Top-jet type spray etching machine

A technology of spray etching and etching machine, which is applied in the field of top spray type spray etching machine, can solve the problems of inability to produce a complete set of equipment for thinning liquid crystal panels, high price, lack of mastering the core technology of thinning liquid crystal panels, etc. Accuracy issues, harm reduction, effectiveness in addressing corrosion issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

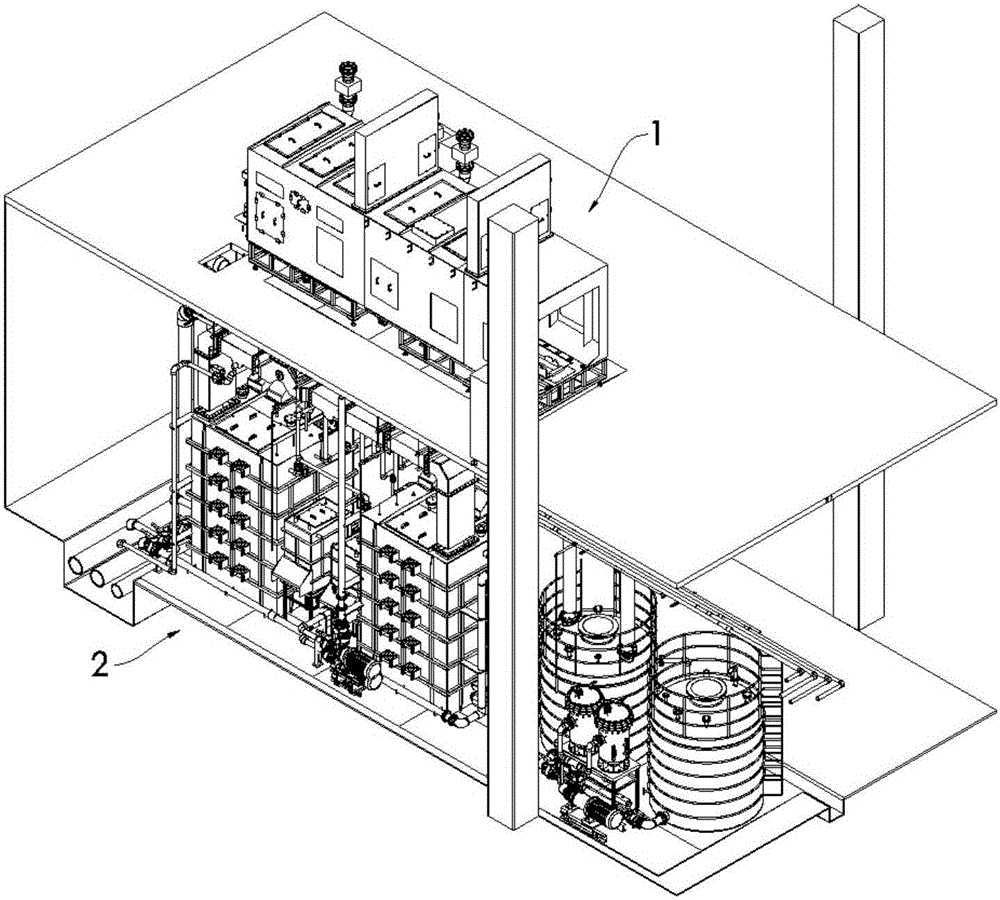

[0029] Such as figure 1 As shown, the present invention discloses a top-spray spray etching machine, which includes two parts: an etching machine body 1 and a chemical liquid circulation system 2 connected with the etching machine body 1 .

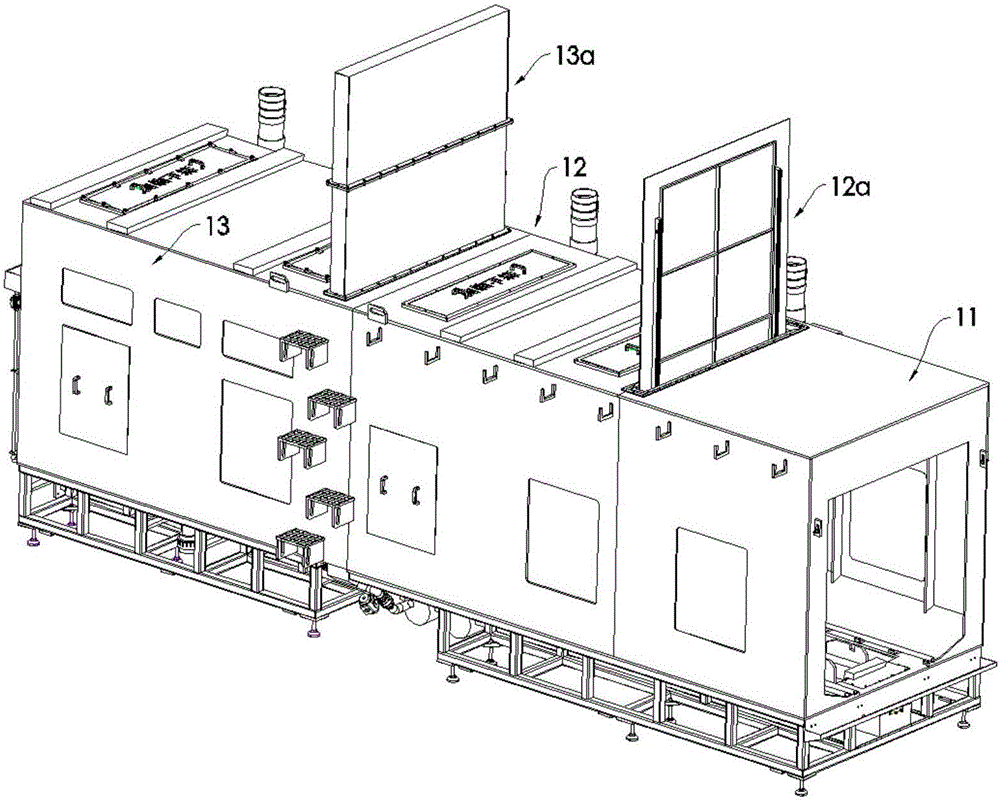

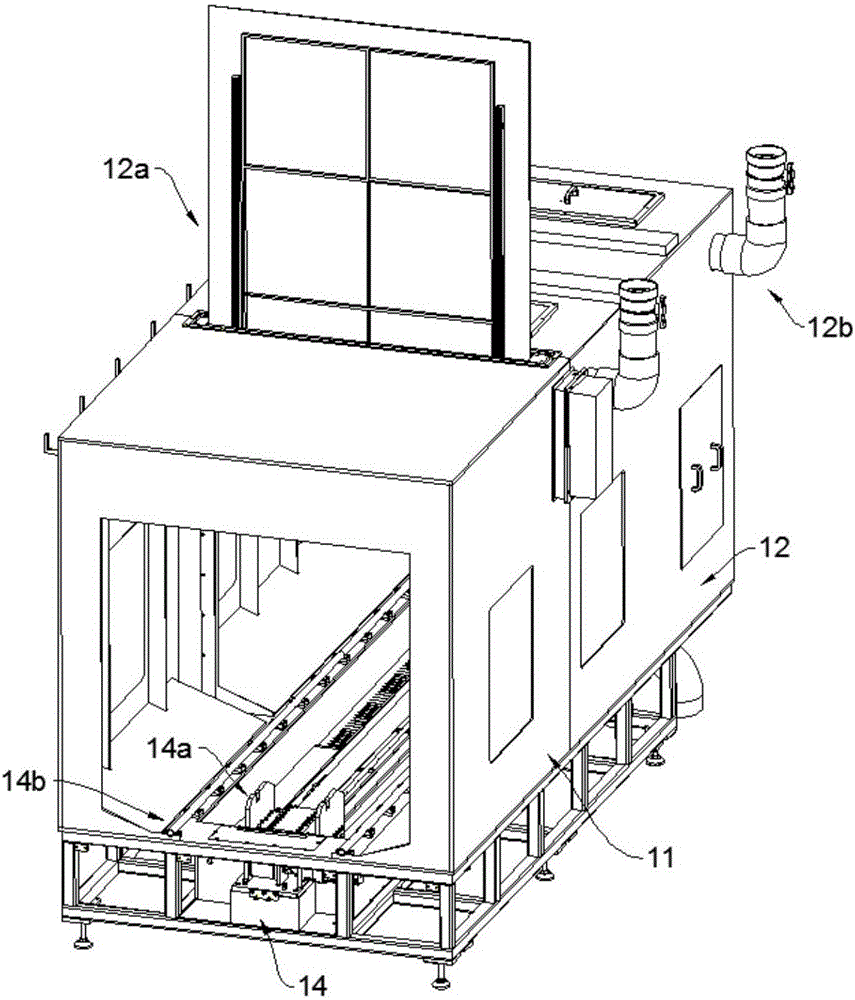

[0030] The etching machine body 1 is composed of three parts, the transition area 11, the cleaning area 12, and the etching area 13, which are sequentially connected and assembled together, as Figure 2~Figure 8 Shown; Cleaning area switch door 12a is installed between the transition area 11 and the cleaning area 12, an etching area switching door 13a is installed between the cleaning area 12 and the etching area 13, and the cleaning area 12 top is fixed Spray device 15, cleaning area exhaust pipe 12b are installed, spray device 15, etching area exhaust pipe 13b are installed on the top of the etching area, and a servo drive motor 14 is installed at the bottom of the transition area 11, and the servo drive motor 14 It is driven and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com