Rotary valve based on methane pressure swing adsorption and adsorption method rotary valve

A pressure swing adsorption and rotary valve technology, applied in separation methods, chemical instruments and methods, gas fuels, etc., can solve the problems of many fault points, poor economy, and large consumption of finished gas, so as to reduce fault points and improve safety , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0156] In order to more clearly and clearly illustrate the specific implementation objectives and implementation modes of the present invention, the technical solution of the present invention will be fully described below, and the described embodiments are part of the embodiments of the present invention, rather than all embodiments. On the premise of no creative work, all other embodiments based on the described embodiments of the present invention belong to the protection scope of the present invention.

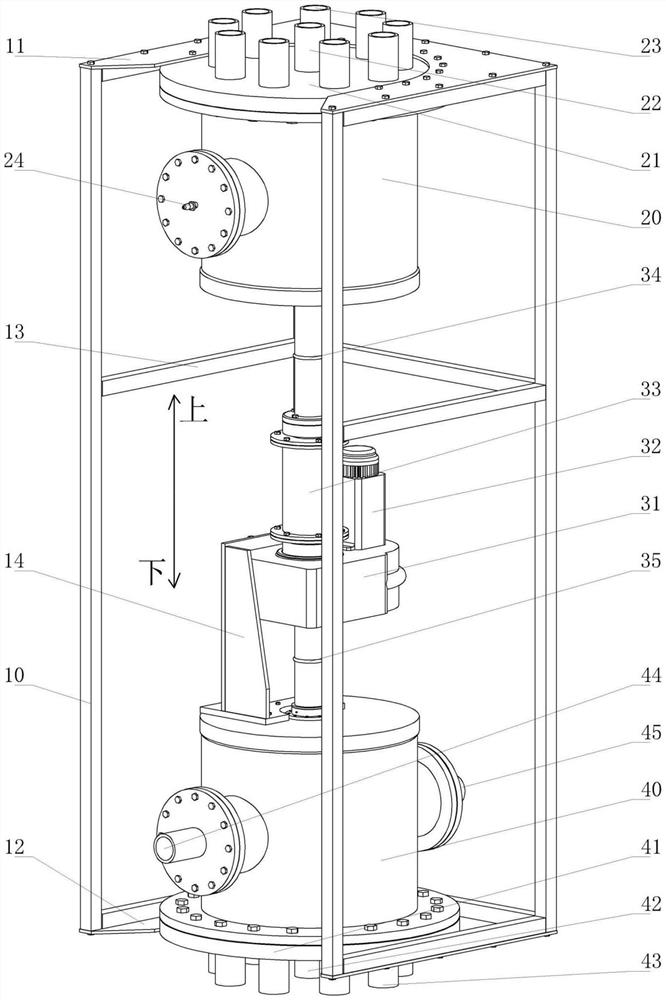

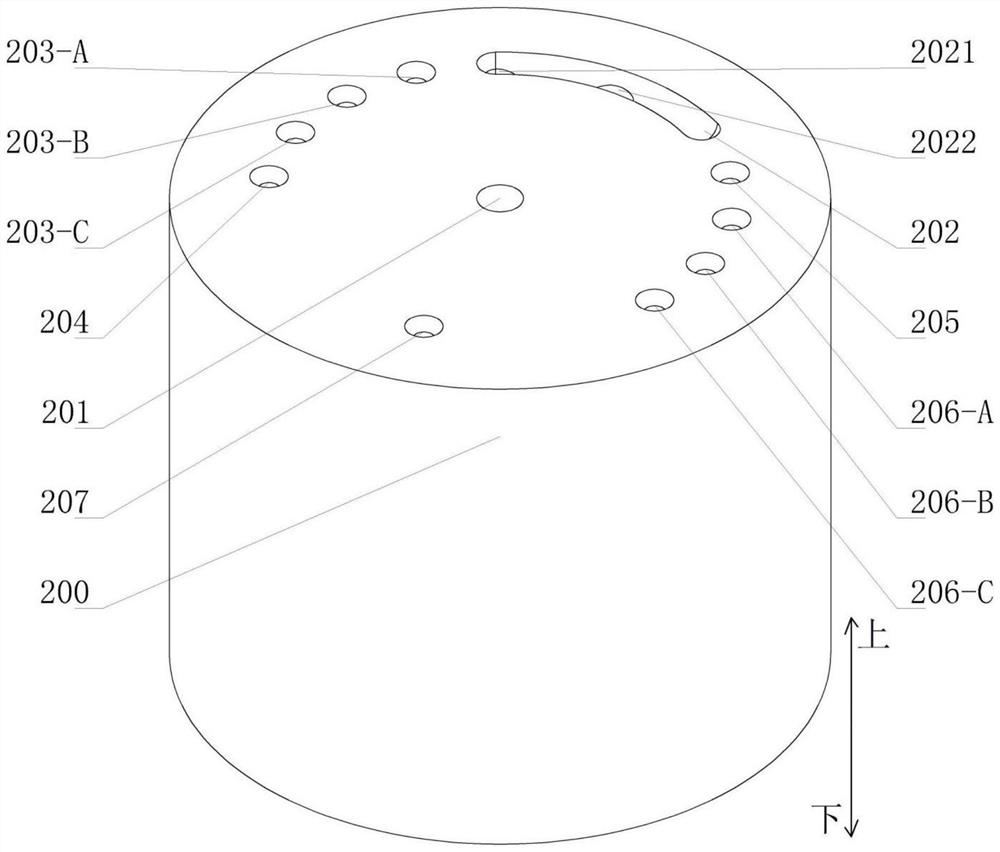

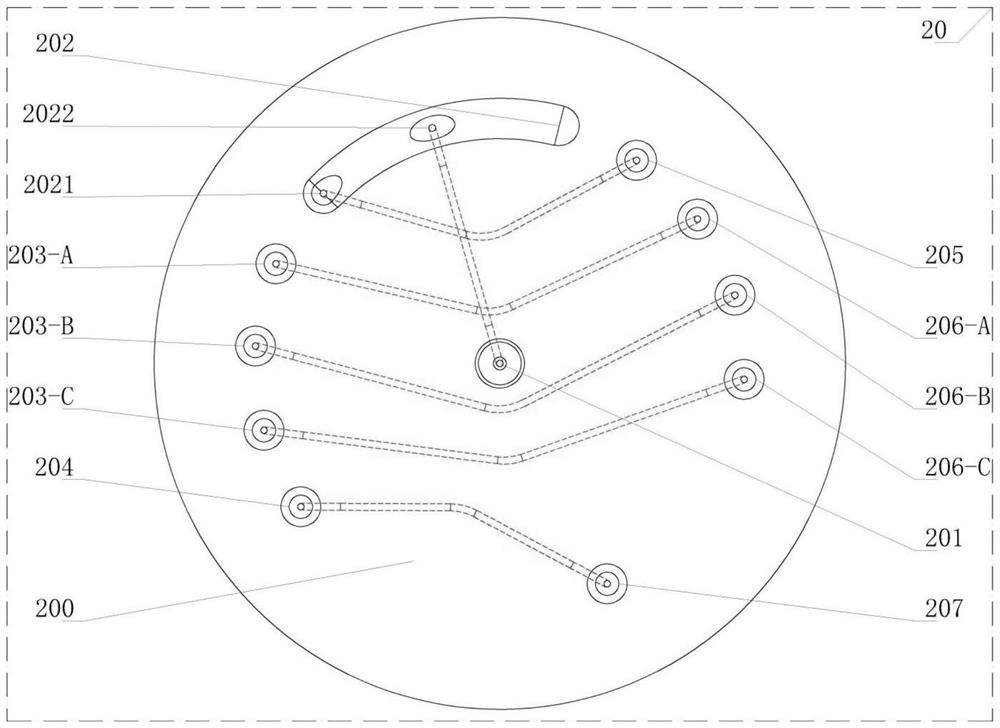

[0157] The present invention is based on the rotary valve of biogas pressure swing adsorption, such as figure 1 As shown, the rotary valve includes: an upper valve 20 and a lower valve 40 arranged coaxially, and the rotary valve is fixedly installed in the support frame 10 .

[0158] The support frame 10 is set as a frame structure, and the upper and lower ends of the support frame 10 are provided with a "U"-shaped upper fixing plate 11 and a lower fixing plate 12, and res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com