A yarn twist tester

A tester and yarn technology, which is applied in the field of textile yarn twist testing and recording, can solve the problems of accurate, convenient and fast measurement of twist, large error in measurement results, and low degree of automation, and achieves complete functions and reliable performance. , advanced circuit design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

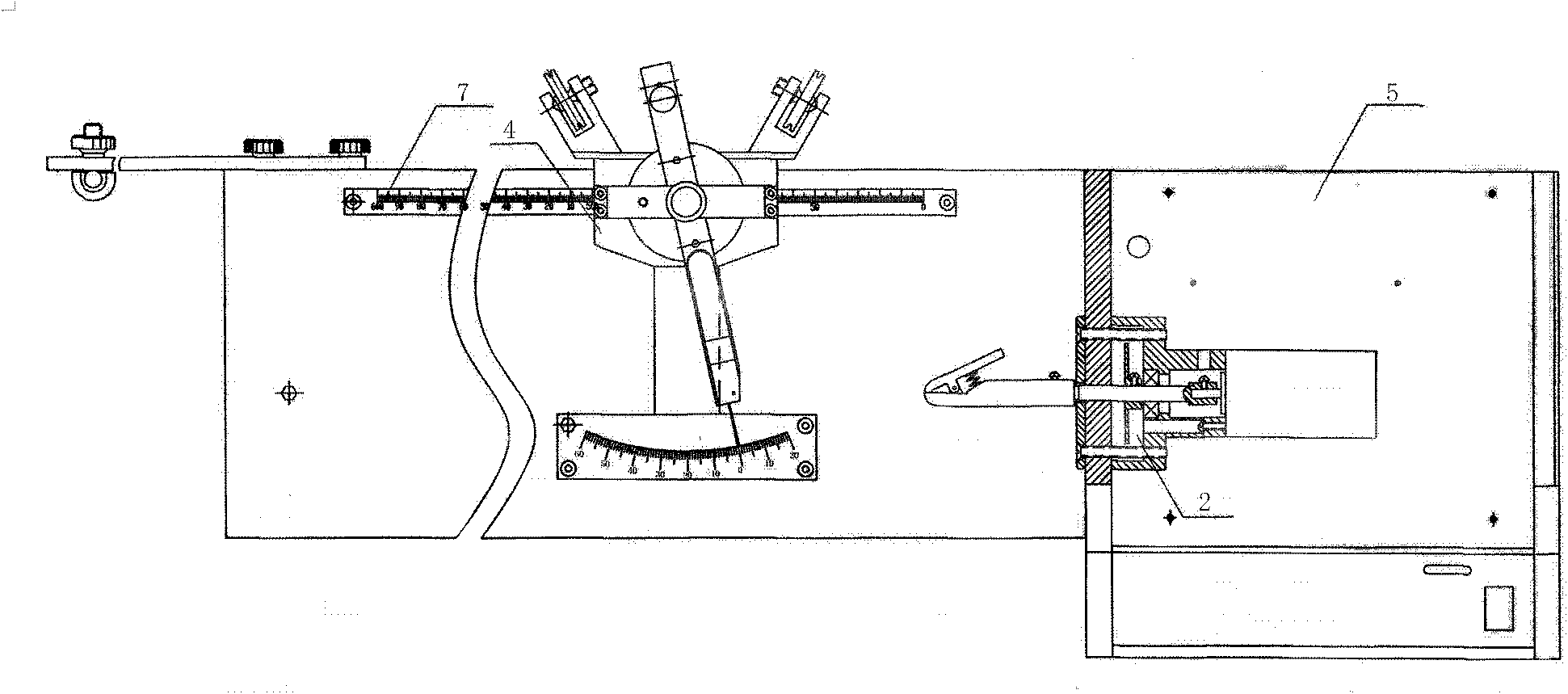

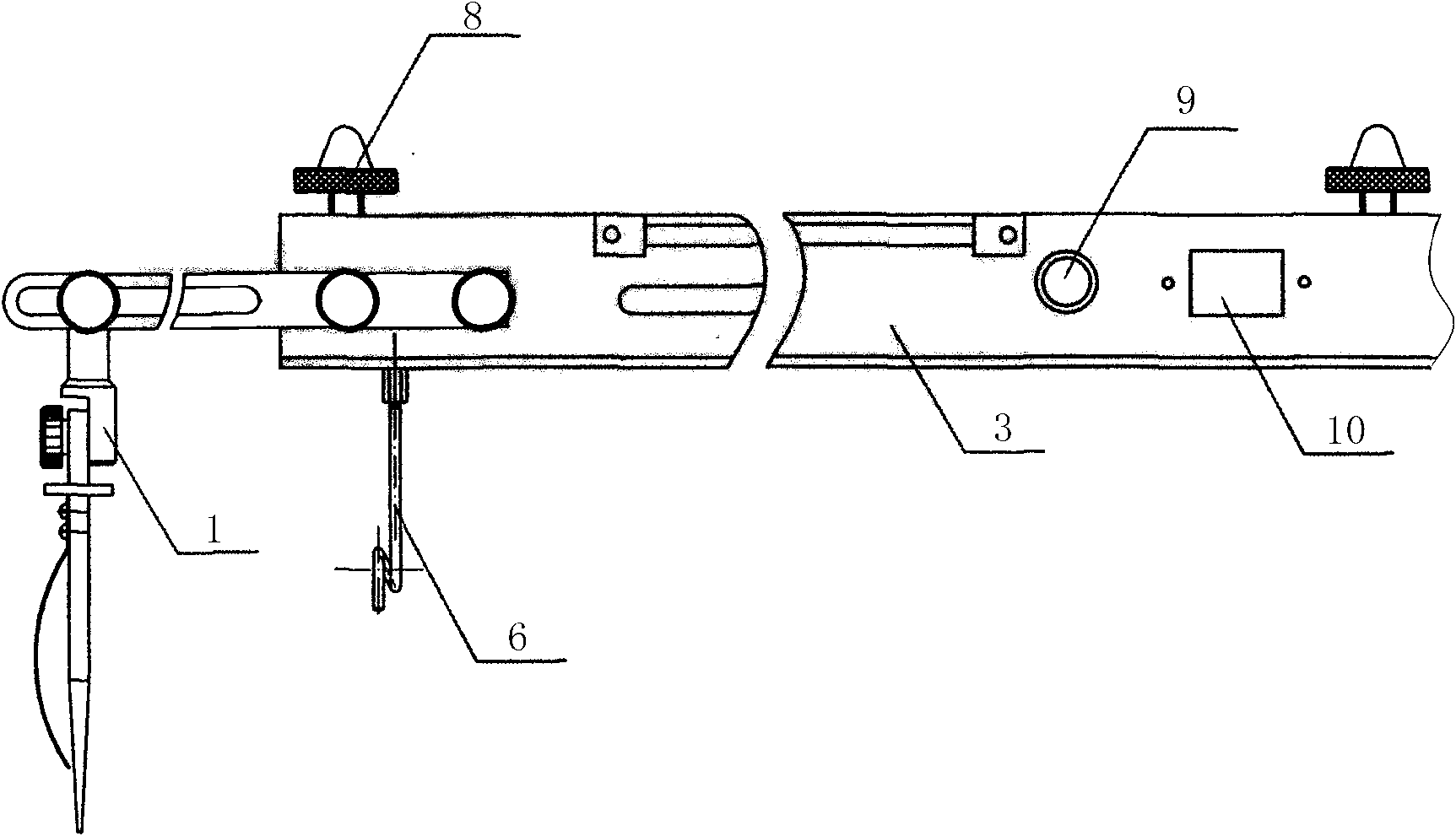

[0017] Example 1: A kind of yarn twist tester provided by the present embodiment, the structure is as follows: figure 1 and figure 2 As shown, it includes a creel assembly 1, a rotating chuck assembly 2, a chassis assembly 3 and a tension adjustment assembly 4. The two ends of the chassis assembly 3 are respectively fixed with the creel assembly 1 and the rotating chuck assembly 2 by bolts. One end of the chuck assembly 2 is provided with a machine head joint 5, and a tension adjustment assembly 4 is installed horizontally on the upper surface of the chassis assembly 3 between the creel assembly 1 and the rotary chuck assembly 2, and on the chassis assembly at one side of the creel assembly. Also be vertically installed with yarn guide hook 6, the top of yarn guide hook is " z " shape, and the bottom yarn guide hook seat of yarn guide hook and chassis assembly 3 adopt bolt connection and fix.

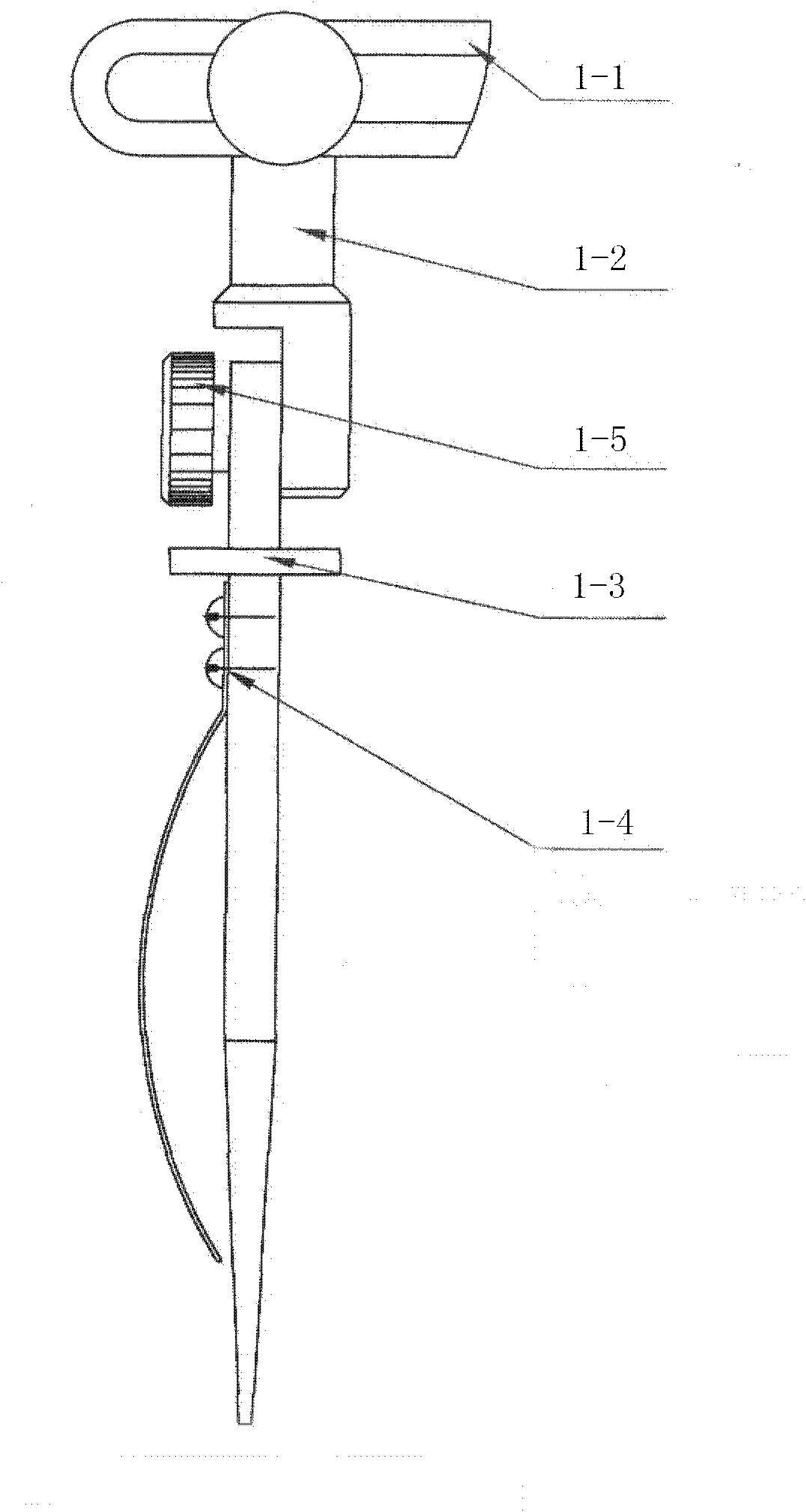

[0018] like image 3 and Figure 4 As shown, the creel assembly includes a wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com