Small two-stroke four-cylinder horizontally-opposed aero-engine

An aero-engine, horizontally opposed technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the complex control of the four air intake oil supply mechanisms, the complex control of the throttle, the crankshaft and the crank mechanism can not be well lubricated, and affect the engine. Power output and other issues, to achieve the effect of simplifying the difficulty of manufacturing and debugging, wide environmental applicability, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

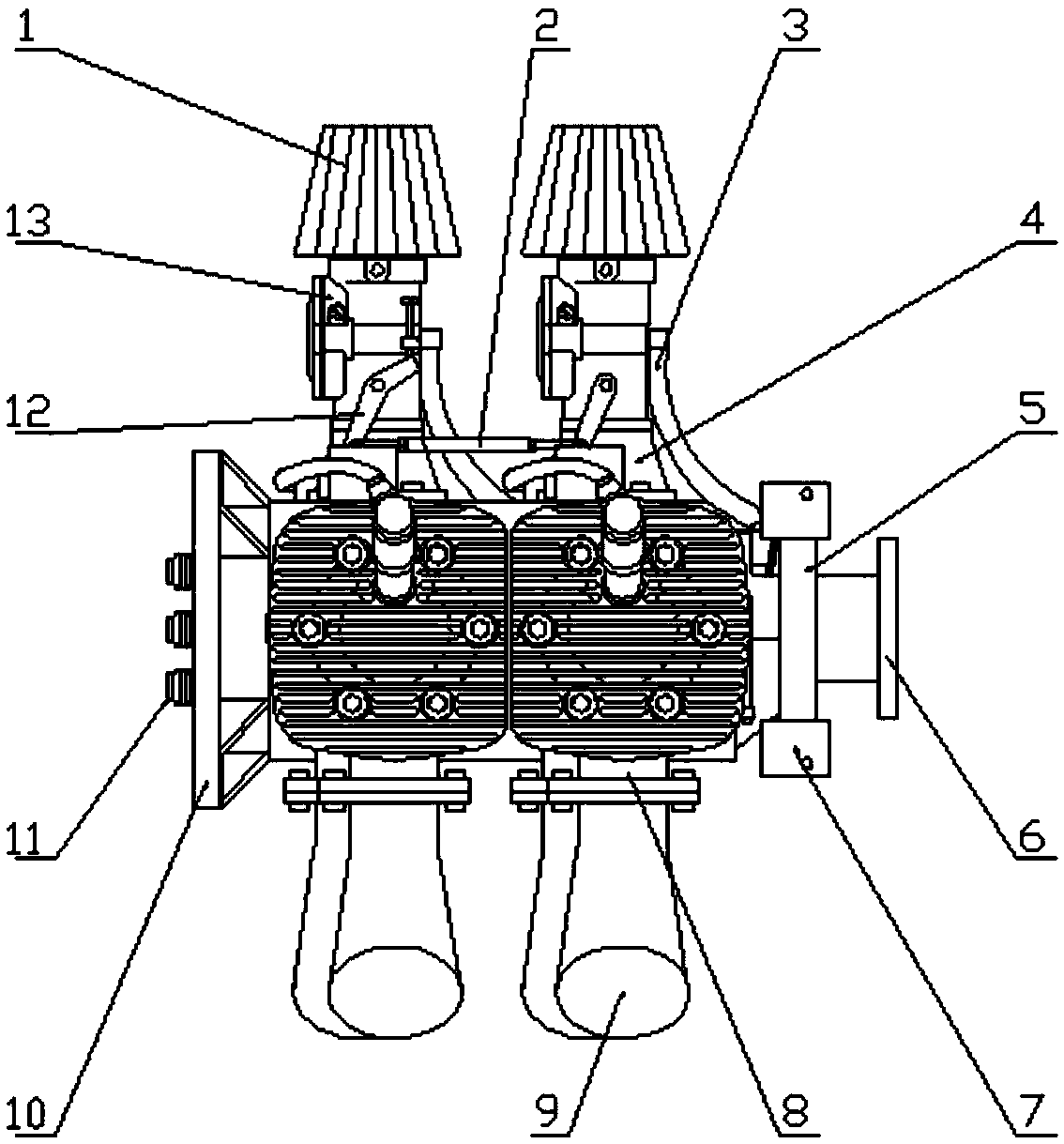

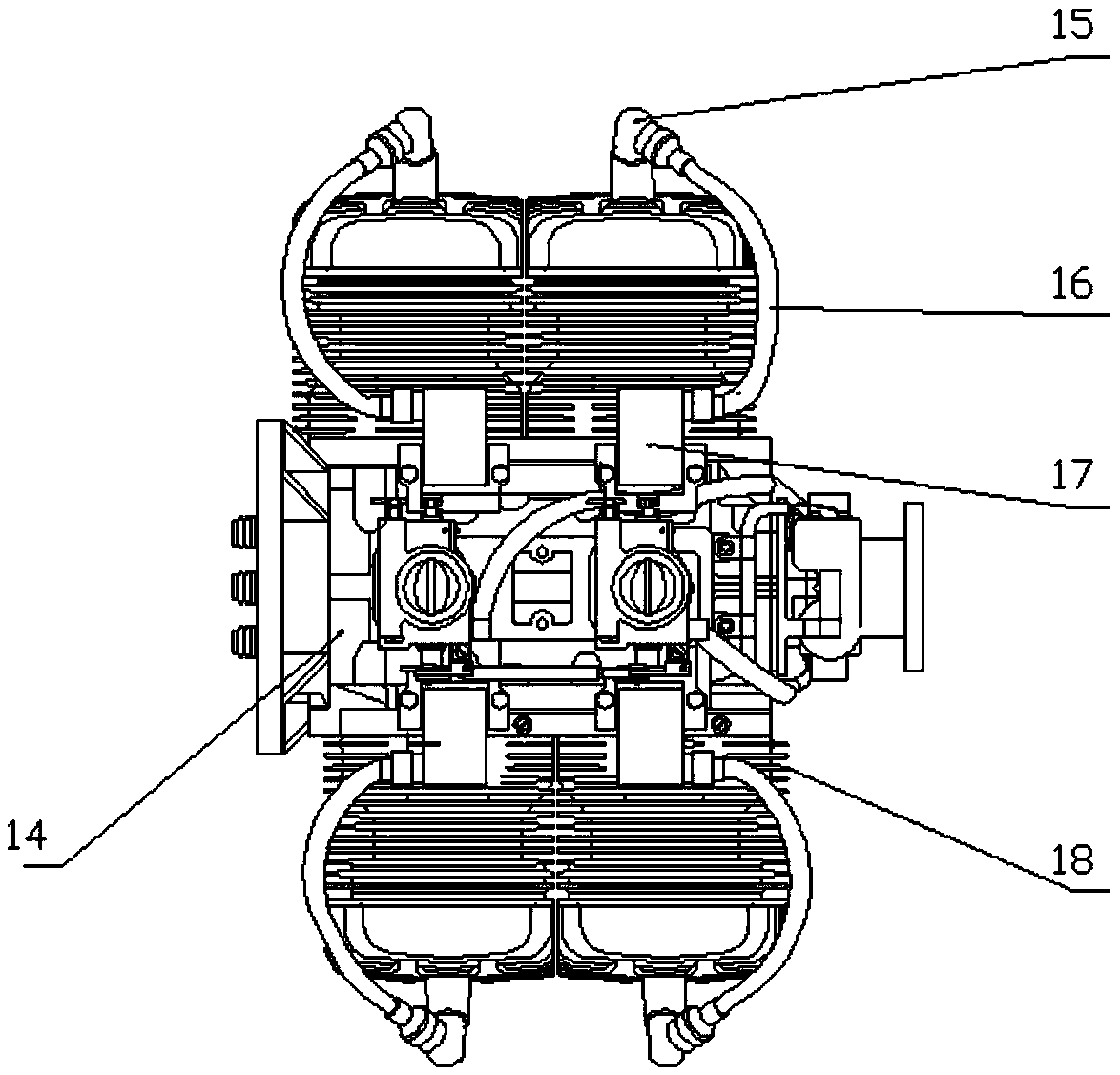

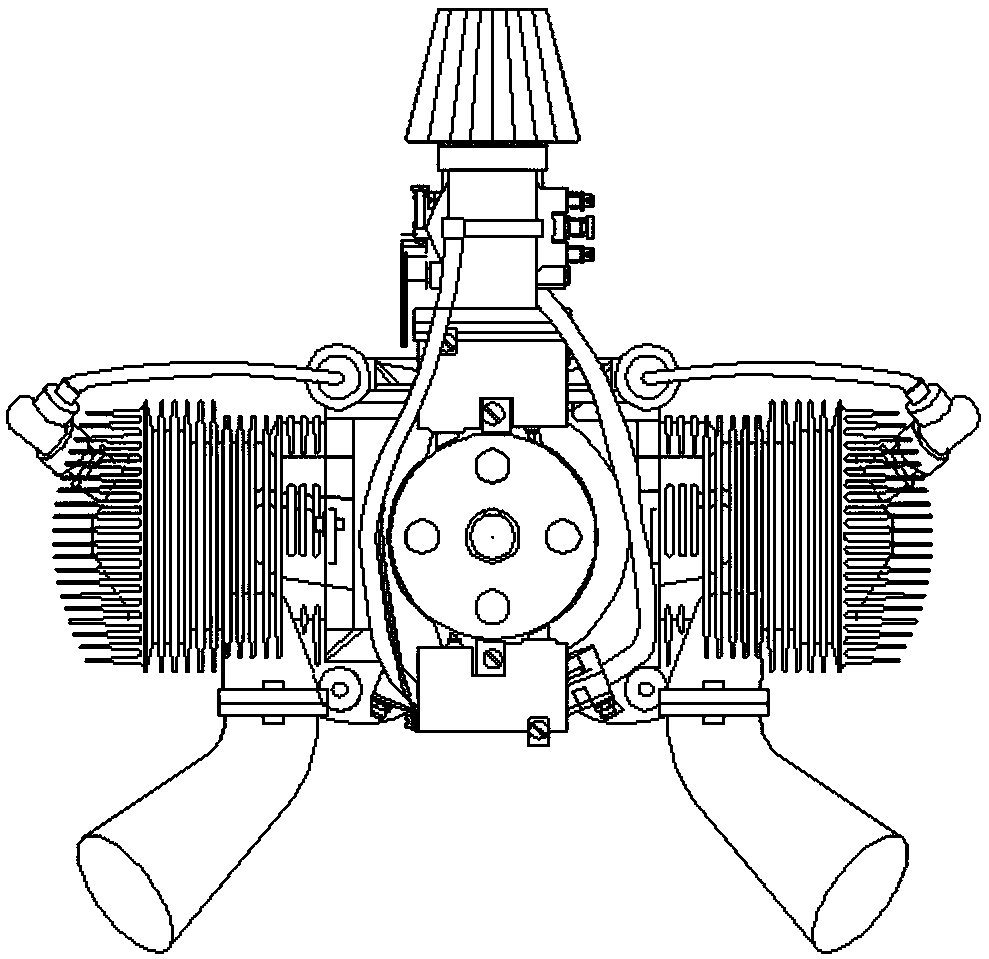

[0025] see Figure 1-Figure 8 , the present invention provides a small two-stroke four-cylinder horizontally opposed piston-type aeroengine, the engine adopts a typical horizontally opposed structure, that is, the crankcase and the crankshaft inside are located on the central axis of symmetry, and the crankshaft is dislocated in pairs along the crankshaft. There are four cylinder blocks located in the center of the crankcase, two carburetor mechanisms or EFI mechanisms on the symmetrical axis of the crankcase; the crankshaft is a two-stage butt joint split structure and adopts a three-support method, and one is installed on the four cranks of the crankshaft. Cracked connecting rod, the crank bearing at the big end of the connecting rod adopts the structure of split needle roller bearings, the small end of the connecting rod is connected to a piston through the integral needle roller bearing, the structure of the piston is a convex three-dimensional curved surface on the top sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com