Processing method and equipment of metal material surface nanometer layer

A metal material and metal surface technology, which is applied to the processing method and equipment field of nano-layers on the surface of metal materials, can solve problems such as low efficiency, high cost, and poor surface quality, and achieve the effect of reducing friction, easy operation, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical features of the present invention will be further described below in conjunction with specific embodiments.

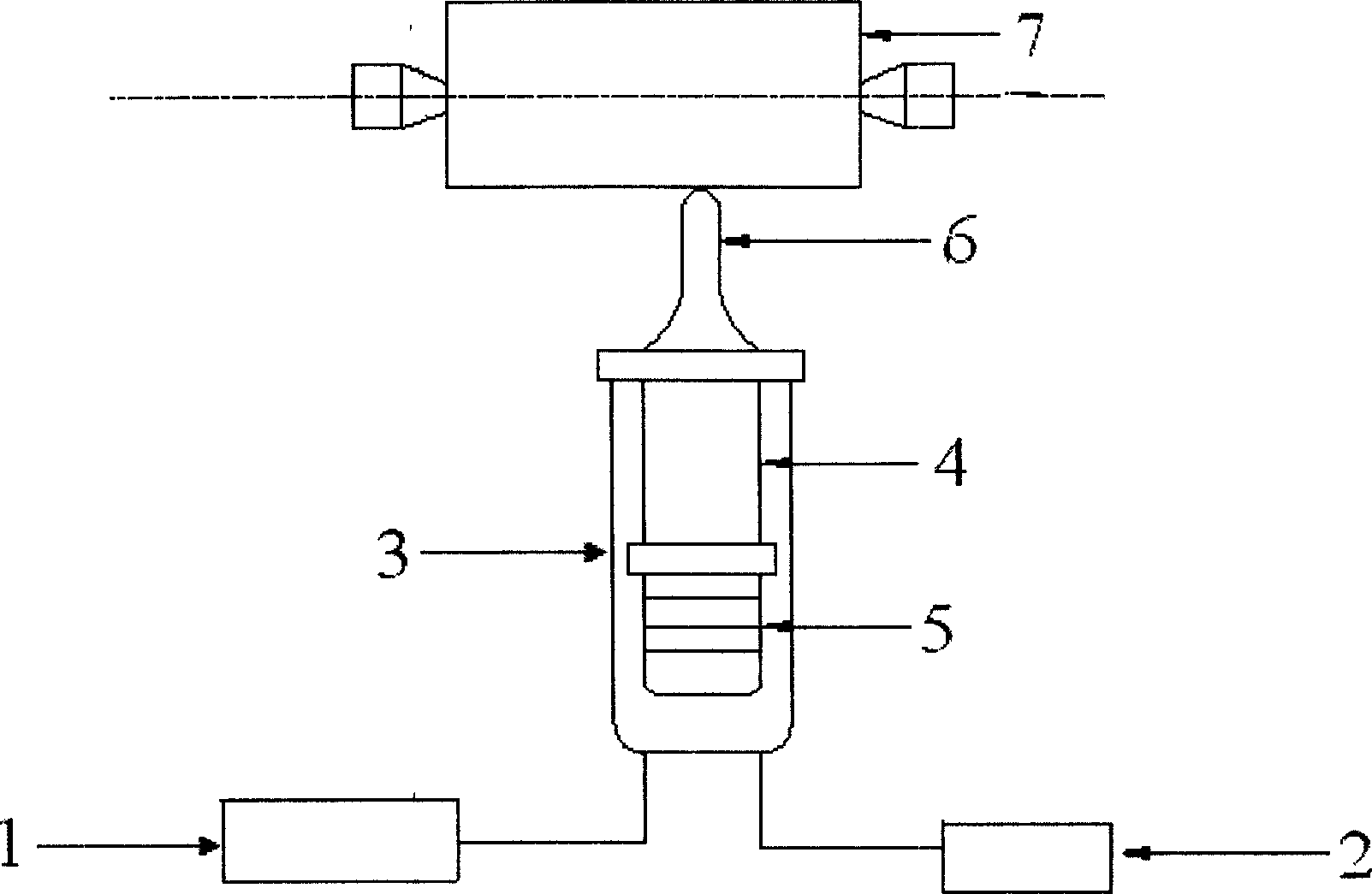

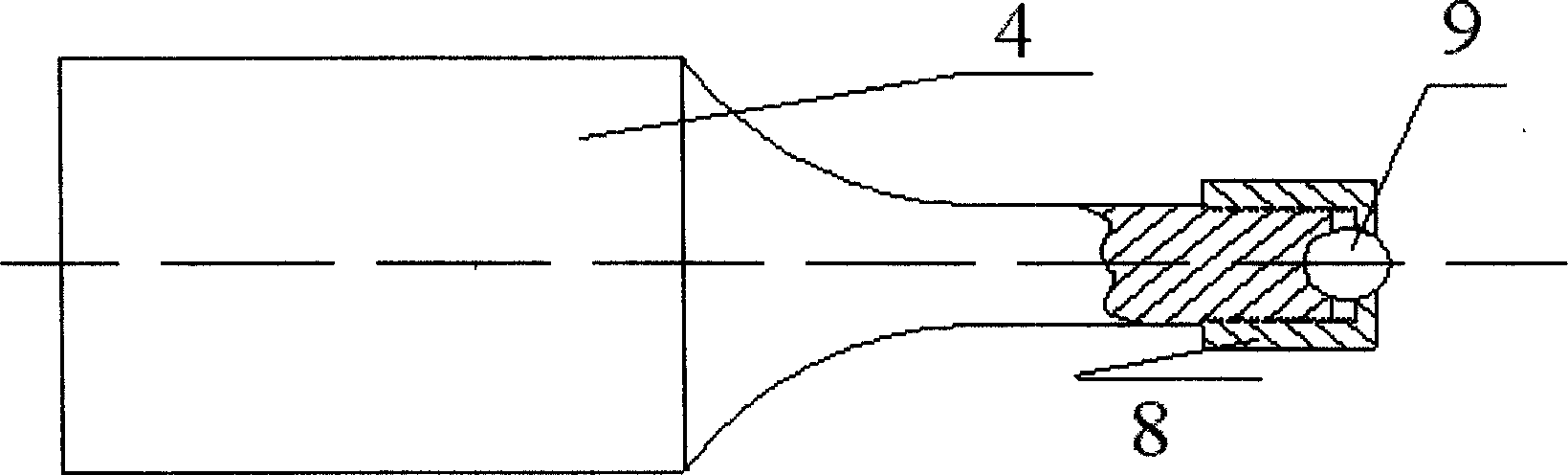

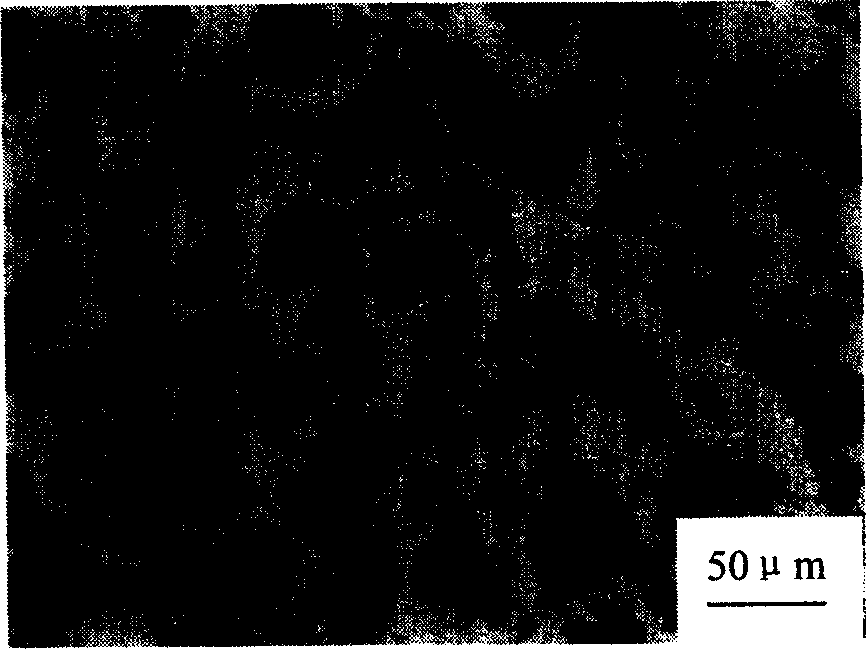

[0030] The processing equipment of the metal material surface nano layer of the present invention is composed of an ultrasonic generator 1, an air pump 2 and a casing 3, a transducer 5 and a horn 4 are arranged inside the casing, and a nano working head 6 is arranged outside the casing , the nano working head can be directly fixed on the horn, or can be fixed on the horn through a threaded structure, and the nano working head can be cylindrical, semi-cylindrical and other shapes, and can also be The wear-resistant ball 9 is fixed on the end of the nanometer working head by fastening the overcoat 8 . The semi-digital and digital control of the ultrasonic generator converts the power frequency alternating current into ultrasonic frequency oscillation to supply energy to the nano working head. High-frequency electrical oscillation signals are convert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com