High-altitude framework type simple plate supporting machine

A frame-type, simple technology, applied in the direction of erection/assembly of bridges, bridges, buildings, etc., can solve the problems of enlarging the design section, common force, cumbersome construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

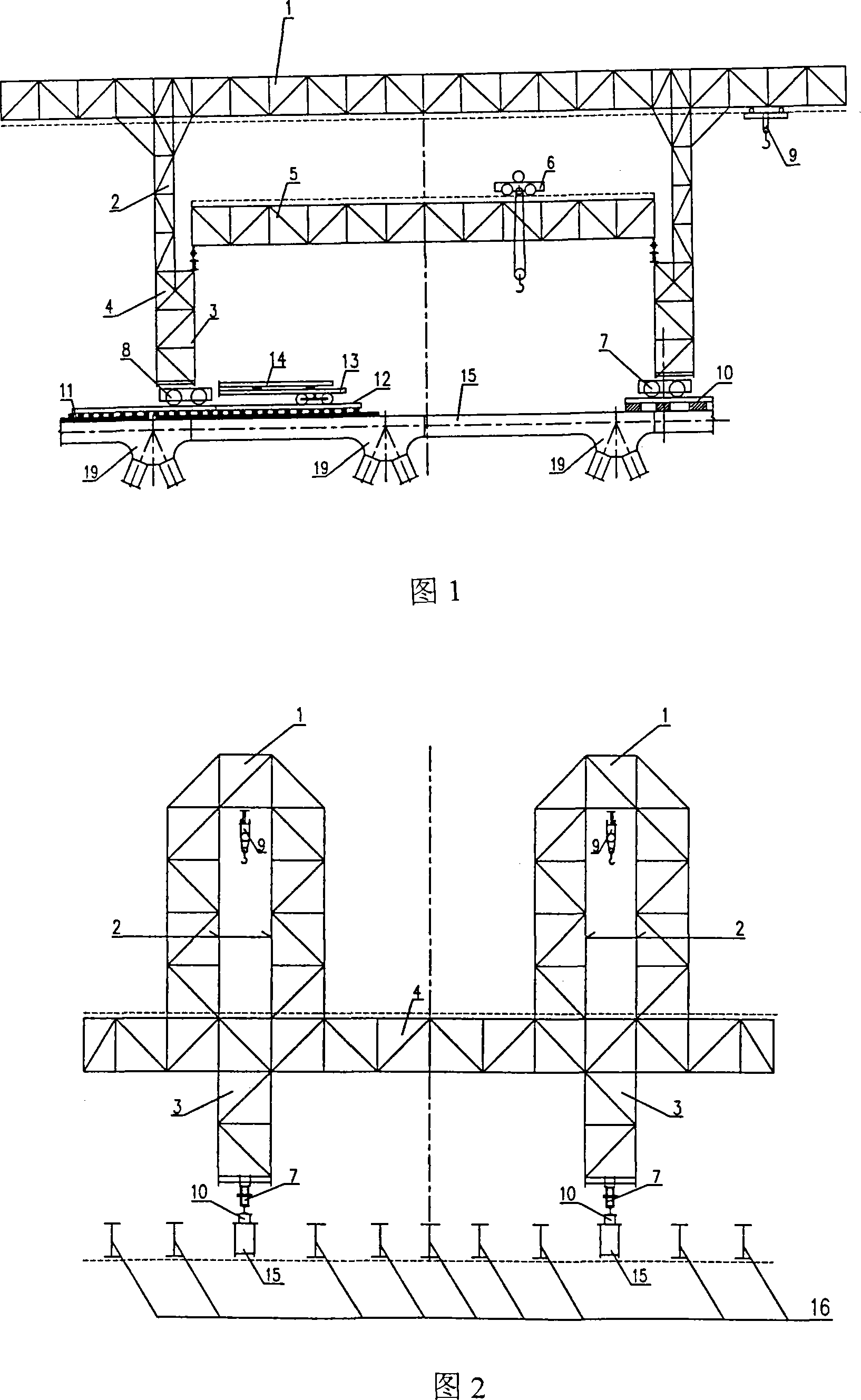

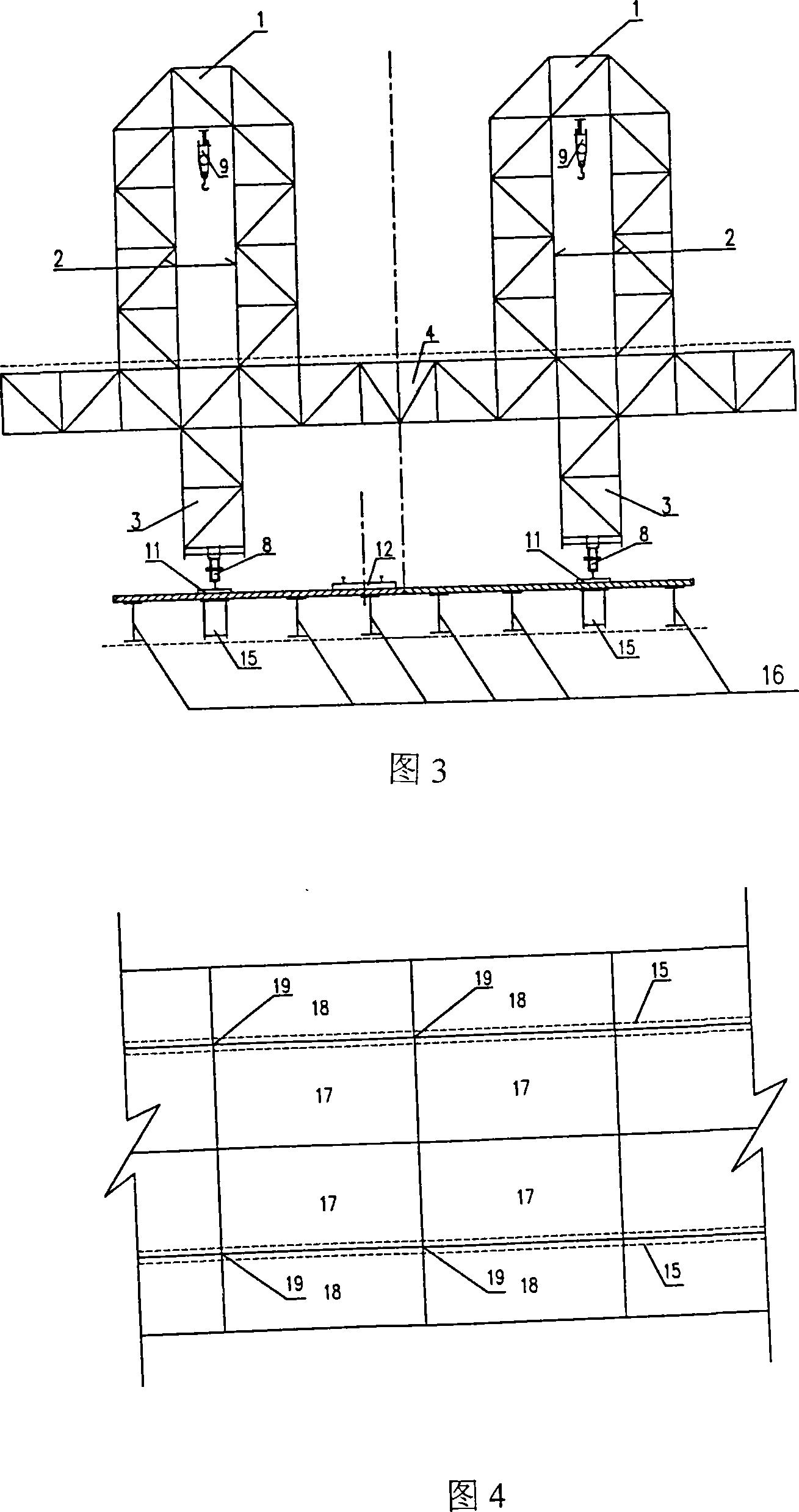

[0011] Referring to the accompanying drawings, its structure includes gantry connecting beam 1, gantry upper column 2, gantry lower column 3, lifting truss aisle beam 4, lifting truss 5, lifting trolley 6, and running system; wherein the gantry The connecting beam 1 is connected with the upper column 2 of the gantry, the upper column 2 of the gantry is connected with the aisle beam 4 of the hoisting truss, the aisle beam 4 of the hoisting truss is connected with the lower column 3 of the gantry, and the lifting trolley 6 is set on the lifting platform. On the truss 5, the front and rear end points of the lifting truss are located on the aisle beam 4 of the lifting truss, and the front traveling wheel box group 7 and the rear traveling wheel box group 8 in the traveling system are arranged under the lower column 3 of the gantry; The upper chords of the steel truss girders are connected as a whole through the upper chord nodes. The front wheel box group 7 in the running system tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com