Abrasive machininging method for ball end mill and four-shaft linkage equipment for abrasive machininging

A ball end mill and grinding technology, which is used in metal processing equipment, milling machine equipment, milling cutters, etc. Complex design and other problems, to achieve the effect of being conducive to economical regrinding and remanufacturing, simple machine tool structure, and avoiding huge waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

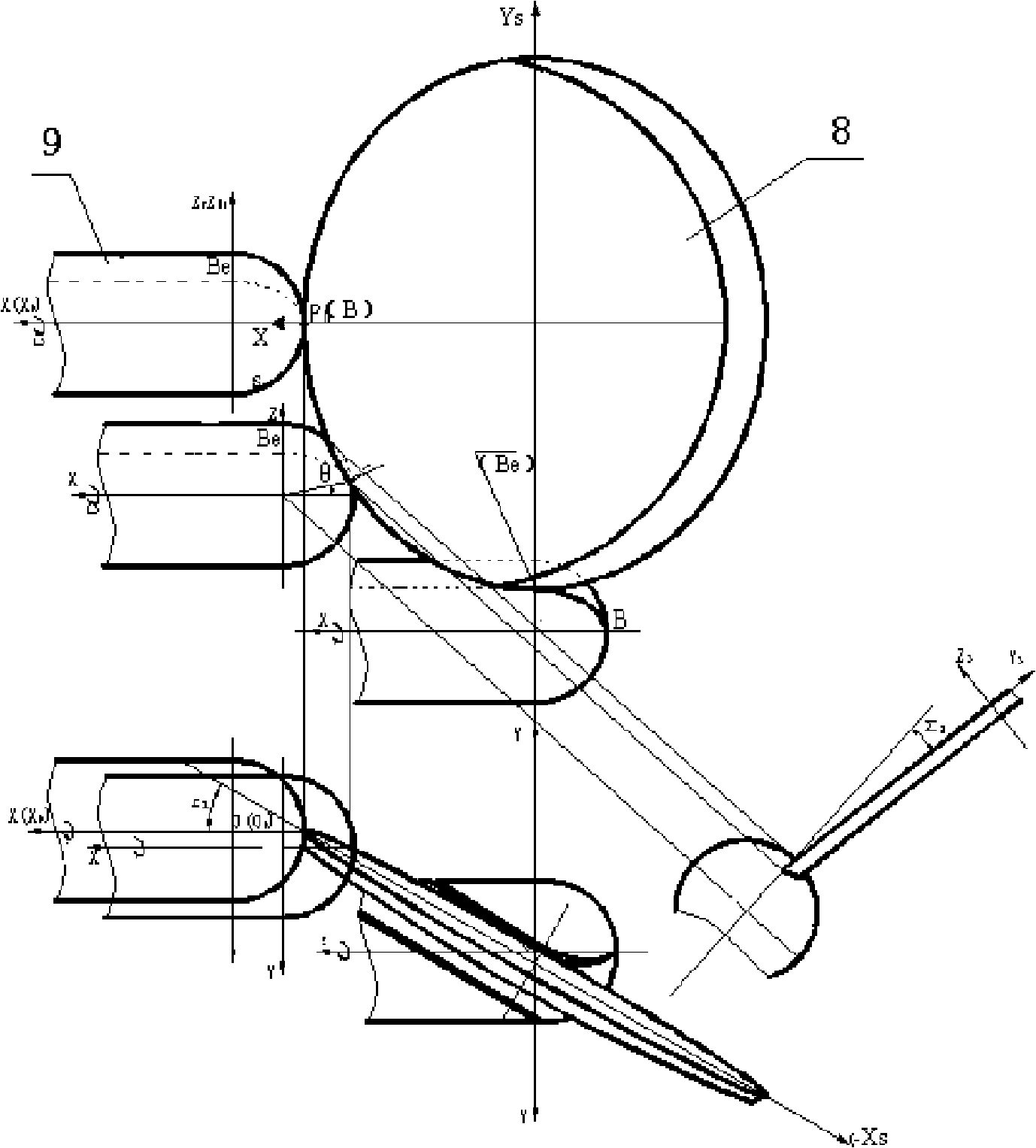

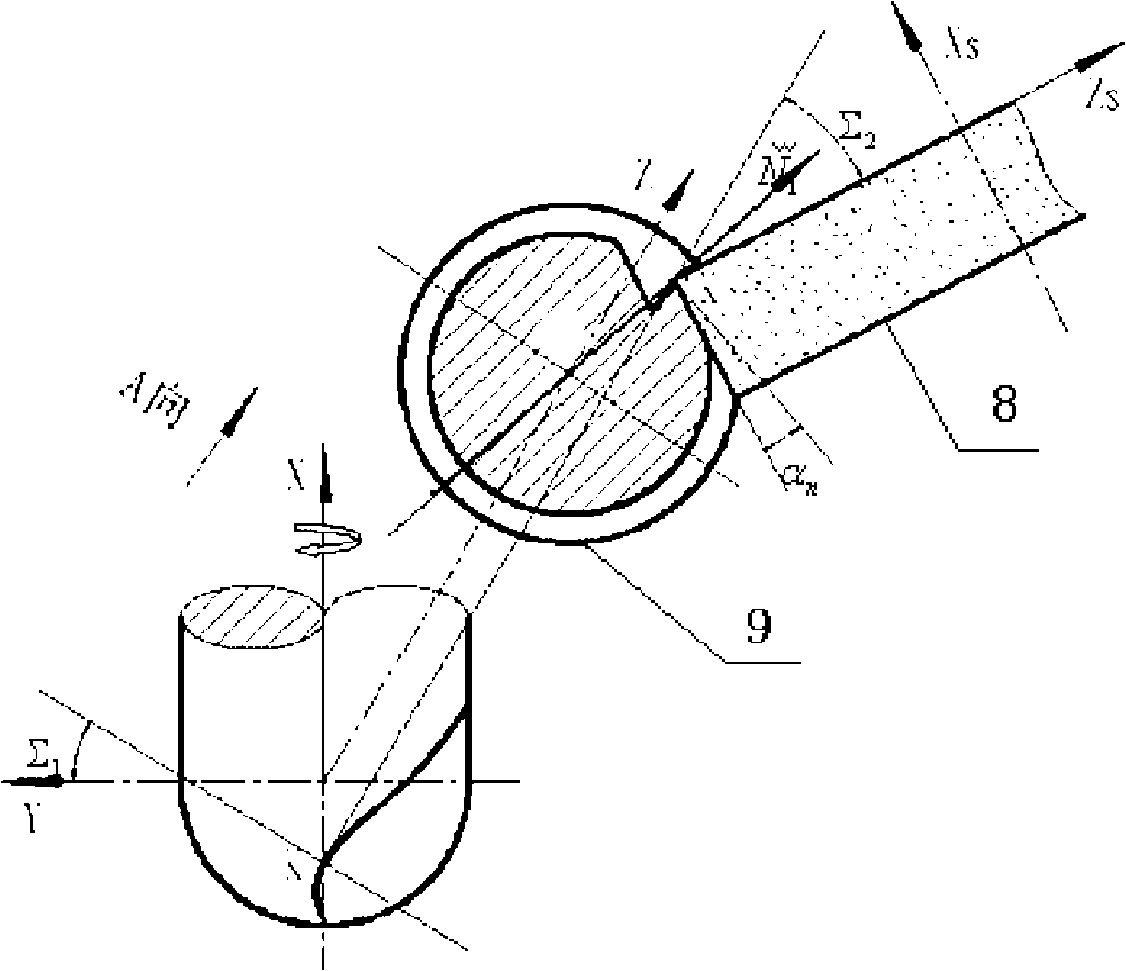

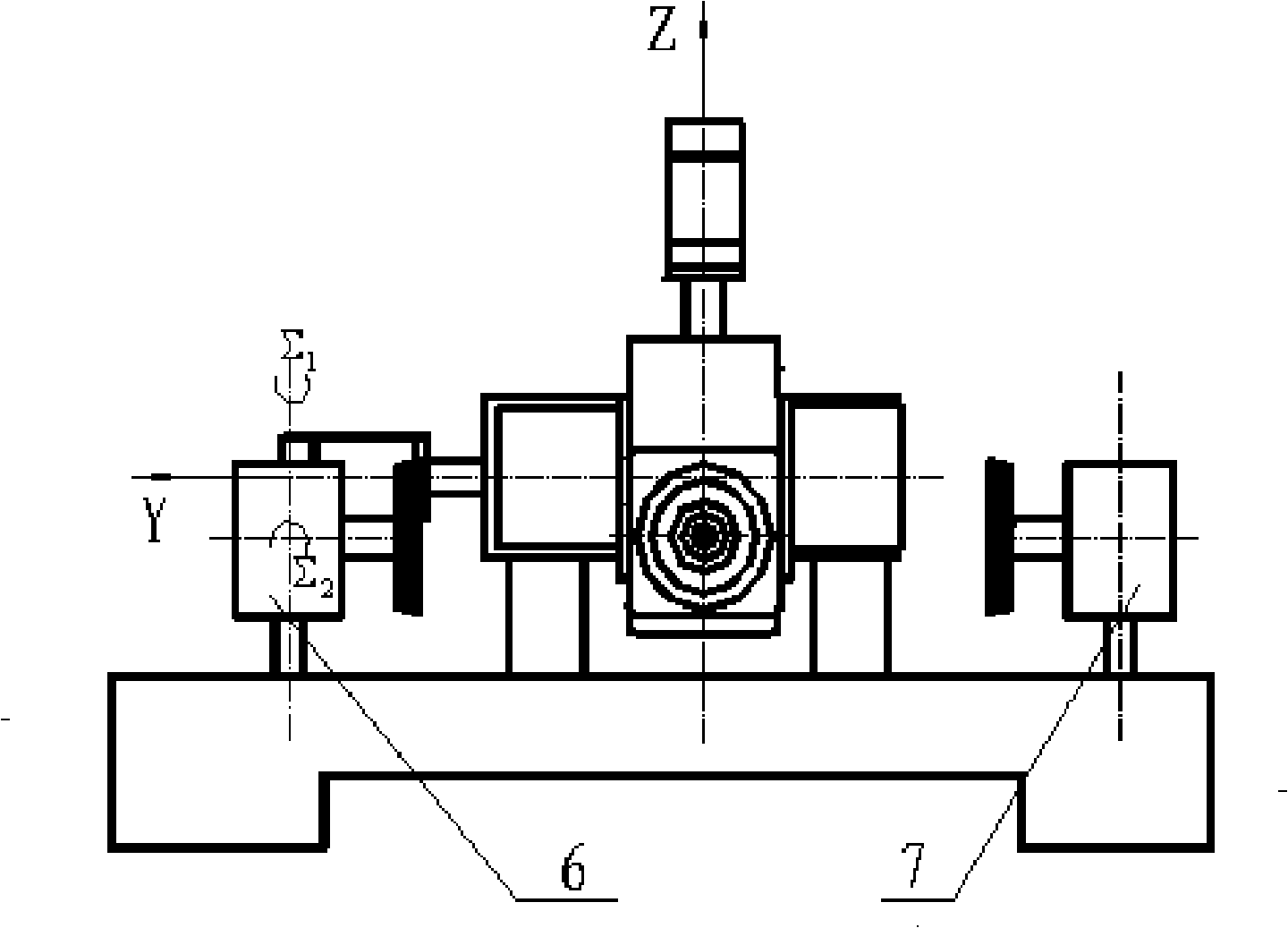

[0021] Embodiment 1 of the present invention: as attached image 3 , 4 shown. Including the bed 1 and the horizontal and longitudinal X-axis linear motion platform 2 installed on the bed 1, the horizontal and horizontal Y-axis linear motion platform 3, the vertical Z-axis linear motion platform 4, the workpiece rotation axis 5, and the rake grinding head 6 And flank grinding head 7. It also includes other auxiliary devices such as hydraulic pneumatic system, lubrication system, cooling system, numerical control system, grinding wheel grinding device and servo motion control system. The bed 1 adopts the MYA6025 universal tool grinder produced by Xianyang Machine Tool Factory. The servo motion control system is composed of Yaskawa's ∑-II series SGDM servo drive (model SGDM-08ADA, SGDM-15ADA), servo motor and PMAC motion. Control card composition. The Y-axis linear motion platform 3 is parallel to the longitudinal movement direction of the tool grinder workbench, and the long...

Embodiment 2

[0024] Embodiment 2 of the present invention: includes a bed 1 and a horizontal and longitudinal X-axis linear motion platform 2 installed on the bed 1, a horizontal and transverse Y-axis linear motion platform 3, a vertical Z-axis linear motion platform 4, and a workpiece rotation axis 5 , The rake grinding head 6 and the flank grinding head 7. It also includes other auxiliary devices such as hydraulic pneumatic system, lubrication system, cooling system, numerical control system, grinding wheel grinding device and servo motion control system. The bed 1 adopts the MYA6025 universal tool grinder produced by Xianyang Machine Tool Factory. The servo motion control system is composed of Yaskawa's ∑-II series SGDM servo drive (model SGDM-08ADA, SGDM-15ADA), servo motor and PMAC motion. Control card composition. The Y-axis linear motion platform 3 is parallel to the longitudinal movement direction of the tool grinder workbench, and the longitudinal and lateral feed mechanisms and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com