Steel bar bending machine

A technology for bending machines and steel bars, applied in the field of steel bar bending machines, can solve the problems of low work efficiency, difficulty in determining the angle, increase the production cost of prestressed square piles, etc., and achieve the effect of easy operation and simple machine design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

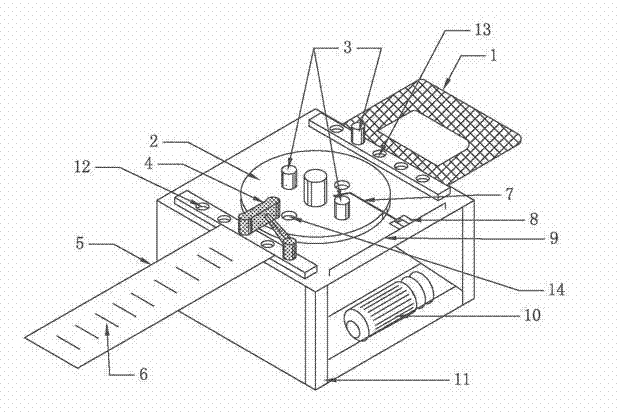

[0015] like figure 2 As shown, a steel bar bending machine, the steel bar bending machine includes a main frame 11 of a body, a motor 10, a reducer, a bending turntable 2, and an operating table 1; The turntable 2 is connected; the operating table is connected to the upper edge of the main frame 11 of the body; the turning turntable 2 is provided with a turntable bending column socket 14; hole 13; the steel bar bending machine also includes a bending column 3 matched with the turntable bending column insertion hole 14 and the bending column insertion hole 13;

[0016] The steel bar bending machine also includes a limit device, which includes a slideway 9, a limiter 8, and a limiter rod 7; the slideway 9 is located on the edge of the upper surface of the main frame 10 of the body, and the limiter 8 is located on the slideway 9. ; One end of the limit rod 7 is connected with the limiter 8, and the other end extends to the bending turntable 2, and the length exceeds the bending...

Embodiment 2

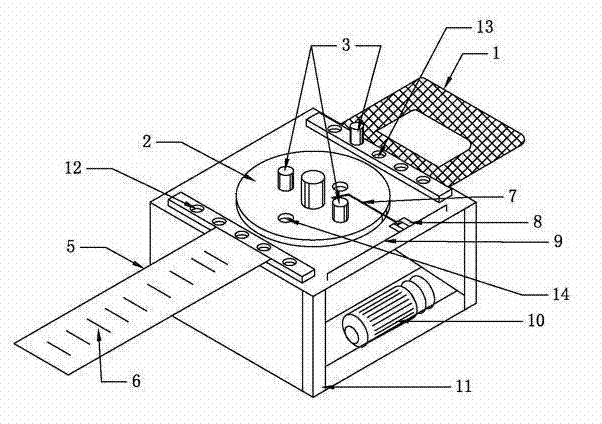

[0023] like figure 1 As shown, a steel bar bending machine, the steel bar bending machine includes a main body frame 11, a motor 10, a reducer, a bending turntable 2, and an operating table 1; The turntable 2 is connected; the operating table is connected to the upper edge of the main frame 11 of the body; the turning turntable 2 is provided with a turntable bending column socket 14; hole 13; the steel bar bending machine also includes a bending column 3 matched with the turntable bending column insertion hole 14 and the bending column insertion hole 13;

[0024] The steel bar bending machine also includes a limit device, which includes a slideway 9, a limiter 8, and a limiter rod 7; the slideway 9 is located on the edge of the upper surface of the main frame 10 of the body, and the limiter 8 is located on the slideway 9. ; One end of the limit rod 7 is connected with the limiter 8, and the other end extends to the bending turntable 2, and the length exceeds the bending colum...

Embodiment 3

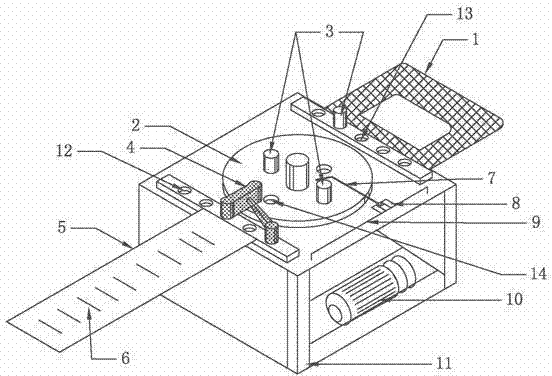

[0029] A steel bar bending machine, the steel bar bending machine includes a body main frame 11, a motor 10, a reducer, a bending turntable 2, and an operating table 1; connection; the operating table is connected to the upper edge of the main frame 11 of the body; the bending turntable 2 is provided with a turntable bending column socket 14; the upper surface of the main body 11 is provided with a front bending column socket 13 near the operating table; The steel bar bending machine also includes a bending column 3 matched with the turntable bending column insertion hole 14 and the bending column insertion hole 13;

[0030] The steel bar bending machine also includes a limit device, which includes a slideway 9, a limiter 8, and a limiter rod 7; the slideway 9 is located on the edge of the upper surface of the main frame 10 of the body, and the limiter 8 is located on the slideway 9. ; One end of the limit rod 7 is connected with the limiter 8, and the other end extends to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com