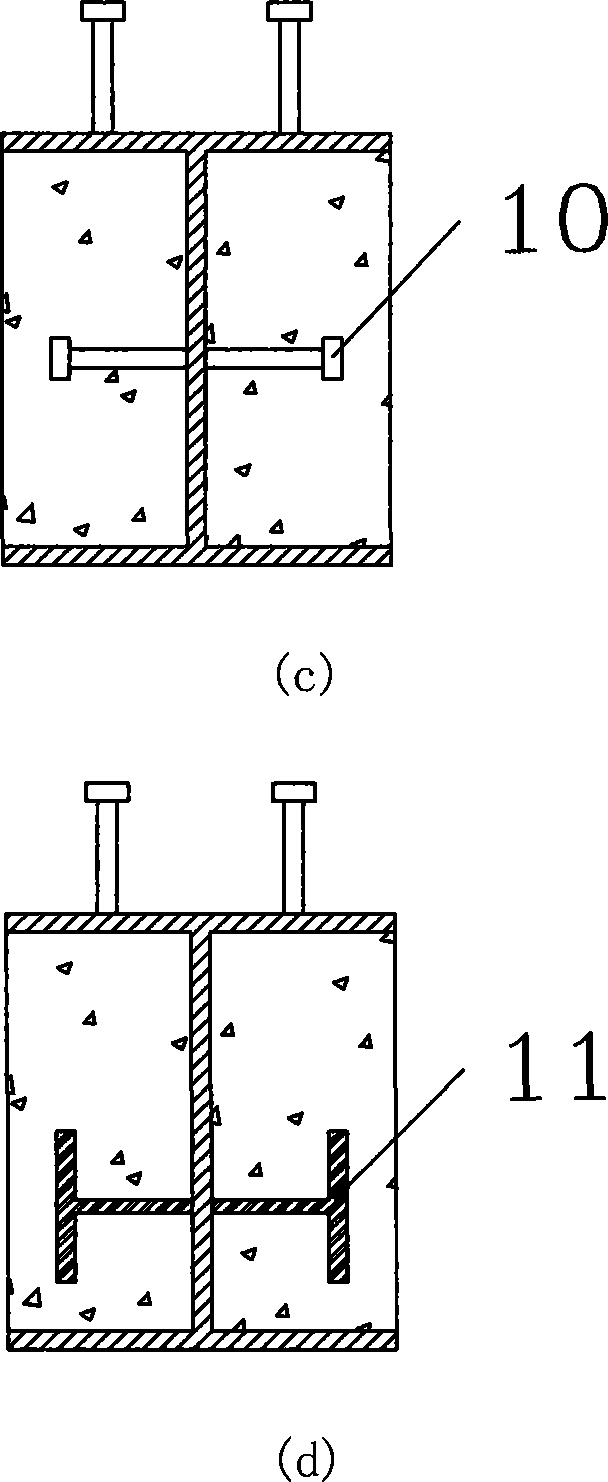

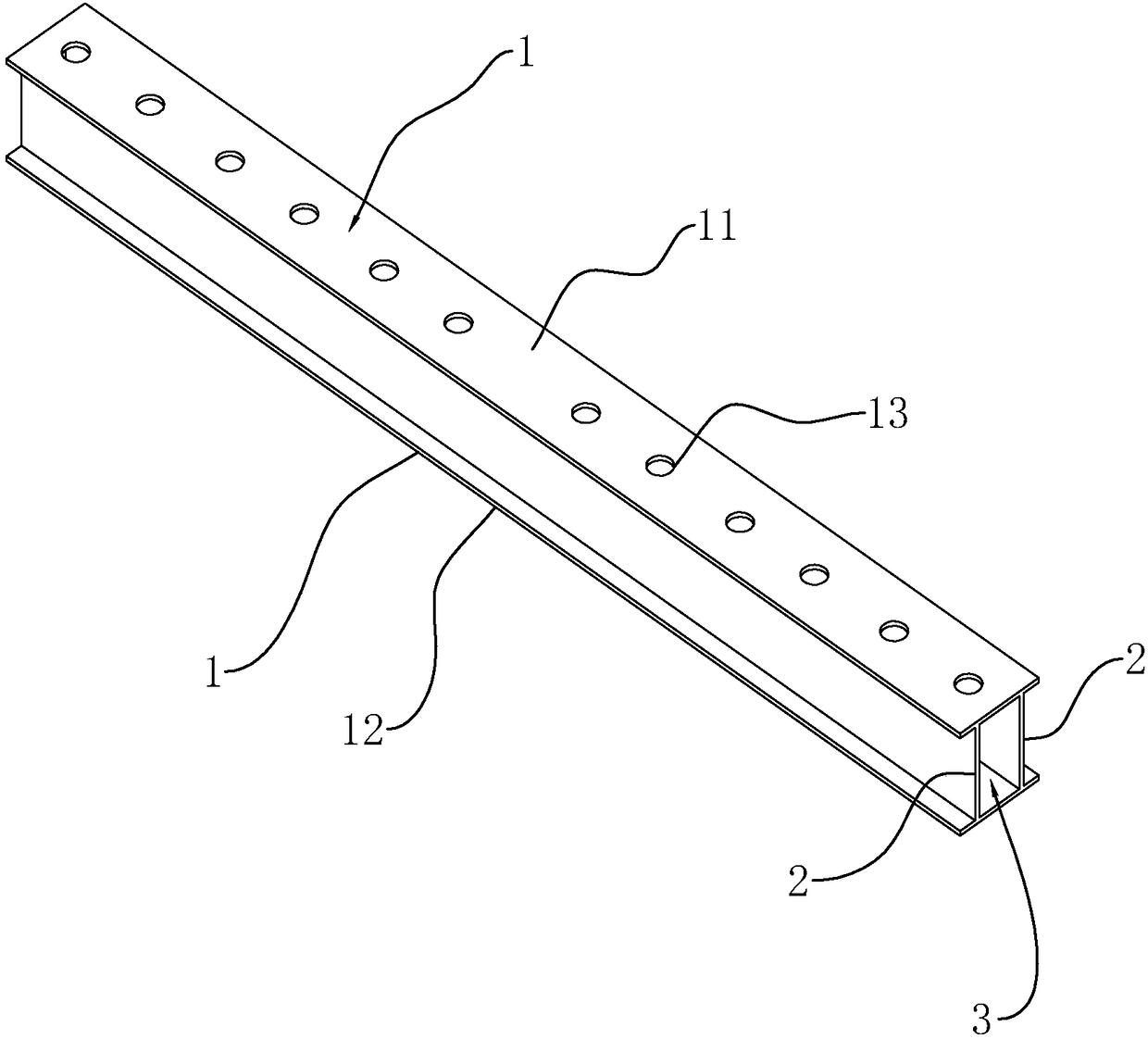

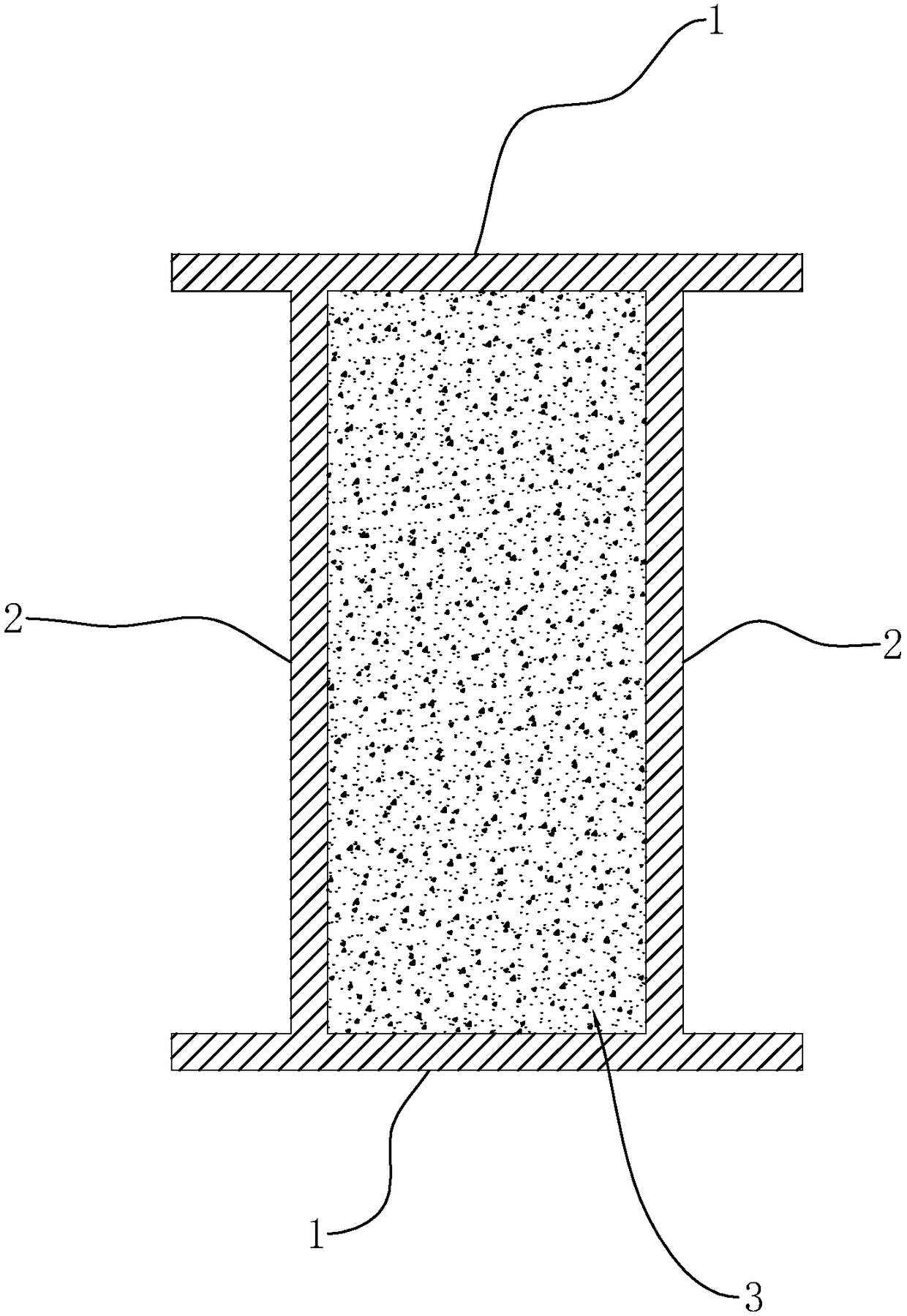

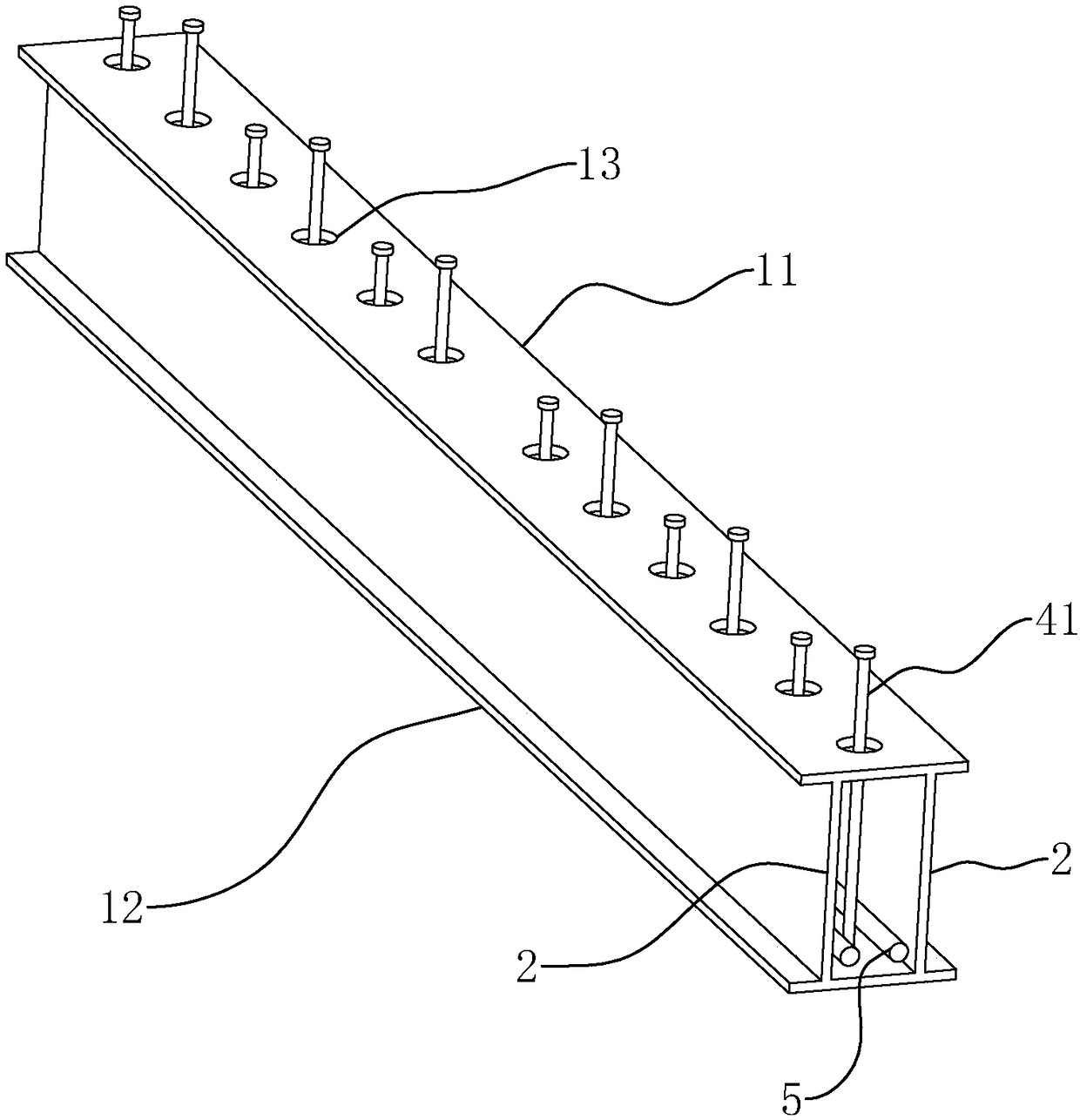

Double-webbed H type steel, and connecting node of double-webbed H type steel and concrete prefabricated slab

PendingCN108412122AImprove bending resistanceImprove torsion resistanceFloorsGirdersArchitectural engineeringMaterial consumption

The invention discloses a double-webbed H type steel, and a connecting node of the double-webbed H type steel and a concrete prefabricated slab. The double-webbed H type steel comprises two flange slabs and two webs, wherein the two flange slabs are in parallel; the two webs are in parallel and are perpendicularly and fixedly connected between the two flange slabs; the two webs and the two flangeslabs form a cavity. According to the H type steel, the material consumption can be reduced, and the integrality is good. According to the connecting node of the double-webbed H type steel and the concrete prefabricated slab, the prefabricated slab and a steel structure are connected through a lateral connecting rib, a first reinforced connecting rod and a poste-poured concrete, so that the integrality and the shock resistance of the connecting node are effectively improved.

Owner:李藏柱

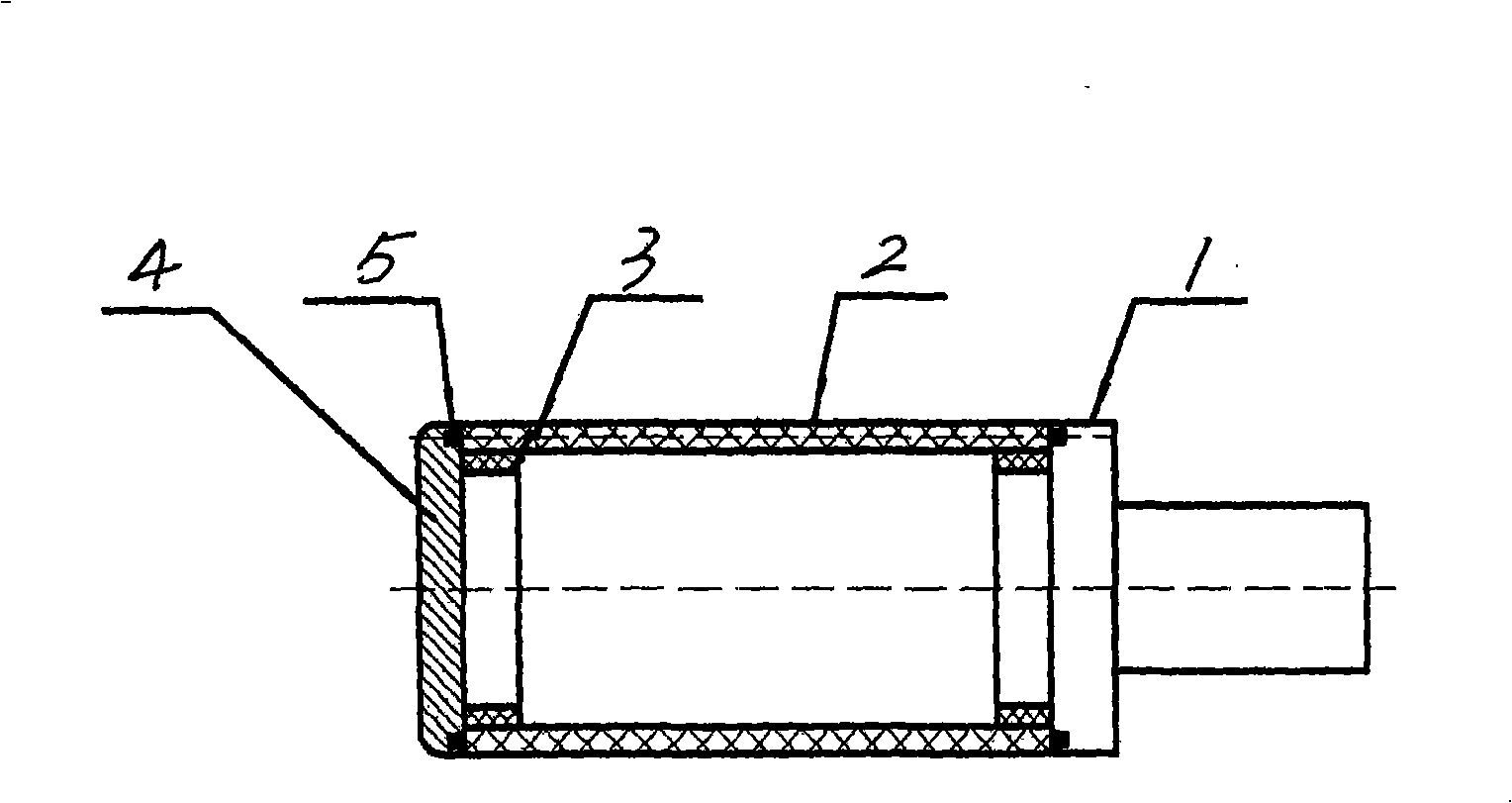

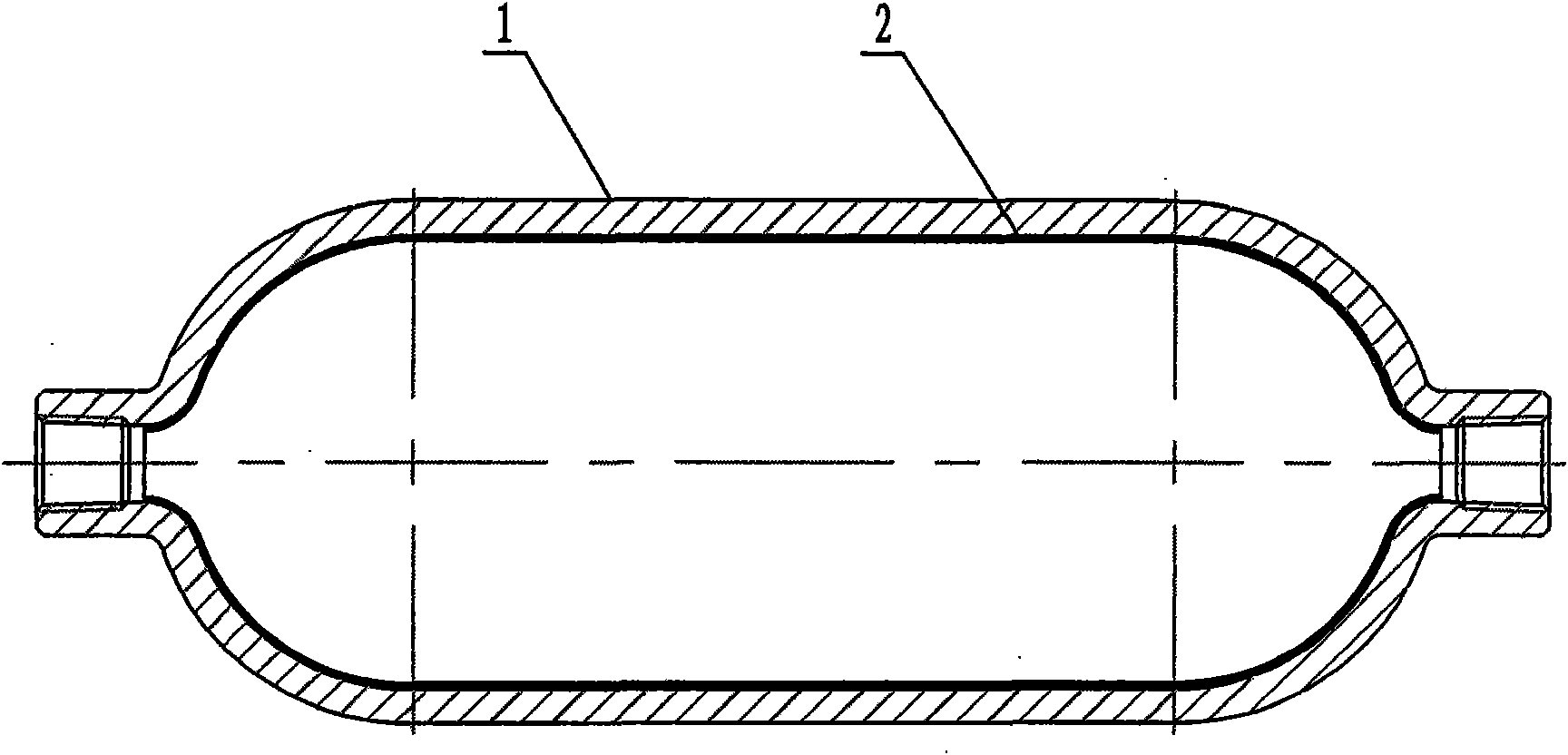

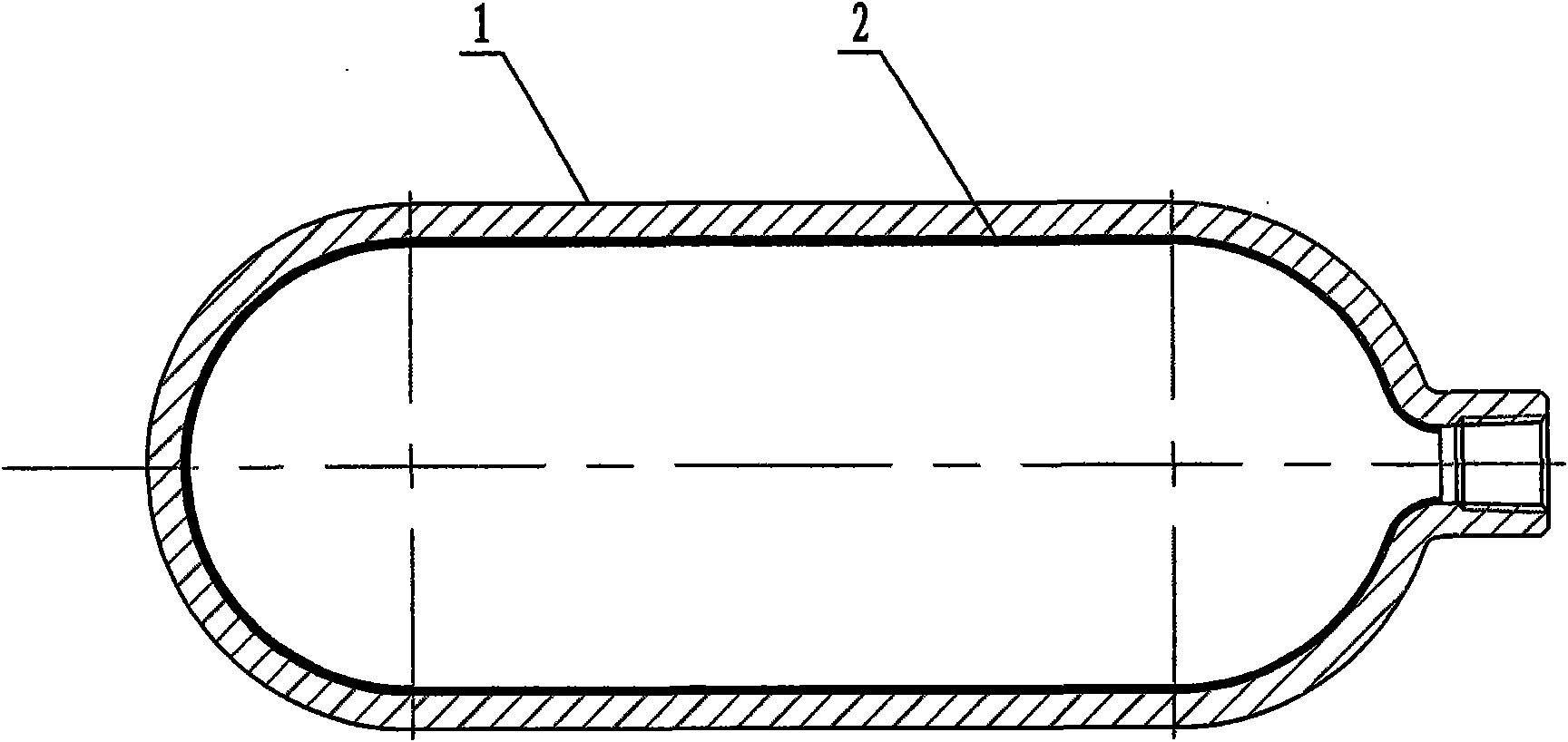

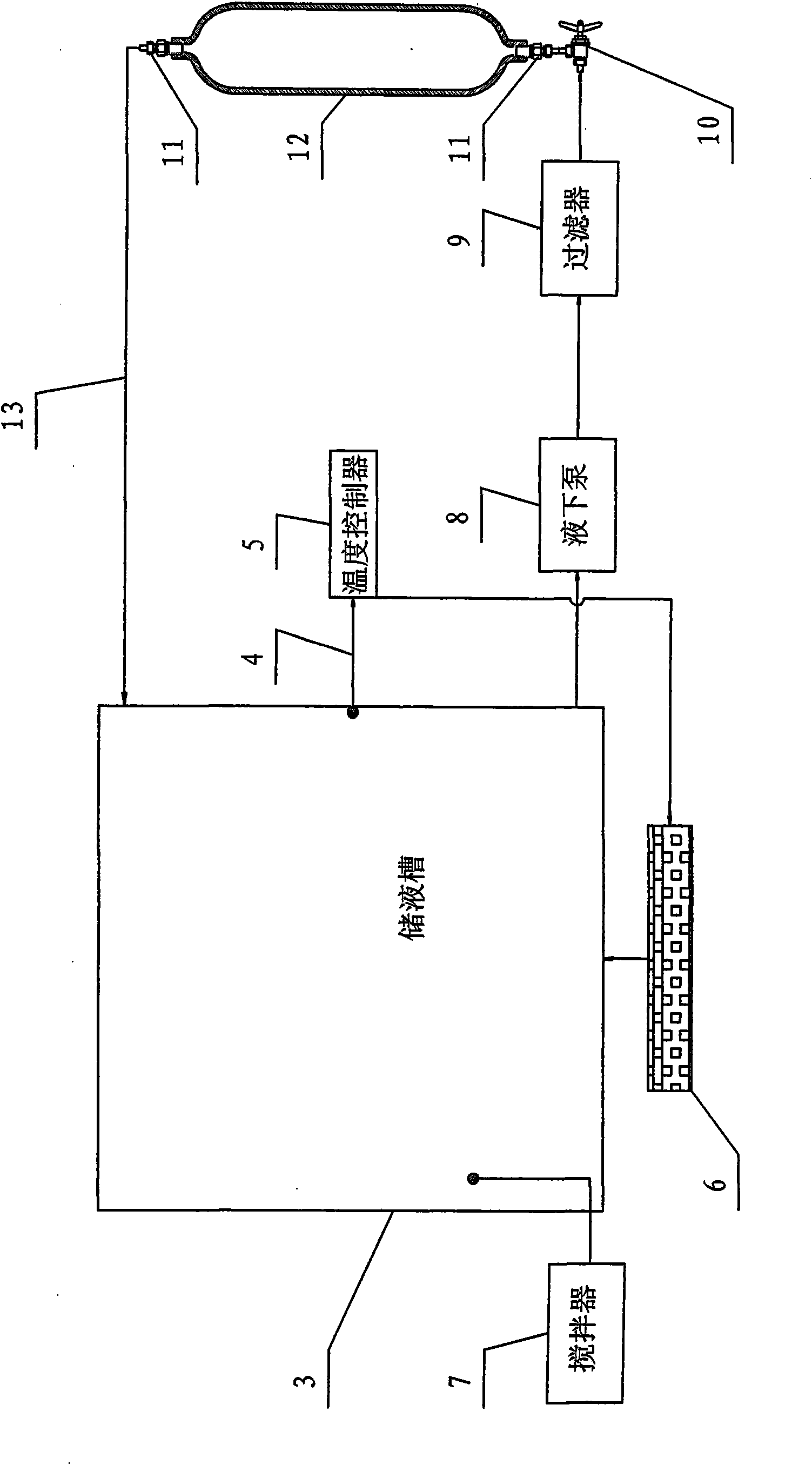

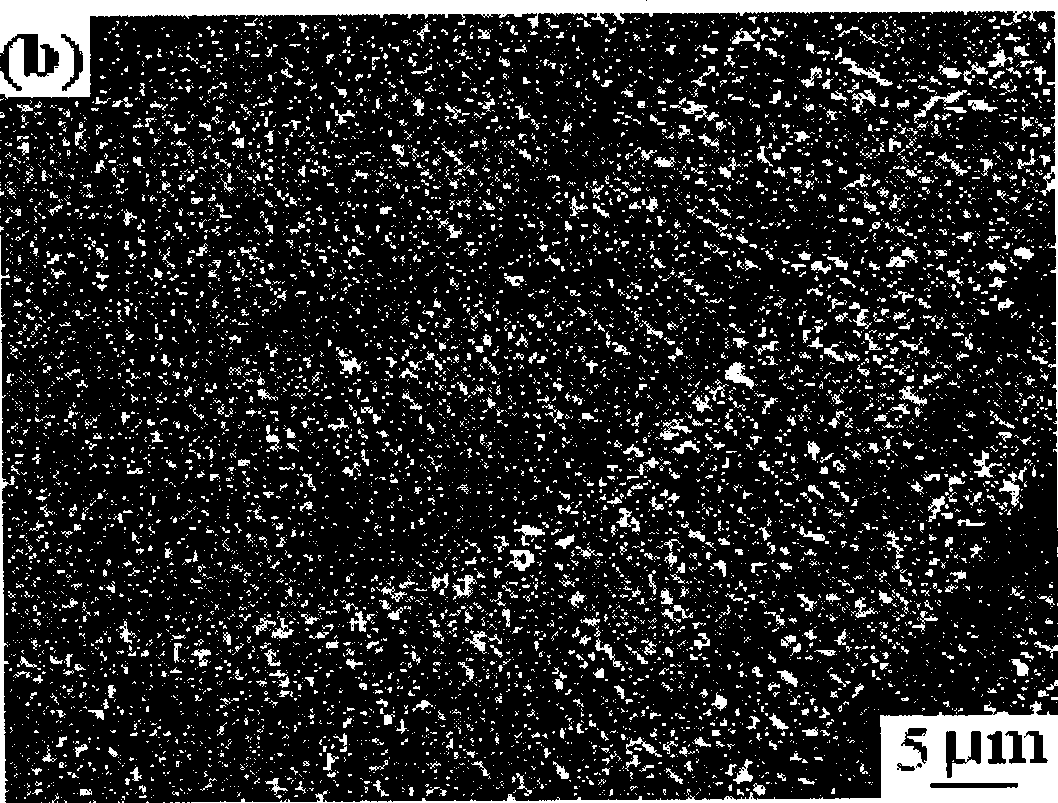

Nickel-phosphorus alloy plated steel cylinder and plating method thereof

ActiveCN101922608AImprove corrosion resistanceHigh hardnessLiquid/solution decomposition chemical coatingPressure vesselsIonChemical plating

The invention relates to a nickel-phosphorus alloy plated steel cylinder comprising a cylinder body, an amorphous state nickel-phosphorus anticorrosive layer is plated on the inner wall of the cylinder body; and the thickness of the amorphous state nickel-phosphorus anticorrosive layer is 3-8 micrometers. A plating method of the nickel-phosphorus alloy plated steel cylinder comprises the following steps of: (1) processing a steel cylinder to be plated, that is to say, sequentially washing with water, washing with acids, washing with water, activating and preheating; (2) carrying out chemical plating on the steel cylinder, placing the steel cylinder into chemical plating equipment, wherein a plating solution is prepared from nickel sulfate, sodium hypophosphite, a complexing agent A, a complexing agent B, a buffering agent A, a buffering agent B, a stabilizer and deionized water, the temperature of the plating solution is controlled between 85 DEG C and 95 DEG C, and plating time lasts till the thickness of the amorphous state nickel-phosphorus anticorrosive layer deposited on the inner wall of the steel cylinder reaches 3-8 micrometers; (3) soaking the steel cylinder subjected to the chemical plating in a Na2CO3 water solution with the concentration of 30-50 g / L at room temperature, then soaking in the deionized water at 85-95 DEG C, and then naturally drying the steel cylinder.

Owner:CHENGDU GREAT HIGH PRESSURE VESSEL

Fence anti-corrosion technology

The invention discloses a fence anti-corrosion technology, which is characterized by comprising the following three steps of descaling, paint spraying and wrapping with a heat shrinkable film: (1) descaling: removing the rust of the fence by means of a laser derusting device; (2) paint spraying: spraying epoxy anti-corrosion series paints, wherein the spraying process is as follows: A, when a brush-painting method is adopted for construction, paints should be brushed in the same direction; B, when a spraying method is used, the movement speed of the spray gun should be uniform and the nozzle should be kept perpendicular to the surface to be sprayed; (3) wrapping with a heat shrinkable film: after the anti-corrosion paints are solidified, wrapping with a heat shrinkable film, heating the heat shrinkable film by use of a flame spray gun to make the surface of the fence evenly wrapped with the heat shrinkable film. First, the method uses laser to remove rust, does not need a derusting agent, is convenient and quick to use, and does not pollute the environment; and then, the method performs a painting spraying treatment so that the original rusty part is covered with the anti-corrosionpaints and the fence can be prevented from being corroded; finally, the method covers the fence with the heat shrinkable film to block the tiny rusty points from contacting with the atmosphere, thereby preventing the corrosion of the rusty points which is difficult to observe.

Owner:JIANGSU GUGELANSHAN PROTECTIVE FACILITIES CO LTD

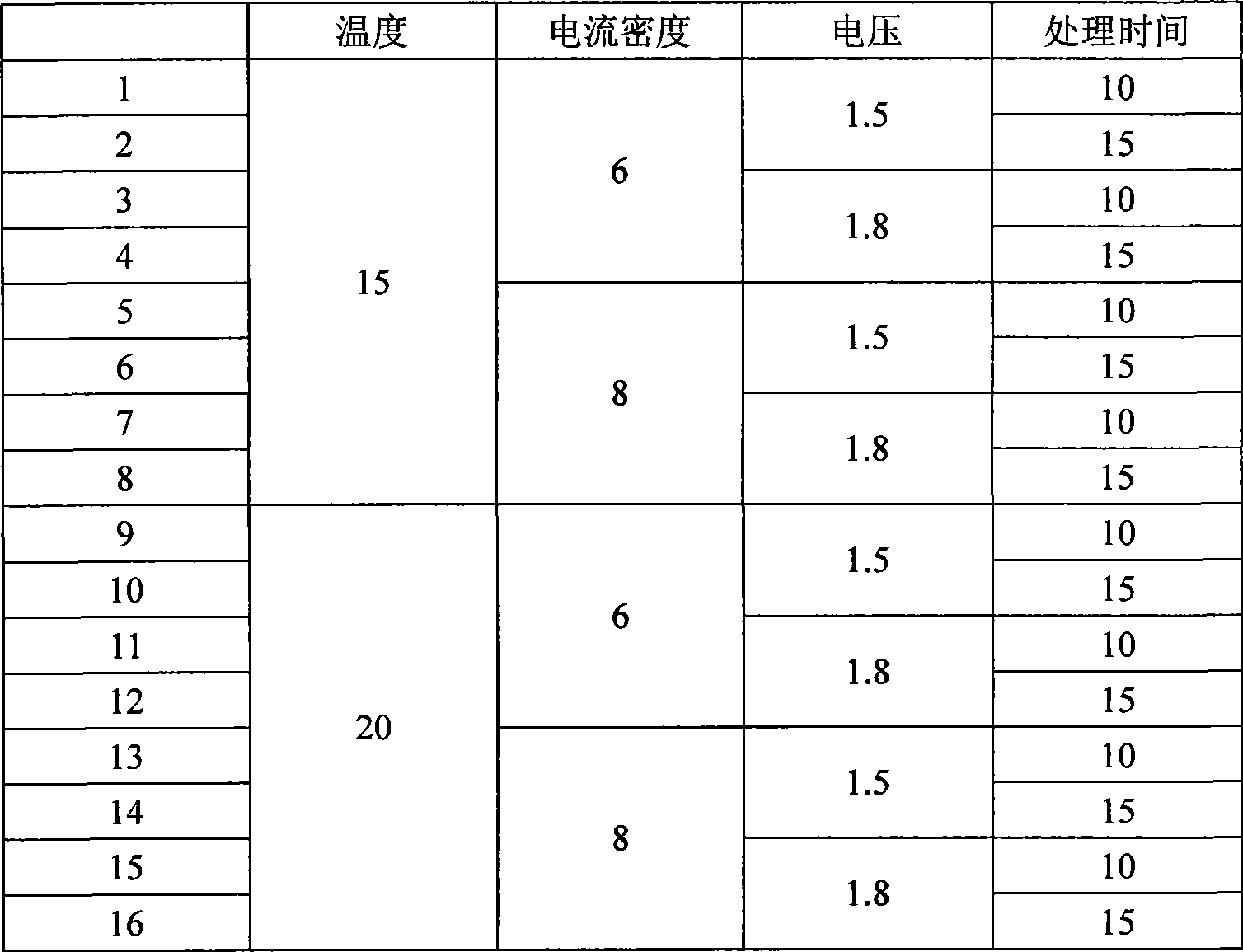

Method for preparing electroforming copper metallographical example and display texture

InactiveCN101509850ASolve the real problemSolve the problem of corrosionPreparing sample for investigationSurface stressCarbide

The invention relates to a method for preparing electrocasting copper-gold phase samples and displaying structure, belonging to the technical field of preparation of gold phase samples. The method comprises the following steps: the electrocasting copper sample is processed by rough grinding to 1000silicon carbide waterproof abrasive paper, then polishing is carried out, the surface state is observed under a microscope, the surface scratch is determined along one direction and electrolytic polishing is carried out to the polished electrocasting copper sample; the composition of the electrolyte is H3PO4 solution with the volume fraction of 80 percent to 90 percent; the temperature is 15 to 20 DEG C, the current density is 6 to 8A / dm, the voltage is 1.5 to 1.8 V, and the processing time is 10 to 15s; then the sample is immersed or wiped for erosion; and the formulation of an erodent comprises FeCl3, HCl and H2O with the proportion of 1:2:20. The method effectively solves the problem of the electrocasting copper caused by soft texture, can basically get rid of the surface stress generated in the polishing process and clearly display electrocasting copper-gold phase microscopic structure.

Owner:UNIV OF SCI & TECH BEIJING

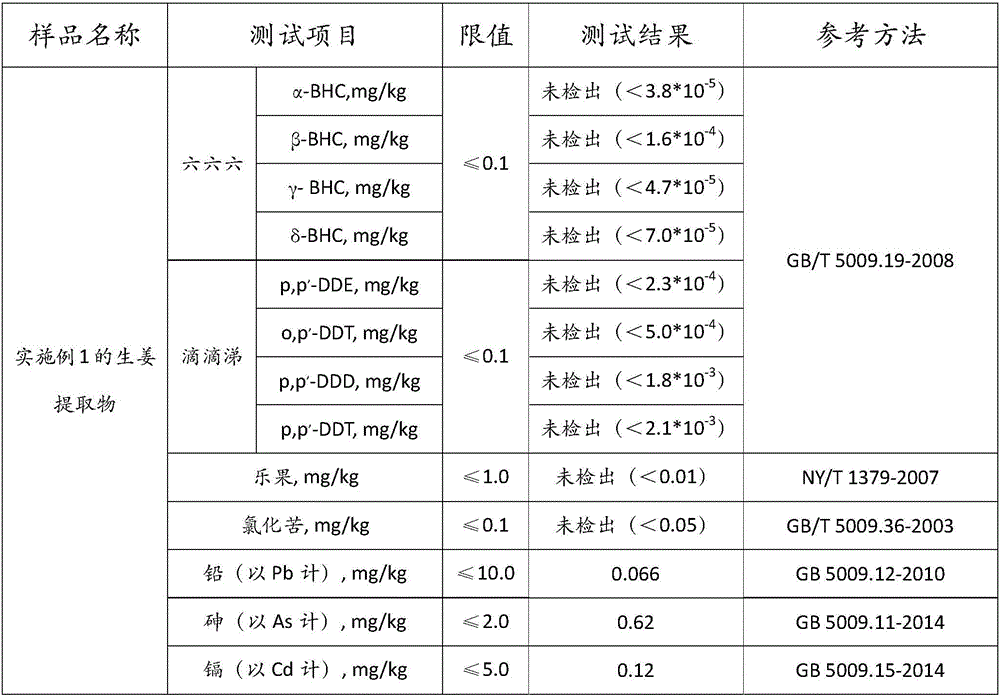

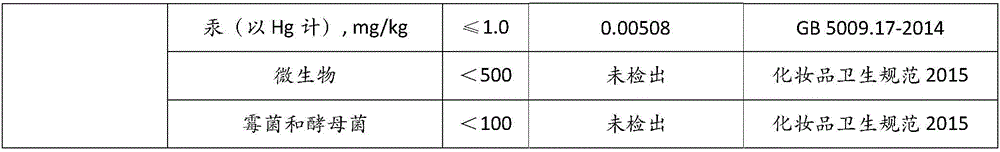

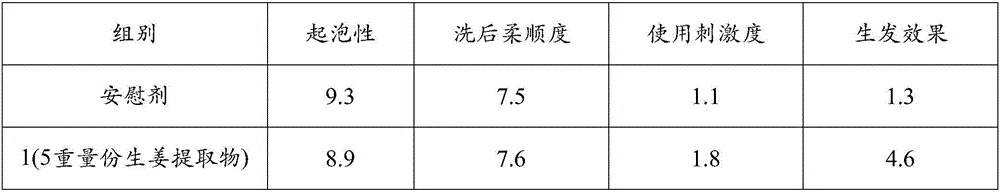

Rhizoma Zingiberis Recens extract and preparation method and application thereof

ActiveCN106309280AKeep original ingredientsExcellent trace elementsCosmetic preparationsHair cosmeticsMedicinePreservative

The invention discloses a Rhizoma Zingiberis Recens extract and a preparation method and application thereof. The preparation method of the Rhizoma Zingiberis Recens extract includes soaking Rhizoma Zingiberis Recens in light salt brine, blanching the soaked Rhizoma Zingiberis Recens in hot water, juicing, filtering through a screen, collecting filtrate, adding a preservative, carrying out clarifying treatment and centrifuging to collect a liquid supernatant so as to obtain crude juice of the Rhizoma Zingiberis Recens; irradiating the crude juice of the Rhizoma Zingiberis Recens by a strong fluorescent lamp until the color of the juice of the Rhizoma Zingiberis Recens is stable and does not fade any longer; filtering, collecting filtrate, filtering by ceramic membrane equipment and collecting permeating liquid so as to obtain the Rhizoma Zingiberis Recens extract. The Rhizoma Zingiberis Recens extract retains normal juice ingredients of the Rhizoma Zingiberis Recens to the greatest extent to enable active ingredients of the Rhizoma Zingiberis Recens to be utilized compressively and can be applied to the field of daily chemical products or food widely.

Owner:GUANGZHOU RIDGEPOLE BIOLOGICAL TECH CO LTD

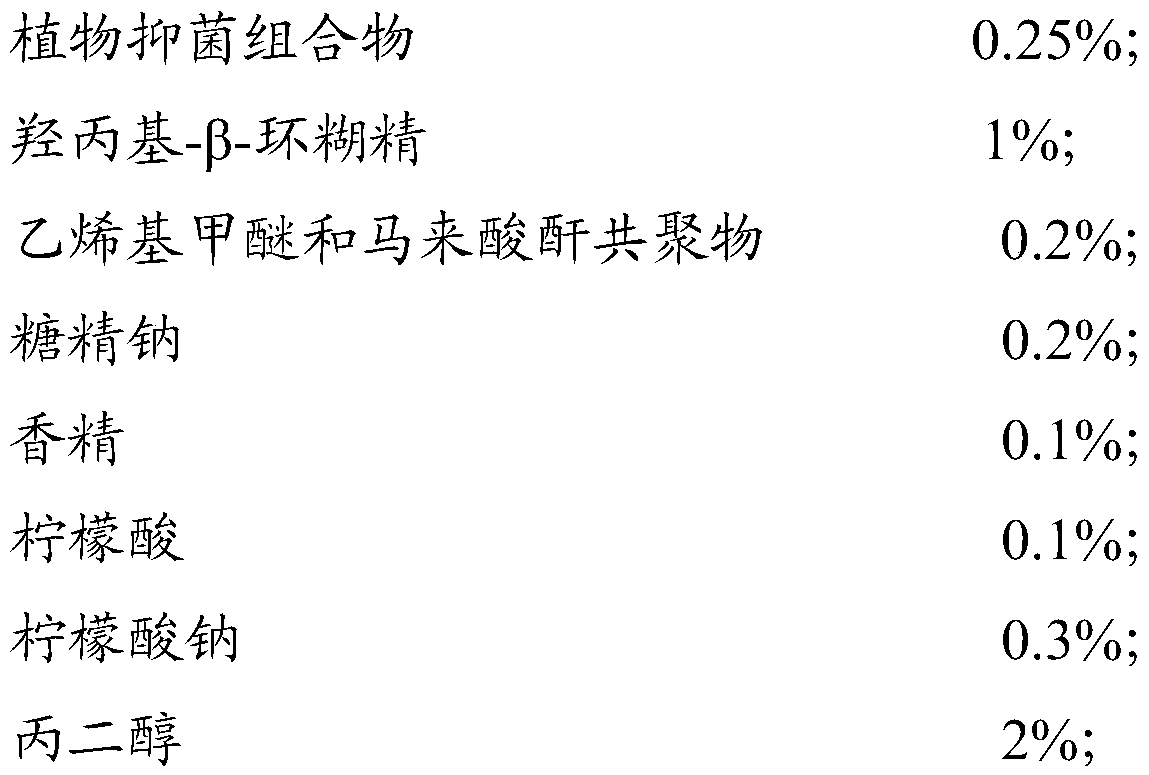

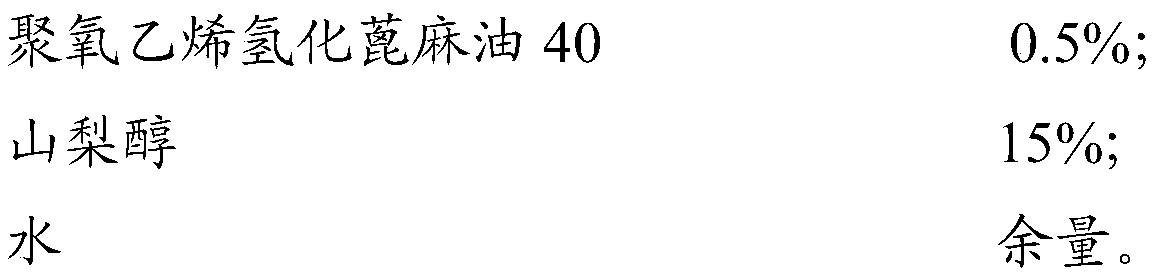

Plant bacteriostatic composition and mouthwash containing same, and preparation method for mouthwash

InactiveCN111346023AOvercoming narrow spectrumImprove antibacterial propertiesCosmetic preparationsToilet preparationsBiotechnologyPSIDIUM GUAJAVA LEAF

The invention belongs to the technical field of oral care products, and specifically relates to a plant bacteriostatic composition and mouthwash containing the same, and a preparation method for the mouthwash. The plant bacteriostatic composition is an essential oil composition composed of guava leaf essential oil, cinnamon essential oil and totarol. The mouthwash provided by the invention mainlycomprises the plant bacteriostatic composition, a sustained-release agent, a solubilizer and orally acceptable auxiliary materials. In the plant antibacterial composition provided by the invention, the antibacterial mechanisms and antibacterial spectrums of all the essential oil components are different, and the components generate a synergistic reaction through compounded combination of the essential oil, so the synergistic interaction effect is further achieved; the narrow spectrum of a single bacteriostatic component is favorably overcome; and the overall antibacterial capability is enhanced. The mouthwash disclosed by the invention can effectively inhibit the growth of common pathogenic bacteria in the oral cavity, has significant long-acting antibacterial effect, has the effects of inhibiting bacteria, diminishing inflammation, relieving swelling and aching of gum bleeding and removing bad breath, and is safe and non-irritating.

Owner:GUANGZHOU LIBY

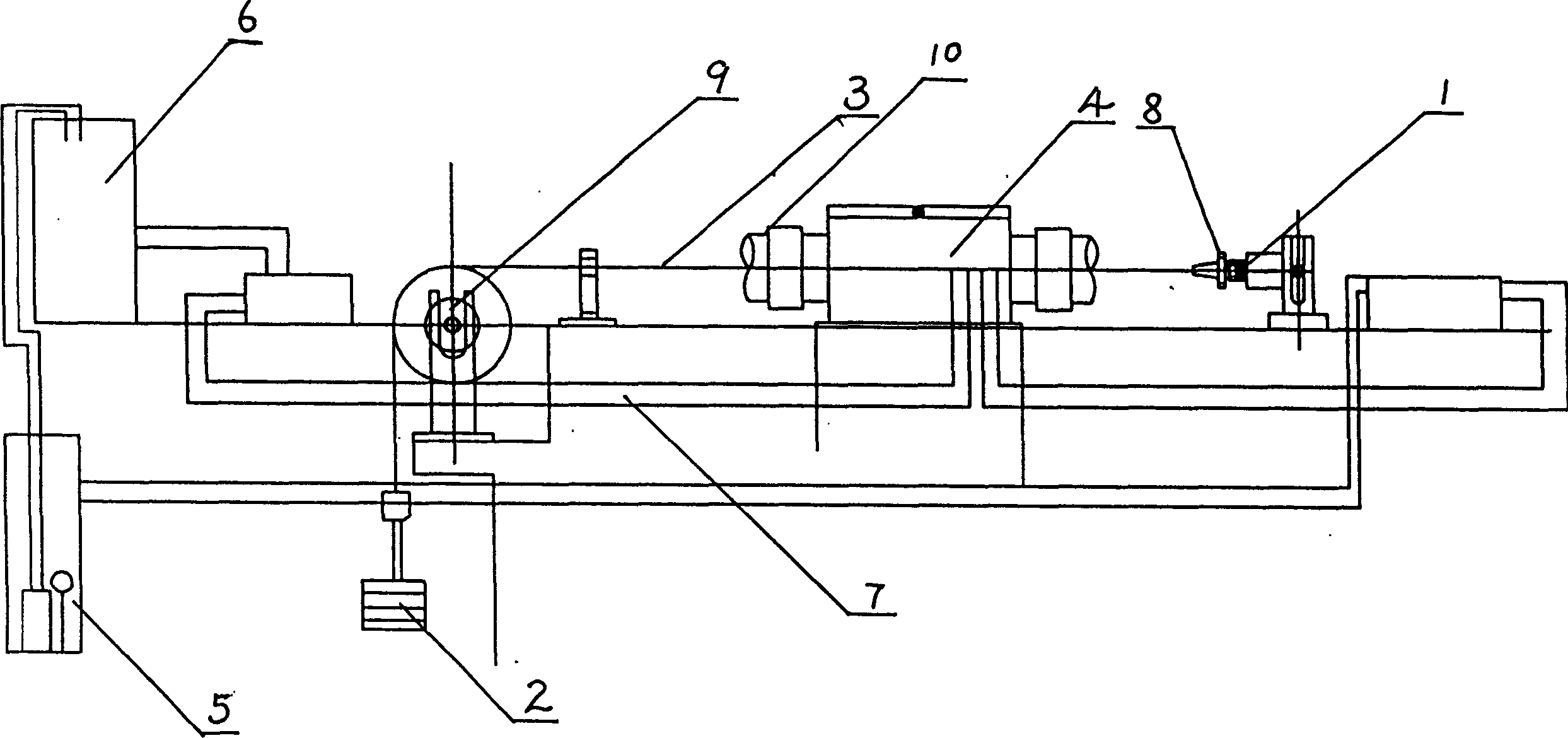

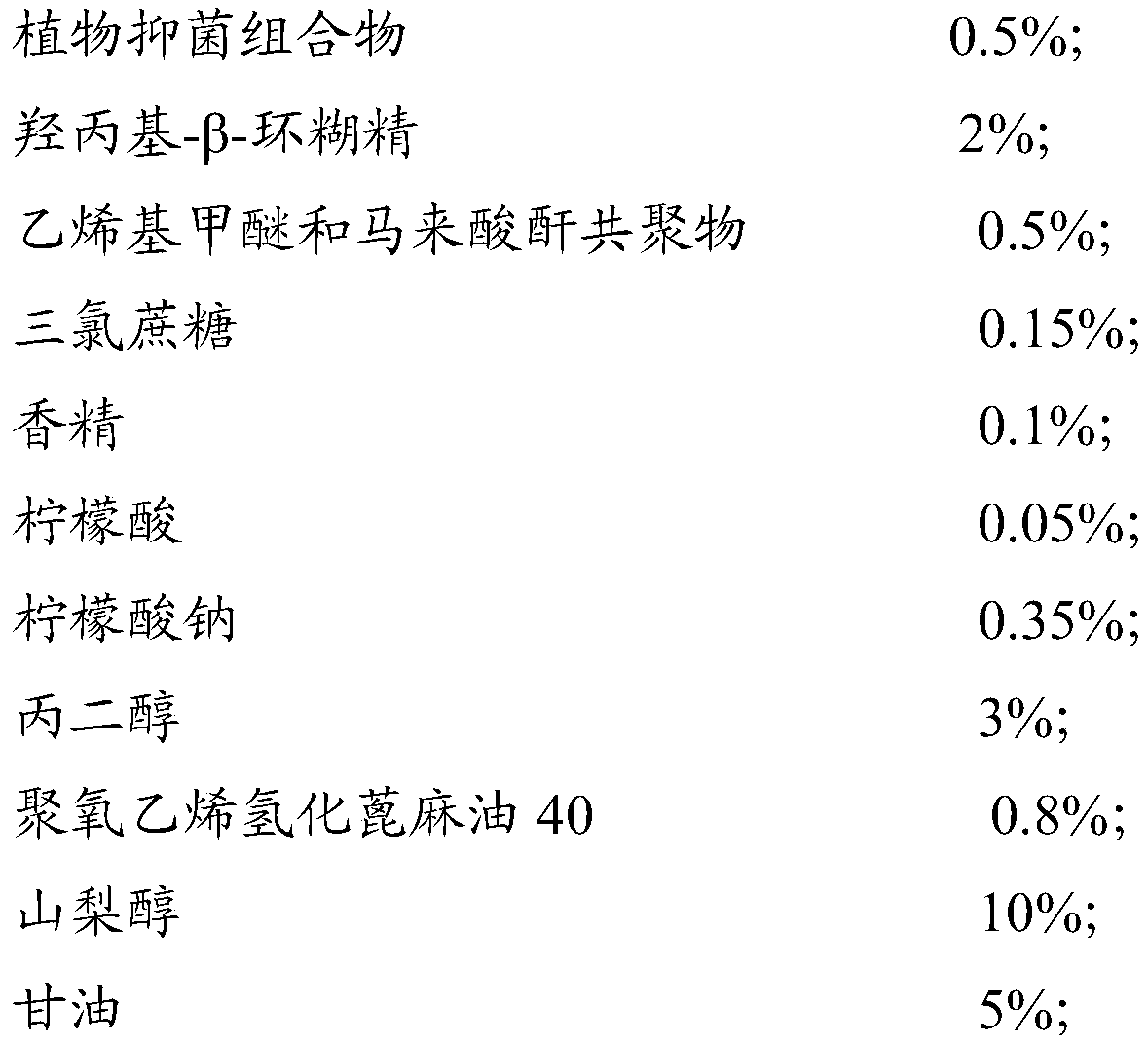

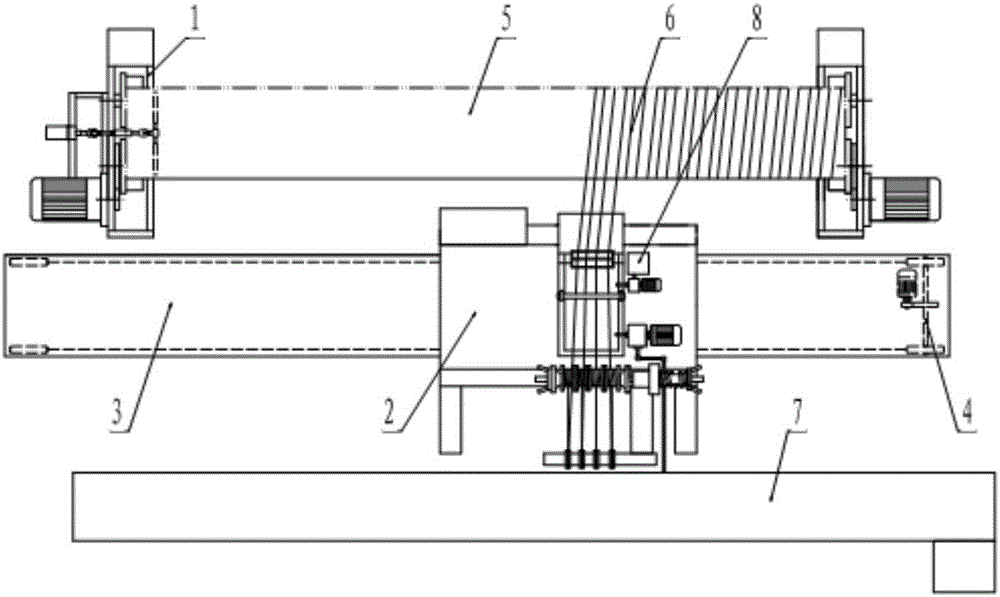

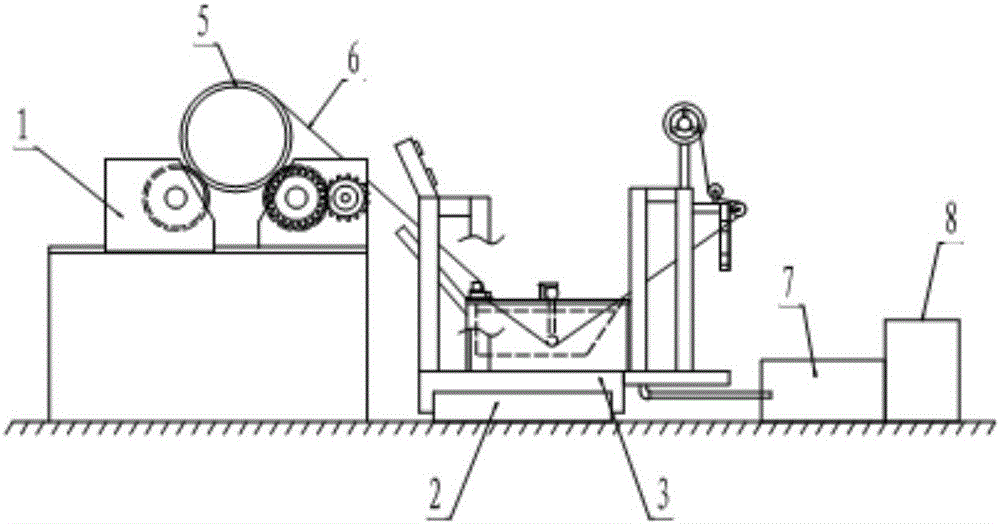

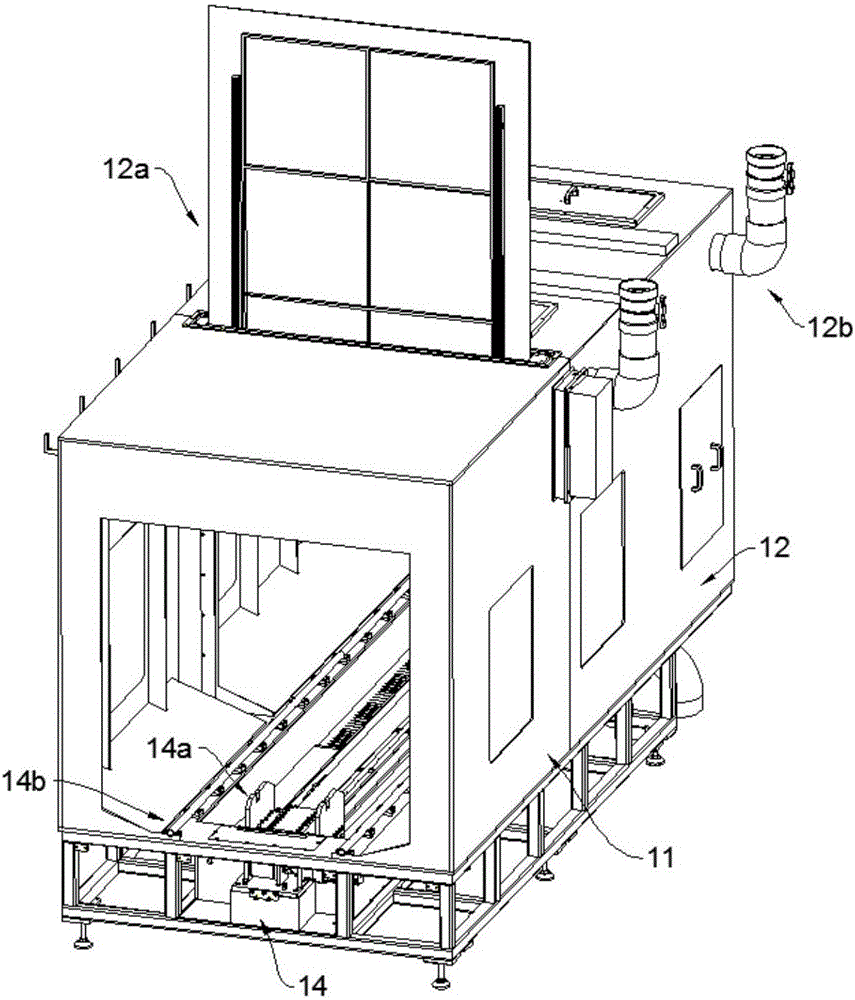

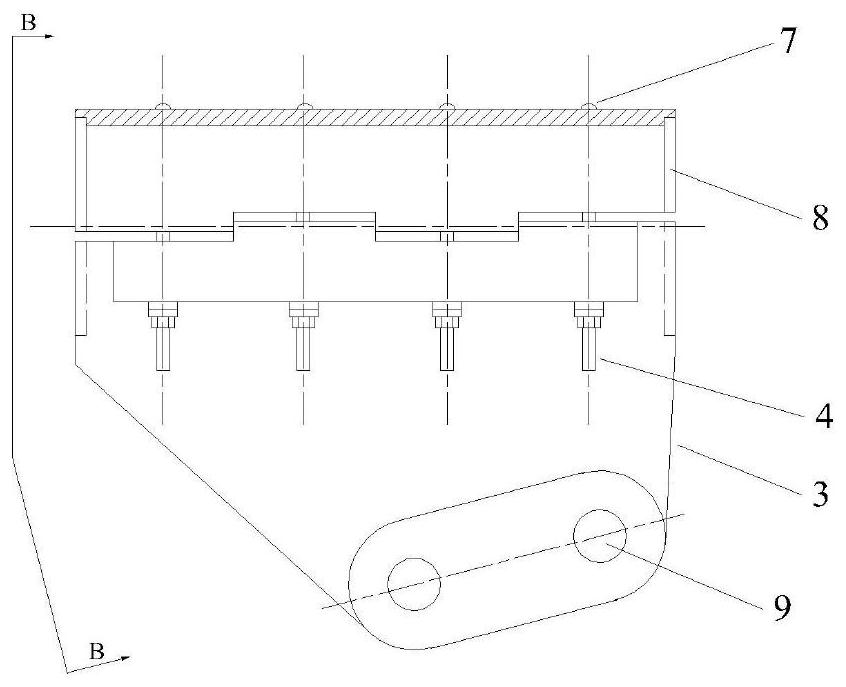

Forming equipment and process for glass steel wire outer protection anticorrosion pipe

InactiveCN106273383ARealize automatic feeding operationSolve the problem of corrosionTubular articlesGear transmissionSteel tube

The invention discloses forming equipment and a process for a glass steel wire outer protection anticorrosion pipe, and belongs to the technical field of manufacturing mechanical products. The forming equipment for the glass steel wire outer protection anticorrosion pipe comprises a workpiece supporting base, a wire winding trolley, a trolley moving guide rail and a trolley driving mechanism; the workpiece supporting base is composed of two parts arranged left and right, and each part is provided with a base, a workpiece rotating motor, a gear transmission mechanism and roller wheels, wherein the roller wheels include driving roller wheels and follow-up supporting roller wheels, and the workpiece rotating motor drives the driving roller wheels to rotate through a gear transmission mechanism to drive a steel pipe workpiece placed on the driving roller wheels and the follow-up supporting roller wheels to rotate; the trolley moving guide rail is fixed to one side of the workpiece supporting base in parallel, and the wire winding trolley and the trolley driving mechanism are assembled on the trolley moving guide rail. The working efficiency of winding glass steel wires is improved, and the winding quality of the glass steel wires is ensured.

Owner:TANGSHAN XINGBANG PIPE CONSTR EQUIP

Water-base paint used for indoor woodware

The invention discloses a water-base paint used for indoor woodware. The paint is prepared from the following components in percentage by weight: 20-30% of silicone acrylic emulsion, 5-20% of color pigments, 5-10% of a modifier, 10-30% of composite filler and 40-50% of water, wherein the color pigments comprise 2-8% of low-arsenic ferric oxide, 5-11% of iron oxide red and 1-2% of methylbenzene; the composite filter comprises 1-5% of silica sol, 5-15% of calcium carbonate and 1-5% of a scratch-resistant wax auxiliary. The water-base paint has the advantages that the low-arsenic ferric oxide, iron oxide red and methylbenzene used as pigments are good in red formation and color homogeneity; the silicone acrylic emulsion can be used for effectively solving the antiseptic problem of the water-base paint to a certain extent; the modifier further improves the curing speed; the indoor woodware is coated with a good effect, and the service life of the woodware is prolonged. The water-base paint is suitable for being popularized.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Two-component heat-insulated waterproof paint

The invention discloses two-component heat-insulated waterproof paint which comprises a slurry A component and a powder B component; the A component comprises the following ingredients by weight: 1-20% of soft water, 0.1-0.25% of organic amine, 80-95% of pure acrylic emulsion, and 2-14% of ethylene-polyvinyl acetate emulsion; the B component comprises the following ingredients by weight: 2-25% of heavy calcium, 2-14% of talcum powder, 1-14% of titanium dioxide, 1-7% of calcined kaolin, 4-17% of borsal hollow microspheres with an average particle size of about 10-80 microns, and 50-90% of cement; the mass ratio of the A component to the B component is 1:0.7-1.4. The invention is applicable to roofs, exterior walls, and the like, has good heat insulation and waterproof effect, good endurance, easy coating, no toxicity, no smell, no harm to human body, and no environment pollution.

Owner:NINGBO HUAGAOKE WATERPROOF TECH

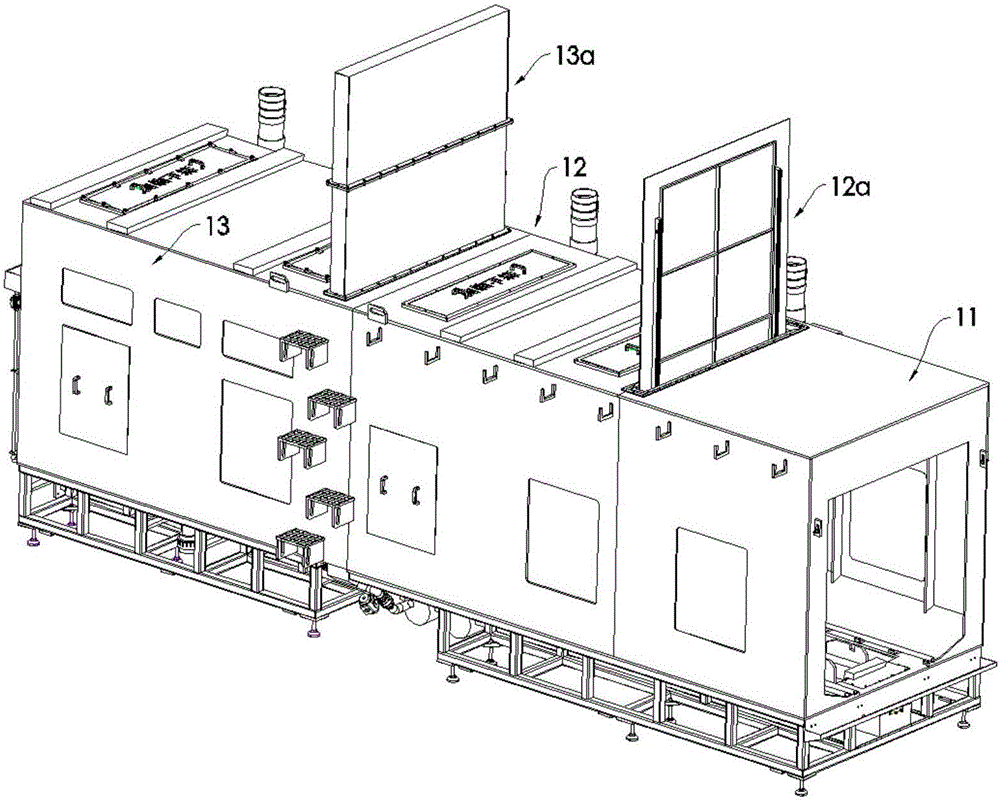

Top-jet type spray etching machine

A top-jet type spray etching machine comprises an etching machine body and a liquid medicine circulating system, wherein the etching machine body is mainly composed of a transition area, a cleaning area and an etching area, spraying devices are arranged on the cleaning area and the etching area respectively, synchronous belt conveying devices are arranged below the transition area and the cleaning area, a servo drive motor is arranged below the transition area, a slide rail penetrating through the transition area, the cleaning area and the etching area is arranged below the etching machine body, etching basket tools are placed on the slide rail, the synchronous belt conveying devices are connected and linked through push rods, and the liquid medicine circulating system is mainly composed of a DI water tank body, a chemical liquid medicine tank body, a heating tank, corresponding pipelines, corresponding valves and a circulating pump. In the glass panel etching process, the temperature, pressure, flow and the like of liquid medicine can be controlled in a full-automatic mode, double-sided waterfall etching is conducted on glass panel, no manual operation is needed in the whole working process, cleaning and etching are both completed automatically, and the etching precision and efficiency are remarkably improved.

Owner:CHENGDU IND INVESTMENT ELECTRONICS EQUIP

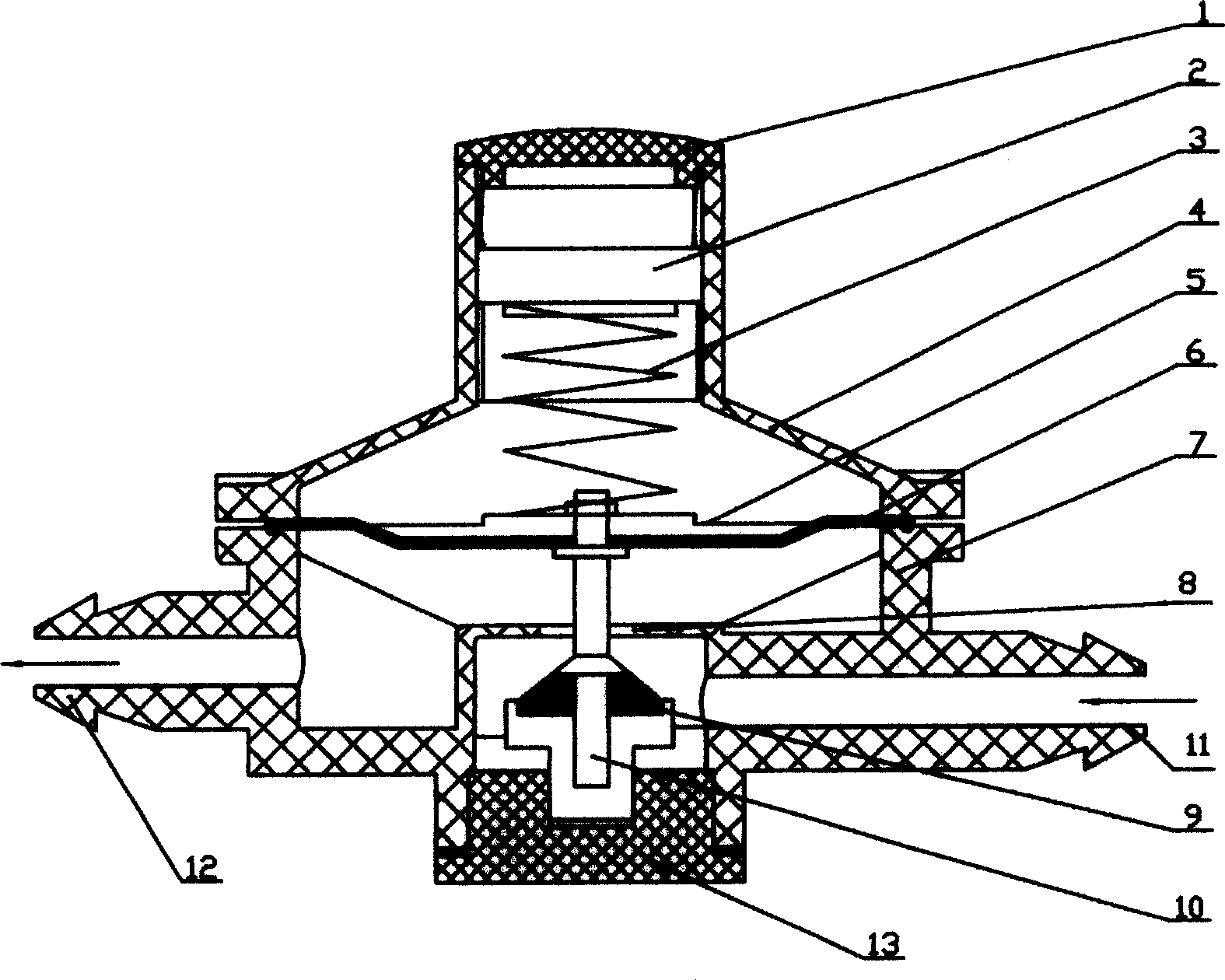

Marsh gas pressure regulator

InactiveCN1664425AHigh sensitivitySolve the problem of corrosionEqualizing valvesSafety valvesRubber materialRubber membrane

The invention relates to a methane pressure regulator that includes block cover, up case body, down case body, pressure regulate block on the top in the up case body, rubber membrane between the up case body and the down case body. A tray is set on the rubber membrane. And a spring is set between the pressure regulate block and the tray. The tray is fixed on the top of the connecting bar through the rubber membrane. The bottom of the connecting bar connects to a valve pad through the valve mouth. The bottom of the case body has valve core supporting cover. The material of blocking cover, up case body, down case body, pressure regulating block, tray, connecting bar and the valve core supporting cover is ABS plastic. And the rubber membrane and the valve pad are made up of rubber material that can endure the cauterization of sulfureted hydrogen. The invention solves the cauterization problem and is easy to install.

Owner:魏光第

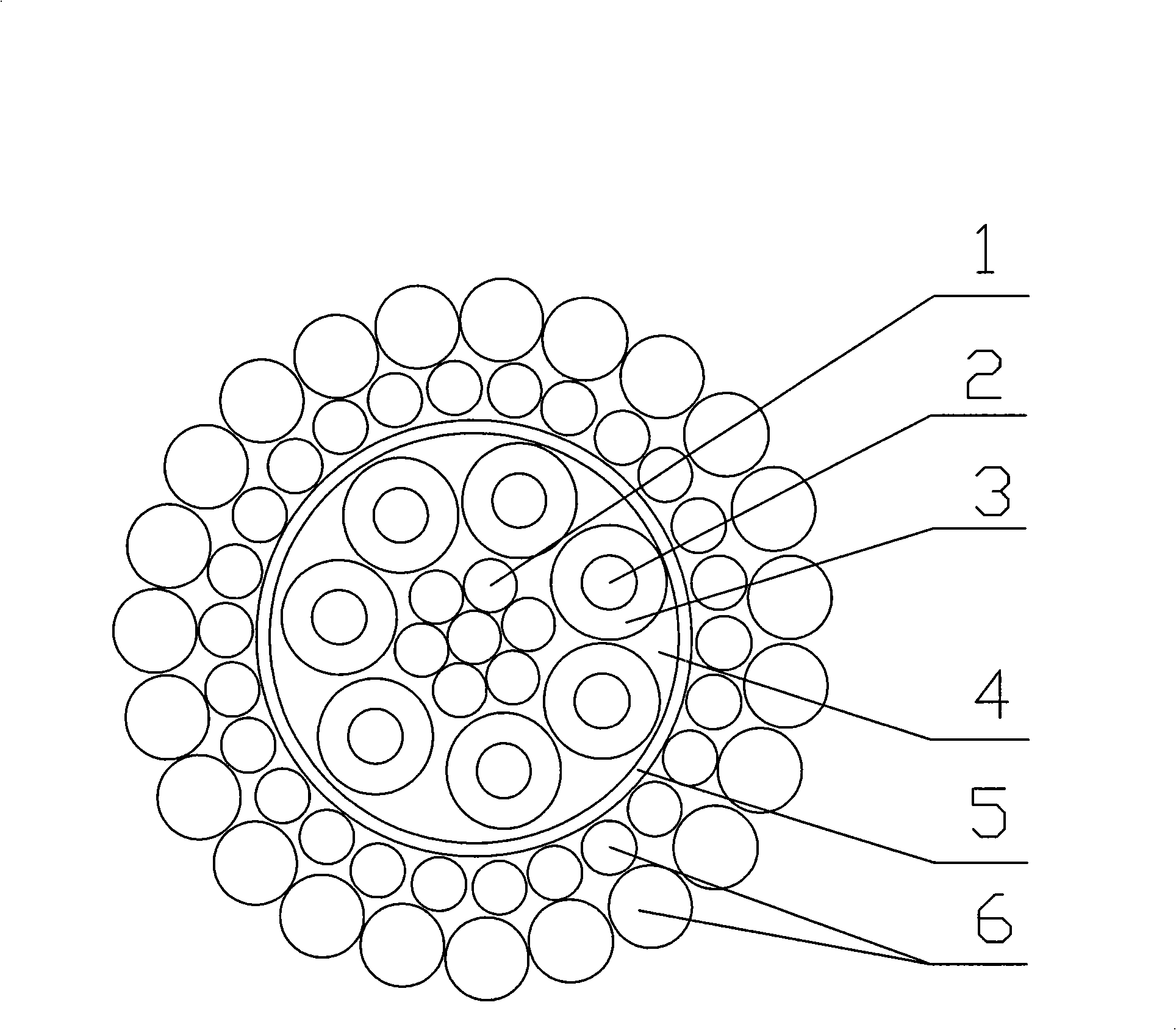

High-temperature cable for high-strength bearing detection

InactiveCN101299353AThere will be no scrappingGuaranteed temperature resistancePlastic/resin/waxes insulatorsInsulated cablesWell loggingEngineering

A high strength bearing detection high temperature cable, belongs to the cable technical field, characterized by being provided with a 1+6 stranding reinforce steel core, a double layer reverse outward armour steel wire and a plurality of insulated cores evenly and closely wound aroud the 1+6 stranding reinforce steel core to compose the cable core. Stuffed inorganic ropes are provided in the cable core, and a special macromolecule material sheath is coated on the cable core; the double layer reverse outward armour steel wire is wrapped at the cirumferential of the sheath; the surface of the steel wire armour is coated with a layer of soft mask rust preventive oil. The invention ahs reasonable and simple structure, easy manufacture, good utilization qualities, strong cable bearing ability, good corrosion-resisting properties, safety and long service life. The cable is the ideal cable in the well logging, the perforation, the river, the gulf, the irrigation works and the exploration and the like.

Owner:BAOSHENG SCI & TECH INNOVATION

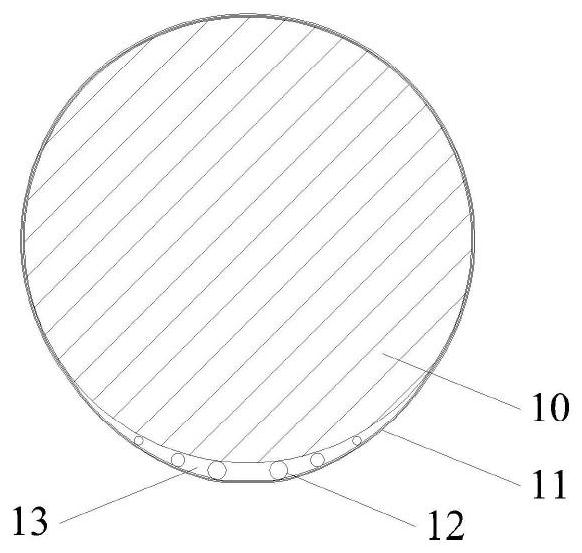

Dehumidification method for main cable of suspension bridge

ActiveCN111945562AReduce initial equipment investmentSmall circulation resistanceSuspension bridgeDrying gas arrangementsSystem maintenanceTower

The invention discloses a dehumidification method for a main cable of a suspension bridge. The surface of the main cable is sealed and wrapped by the wrapping tape, and the wrapping tape and the internal main cable steel wires form cavities at the top and the bottom, thereby facilitating the flowing of dry gas. The principle that moisture in the main cable circularly rises and falls day and nightis ingeniously utilized, and when the moisture is gathered in the cavity, dry gas is introduced to discharge the moisture. Dry gas flow resistance is small, required operation time is short, energy consumption is low, an air feeder does not need to be installed on the upper portion of the bridge tower, and investment is saved; moreover, dry gas can flow at low pressure, the wrapping tape is not easy to break, a special gas inlet cable clamp, a special gas outlet cable clamp and a corresponding pipeline system are not required to be mounted, high-altitude operation in system maintenance is reduced, and the maintenance cost is reduced.

Owner:ZHENGZHOU UNIV

Steel pail with antiseptic plastic inner container and manufacturing method thereof

InactiveCN101033023ASolve the problem of corrosionGuaranteed qualityPackage recyclingFlexible coversWater basedBarrel Shaped

The steel pail with anticorrosive plastic inner container suitable for holding water-base paint and chemical material includes one pail body and one inner container. The plastic inner container is made with plastic and through pressing into sheet and vacuum forming in a pail-shaped hollow mold, and has the same inner diameter and shape as that of the pail body. The steel pail with anticorrosive plastic inner container is anticorrosive and can ensure the quality of the held material. The inner container has low cost and simple production process, and the steel pail may be reused to save resource.

Owner:李俊贤

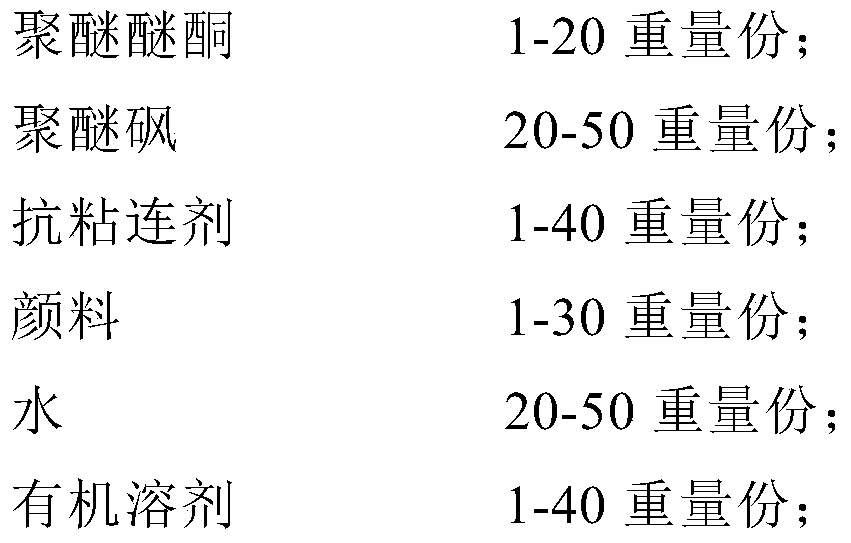

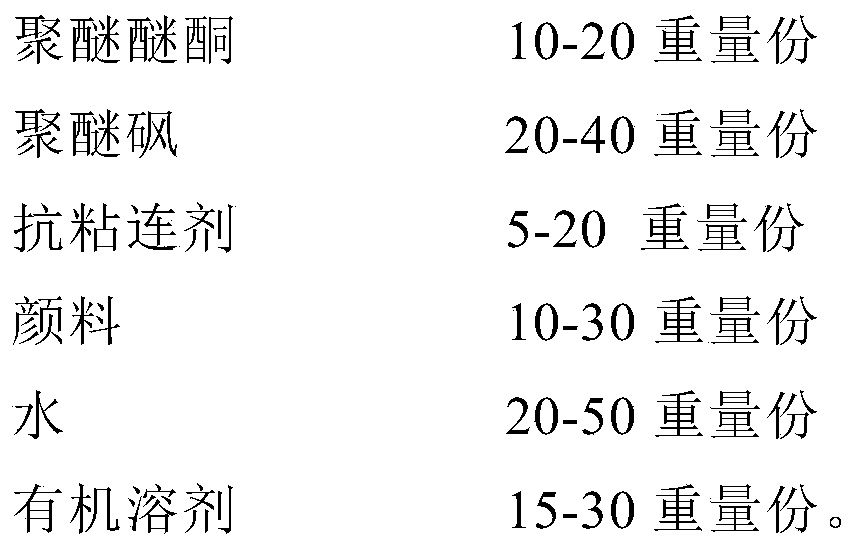

Anti-adhesion paint and product coated by the anti-adhesion paint

InactiveCN105482685ALower glass transition temperatureGood weather resistanceLayered productsAnti-corrosive paintsPoly ether ether ketoneAnti-Adhesion Agent

The invention relates to an anti-adhesion paint and a product coated by the anti-adhesion paint. The purpose of the anti-adhesion paint is to solve the problems of relatively bad leveling performance and bad post-film-formation flatness of poly-(ether-ether-ketone). According to the invention, polyether sulphone is added into the poly-(ether-ether-ketone) paint and the proportions of the ingredients are adjusted, so that an anti-adhesion paint of good leveling performance, excellent high-temperature resistance, excellent corrosion resistance and excellent weather resistance is obtained. The anti-adhesion paint disclosed by the invention comprises the following ingredients in parts by weight: 1-20 parts of poly-(ether-ether-ketone), 20-50 parts of polyether sulphone, 1-40 parts of anti-adhesion agent, 1-30 parts of pigment, 20-50 parts of water and 1-40 parts of organic solvent. The anti-adhesion paint disclosed by the invention can be used for products with anti-adhesion requirements and especially for outdoor products or kitchenware products with relatively high weather-resisting and scratch-resisting requirements.

Owner:曾志玲

Environmentally-friendly wood preservative and preparation method thereof

InactiveCN110091400AImprove anti-corrosionEnvironmentally friendly and efficient anti-corrosion effectBiocideWood treatment detailsEnvironmental resistancePreservative

The invention relates to an environmentally-friendly wood preservative and a preparation method thereof, and belongs to the technical field of microbial control preservatives. The preparation method comprises the following steps: 1, preparing 1-200 parts of a quaternary ammonium salt, 1-100 parts of amine oxide, 1-300 parts of paraffin, 0-100 parts of a pest repellent, 1-200 parts of ethylene glycol, 1-200 parts of an imidazole original drug and 1-1000 parts of water; 2, dissolving the imidazole original drug and the pest repellent in an amine solution of the quaternary ammonium salt at 20-60DEG C, and adding a cosolvent during the dissolving; an 3, forming a stable oil phase after the imidazole original drug and the pest repellant original drug are completely dissolved, sequentially adding the paraffin waterproof additive while stirring, and heating and stirring the obtained mixture to obtain the novel environmentally-friendly wood preservative. The environmentally-friendly wood preservative has the advantages of solving of the problem that preservatives cannot guarantee the anticorrosive, mildew-proof, pest-proof and rainproof functions of treated wood, simple preparation process, and easiness in production.

Owner:南京天诗蓝盾生物科技有限公司

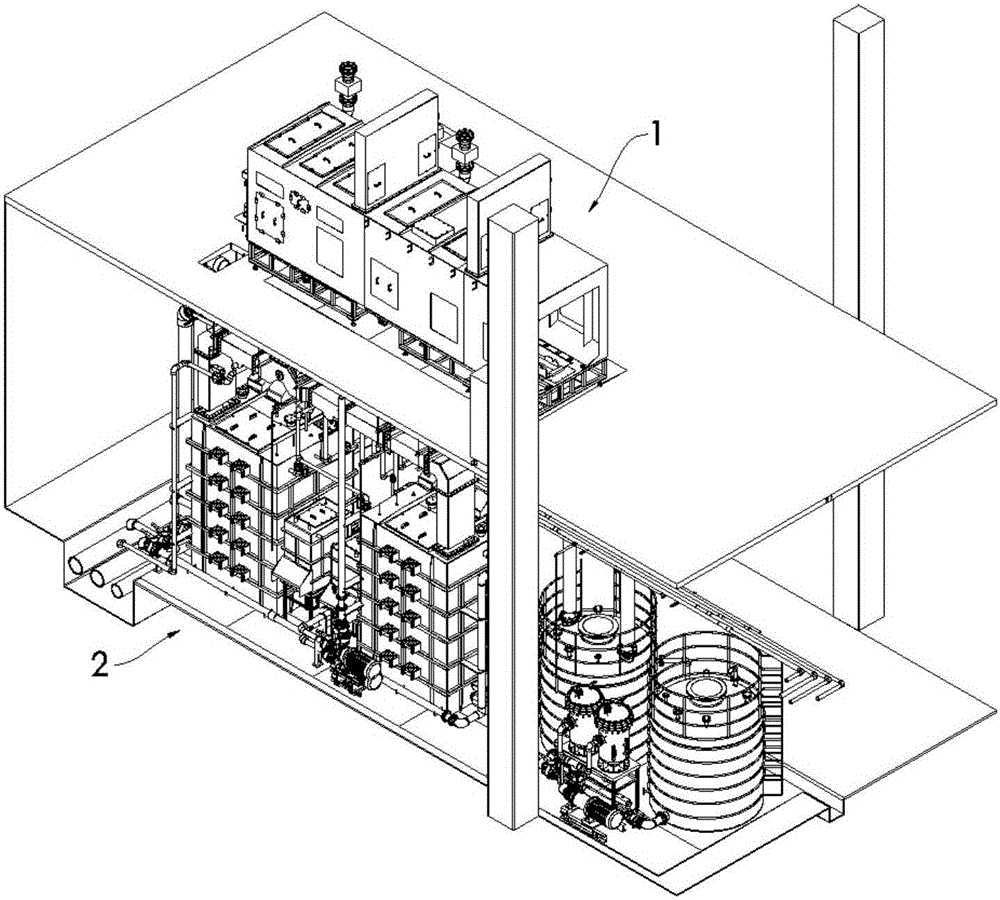

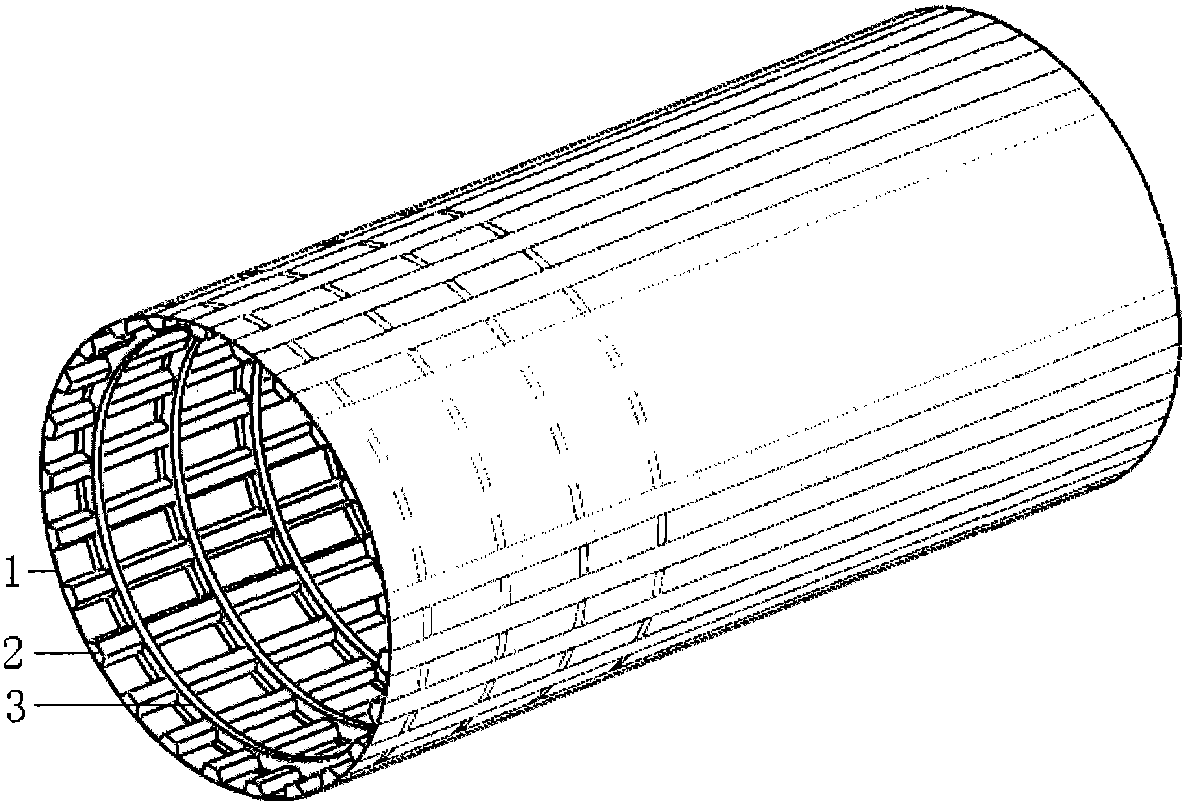

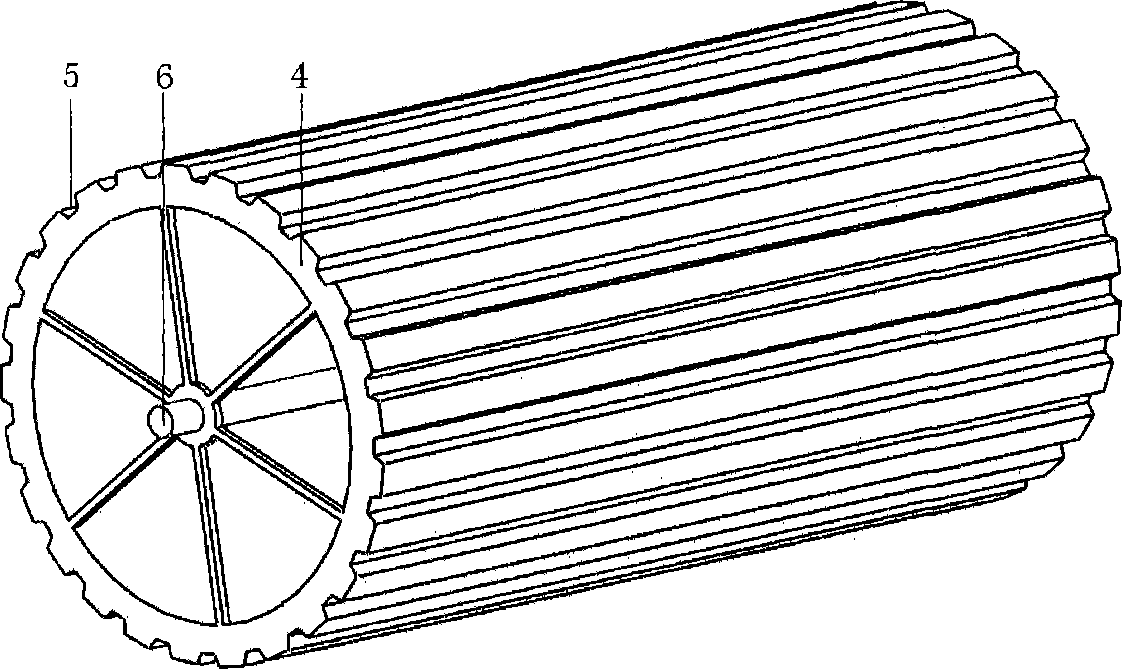

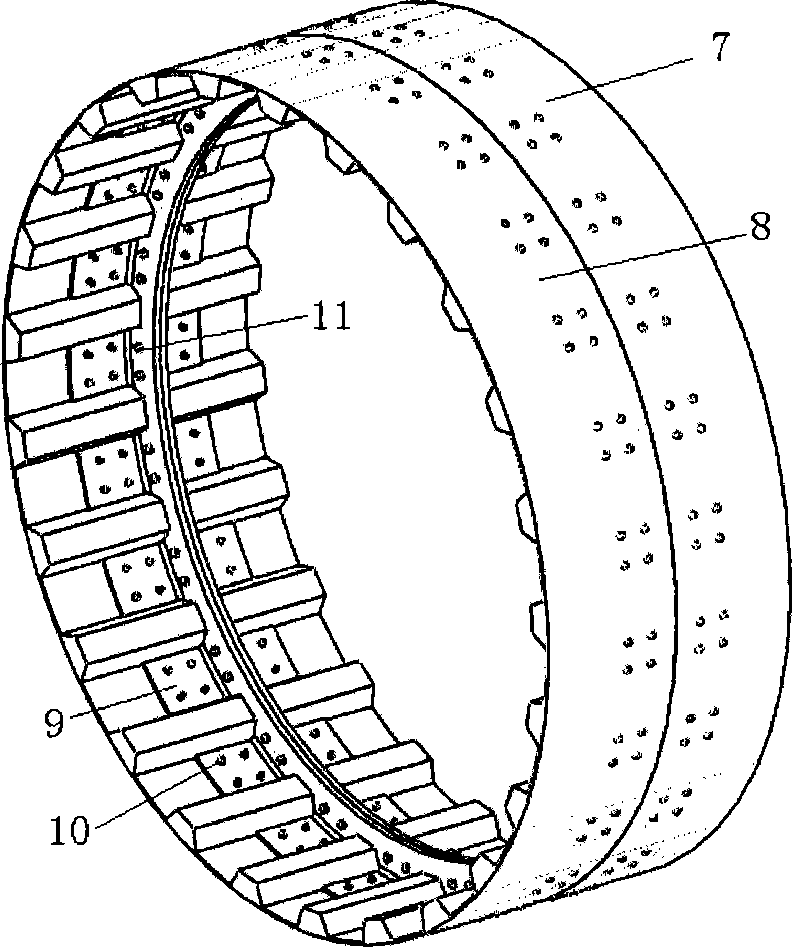

Composite material tower drum of wind driven generator as well as preparation method and preparation mold of composite material tower drum

InactiveCN103644083ASolve the problem of corrosionReduce maintenance costsFinal product manufactureWind energy generationPurlinWind driven

The invention relates to a composite material tower drum of a wind driven generator as well as a preparation method and a preparation mold of the composite material tower drum. The composite material tower drum adopts a tapered tubular structure, and comprises a covering 1, long purlins 2 and ordinary partition frames 3, wherein the long purlins 2 are distributed on the circumference of the wall of the tower drum at a certain distance, fixed on the inner diameter of a tower drum support formed by the purlins 2 through the ordinary partition frames 3 and covered with the covering 1 on the outer diameter of the tower drum support formed by the purlins 2; and the ordinary partition frames 3 are distributed axially on the tower drum at a certain distance. At the same time, segmented tower drums can be connected by connection frames 9 according to the actual use requirement of the tower drum of the wind driven generator. The tower drum is made of a composite material, the anti-corrosion problem of the tower drum is completely solved, and the maintenance cost of the tower drum is greatly reduced; the composite material tower drum of the wind driven generator has the characteristic of light weight, and the transport and mounting cost of the tower drum is reduced; and besides, the composite material tower drum can be manufactured on the spot, the manufacturing cost is reduced, hereby manufacturing equipment is assembled in a standard truck and a container, and the transportation cost is reduced.

Owner:INNER MONGOLIA JINGANG HEAVY IND

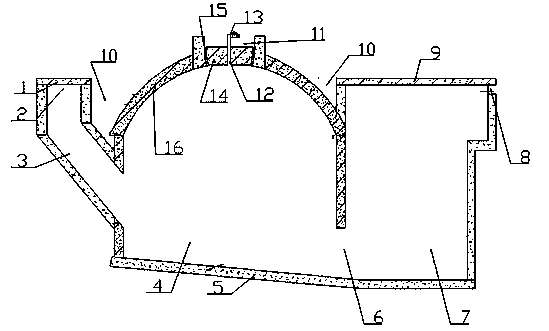

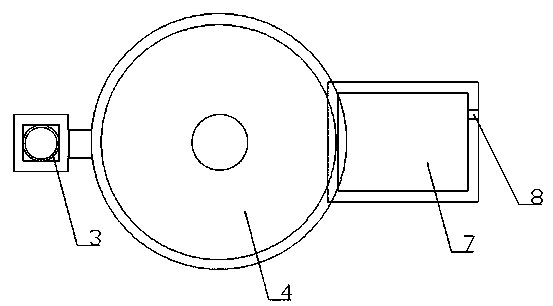

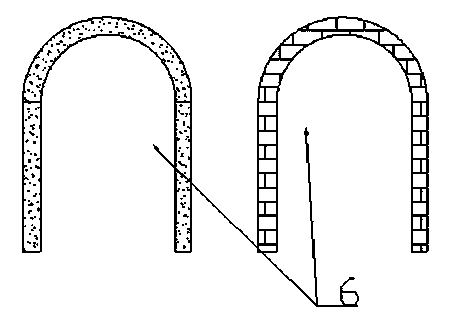

Construction method for novel round-pot-shaped high-efficiency combined methane tank

InactiveCN103966077APrevent water and air leakageSolve earthquake resistanceGas production bioreactorsWaste based fuelWater storageWater leakage

The invention discloses a construction method for a novel round-pot-shaped high-efficiency combined methane tank, which relates to a construction method for a methane tank. The methane tank comprises an inlet pipe, a fermenting tank and a hydraulic discharging chamber, wherein the fermenting tank is arranged below the ground, the bottom of the fermenting tank is an inclined tile bottom, the hydraulic discharging chamber is arranged at the side surface of the lower bottom of the fermenting tank, the inlet pipe is obliquely arranged at one side of the higher bottom of the fermenting tank, the lower end of the inlet pipe is communicated with the lower part of the sidewall of the fermenting tank, the top of the fermenting tank is provided with a cut spherical shell-like tank arch which has an upward spherical surface, recessed parts at the periphery of the top of the cut spherical shell-like tank arch are provided with rammed earth, the central position of the cut spherical shell-like tank arch is equipped with a movable cover, a water storage loop is mounted on the movable cover, the center of the movable cover is provided with a gas conveying pipe communicated with the interior of the fermenting tank and the outside, a methane safety valve is mounted on the upper end of the gas conveying pipe, the top of the sidewall of the hydraulic discharging chamber is provided with an overflow port, and a hydraulic chamber cover plate is arranged on the top of the hydraulic discharging chamber. The construction method provided by the invention overcomes the problems of water leakage, gas leakage, insufficient gas storage space, a short service life, great potential safety hazards and a great occupied land area of conventional methane tanks.

Owner:郭禄昌

Slow-release dry-type aqueous inorganic zinc-rich coating and preparation method thereof

ActiveCN102775828AStrong chemical bondSolve the problem of corrosionAlkali metal silicate coatingsAnti-corrosive paintsSand blastingFirming agent

The invention relates to a slow-release dry-type aqueous inorganic zinc-rich coating. The slow-release dry-type aqueous inorganic zinc-rich coating mainly comprises a host agent and a curing agent, wherein the part by weight of the host agent to the curing agent is 100:30-100:50. The slow-release dry-type aqueous inorganic zinc-rich coating is prepared from a slow-release dry-type modifier which is matched with zinc powder and functional fillers, overcomes the rigorous condition restriction that when the conventional aqueous inorganic zinc-rich coating is applied to outdoor construction, wind force cannot be higher than the 3rd grade, and the temperature of base materials cannot be higher than 30 DEG C, can be coated on the surface of steel base materials subjected to sand blasting under the conditions that the outdoor wind force is at the 5th grade, and the temperature is 50 DEG C, can avoid the paint film defects of film cracking, film rolling in recoating and dry coating when the film thickness is 50-100 mu m, and plays an excellent role of anticorrosion on steel board workpieces. The slow-release dry-type aqueous inorganic zinc-rich coating is used for surface coating of steel boards and steel structure workpieces (such as oil tanks, air tanks and steel structure buildings) which are subjected to sand blasting.

Owner:TIANJIN COLOROAD COATING & CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com