Method for preparing electroforming copper metallographical example and display texture

An electroforming and sample technology, applied in the field of preparing electroformed copper metallographic samples, can solve problems such as little research, and achieve the effect of clear microstructure, solving difficult corrosion, and eliminating false structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

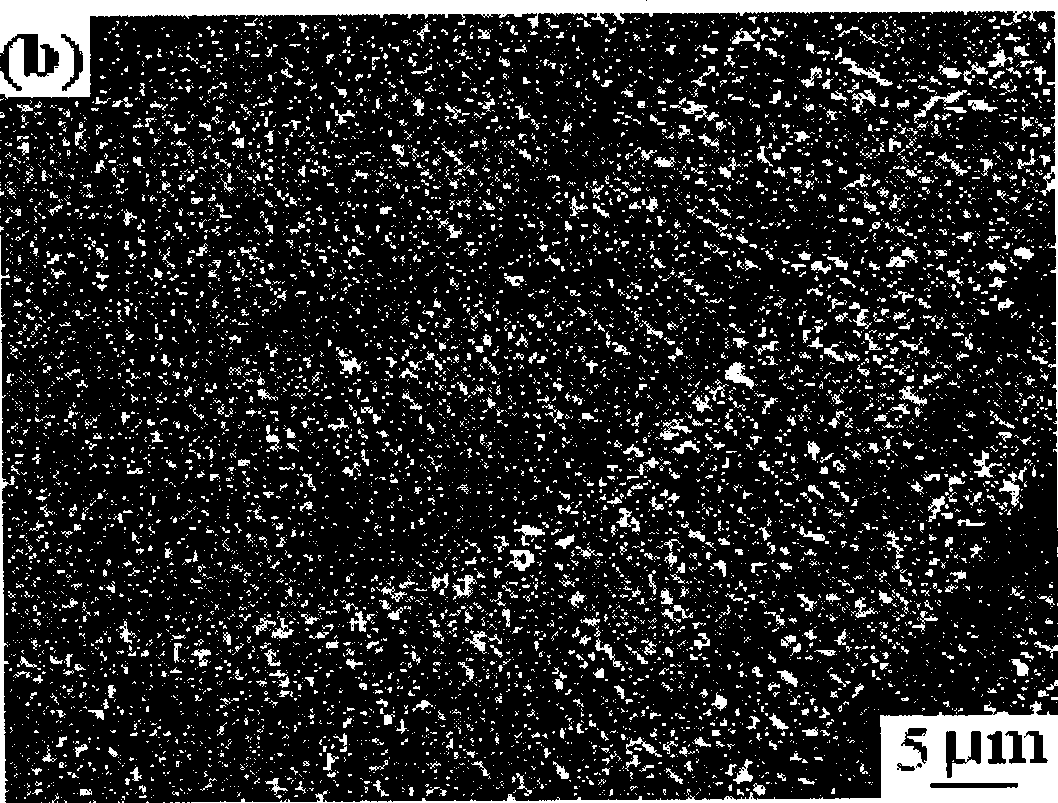

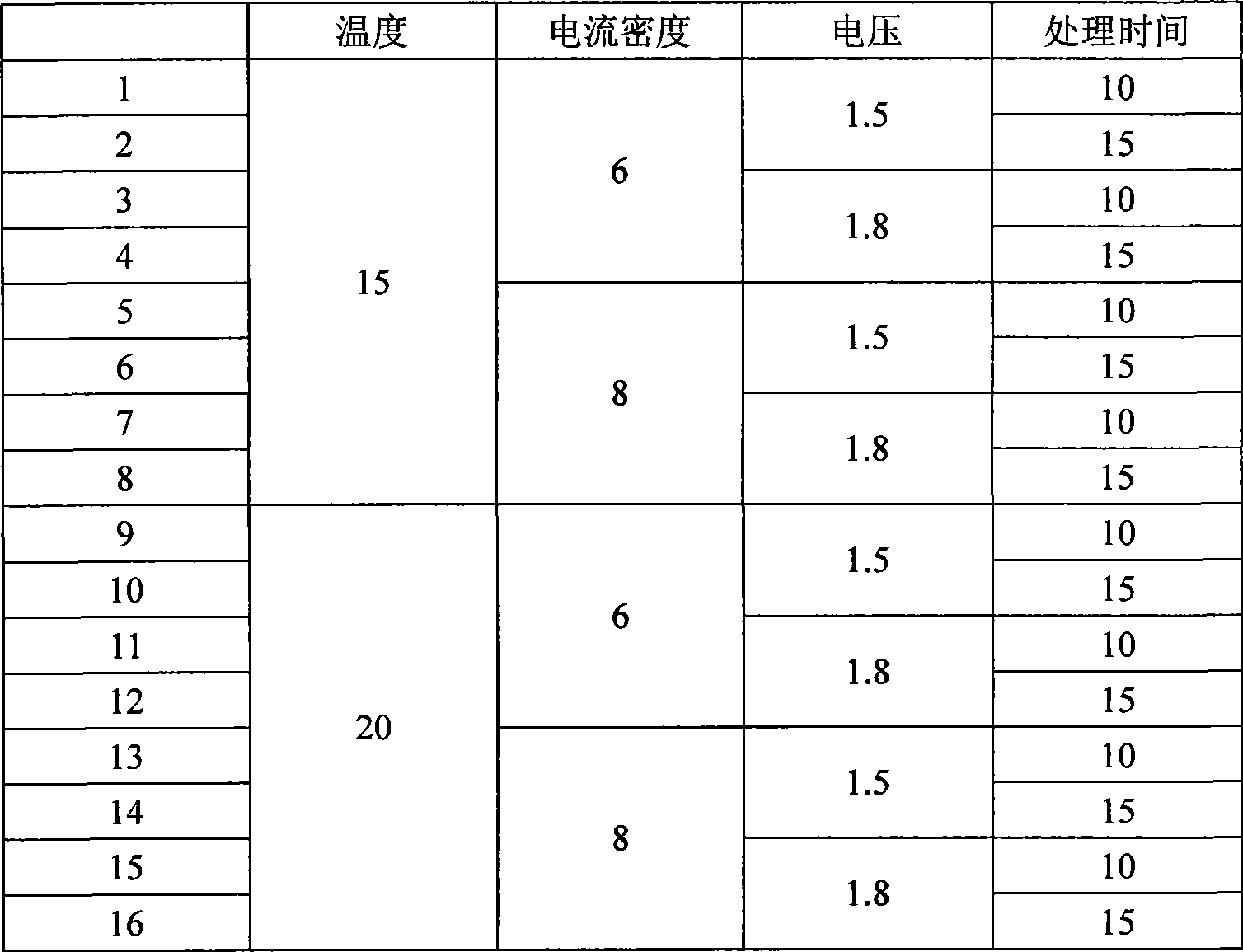

[0016] Divide the samples into 16 groups (Table 3), and first rough grind to 1000 # Silicon carbide water sandpaper, the force should be light, the speed of the grinding disc should be slow, about 300-500rpm; the roughly ground sample should be cleaned in an ultrasonic instrument, and polished on a polishing flannelette. At this time, use 1μm diamond polishing agent , using ethanol as a lubricant. After polishing for about 5 minutes, observe the surface state under a microscope to confirm that the surface scratches are along one direction. Clean the ground sample in an ultrasonic instrument, replace it with a 0.5 μm diamond polishing agent, and use ethanol as a lubricant. After polishing for about 5 minutes, observe the surface state under a microscope to confirm that the surface scratches are along one direction. Then carry out electrolytic polishing, the electrolyte composition of electrolytic polishing is 80% H 3 PO 4 and 20% H 2 O, on this basis and then chemically et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com