Fish scale removing machine

A descaling machine and fish scale technology, applied in the direction of fish cleaning/descaling, can solve the problems that the quality standard is not easy to control, the labor intensity of the operators is high, and a large amount of manpower and material resources are invested, and the descaling effect is good, the structure is simple, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

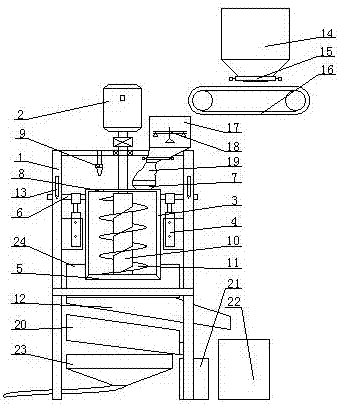

[0024] The fish scale descaling machine is composed of a frame 1, a sieve discharge device, a feeding device, a weighing device and a friction descaling device: the friction descaling device is installed on the frame 1.

[0025] The friction descaling device is composed of a driving motor 2, a descaling bucket 3 and a descaling roller. The descaling bucket 3 is slidably installed on the frame 1; The bottom of the jacking cylinder 4 is provided with; the jacking cylinder 4 is fixedly connected with the assembly slide bar 6; the frame 1 on one side of the assembly slide bar 6 is longitudinally provided with a guide slide hole 13, and the assembly slide bar 6 passes through the guide slide hole 13 and Rack 1 sliding connection.

[0026] The jacking cylinder 4 can drive the descaling bucket 3 to move up and down by assembling the slide bar 6 . The purpose of setting the guide slide hole 13 is to make the descaling bucket 3 move up and down along the frame 1 under the guidance of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com