External circulating fermentation technique and device thereof

A fermentation process and external circulation technology, applied in the field of external circulation fermentation process and equipment, can solve the problems of poor operation safety, high operation cost, large investment, etc., to prevent the influence of anaerobic bacteria, save equipment investment, and simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

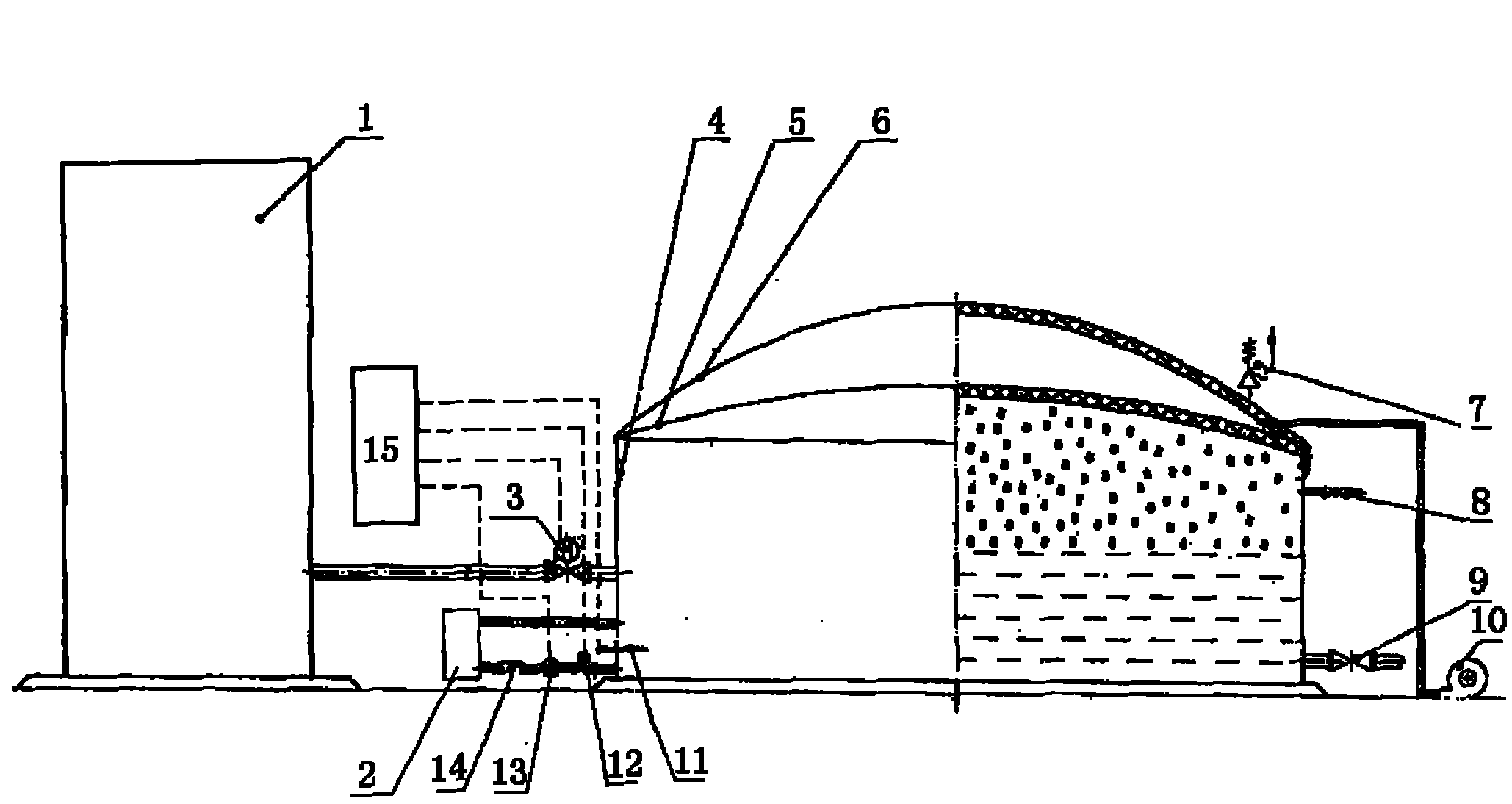

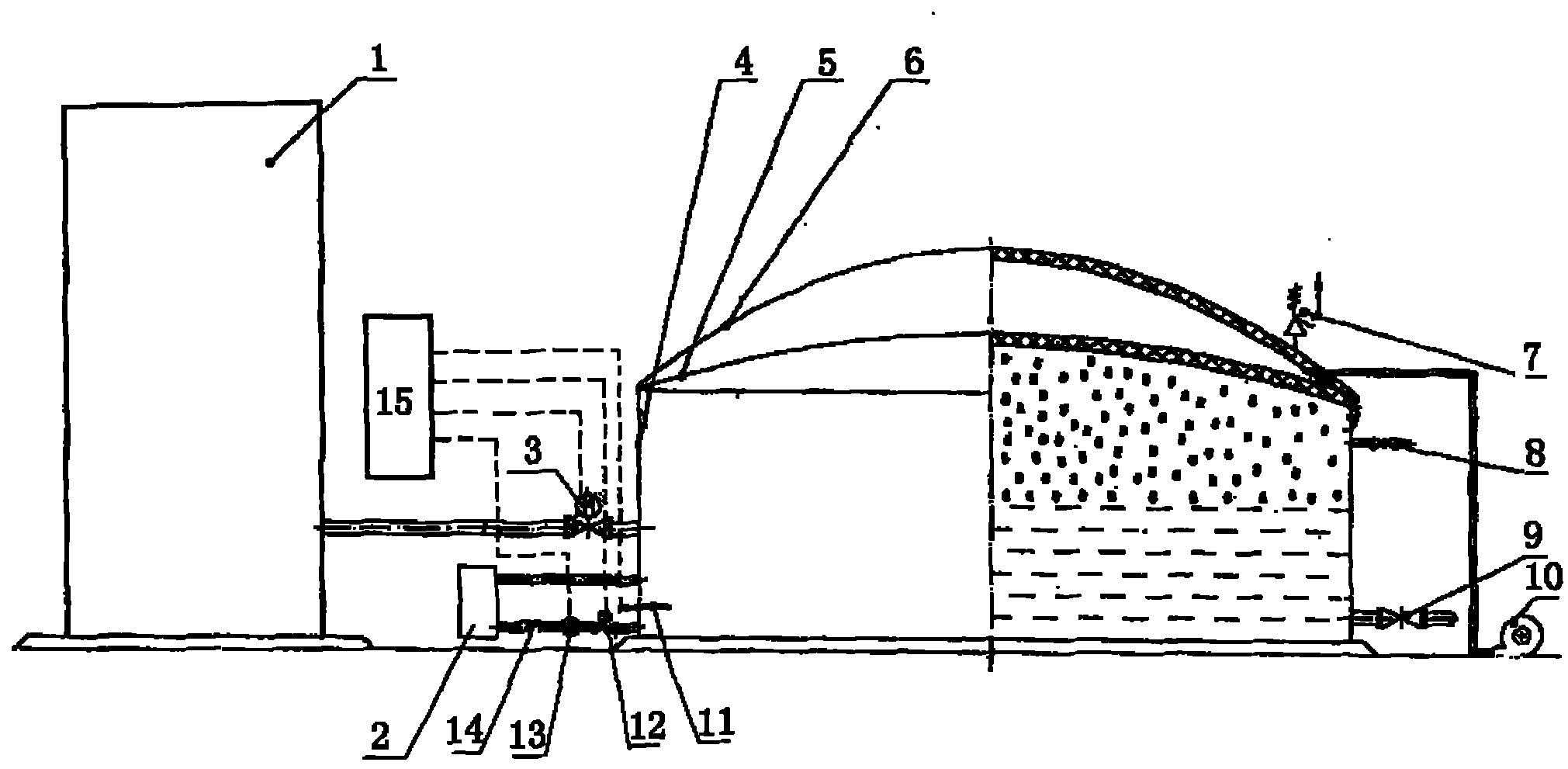

[0018] An external circulation fermentation process, comprising the process steps in the following order: (A) feeding; (B) heating and heat preservation fermentation; (C) discharging, characterized in that the process steps (A), (B), (C ) is carried out in the hydraulic circulation process device, and step (A) flows naturally in the fermenter 4 of the hydraulic cycle process device by the outlet of dry fermentation device 1; Step (B) is by being arranged on the fermenter 4 The temperature sensor 11 detects the temperature in the fermentation tank. When the temperature is lower than the design temperature, the control system 15 of the device automatically turns on the circulation pump 13 to pump the material in the fermentation tank 4 into the heat exchange device 2. After the temperature rises, the material passes through Circulation pump 13 returns in fermenter 4, circulates this step and stirs the material in fermenter 4, reaches design temperature simultaneously; Step (C) ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com