Anti-adhesion paint and product coated by the anti-adhesion paint

An anti-blocking and coating technology, applied in the direction of anti-corrosion coatings, layered products, etc., can solve the problems of weak two-phase interface force and poor compatibility, and achieve improved thermal fluidity, excellent weather resistance, and good leveling properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

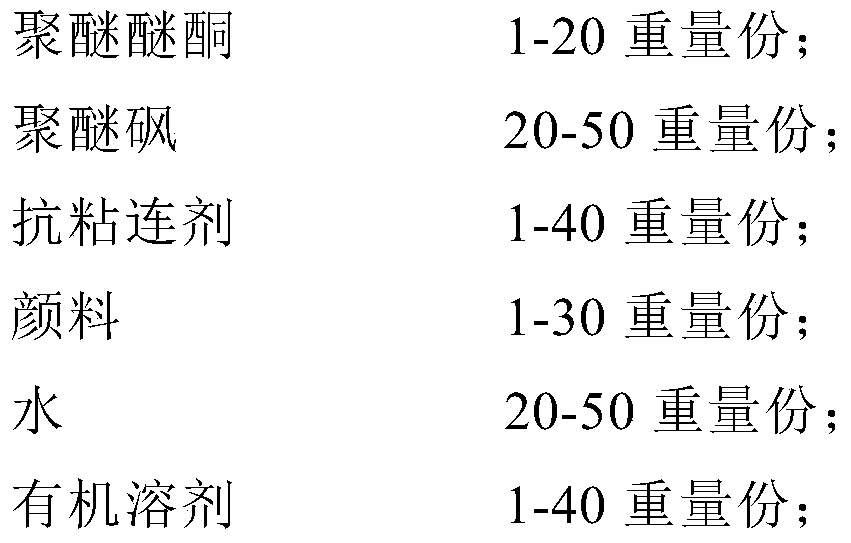

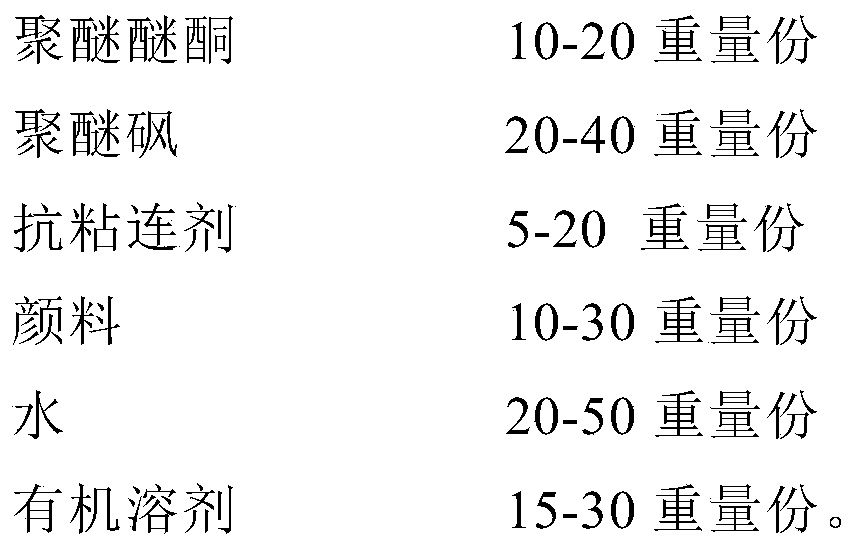

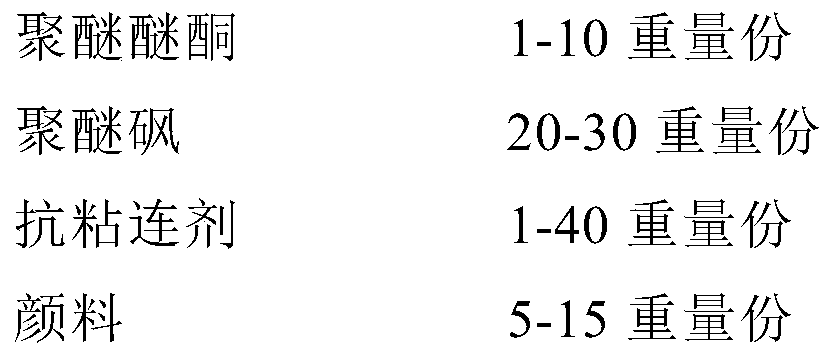

[0056] Put polyethersulfone, polyether ether ketone resin, pigment, deionized water and ketone alcohol ether amine mixed solvent into the container according to the ratio shown in Table 2, and disperse with a high-speed disperser (800-960 rpm) for 30 minutes Finally, filter through a 200-400 mesh filter screen, then add polytetrafluoroethylene resin according to the following ratio, and stir at a low speed (60-100 rpm) for about 20 minutes to obtain the anti-blocking coating of the present invention.

[0057] Table 2

[0058]

preparation example 1-14

[0068] According to the content of the following table 4, the coatings of Examples 1-8 and Comparative Examples 1-8 were sprayed on the aluminum substrate in different ways (single layer, double layer or multi-layer) to obtain the coatings of Preparation Examples 1-14. layers, as shown in Table 4.

[0069] Table 4

[0070]

[0071]

[0072] The coating products of the preparation examples of the present invention were evaluated according to the test method described above, and the effects of the coatings of the preparation examples are shown in Table 5.

[0073] table 5

[0074]

[0075] The above results show that: the anti-blocking coating of the present invention uses polyethersulfone and polyether ether ketone resin in combination, and the coating formed by the coating is smoother, has better wear resistance, and its adhesion and non-stick properties are better than Coatings formed by conventional anti-block coatings. In addition, preliminary tests show that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com