Patents

Literature

43 results about "Methane pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methane has a boiling point of −164 °C (−257.8 °F) at a pressure of one atmosphere. As a gas it is flammable over a range of concentrations (5.4–17%) in air at standard pressure. Solid methane exists in several modifications.

Normal temperature methane high-efficiency adsorption material

ActiveCN105312026AHigh separation factorLow separation factorProductsOther chemical processesCeramic compositeCeramic molding

The invention relates to a normal temperature methane high-efficiency adsorption material and a preparation method thereof. The material is characterized in that a metal organic skeleton composite material containing transition metals Fe III, Zn II, Cu II, Ni II and Co III grows on an active carbon ceramic mainly prepared from active carbon and molecular sieve in an in situ manner. The preparation method of the normal temperature methane high-efficiency adsorption material comprises the following steps: carrying out dry mixing and ball milling on one or more of chlorides and sulfates of Fe<3+>, Zn<2+>, Cu<2+>, Ni<2+> and Co<3+>, high-specific surface area coconut shell active carbon, Y molecular sieve, attapulgite, kaolin and methyl cellulose in proportion, adding a certain amount of water, carrying out wet mixing, kneading, carrying out vacuum pugging, ageing, carrying out extrusion molding, drying in the shade, carrying out microwave irradiation sizing to obtain an active carbon ceramic molding material containing transition metals, immersing the molding material in a mixed solution containing an organic solvent, an deprotonated alkali and an organic carboxylic acid ligand according to a certain ratio, reacting at 120-180DEG C for 6-24h, carrying out solid-liquid separation, washing, and carrying out microwave vacuum drying to obtain a metal organic skeleton-active carbon ceramic composite material. The material has the characteristics of large specific surface area, developed aperture, high compressive strength, large methane adsorption capacity and high CH4 / N2 and CH4 / CO2 separation coefficients, and can be widely used in the fields of methane pressure swing adsorption separation and low-concentration methane recovery.

Owner:江苏瑞丰科技实业有限公司

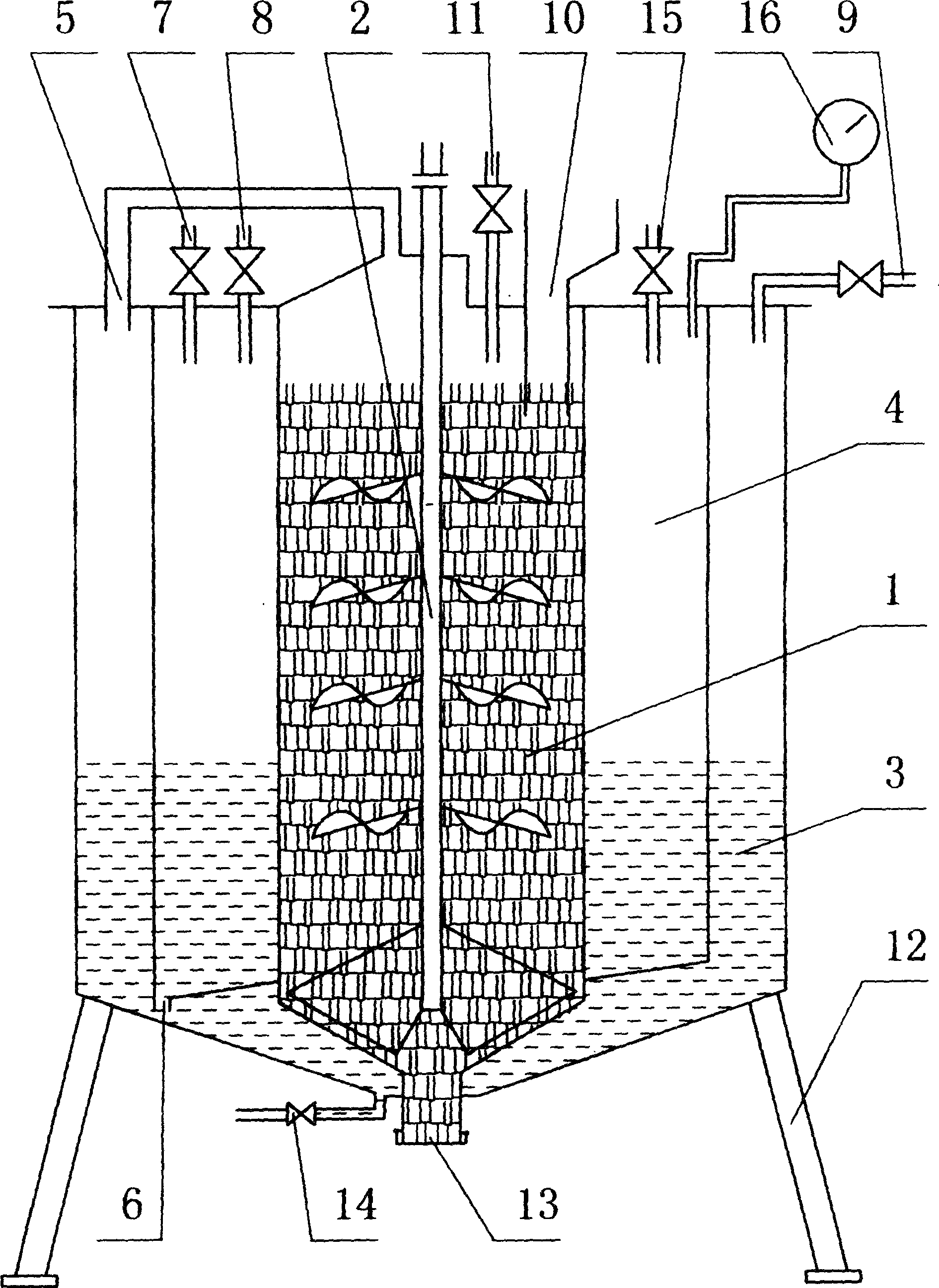

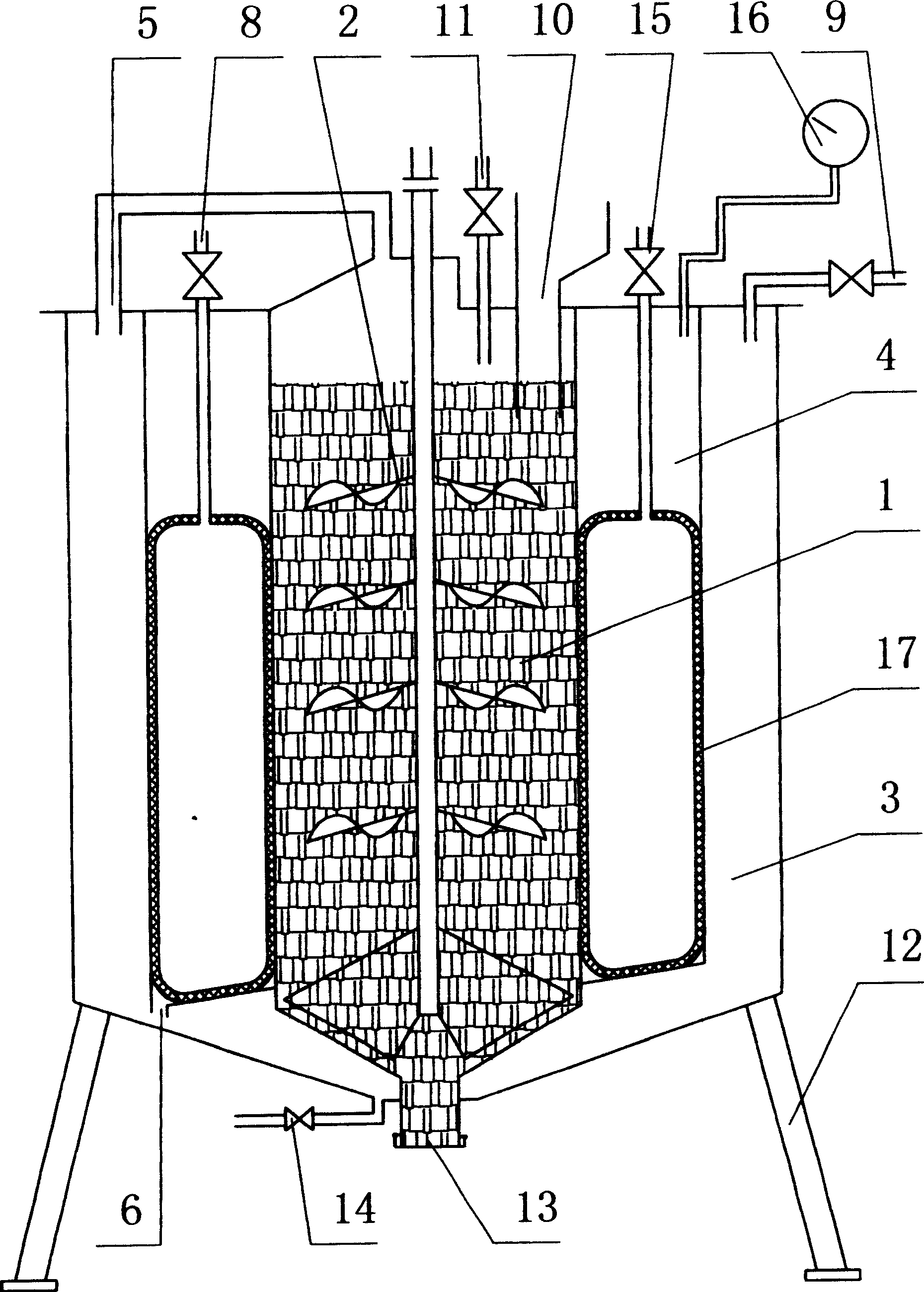

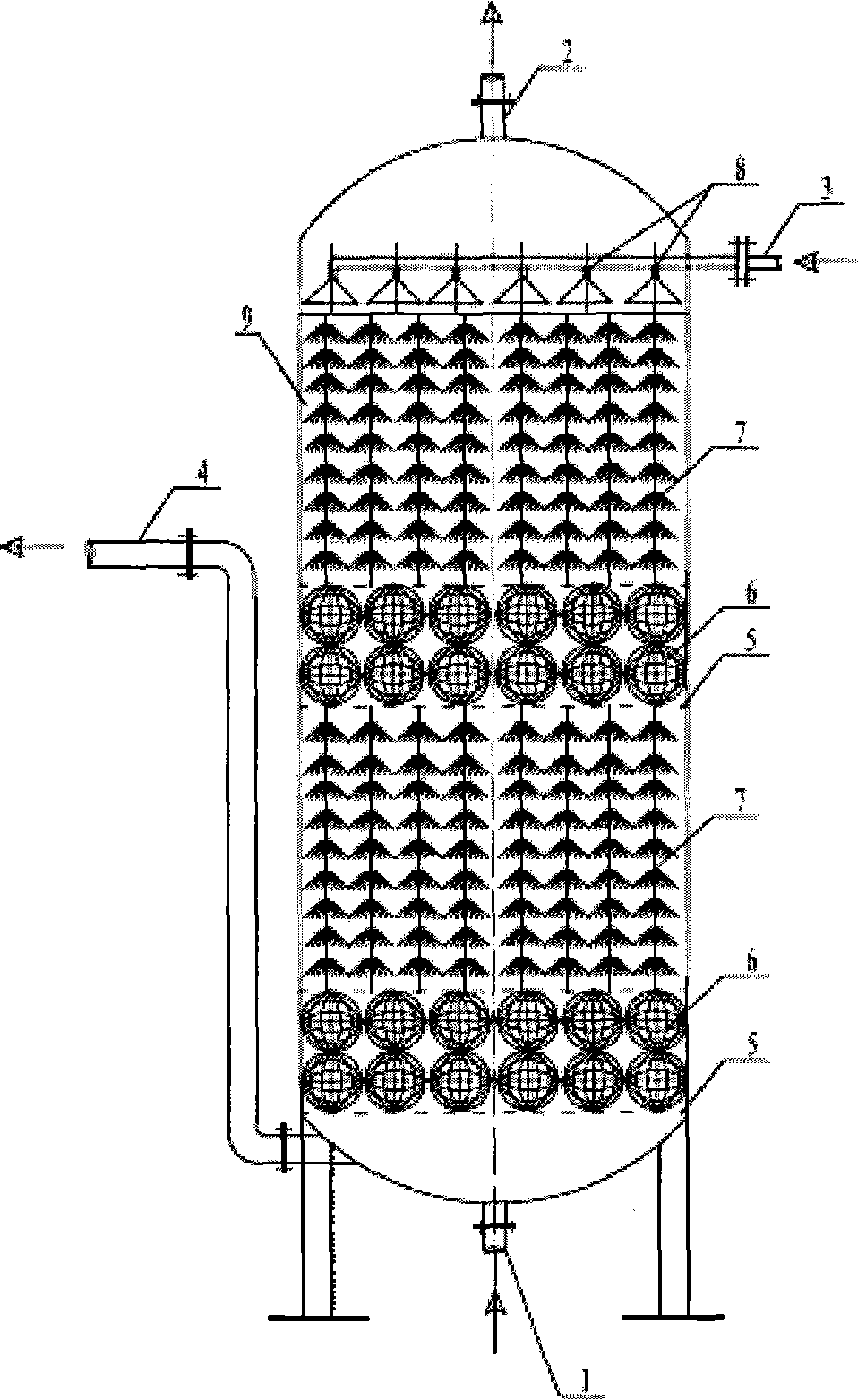

Anaerobic biological desulfurization method and device for methane

Owner:BIOGAS SCI RES INST MIN OF AGRI

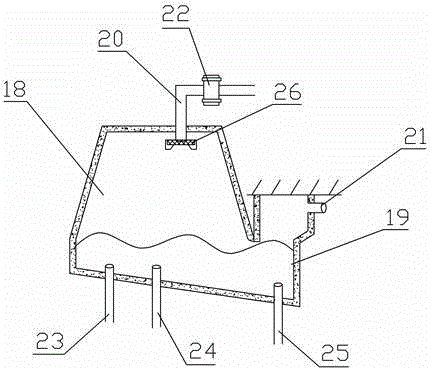

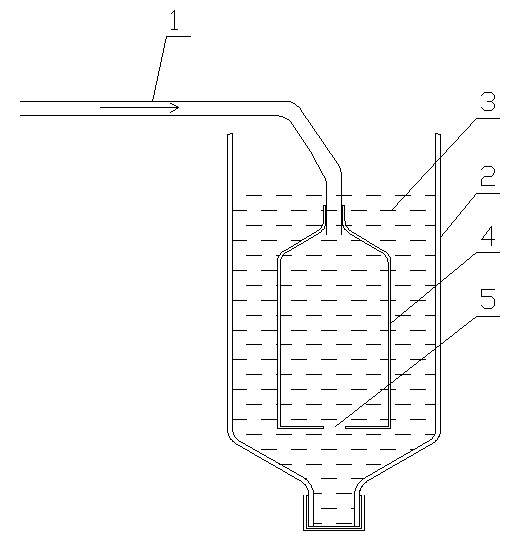

Hydraulic pressure floating hood type methane tank

InactiveCN102766570ASimple structureLow costGas production bioreactorsWaste based fuelLiquid densityEngineering

The invention discloses a hydraulic pressure floating hood type methane tank. A hood body comprises a hood cover, a hood wall and an air tube and is coated on the inner bottom of a container; a distance interlayer is arranged between the hood wall and the wall of the container, the hood body is provided with a device for leading a material liquid into the hood, a device for controlling the height of a plane in hood covers of air storage chambers and a liquid level to be larger than zero, a positioning device for enabling the hood cover to freely float up and down and a device for discharging residue; the height of a feeding port is higher than a zero-pressure liquid surface, and the height of the wall of the hood is at least equal to a value which is obtained via algorithm as follows: a vertical upward cross stress area impulses the maximum output methane pressure in the gas storage chambers and divides the product of an average area of liquid surface cross hood wall and liquid density. According to a buoyancy principle and a simple structure, technical problems including high manufacturing cost of methane tanks, troubles of automatic residue discharging and automatic pressure stabilizing, less gas storage capacity and the like in the prior art are solved. Therefore, people can process a large amount of straw, household garbage and waste with low cost, and meanwhile, reproducible energy firedamp can be obtained.

Owner:罗显平

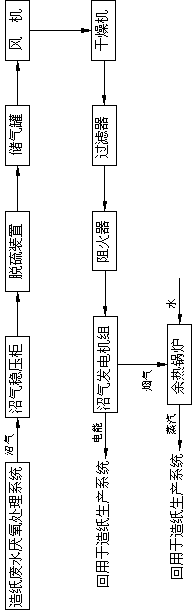

Recovery power generation technology of methane generated by paper-making wastewater treatment

InactiveCN102977962AEfficient desulfurizationEfficient dryingInternal combustion piston enginesGaseous fuelsPressure stabilizationFiltration

The invention discloses recovery power generation technology of methane generated by paper-making wastewater treatment. First, the methane generated by a paper-making wastewater anaerobic treatment system is conveyed to a methane pressure-stabilizing cabinet for pressure stabilization; then the methane is conveyed to a desulfurization system for desulfurization treatment; the content of hydrogen sulfide (H2S) decreases from 200 grams per liter to 0.05 gram per liter after the desulfurization treatment; then the methane after the desulfurization treatment is conveyed to a methane storage tank for collection and conveyed into a drier through a draught fan for dehydration and drying until no free water exists in the methane, and the water content of the methane is lower than 40 grams per cubic nanometer; then the methane after being dried passes through a filter for filtration treatment, large grained impurities in the methane is filtered out; finally, the methane after filtration is conveyed to a methane generating set for power generation; and the front end of the methane generating set is provided with a fire arrestor device so that the burning methane is prevented from returning to the device at the front end. The recovery power generation technology of the methane generated by the paper-making wastewater treatment not only effectively solves the environment problems caused by methane drainage but also well uses methane resources to produce considerable economic value.

Owner:SHANYING INT HLDG CO LTD

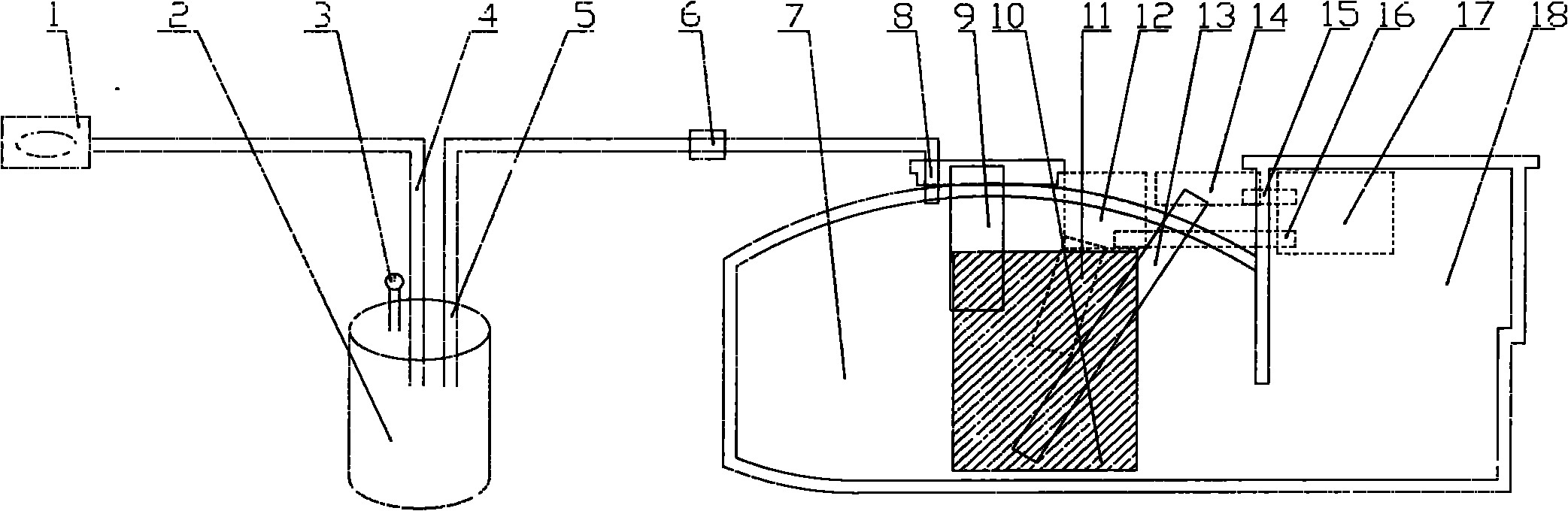

Automatically controlled underground coal mine gas configuration experiment device

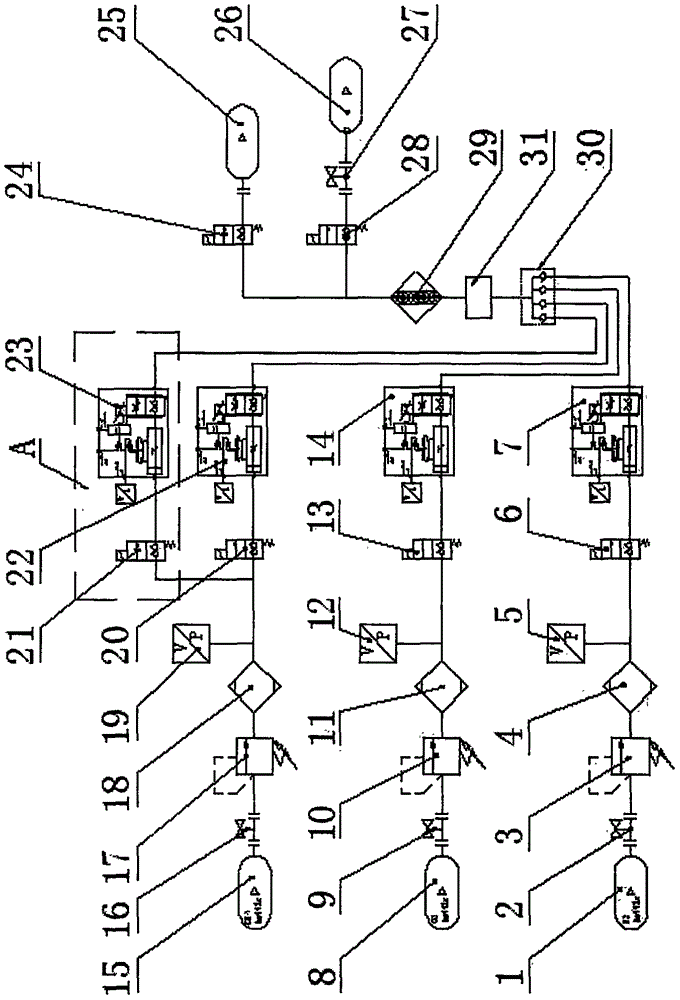

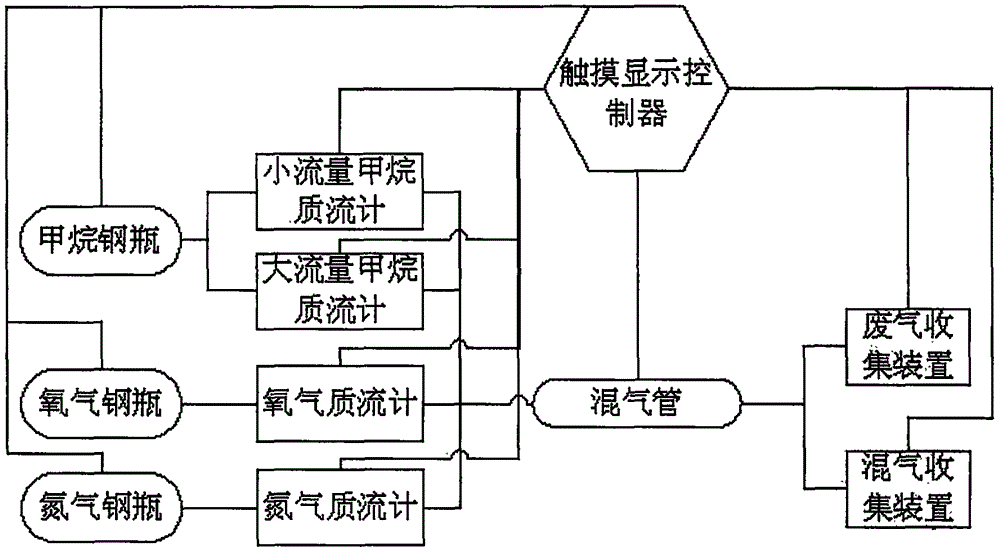

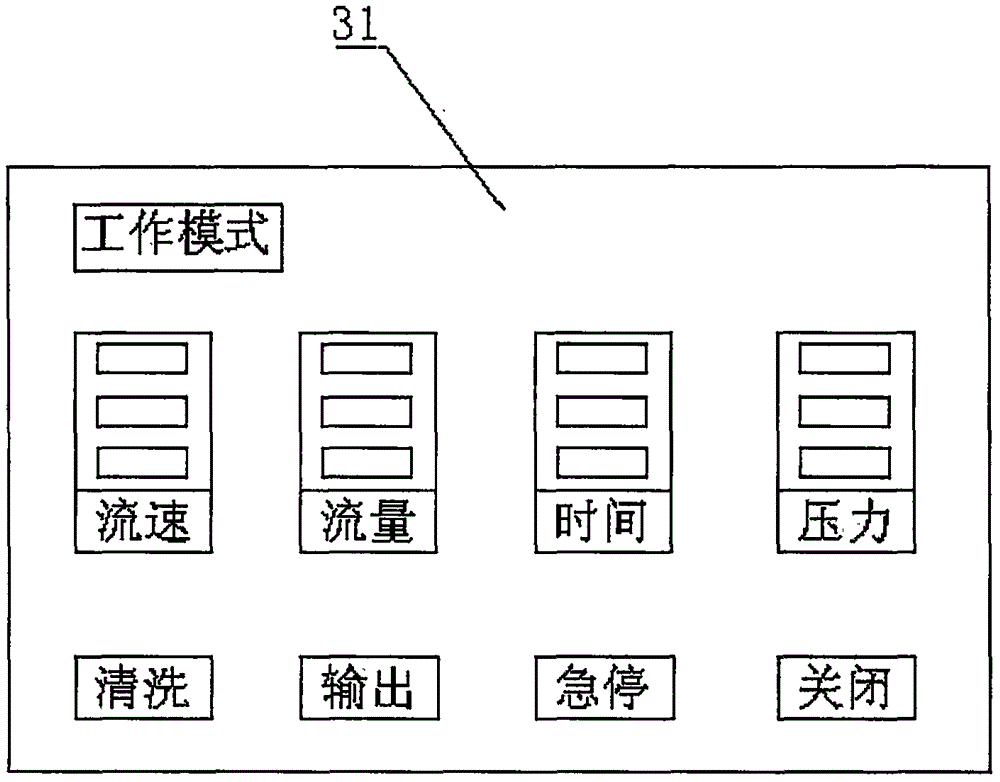

PendingCN106731936AMonitor temperature in real timeMonitor pressure in real timeFlow mixersTransportation and packagingAutomatic controlNitrogen

The invention relates to an automatically controlled underground coal mine gas configuration experiment device which comprises a methane steel cylinder, an oxygen steel cylinder and a nitrogen steel cylinder, wherein a methane switching valve and a methane pressure-reducing valve are mounted on the methane steel cylinder; the right end of the methane steel cylinder is connected with a methane drying tube; the right end of the methane drying tube is connected with a methane pressure sensor; the right end of the methane pressure sensor is connected with a high-flow methane electromagnetic valve and a low-flow methane electromagnetic valve; the right end of the high-flow methane electromagnetic valve is connected with a high-flow methane mass flow meter; the right end of the low-flow methane electromagnetic valve is connected with a low-flow methane mass flow meter; an oxygen switching valve and an oxygen pressure-reducing valve are mounted on the oxygen steel cylinder; the right end of the oxygen steel cylinder is connected with an oxygen drying tube; the right end of the oxygen drying tube is connected with an oxygen pressure sensor. The experiment device has the advantages of being reasonable in design, low in cost, convenient to install and use, high in working efficiency, economic in manpower, safe and reliable in use, accurate in data, stable in operation, strong in automatic control ability, long in service life, comprehensive in functions and strong in practicability.

Owner:HENAN INST OF ENG

Marsh gas pressure regulator

InactiveCN1664425AHigh sensitivitySolve the problem of corrosionEqualizing valvesSafety valvesRubber materialRubber membrane

The invention relates to a methane pressure regulator that includes block cover, up case body, down case body, pressure regulate block on the top in the up case body, rubber membrane between the up case body and the down case body. A tray is set on the rubber membrane. And a spring is set between the pressure regulate block and the tray. The tray is fixed on the top of the connecting bar through the rubber membrane. The bottom of the connecting bar connects to a valve pad through the valve mouth. The bottom of the case body has valve core supporting cover. The material of blocking cover, up case body, down case body, pressure regulating block, tray, connecting bar and the valve core supporting cover is ABS plastic. And the rubber membrane and the valve pad are made up of rubber material that can endure the cauterization of sulfureted hydrogen. The invention solves the cauterization problem and is easy to install.

Owner:魏光第

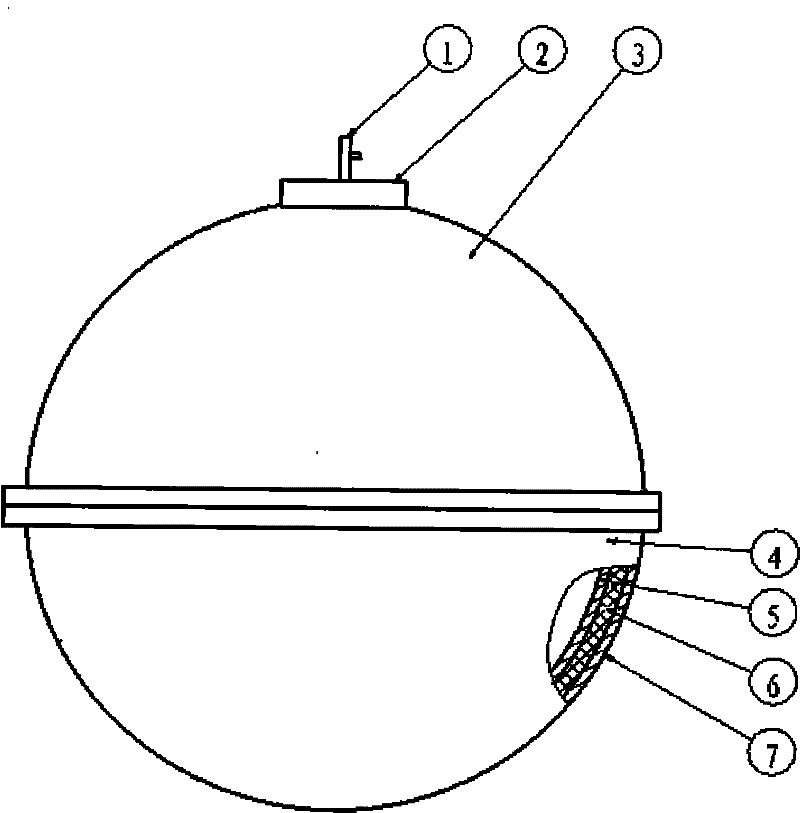

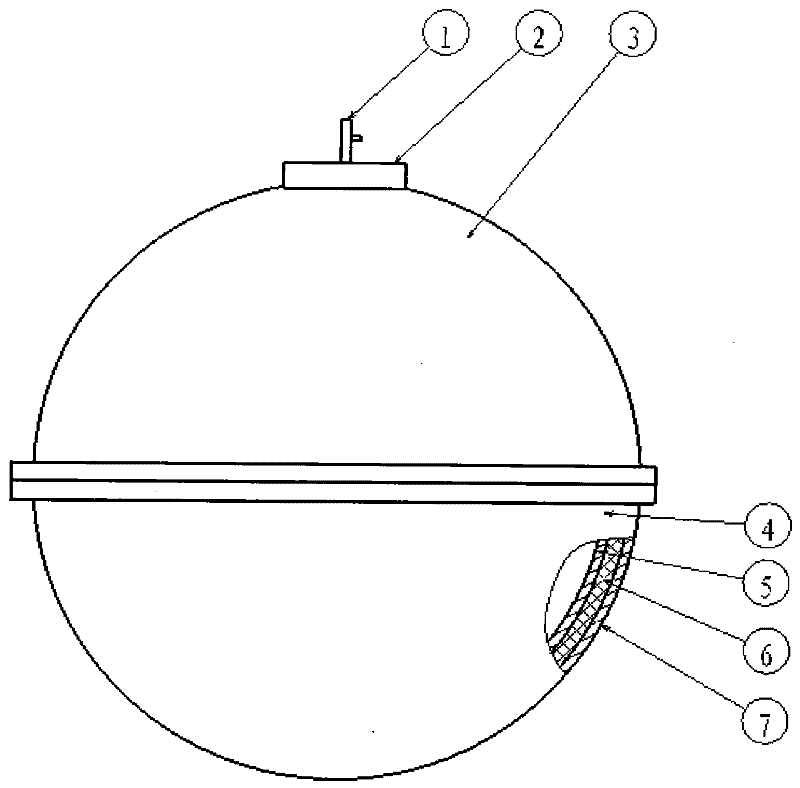

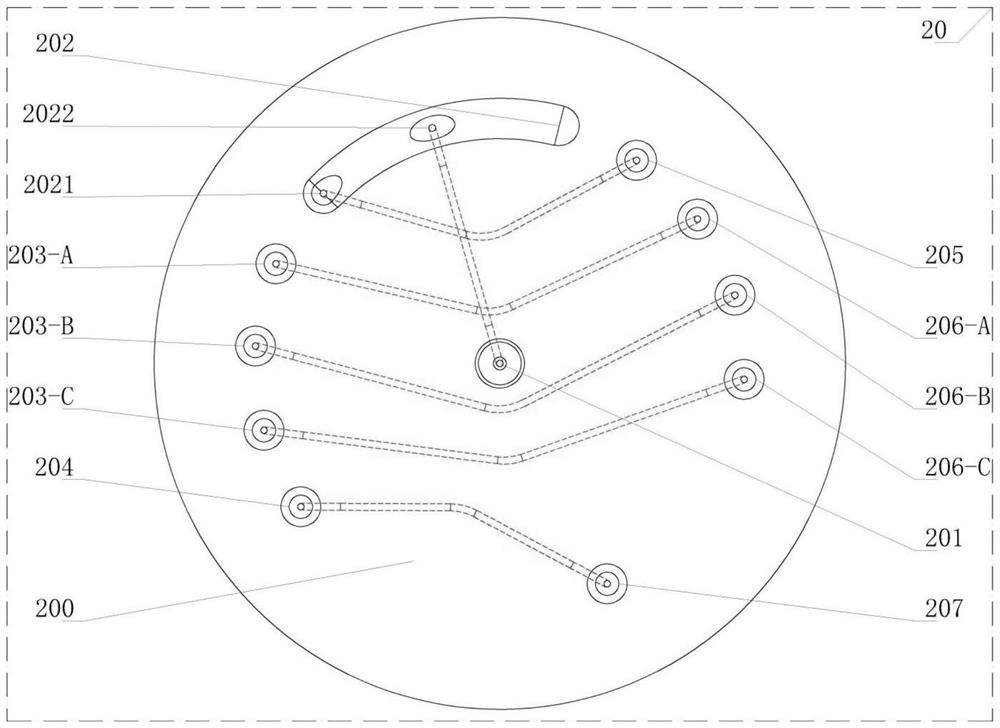

Spliced thermal insulation methane tank

InactiveCN102181362AImprove insulation effectImprove structural strengthGas production bioreactorsWaste based fuelThermal insulationUltimate tensile strength

The invention discloses a spliced thermal insulation methane tank which is a spherical or cylindrical tank. The tank is formed by splicing an upper tank (2) and a lower tank (3), wherein the upper tank and the lower tank are connected by using a prearranged flange and are adhered; the upper tank is provided with a feed and discharge port, so that feed and discharge are facilitated; the feed and discharge port is firmly connected with a sealing cover by using bolts, so that air-tightness of the tank is guaranteed; the sealing cover is provided with an air nozzle and a pressure relief module (1), so that external gas supply and methane pressure in the tank do not exceed a safety range; and the tank is divided into an inner layer (5), a thermal insulation layer (6) and an outer layer (7). The spliced thermal insulation methane tank has the advantages of simple structure, high thermal insulation performance, high strength, practicability, easiness for disassembly and assembly, science and preciseness, convenience for industrial production, installation and transportation and simplicity in operation and maintenance.

Owner:顺平县普惠农丰新能源科技有限公司

Methane storage cabinet and methane tank containing same

InactiveCN104087504ANo pollutionAvoid accumulationContainer filling methodsGas production bioreactorsSludgeMethane yield

The invention discloses a methane storage cabinet and a methane tank containing the methane storage cabinet. The methane storage cabinet comprises a sludge tank and a gas storage cabinet communicated with the sludge tank, wherein the bottom of the gas storage cabinet inclines down to the place where the sludge tank is communicated with the gas storage cabinet and the bottom of the gas storage cabinet extends to a side wall where a water outlet hole of the sludge tank is located, the cross section of the bottom of the gas storage cabinet is an indent hemisphere. The methane tank containing the methane storage cabinet comprises a main tank and a hydraulic pressure room, wherein a dung inlet is formed in one side of the main tank, a dung outlet is formed between a fermentation tank and the hydraulic pressure room, and the dung outlet is formed in the other side wall of the fermentation tank; the upper edge of the dung inlet and the top of the dung outlet are arranged on the same horizontal line; the bottom of the fermentation tank inclines downwards from the side wall where the dung inlet is located to the hydraulic pressure room and extends to the side wall where an overflow hole of the hydraulic pressure room is located; and a dung drainage channel with the cross section in an indent hemisphere shape is formed in the bottom of the fermentation tank. The invention aims to provide a methane storage cabinet with a simple structure, low cost and long service life and a methane tank which is constant in methane pressure, convenient for deslagging and high in methane yield and hardly causes crusting.

Owner:何跃超

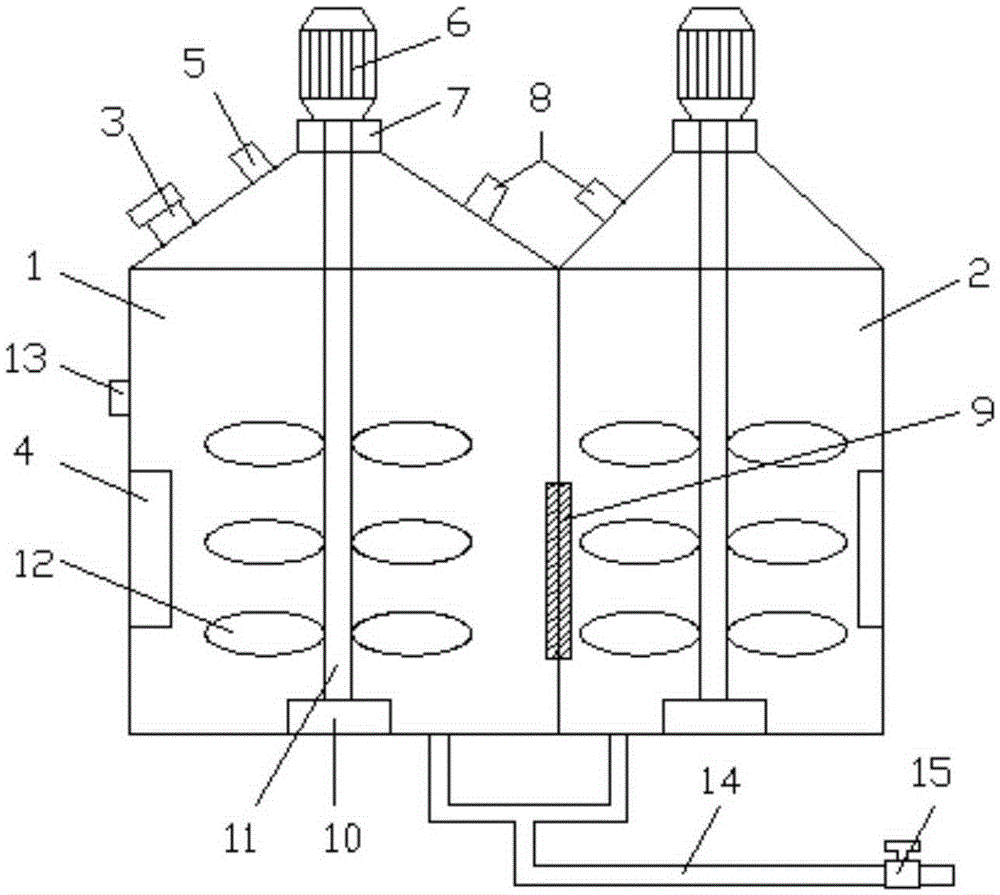

Methane tank with stirring function

InactiveCN106834090AWith stirring functionAvoid accumulationBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringPressure release

The invention discloses a methane tank with a stirring function. The methane tank with the stirring function comprises a first methane tank, a second methane tank, a pressure release valve, stirring motors, a gas outlet and a residue discharge pipeline; a feeding port is formed in one upper side of the first methane tank; the second methane tank is arranged on one side of the first methane tank; viewing windows are arranged on the side walls of the first methane tank and the second methane tank; the stirring motors are arranged on the upper sides of the first methane tank and the second methane tank; stirring rods are arranged on the lower sides of the stirring motors; the stirring rods extend to the bottoms of the first methane tank and the second methane tank; rotary seats are arranged on the lower sides of the stirring rods; the rotary seats are fixedly arranged at the bottoms of the first methane tank and the second methane tank. According to the methane tank with the stirring function, the stirring motors are arranged on the first methane tank and the second methane tank, so that methane reaction is conducted more completely; furthermore, redundant pressure is released by the pressure release valve, so that breakage of the methane tank caused by excessive methane pressure is avoided.

Owner:CHONGQING FENGGUI MATERIALS RECOVERY CO LTD

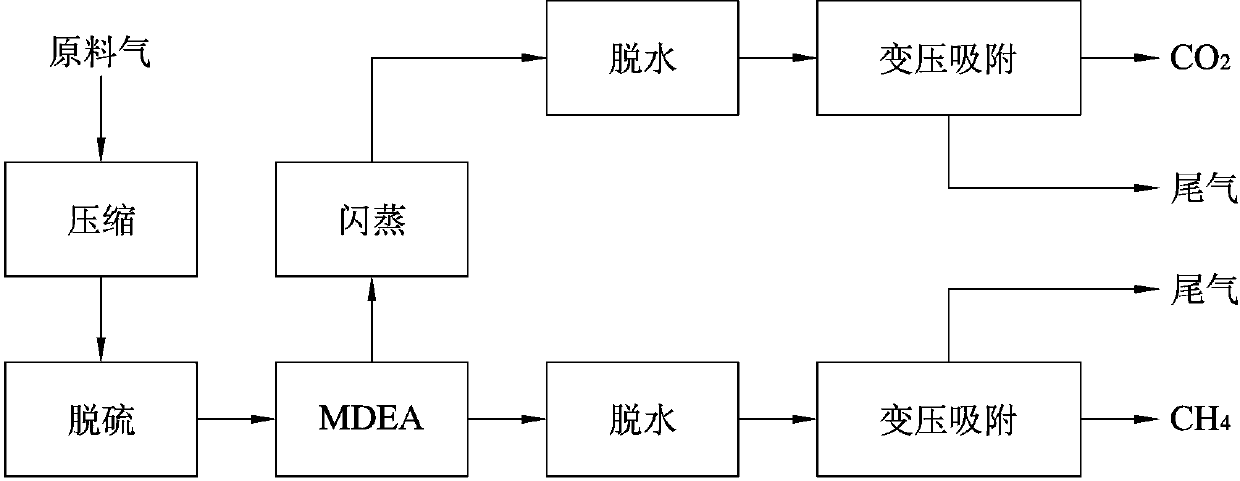

Landfill gas separating and purifying process and device

The invention relates to a landfill gas separating and purifying process which comprises the following steps: separating landfill gas by adopting a methyldiethanolamine method; performing dehydration and pressure swing adsorption on a gas obtained by separation to obtain methane product gas; and performing flash evaporation and dehydration on a solution obtained by separation and then performing pressure swing adsorption to obtain carbon dioxide product gas. A landfill gas separating and purifying device comprises an absorption tower filled with methyldiethanolamine solution, a methane dehydrating device, a methane pressure swing adsorption device, a flash evaporation tower, a carbon dioxide dehydrating device and a carbon dioxide pressure swing adsorption device; a gas inlet of the absorption tower is connected with a raw material gas source, a gas outlet in the upper section of the absorption tower is sequentially connected with the methane dehydrating device and the methane pressure swing adsorption device; a solution outlet in the lower section of the absorption tower is sequentially connected with the flash evaporation tower, the carbon dioxide dehydrating device and the carbon dioxide pressure swing adsorption device. The process and the device disclosed by the invention can be used for simultaneously recovering carbon dioxide and methane from landfill gas, thereby reducing the emission of greenhouse gases and improving the purity of the gases.

Owner:SUZHOU SUJING PROTECTIVE ATMOSPHERE

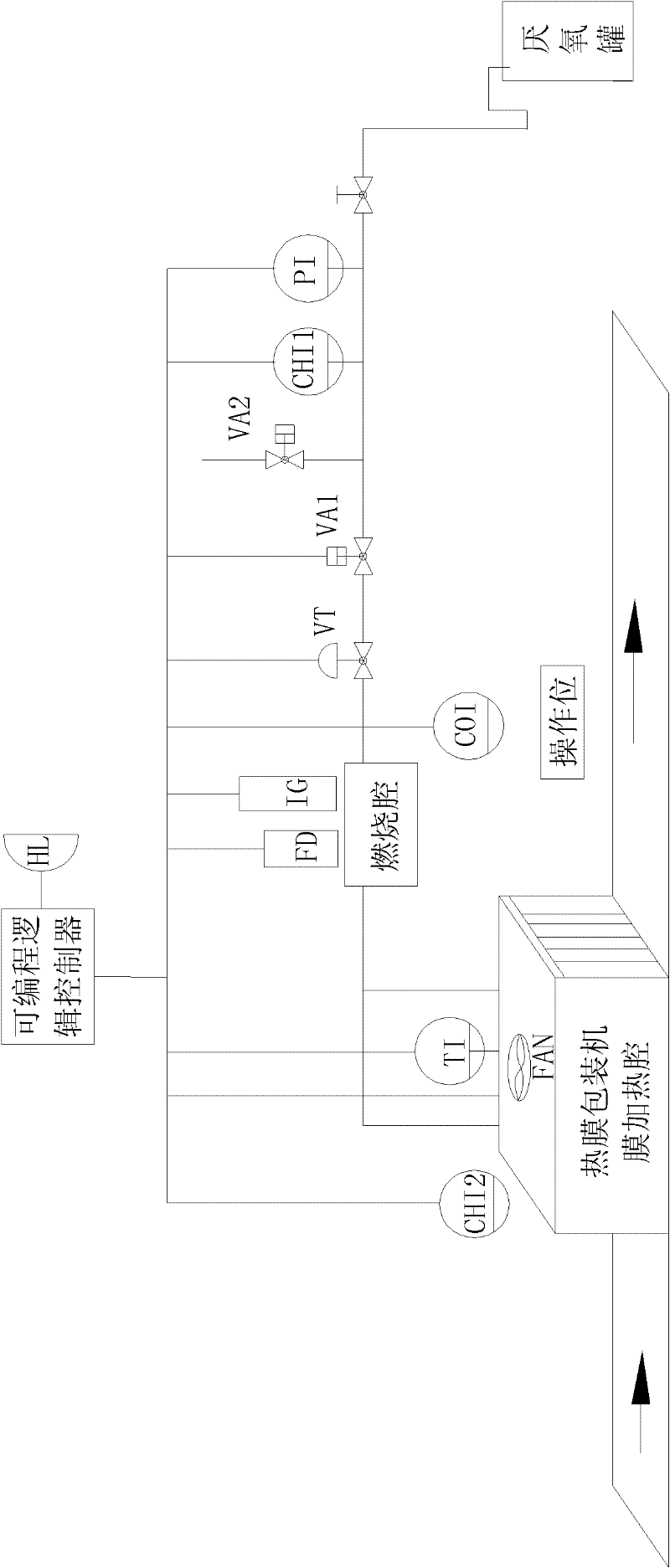

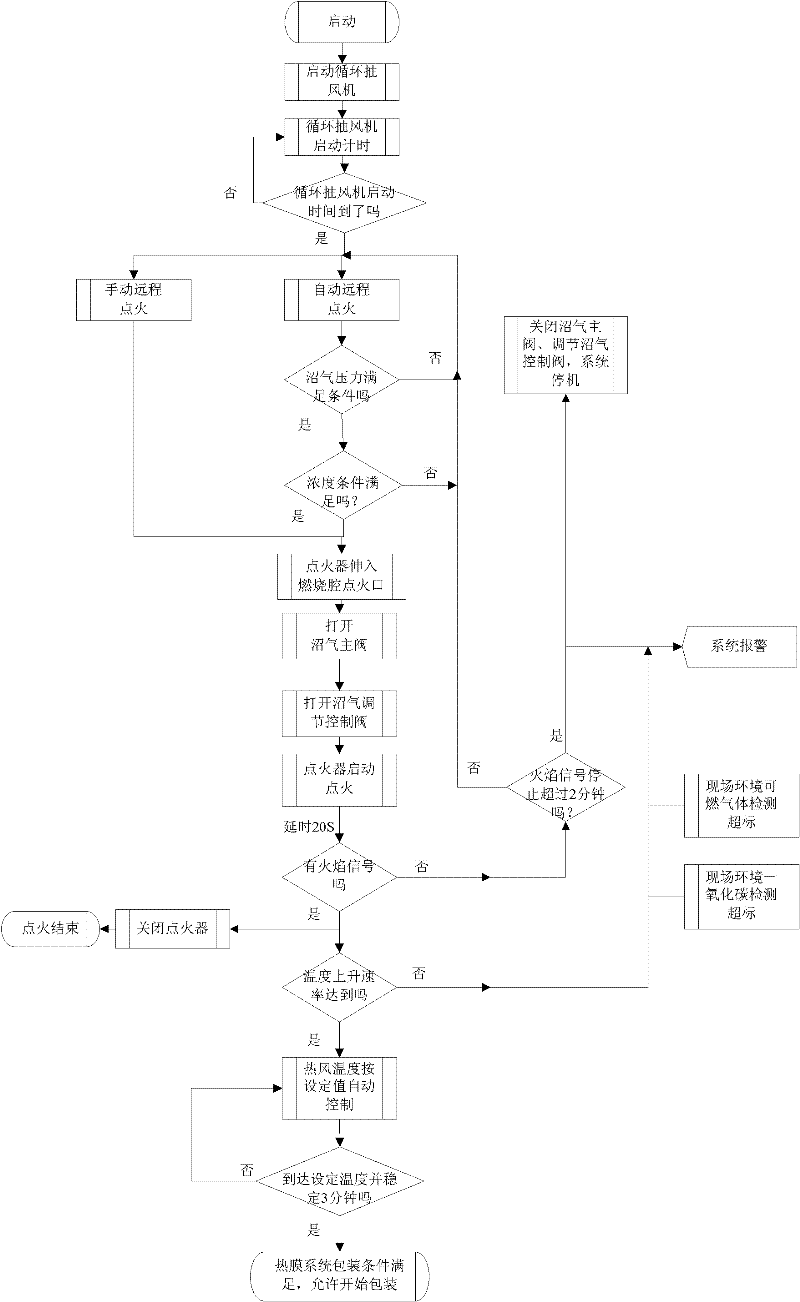

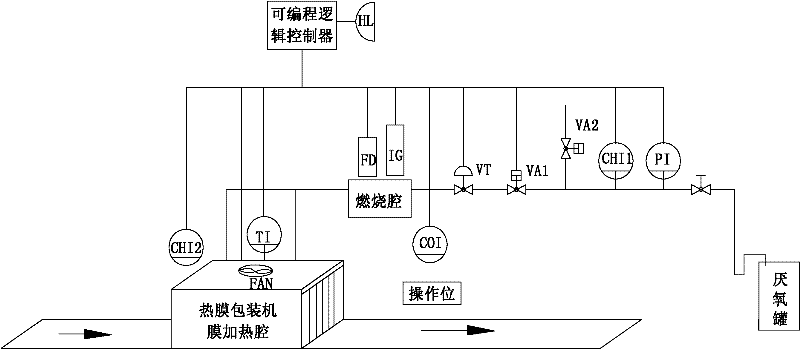

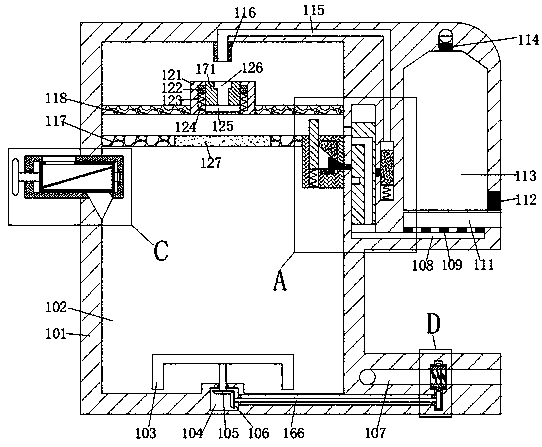

Hot film biogas hot air utilization control system and its operation control method

ActiveCN102295085ASave electricityReduce manufacturing costWrappers shrinkageGas production bioreactorsWind systemHigh energy

The invention discloses an operation control method of a hot film methane hot wind utilization control system, wherein methane generated during the beer production process is recycled and utilized. Meanwhile, hot wind generated during the methane combustion process is adopted for the plastic heat shrinkable film packaging of beers, instead of a high-energy electrical-heating hot wind system of a hot film packing machine. Thus, the electric energy of about 4 KWH per ton of beer is saved and the production cost is reduced. In addition, a methane combustion regulation valve is operated with the cooperation of the online arrangement of a methane density sensor, a methane pressure sensor and a hot wind temperature detection sensor in a pipeline, while the temperature of hot wind is adopted as the master feedback of a piping and instruments diagram (PID), with the methane density and the methane pressure as the feedforward of the system. Thus, the opening degree of the methane combustion regulation valve is timely corrected and the temperature of hot wind is controlled relatively stable within the range of 260 + / -10 DEG C. The hot film packaging quality is then ensured.

Owner:YANJING BEER GUILIN LIQUAN +1

Meal waste fermentation warm supply device based on waste classification

InactiveCN110527619AControl pressureReduce usageBioreactor/fermenter combinationsBiological substance pretreatmentsWaste treatmentFermentation

The present invention discloses a meal waste fermentation warm supply device based on waste classification. The meal waste fermentation warm supply device based on the waste classification comprises adevice main body, a fermentation cavity for fermentation is arranged in the device main body, users can throw meal waste into the fermentation cavity, so that the meal waste is fermented in the fermentation cavity to generate methane, an isolation fixed block is fixedly arranged in an inner wall of a left side of the fermentation cavity, a partition device is arranged in the isolation fixed block, the partition device can separate the fermentation cavity from outside when the users throw the waste, a heating device is arranged in an inner wall of a right side of the fermentation cavity, a ventilation device is arranged between the heating device and the fermentation cavity, and the ventilation device can introduce the methane into the heating device when methane pressure intensity in thefermentation cavity reaches a preset value. The present invention aims to design the waste treatment device capable of fermenting the meal waste and using the methane generated by the fermentation forwarm supply.

Owner:乐晓东

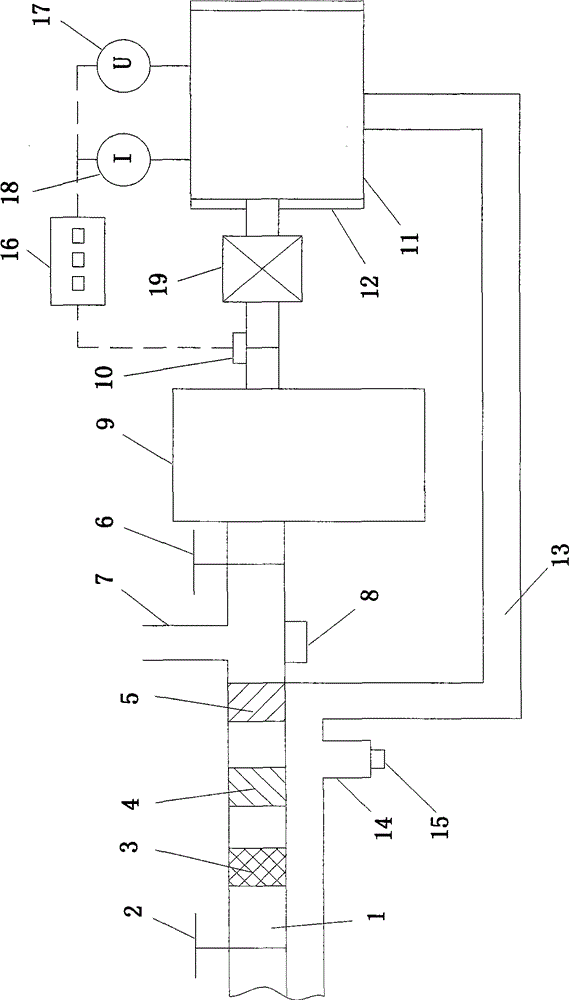

Improved methane power generation device

InactiveCN104454151AQuality improvementImprove stabilityLiquid coolingInternal combustion piston enginesFlame arresterEngineering

The invention discloses an improved methane power generation device. The improved methane power generation device comprises a methane inlet pipeline, a first switch valve, a filter net, a drying device, a desulfurizer and a second switch valve are sequentially arranged on the methane inlet pipeline, installing rings are installed at the two ends of the filter net, installing rings are installed at the two ends of the drying device, installing rings are installed at the two ends of the desulfurizer, external threads are arranged on the installing rings, internal threads are arranged inside the methane inlet pipeline correspondingly, and the filter net, the drying device and the desulfurizer are connected with the methane inlet pipeline through the threads. An emptying pipe and a vacuum breaking valve are further arranged on the methane inlet pipeline, the second switch valve is connected with a methane pressure stabilization tank, an electric pressure regulating valve is arranged at the outlet of the methane pressure stabilization tank, a flame arrester is connected to the electric pressure regulating valve and connected with a generator set, a voltage sensor and a current sensor are arranged inside the generator set, and a cooling water coil is arranged on the outer side of the generator set. The stability of methane power generation is improved, and meanwhile maintaining operation is simplified.

Owner:沈乃伟

Methane safety pressure-limiting valve

InactiveCN102220231ABiogas pressure reductionAvoid enteringGas production bioreactorsWaste based fuelEnvironmental engineeringExhaust pipe

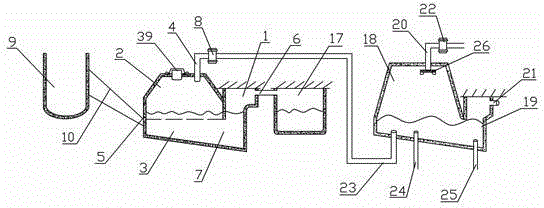

The invention discloses a methane safety pressure-limiting valve, which comprises a pressure-limiting exhaust pipe and an open container containing water, wherein one end of the pressure-limiting exhaust pipe is communicated with the methane chamber of a methane pool, and the other end of the pressure-limiting exhaust pipe extends to a place below the water surface in the open container; the methane chamber of the methane pool is communicated with the methane safety pressure-limiting valve; the methane pressure in the methane pool is limited by using the action of the water seal of the open container; when the methane pressure is within a control range, the methane is sealed under the action of the water seal; and when the methane pressure is overhigh and the water seal does not work, the methane escapes from the open container, so that the methane pressure in the pool is lowered, normal methane pressure is retained, and the safety hazards, such as blasting, caused by the overhigh methane pressure in the pool are prevented. In addition, the methane safety pressure-limiting valve can be mounted at a bottommost position of a methane pipe to collect the condensed water in the methane pipe, so water is supplied to the open container and the condensed water is prevented from flowing to a desulfurizer. The methane safety pressure-limiting valve can be made of waste plastic, the manufacture is simple, the cost is low, and the service life of the methane safety pressure-limiting valve is long.

Owner:金柳

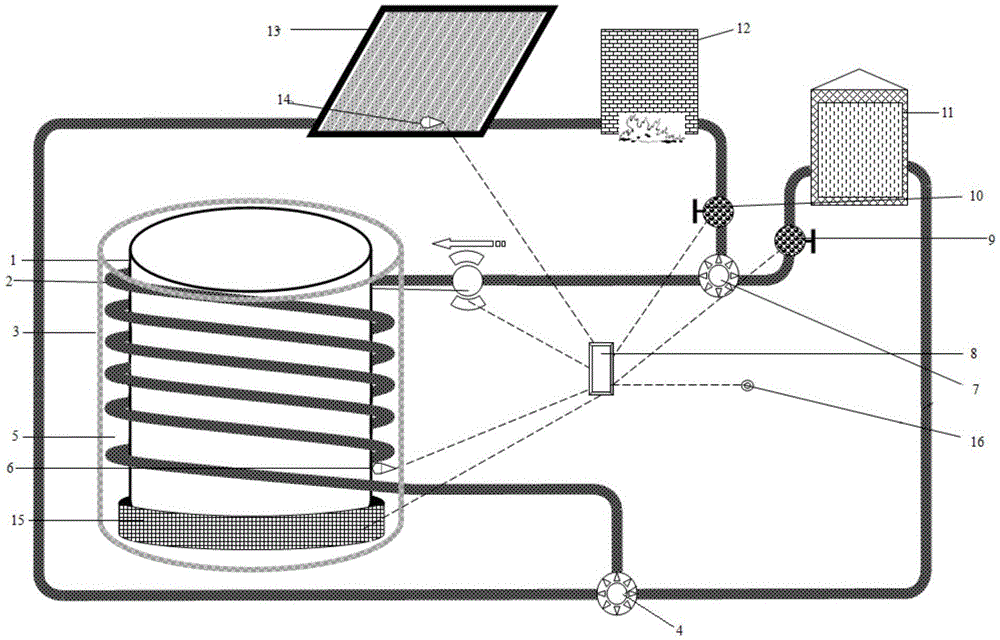

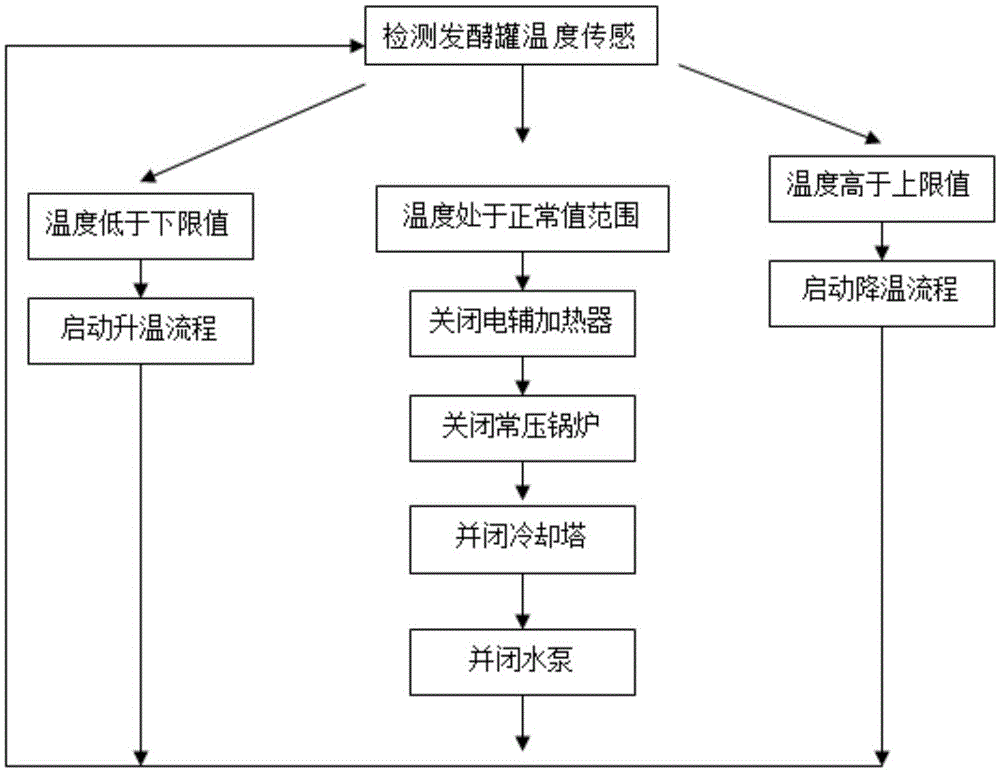

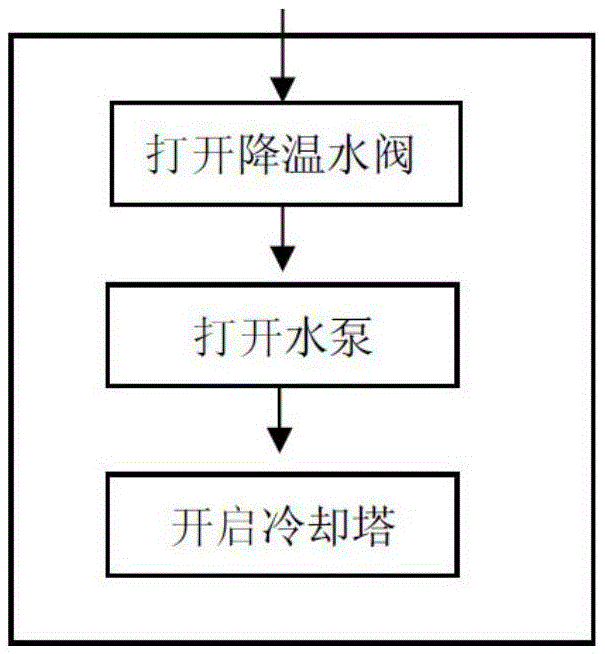

Automatic temperature control methane fermentation device

ActiveCN105462832AStable outputQuality improvementBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlAutomatic control

The invention discloses an automatic temperature control methane fermentation device. The device comprises a fermentation tank, a shell, a heat exchange tube, a heating system, a cooling system, a first temperature sensor, a control template and a methane pressure probe, wherein the shell is arranged on the periphery of the fermentation tank to form a cavity structure, and a middle hot water layer is arranged in the cavity portion; the heat exchange tube is wound around the outer wall of the fermentation tank in a spiral mode, and the two ends of the heat exchange tube are communicated with the heating system and the cooling system to form a circuit; a first water pipe gather junction and a second water pipe gather junction are arranged at the positions where the heat exchange tube is connected with and intersects with the heating system and the cooling system respectively, a water pump, a heating water valve and a cooling water valve are arranged on the heat exchange tube, and the first temperature sensor is arranged on the outer wall of the fermentation tank; the methane pressure probe is arranged in a methane storage bag, and the control template is connected with the first temperature sensor, the water pump, the heating water valve, the cooling water valve and the methane pressure probe. An automatic control device is adopted, and relative stability of the yield and quality of methane is guaranteed.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Pressurization type generator of marsh gas

InactiveCN1687387AStable pressureIncrease pressureGas production bioreactorsWaste based fuelEngineeringAtmospheric pressure

The present invention discloses a methane pressurizing generator, which has the purpose of providing one kind of the pressurizing generator. Including the generating cavity and the independence pressurizing cavity, two cavities are connected by air pipe, the pressurizing cavity has the water inlet pipe or / and the air inlet pipe, above two cavities with gas outlet pipe connected with the methane apparatus, the generating cavity has charging port and mixer. When the barometric pressure in the pressurizing cavity is excessively low, then pours water or air to the pressurizing cavity, which causes the space of the pressurizing cavity change small, then the methane pressure raises.

Owner:王海金

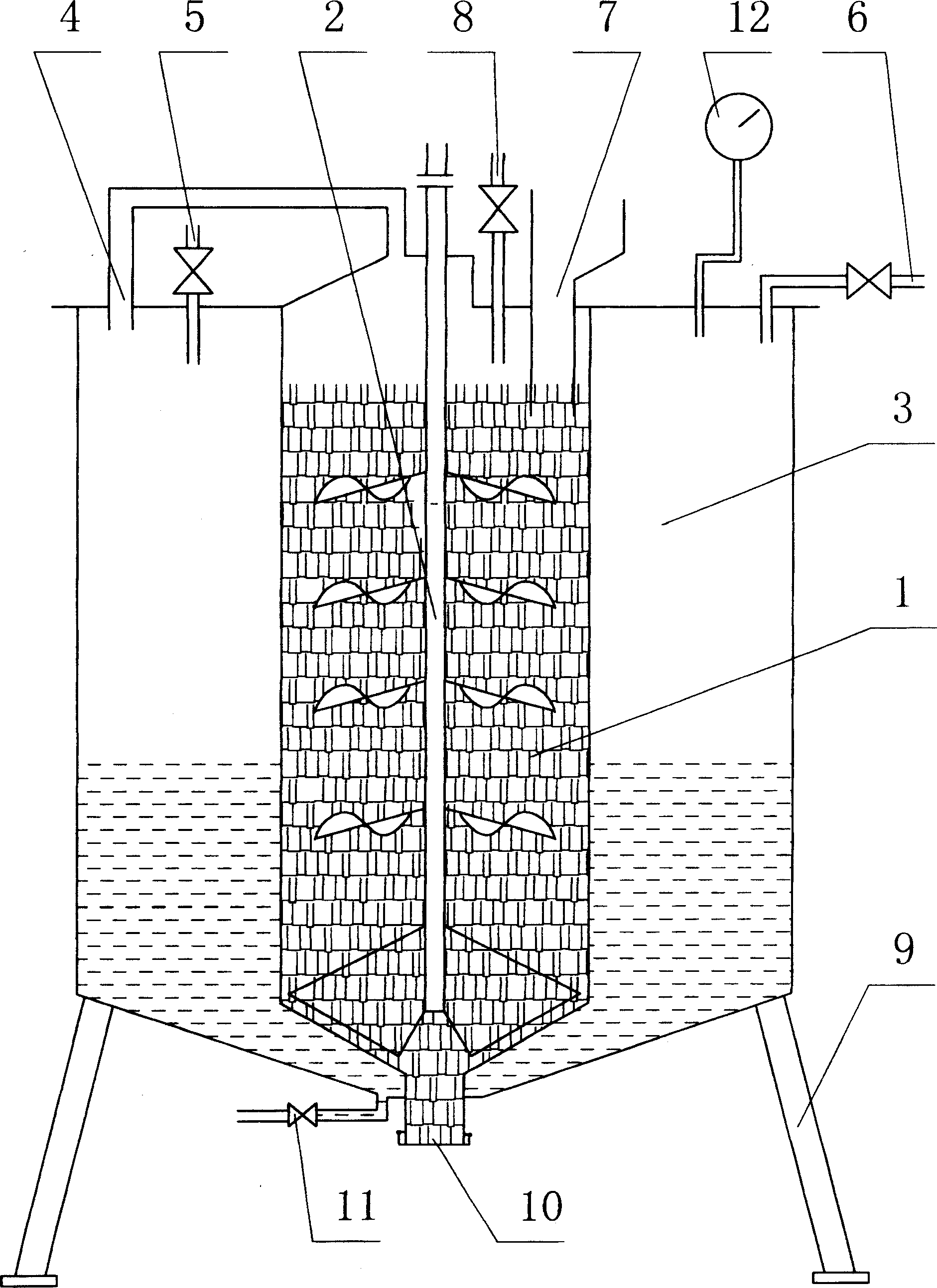

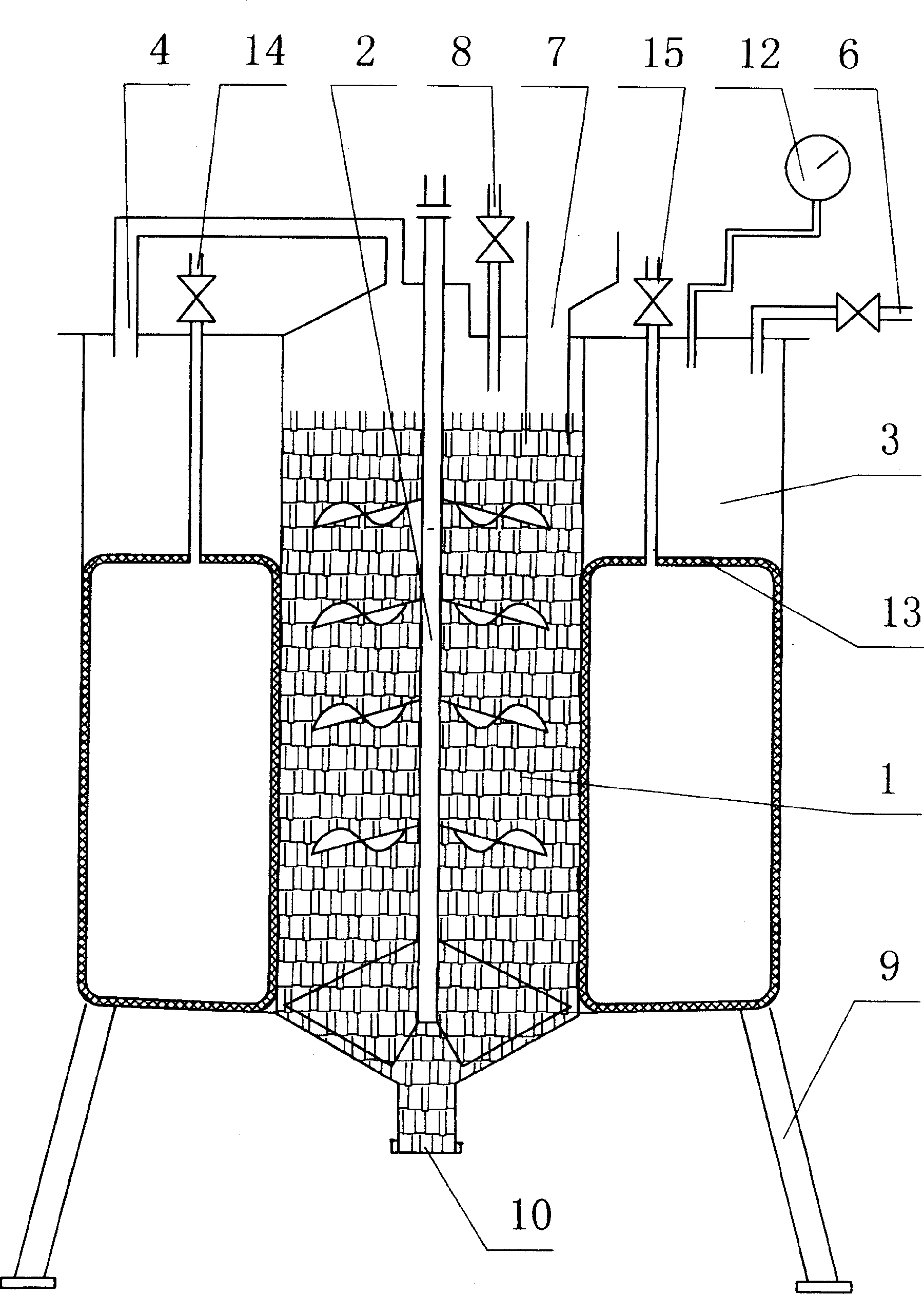

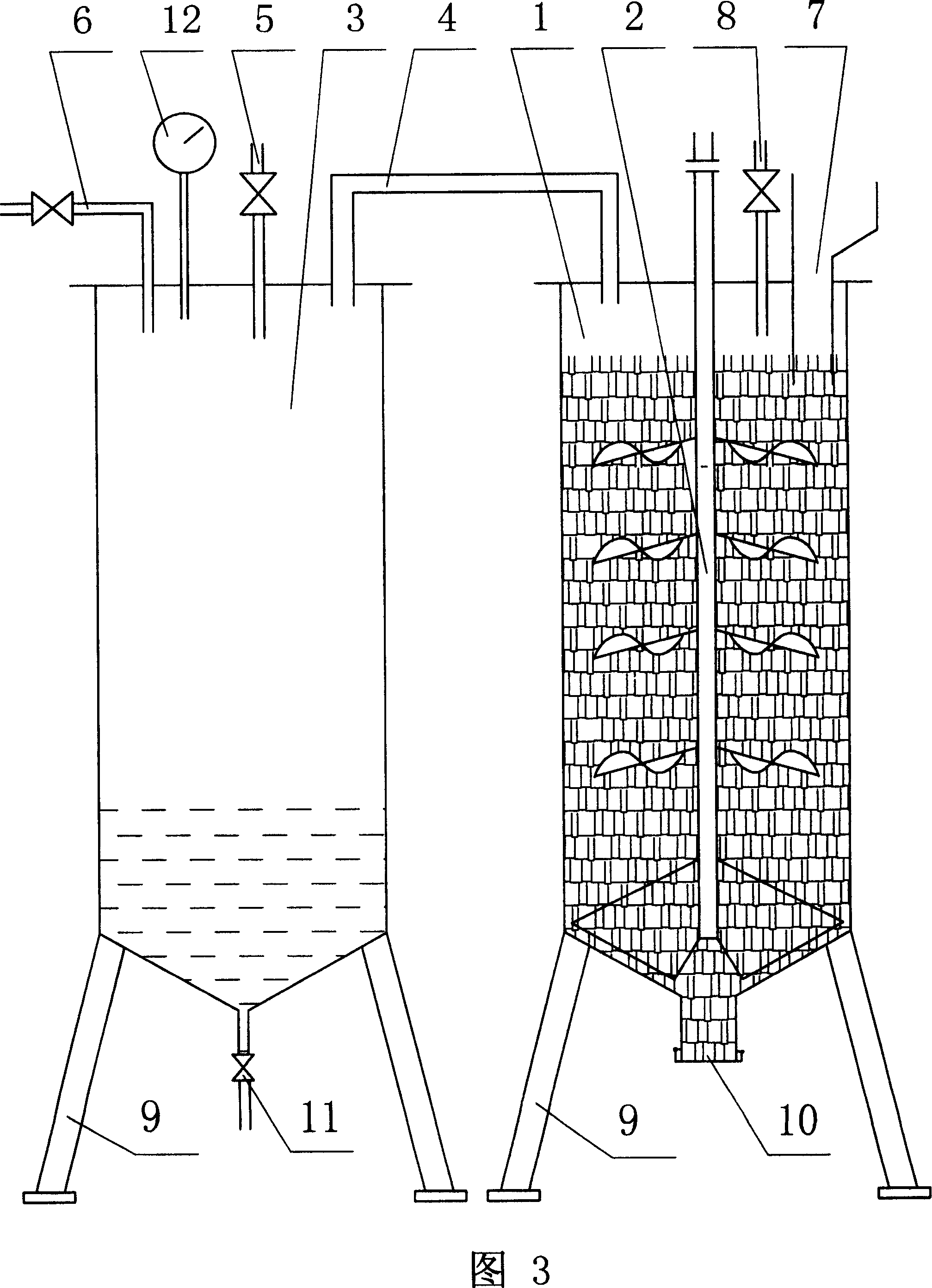

Methane pressure stabilizing device and manufacturing process thereof

InactiveCN102464439ASimple structureExtend your lifeWaste based fuelBiological sludge treatmentRenewable energy technologyEngineering

The invention belongs to the technical field of renewable energy sources, and in particular relates to a methane pressure stabilizing device and a manufacturing process thereof. The methane pressure stabilizing device is characterized by utilizing a principle of separate storage in two pools, i.e. one material fermentation device and a methane storage and pressure stabilizing device are constructed; when methane in the pools is generated continuously and the pressure of the pool bodies is increased, the methane continuously flows to a methane storage tank (2) through a methane guide pipe (8); the more the methane is generated, the higher the pressure of the methane storage tank (2) becomes; when the methane stored in the methane storage tank (2) is too much or the amount of the methane used by farmers is too small, excessive methane is drained through a pressure relief valve (3), and the pressure of the methane supplied to the farmers is unchanged; and a one-way valve (6) is installed on the methane guide pipe (8), when the methane generation amount of a fermentation pool (7) is less, the one-way valve (6) can ensure the pressure in the methane storage tank (2) and prevent methane in the methane storage tank (2) from flowing back to the fermentation pool (7), and the pressure of the methane supplied to the farmers is unchanged.

Owner:戴宝成

Fully-automatic quantitative and energy-saving material dispatching system

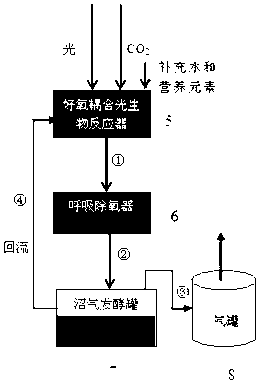

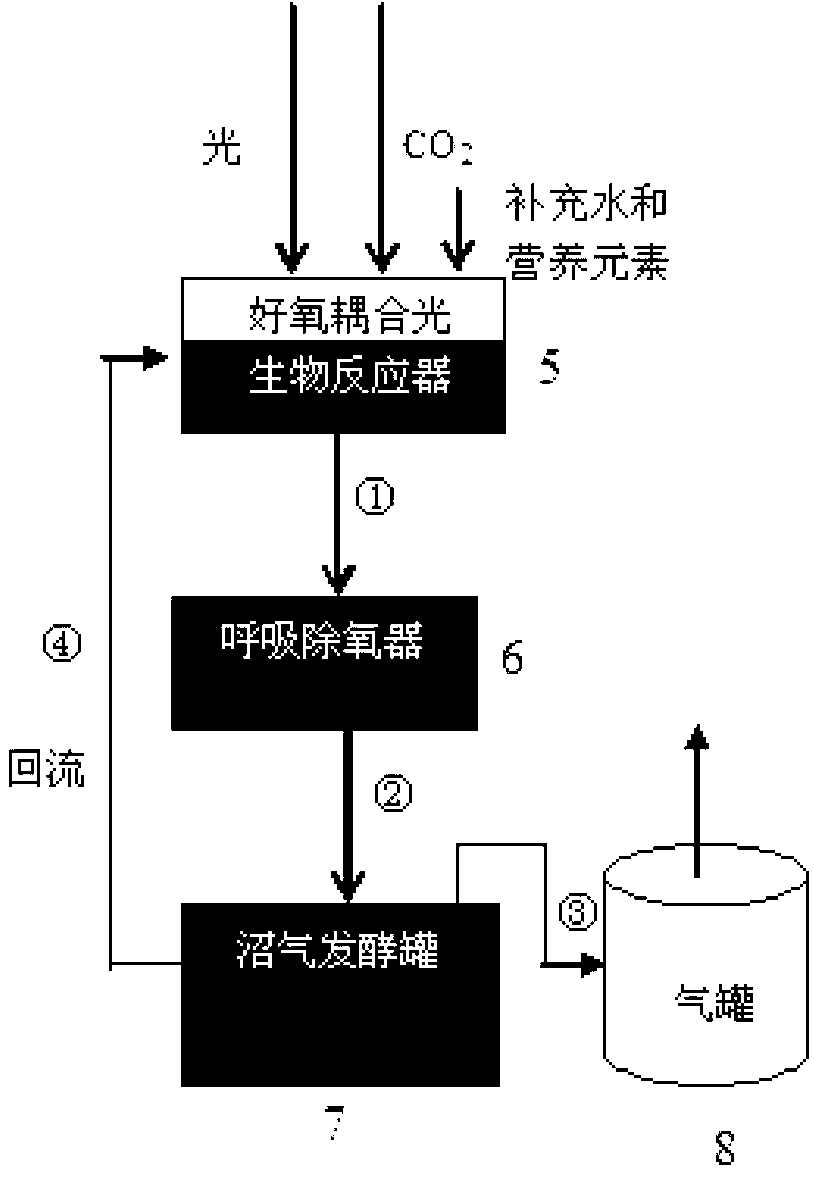

ActiveCN103232938ANo human interventionReduce usageBioreactor/fermenter combinationsBiological substance pretreatmentsCouplingMethane fermentation

The invention relates to a fully-automatic quantitative and energy-saving material dispatching system comprising an aerobic coupling photobioreactor, a breathing deaerator and a methane fermentation tank which are sequentially and vertically arranged, wherein the aerobic coupling photobioreactor is connected with the breathing deaerator through a pipeline a; the breathing deaerator is connected with the methane fermentation tank through a pipeline b; the methane fermentation tank is connected with an air storage tank through a pipeline c and connected with the aerobic coupling photobioreactor through a return pipeline d; and the pipeline a, the pipeline b, the pipeline c and the return pipeline d are all connected with a liquid level control mechanism. Compared with the prior art, the fully-automatic quantitative and energy-saving material dispatching system has the advantages that the fully-automatic operation of the integral system and the quantitative conveyance of all materials can be driven only by means of the methane pressure energy inside the system through coupling methane pressure, fluid gravity and liquid level control, almost no energy from the outside of the system is needed, and meanwhile, no manual intervention is needed.

Owner:SHANGHAI JIAO TONG UNIV

Constant-pressure methane storage tank

InactiveCN104848031AAutomatic pressure adjustmentSolve storage problemsVariable capacity gas holdersPressure stabilizationEngineering

The invention discloses a constant-pressure methane storage tank comprising a support, a tank body and a reservoir. A certain amount of water is contained in the reservoir, two observation holes are formed in the bottom of the reservoir, a gas inlet pipe and a gas outlet pipe penetrate out respectively via the observation holes after passing through water, the support is fixed over the reservoir, the tank body is arranged in the reservoir in an upside down manner, an enclosed space formed between the tank body and the water surface is a gas storage chamber, the bottom surface of the tank body is provided with a plurality of counterweights, and an overflow gas pipe penetrates the bottom surface of the tank body and communicated with the outside through the overflow gas pipe. The buoyancy principle is utilized, the counterweights are increased and decreased according to a set pressure value, gravity of the counterweights is kept equal to methane pressure in the gas storage chamber, pressure of the methane is regulated automatically and quite accurately, the problem of storage of the methane generated by the methane tank is solved, and the problem about pressure stabilization required by methane appliances such as methane cookers is solved. One-time investment is adopted, no follow-up maintenance is required basically, the requirement of accurately using the methane can be met easily, and production and living needs can be satisfied better.

Owner:周之淮

High-speed pressurized generator for marsh gas

InactiveCN1687388ASave spaceIncrease pressureGas production bioreactorsWaste based fuelDownspoutEngineering

The present invention discloses a methane generator with high speed and the pressurizing characters. Including the methane occur cavity, air storing cavity, the pressurizing cavity, the upper of the cavity and air storing cavity with the airway connected; the lower of the air store cavity and downspout with the pressurizing cavity connected; outside meeting in the pressurizing cavity has induction pipe or / and the air feeder, above termination of stores air feeder has the trachea with the methane apparatus connected, which has the cavity in upper extreme system which has aperture. Moreover, the entire methane with high speed and pressurizing generator and the base armbrace is transportable. When the inside barometric pressure of stores air cavity is excessively low, by inductionpipe either / and air feeder with turbo-charged cavity pouring water or / air, water in the pressurizing cavity passes through aqueduct again and enters stores air cavity when the space store air cavity changes small, then the methane pressure rise.

Owner:王海金

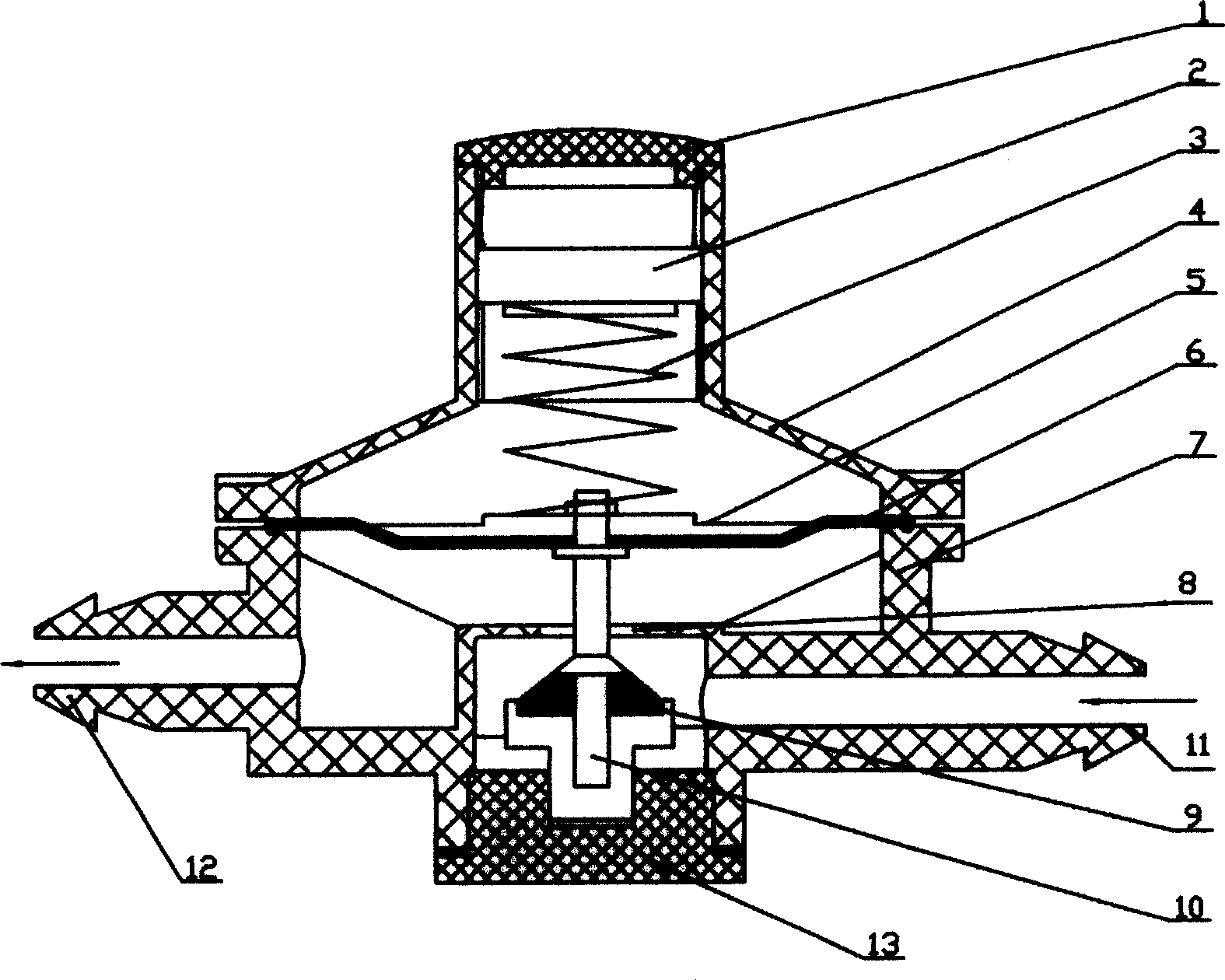

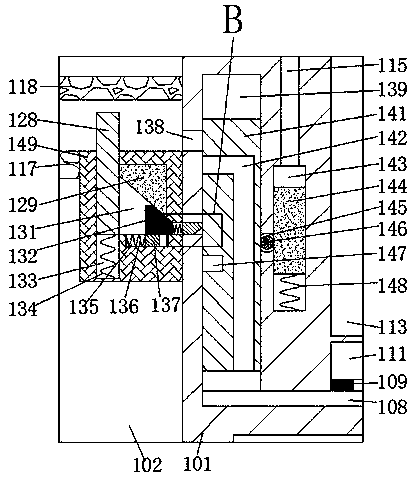

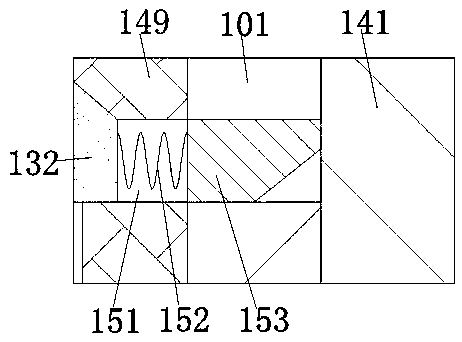

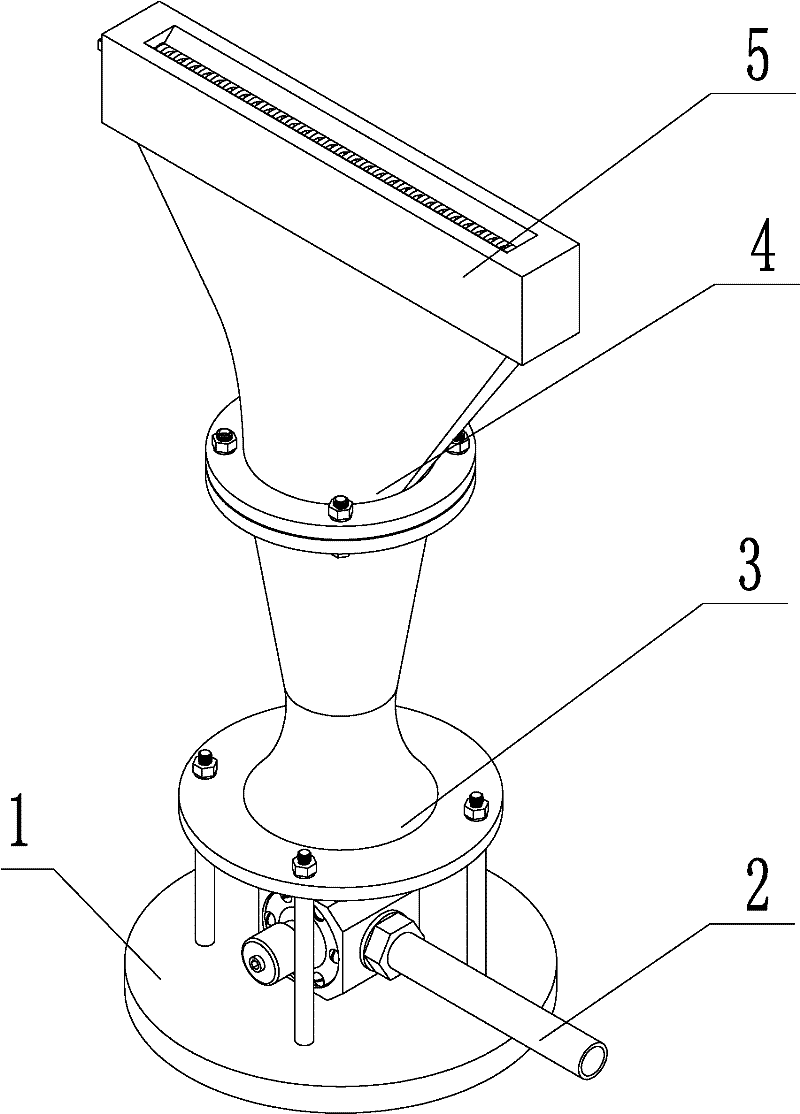

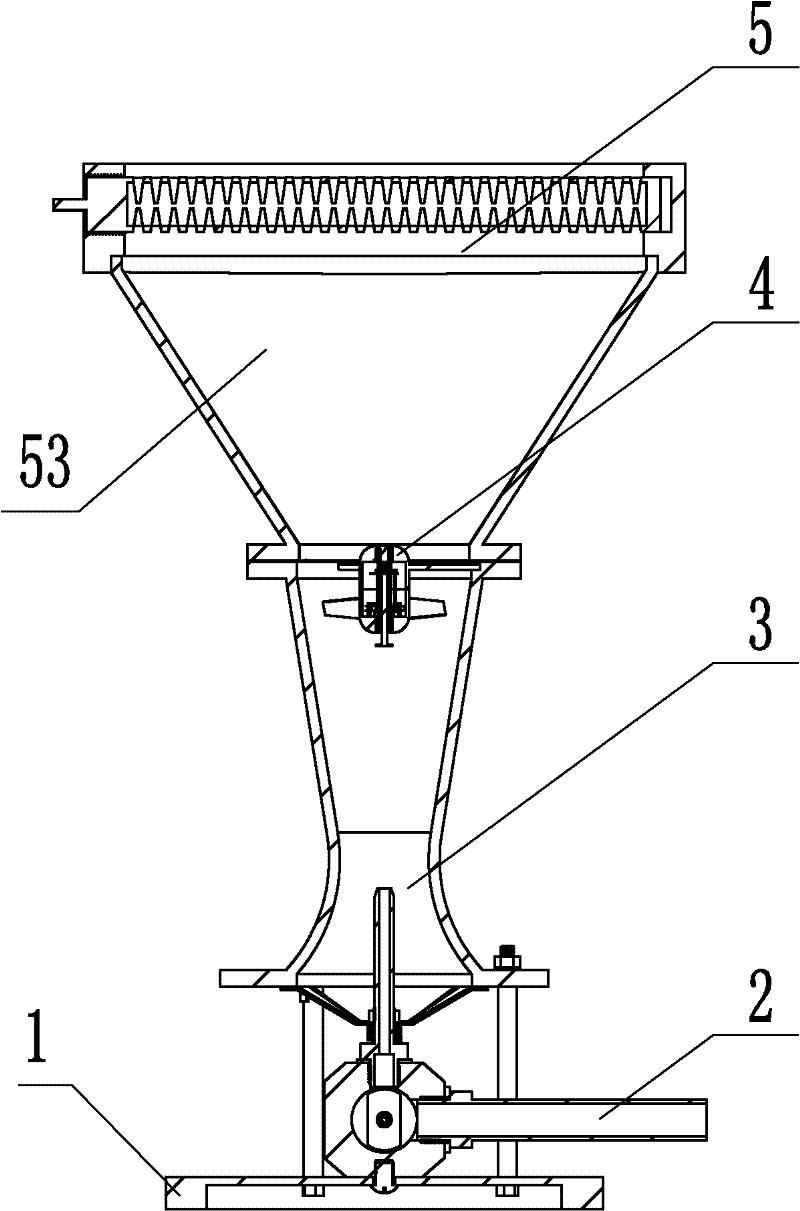

Methane nozzle device structure of methane fan heater combustor

InactiveCN102213428AAvoid environmental pollutionSave high quality energyHot-air central heatingGaseous fuel burnerCombustorEngineering

The invention belongs to a component structure of a methane fan heater, and in particular relates to a methane nozzle device structure of a methane fan heater combustor. The methane nozzle device structure is characterized in that a methane nozzle device (2), a venturi (3), a premixer (4) and a methane burner nozzle (5) at the top which are arranged in sequence from top to bottom are arranged on a base (1); a methane inlet pipe (24) of the methane nozzle device (2) is horizontally and transversely connected to a nozzle seat body (25); a damper regulator (22) is arranged between a methane outlet on the nozzle seat body (25) and an inlet of the venturi (3), consists of a plurality of fan-shaped pieces the weights of which are mutually staggered, and is pressed under the elastic force of a spring arranged under the damper regulator (22); the methane pressure regulating assembly (23) is arranged in a tube hole and takes the shape of a cylinder and is provided with parts, such as a throttling regulator (234), a sealing gasket (231), a sealing elastic film (232), a bolt (235), a nut (236), a regulating spring cover (238), a regulating spring (237) and a regulating spring thread sleeve (239) which are sequentially arranged in the axial direction from inside to outside; and the throttling regulator (234) takes the shape of a rectangular frame. By utilizing the methane nozzle device structure, the purposes of complete combustion, stable combustion and high combustion value can be still achieved even if a methane source is not stable and the pressure and flow fluctuate.

Owner:SHANGHAI UNIV OF ENG SCI

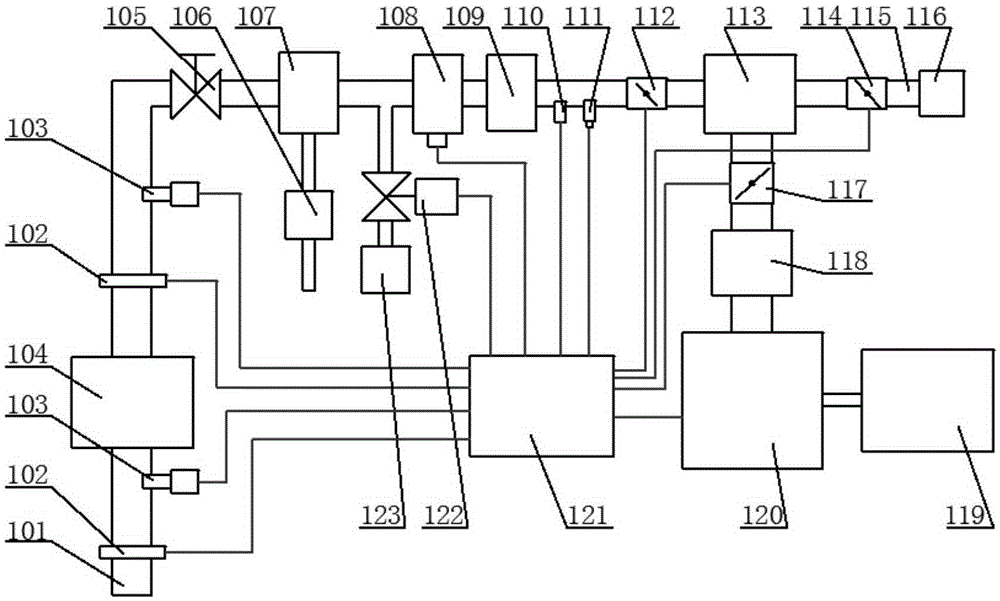

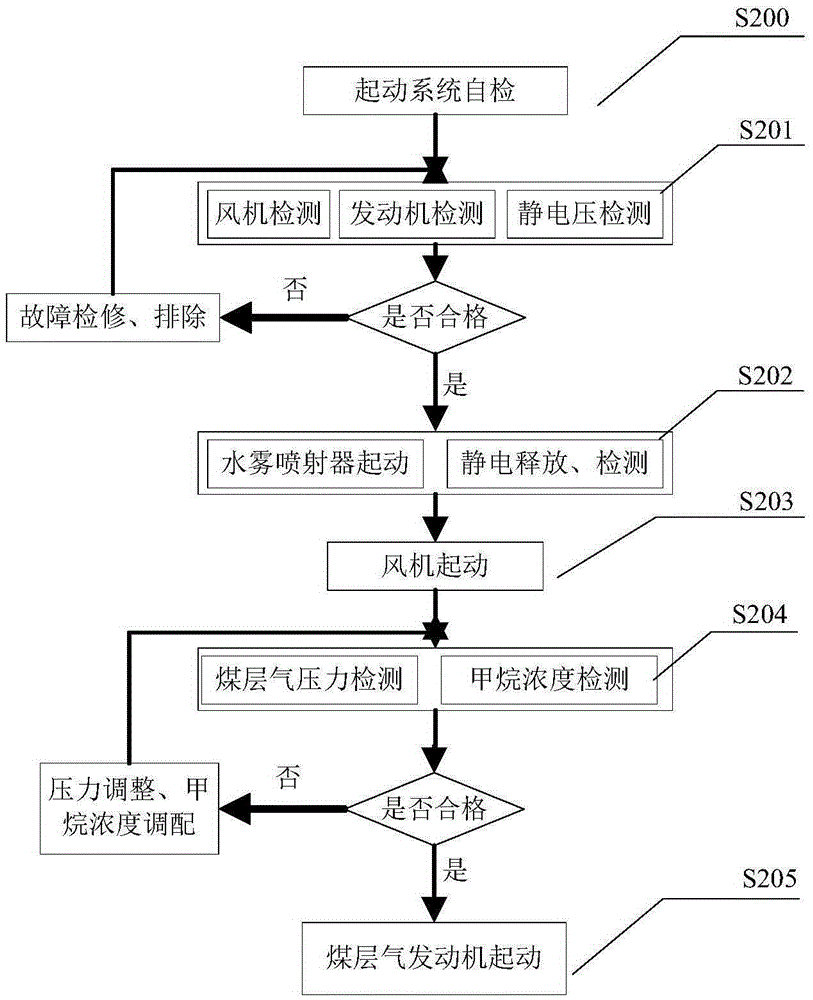

Low-concentration coal-bed methane engine anti-explosion gas supply system and operation method

InactiveCN105275673ASave waterAvoid emissionsInternal combustion piston enginesFuel supply apparatusCombustionProcess engineering

The invention discloses a low-concentration coal-bed methane engine anti-explosion gas supply system and an operation method. The low-concentration coal-bed methane engine anti-explosion gas supply system comprises a gas conveying pipeline. A coal-bed methane extraction device is installed at the head of the gas conveying pipeline. Starting from the outlet of the coal-bed methane extraction device, an anti-static device, a water and dust removal device, a coal-bed methane content regulating device and a coal-bed methane pressure adjustment device which are controlled through a control cabinet are sequentially arranged on the gas conveying pipeline in the output direction of coal-bed methane. A coal-bed methane and air mixing device is arranged at the tail of the gas conveying pipeline and used for feeding gas mixed by the coal-bed methane and air mixing device into a coal-bed methane engine for combustion and doing work, and then the coal-bed methane engine drives a generator to work. By means of the method, the low-concentration coal-bed methane can be safely extracted and conveyed, the low-concentration coal-bed methane enables the engine to operate continuously and stably after being regulated, and therefore the purposes of saving energy and reducing emission are achieved.

Owner:SHANDONG UNIV

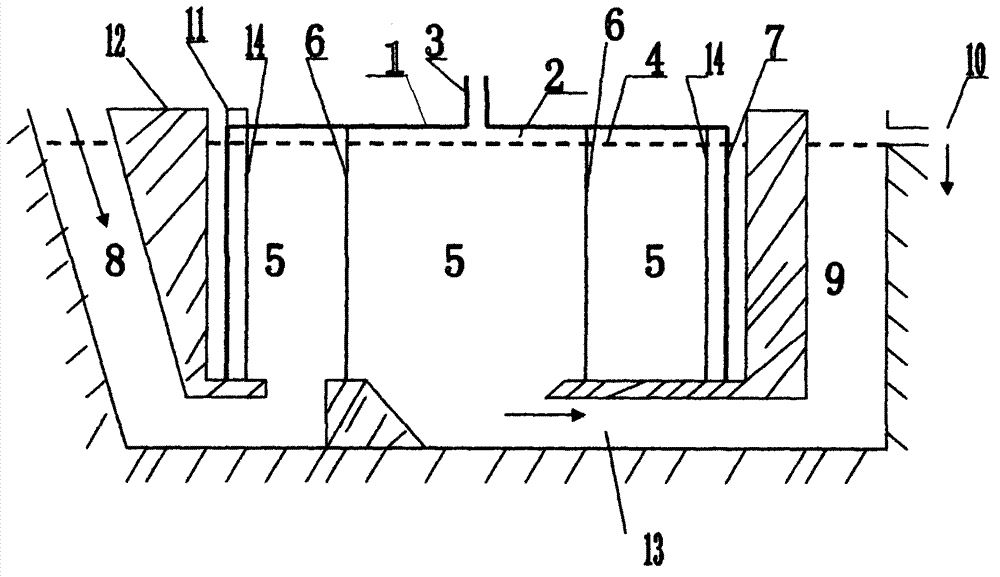

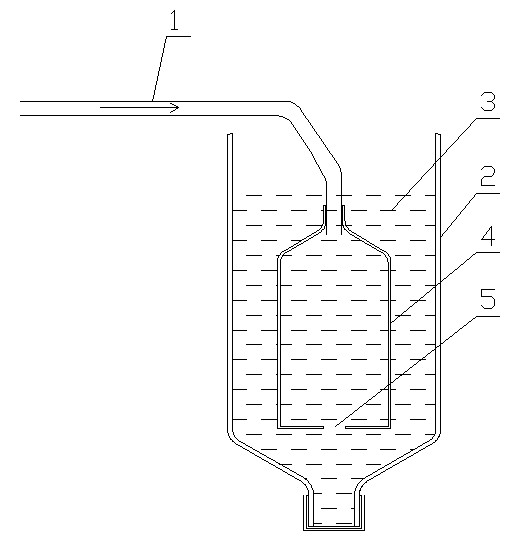

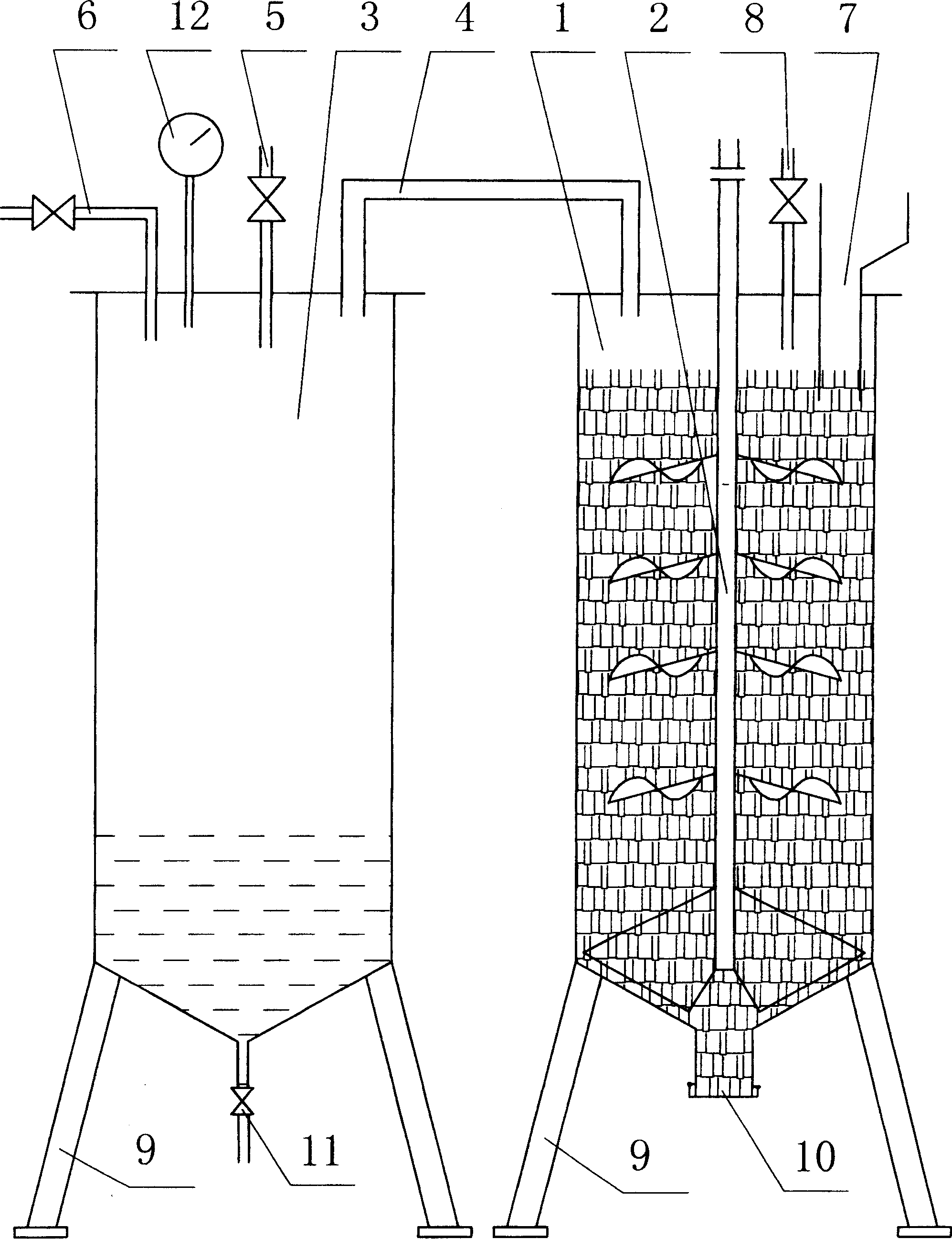

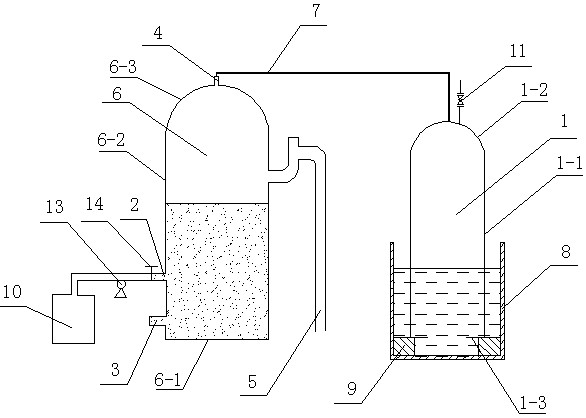

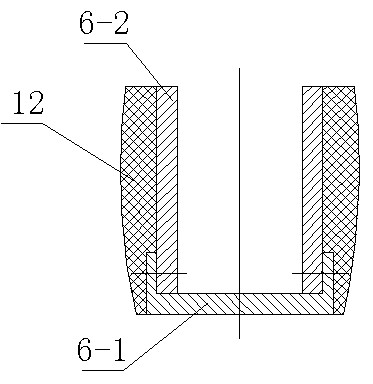

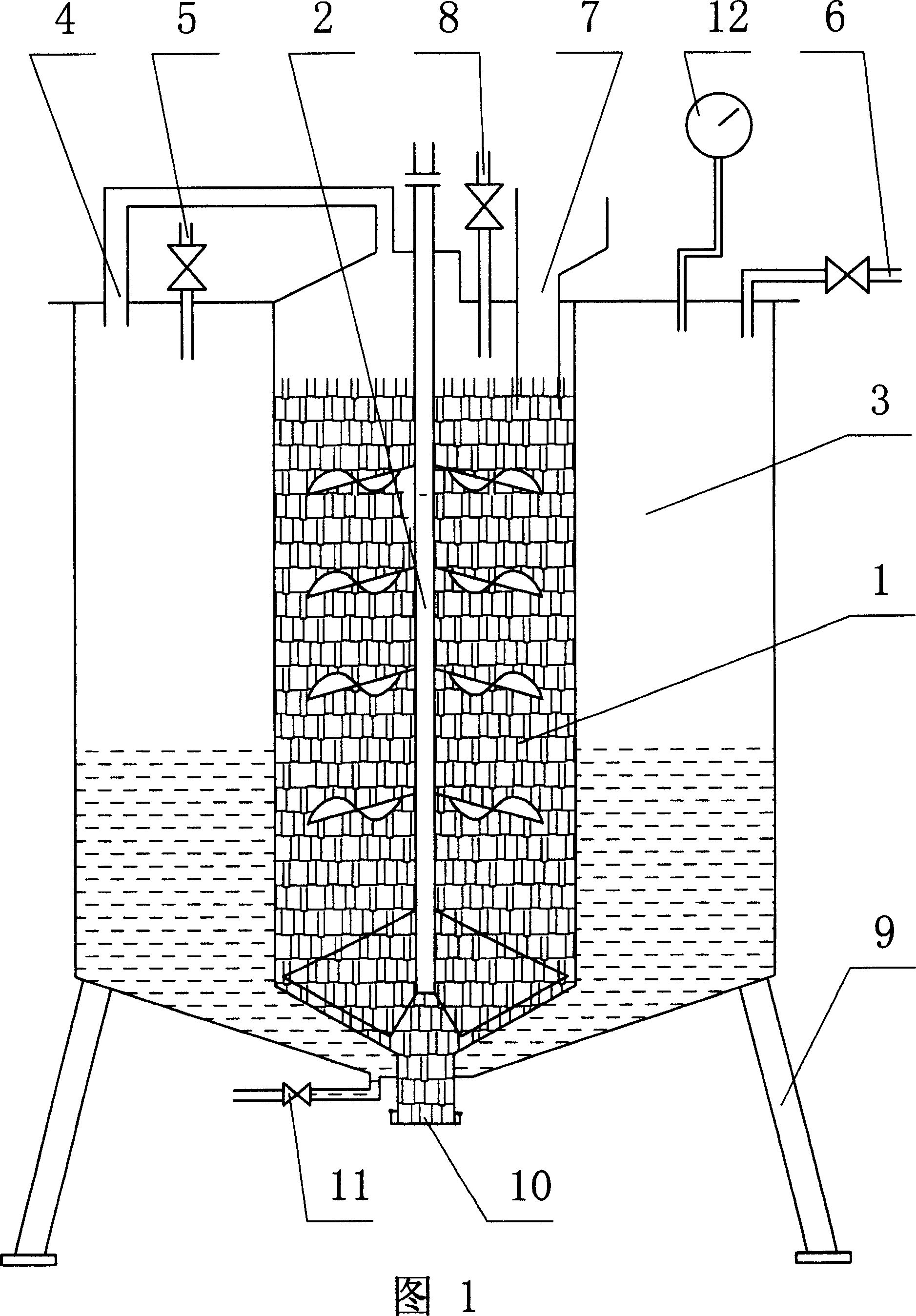

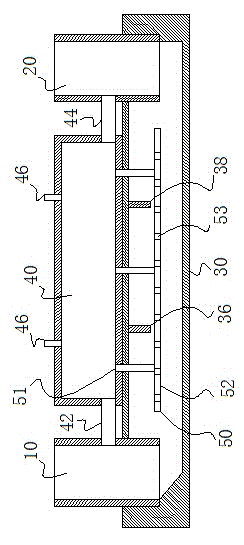

Ground methane tank capable of regulating methane pressure and manufacturing method thereof

ActiveCN102321526AInsufficient supplyProduction and life are smoothGas production bioreactorsWaste based fuelProcess engineeringAtmospheric pressure

The invention discloses a ground methane tank capable of regulating methane pressure. The ground methane tank comprises a methane storage tank (1) and a fermenting tank (6) with a feed inlet (2), a feed outlet (3), a methane outlet (4) and a water outlet (5). The methane storage tank (1) and the fermenting tank (6) compose a split type structure and are communicated with each other by a methane pipe. An upper end of the methane storage tank (1) is an exhaust opening (11). A lower end of the methane storage tank (1) is arranged in a pool (8). The bottom of the methane storage tank (1) is communicated with the pool (8). The invention also discloses a manufacturing method of the ground methane tank capable of regulating methane pressure. The ground methane tank capable of regulating methane pressure adopts the split type structure of the methane storage tank (1) and the fermenting tank (6) and can regulate methane pressure in the methane storage tank (1) to maintain throughout the balance between the methane pressure and the atmospheric pressure. The ground methane tank capable of regulating methane pressure can be formed directly from flexible materials through curling and thus overcoming volume limitation. The ground methane tank capable of regulating methane pressure is suitable for large-scale production and popularization, has a simple structure, is beneficial for manufacture, and is convenient for use.

Owner:DEYANG HAOYUN COMPOSITE MATERIAL +2

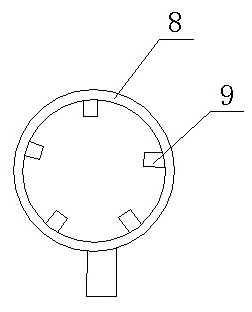

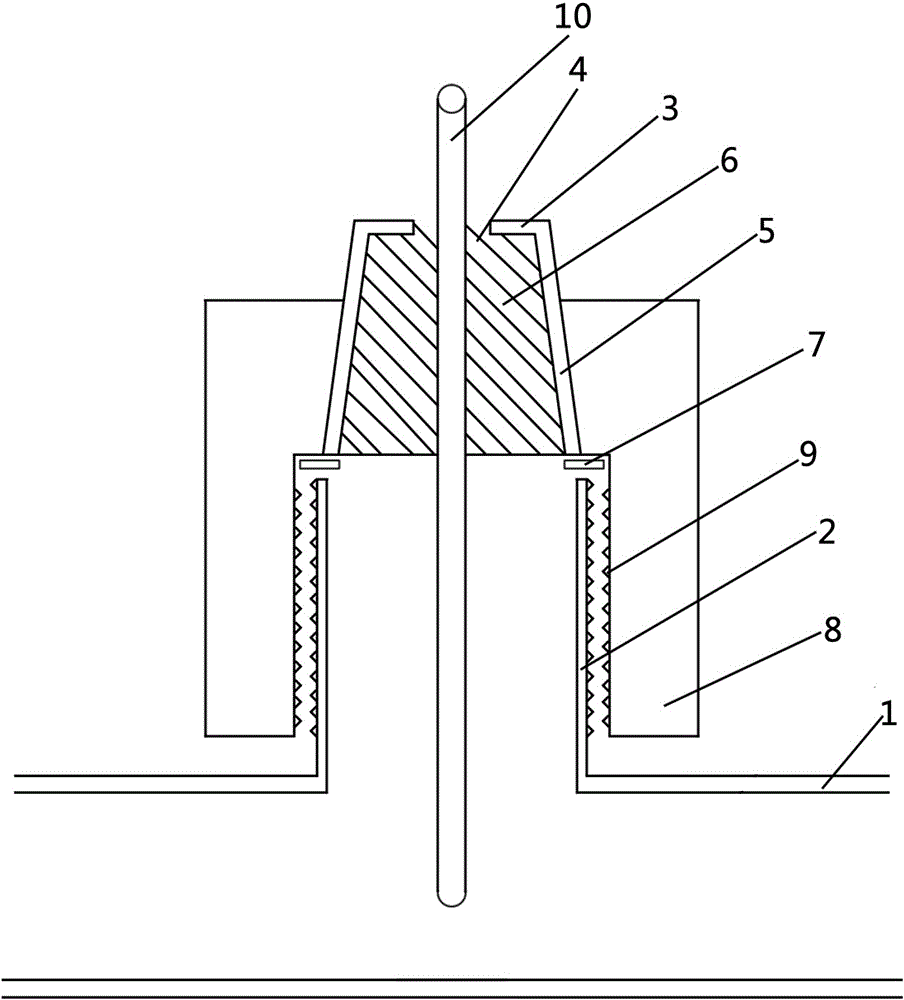

Measuring method for gas production rate in methane project

InactiveCN105806442AAccurate and reliable measurement resultsHave horizontal comparabilityVolume measurement apparatus/methodsPipeline.airProduction rate

The invention relates to a measuring method for the gas production rate in a methane project in the energy field. By using a sampling hole or other orifices reserved in a methane conveying pipeline, the methane flow rate is measured with a pipeline air speed sensor, methane pressure is measured with a pressure sensor, the methane temperature is measured with a temperature sensor, an instrument carries out measurement continuously and automatically records and stores barometric pressure, the flow is calculated through a formula, and then the gas production rate in the methane project is obtained. A measuring device of the measuring method is formed by a sensor (10), a rubber plug (6), a conical sleeve (5) and a nut (8), wherein the sensor (10) is inserted into the rubber plug (6), the rubber plug (6) is installed in the conical sleeve (5), and the conical sleeve (5) is fixed to an orifice (2) reserved in the methane pipeline (1) through the nut (8). The defects that an existing method is insufficient in precision and low in applicability, and measurement values of the gas production rate are not transversely comparable are overcome; the provided measuring method for the gas production rate in the methane project and the measuring device are simple, operation is convenient, and measurement results are stable, reliable and transversely comparable.

Owner:BIOGAS SCI RES INST MIN OF AGRI

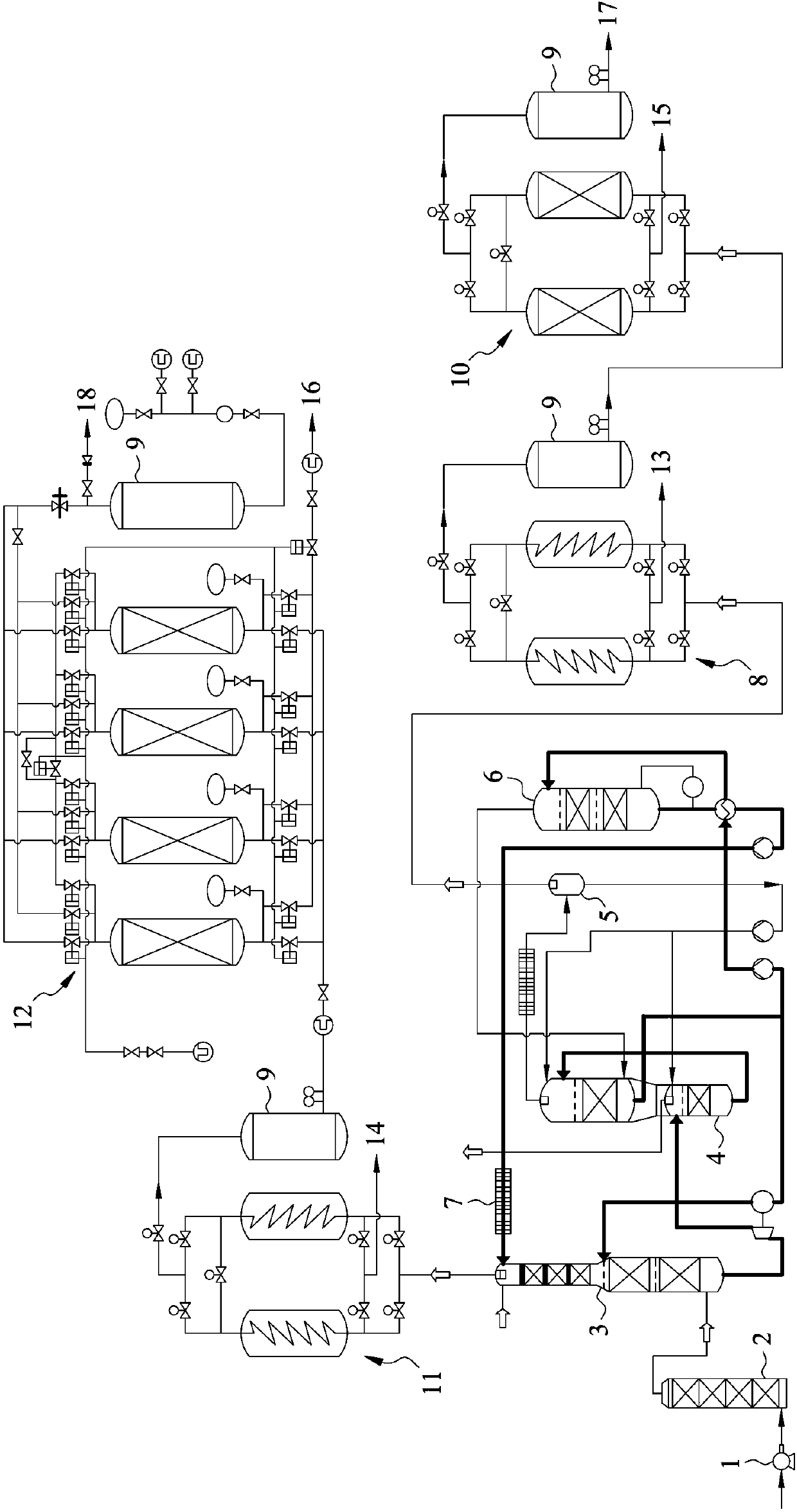

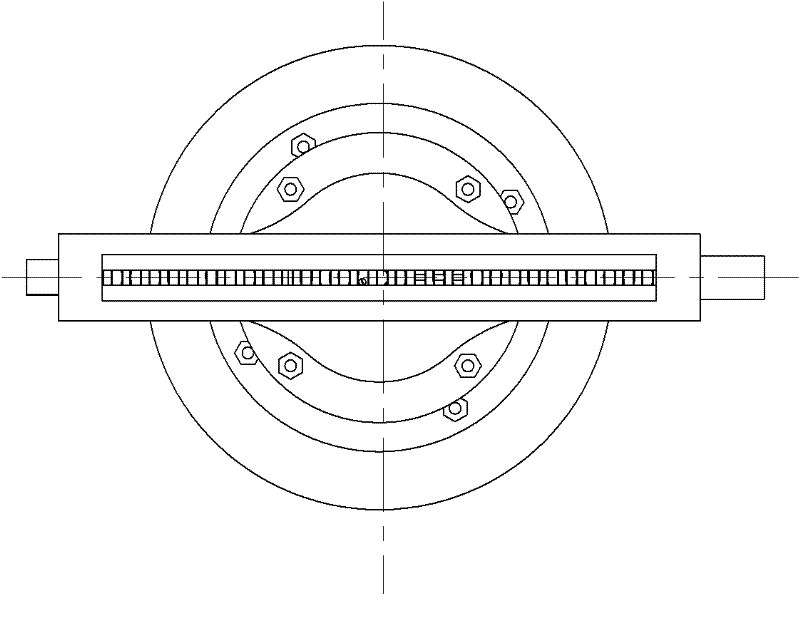

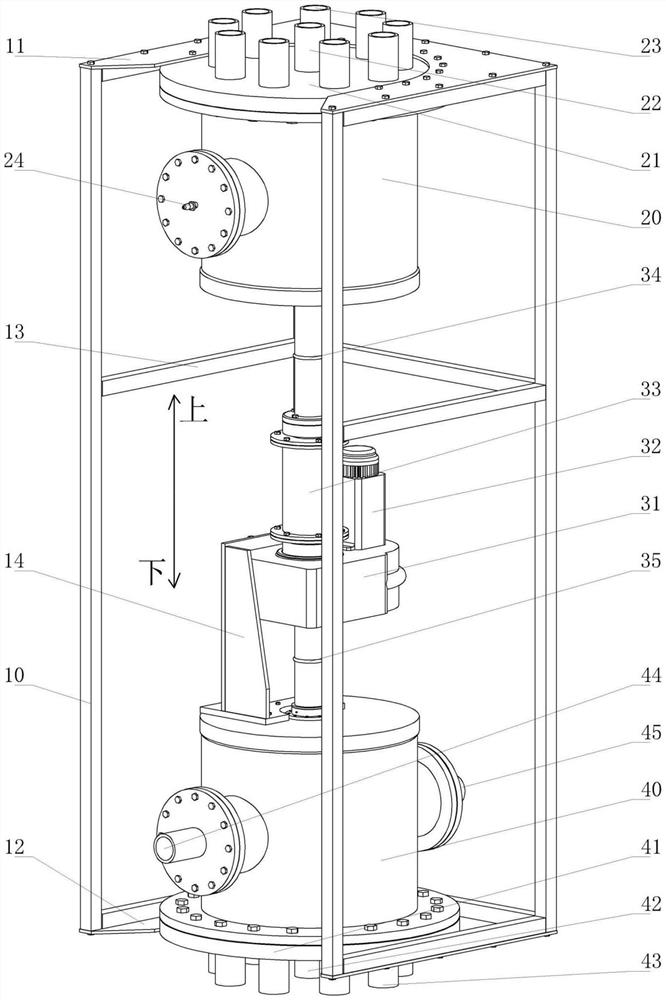

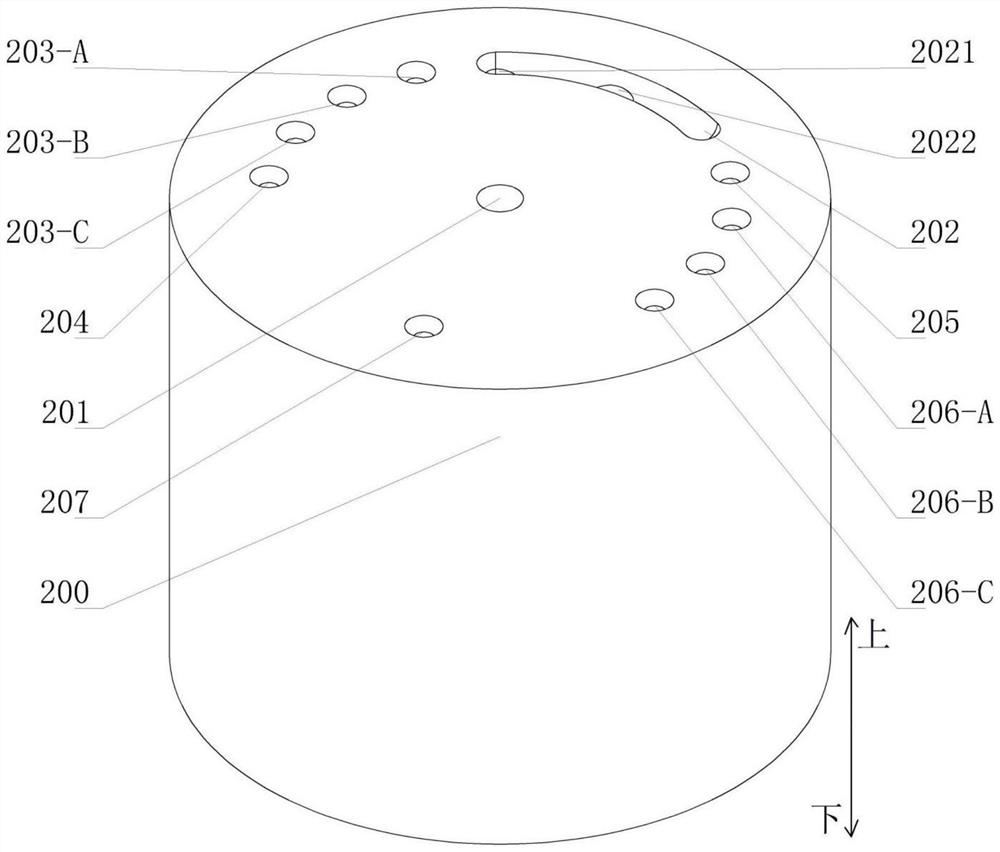

Rotary valve based on methane pressure swing adsorption and adsorption method rotary valve

PendingCN113637508AReduce points of failureImprove securityGas treatmentGaseous fuelsElectric machineRotary valve

The invention relates to a rotary valve based on methane pressure swing adsorption and an adsorption method of the rotary valve. The rotary valve comprises an upper valve, a lower valve and a support frame for fixing the rotary valve; the upper valve comprises an upper valve element, a finished product gas exhaust hole, a finished product gas exhaust groove, a first even-drop hole, a second even-drop hole, a third even-drop hole, a first low-pressure constant-pressure hole, a high-pressure constant-pressure hole, a first even-rise hole, a second even-rise hole, a third even-rise hole and a second low-pressure constant-pressure hole. The lower valve comprises a lower valve core, a product gas inlet hole, a product gas inlet groove, a desorption groove, a vacuum groove, an upper ring groove, a lower ring groove and a sealing ring. A speed reducer is arranged between the upper valve and the lower valve. According to the speed reducer, a power input shaft is coaxially connected with a driving motor, a power output shaft extends upwards and downwards to be provided with a coaxial main rotating shaft, and the upper end and the lower end of the main rotating shaft are provided with an upper connecting shaft and a lower connecting shaft. According to the rotary valve based on methane pressure swing adsorption and the adsorption method of the rotary valve, the opening and closing functions of multiple valves are integrated, the control process is simple, and the use amount of finished gas in the desorption process is reduced.

Owner:山东津挚环保科技有限公司

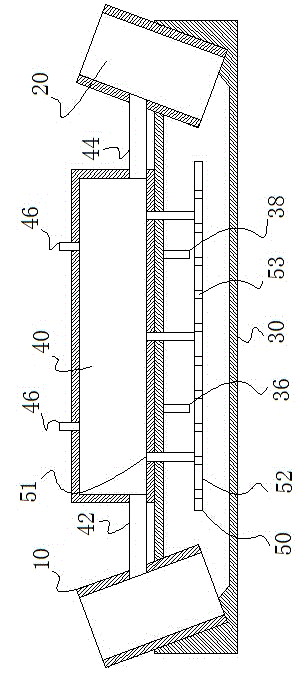

Modularized universal methane tank with adjustable volume

InactiveCN102181363AVersatileSimple structure and processGas production bioreactorsWaste based fuelAir tightnessGas supply

The invention discloses a modularized universal methane tank with an adjustable volume. The tank is cylindrical, square or elliptical and is formed by splicing tank end head modules (1), a tank feed and discharge module (2) and volume adjusting modules (3); and the volume of the tank can be adjusted within a certain range by increasing or reducing the number of the mounted volume adjusting modules. The tank end head modules are arranged at the two ends of the tank, and the tank feed and discharge module and the volume adjusting modules are arranged in the middle of the tank, so that closeness of the tank is guaranteed; the modules are connected by using a prearranged flange and are adhered; the tank feed and discharge module is provided with a feed and discharge port, so that feed and discharge are facilitated; the feed and discharge port is firmly connected with a sealing cover (4) by using bolts, so that air-tightness of the tank is guaranteed; and the sealing cover is provided with an air nozzle and a pressure relief module (5), so that external gas supply and methane pressure in the tank do not exceed a safety range. The methane tank has the advantages of simple structure, high universality and strength, practicability, easiness for disassembly and assembly, convenience for industrial production, installation and transportation and simplicity in operation and maintenance.

Owner:顺平县普惠农丰新能源科技有限公司

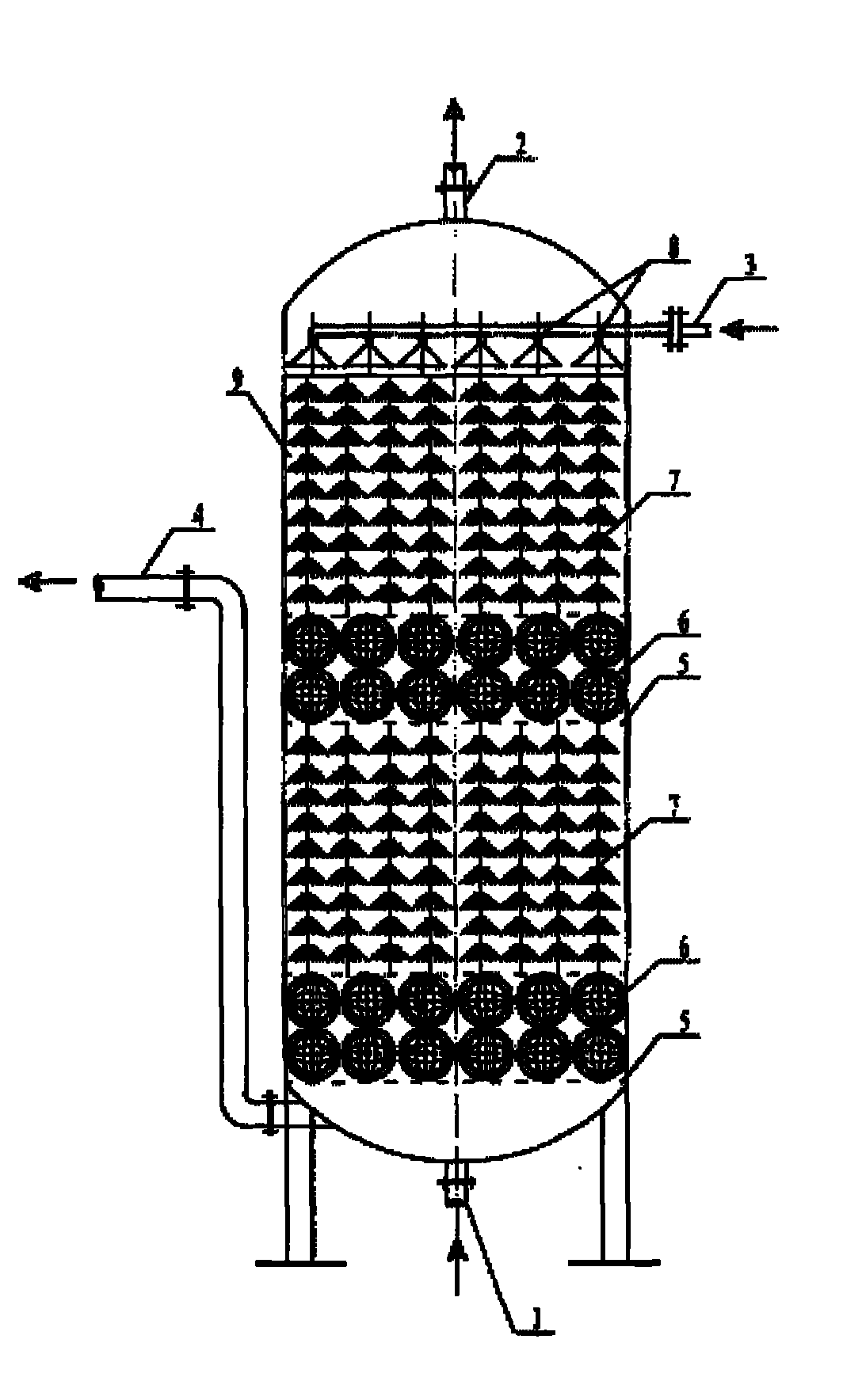

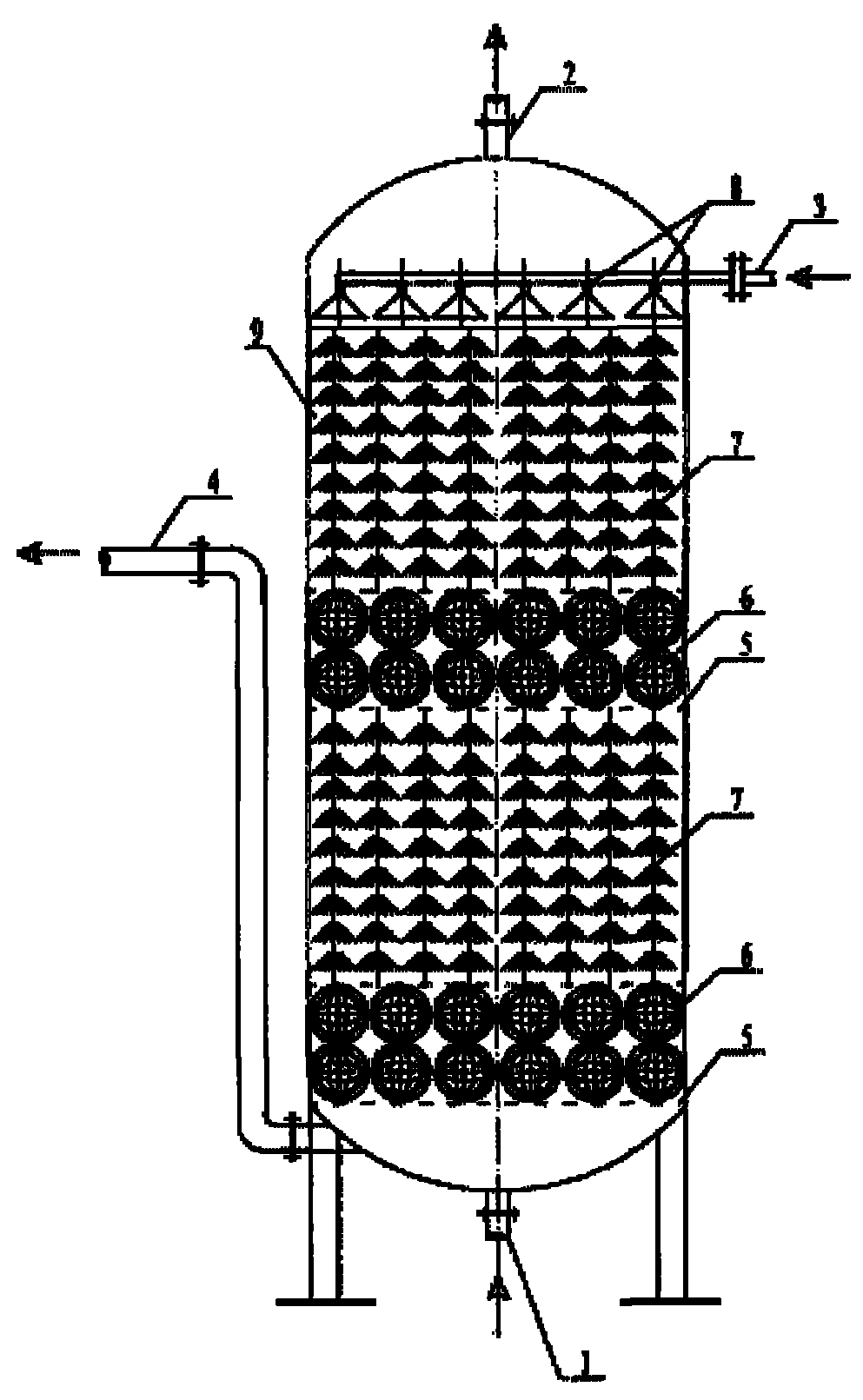

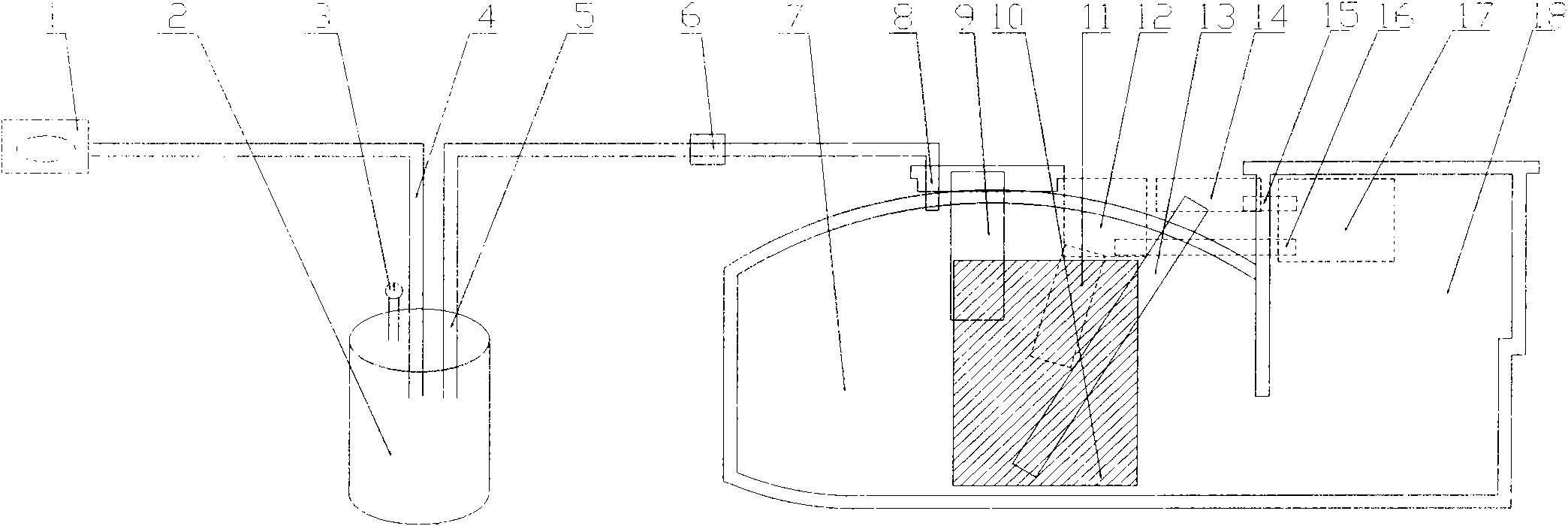

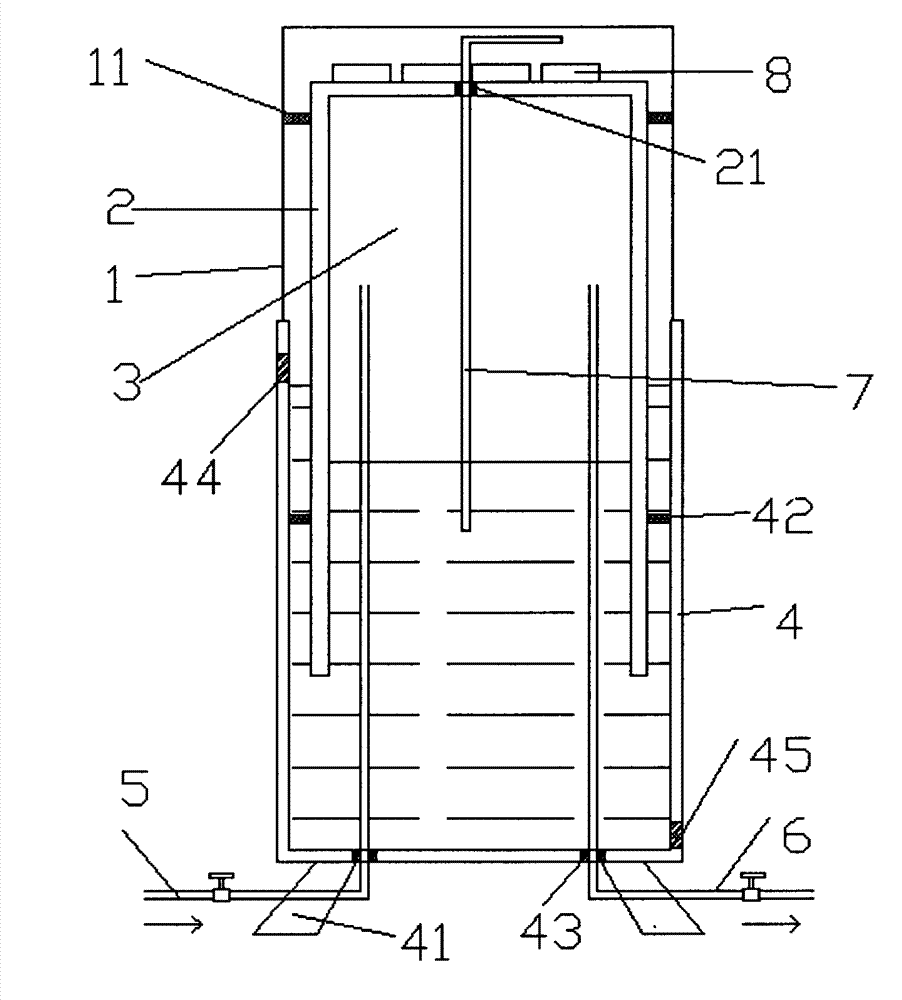

Anaerobic biological desulfurization method and device for methane

The invention discloses a methane desulfurization and purification method and a methane desulfurization and purification device. The invention comprises that: wastewater or treated effluent containing oxides such as NO3-, NO2-, Fe3+ and the like is introduced into a desulfurizing tower from a spraying liquid inlet (3) and is uniformly sprayed on an elastic filler (7) through a spray nozzle; methane enters the desulfurizing tower through a methane inlet (1) at the bottom of the desulfurizing tower, is uniformly distributed through a porous gas distribution plate (5) and alternately passes through a microbe-attached plastic air balloon (6) and the elastic filler (7); the plastic air balloon (6) and the elastic filler (7) are alternately arranged; the desulfurization microbes are attached to the plastic air balloon (6) and the elastic filler (7) or blocked in reaction solution by the filler; and hydrogen sulfide is converted into sulfur or sulfate by taking NO3-, NO2- and Fe3+ as electron acceptors so as to fulfill the aim of methane desulfurization. The desulfurized methane is exhausted from a methane outlet (2) on the top of the tower; the desulfurized spraying liquid enters the bottom of the desulfurizing tower and is discharged through a spraying liquid outlet (4); and the height of a vertical pipe connecting the spraying liquid outlet (4) and the bottom of the tower is about 2 times that of methane pressure (a water column).

Owner:BIOGAS SCI RES INST MIN OF AGRI

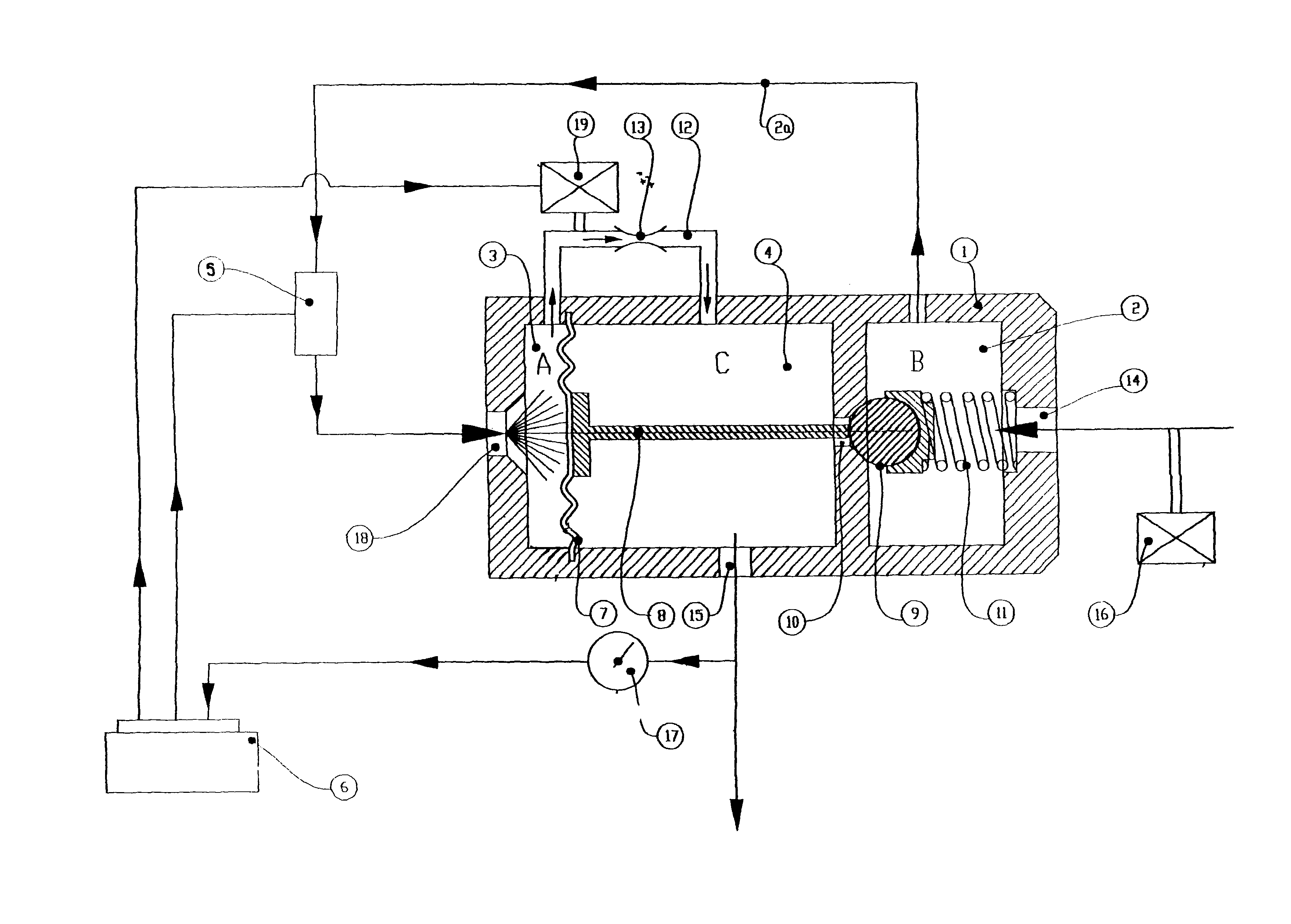

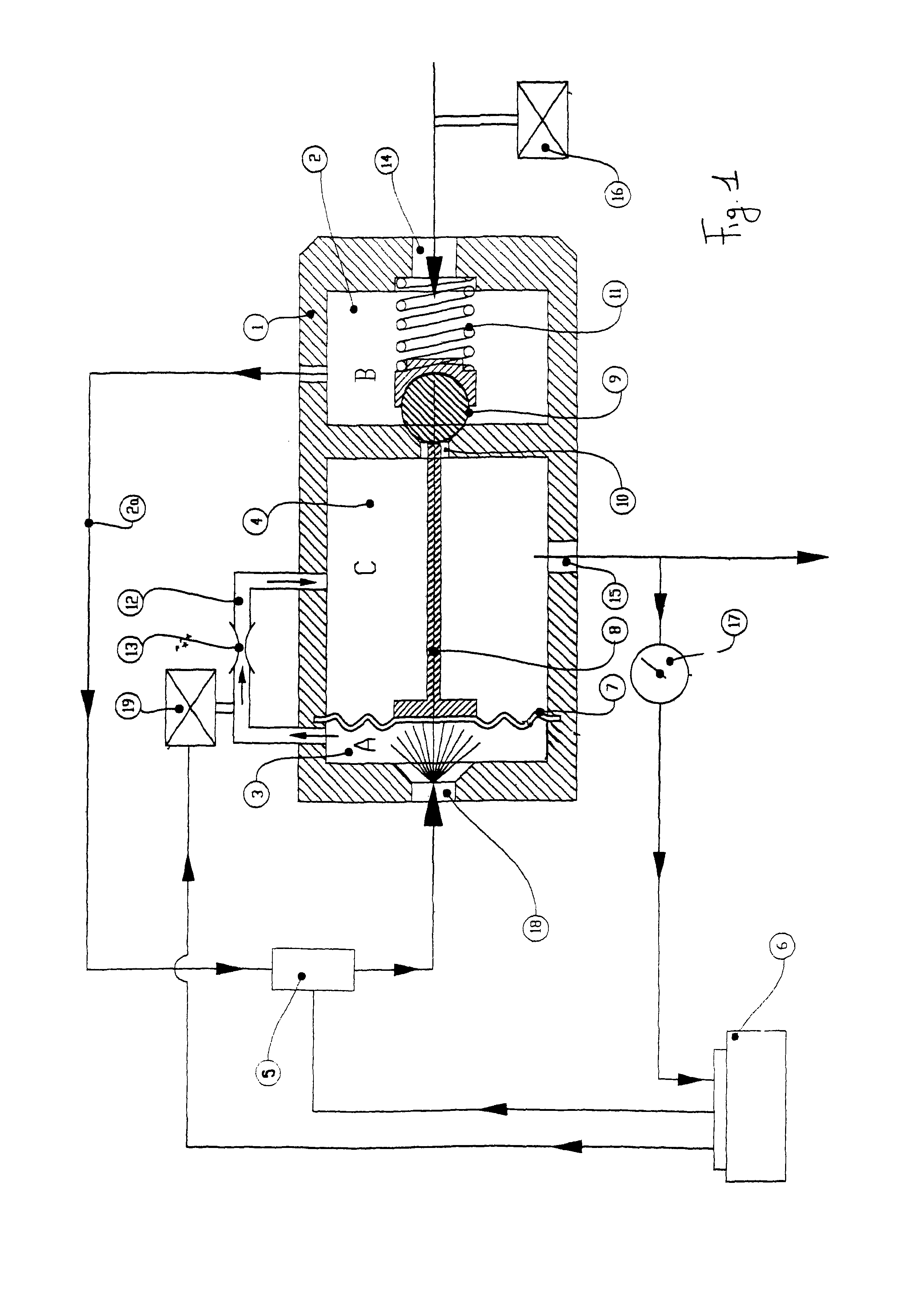

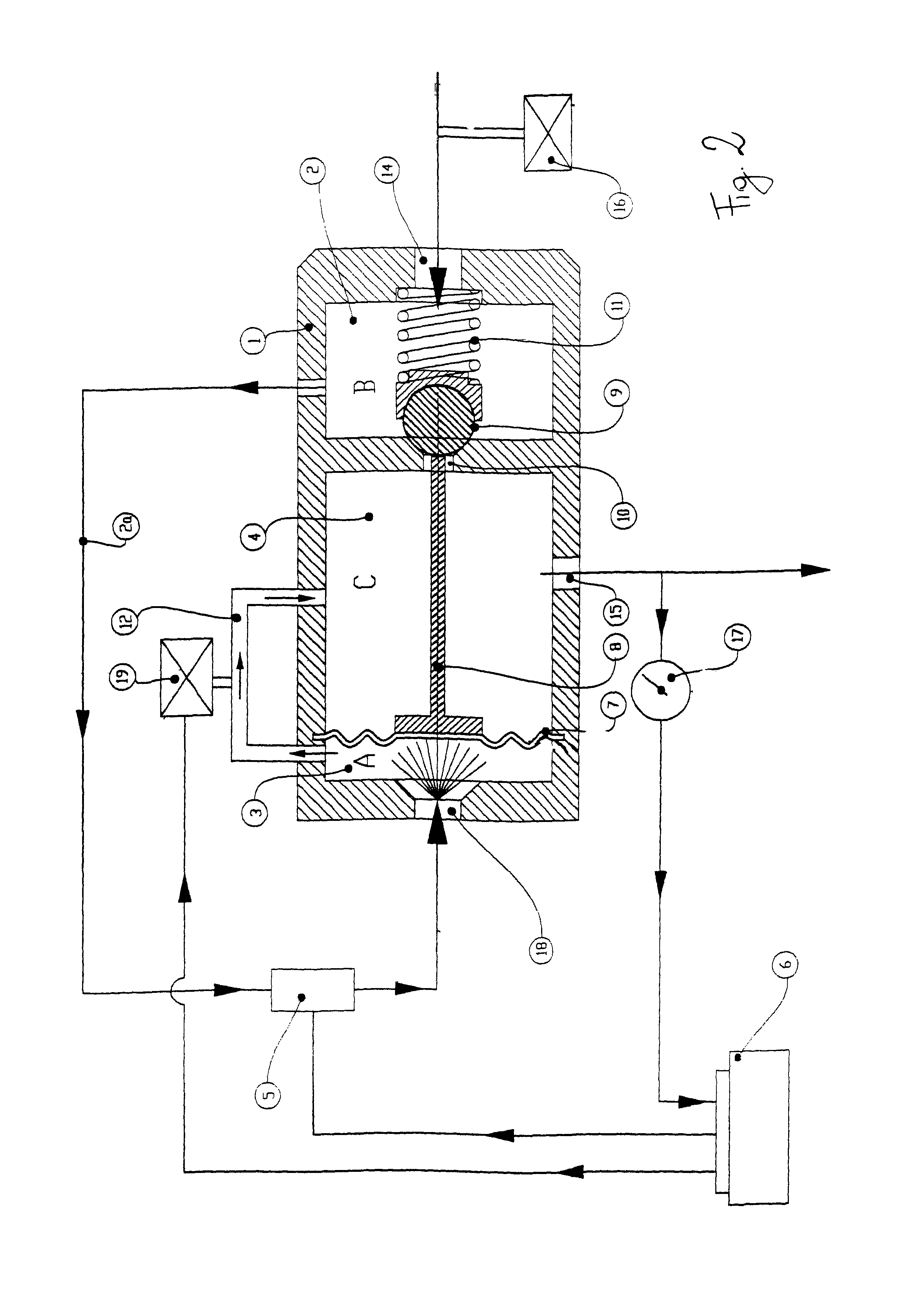

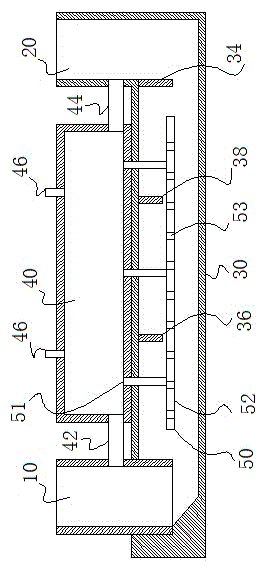

Pressure reducer-regulator for feeding internal combustion engines with methane or other similar fuels

ActiveUS9194289B2Internal combustion piston enginesFuel supply apparatusHigh resistanceExternal combustion engine

The object of the present invention is a methane pressure reducer / regulator for feeding internal combustion engines which comprises a body divided into three chambers, communicating with each other by means of high resistance conduits and by means of an opening / closing element which is integral with an elastic diaphragm, whose surface is proportionally larger than the opening / closing element so that a modest pressure in the chamber upstream from the elastic diaphragm is sufficient to bend it, overcoming both the methane pressure resistance in the adjacent chamber, and the methane pressure resistance in the chamber directly connected to the tank(s), as well as the counter spring resistance. When the elastic diaphragm bends, it pushes a stem whose end is integral with the opening / closing element that allows or prevents the methane passage through a hole connecting the chamber from which methane is sent to the engine to the chamber wherein methane comes directly from the tank(s). Further, a conduit connects the chamber where a sufficient pressure is reached to bend the diaphragm, to the chamber from which low pressure methane is sent to the feeding system of the engine; according to a configuration, said conduit is provided with an on-off valve and a throat, or, alternatively, only with the on-off valve. The pressure regulator / reducer is completed by a pressure sensor, a pressure control valve, valves and connections to electronics which controls the engine feeding operation.

Owner:ICOMET SPA

Pressurization type generator of marsh gas

InactiveCN100341999CStable pressureIncrease pressureGas production bioreactorsWaste based fuelEngineeringAtmospheric pressure

The present invention discloses a methane pressurizing generator, which has the purpose of providing one kind of the pressurizing generator. Including the generating cavity and the independence pressurizing cavity, two cavities are connected by air pipe, the pressurizing cavity has the water inlet pipe or / and the air inlet pipe, above two cavities with gas outlet pipe connected with the methane apparatus, the generating cavity has charging port and mixer. When the barometric pressure in the pressurizing cavity is excessively low, then pours water or air to the pressurizing cavity, which causes the space of the pressurizing cavity change small, then the methane pressure raises.

Owner:王海金

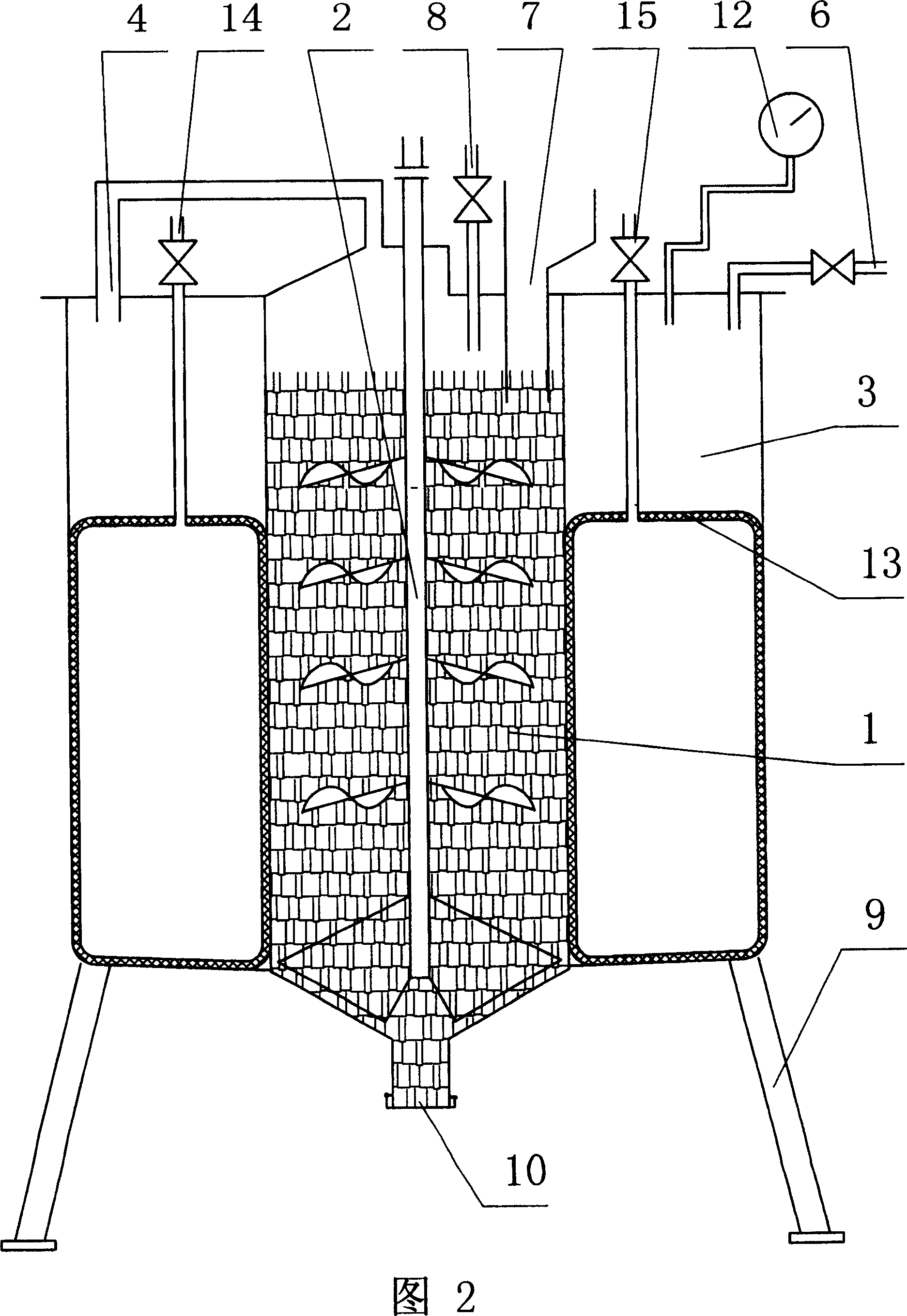

Method for producing methane by virtue of dual-tube passage-type methane generation device with biogas slurry convective stirring function

InactiveCN104531770AStrong stirringPromote in-depthGas production bioreactorsWaste based fuelEngineeringAtmospheric pressure

The invention discloses a method for producing methane by virtue of dual-tube passage-type methane generation device with a biogas slurry convective stirring function. According to the method, fermenting raw material is poured inside a fermenting system and fermented to produce methane, methane is respectively gathered inside fermentation zones formed between the side wall of a material inlet / outlet pipe and adjacent air baffle plates or the fermentation zones formed between adjacent air baffle plates so that the methane pressure inside the fermentation zones is increased to push the biogas slurry from a fermenting pipeline to flow towards the material inlet pipe and the material outlet pipe material, the biogas slurry levels in the material inlet pipe and the material outlet pipe continuously rise, and when the lowest point position of the material inlet pipe drainage pipe is firstly reached, the biogas slurry levels in the material inlet pipe and the material outlet pipe further continuously rise, when the lowest point position of the material outlet pipe drainage pipe is reached, the biogas slurry flows inside a hydraulic pressure room from the fermenting pipeline by virtue of the material outlet pipe drainage pipe; when the methane inside any fermentation zone is used, the methane pressure inside the fermentation zone is reduced, the biogas slurry stored in the hydraulic pressure room flows back inside the fermenting pipeline by virtue of the material outlet pipe drainage pipe and the material inlet pipe drainage pipe to complete the circulating flow of the biogas slurry; when the methane inside another fermentation zone is used, methane is circularly produced according to the above steps and used.

Owner:张伟伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com