Patents

Literature

241 results about "Simple machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A simple machine is a mechanical device that changes the direction or magnitude of a force. In general, they can be defined as the simplest mechanisms that use mechanical advantage (also called leverage) to multiply force.

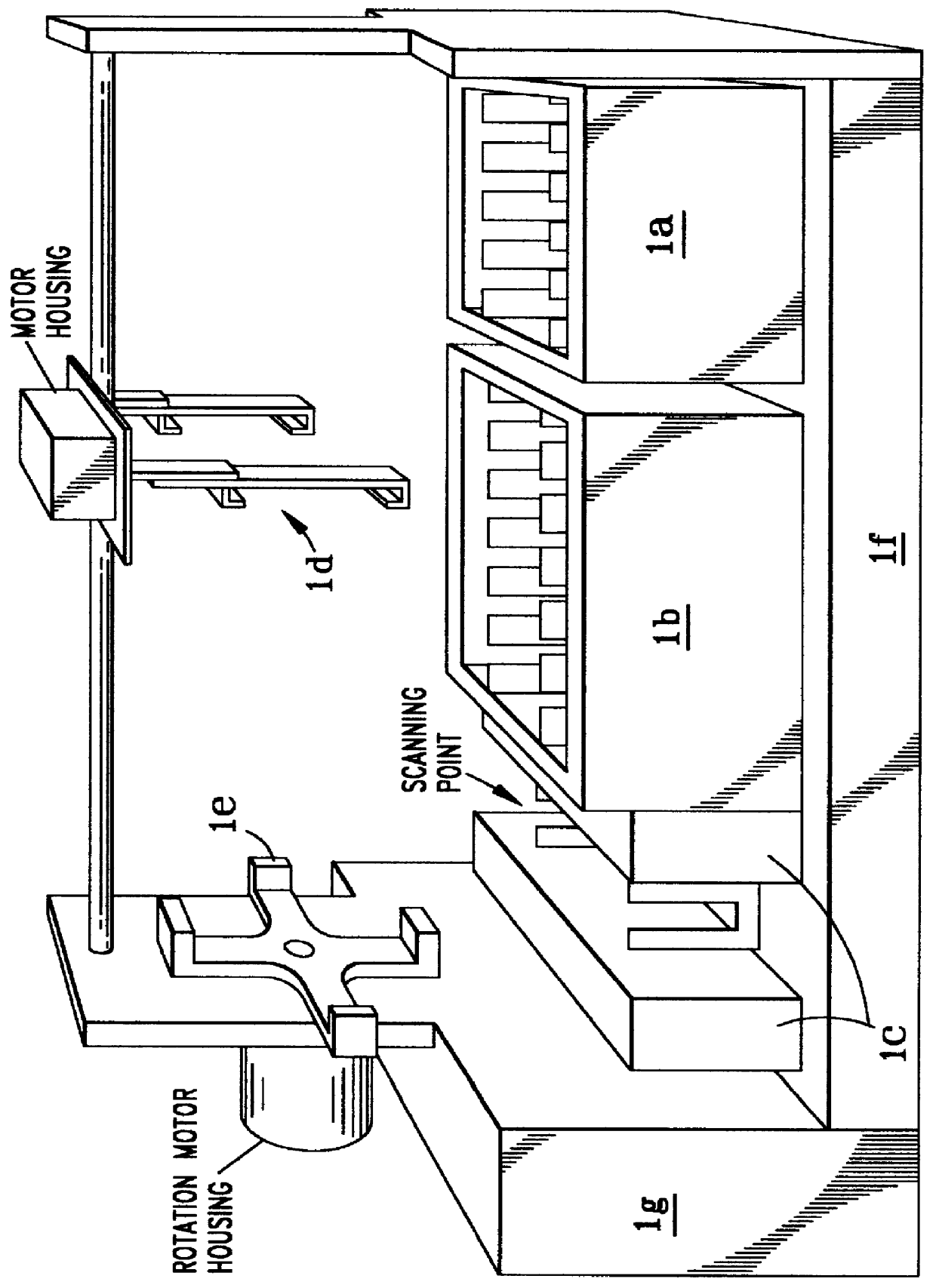

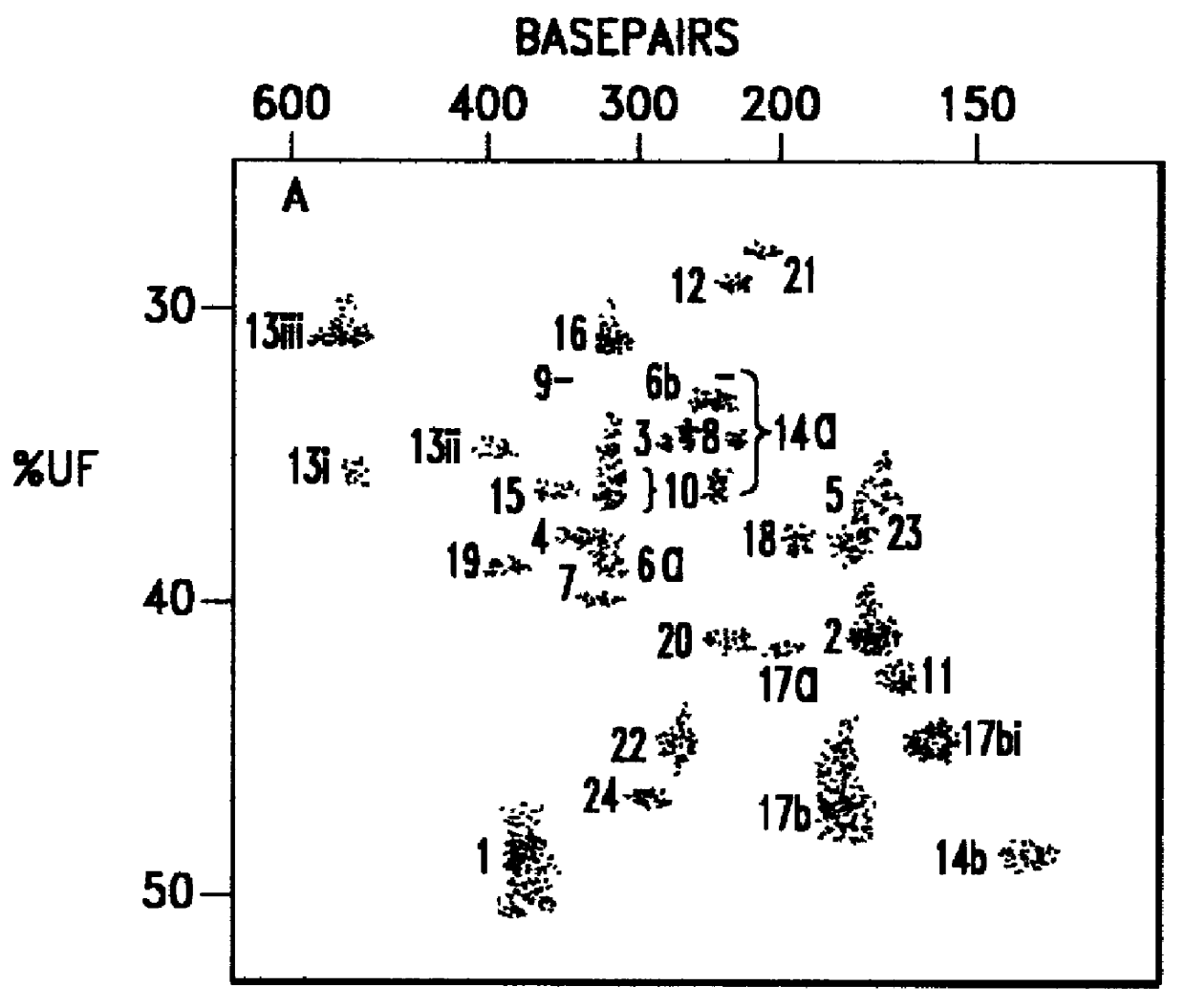

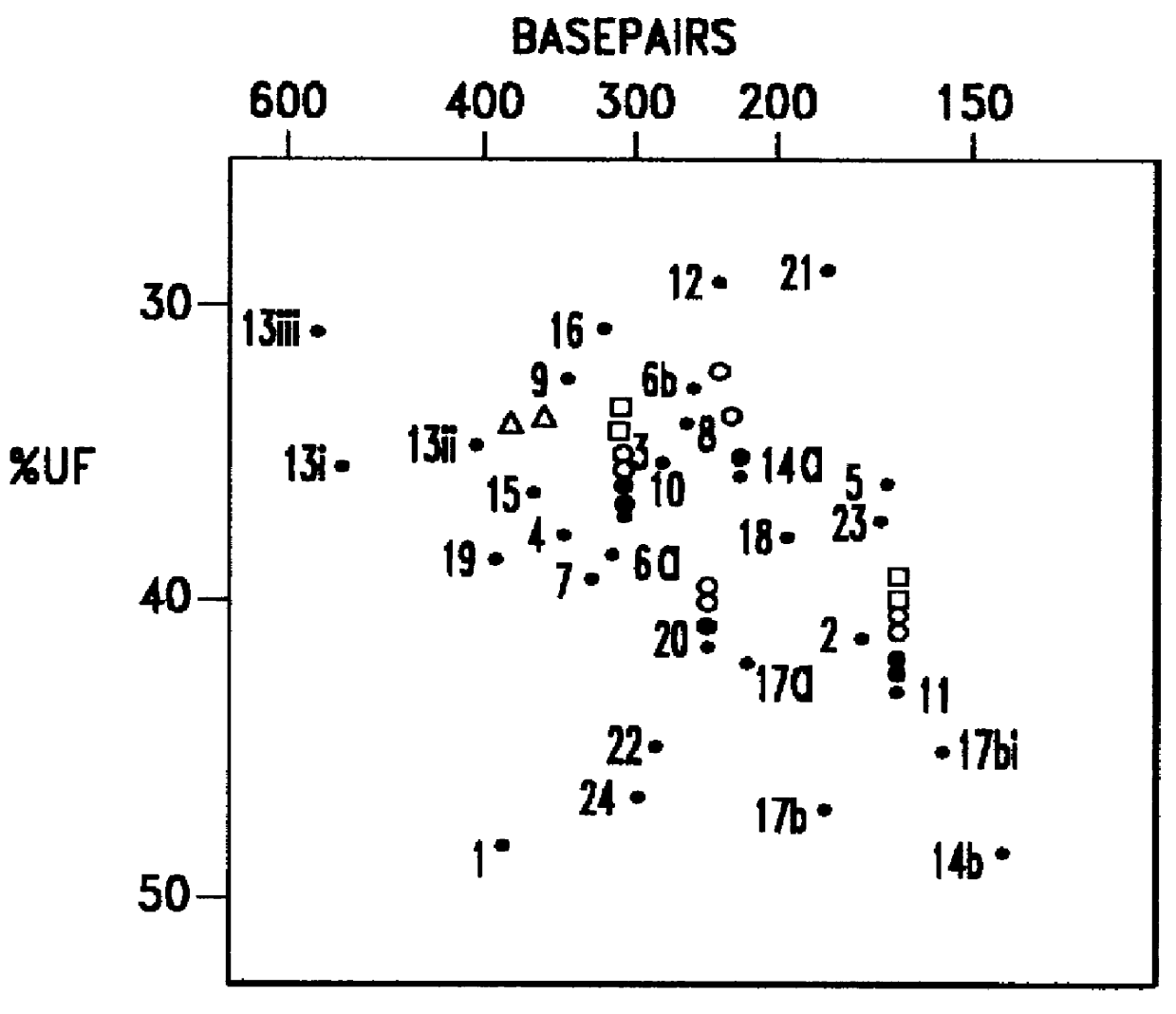

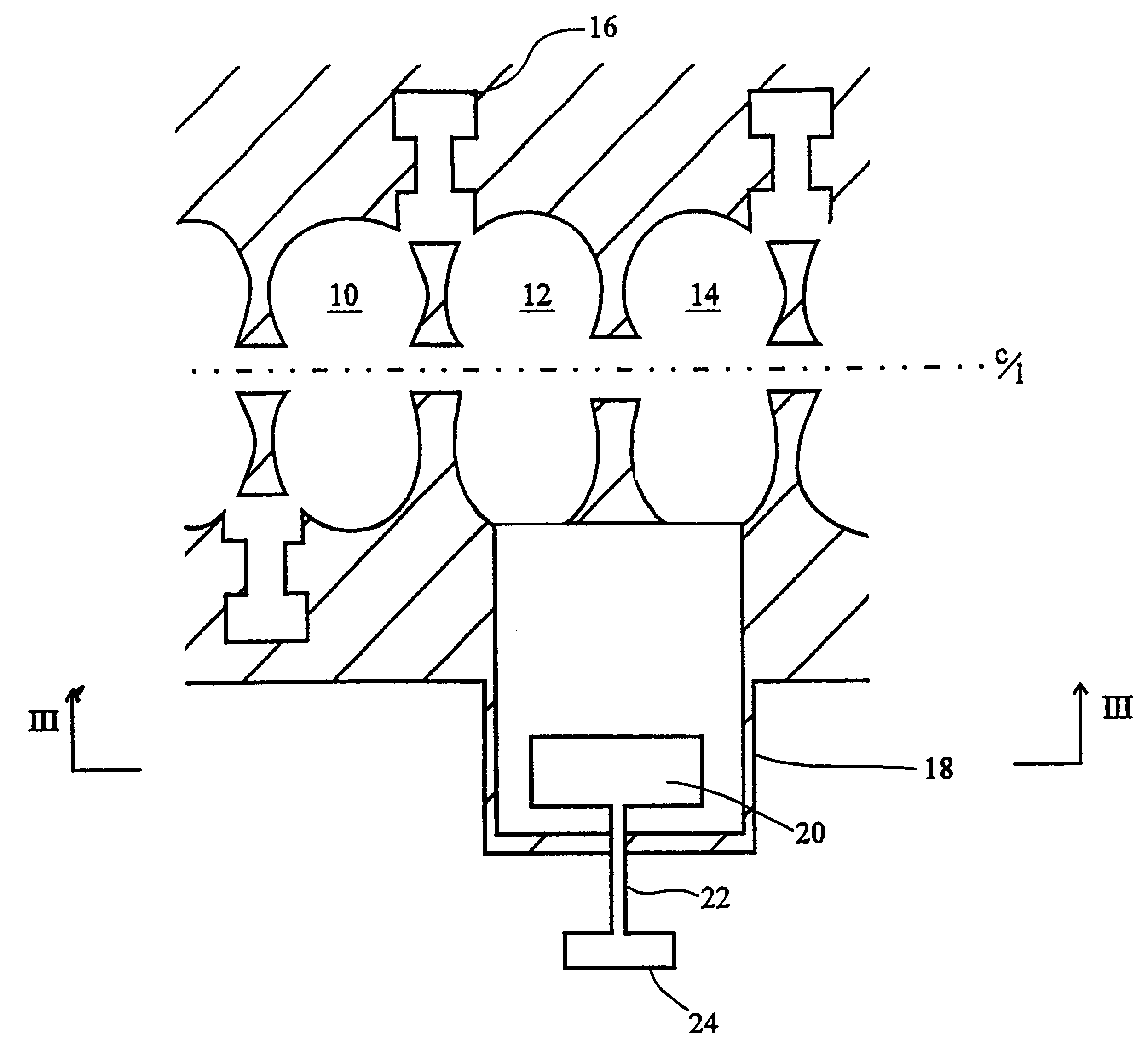

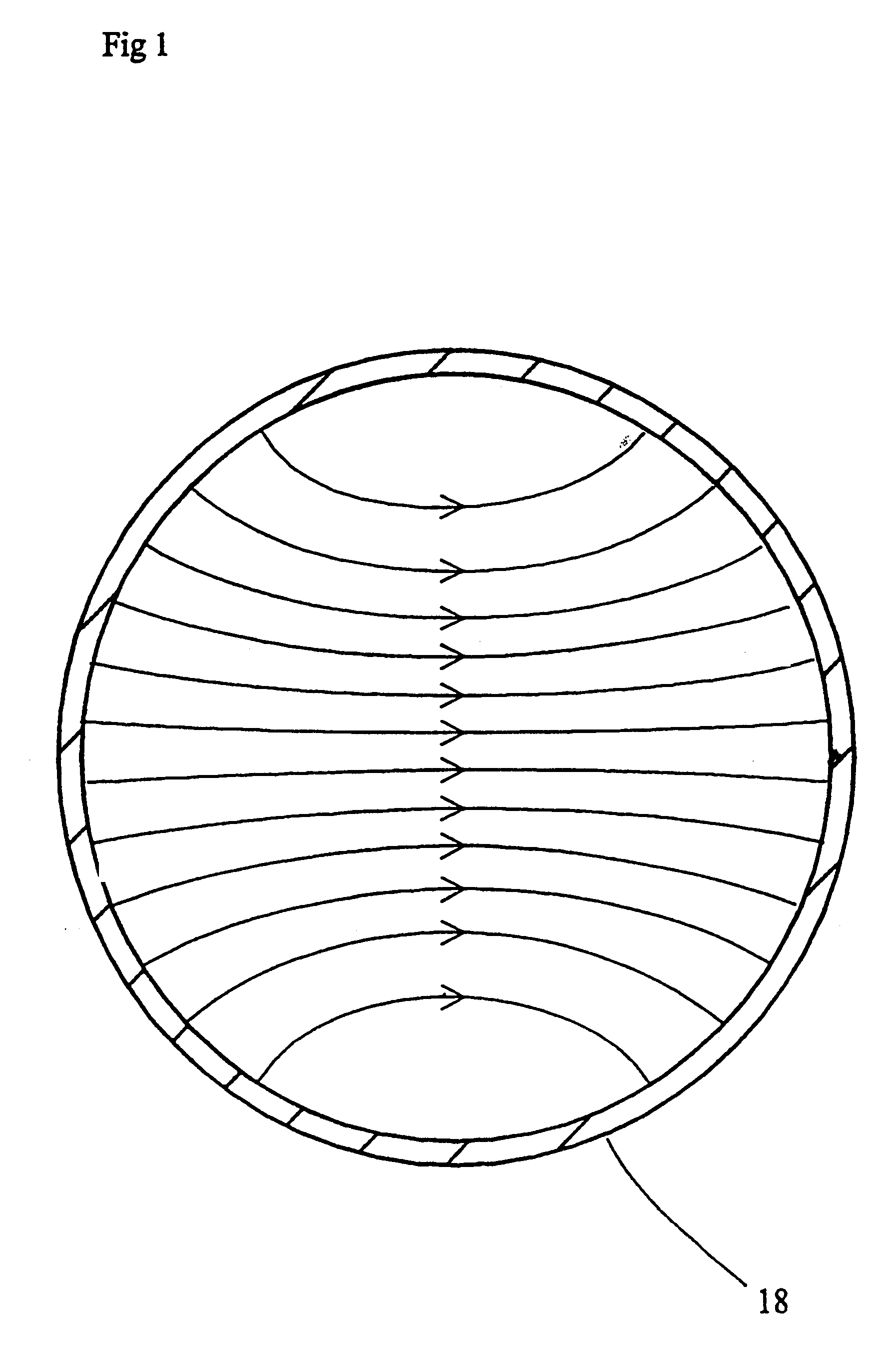

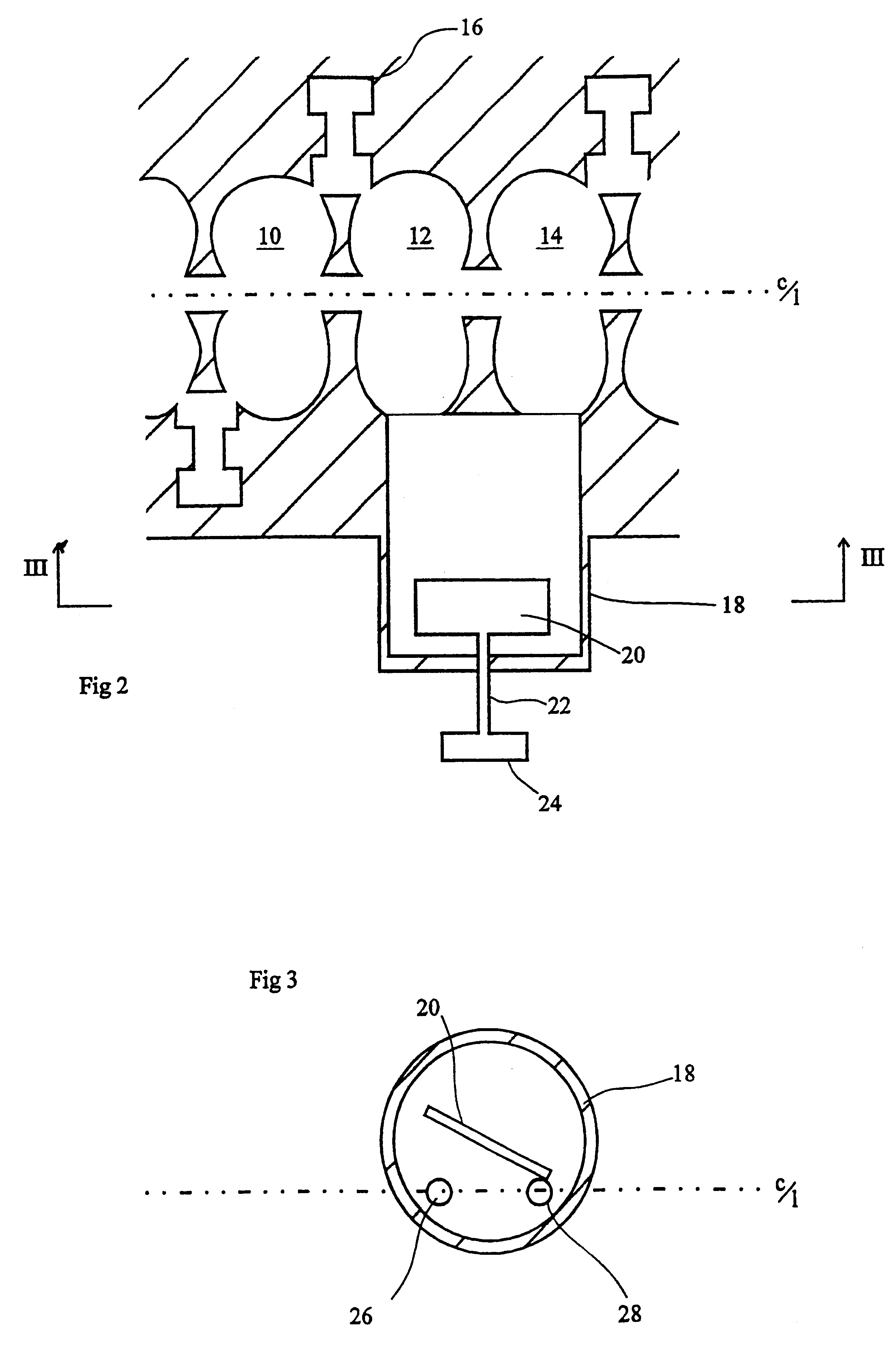

Automatic protein and/or DNA analysis system and method

A fully automated protein and / or DNA gene fragment analyzing machine and method are disclosed in which, in a simple machine structure, a plurality of electrophoresis calls each containing such fragments, are robotically, under computer programming, inserted into an electrophoresis housing and subjected to voltage for producing electrophoretic migration in one dimension (horizontally), and then preferably after robotic 90 DEG rotating of the cells, are voltage migrated in an orthogonal direction to separate the fragments vertically, and then robotically presented to an optical image scanner for identifying the brightest fragments and classifying the same, with comparison with reference image fragment locations of normal or variant fragments, and for computer storing all relevant data.

Owner:ACAD OF APPL SCI INC

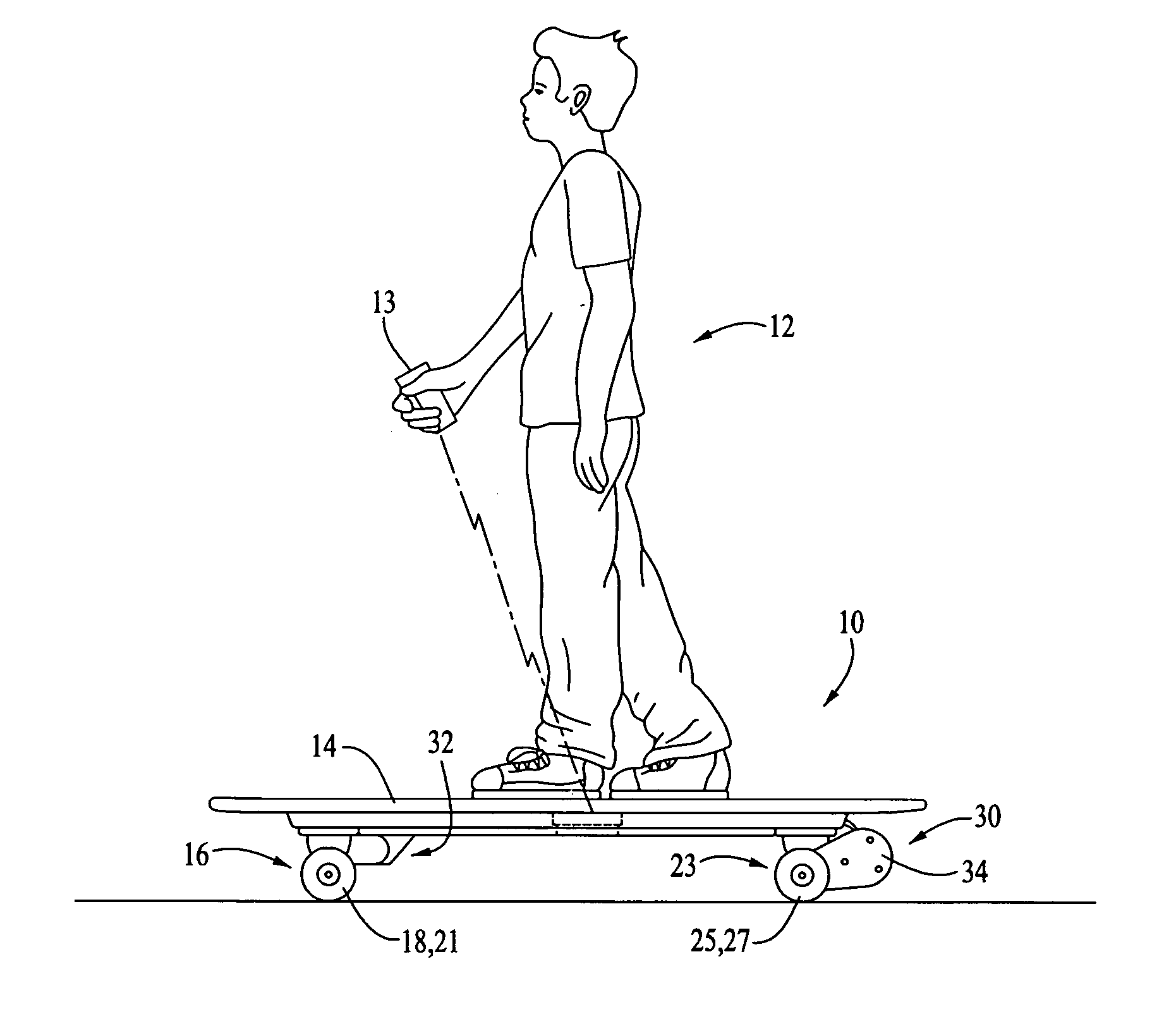

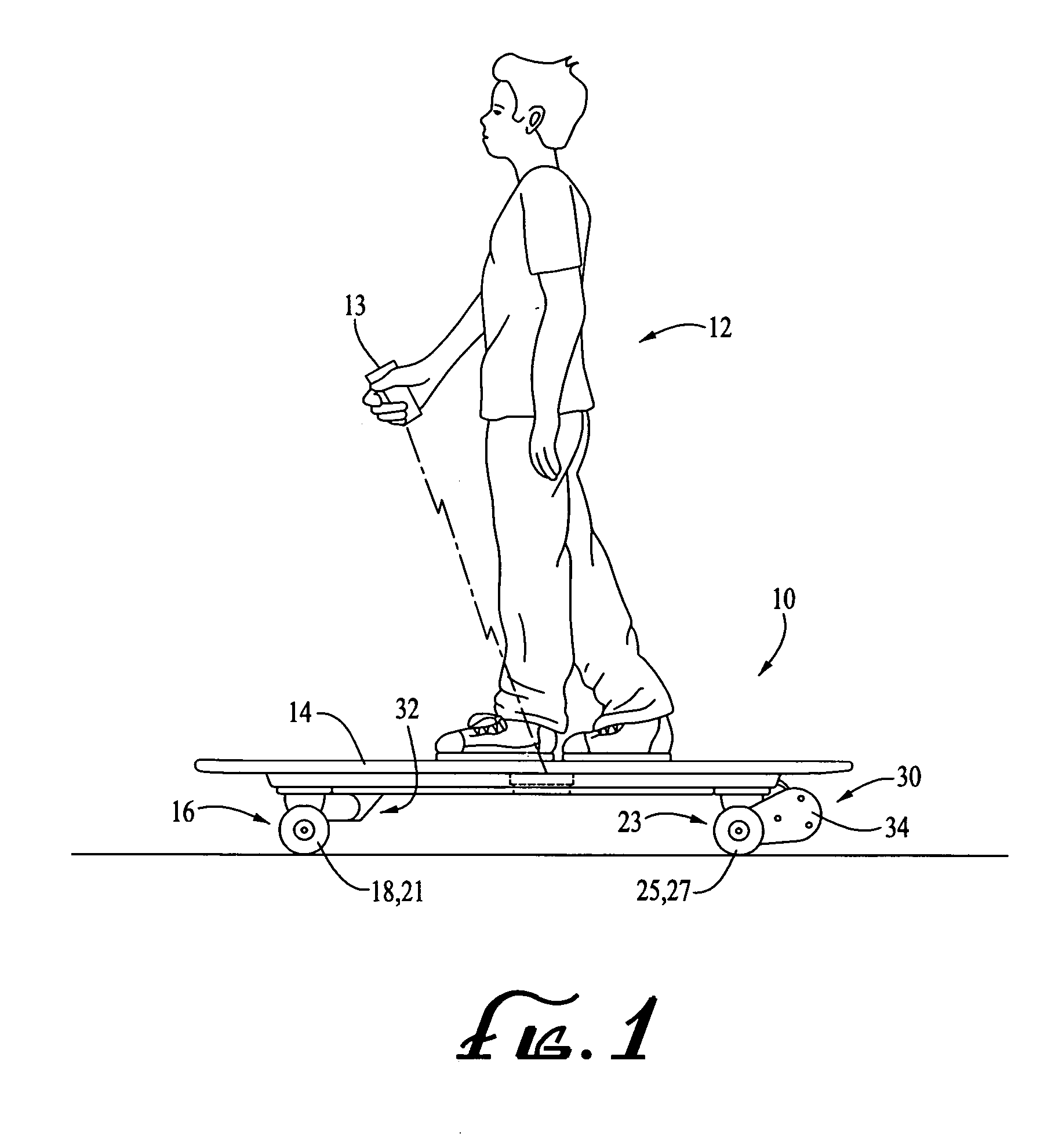

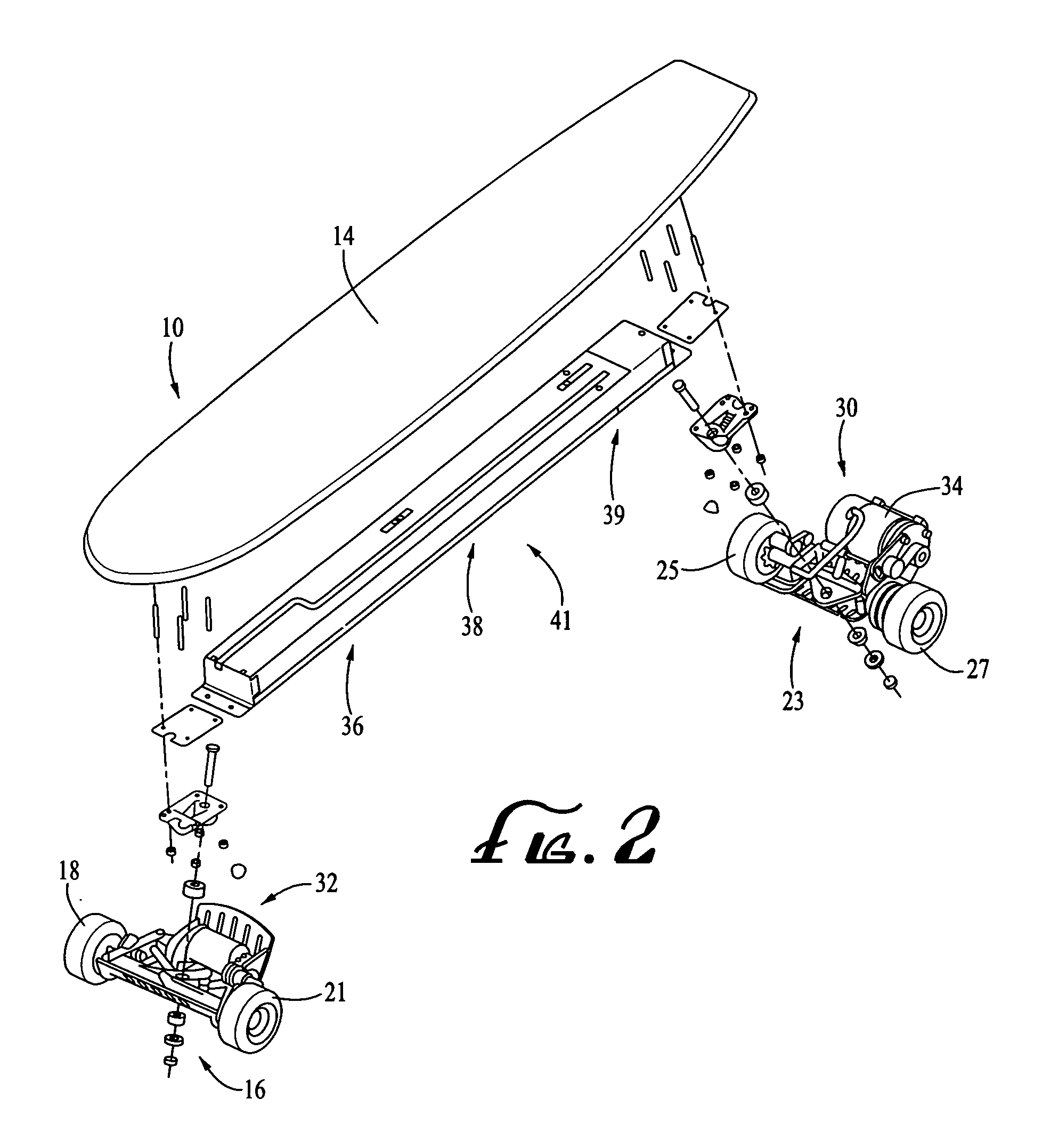

Skateboard with motorized drive and brake systems

InactiveUS20060032682A1Prevent rotationImprove featuresElectric propulsion mountingSkate-boardsRemote controlSlide plate

A skateboard includes a motorized drive assembly and a motorized brake assembly, both operable with a wireless remote control to be carried by a rider. The drive assembly is free-wheeling permitting normal use of the skateboard in the event of battery depletion. The brake system includes a motor operable through a simple machine structure to move a brake pad against a brake disk mounted against a wheel. A self-adjustment mechanism presets the brake pad a predetermined distance from the disk prior to brake application. Motor enertia is relied on to store potential energy in a wheel axel in accordance with an associated method of operation.

Owner:HILLMAN INDS

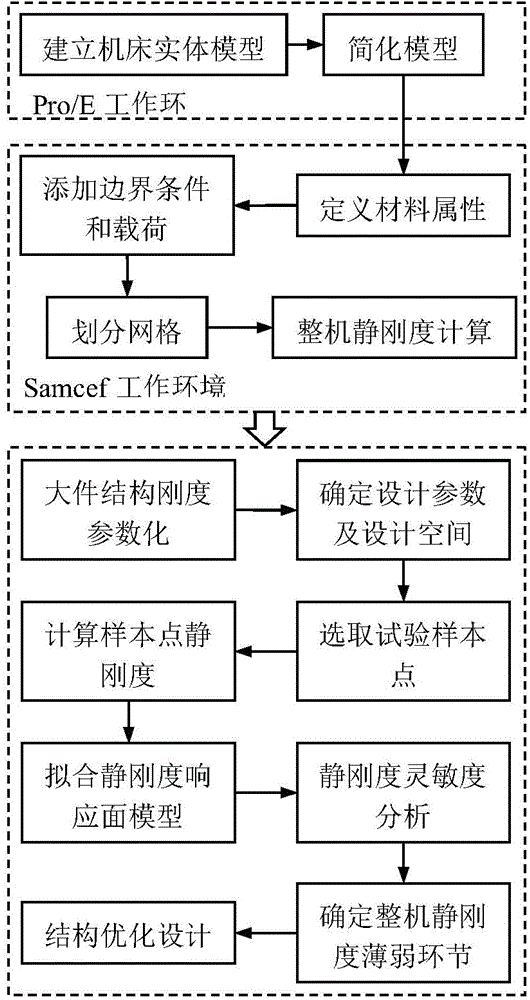

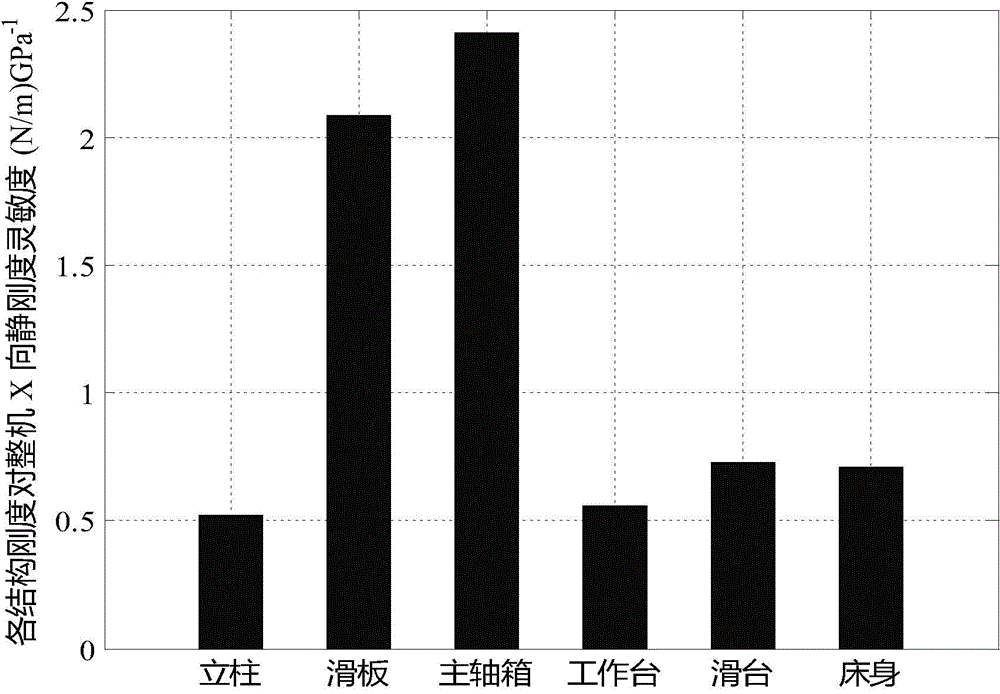

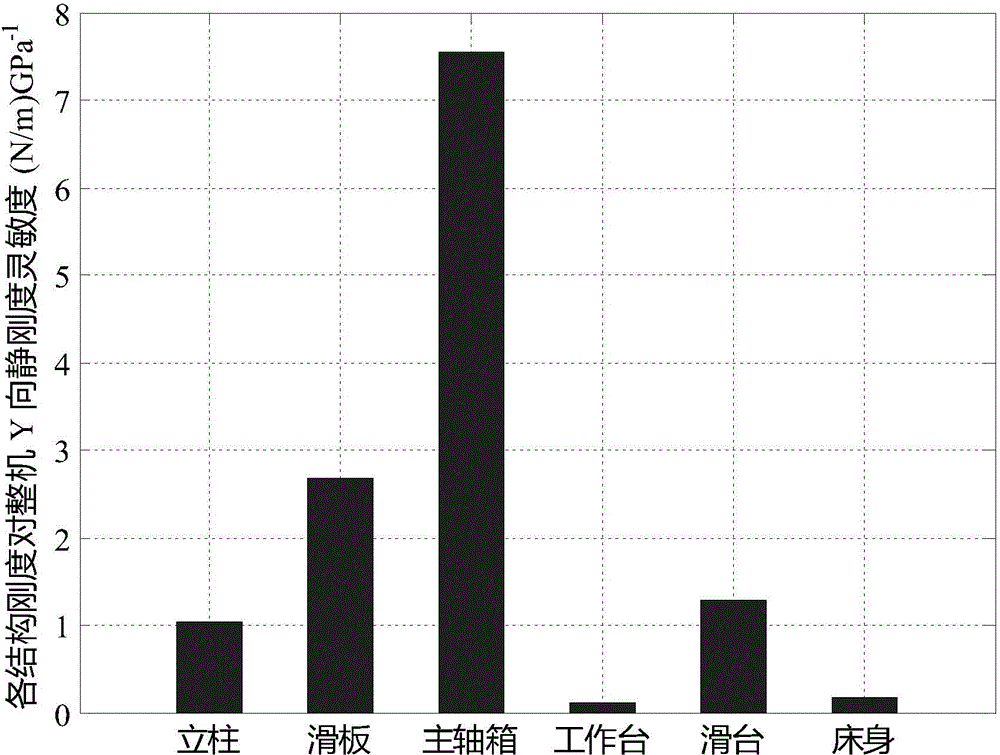

Optimized design method of overall static rigidity of machine

InactiveCN104156501AIncrease the static stiffness value at the end of the machineReduce stress deformationSpecial data processing applicationsReduced modelElement model

The invention discloses an optimized design method of overall static rigidity of a machine. The method includes the steps of establishing a simple machine model by Pro / E software; importing the simple machine model into SAMCEF software to establish a machine finite element model; parameterizing rigidity features of large structures of the machine to determine design parameters and a design space; selecting test sample points for finite element analysis by a central composite experiment design method; subjecting the test sample points to finite element analysis to obtain machine static rigidity response values of the test sample points; establishing a response surface model for large structure rigidity feature parameters and machine static rigidity; analyzing sensitivities of large structure rigidities to the machine static rigidity so as to determine a static rigidity weak link, and performing optimized design. The optimized design method of overall static rigidity of the machine has the advantages that the sensitivities of the structures of the machine to the machine static rigidity are effectively determined, the weak link restricting the improvement of the machine static rigidity is effectively found, and accordingly important basis for the optimized design of machine structure is provided to guide designers to optimally design the weak large structures of the machine.

Owner:TIANJIN UNIV

Linear accelerator

InactiveUS6376990B1Good flexibilityGreat flexibility.TheTravelling-wave tubesElectric arc lampsElectrical resistance and conductanceRelative magnitude

This device allows the variation of the coupling between two points in an RF circuit in a very simple way while maintaining the RF phase relationship and varying the relative magnitude of the RF fields. The device is characterized by a simple mechanical control of coupling value, that has negligible effect on the phase shift across the device. This is achieved by the simple rotation of the polarisation of a TE111 mode inside a cylindrical cavity. Such a device does not contain resistive elements, and the sliding mechanical surfaces are free from high RF currents. This device finds an application in standing wave linear accelerators, where it is desirable to vary the relative RF field in one set of cavities with respect to another, in order that the accelerator can operate successfully over a wide range of energies.

Owner:ELEKTA AB

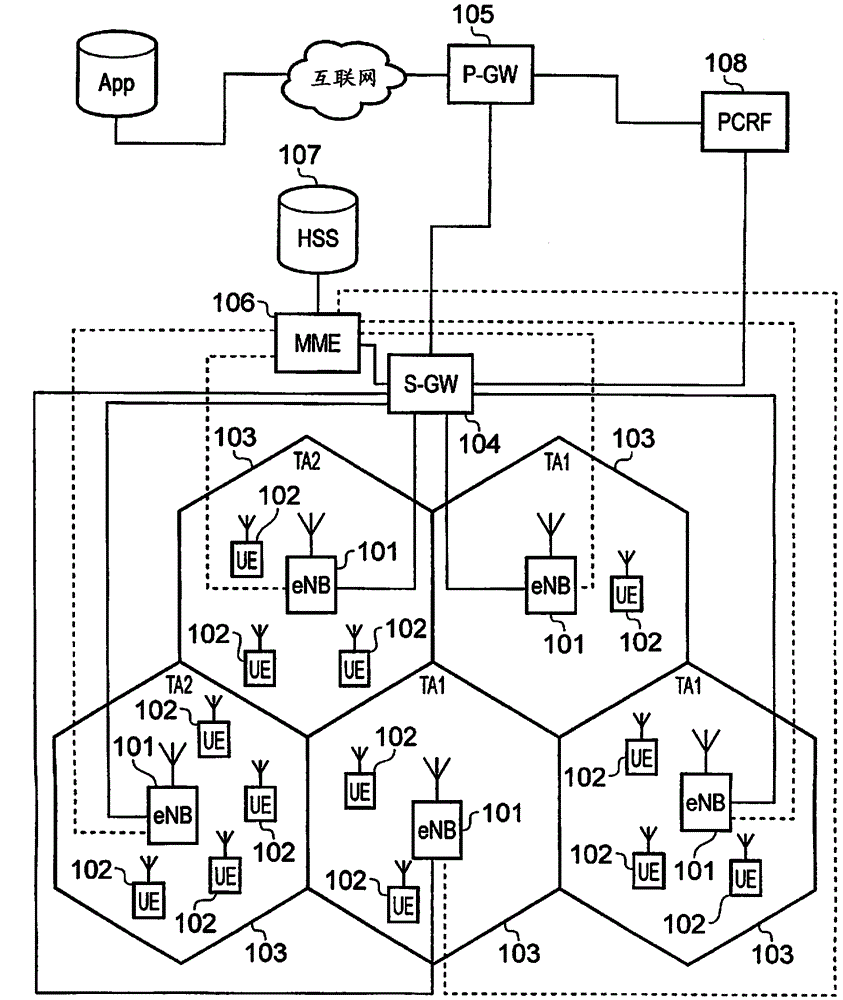

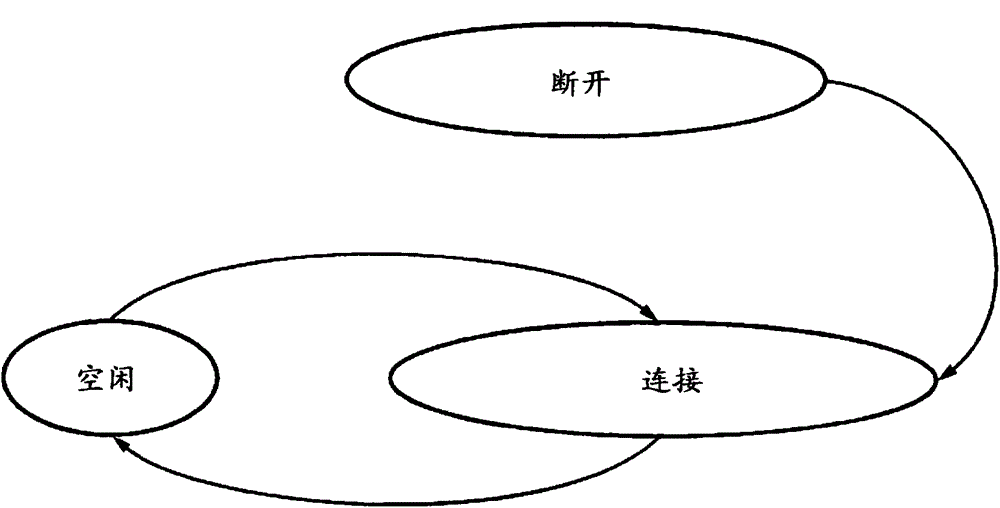

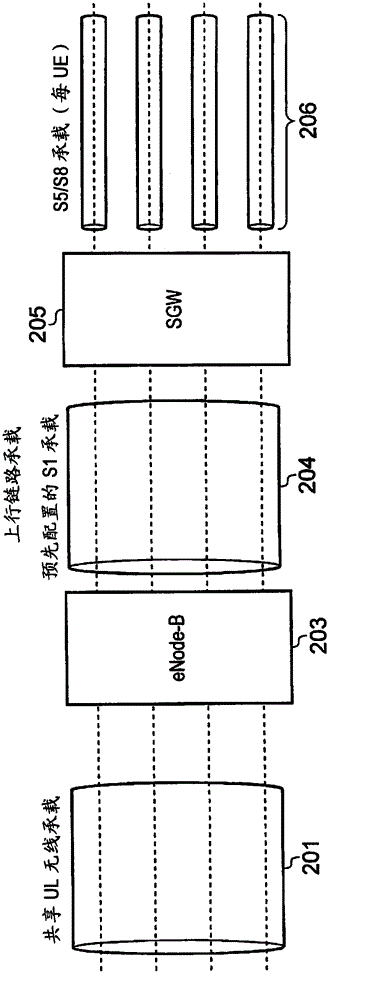

Mobile communications network and method

InactiveCN103563440AReduce the numberNetwork traffic/resource managementConnection managementQuality of serviceRadio networks

Owner:INTELLECTUAL VENTURES HOLDING 81 LLC

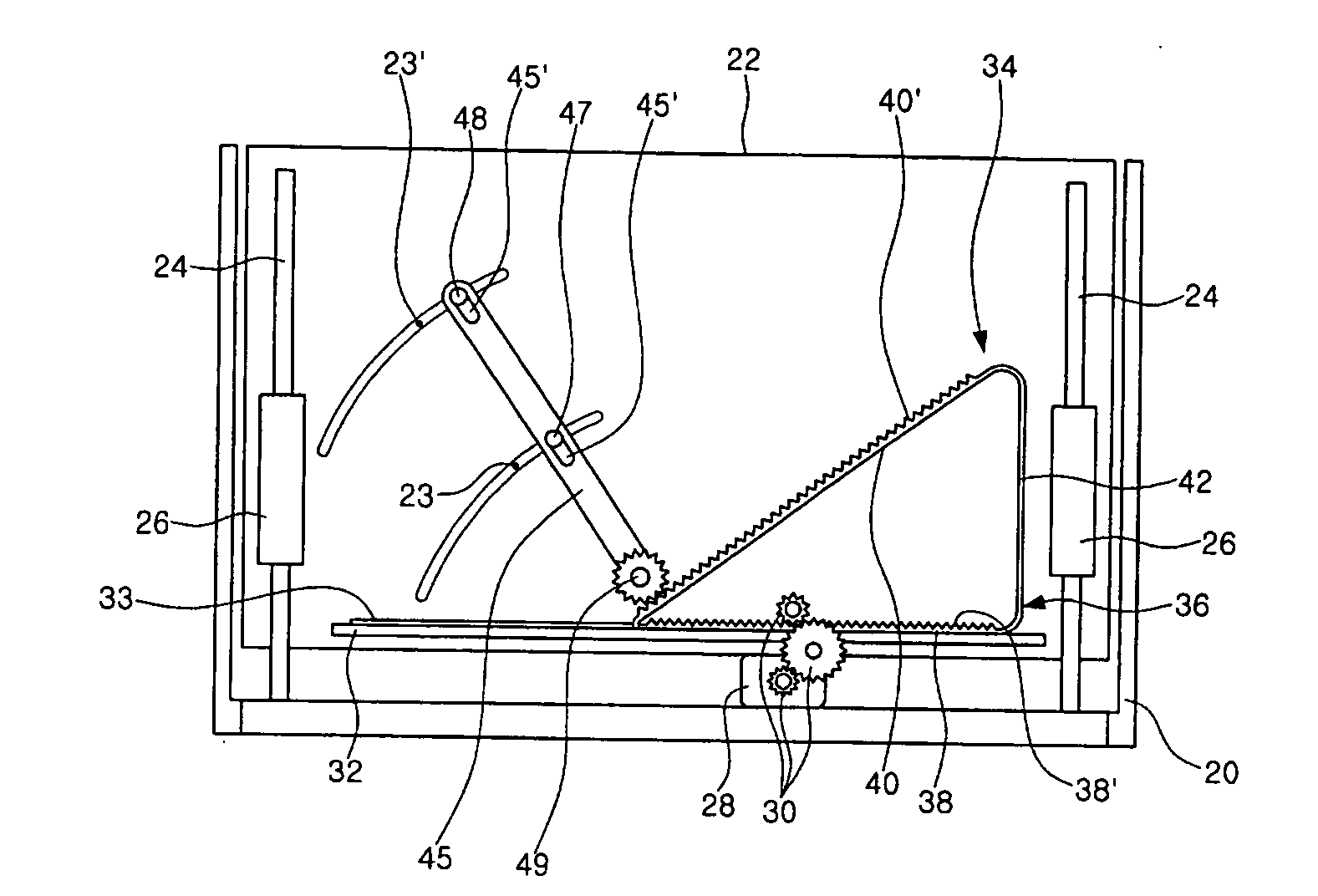

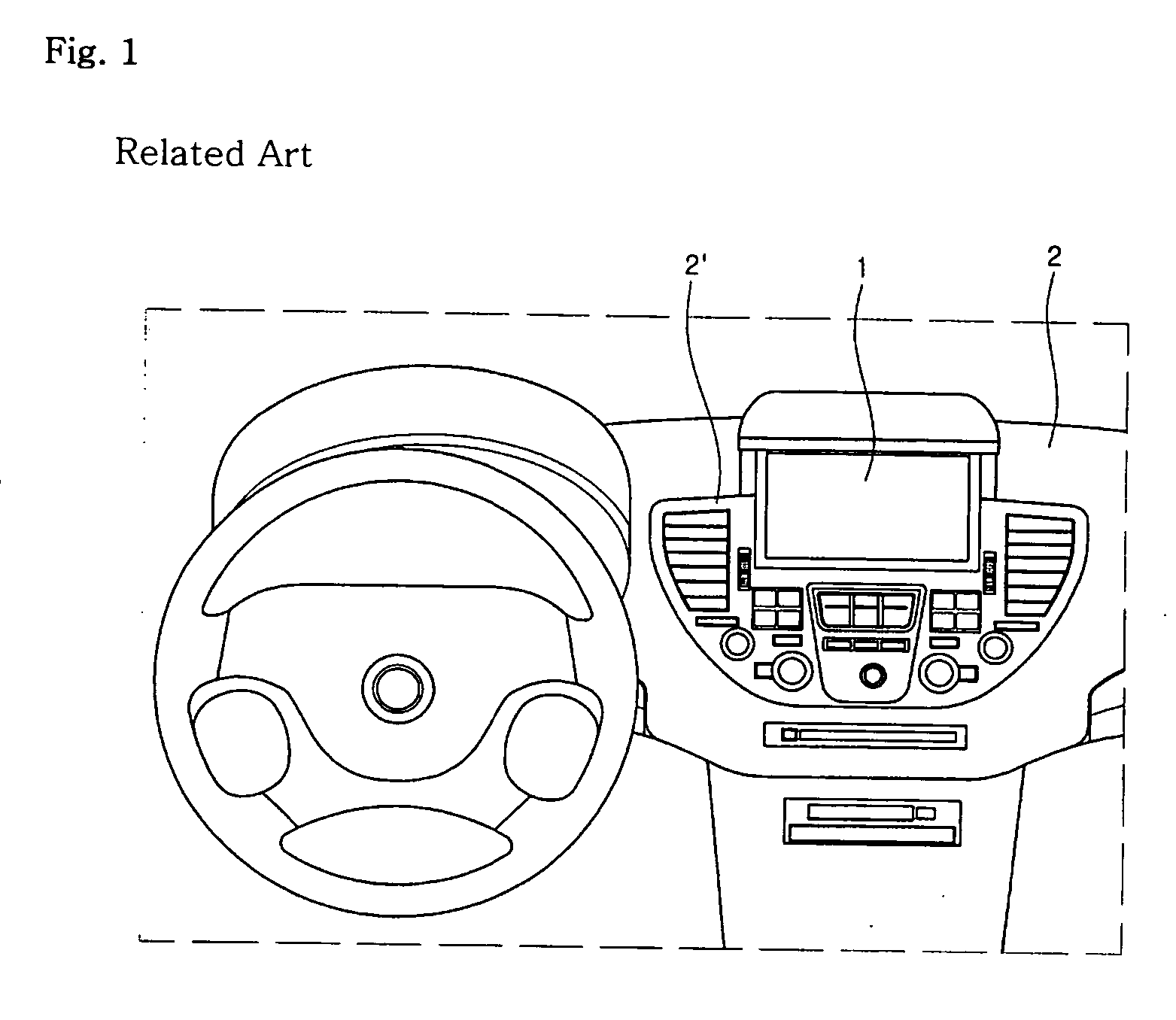

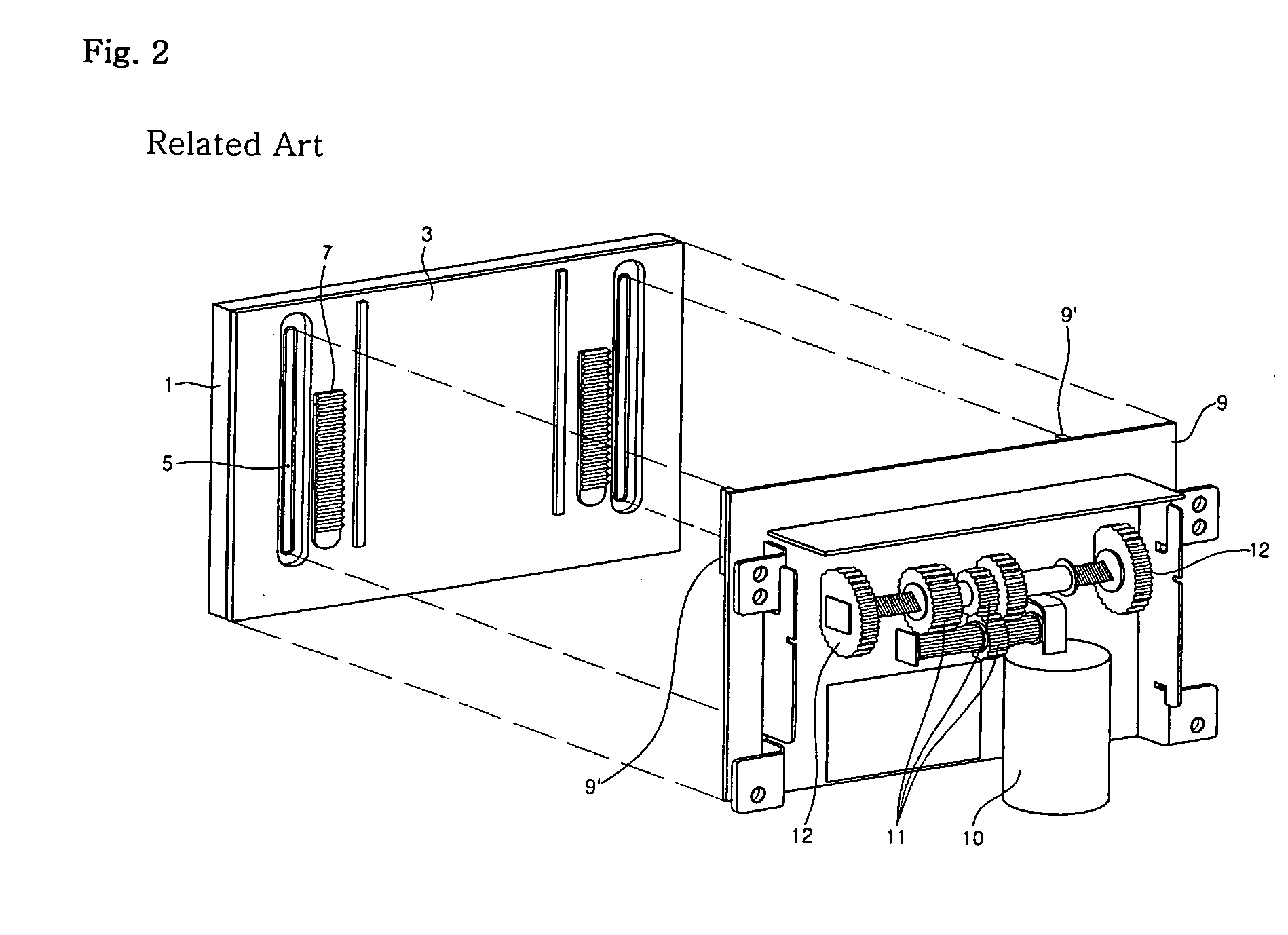

Display device for vehicle

InactiveUS20060108900A1Static indicating devicesDigital data processing detailsDisplay deviceEmbedded system

Embodiments of a display device for a vehicle and methods for the same can adjust operation velocity and stroke of a monitor by changing simple mechanical configurations of a driving apparatus for the monitor in the display device. The display device for a vehicle can include a monitor in a case for displaying an image on its front surface and a movable unit that can be installed to the case to reciprocally move the monitor. A control lever can be installed between the monitor and the movable unit to be inclined at a predetermined angle and configured to cooperate with the movable unit. Therefore, it is possible to provide an inexpensive display device capable of satisfying a variety of users' needs and design requirements.

Owner:LG ELECTRONICS INC

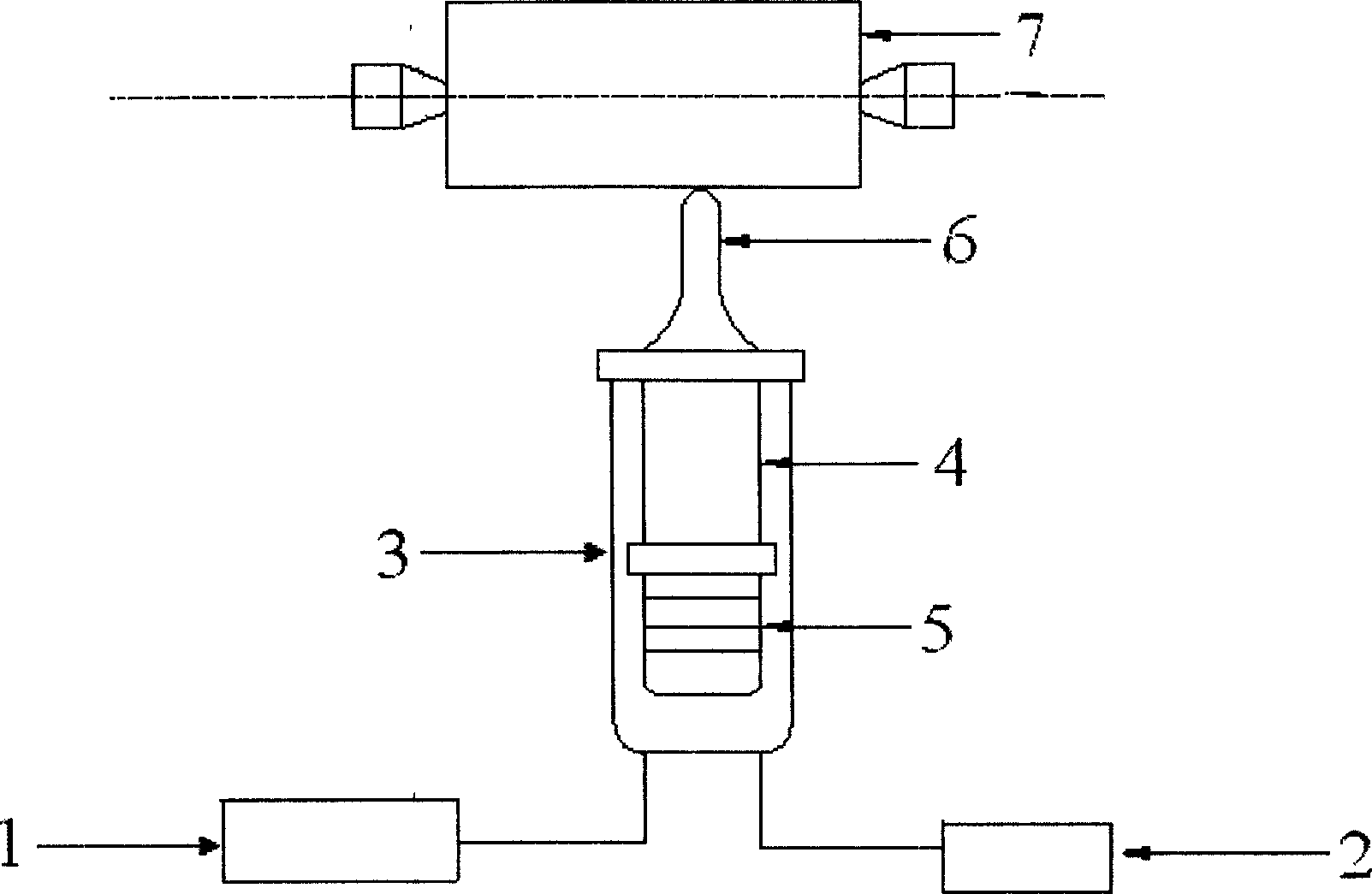

Processing method and equipment of metal material surface nanometer layer

The present invention discloses machining process of forming nanometer layer on the surface of metal material. The machining process includes chucking the nanometer machining head of the ultrasonic metal surface nanometer processing apparatus onto the tool carrier of lathe; and turning on the power and the control switches in the ultrasonic generator and the executor and regulating the machining parameter to machine the metal material. The said parameters includes the main lathe shaft rotation speed of 50-1200 rpm, the feeding amount of the nanometer machining head in 0.02-0.5 mm / r, the linear machining rate of 1-600 mm / min, the reciprocating time number of 1-10 and the output amplitude of the ultrasonic surface machining head in 5-50 microns. The present invention has simple machining condition, high machining quality, less pollution and other advantages.

Owner:天津益普科技发展有限公司

On-line repair method and special combined machine tool thereof

InactiveCN1454744AStable cutting processGuaranteed uptimeOther manufacturing equipments/toolsLarge fixed membersFrequency conversionEngineering

The present invention provides a kind of special combination machine tool repairing the large-scale unmovable overhead device; it possesses all kinds of function such as boring, milling and cutting and belongs to the machining device field. According to different machining object the present invention can assemble and unassemble different machine tool, many functions can be piled up. The machine tool structure adopts floor milling machine frame, and its circuit adopts one-drive-two frequency conversion control technique, to fit milling, boring and cutting device together. The machine tool can quickly move toward three-dimensional direction and lock any direction to make machining steady going. Moreover it has highly precision and simple machine structure.

Owner:NANJING NANGANG IND DEV CO LTD

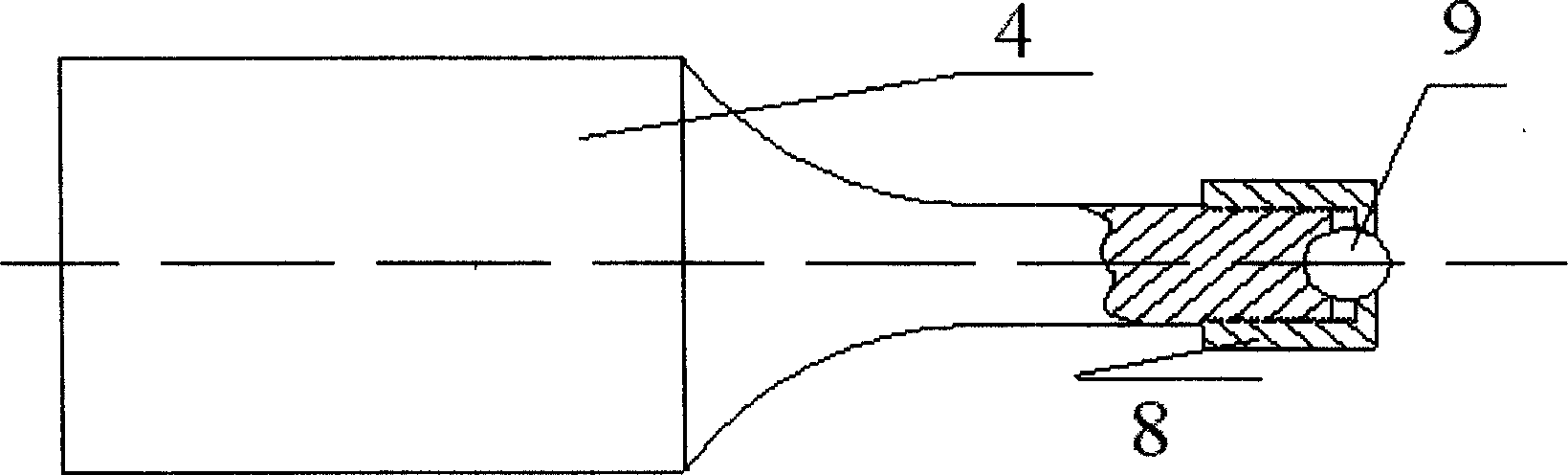

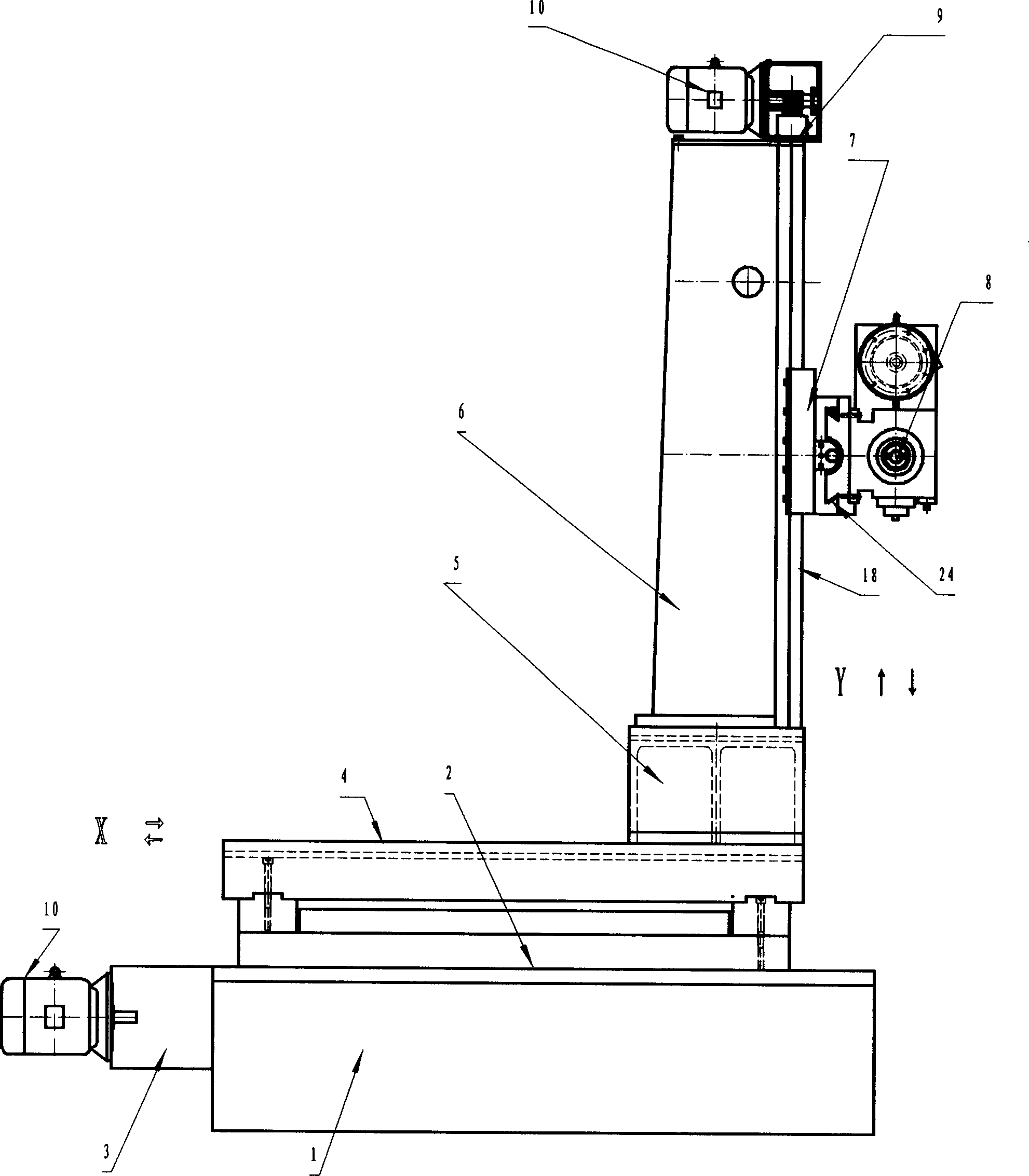

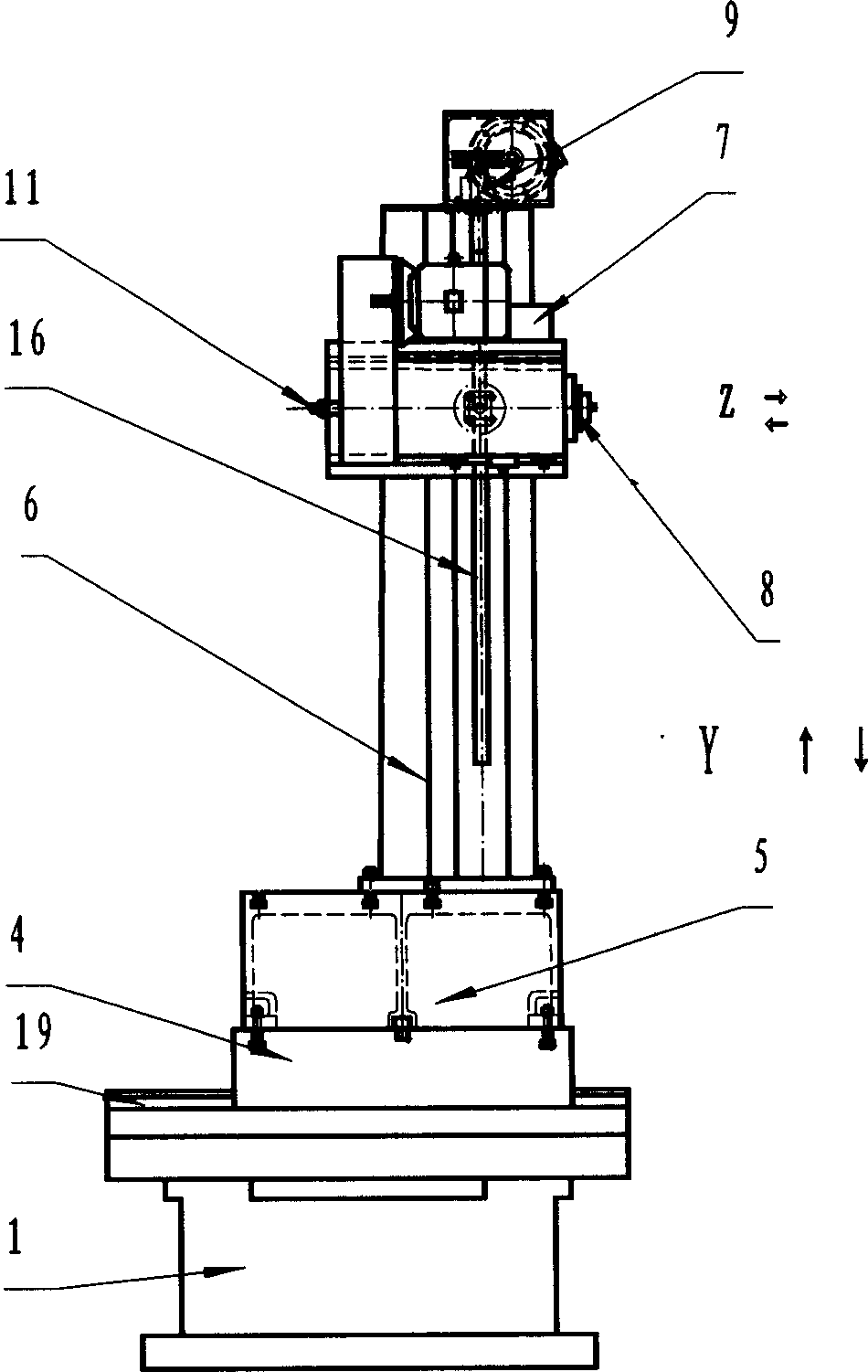

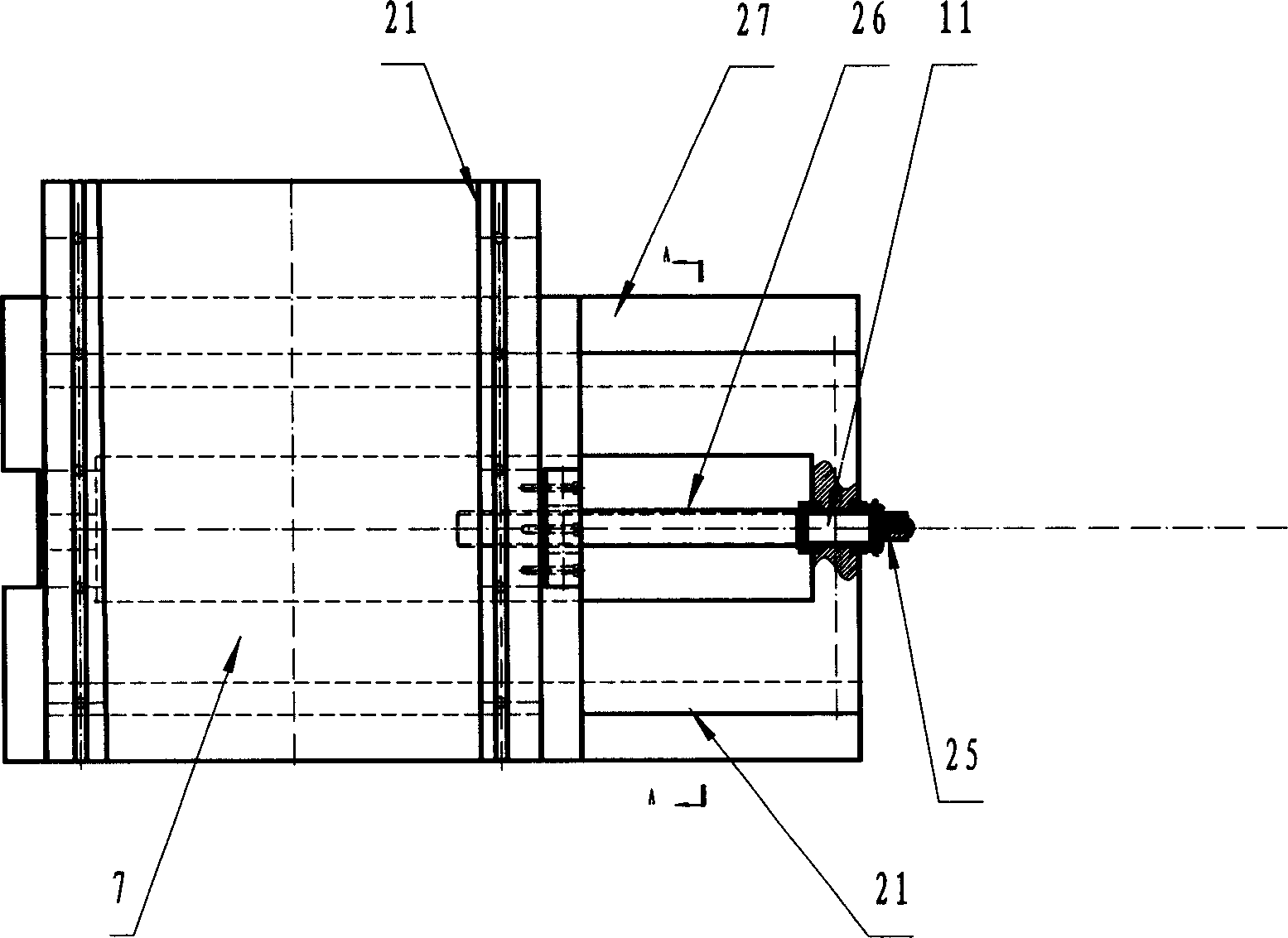

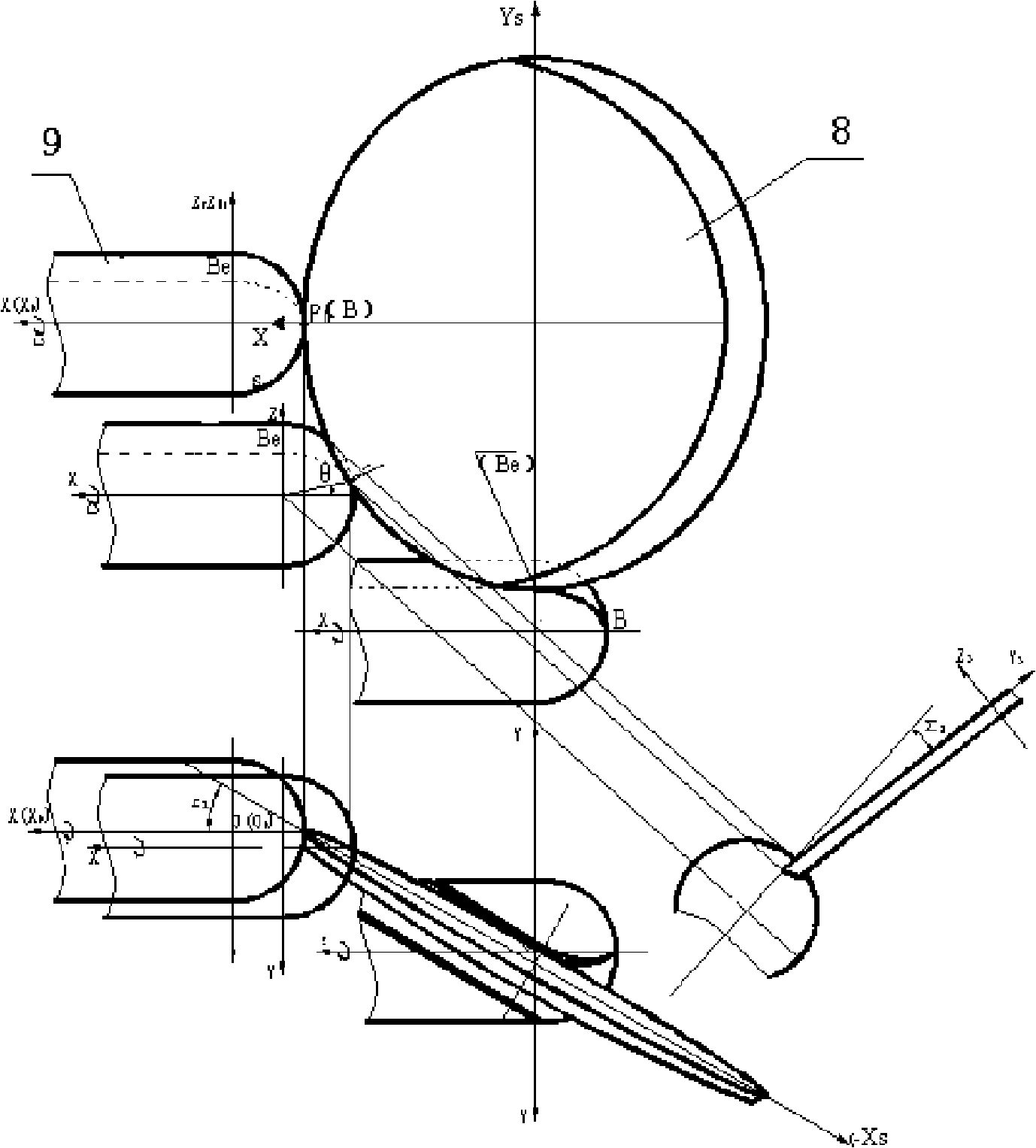

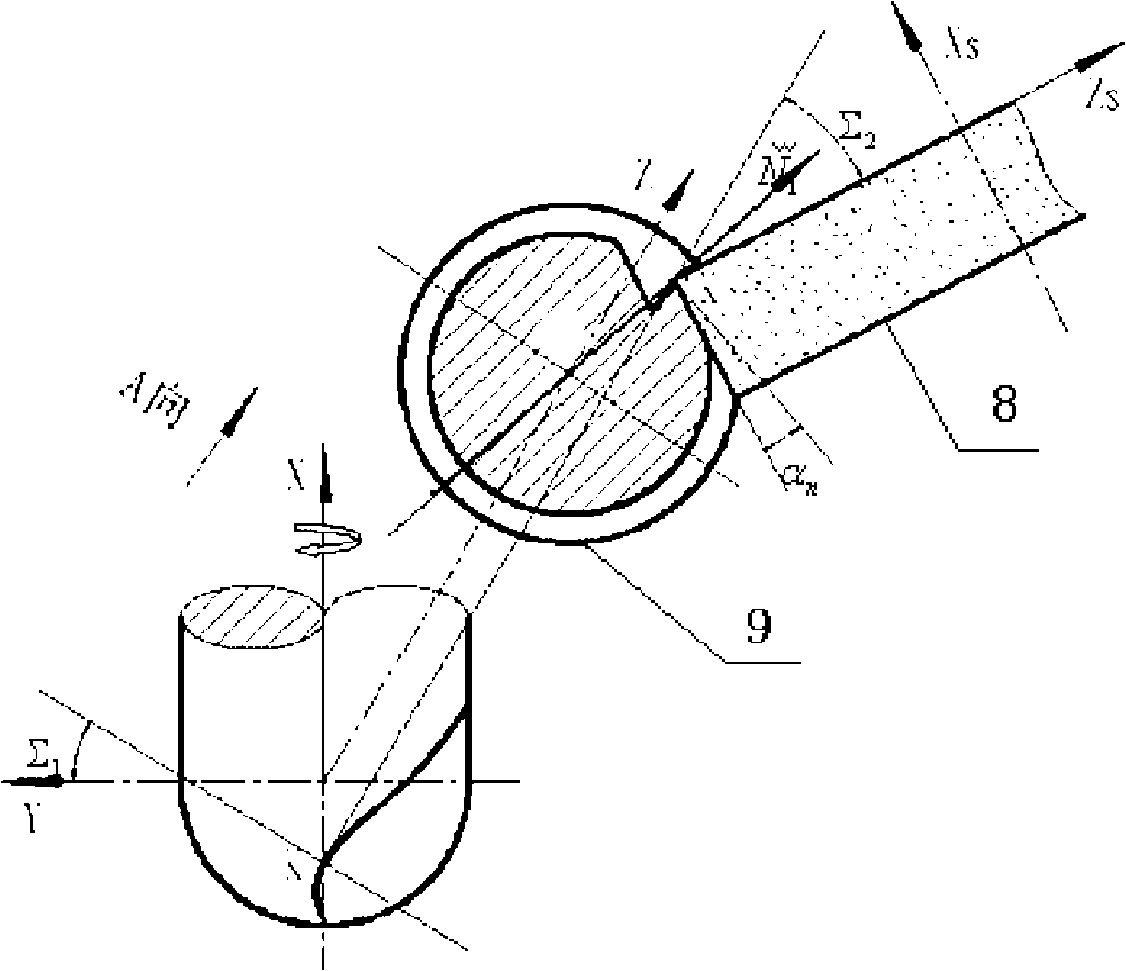

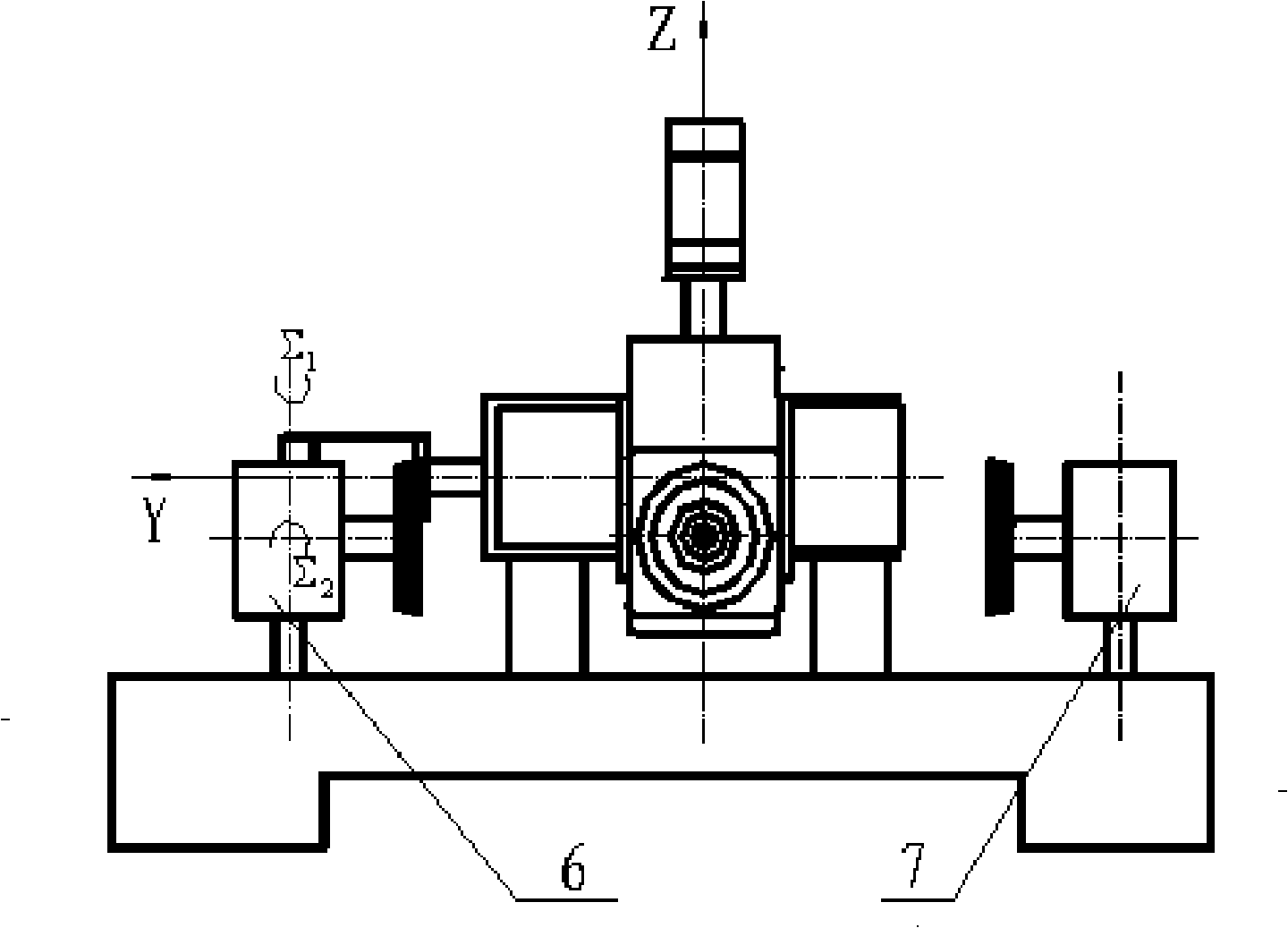

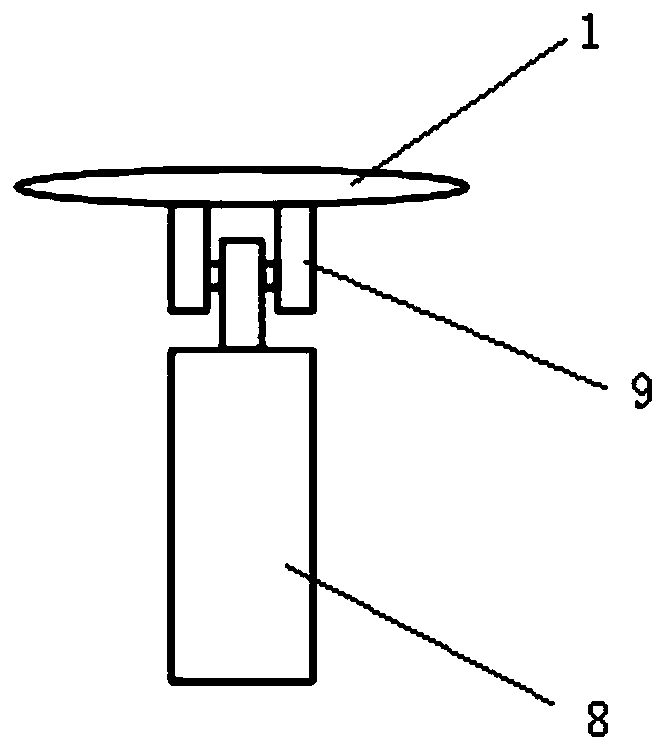

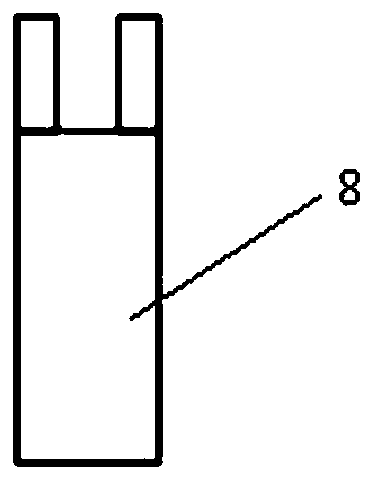

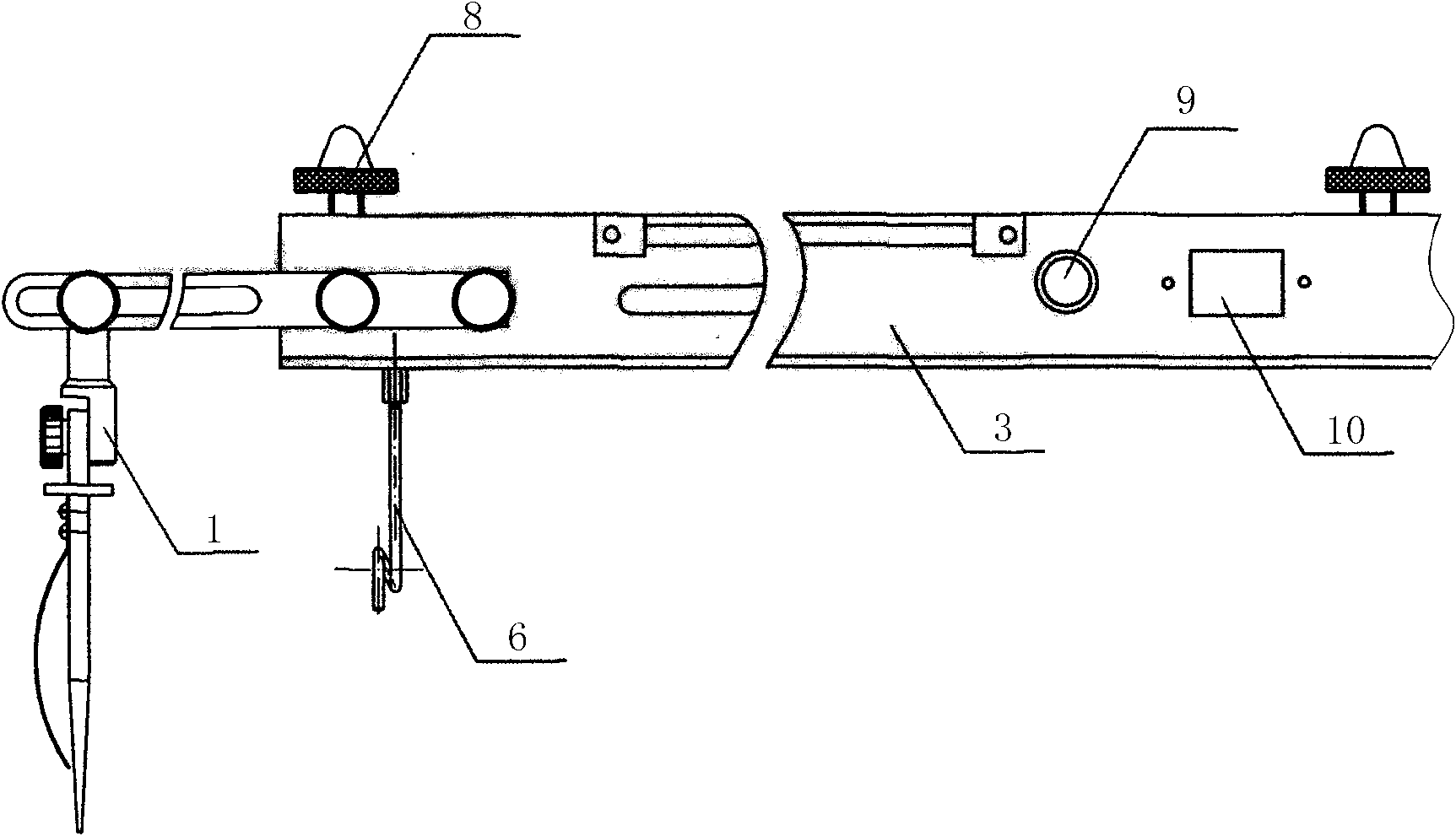

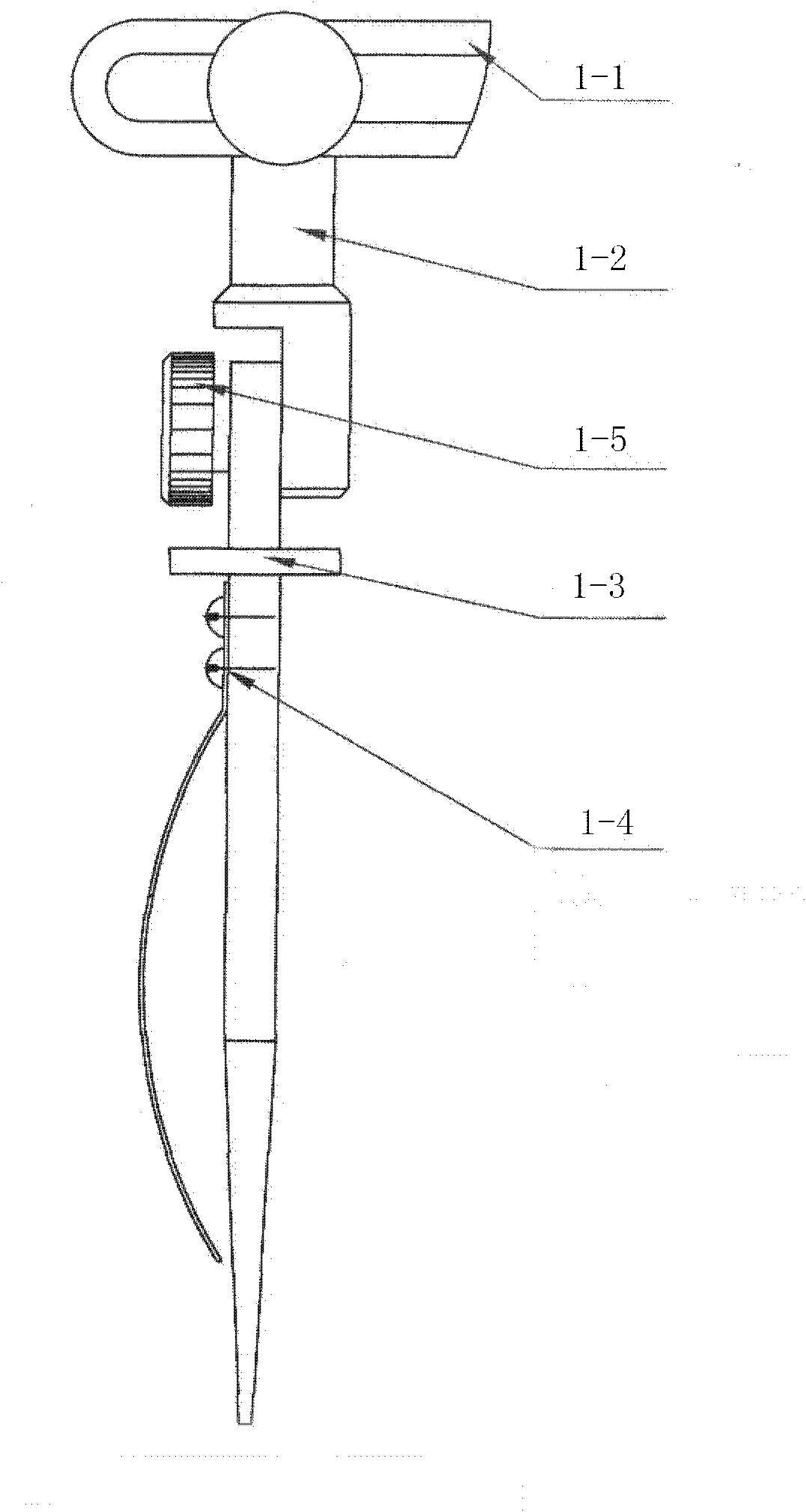

Abrasive machininging method for ball end mill and four-shaft linkage equipment for abrasive machininging

The invention discloses a method for grinding and machining a ball-nose end milling cutter and a four-axis coordinated grinding and machining device. In the grinding process, on the one hand the device leads a grinding wheel (8) to do rotary motion around a spindle and leads the ball-nose end milling cutter (9) to rotate around an axis X, on the other hand, the device leads the ball-nose end milling cutter (9) to translate along the axis X, at the same time, the device leads the ball-nose end milling cutter (9) to move along a horizontal axis Y which is vertical to the axis X and to move along an axis Z which is vertical to the axis X and the axis Y, thus forming the four-axis coordinated grinding and machining. The invention can clamp and grind as well as machine the ball-nose front knife surface and the circum front knife surface of the ball-nose end milling cutter in one time, thus realizing the grinding of all front and back knife surfaces on one special purpose machine tool. Compared with a five-axis coordinated machining center, one rotation axis is reduced in the grinding device of the invention, thus leading to simpler machine tool structure, ensuring precision among moving parts and effectively reducing the equipment cost.

Owner:GUIZHOU UNIV

Method for mounting prefabricated members of roof or floor in place and mounting equipment

Owner:SHENZHEN CONSTR GRP

Method for machining aluminum alloy thin-wall cabin

InactiveCN102229048AImprove surface qualityMeet sealing requirementsOther manufacturing equipments/toolsNumerical controlMilling cutter

The invention discloses a method for machining an aluminum alloy thin-wall cabin. A position of a milling tool is changed by modifying a machine tool, and in the process of machining a long cylindrical thin-wall part, milling is replaced by turning, and complex thin-wall parts are machined in a turning and milling combined mode. Some large-size sealing grooves of the cabin are machined by a milling method, a high-quality key groove milling tool is adopted, numerical control programming is performed and a circular trace is formed; the machining method has simple machining processes, product yield is high and the products have stable quality; and in the machining process, a spindle rotating speed, feeding amount and other cutting parameters are required strictly, so high surface quality can be guaranteed, and the sealing requirement is met.

Owner:WUJIANG TIANLONG MACHINERY

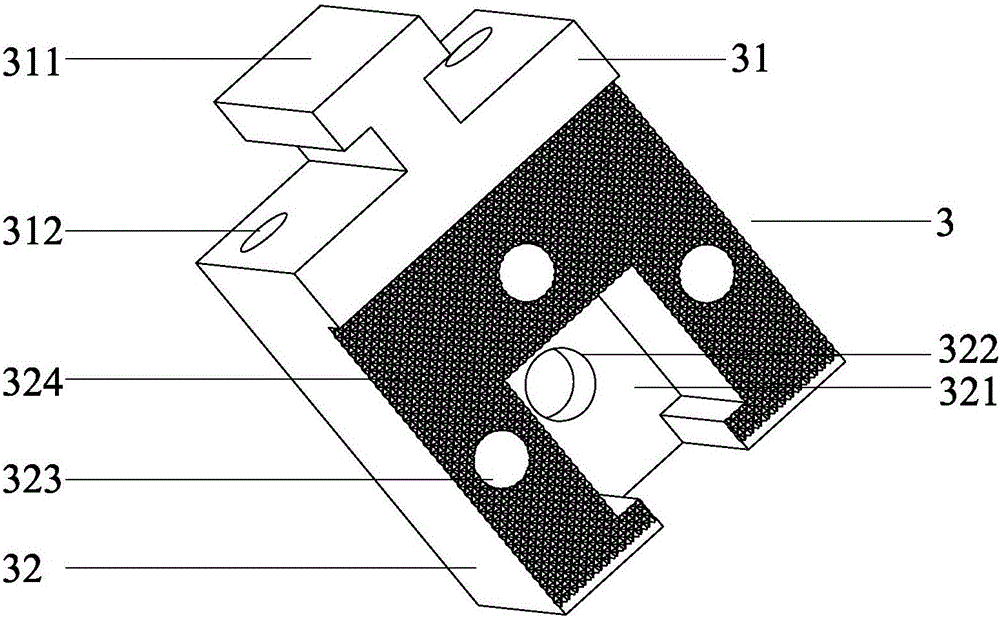

Metal plate pulling-pressing experiment device in pure mechanical structure form

InactiveCN105928785APrevent bucklingSimple structureMaterial strength using tensile/compressive forcesEngineeringHydraulic equipment

The invention discloses a metal plate pulling-pressing experiment device in a pure mechanical structure form. The device comprises an upper connection rod, a locking nut, an upper clamp block (I), an upper clamp block (II), a lateral clamping plate, a lower clamp block (I), a lower clamp block (II), guide rollers, a clamp base plate, and a lower connection base plate, and is characterized in that two sides of a test piece are clamped by the lateral clamping plate, the upper end of the test piece is clamped by the upper clamp block (I) and the upper clamp block (II), then the upper clamp block (I) and the upper clamp block (II) are connected by the upper connection rod, through the locking nut, the upper connection rod is locked on a sensor of a tensile test machine, two side of the lower end of the test piece are provided with a guide roller respectively, the lower end of the test piece is clamped by the lower clamp block (I) and the lower clamp block (II), and then the lower clamp block (I) and the lower clamp block (II) are fixed by the clamp base plate. Through simple mechanical principle and mould technology, pricy hydraulic equipment and air pressure equipment are not needed, the structure is simple, the processing is easy, the experiment cost is saved, the operation is convenient, and the experiment results are precise.

Owner:DALIAN UNIV OF TECH

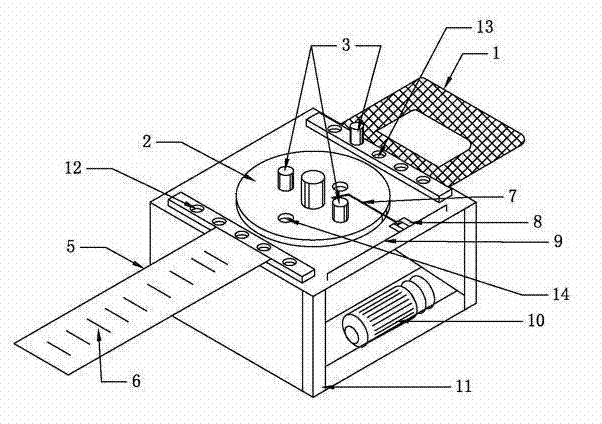

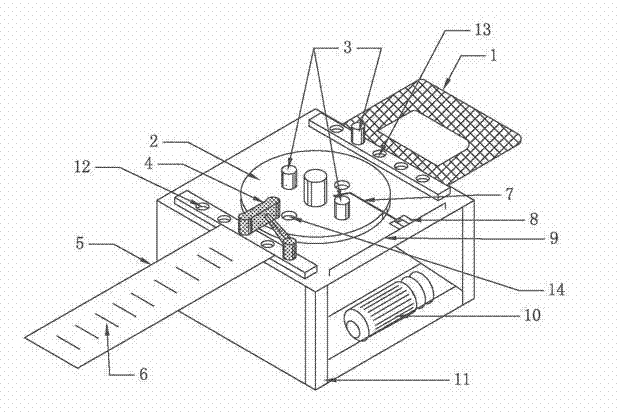

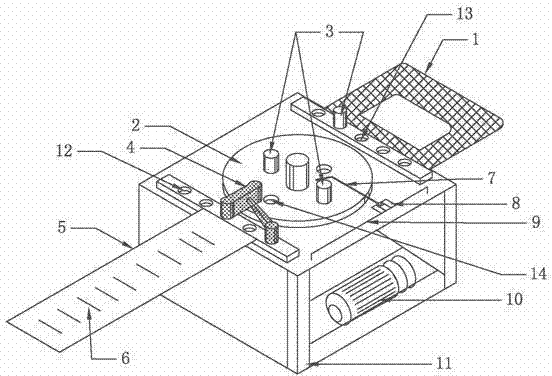

Steel bar bending machine

The invention discloses a steel bar bending machine, and relates to the field of building construction. The steel bar bending machine comprises a machine body main frame (11), a motor (10), a reducer, a bending turntable (2), a console (1), and bending columns which are matched with turntable bending column insertion holes (14) and front platform bending column insertion holes (13), wherein the motor (10) is connected with the bending turntable (2) on the machine body main frame (11) through the reducer; the console is connected to the upper edge of the machine body main frame (11); the bending turntable (2) is provided with the turntable bending column insertion holes (14); and the front platform bending column insertion holes (13) are formed at the positions, which are close to the console, on the upper surface of the machine body main frame (11). The steel bar bending machine has simple machine design, is flexible, applicable and convenient to operate, greatly improves work efficiency, saves the production cost of square piles, and improves the industrial production efficiency.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

Method for preparing micro-fluidic chip

InactiveCN102218595AGood optical processing performanceGood chemical stabilityLaser beam welding apparatusMachine partsGlass chip

The invention relates to a method for preparing a micro-fluidic chip. A glass substrate sheet is ablated by a femto-second laser; during the machining process, a cleaning solution always carries out effective cleaning on a machining part inside the sheet; heat treatment is carried out on the glass substrate sheet that is machined by the femto-second laser; after the heat treatment, the diameter of a micro-fluidic passage and the dimension of a liquid bath in the sheet are reduced; the internal surfaces of the micro-fluidic passage and the liquid bath are smooth; a PDMS (Polydimethylsiloxane) sheet is selected as a connecting body; the position on the PDMS sheet corresponding to the longitudinal passage opening position of a micro-fluidic glass chip is bored; and subsequently the PDMS sheet is bonded with the micro-fluidic glass chip, thereby obtaining the micro-fluidic chip. The method has simple machining process and ensures that the laser can carry out continuously stable ablation on substration material; and the integrated micro-fluidic chip with complex and multi-layer structures can be prepared in the glass substrate. The prepared micro-fluidic chip has the characteristics of miniaturization and integration, has the functions of separation, reaction and detection, and can be widely applied to the analysis fields.

Owner:HARBIN INST OF TECH AT WEIHAI

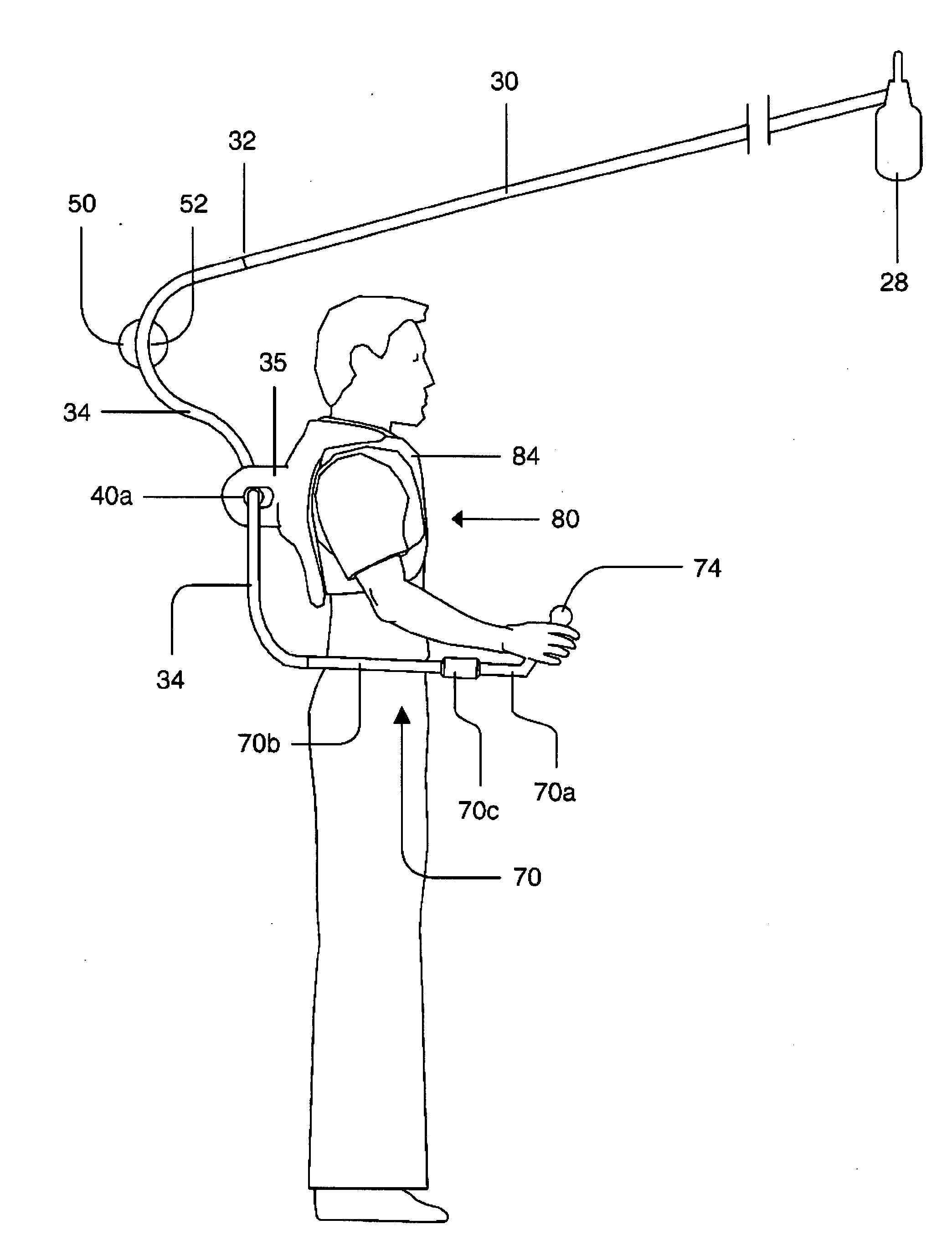

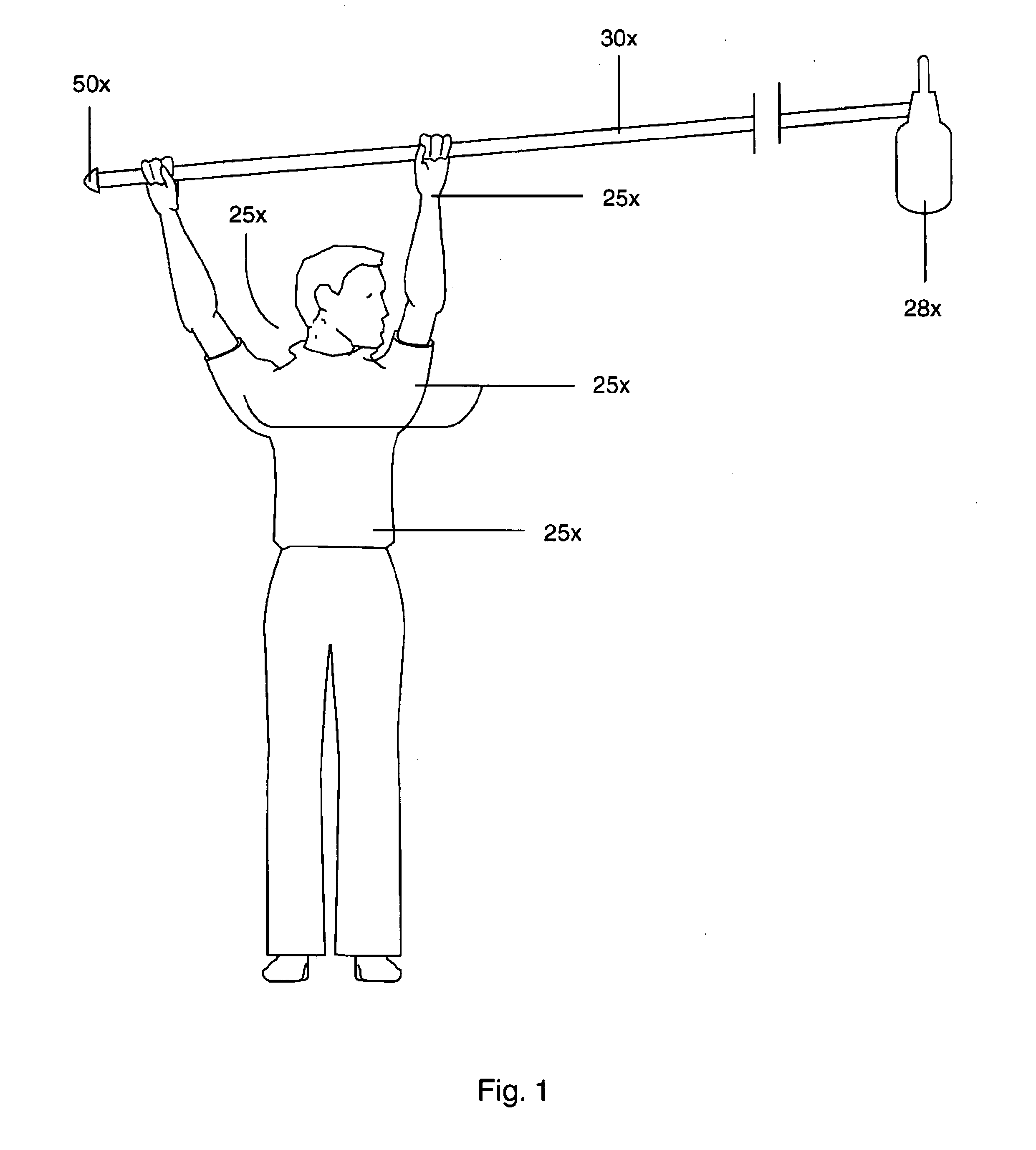

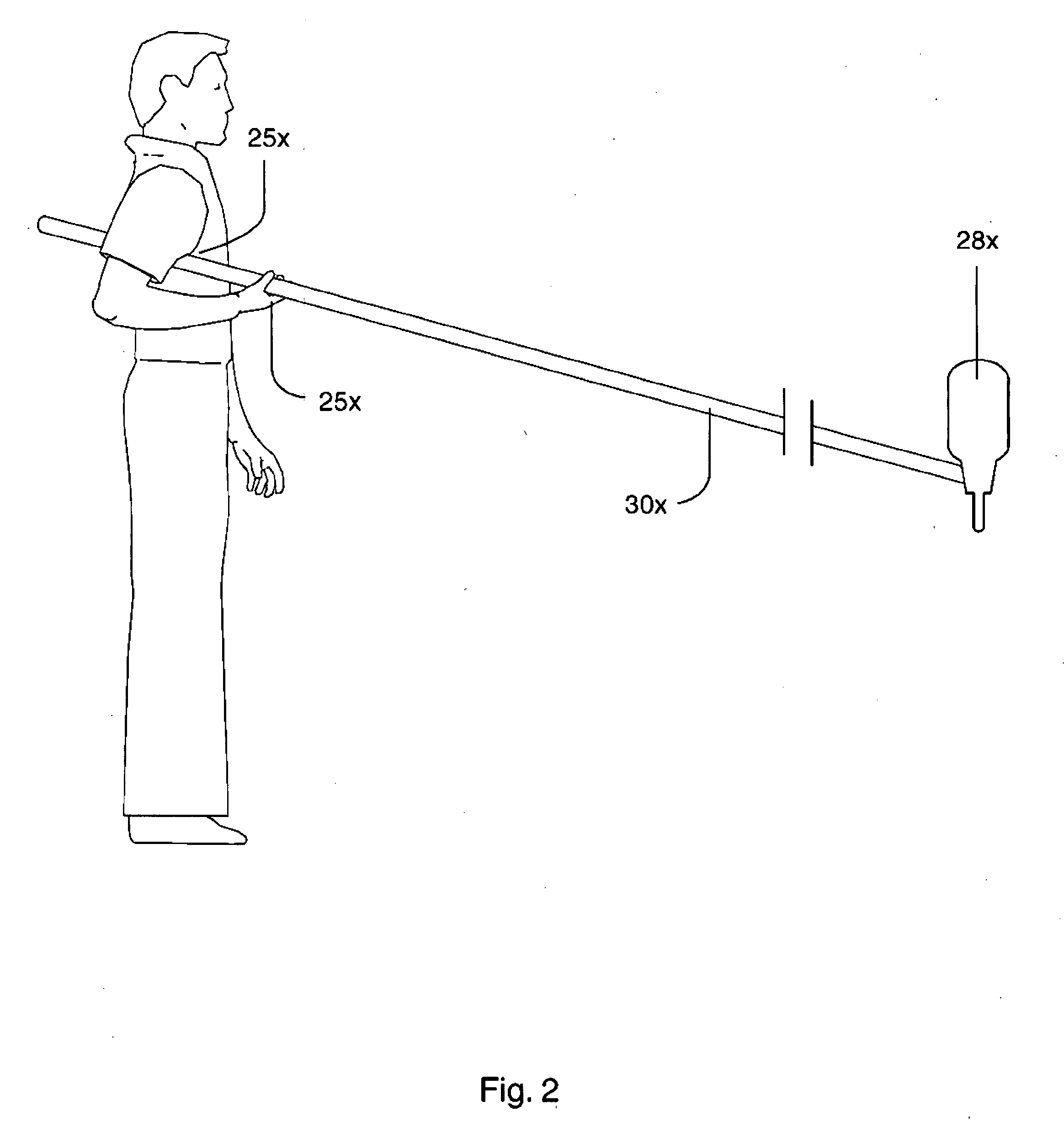

Ergonomic Support and Control Harness for Boom Pole Operation

InactiveUS20080304687A1Comfortable supportSimple designPiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesHand armPosition control

This invention relates generally to film and television production. It is designed to easily control and support a boom pole for long periods of time while allowing the operator to maintain comfortable ergonomic positioning and movement of the head, arm and hands during operation. It achieves this by means of a simple machine. The basic embodiment of the invention consists of five (5) main components. 1. An ergonomically positioned control handle which the operator grips; the boom pole itself (or a holder to which may be fastened in position an existing boom pole), which is rigidly connected to the control handles. 3. A means for pivoting (the fulcrum), or other machine means for transferring force, mounted to a harness, and to which is attached the connecting segment, allowing the boom to rotate and move when force is applied to the control handles. 4. Counterweights which can be fastened to the connecting segment at the farthest point possible opposite the fulcrum from the extended end of the boom pole, and / or mechanisms for fastening such weights. 5. A wearable harness including shoulder straps which can be connected in front, and optionally including a belt around the waist where additional support is required, and to which is mounted, on the back, the pivoting assembly, and the rest of the apparatus. By applying force to the control handle, the operator is able to move the boom pole up and down, side to side, or to rotate it.

Owner:HOWELL EDWARD LAMAR

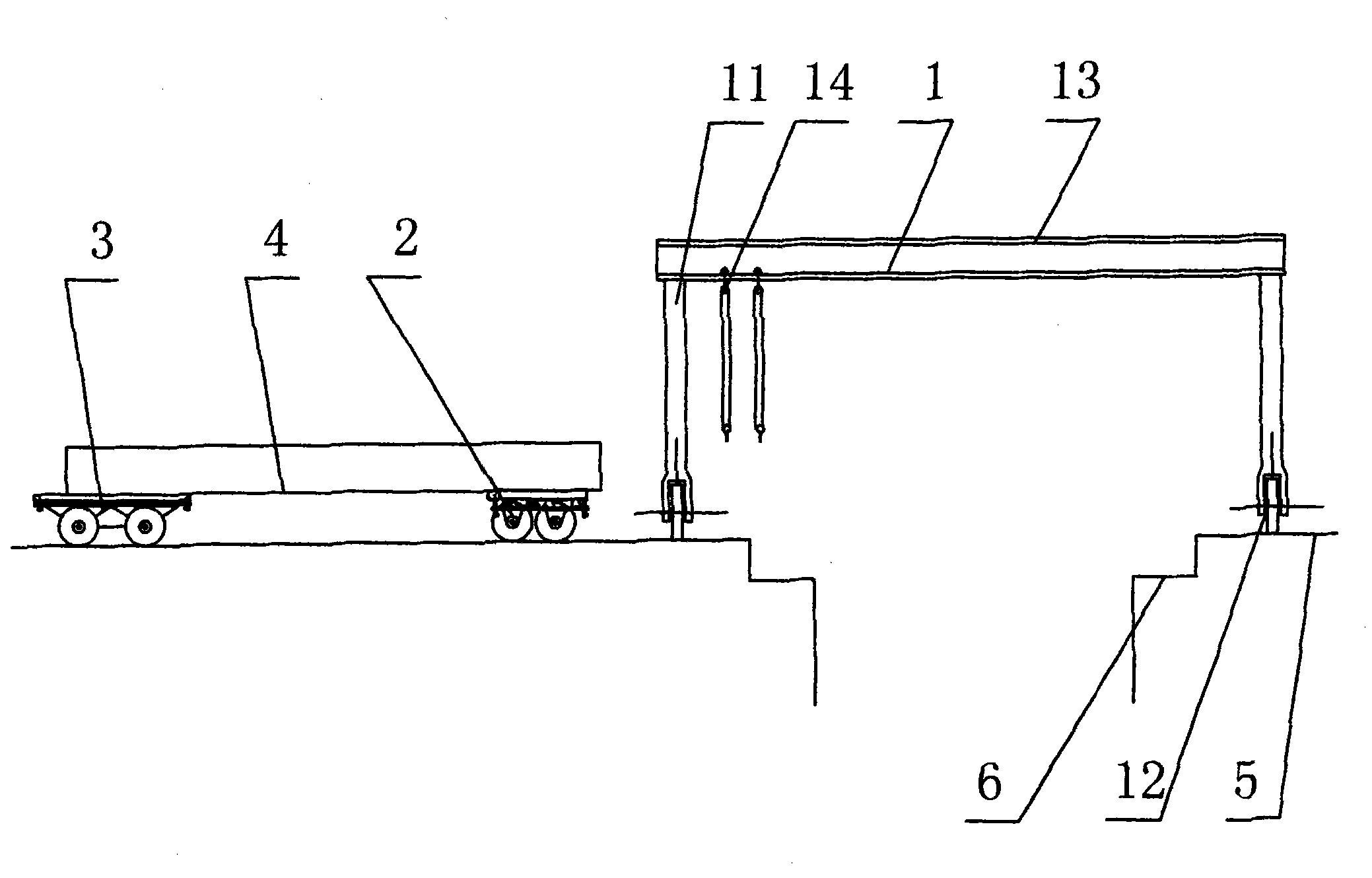

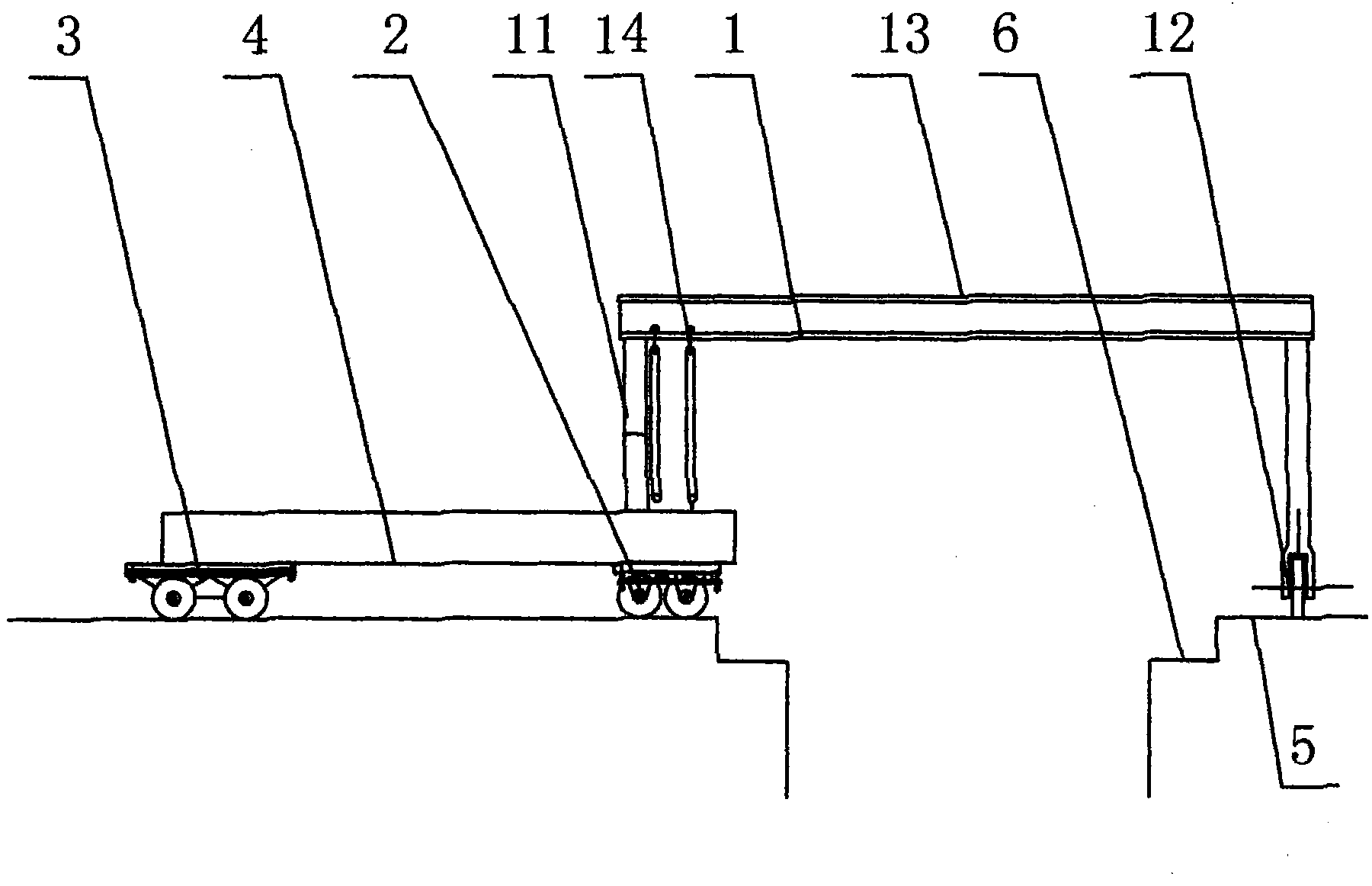

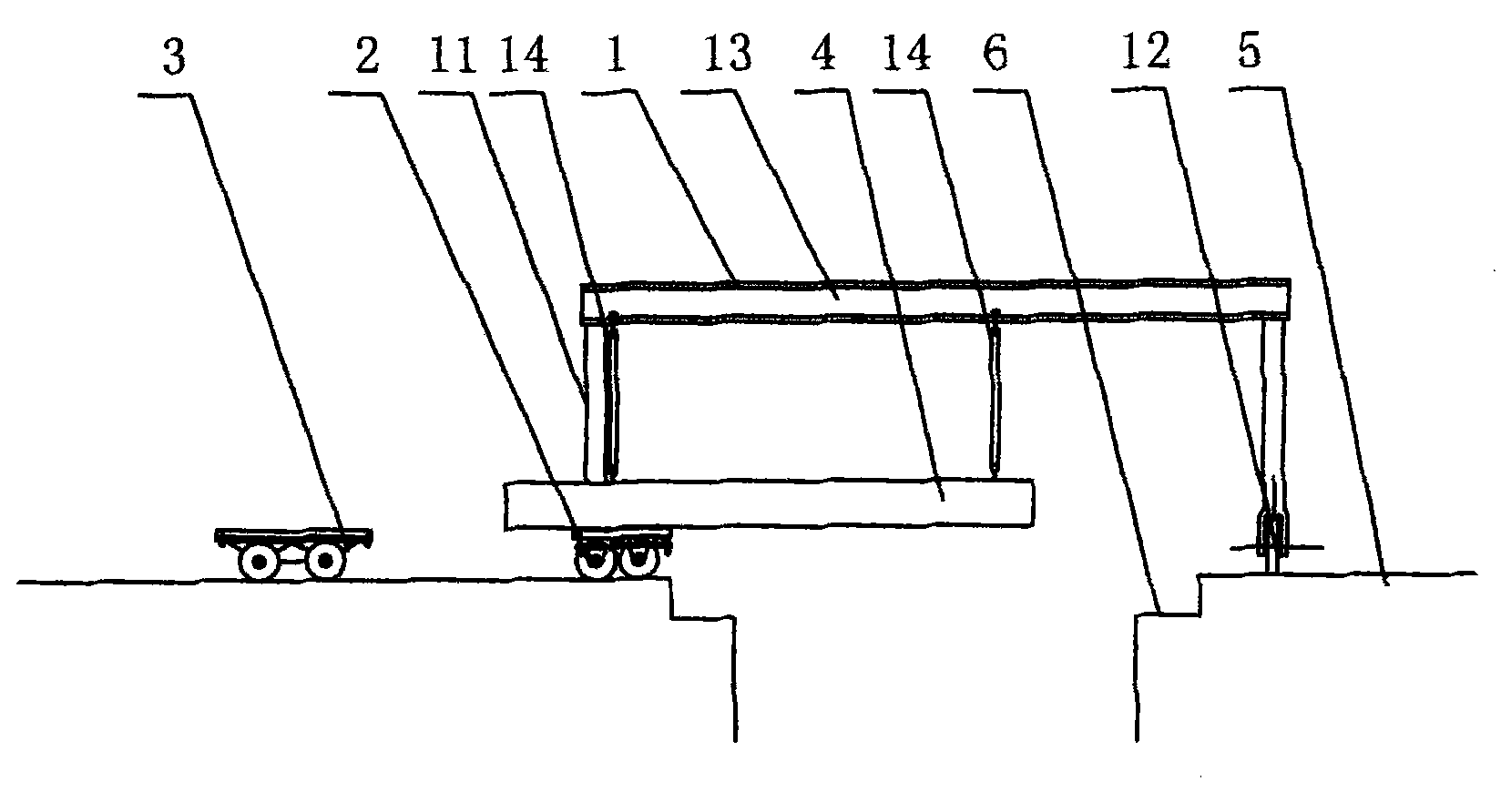

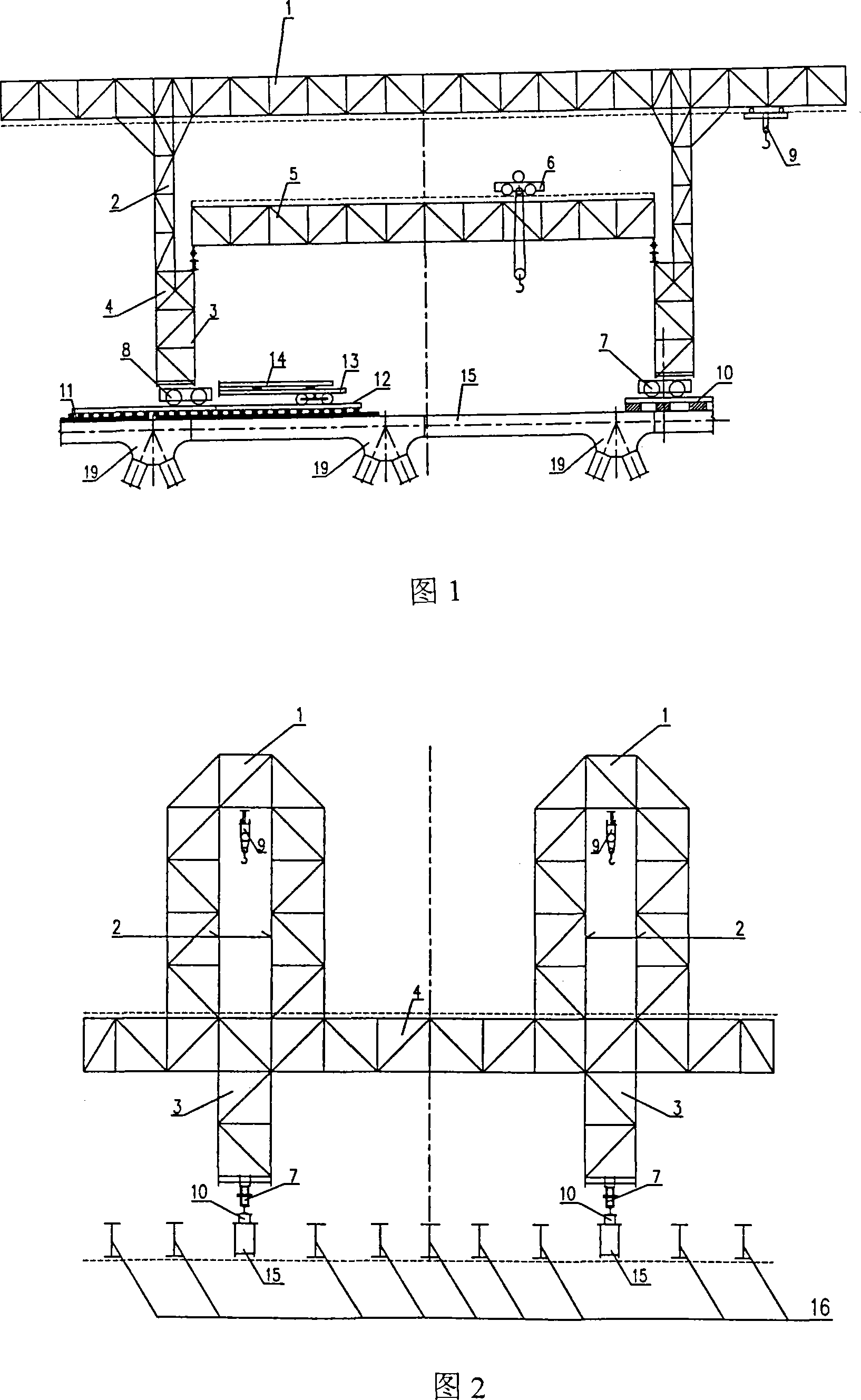

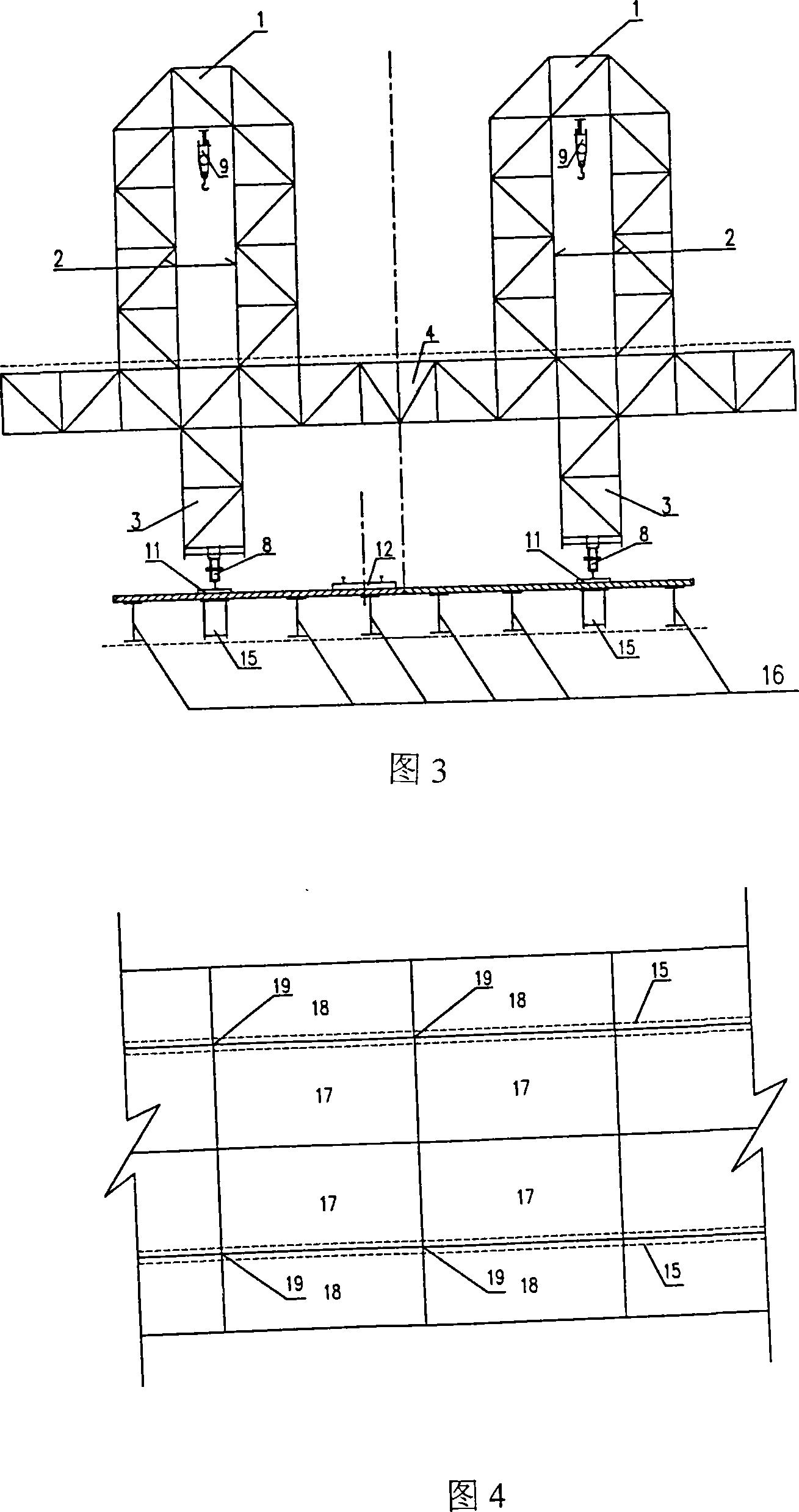

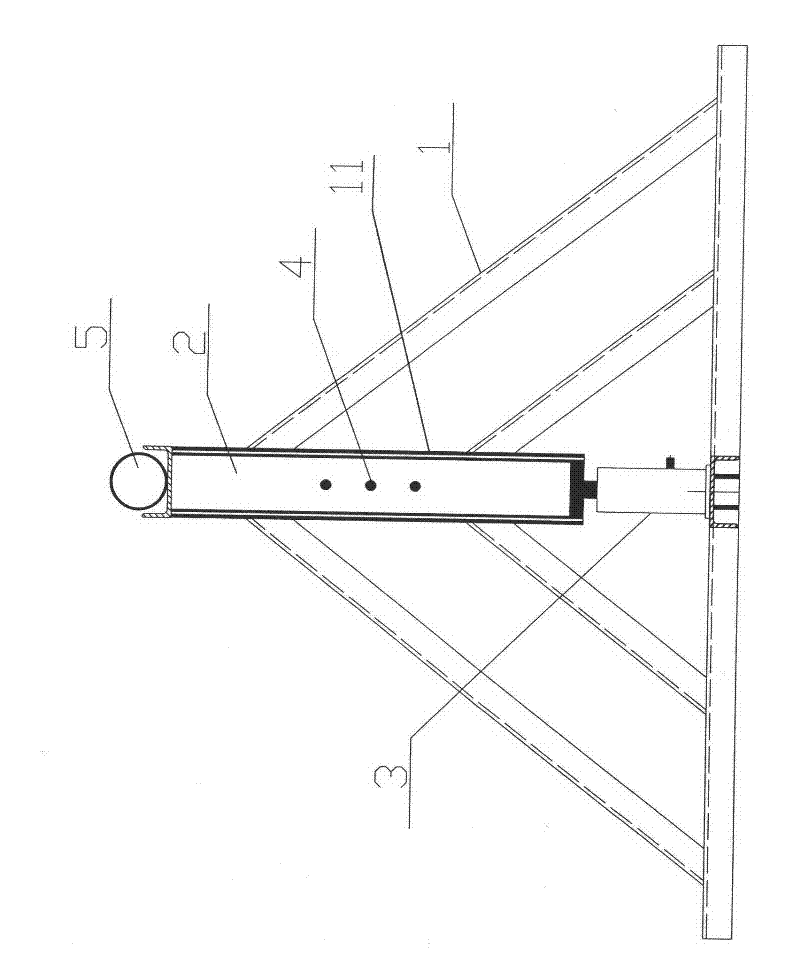

High-altitude framework type simple plate supporting machine

ActiveCN101117794AImprove wind load resistanceAssembly time is shortBridge erection/assemblyLoad resistanceBridge deck

The present invention relates to a high altitude frame simple machine for an erecting plate, the structure is stated below: a gantry binding beam is connected with an upper column of the gantry, which is connected with a walkway beam of a hoisting truss, which is connected with a lower column of the gantry. The hoisting trolley is arranged on the hoisting truss. The front end and the rear end of the hoisting truss are positioned on the hoisting truss. A front walking wheel box group and a rear walking wheel box group are arranged under the lower column of the gantry; the front walking wheel box group and the rear walking wheel box group are arranged at a walkway of a transportation board of a trolley and a front walking wheel rail and a rear walking wheel are arranged at the lower position of the walkway of the transportation road; a plurality of upper stringer joints of the steel truss are arranged on an upper stringer rod of the steel truss, a longitudinal beam of the steel truss beam is connected with the upper string rod of the steel truss beam, and an electric hoist is positioned at the bottom of the gantry binding beam. The present invention has the advantages of free transverse and longitudinal travel, four concrete bridge decks between joints are erected one time; normal universal rod structures are used to make a frame structure. the present invention has the advantages of sound stability, high air-load resistance, short manufacturing time and low production cost, easy and convenient use.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP

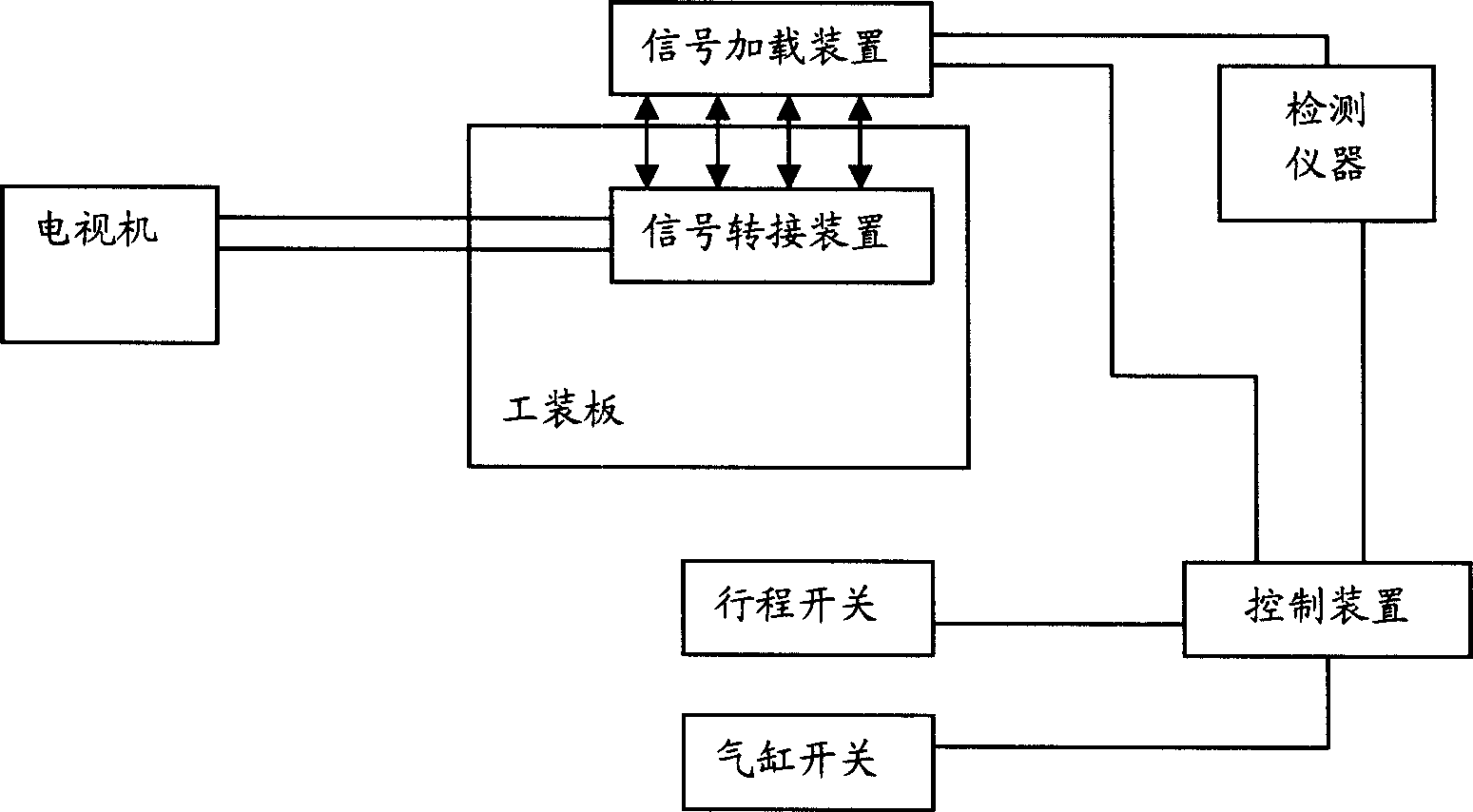

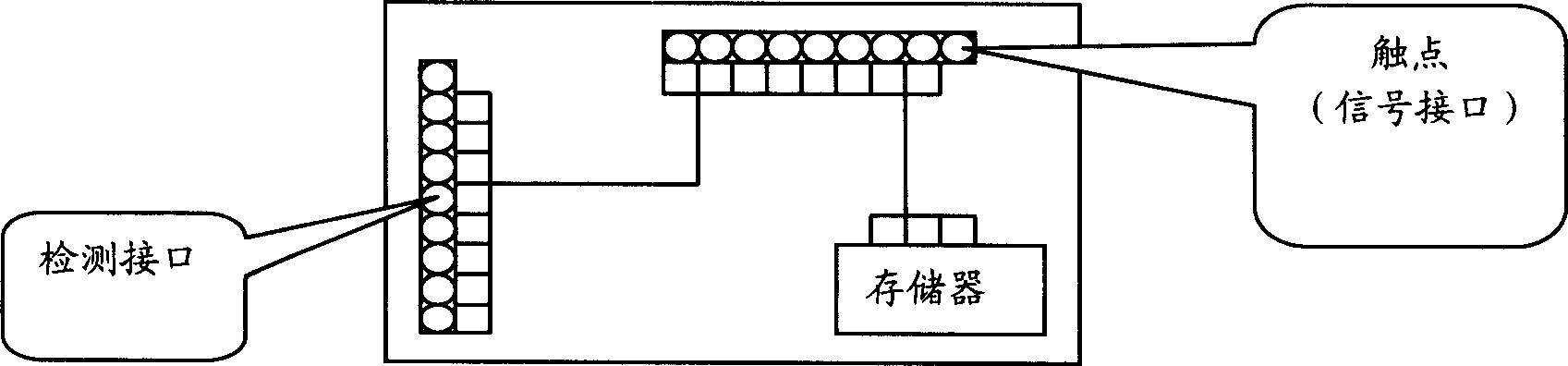

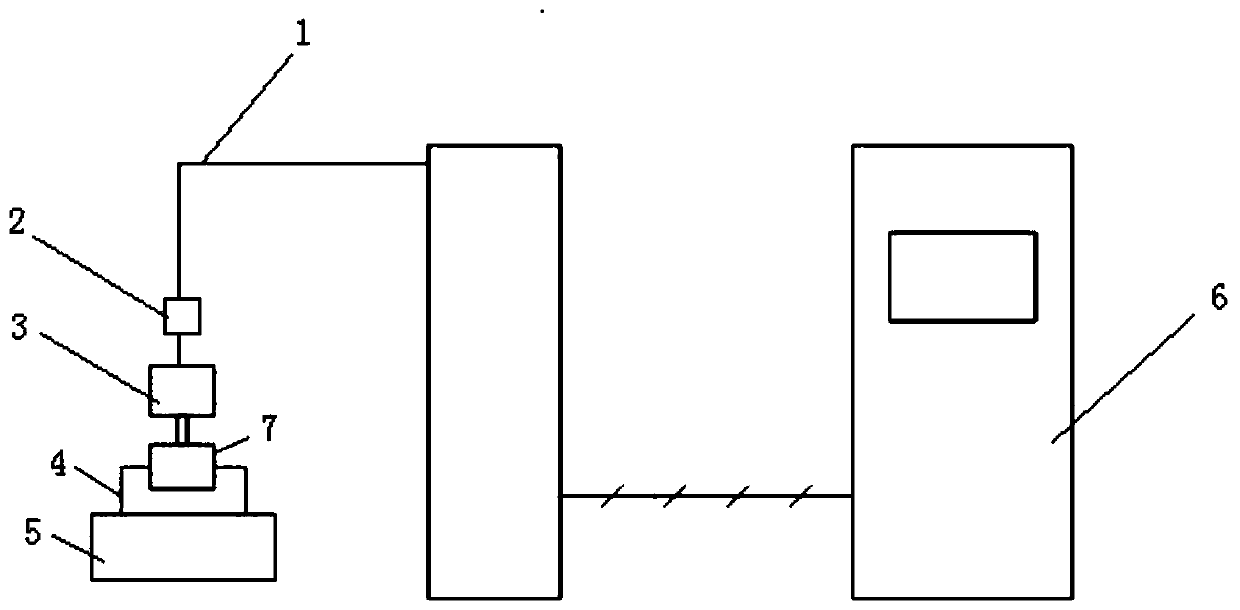

Automatic detecting device and method for TV set

InactiveCN1822679AEasy to read automaticallyImprove operational efficiencyTelevision systemsProduction lineDependability

Present invention discloses an automatic-detection device for TV set. It contains signal switch over device, loading unit, controller and detection instrument, through using signal switch over device and loading unit to make connection between TV set and detection instrument standardization in interface butted form, and completed in controller controlled simple mechanical movement. Said invented also provides automatic-detection method adopting above-mentioned device. Said invented has advantages of realizing whole test procedure automatization and production line efficiency and reliability.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

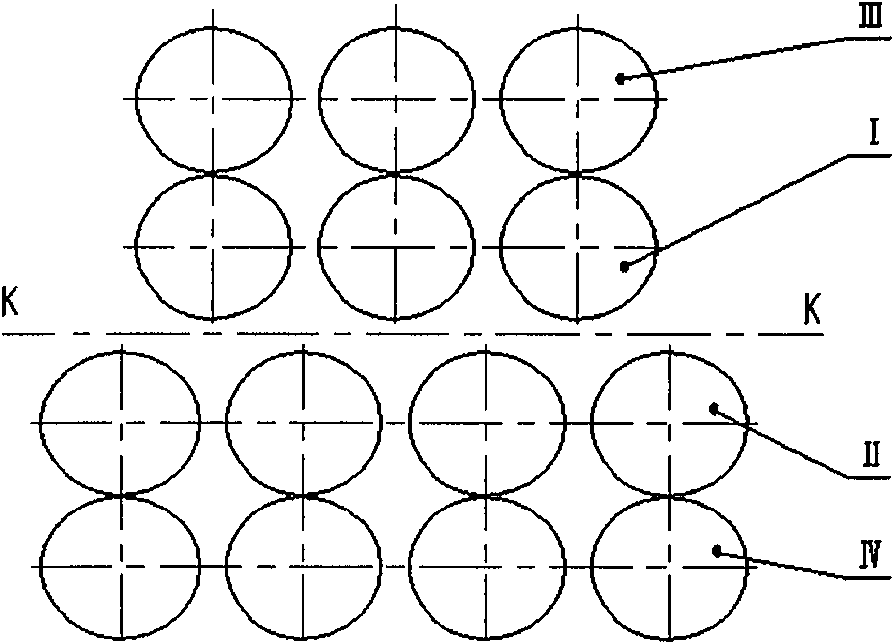

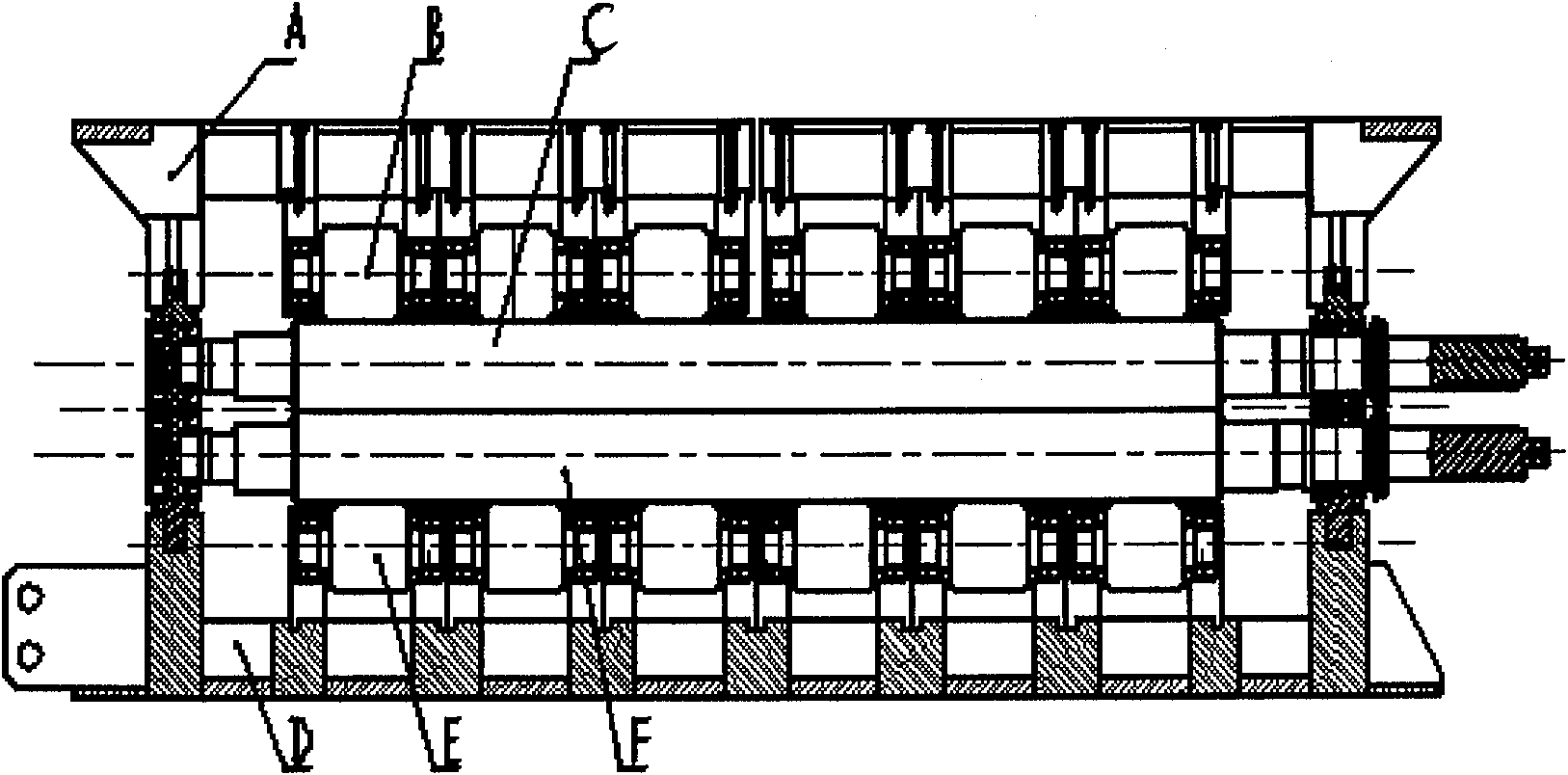

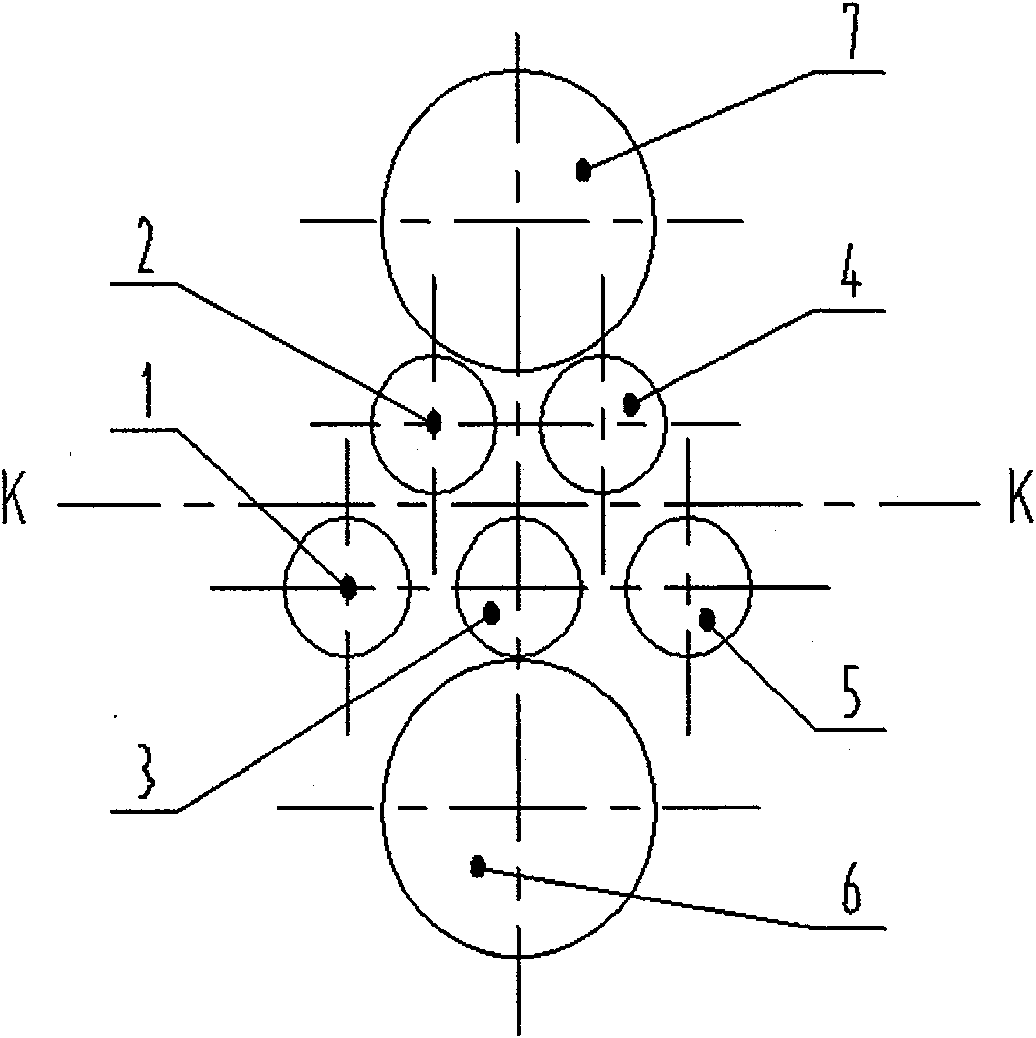

Five-roll metal plate and strip straightening machine

The invention discloses a five-roll metal plate and strip straightening machine, and belongs to the technical field of metal plate and strip straightening machines. The straightening machine comprises a power transmission device and straightening rolls, support rolls and a pressing device which are arranged in a frame. The straightening machine is characterized in that: a roll system structure consists of two upper straightening rolls and three lower straightening rolls staggered along a rolling center line, and the middle position above the two upper straightening rolls is provided with an upper support roll, the diameter of which is 3 to 5 times that of the straightening rolls. A lower support roll, the diameter of which is 3 to 5 times that of the straightening rolls, is arranged belowthe middle straightening roll of the three lower straightening rolls. Compared with the prior art, the straightening machine has the advantages of reasonable roll system arrangement, simple machine structure, small volume and light weight.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

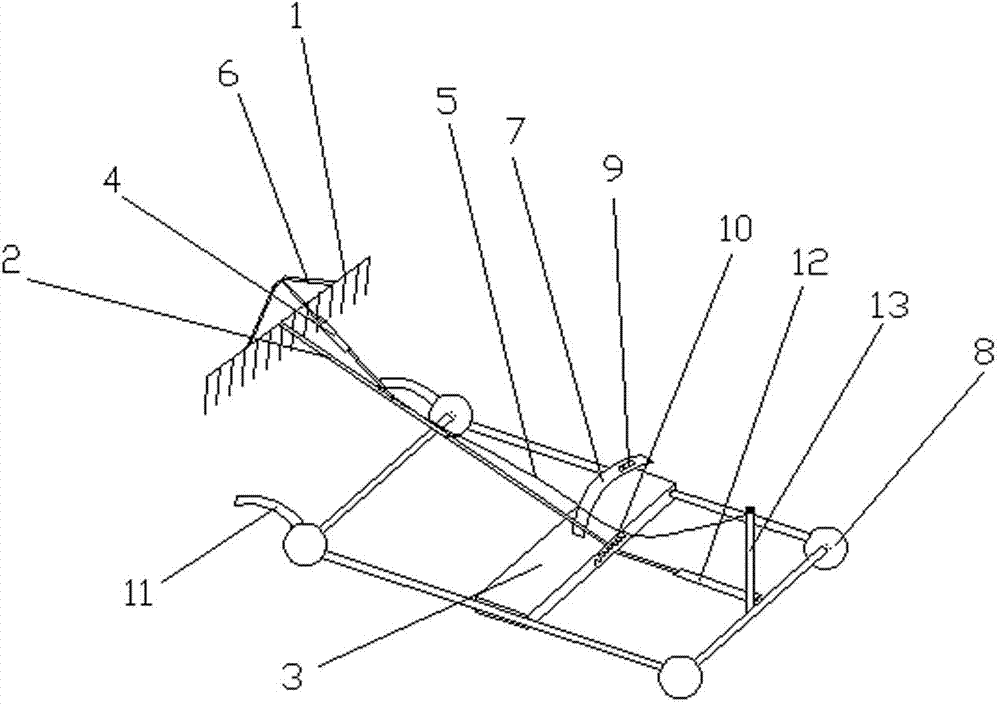

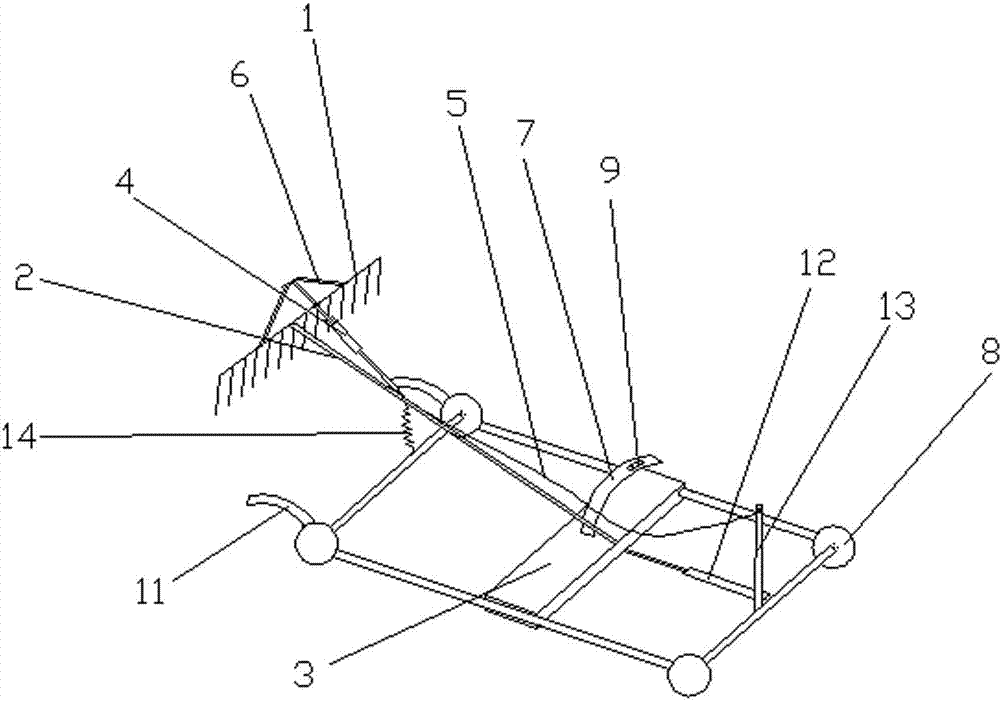

Soil turning machine

InactiveCN103650738AAvoid damageReduce labor intensityDiggersWater ChestnutsAgricultural engineering

The invention relates to a soil turning machine. The soil turning machine comprises a rake, a rake handle and a prying rod, which are arranged on a rack, wherein the prying rod is downwards connected with the rack, the rear end of the prying rod is connected with a reciprocating mechanism A, and the other end of the reciprocating mechanism A is connected with the rake handle connected to the rear end of the rake, so that the rake, the prying rod and the reciprocating mechanism A form a triangular soil turning structure; the rake handle is connected to the rear end of the prying rod, and is movably connected to a sliding frame through a coil spring or is connected to the rack or another part on the rack through a retractable spring; a support structure capable of supporting the rake handle is arranged on the sliding frame; the sliding frame is also connected with a reciprocating mechanism B; the other end of the reciprocating mechanism B is connected with a bracket; a chain cable is also arranged on the rake handle; the other end of the chain cable is connected with the bracket arranged at the tail end of the rack. The soil turning machine has the characteristics of convenience in use, simple structure, high mechanization degree, reduction in labor cost and high working efficiency, water chestnuts, arrowheads and the like can be collected in cold winter, and the probable problems of manual collection are solved.

Owner:黄德胜

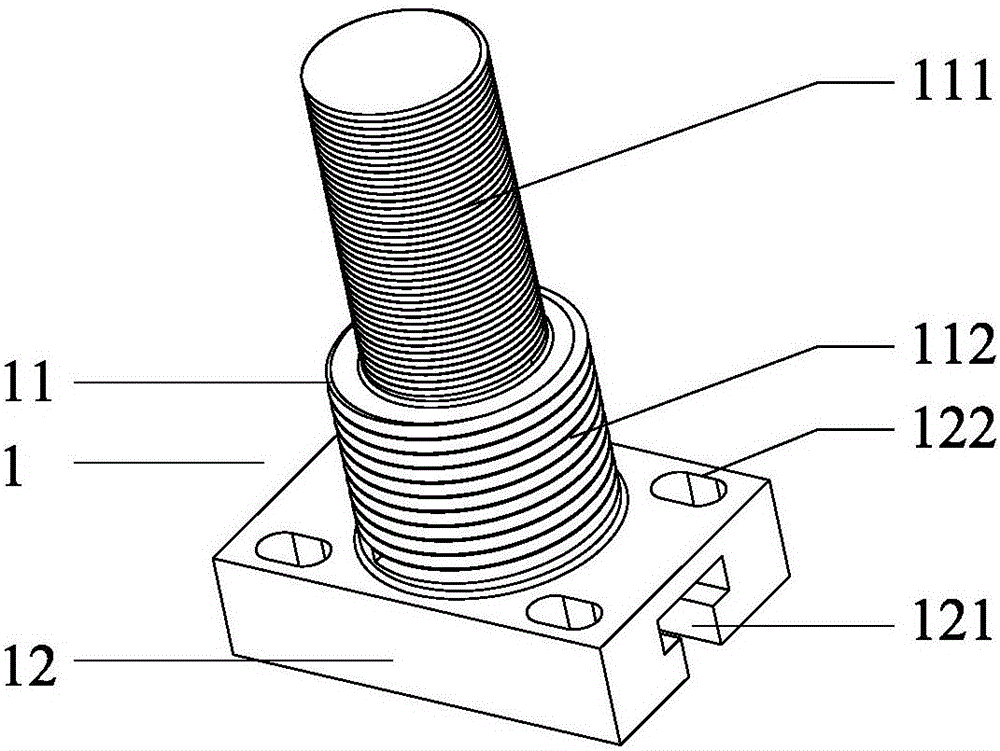

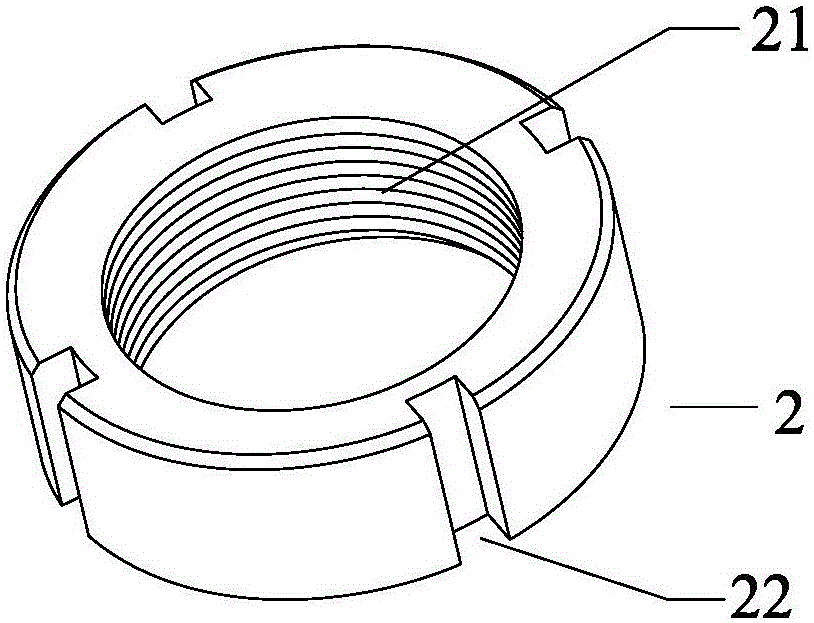

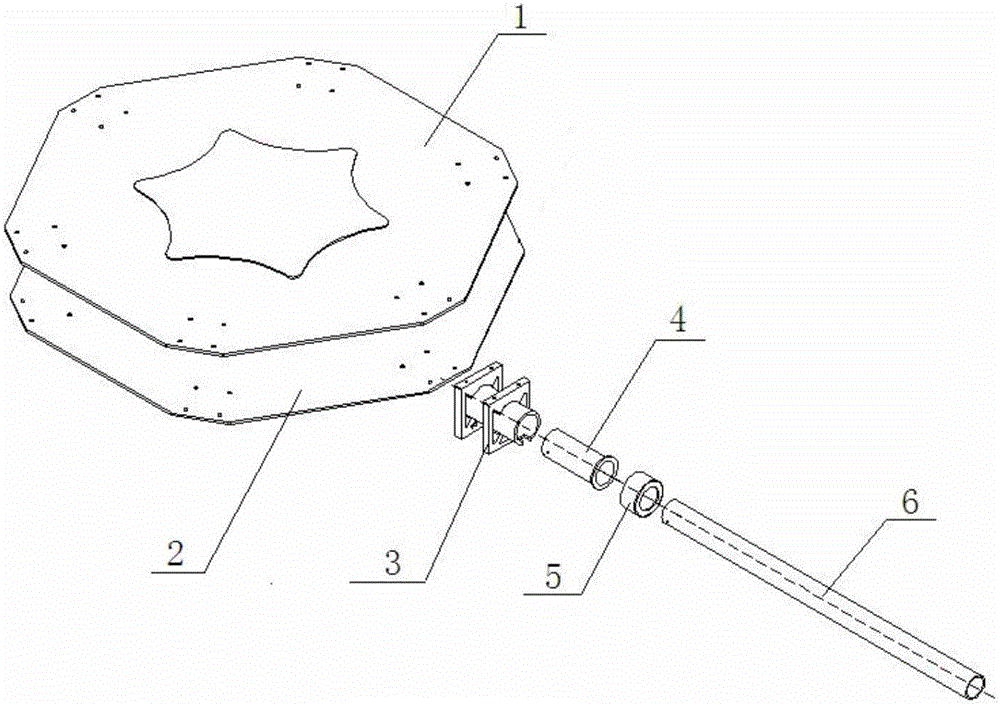

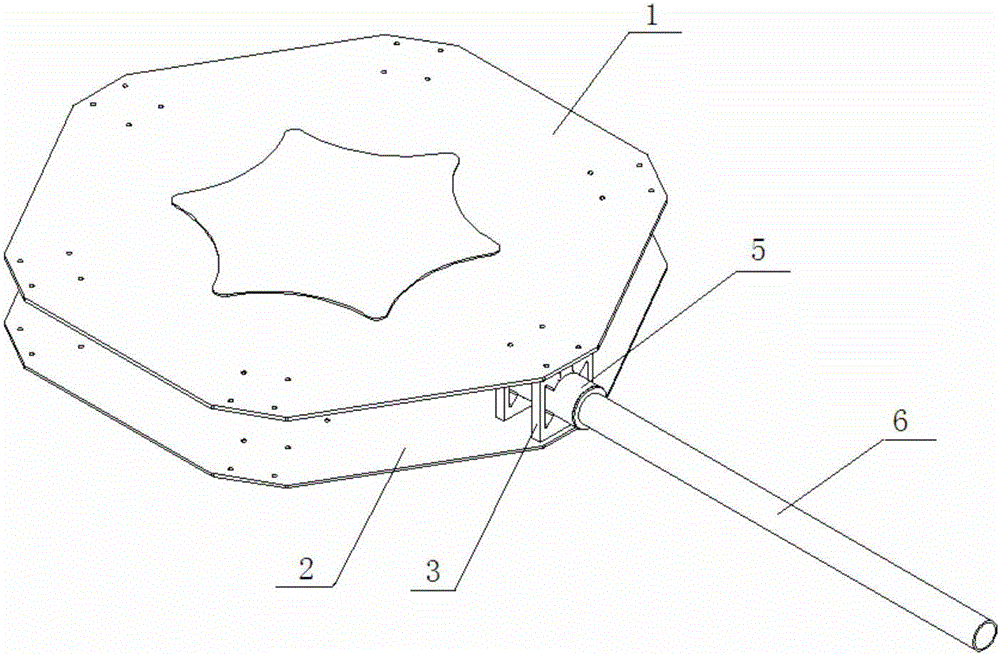

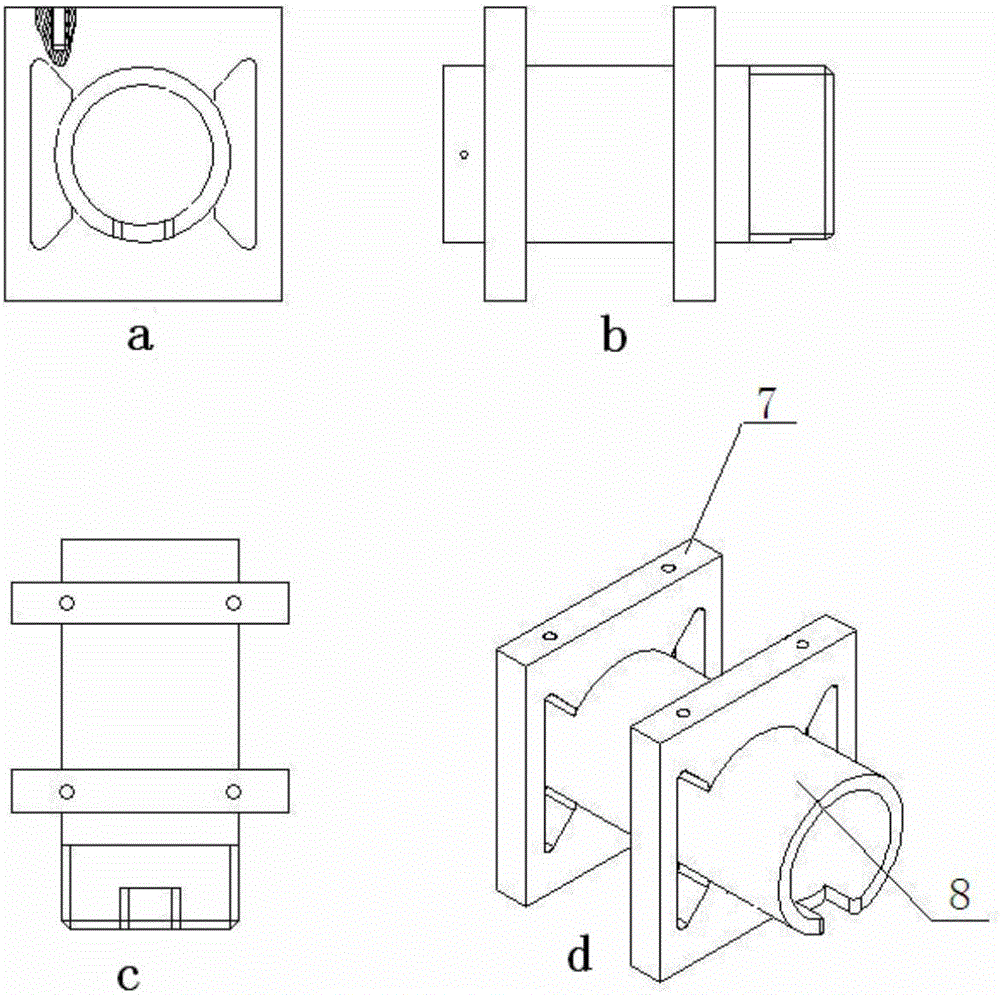

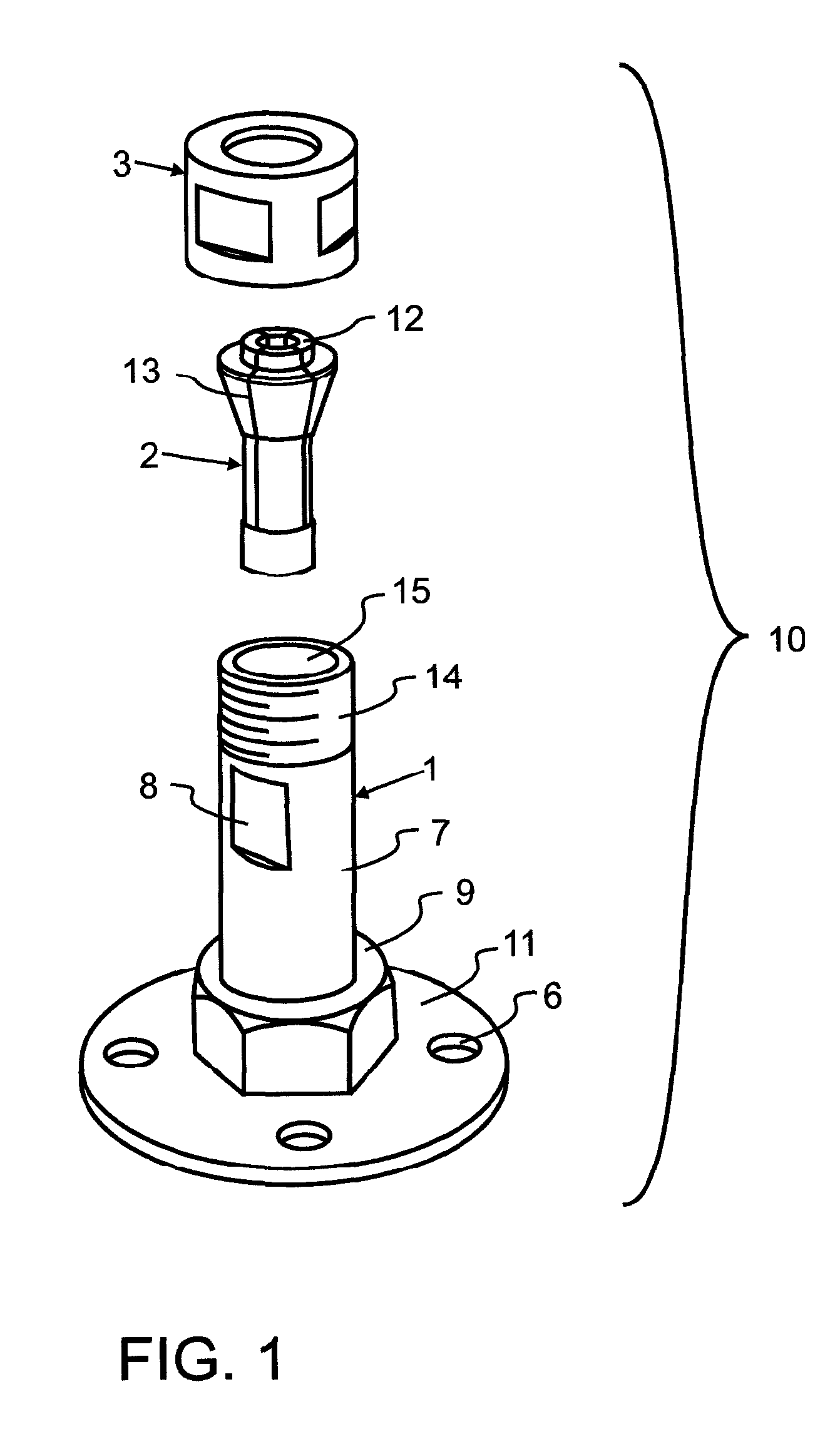

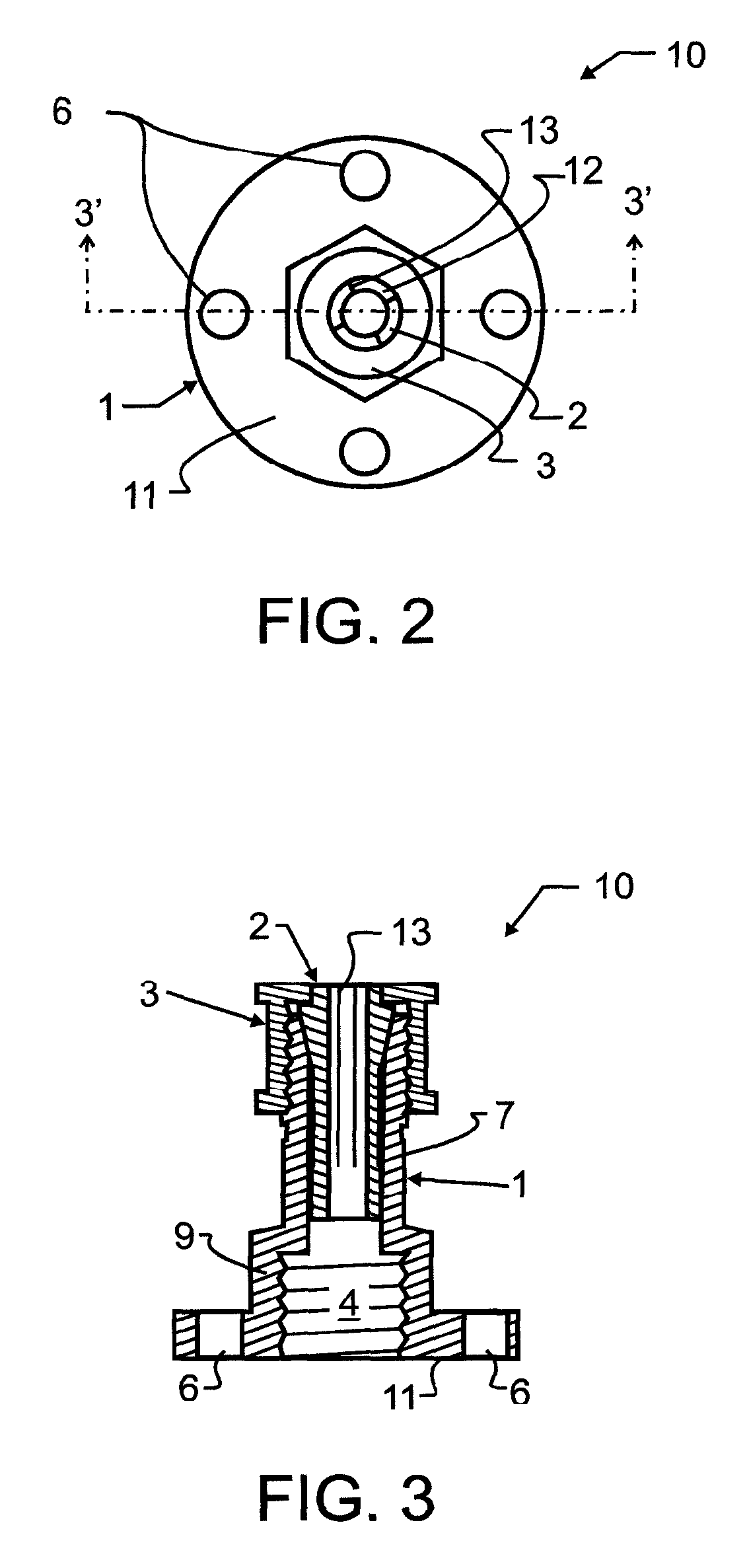

Arm connecting device for unmanned aerial vehicle

PendingCN105857601ACan not be disassembledThe problem that the solver is difficult to disassembleFuselage framesAircraftsFlight vehicleUncrewed vehicle

The invention provides an arm connecting device for an unmanned aerial vehicle. The arm connecting device for the unmanned aerial vehicle comprises an arm connector, a shaft sleeve and a locking nut, wherein the arm connector is fixed between an upper body plate and a lower body plate through two supports of the vehicle arm connector. The shaft sleeve is installed in a sleeve of the arm connector. A wing connecting rod is installed in the shaft sleeve and is locked through the nut. The arm connecting device effectively integrates the advantages of screw connection and can be used for connection of a body and an arm of a heavy-duty aircraft, and the problem that in the prior art, an aircraft body and a wing cannot be disassembled or are difficult to disassemble is effectively solved; and the arm connecting device for the unmanned aerial vehicle has the characteristics that the structure is simple, the mechanical strength is high, and secondary disassembly and assembly are rapid and convenient.

Owner:SANYI AVIATION TECH NANTONG CO LTD

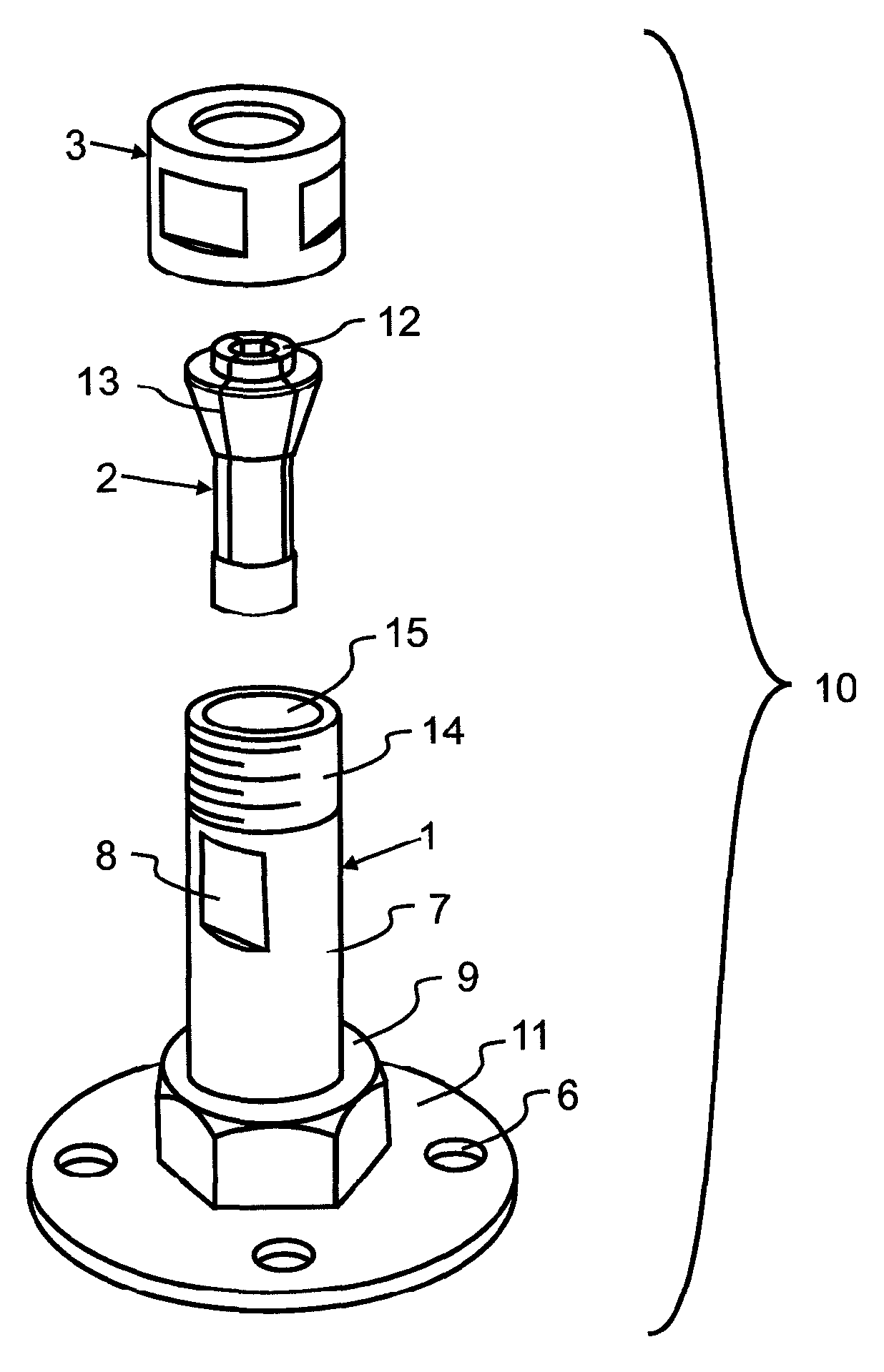

Angle grinder and angle grinder spindle-collet adaptor

InactiveUS7717771B1Improved angle grinding operationAllow flexibilityGrinding wheel securing apparatusSleeve/socket jointsAngle grinderEngineering

A simple three piece machined steel Collet-Spindle Adaptor for angle grinders includes a hat-shaped base having interior threading for coupling with a threaded spindle on an angle grinder. A sleeve extends therefrom and has an interior surface which engages with a collet. The preferred adaptor converts an angle grinder to accept die grinding tools and other similar tools, thereby providing flexibility of tooling, flexibility of application and work area, ergonomics in operator comfort by providing two hand operation, safety in lower operating tool speed, and reduced cost as an additional die grinder and expensive air compressor are not required. Simple machined design allows rapid change over and small size allows easy toolbox storage.

Owner:LYERLY DENNIS J

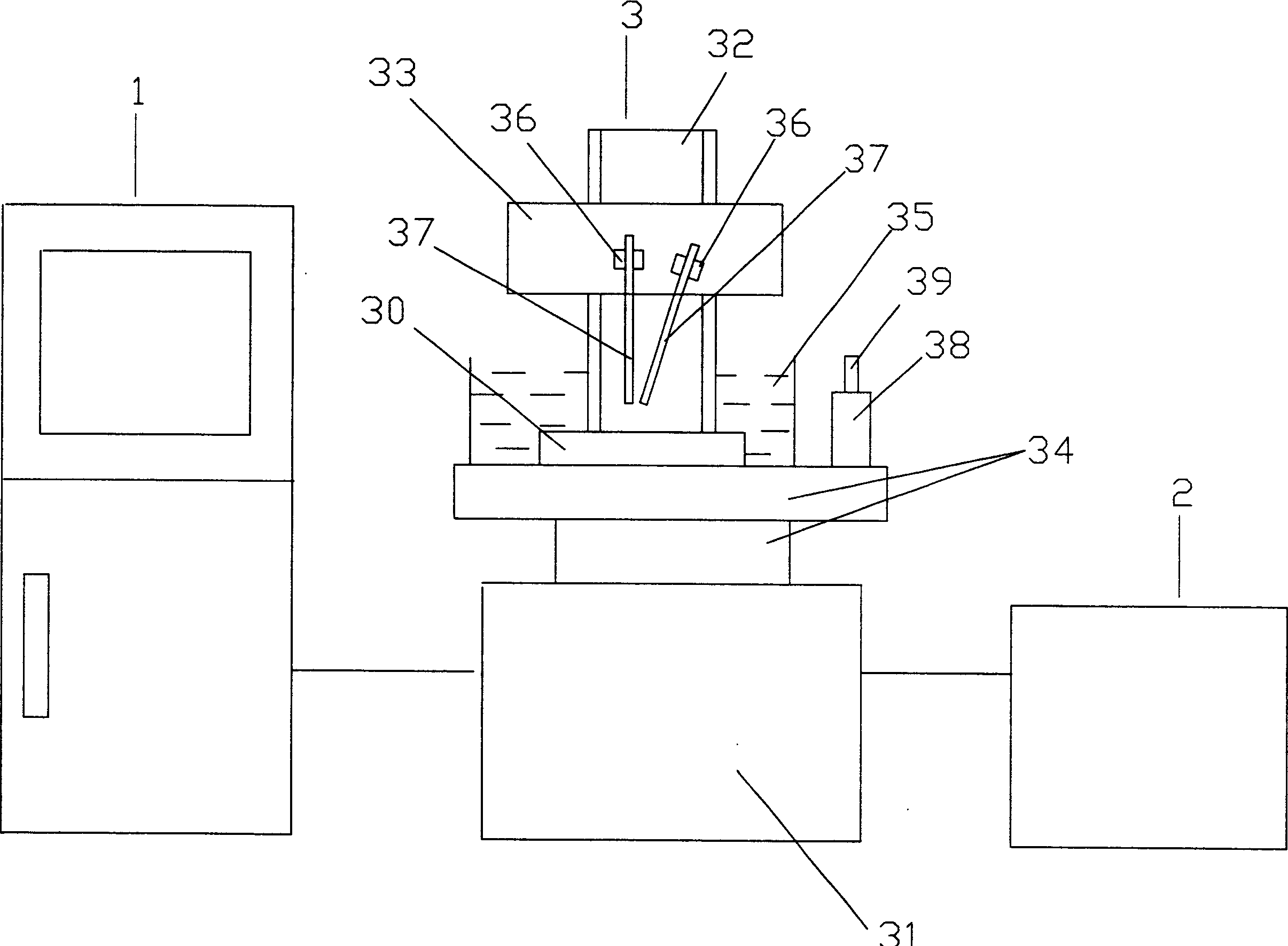

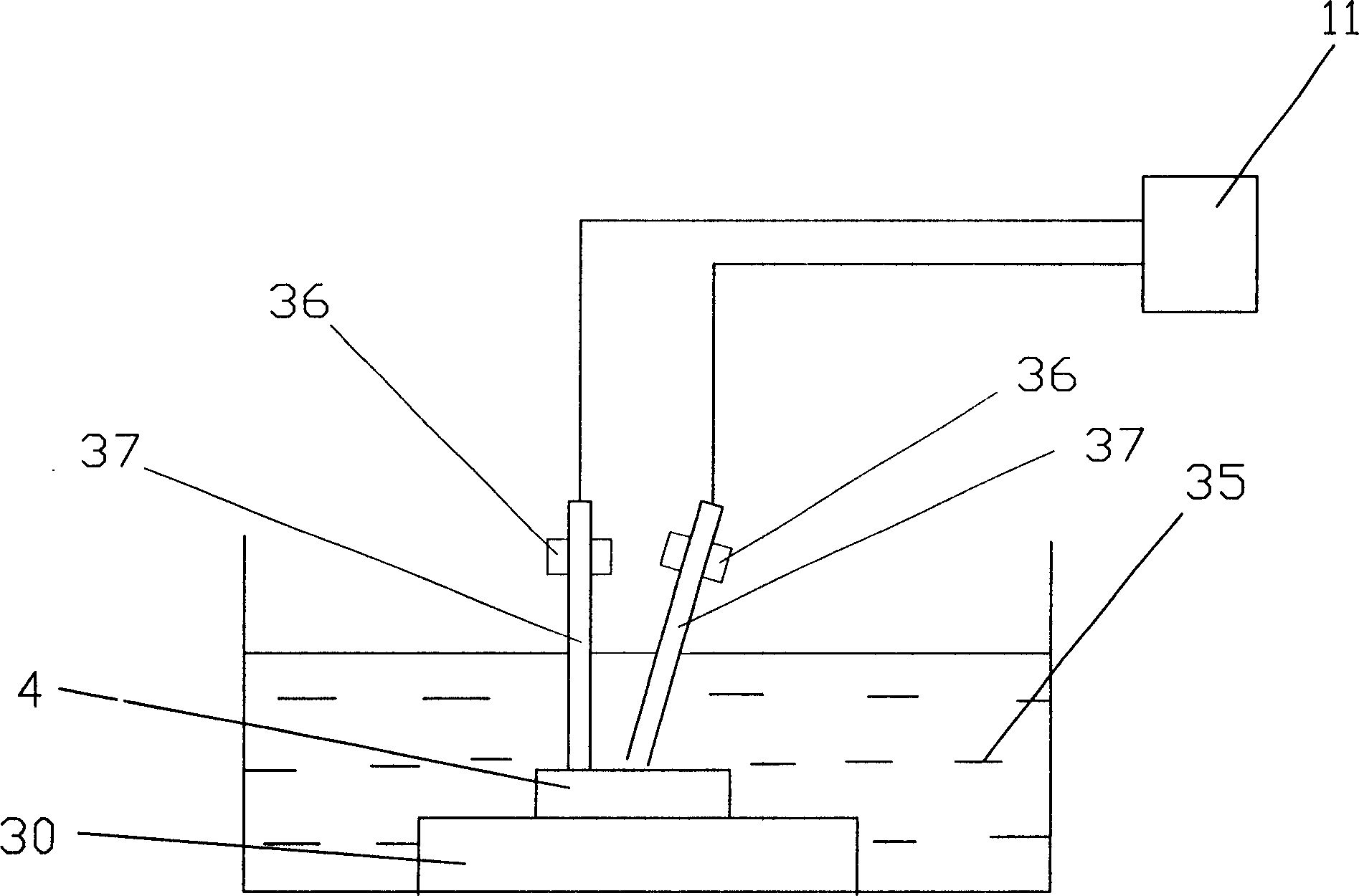

Electric spark forming processing machine tool for processing non-conductive hard material and its processing method

InactiveCN1820884AThe process is simple and reliableImprove power utilizationMeasurement/indication equipmentsElectric circuitsLiquid mediumPulse power supply

The present invention discloses a kind of electric spark forming machine for processing non-conductive hard material and its processing method. The forming machine includes a work table, a work solution tank on the work table for holding circular work solution, an insulating pedestal for holding workpiece and set inside the work solution tank, a pair of discharge electrodes set in the processing site, submerged inside the work solution tank and with micron level gap in between, and a pulse power supply with two poles connected separately onto the electrodes. The processing method is that inside the liquid medium, the workpiece is cut through serial pulse discharges. The present invention has simple machine equipment and stable processing.

Owner:JIANGSU UNIV OF TECH

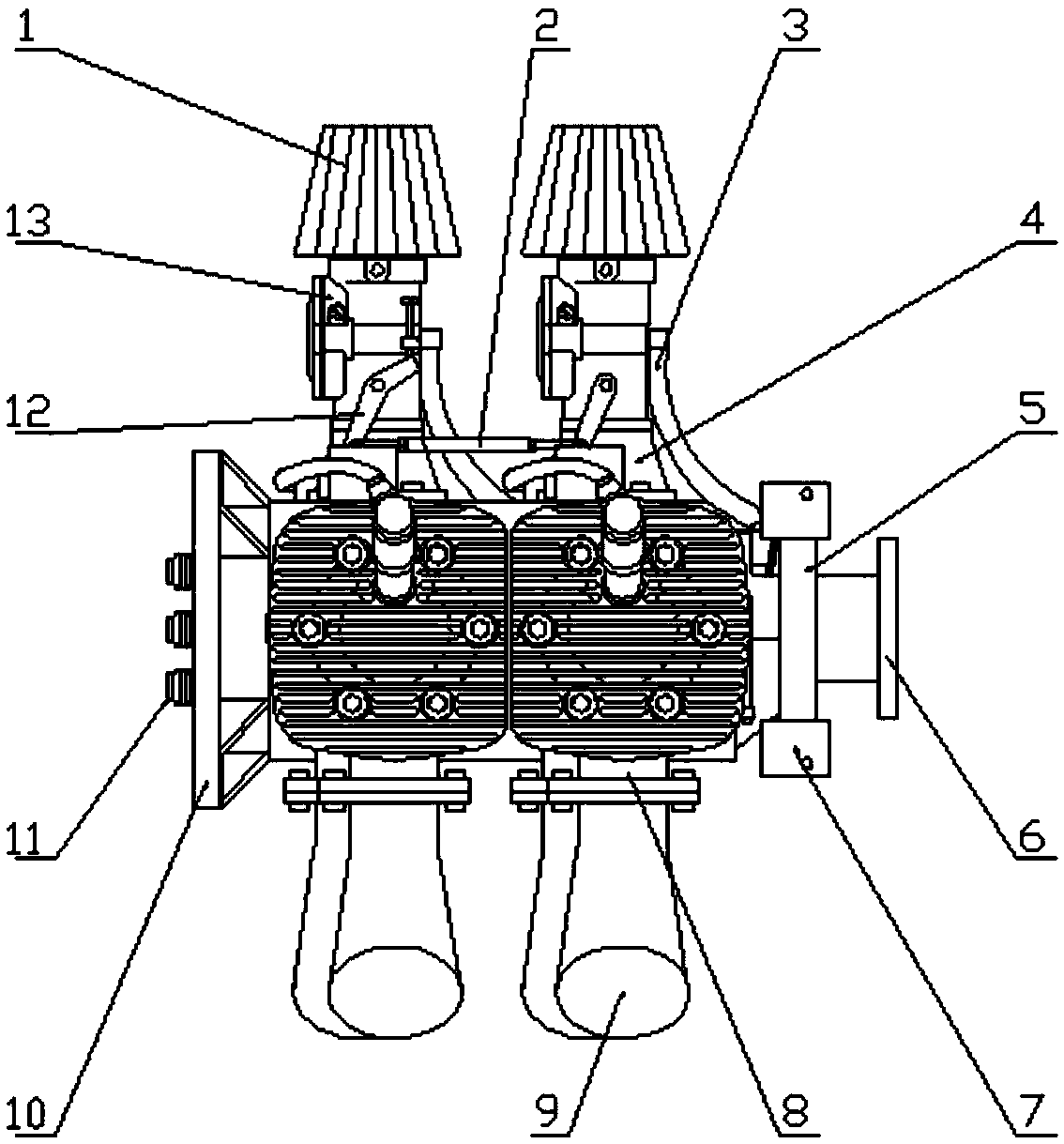

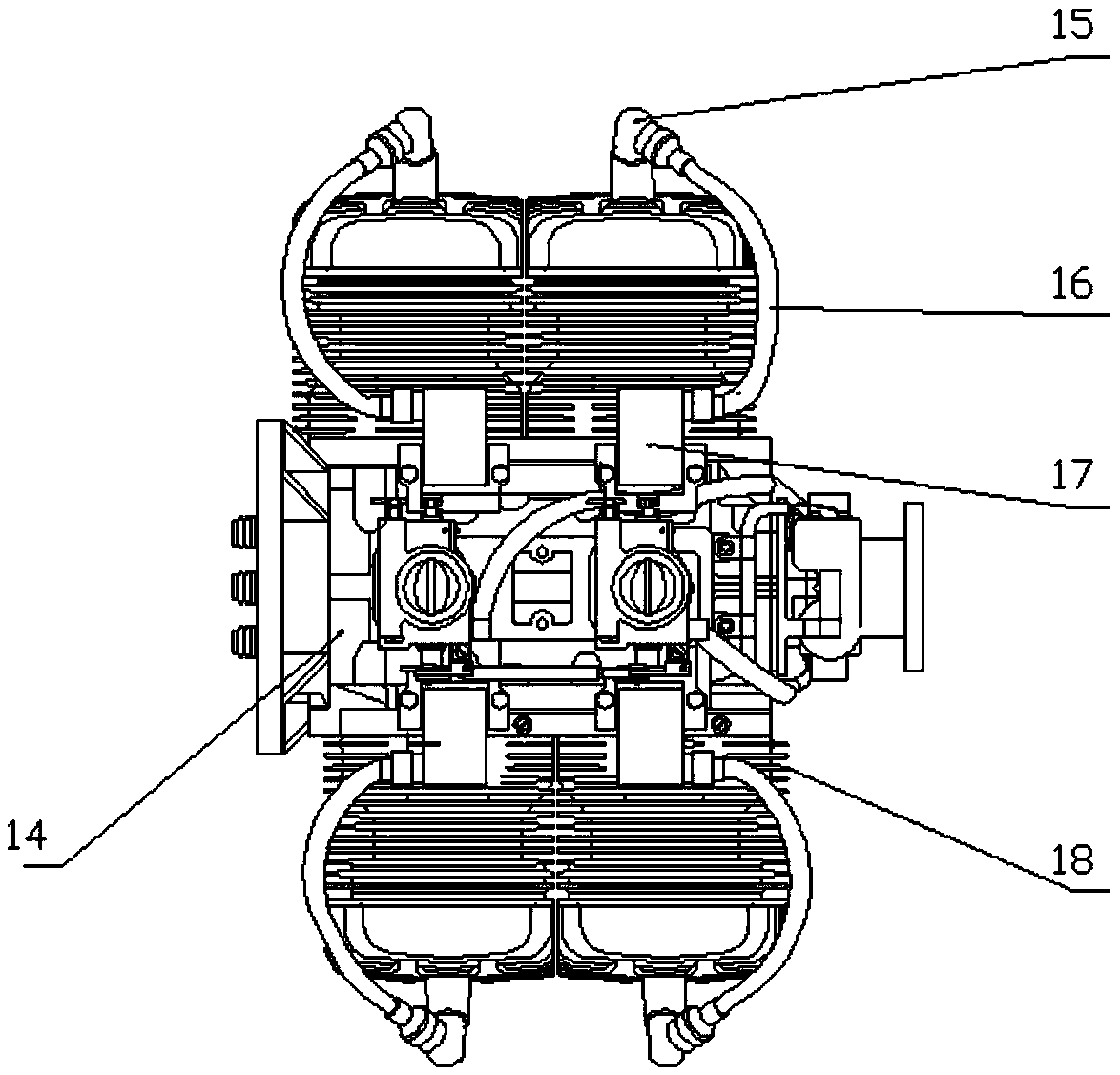

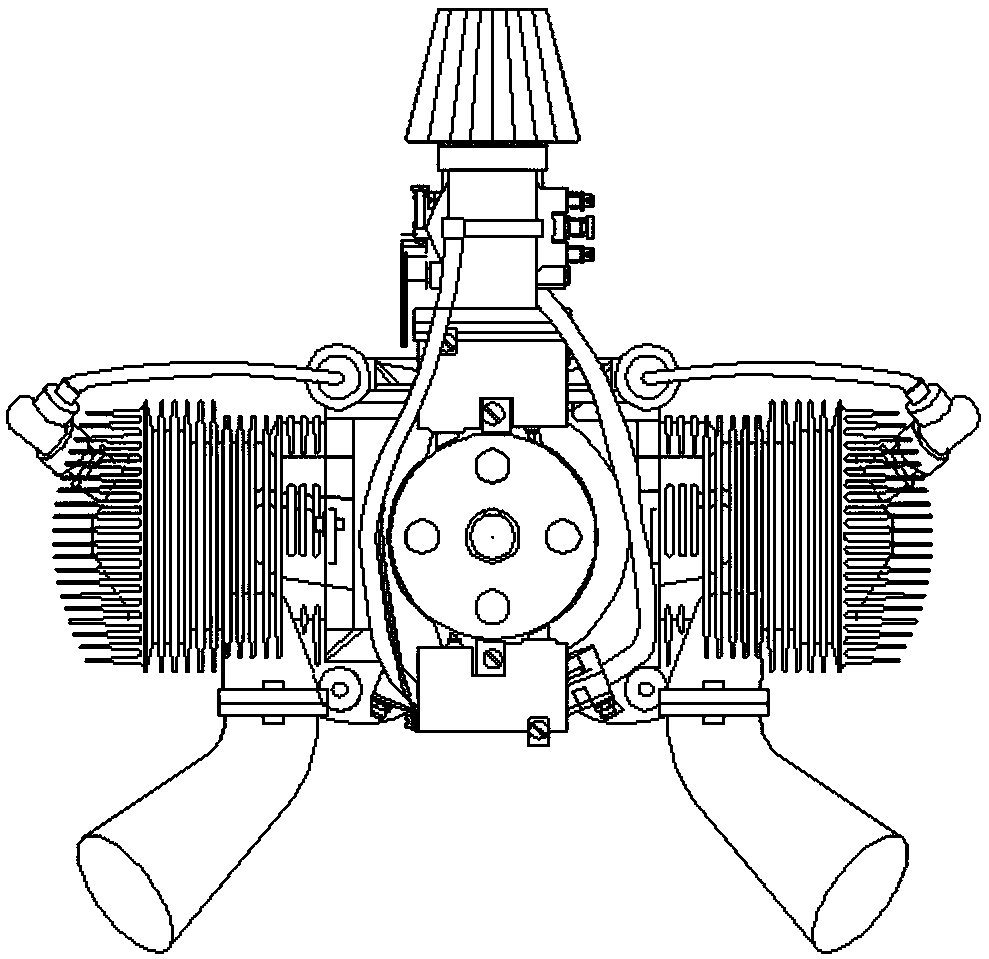

Small two-stroke four-cylinder horizontally-opposed aero-engine

PendingCN108661793ACompact structureHigh mechanical strengthCasingsMachines/enginesAviationControl system

The invention relates to a small two-stroke four-cylinder horizontally-opposed aero-engine compact and simple in structure, high in mechanical strength, wide in environment applicability, small in weight, high in efficiency and reliably, good in manufacturability and high in adaptability. According to the small two-stroke four-cylinder horizontally-opposed aero-engine, the manufacturing and debugging difficulty of an air door control system is simplified, the lubrication condition of a two-stroke engine crankshaft mechanism is effectively improved, and the problem about cooling during runningof a crank connecting rod motion pair is solved. The small two-stroke four-cylinder horizontally-opposed aero-engine meets the aviation high-strength flight requirement through a crankshaft, a connecting rod, a piston, a cylinder and a crankshaft box structure, and continuous cruising running for 10 h can be achieved at the altitude of 3,500 m or above under the work condition of 5,000 r / min.

Owner:XIAN AISHENG TECH GRP +1

Electronic shifter shift calibration equipment and operation method thereof

PendingCN111323215AEasy to disassemble and assemble quicklyConvenient and fast positioningMachine part testingElectric/magnetic position measurementsControl engineeringMechanical equipment

Electronic shifter shift calibration equipment and an operation method thereof belong to the technical field of mechanical equipment, and the electronic shifter shift calibration equipment comprises amechanical arm, a force sensor, a shift link mechanism, a quick change mechanism, a horizontal table, a magnetic sensor and a control cabinet. The shift link mechanism and the quick changing mechanism can be customized according to different product structures and appearances and can adapt to products of various shapes, and the problem that the whole equipment is repeatedly designed is avoided. The numerical information of the operating force value, the gear shifting angle and the sensing angle can be accurately detected, the coordinate graph can be drawn, the proper numerical value is selected for gear calibration according to the detected numerical value and the detected coordinate graph, the calibration precision is high, the detection method is convenient and simple, and special training is not needed. The equipment has the advantages of being simple in design, flexible in mechanical structure design, short in earlier-stage scheme design verification period and the like, multi-product verification can be conducted, and therefore cost is saved.

Owner:GEARCHIEF EISSMANN CHANGCHUN AUTOMOTIVE PARTS

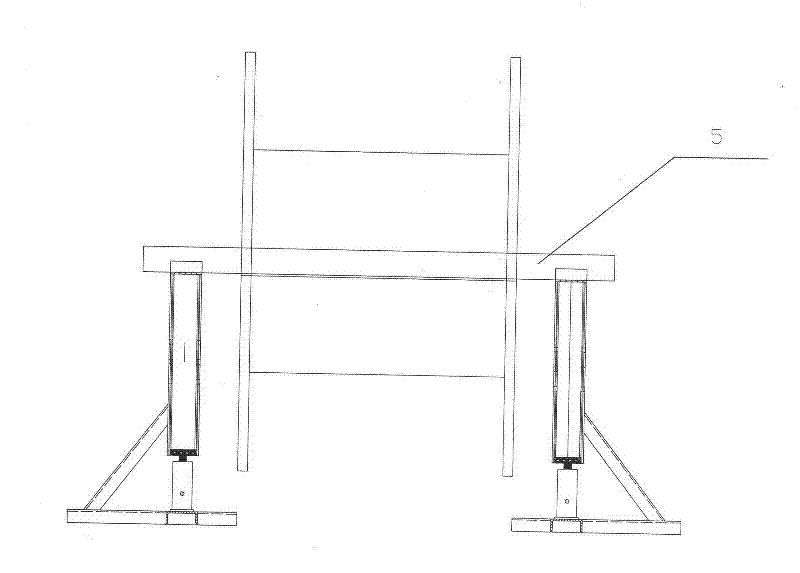

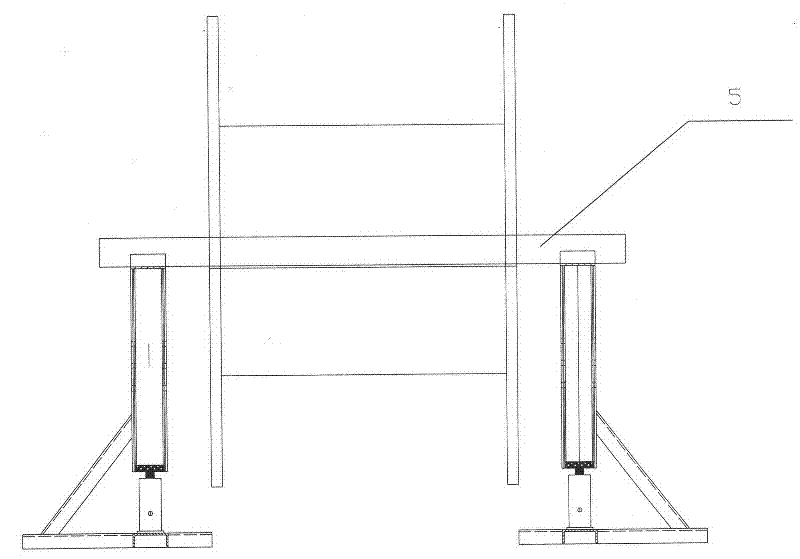

Cable and steel wire rope roller supporting device

InactiveCN102390755AReduce investmentSimple processing technologyFilament handlingJackscrewEngineering

The invention relates to a cable and steel wire rope laying equipment, in particular to an improved cable and steel wire rope roller support frame. The improved cable and steel wire rope roller support frame comprises two mutually independent support frames and a rolling rod, wherein each support frame comprises a support frame body, a movable bracket, a jack and a positioning pin shaft; each support frame body is provided with a steel pipe arranged vertically; the movable bracket is installed in each steel pipe; the jacks are installed below the movable brackets; the movable brackets and the steel pipes are provided with height regulation holes matched with the positioning pin shafts; the positioning pin shafts are inserted in the height regulation holes to position the movable brackets; the rolling rod is horizontally arranged; and two ends of the rolling rod are arranged on two support frames. The cable and steel wire rope laying equipment has the beneficial effect that the device has simple machining technology, is convenient and flexible to install and use, can be assembled on site if being used; as height of the cable and steel wire rope laying equipment can be regulated by backup movable supports with different heights, the cable and steel wire rope laying equipment can be reused, and further the investment in construction equipment such as cranes and the like can be reduced and manpower and materials can be saved.

Owner:CHINA COAL NO 5 CONSTR

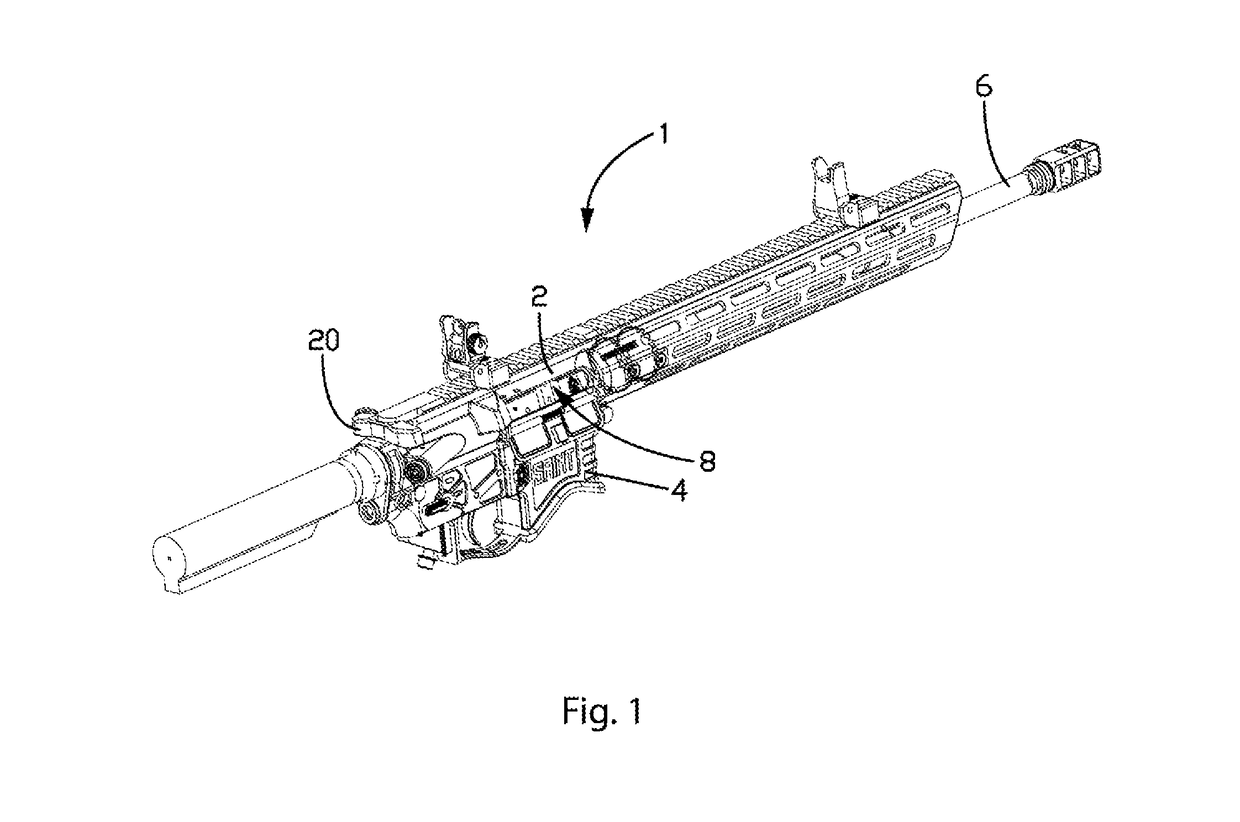

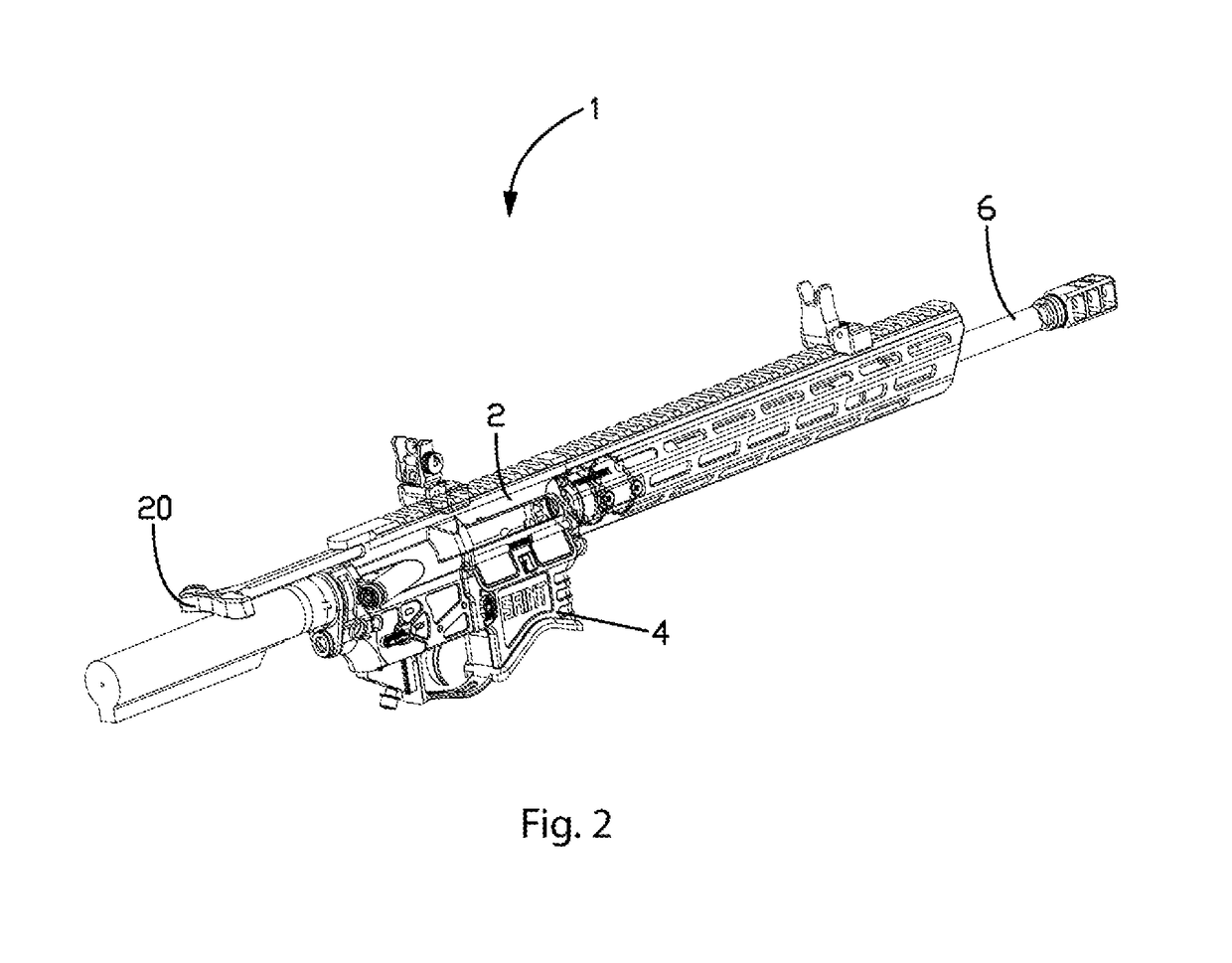

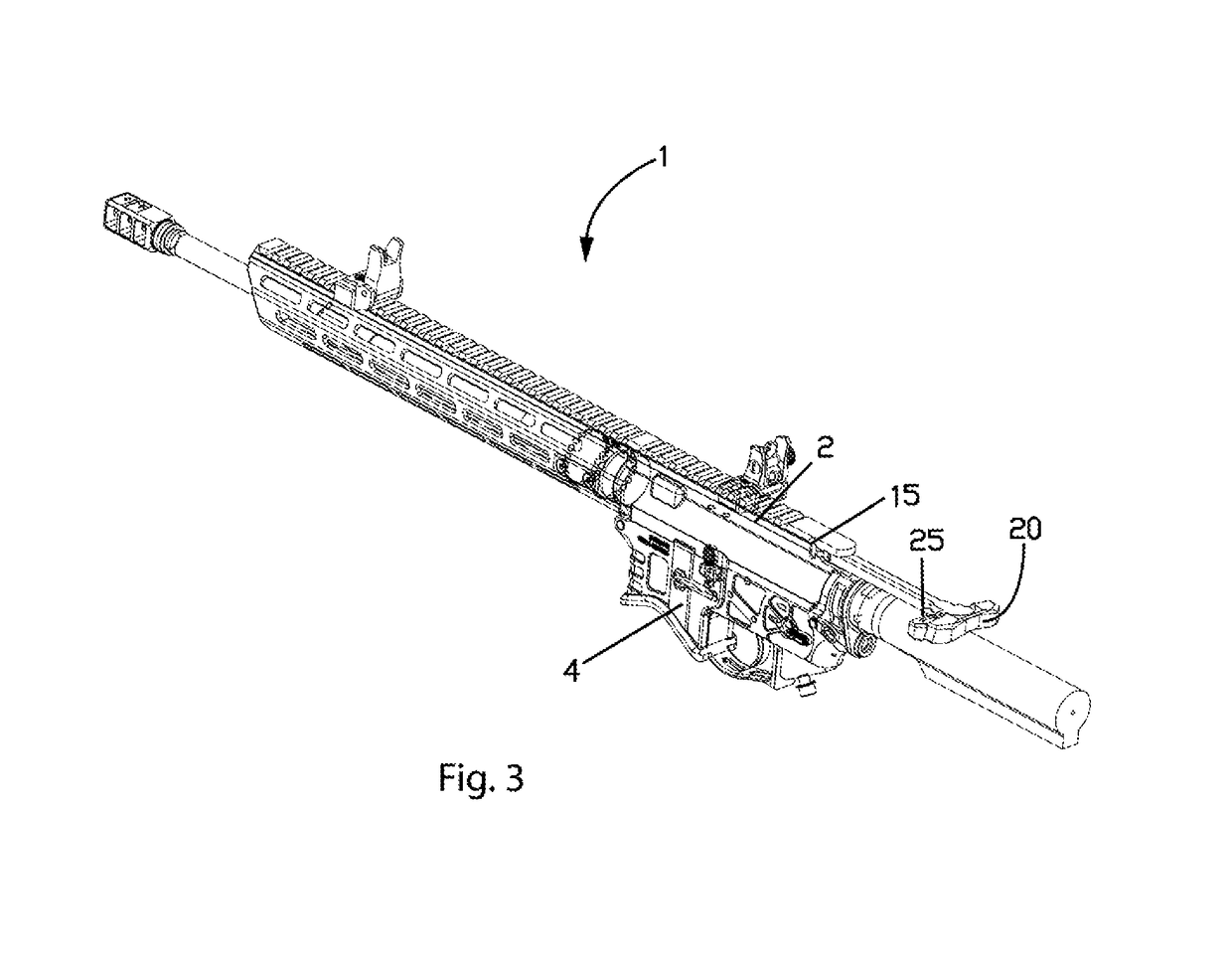

Latched charging handle with mechanical advantage separator

Charging handles having a mechanical advantage separator for separating an end of the charging handle from a portion of a firearm are disclosed. Specifically, charging handles having a simple machine, such as a lever, are disclosed. Advantageously, the simple machine can multiply the force applied by a user on the charging handle. Additionally, in at least some instances, the simple machine will actuate a charging handle latch so as to disengage the charging handle latch from a receiver of the firearm.

Owner:SPRINGFIELD

Conveniently and easily assembled and disassembled transparent reflecting heat-insulating window film for building window

The invention discloses a conveniently and easily assembled and disassembled transparent reflecting heat-insulating window film for a building window, a sealed balcony and the like. A base material film of the window film is a non-flexible terylene film or polyester film or one of other similar transparent plastic films which has certain rigidity and can be curled; the thickness of the base material film is between 0.05 and 1.5mm; and a nano transparent heat-insulating paint is coated on the surface of the base material film to form the transparent reflecting heat-insulating window film. The transparent reflecting heat-insulating window film is arranged by using a transparent adhesive tape or is arranged on the surface of window glass by using a simple machine, and can reflect infrared heat radiated to the window by sunshine in summer without obviously affecting the permeability of visible light. The transparent reflecting heat-insulating window film can be conveniently disassembled when the infrared heat radiated to the window by the sunshine is needed in winter.

Owner:ANHUI INST OF BUILDING RES & DESIGN

A yarn twist tester

The invention relates to a yarn twist tester, which comprises a creel assembly, a rotary chuck assembly, a chassis assembly and a tension adjustment assembly. The two ends of the chassis assembly are respectively fixed with the creel assembly and the rotary chuck assembly by bolts. A tension adjustment assembly is installed horizontally on the upper surface of the chassis assembly between the assembly and the rotary chuck assembly, and a yarn guide hook is vertically installed on the chassis assembly at one side of the creel assembly. The invention has simple appearance, advanced circuit design, high integration, reliable performance, complete functions, and simple operation. The mechanical part adopts the internationally popular horizontal pulley balance swing structure, which is directly loaded with tension and can adapt to a wide range of twists. Test experiment.

Owner:TAICANG HONGDA FANGYUAN ELECTRIC

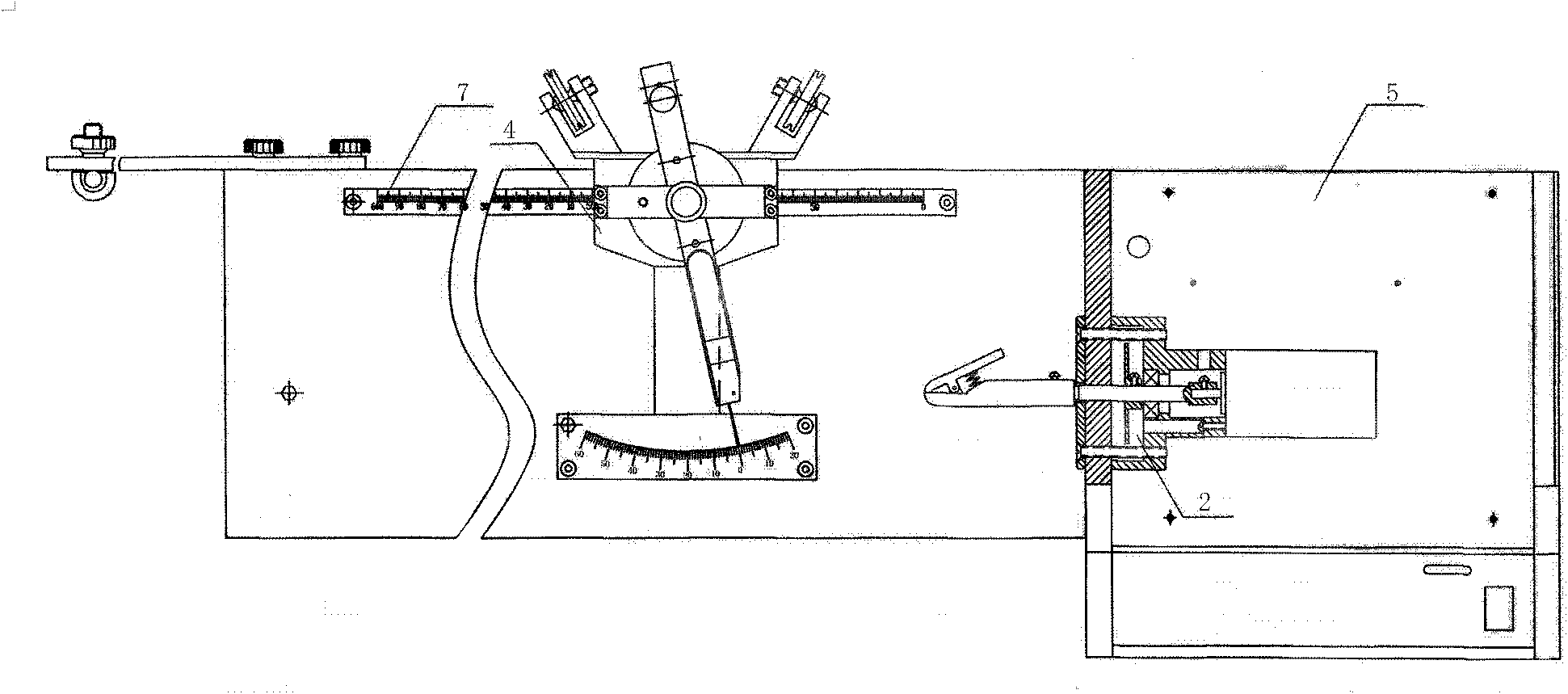

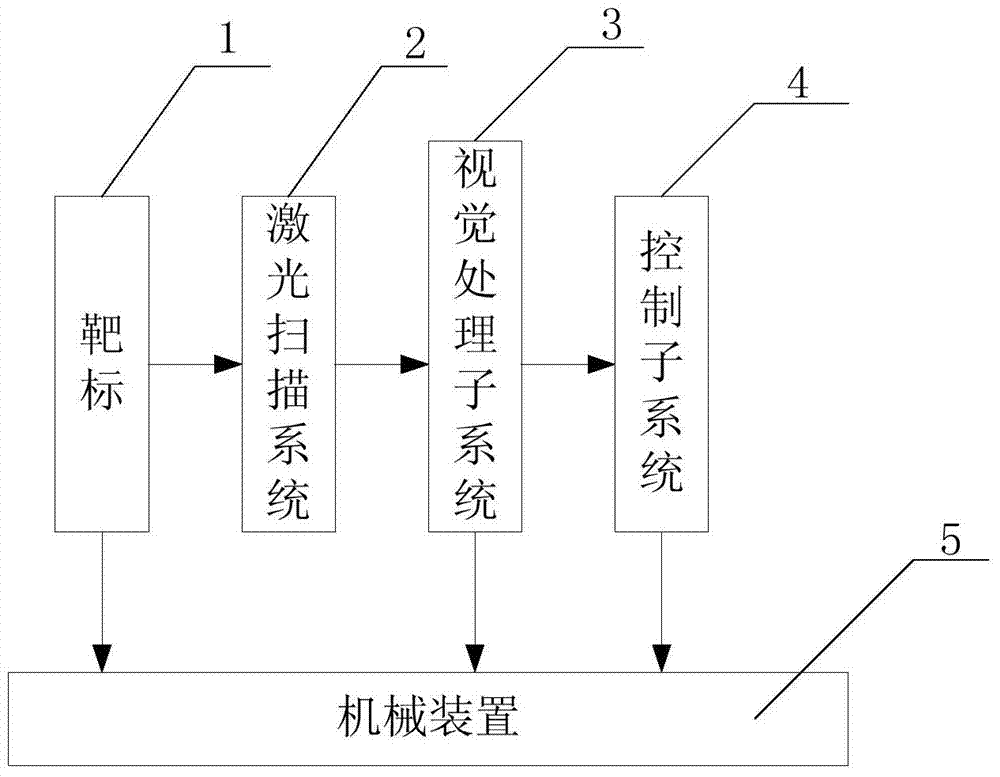

Measuring system for honing machine and measuring method

InactiveCN103358230AHigh precisionAccurate contourGrinding feed controlVision processingLaser ranging

The invention belongs to the practical technical field of honing machines, and discloses a measuring system for a honing machine and a measuring method. The measuring system mainly comprises a target, a laser scanning system, a vision processing subsystem, a control subsystem and a mechanical device. The measuring system is high in precision, has the initiative, and is simple in technology, real-time and quick; a mechanical part only consists of a motor achieving two freedom degrees and a mounting bracket for fixing a camera and a laser range finder, so that the measuring system is convenient to process and mount; the measuring system has the characteristics of small size and light weight, can be integrated to other systems very easily, serves as a functional unit, and is simple to operate, high in accuracy rate and very good in practical application value.

Owner:NANJING UNIV OF TECH

Fish scale removing machine

ActiveCN107041415ASimple structureIncrease productivityFish washing/descalingFish processingUltimate tensile strength

The invention relates to fish scale removing machine, which belongs to the technical field of food processing machinery. The fish scale removing machine consists of a stander, a sieving and discharging apparatus, a feeding apparatus, a weight measuring apparatus and a friction scale removing apparatus; the stander is provided with the friction scale removing apparatus, the weight measuring apparatus is arranged above the friction scale removing apparatus, the feeding apparatus is arranged above one side of the weight measuring apparatus, and the feeding apparatus is communicated with the friction scale removing apparatus by virtue of the weight measuring apparatus; and the sieving and discharging apparatus is arranged below the friction scale removing apparatus. The fish scale removing machine is simple in structure, the production efficiency is high, the continuous mechanical fish scale removal production is realized, the problems that the labor intensity is high and the production efficiency is low when fish scales are removed manually are solved, and the fish scale removing machine is particularly applicable to the treatment before fish is processed in production enterprises.

Owner:YANGTZE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com