Composite material tower drum of wind driven generator as well as preparation method and preparation mold of composite material tower drum

A technology of wind turbines and composite materials, applied in wind turbine components, wind engines, wind power generation, etc., which can solve the problems of rusty casing and short life, and achieve the effects of reduced maintenance costs, light weight, and reduced transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Prepare a 60m-high conical tower, which is formed by connecting 3 sections

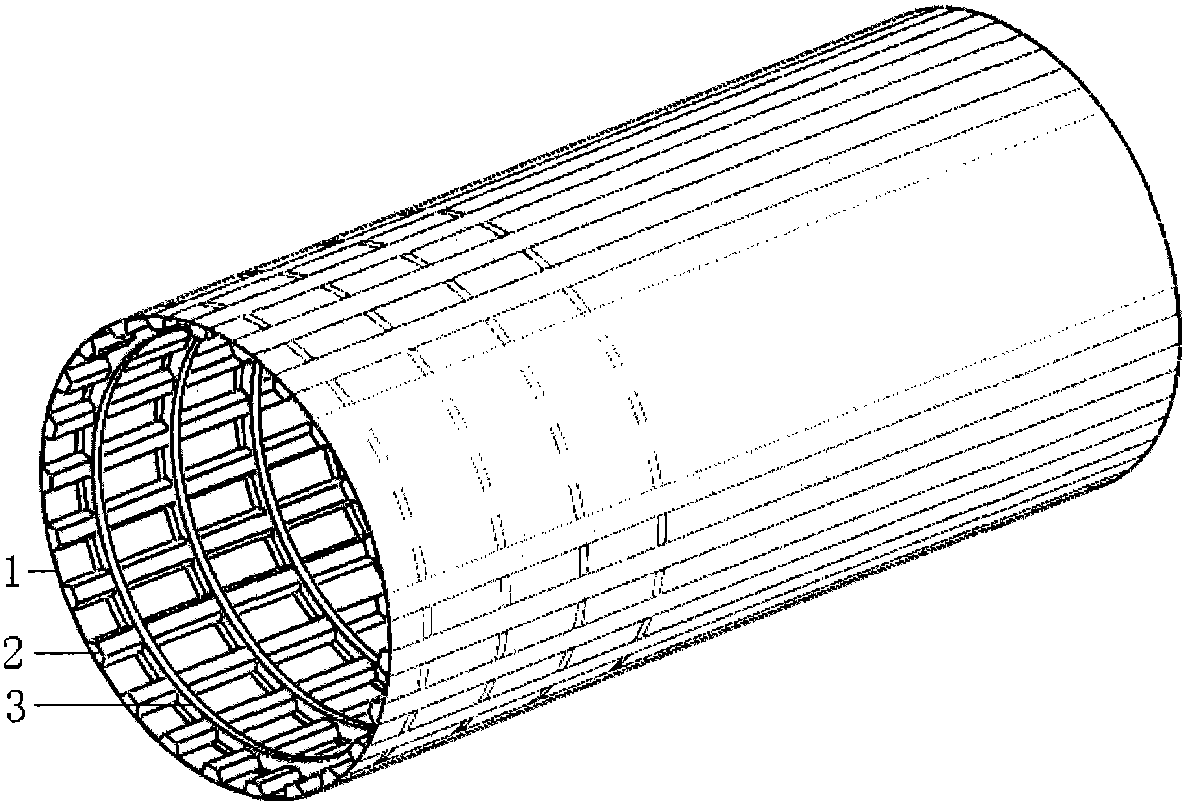

[0029] Such as figure 1 As shown, the skin 1 and 25 stringers 2 are formed by co-curing, the 25 stringers 2 are evenly distributed on the inner surface of the skin 1, and the ordinary partition frames 3 are evenly distributed along the height direction of the tower and perpendicular to the stringer 2 Install. The long stringer 2 is "Ω" shape, and the bulkhead 3 is "C" shape.

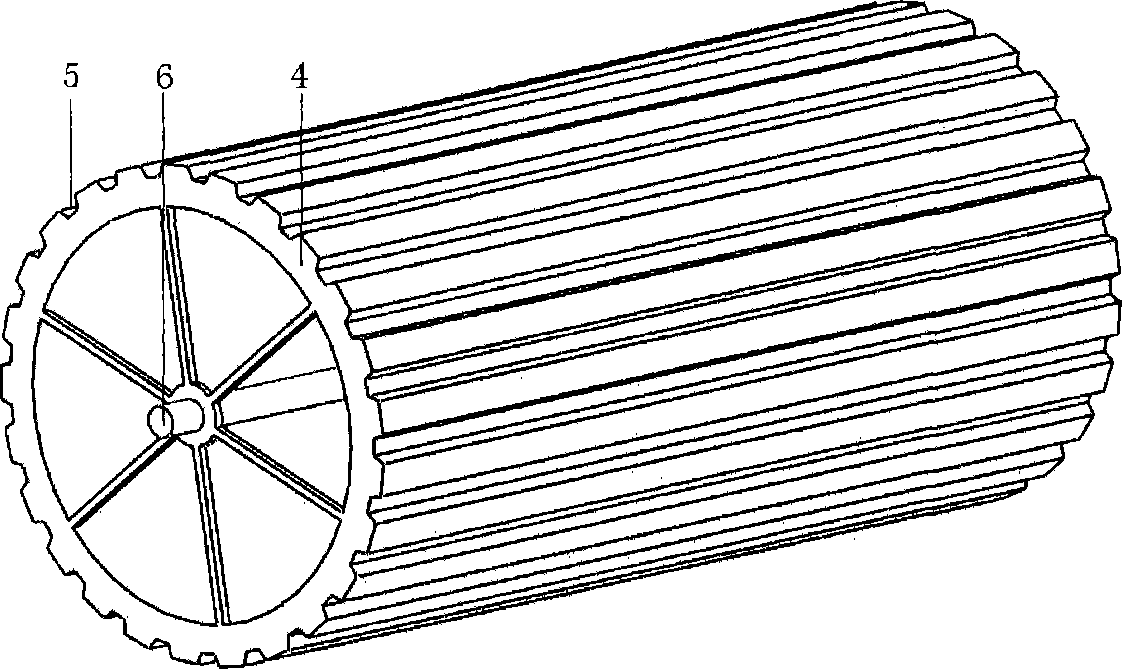

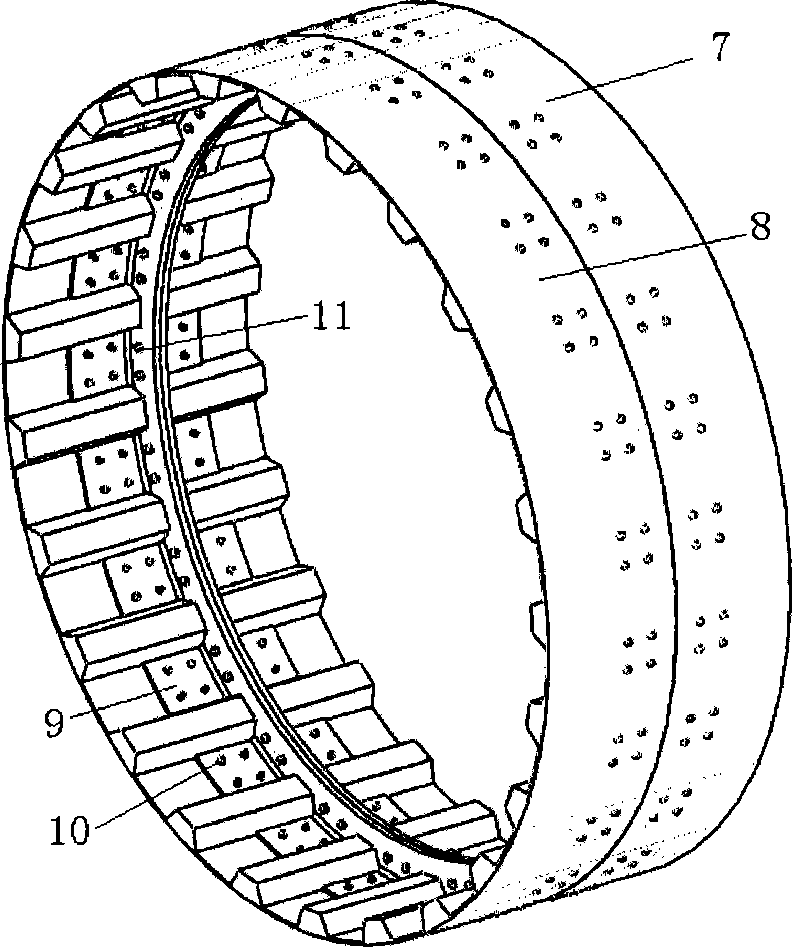

[0030] Such as figure 2 As shown in , the mold 4 has 25 evenly distributed "Ω"-shaped grooves 5, and the rotating shaft 6 of the mold 4 can rotate and move axially. The raw materials are: glass fiber, epoxy resin, PVC foam, quartz sand. The common partition frame 3 is pre-prepared by a compression molding process. The connection frame 9 is made of metal materials, as shown in FIG. 5 .

[0031] The preparation method comprises the following steps:

Embodiment 2

[0036] Prepare a 100m-high conical tower, which is connected by 5 sections. The difference from Example 1 is that the skin 1 is reinforced by mixing glass fiber and carbon fiber, the stringer core of the stringer 2 is made of balsa wood, and the ordinary frame 3 is made of "L" shaped frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com