Method for mounting prefabricated members of roof or floor in place and mounting equipment

A technology for prefabricated components and floor layers, which is applied in building construction, construction, and building materials processing, etc., and can solve problems such as large manpower, inability to hoist and install components, and large manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

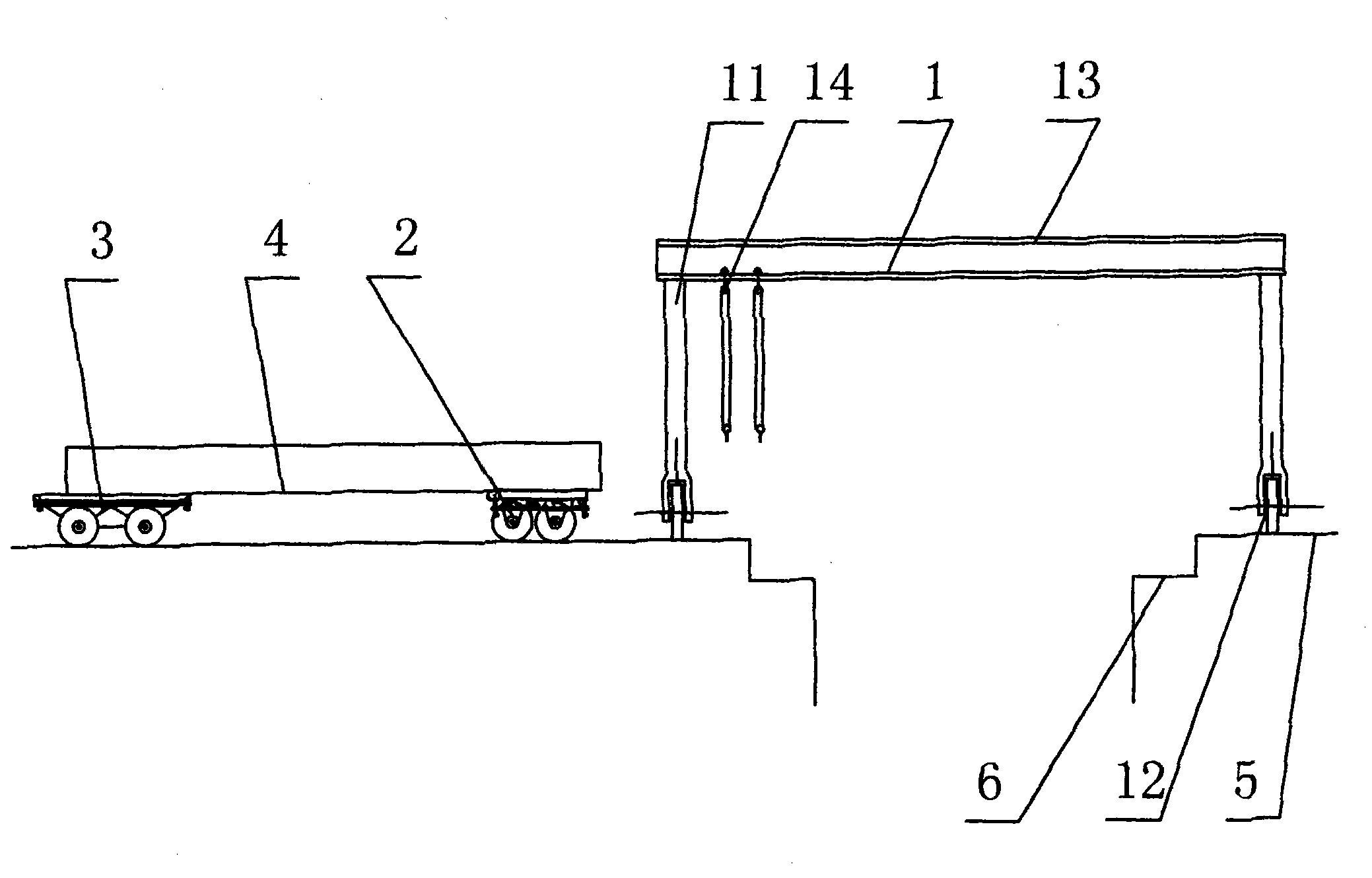

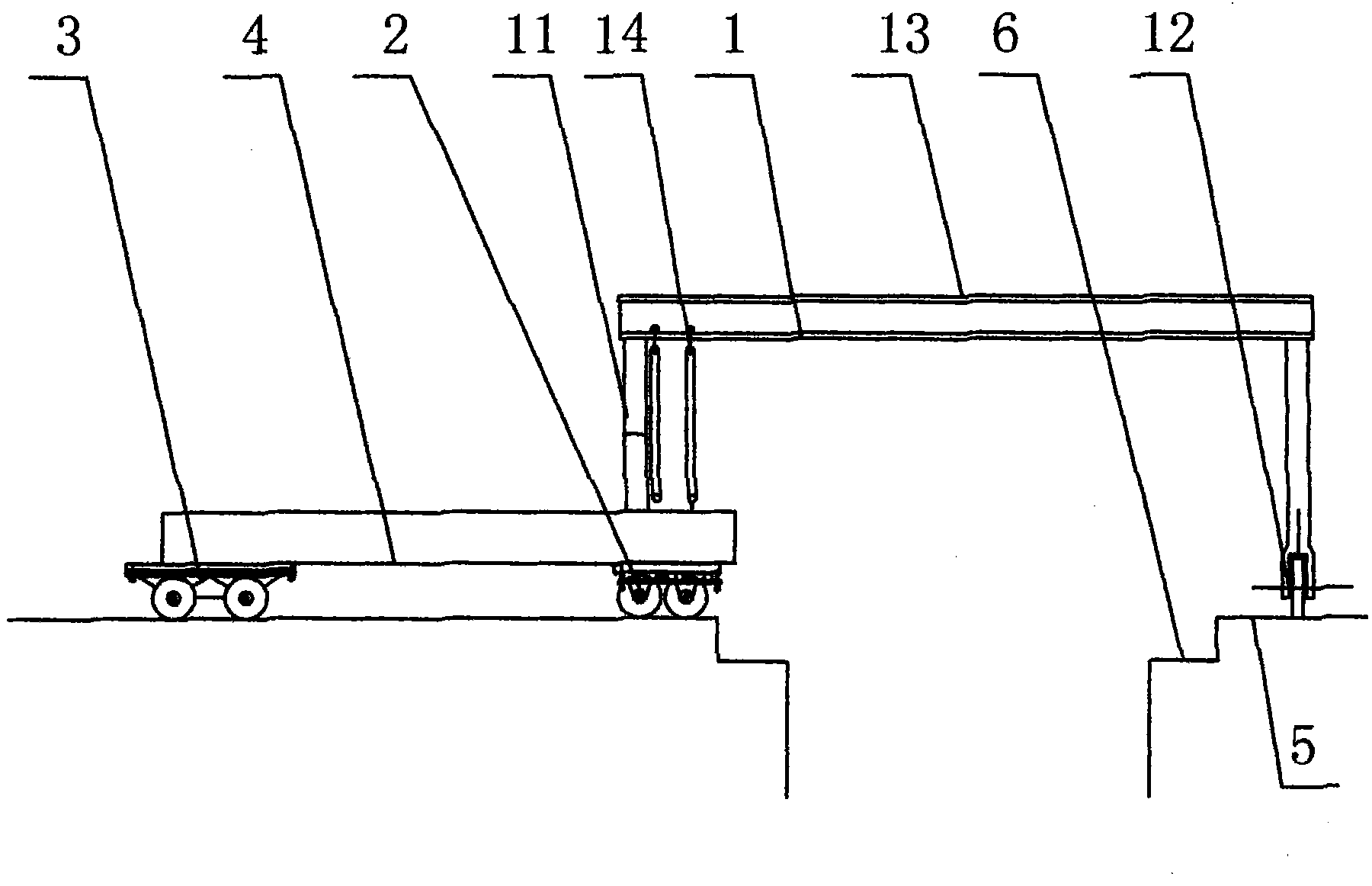

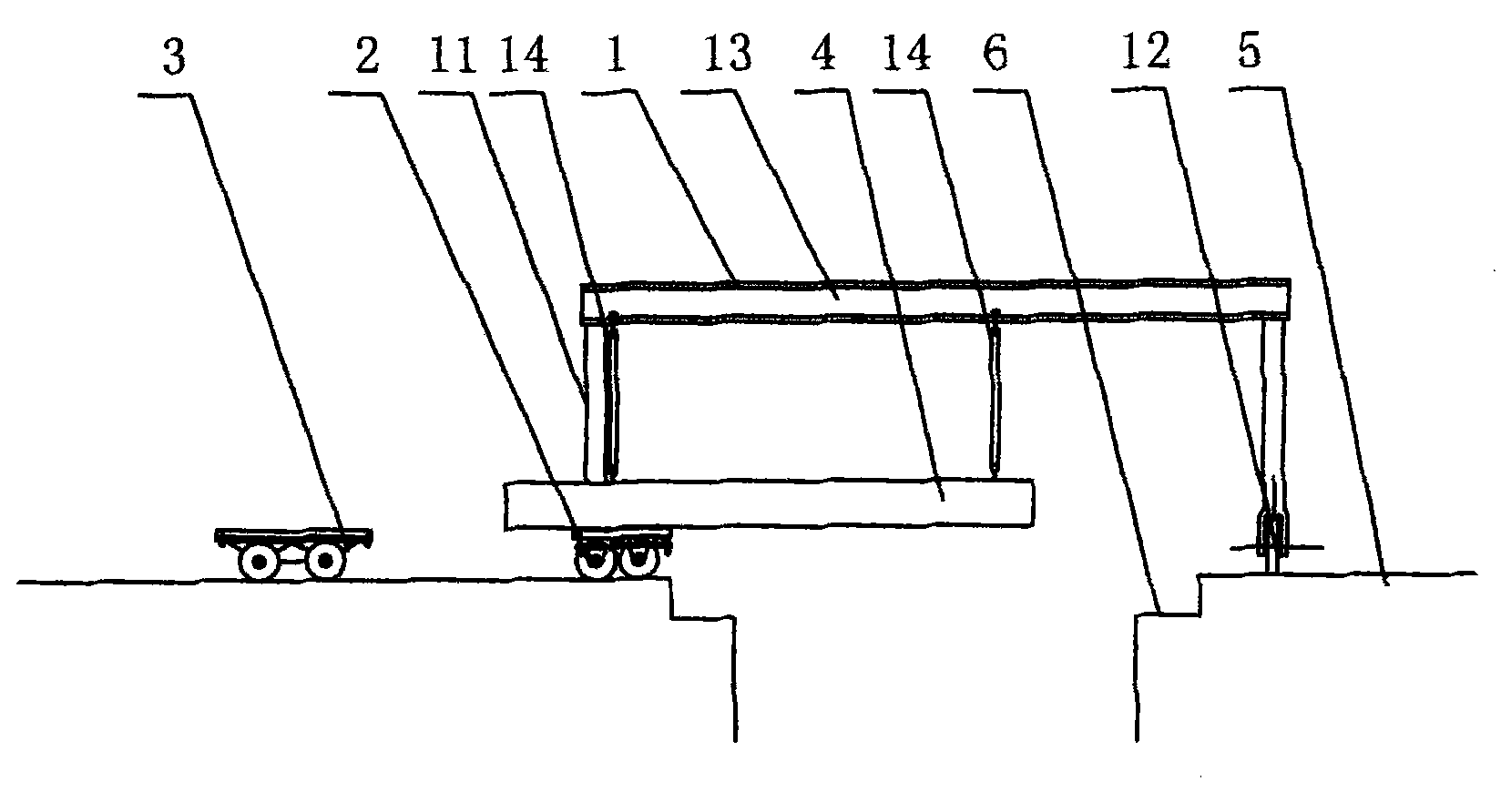

[0030] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown: A method for in-situ installation of roof or floor components, which uses a tower crane to hoist the components to the roof or floor, and then hoisting, including the following installation steps:

[0031] A. Support the two ends of the component on the front and rear two trolleys respectively, set a gantry hanger, the gantry hanger spans the two sides of the component installation place, adjust the front and rear two trolleys position, so that the member and the crossbeam of the gantry hanger are on the same vertical plane; as figure 1 As shown, in this embodiment, the front and rear trolleys can be moved manually, or the trolley can be controlled by the power and control system to automatically place the components on the same vertical plane as the crossbeam of the gantry hanger. The beams of the gantry hanger can be selected with different lengths according to the needs, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com