Double-webbed H type steel, and connecting node of double-webbed H type steel and concrete prefabricated slab

A technology for connecting nodes and H-beams, applied in the direction of floor slabs, elongated structural members for load-bearing, structural elements, etc., can solve the problems of the increase of the weight of the H-beam itself, the decrease of the stability of the H-beam, and the low utilization rate of steel. , to solve the problem of anti-corrosion, improve the tensile capacity, and improve the effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

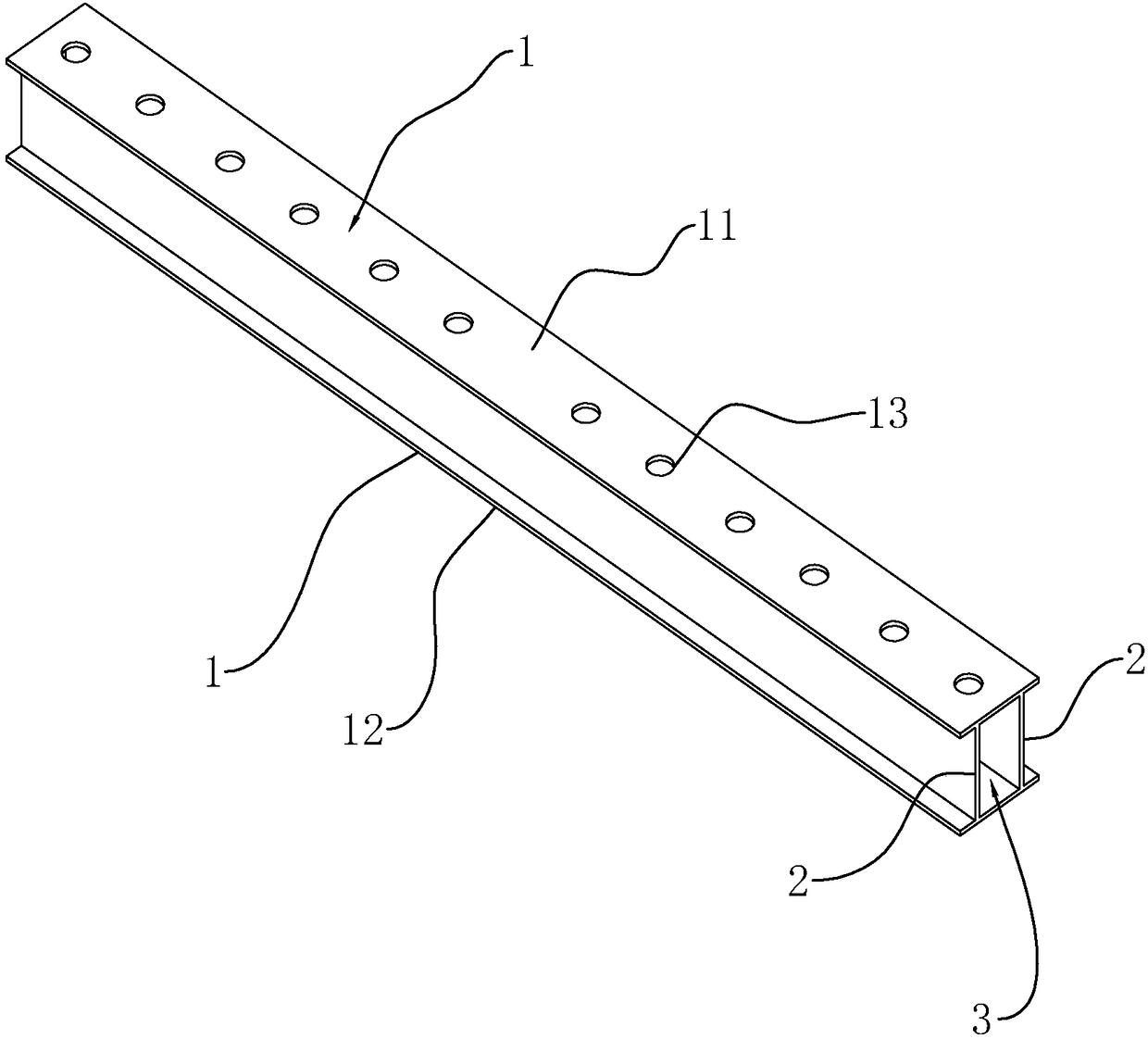

[0063] Such as figure 1 As shown, a double-web H-shaped steel includes two flange plates 1 and two web plates 2, the two flange plates 1 are parallel to each other, the two web plates 2 are parallel to each other, and the web plates 2 are vertically fixed on the two Between the two flange plates 1; two webs 2 and two flange plates 1 form a cavity 3. The two flange plates 1 are a first flange plate 11 and a second flange plate 12 . Compared with the H-shaped steel with single web 2 in the prior art, the double web 2 has better torsion resistance and better overall rigidity. When the total thickness of the double-layer web 2 is the same as that of the single-layer web 2, the same bending performance can also be achieved, and the setting of the double-layer web 2 can reduce the weight of the web 2 under the same conditions. height, thereby reducing the amount of steel used.

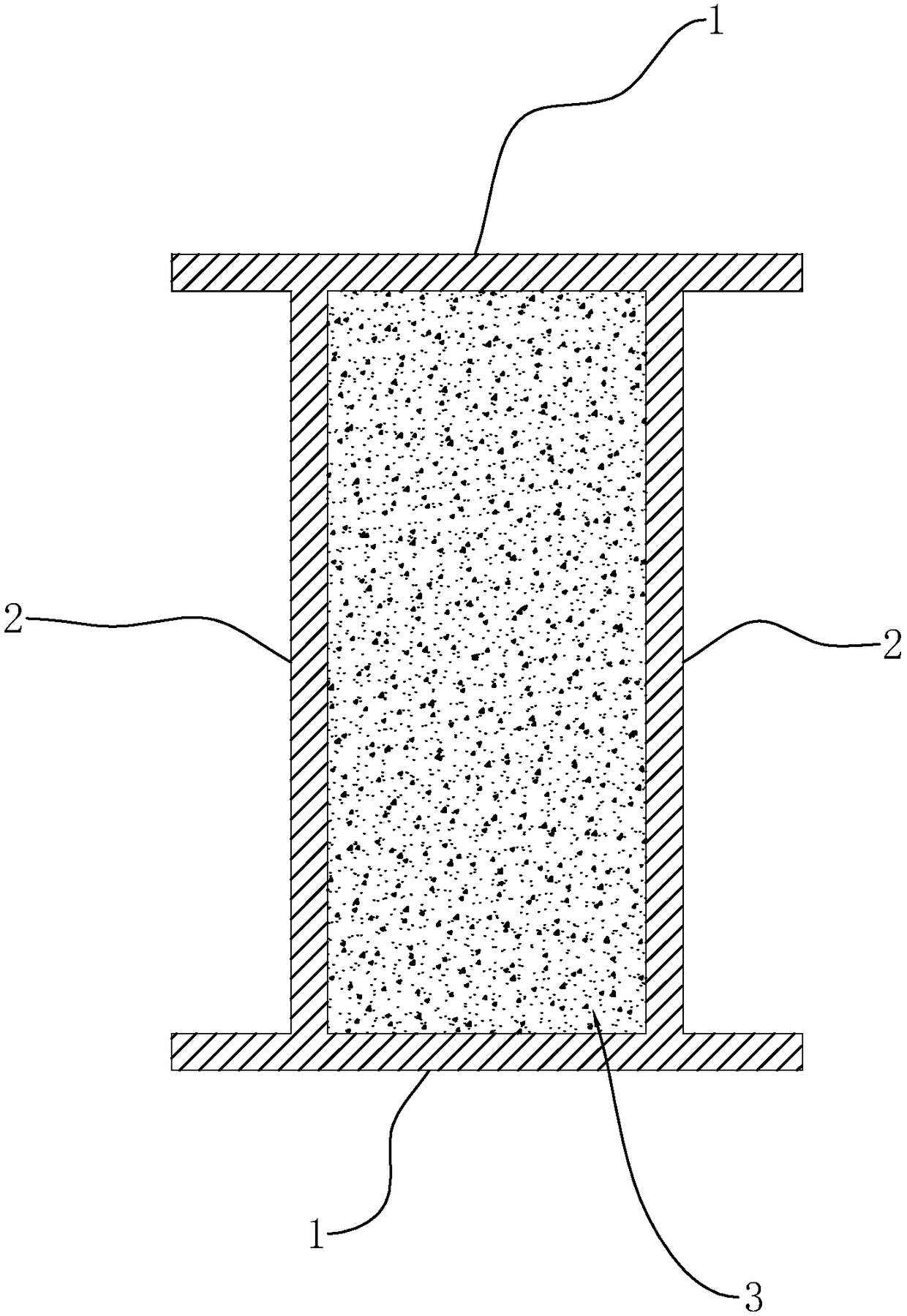

[0064] Such as figure 2 As shown, further, concrete is poured into the cavity 3 . The concrete pour...

Embodiment 2

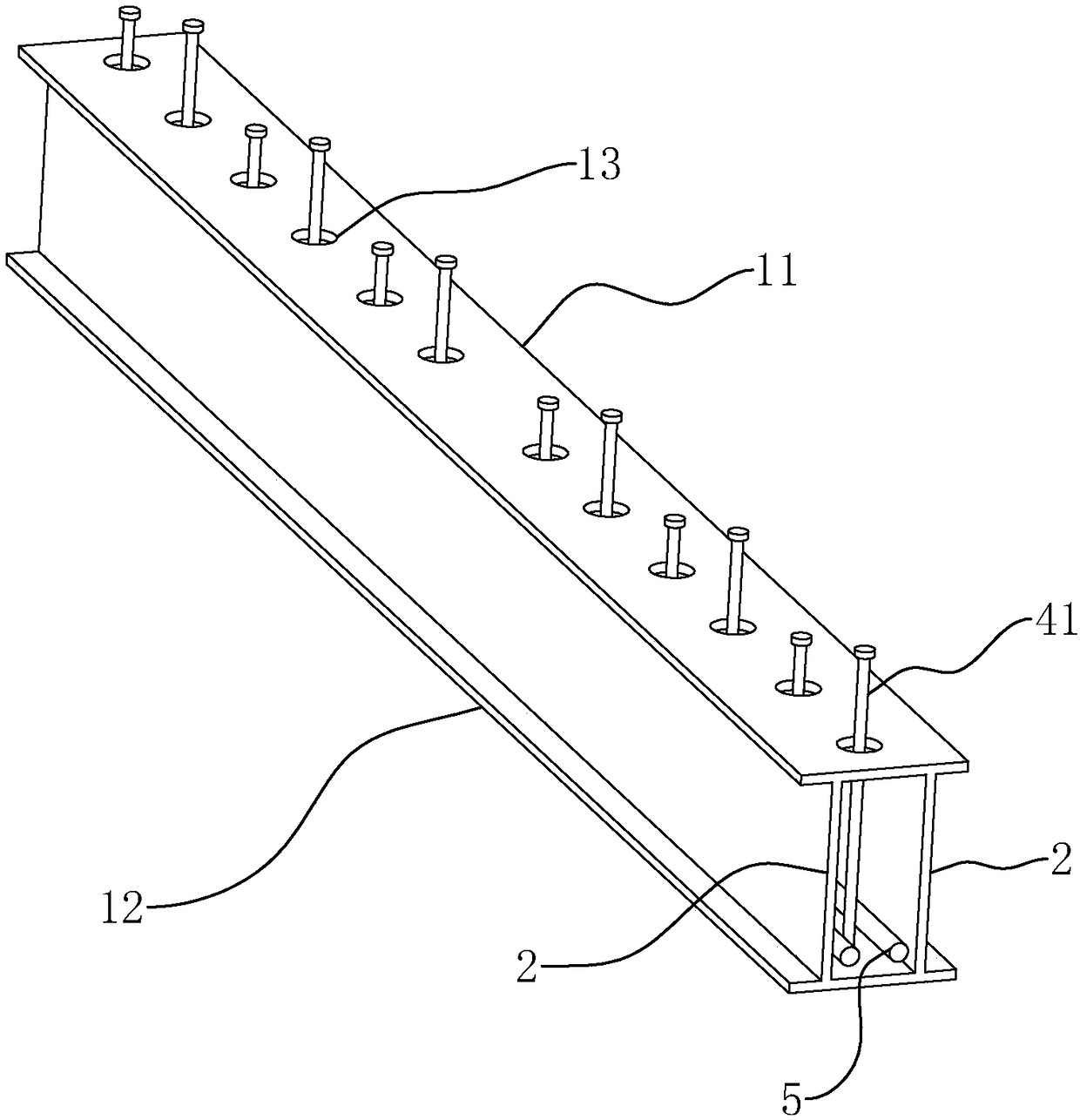

[0076] Such as Image 6 and Figure 7 As shown, a connection node between a double-web H-shaped steel and a concrete prefabricated slab includes two prefabricated floor slabs 9 and a double-web H-shaped steel; the double-web H-shaped steel includes a through hole 13 and a first reinforced connecting rod 41; two The prefabricated floor 9 is located on the same side of the first flange plate 11 of the double-web H-shaped steel, and the first post-cast belt 104 is formed between the two prefabricated floor slabs 9, and the first post-cast belt 104 pours concrete; the prefabricated floor 9 is close to the second The end surface of a post-casting belt 104 is provided with lateral connecting ribs 91, a part of which is pre-embedded in the prefabricated floor 9, and a part protrudes from the prefabricated floor 9; the lateral connecting ribs 91 of the two prefabricated floors 9 and The first reinforcing connecting rods 41 of the double-web H-shaped steel are connected to each other....

Embodiment 3

[0080] Such as Figure 8 As shown, a double-web H-shaped steel is different from Embodiment 1 in that the two ends of one flange plate 1 are bent outward to form a clamping plate 14 .

[0081] Such as Figure 9 As shown, a connection node between a double-web H-shaped steel and a concrete prefabricated slab includes a prefabricated wall panel 7 and the double-web H-shaped steel described in this embodiment. The double-web H-shaped steel is arranged on the top surface of the prefabricated wall panel 7 , and the two clamping plates 14 clamp the prefabricated wall panel 7 .

[0082] This structure strengthens the connection between the double-web H-shaped steel and the prefabricated wall panel 7, and the structure is more firm.

[0083] Such as Figure 10 As shown, the second embodiment and the two structures in this embodiment can also be combined to form the connection nodes of the prefabricated wall panel 7, the double-web H-shaped steel and the prefabricated floor slab 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com