Cable and steel wire rope roller supporting device

A technology of wire rope rollers and supporting devices, applied in the field of cables and wire rope laying equipment, can solve the problems of high cost input and manpower, and achieve the effect of flexible and convenient installation and use, reducing investment in construction equipment, and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

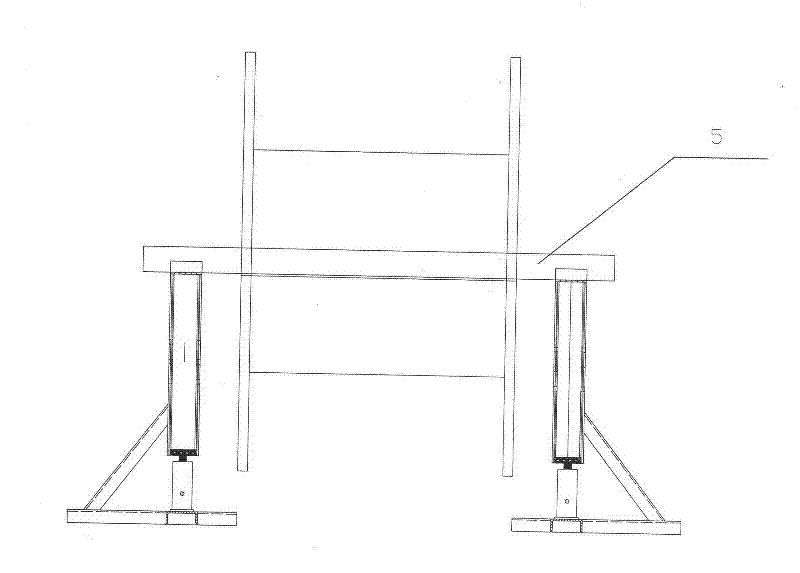

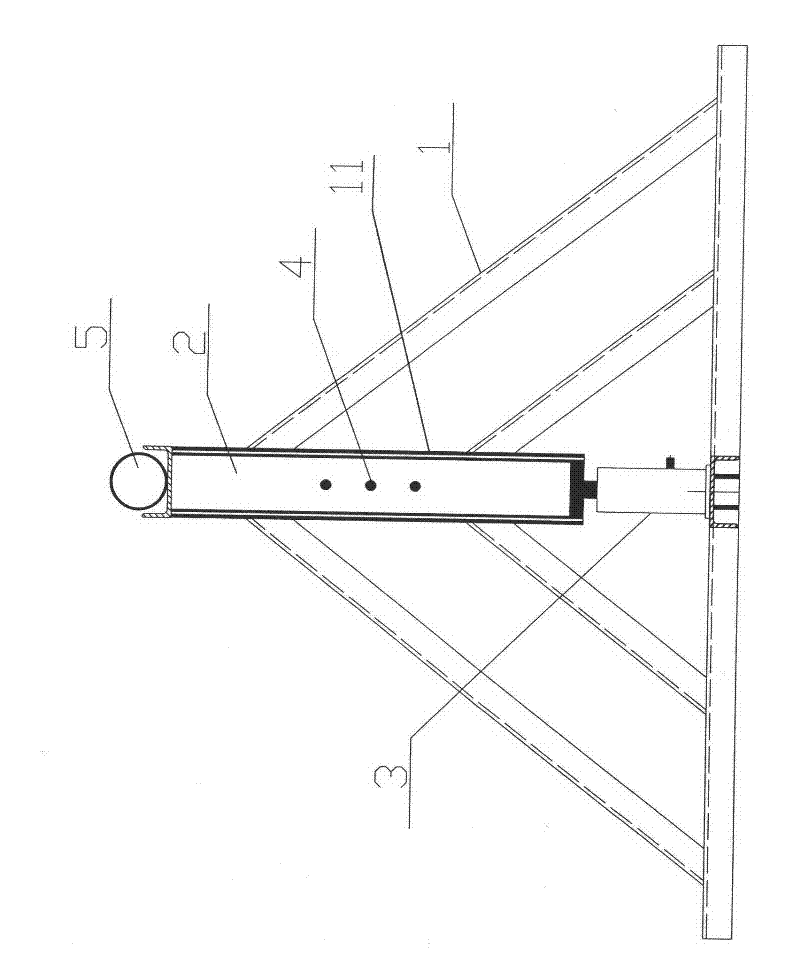

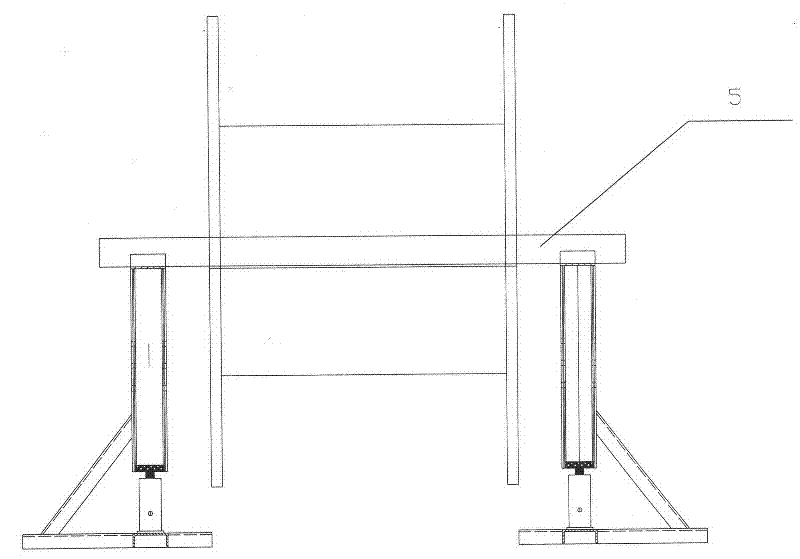

[0011] like figure 1 , figure 2 As shown, the cable and wire rope roller support device includes two mutually independent support frames and a horizontally placed roller bar 5, and the two ends of the roller bar 5 are respectively placed on the two support frames; the support frame includes a support frame main body 1, a movable support 2 , jack 3, positioning pin 4; described support frame main body 1 has a steel pipe 11 vertically installed, movable support 2 is installed in steel pipe 11, and jack 3 is installed in the following of movable support 2, on movable support 2 and steel pipe 11 There is a height adjustment hole matched with the positioning pin shaft 4, and the movable support 2 is positioned by passing the positioning pin shaft 4 into the height adjustment hole.

[0012] According to the weight of the pre-laid cables or steel wire ropes and the height of the cable or steel wire rope rollers, the specifications, models and sizes of the materials used for the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com