Five-roll metal plate and strip straightening machine

A straightening machine and strip technology, applied in the field of metal strip straightening machinery, can solve problems such as poor working conditions, heavy weight, and large equipment volume, and achieve improved bearing working conditions, reduced roll weight, and simplified equipment structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

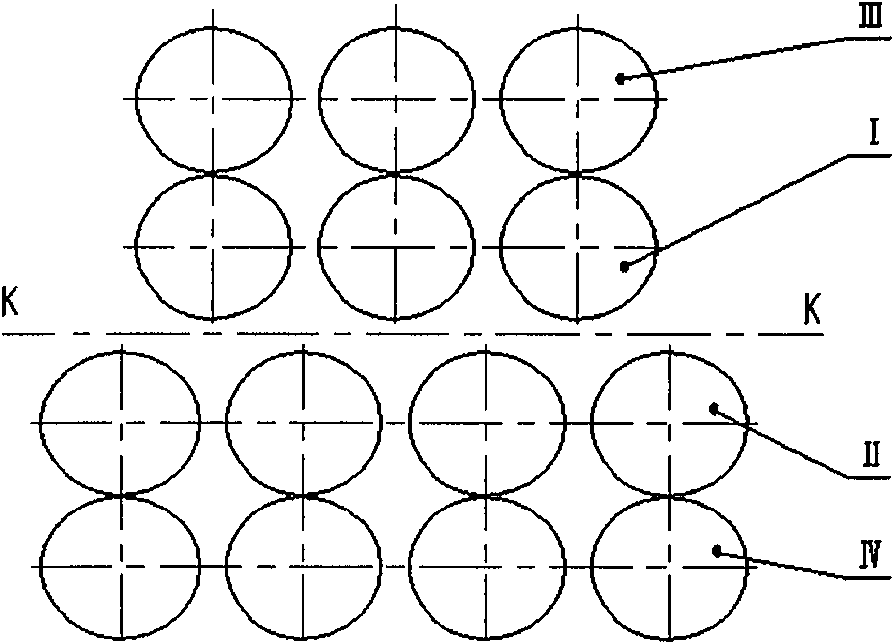

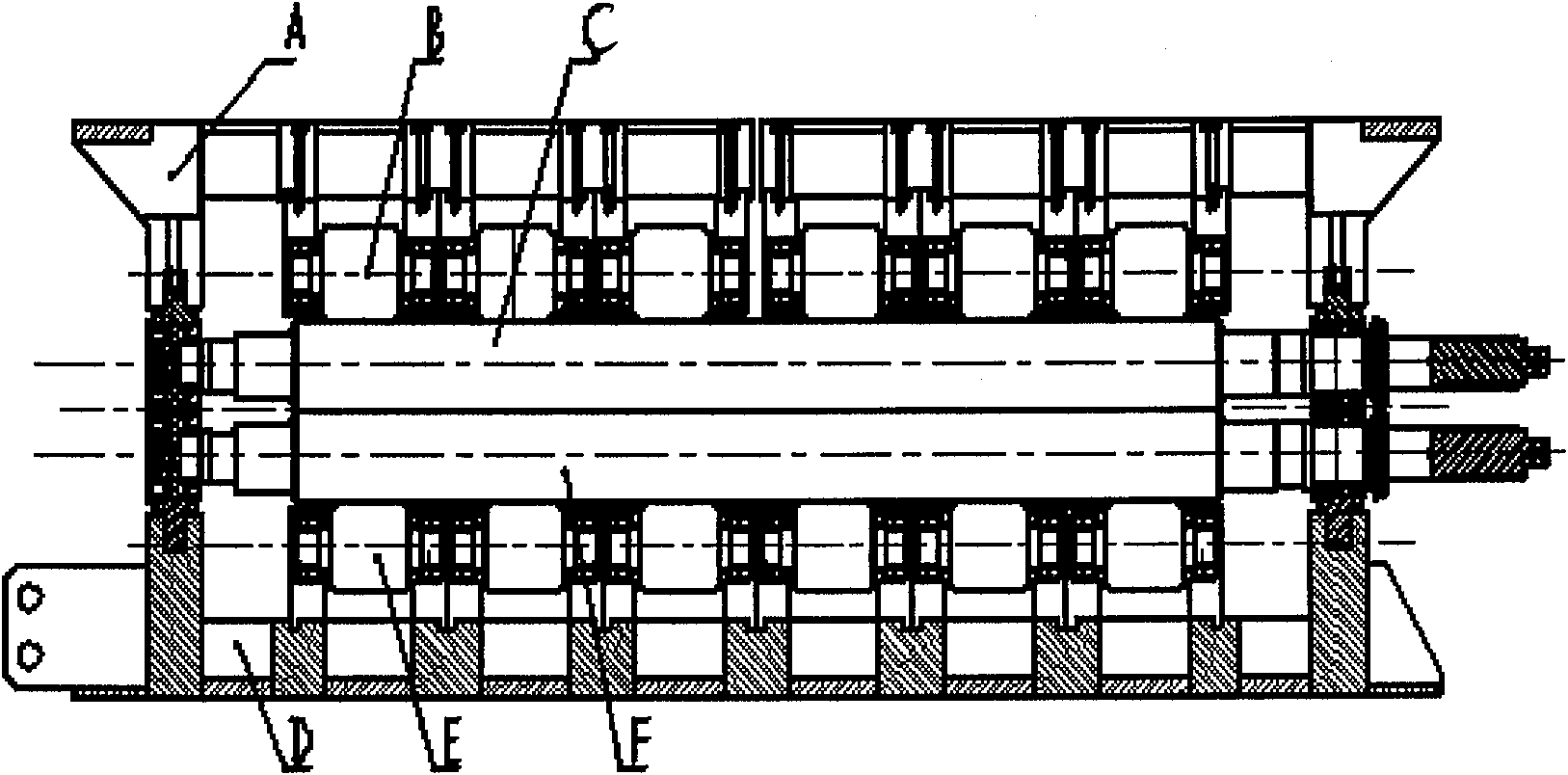

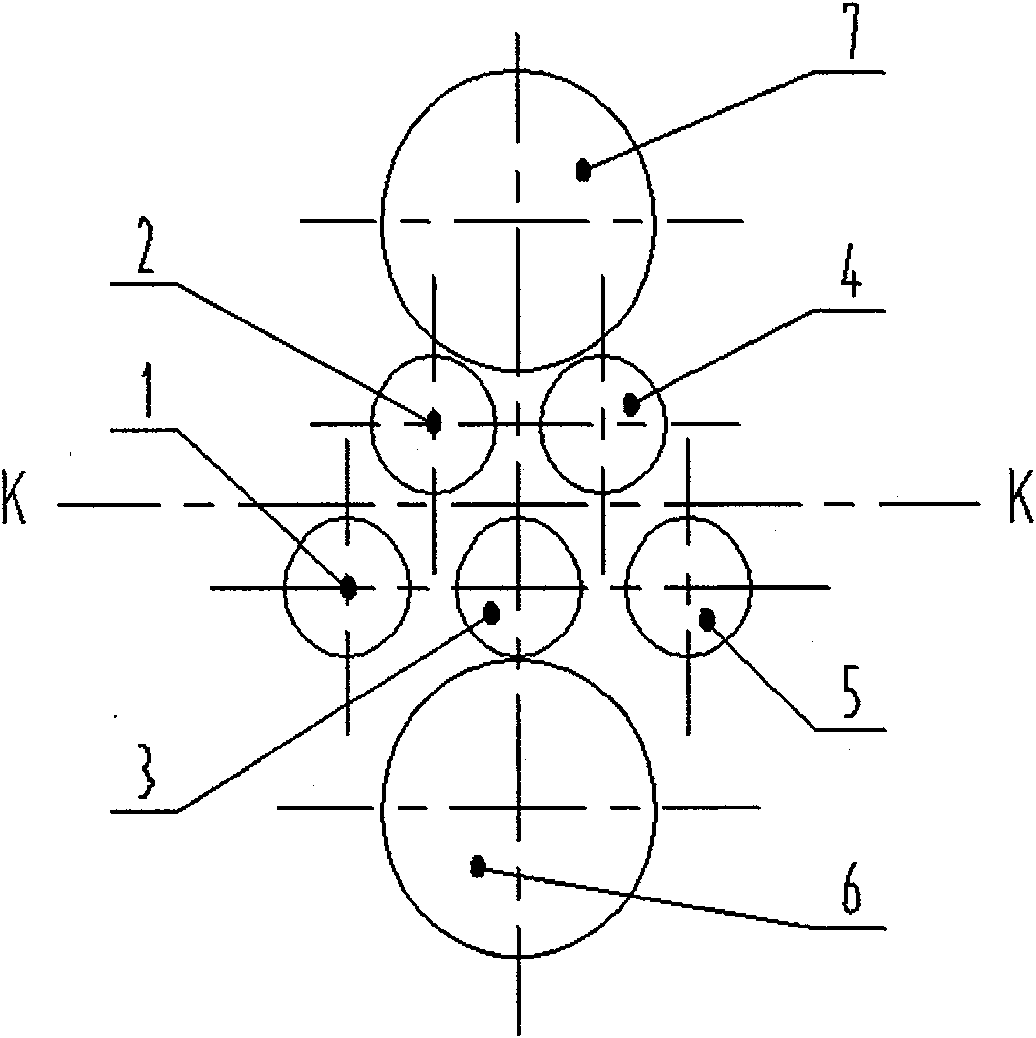

[0009] Such as image 3 Shown is a schematic diagram of the arrangement of the support mode of the roll system in the present invention. Among the figures, 2 and 4 are upper straightening rolls, 1, 3, and 5 are lower straightening rolls, K-K is the rolling center line, and upper straightening rolls 2 and 4 are The lower straightening rolls 1, 3, and 5 are alternately arranged along the rolling center line K-K, the diameters of the upper and lower straightening rolls are equal, and the upper support roll 7 with a diameter 3-5 times the diameter of the straightening rolls is installed on two On the middle position above the straightening rollers 2,4 (being the vertical center line of the straightening machine), its roll surface is in contact with the roll surfaces of the straightening rollers 2,4. The lower backup roll 6 that diameter is 3-5 times of straightening roller diameter is installed on the following of lower straightening roller 3 (being the vertical center line of str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com