Electric spark forming processing machine tool for processing non-conductive hard material and its processing method

A hard material, forming processing technology, applied in the direction of metal processing machinery parts, electric processing equipment, metal processing equipment, etc., can solve the problems of no industrial production, to avoid short circuit phenomenon, high power utilization rate, simple and reliable process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

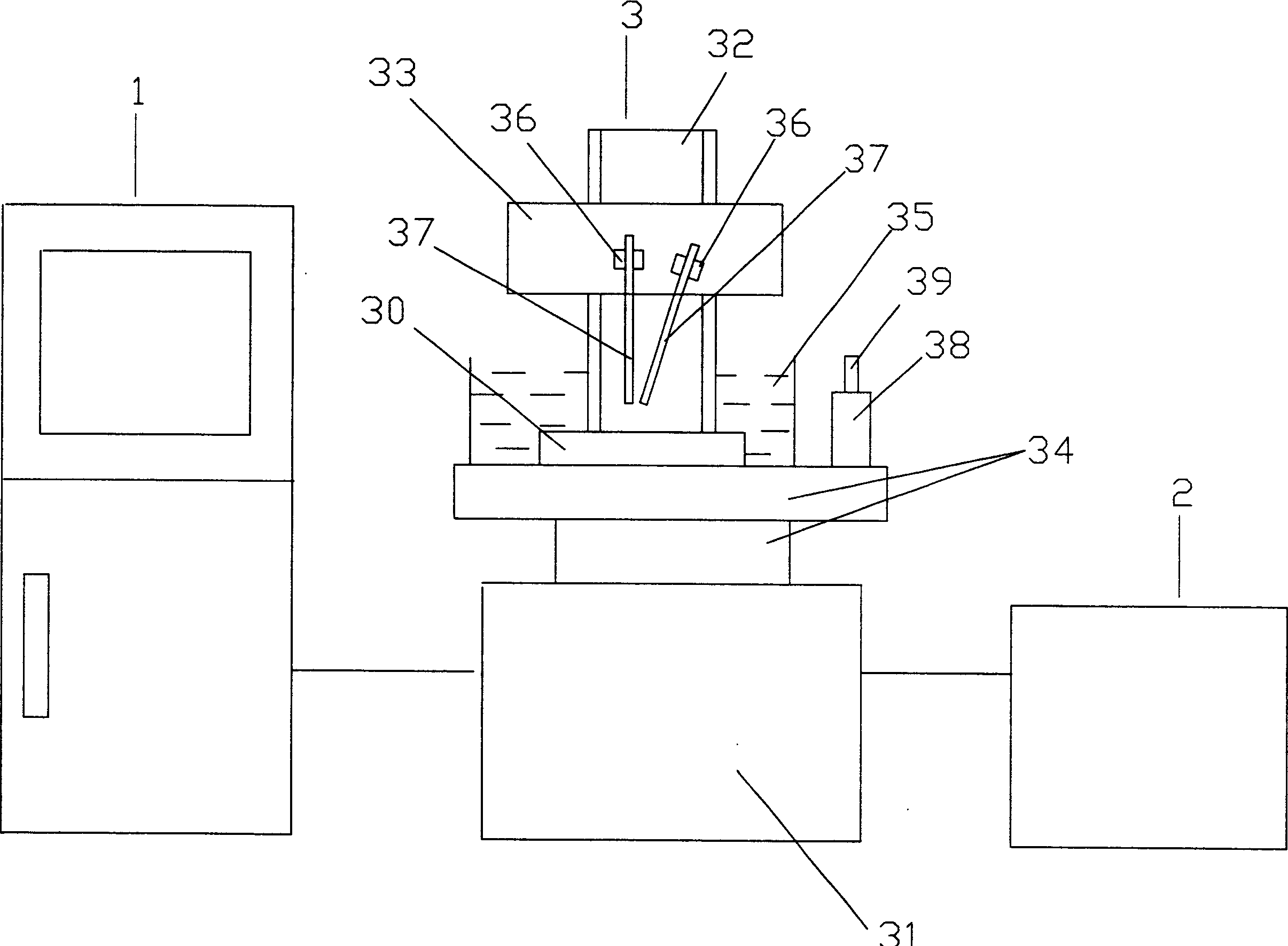

Embodiment 1

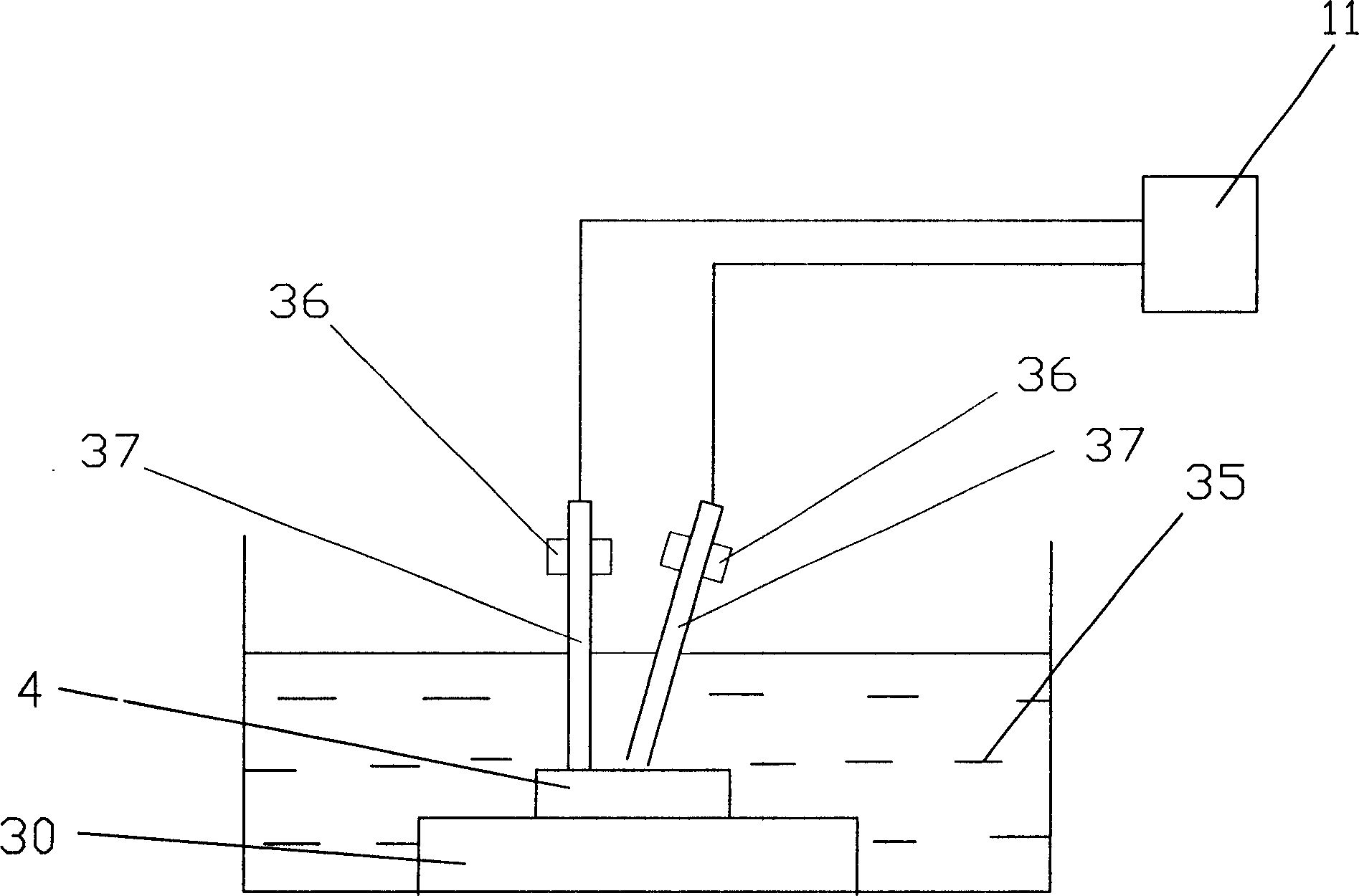

[0019] Such as figure 1 As shown, the machine tool of the present invention has a control electric cabinet 1, a working fluid tank 2 and a processing host 3, wherein the control electric cabinet 1 has a pulse power supply, an electric discharge machining numerical control system and an operation panel, and the electric discharge machining numerical control system realizes the control of the machine tool control and management. Working fluid tank 2 provides circulating working fluid for EDM process. The processing host 3 includes a bed 31, a column 32, a spindle head 33, a worktable 34, a working fluid tank 35, an electrode direct drive device 36, an electrode 37, an electrode clamping length measuring device 38, a high-precision inductive displacement sensor 39 and an insulating base 30. The workbench 34 has an upper layer that completes the linkage of the X-Y two coordinate axes and a lower layer that completes the circular feed motion. The working fluid tank 35 is install...

Embodiment 2

[0023] The rest are the same as in Embodiment 1, except that the distance between the tops of the two electrodes is precisely adjusted to 7 microns; the bottom of the electrodes is in contact with the processed non-conductive engineering ceramic material 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com