On-line repair method and special combined machine tool thereof

A combined machine tool and combined platform technology, which is used in metal processing machinery parts, other manufacturing equipment/tools, large fixed members, etc., can solve the problems of unguaranteed machining accuracy, short repair construction period, machining accuracy, and labor intensity of workers. , to achieve the effect of less failure points, extended processing range and convenient on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

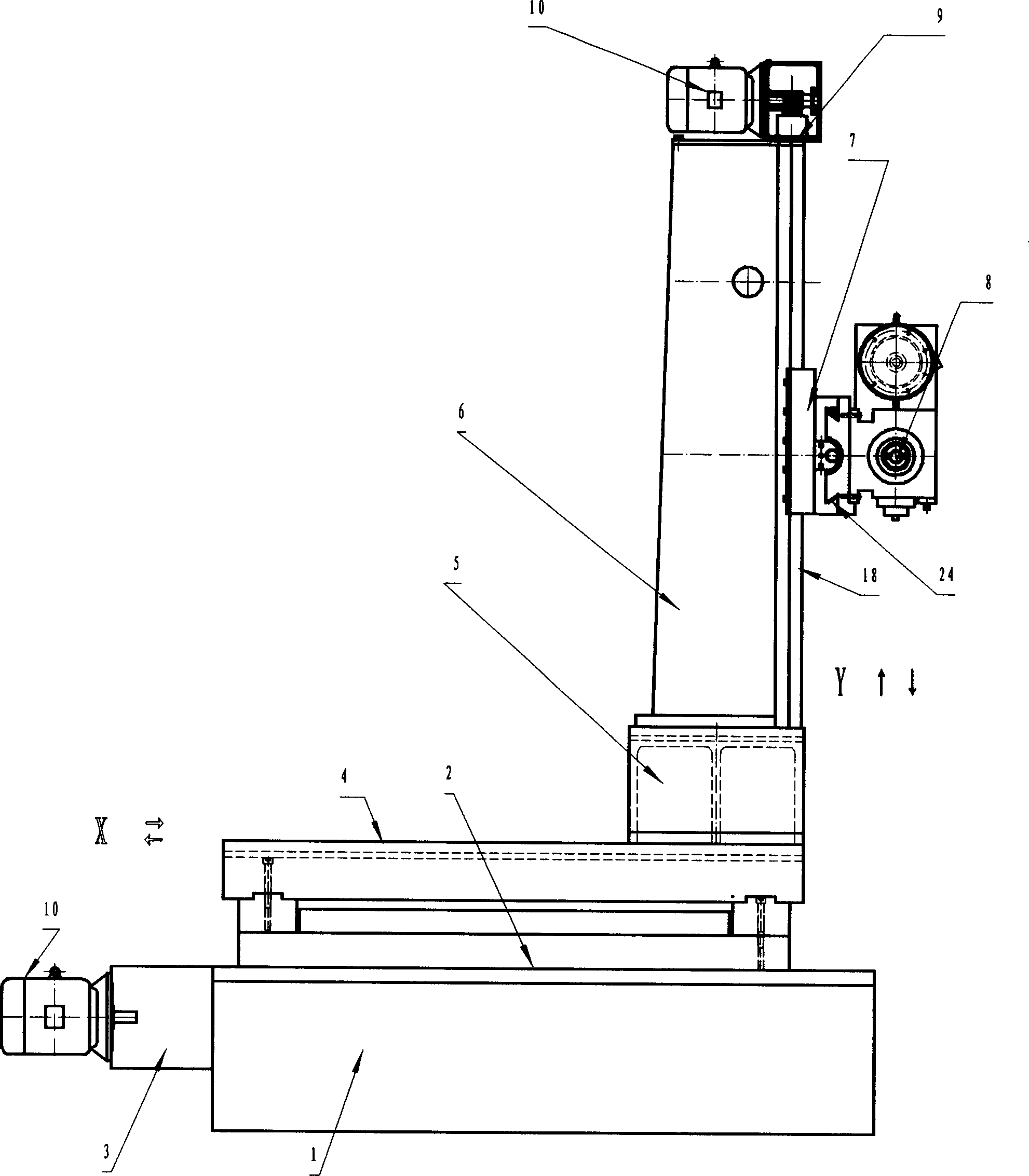

[0034]Embodiment 1: The large-scale archway of the four-high rolling mill for repairing and processing medium and heavy plates is 1.4-1.5 meters high and 4.42 meters long. Set up a mattress 17 inside the frame of the rolling mill archway, the mattress 17 is to be placed on the support roller seat surface of the roll changing car in and out, the planer body 1 and the combination platform 4 are installed on the mattress 17, when the in and out car 28 enters In the working span of the rolling mill, the upper part of the column 6 of the special combined machine tool is installed to enter the processing position.

[0035] The assembly process of the combined machine tool is as follows:

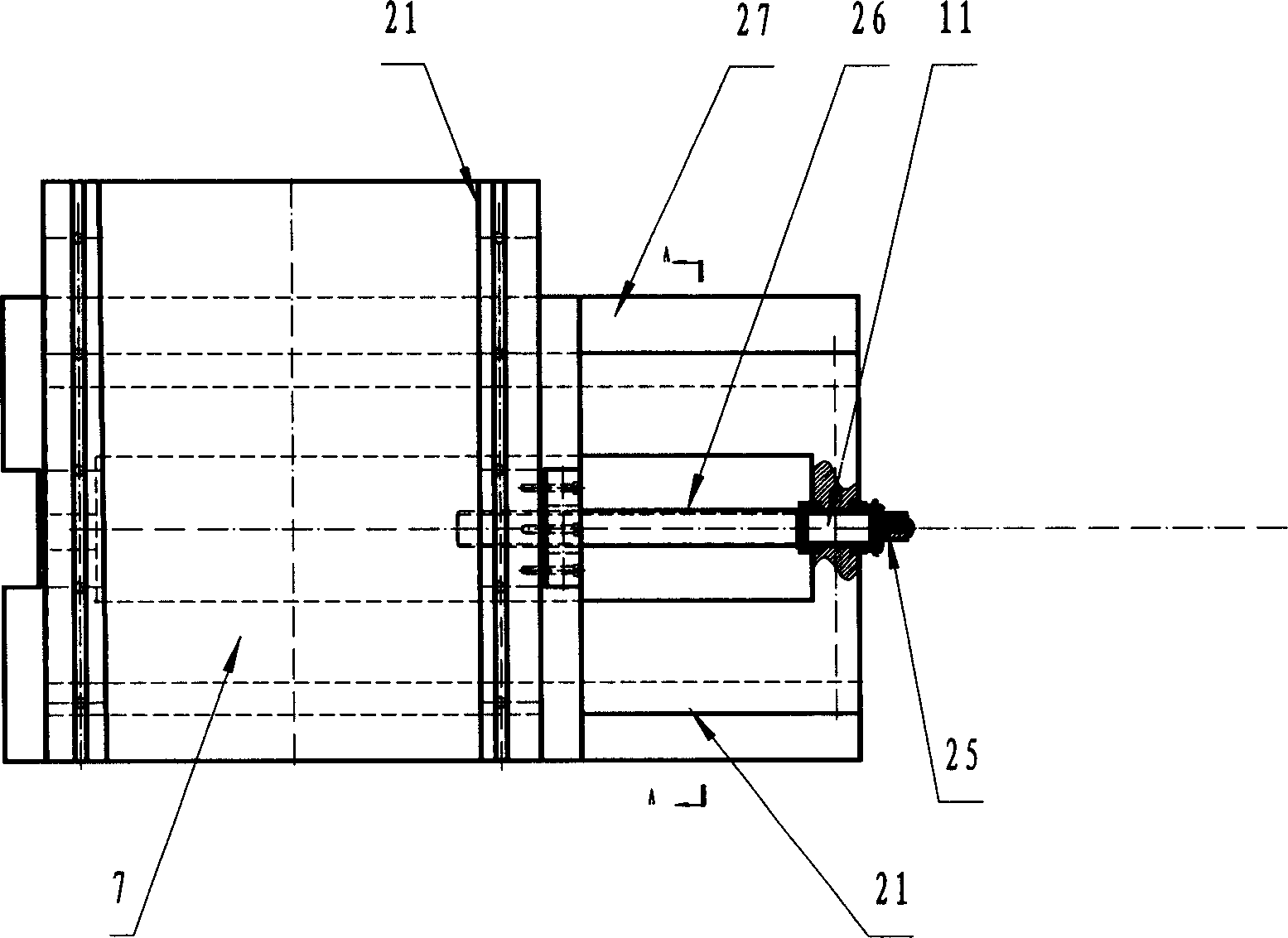

[0036] Place mobile planer bed 1 and planer slide table 2 on mattress 17, the bed length is 5 meters, X guide rail 18 and screw mandrel 16 are arranged on bed bed 1, slide table 2 is installed on bed body 1 top, slide table 2. It can move left and right along the guide rail 18. The guide rail 18 i...

Embodiment 2

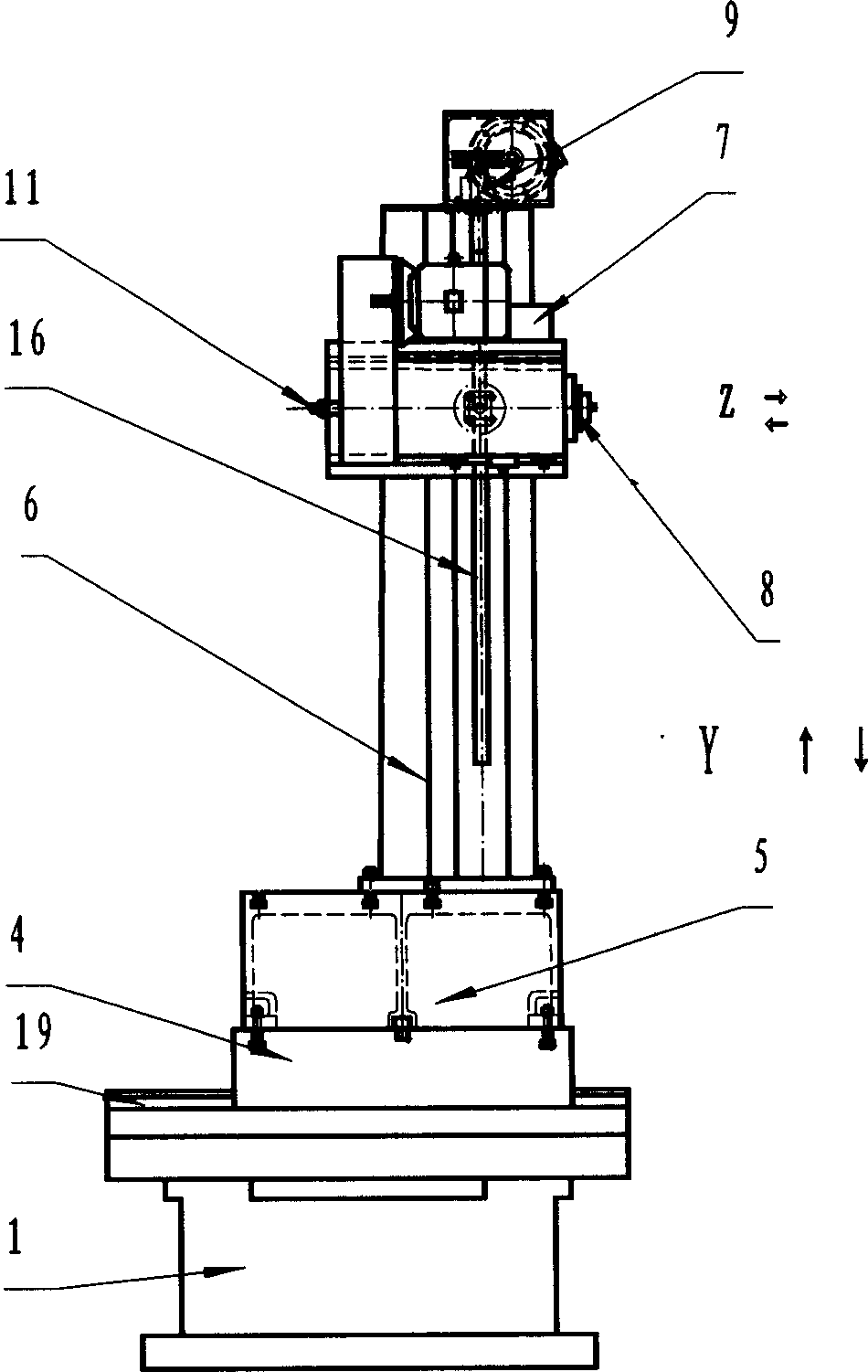

[0055] Embodiment 2: Repair and process the large archway window of the three-roll rolling mill for medium and heavy plates with a height of 3 meters and a width of 500mm. Place a flat surface 13 inside the frame of the rolling mill archway. The length of the flat plate is 3.6 meters. The column seat and special combined machine tool are installed on the workbench of the movable slide table 27, excluding the bed and the slide table part, the combined machine tool is provided with the feed in the X direction by the 600*3500mm mobile slide table 27, the column, the cross slide, and the milling power The head provides feed and milling power in the Y direction and Z direction. The transmission of the mobile slide table adopts the fast feed motor 29 and the slide table feed motor 30 to supply, and the displacement of the cross slide on the column is controlled by the variable frequency motor 10 on the column top plate.

[0056] The assembly process is as follows: install a 600*350...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com