Electronic shifter shift calibration equipment and operation method thereof

An electronic shifter and shifter technology, applied in the direction of instruments, using electric devices, using electromagnetic means, etc., can solve the problems of continuous measurement, different requirements for gear recognition areas, etc., achieve convenient and simple detection methods, and avoid repetition Design, Design Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

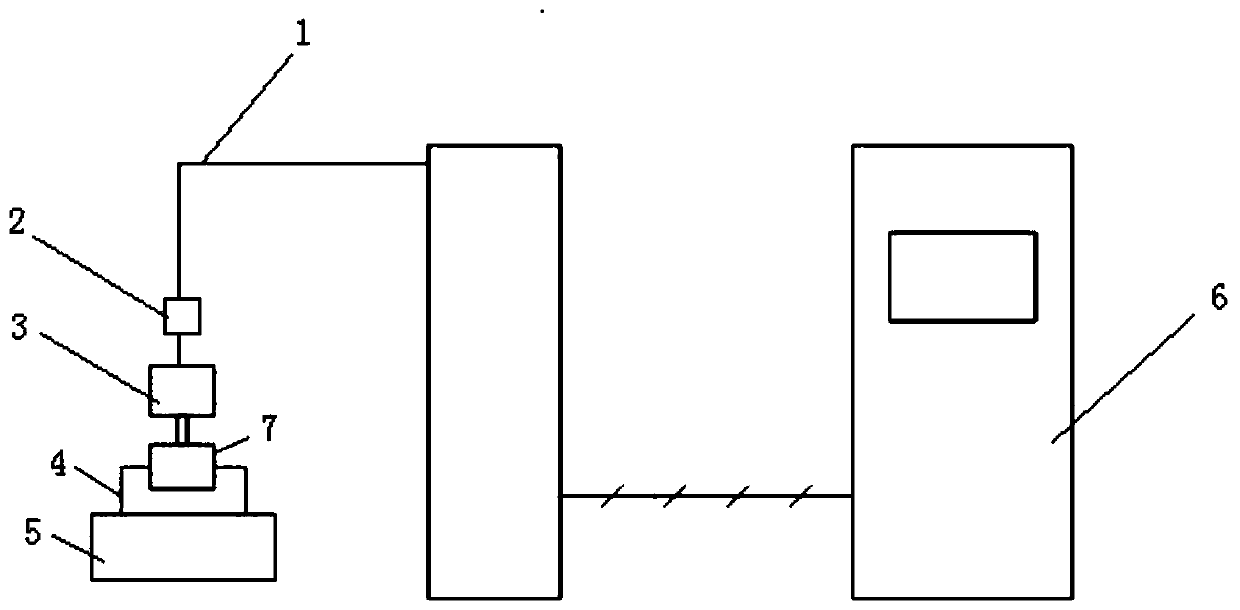

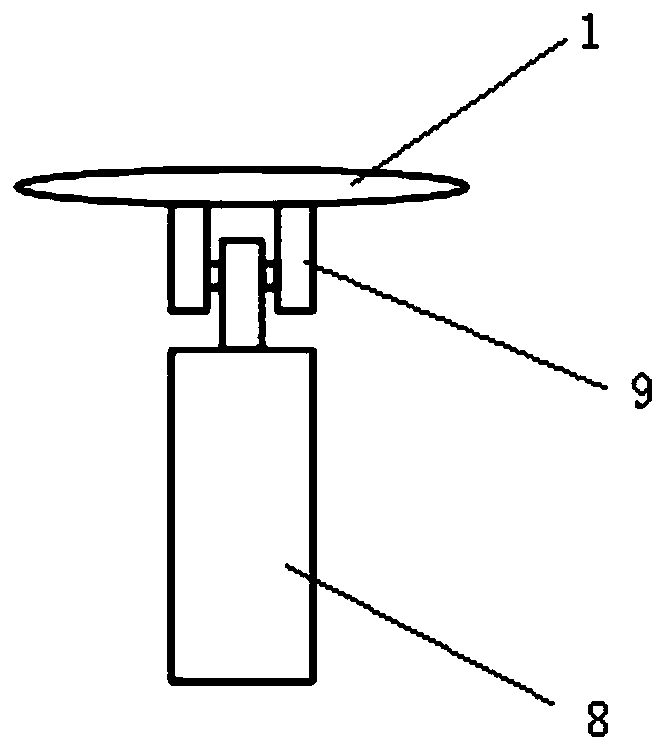

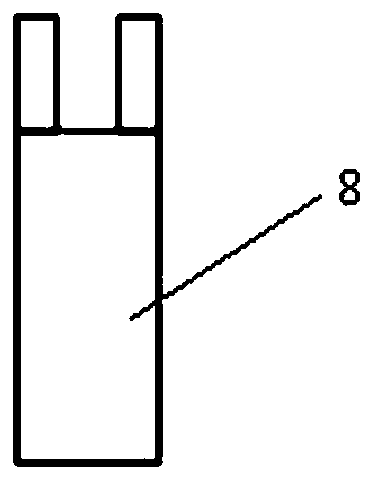

[0036] As shown in the figure, an electronic shifter shift calibration equipment includes a mechanical arm 1, a force sensor 2, a shift linkage mechanism 3, a quick change mechanism 4, a horizontal platform 5 and a control cabinet 6,

[0037] The lower part of the mechanical arm 1 is fixedly installed on the upper side of the horizontal platform 5, the knuckle end of the last joint of the mechanical arm 1 is fixedly connected with the shift linkage mechanism 3, and the third knuckle of the mechanical arm 1 is fixedly installed. The sensor 2 can record the current shift force in real time according to the trajectory of the mechanical arm movement; the upper part of the quick-change mechanism 4 is fixedly connected with the tested shifter 7 through the clamping part, and the lower part of the quick-change mechanism 4 is connected to the horizontal platform The upper part of 5 is fixedly connected; the control cabinet 6 is electrically connected with the mechanical arm 1 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com