Storage tank lifting construction method applicable to heavy wind areas

A construction method and hoisting technology, which is applied in the hoisting construction field of storage tanks in windy areas, can solve problems such as impact and storage tank construction impact, and achieve the effects of simple operation steps, low cost, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

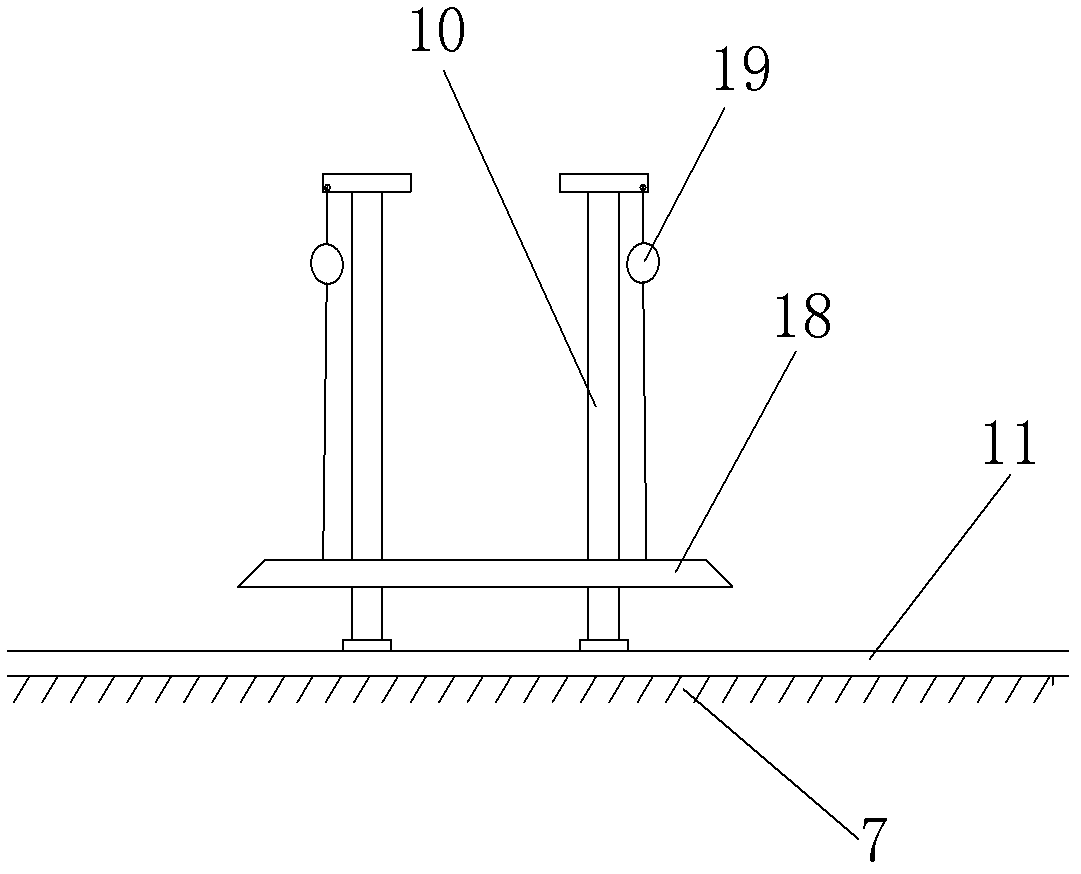

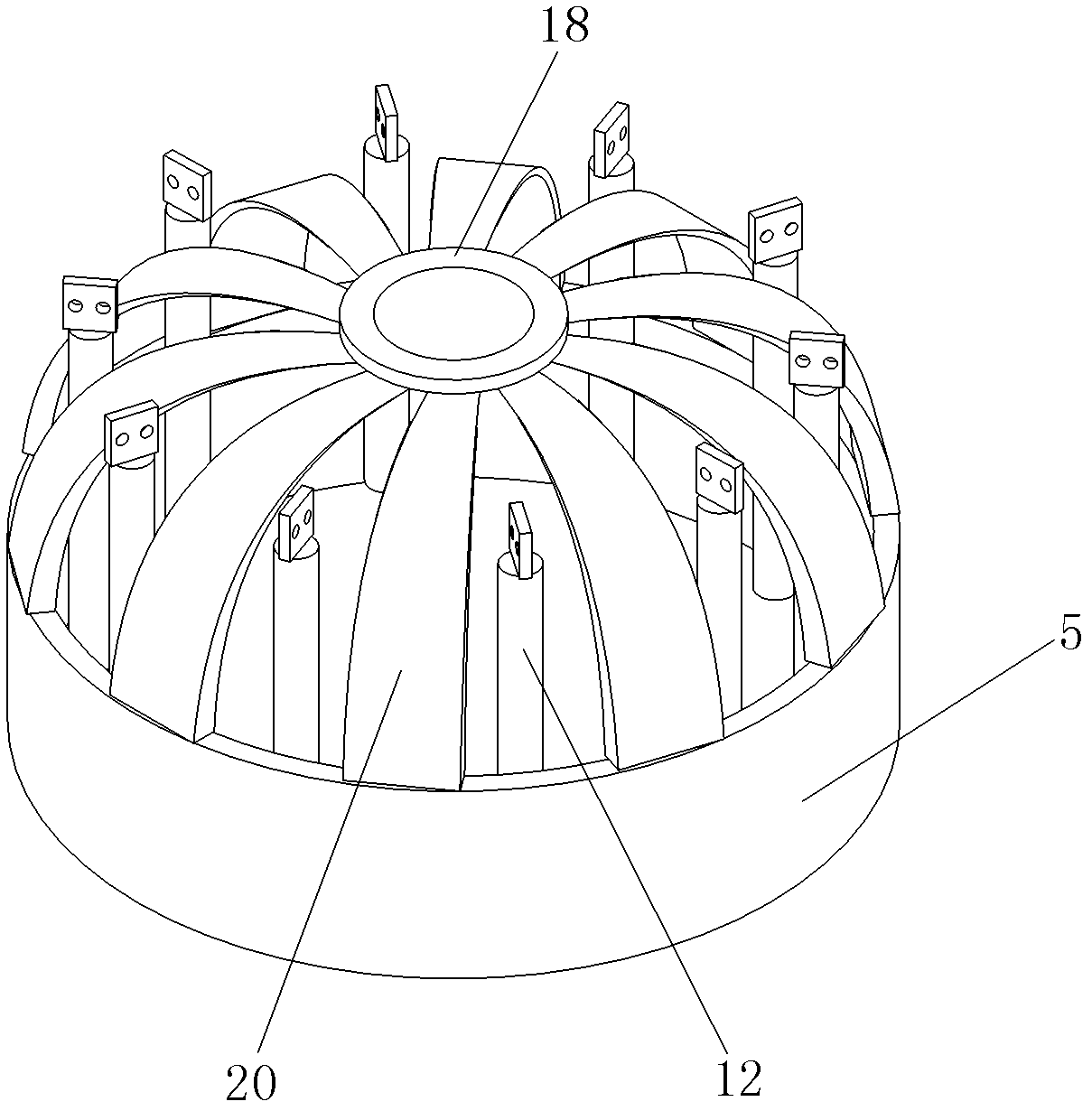

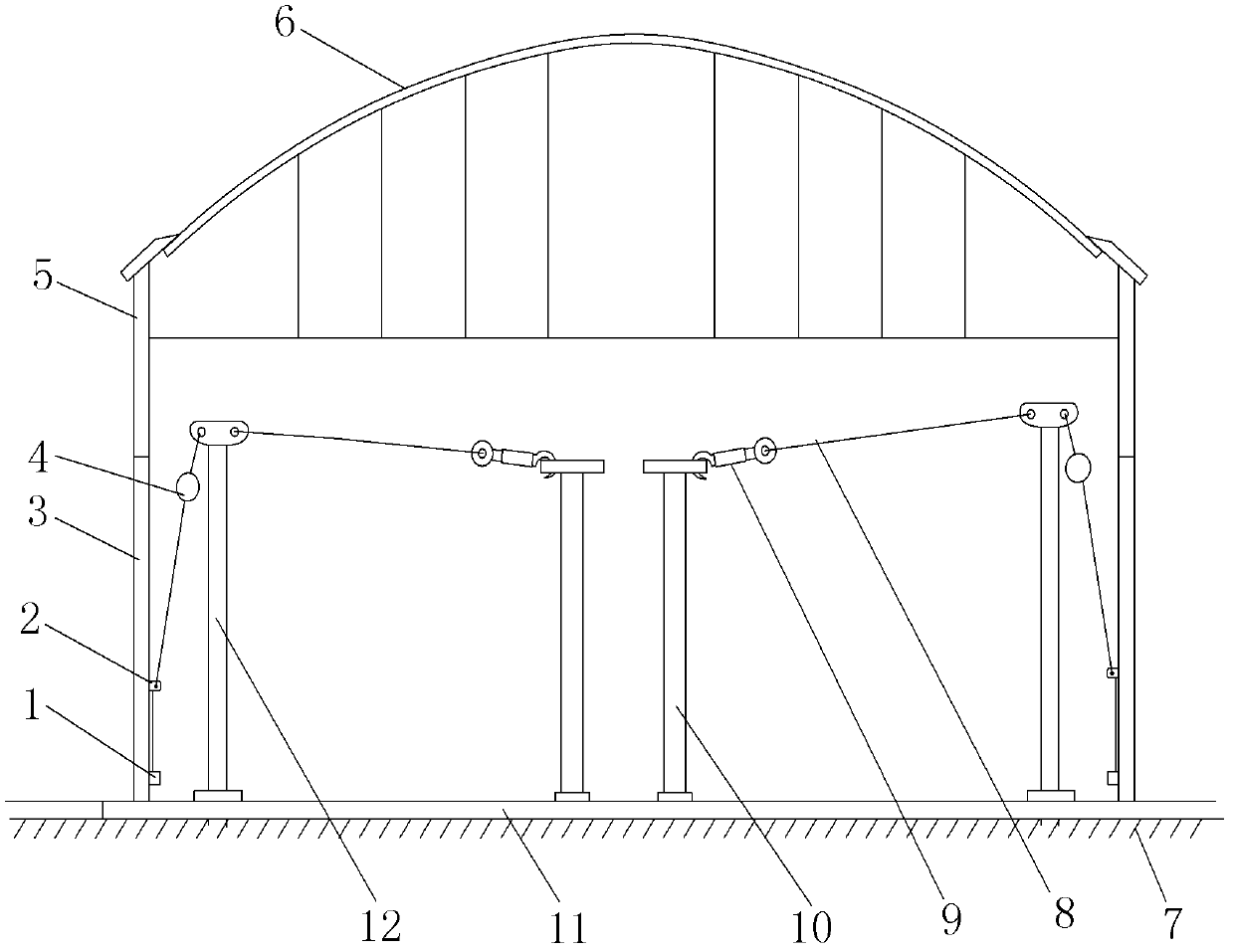

[0034] Such as figure 1 , figure 2 , image 3 and Figure 4 A storage tank hoisting construction method suitable for windy areas is shown, which is characterized in that it includes the following steps:

[0035] Step 1. Preparations before hoisting and construction: lay out the foundation, install the bottom plate 11 on the foundation 7, and then set a plurality of buttresses 15 on the bottom plate 11 for supporting the wall of the storage tank, on the foundation 7 and on the buttresses 15 A circle of anchoring belt 14 is arranged on the outer side of the storage tank, and a plurality of lifting lugs 13 are arranged on the anchoring belt 14; a plurality of buttresses 15 are arranged along the circumferential direction of the storage tank, and the number of lifting lugs 13 is 24.

[0036] Step 2. Lifting of the first circle of wall panels and tank roof: first assemble the first circle of wall panels 5 on the pier 15, and install the expansion ring 1 on the bottom inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com