Marsh gas pressure regulator

A pressure regulator and biogas technology, applied in the direction of safety valves, engine components, balance valves, etc., can solve the problems of unsuitable use of pressure regulators, unacceptable by farmers, short service life, etc., to solve anti-corrosion problems, easy installation, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

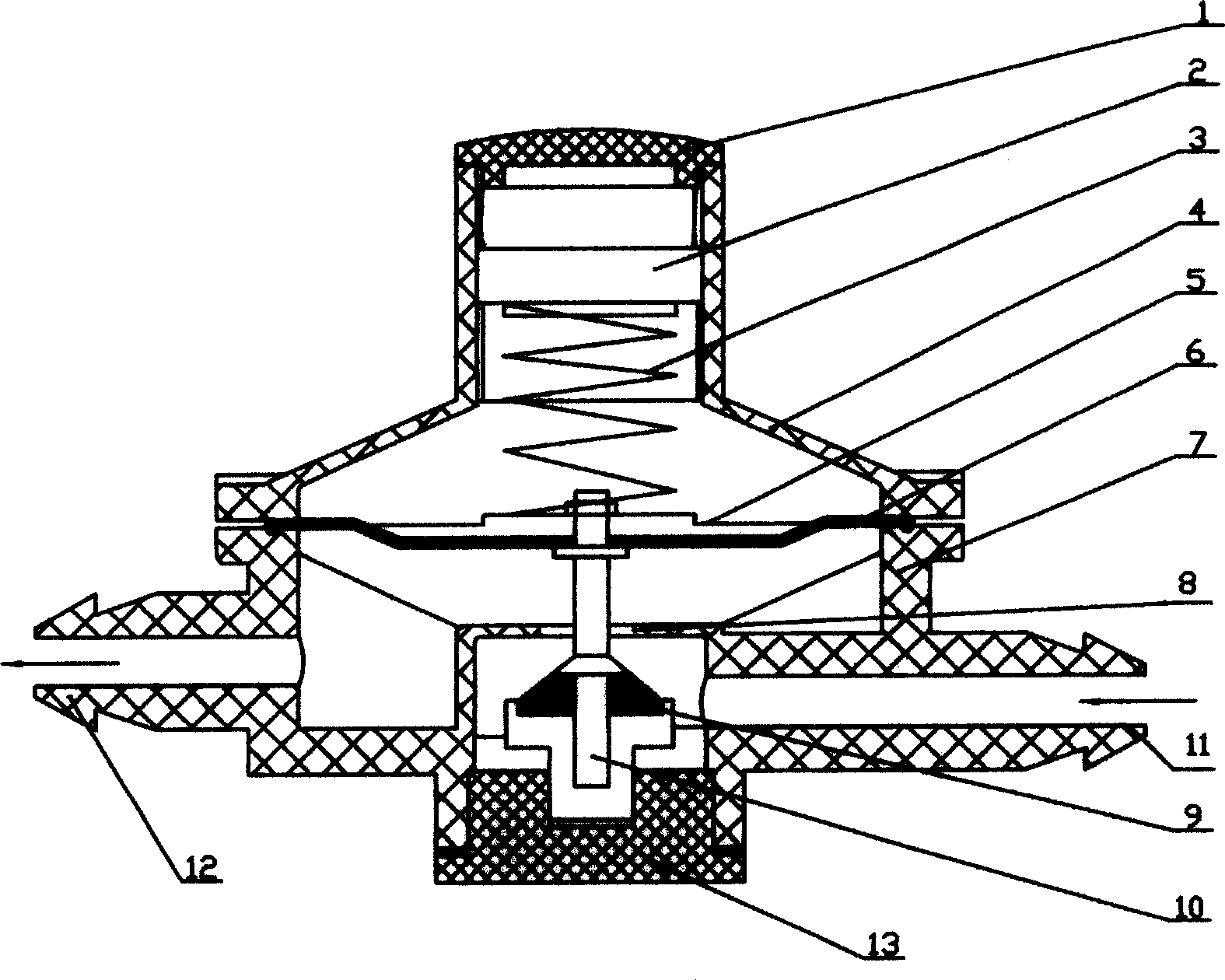

[0011] Such as figure 1 As shown, a biogas pressure regulator includes a plug cover 1, an upper casing 4, a lower casing 7, an air inlet nozzle 11 and an air outlet nozzle 12 arranged on the lower casing 7, and the inner casing of the upper casing is arranged There is a pressure regulating block 2, and a screw fit is arranged between the pressure regulating block 2 and the upper casing 4, so that the position of the pressure regulating block 2 can be adjusted. A rubber diaphragm 6 is clamped between the upper housing 4 and the lower housing 7, and the rubber diaphragm 6 is a rubber sandwich fabric film resistant to hydrogen sulfide corrosion, so that the rubber diaphragm 6 has enhanced aging resistance and elasticity. uniform. A tray 5 is arranged on the top of the rubber diaphragm 6 , and a spring 3 is arranged between the pressure regulating block 2 and the tray 5 , and the elastic force of the spring 3 can be adjusted by adjusting the position of the pressure regulating bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com